Patents

Literature

57results about How to "Production delay" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

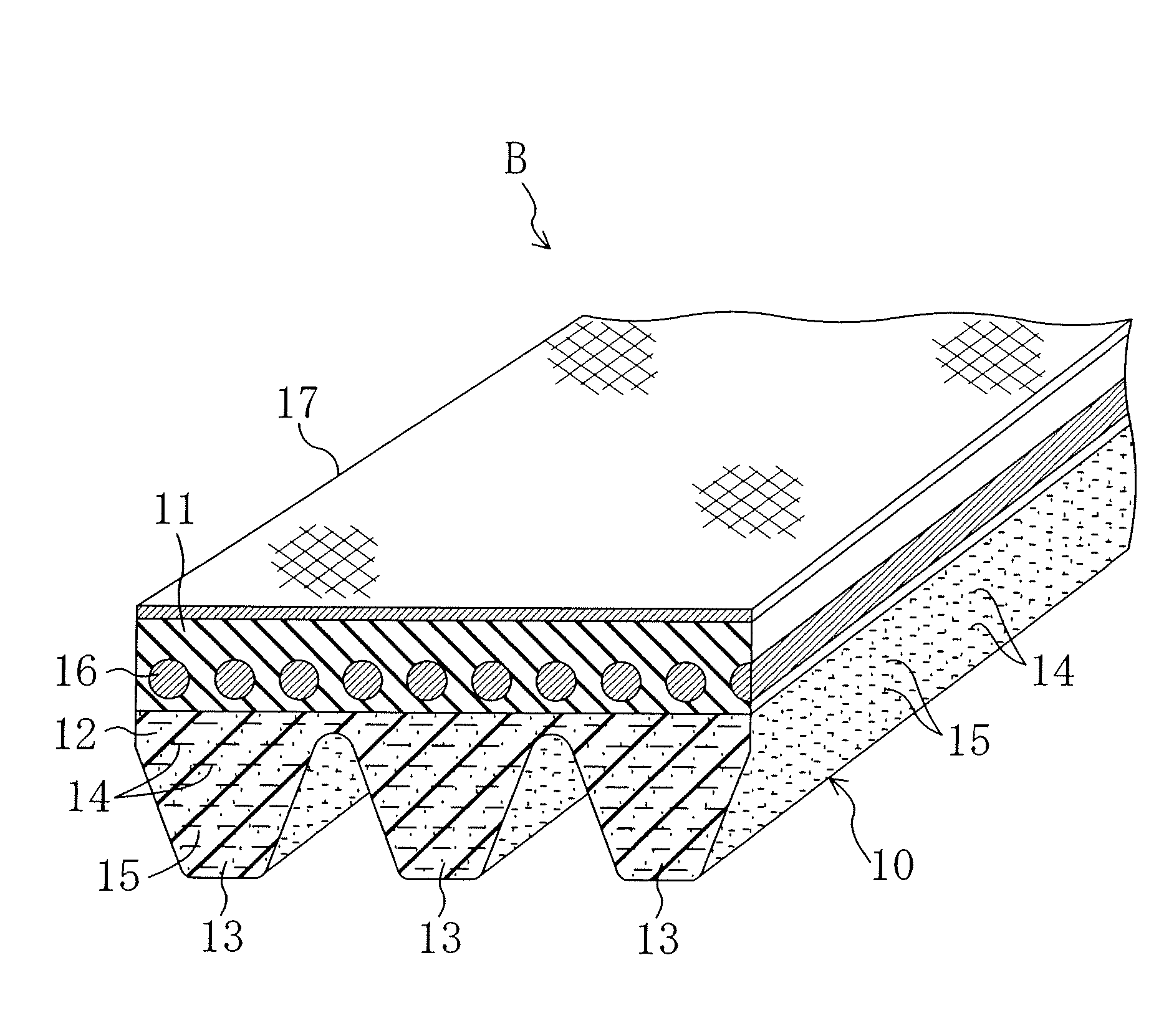

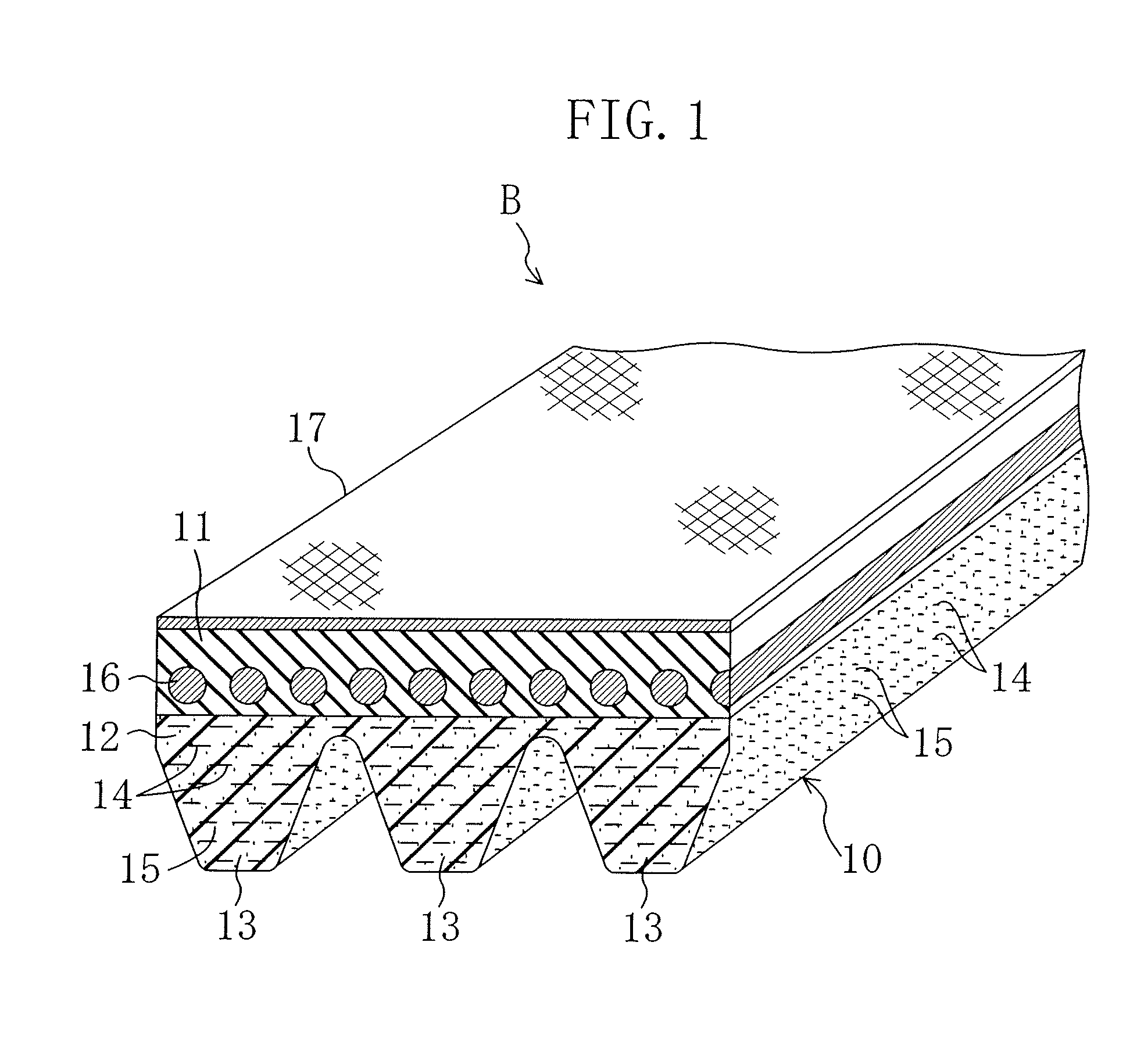

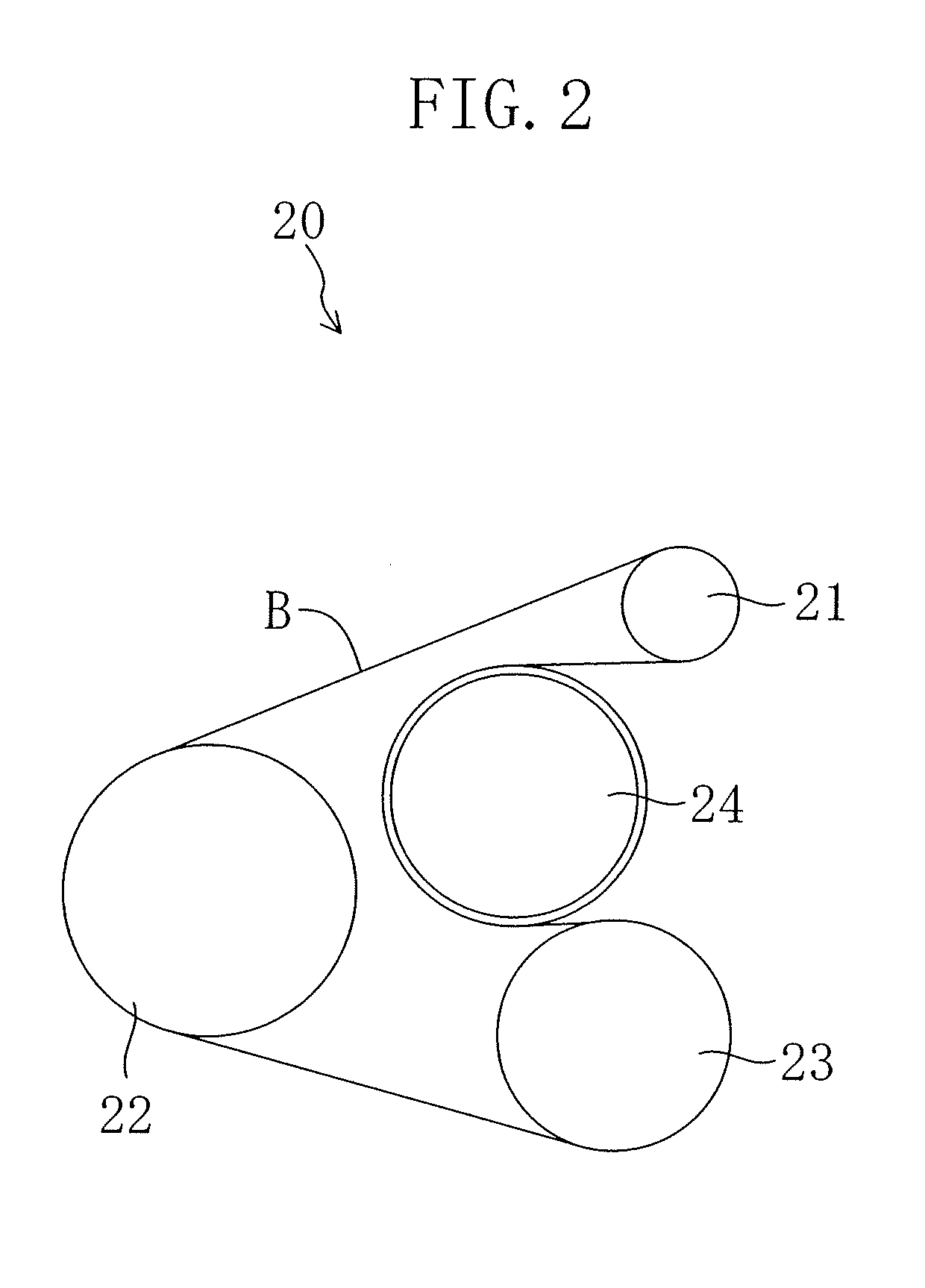

V-ribbed belt and automotive accessory drive belt drive system using the same

InactiveUS20090048048A1Production delayImprove heat resistanceV-beltsRopes and cables for vehicles/pulleyElastomerEngineering

A V-ribbed belt B includes a plurality of V-ribs 13 each formed to extend in a lengthwise direction of the belt, the plurality of V-ribs 13 are disposed in juxtaposition in a widthwise direction of the belt on the belt inner face, and the V-ribbed belt B is wrapped around a pulley to bring the plurality of V-ribs 13 into contact with the pulley for power transmission. The plurality of V-ribs 13 are made of a rubber composition in which 5 to 50 parts by mass of thermoplastic resin having a melting point of 110° C. or higher is mixed with 100 parts by mass of ethylene-α-olefin elastomer rubber which is raw rubber.

Owner:BANDO CHEM IND LTD

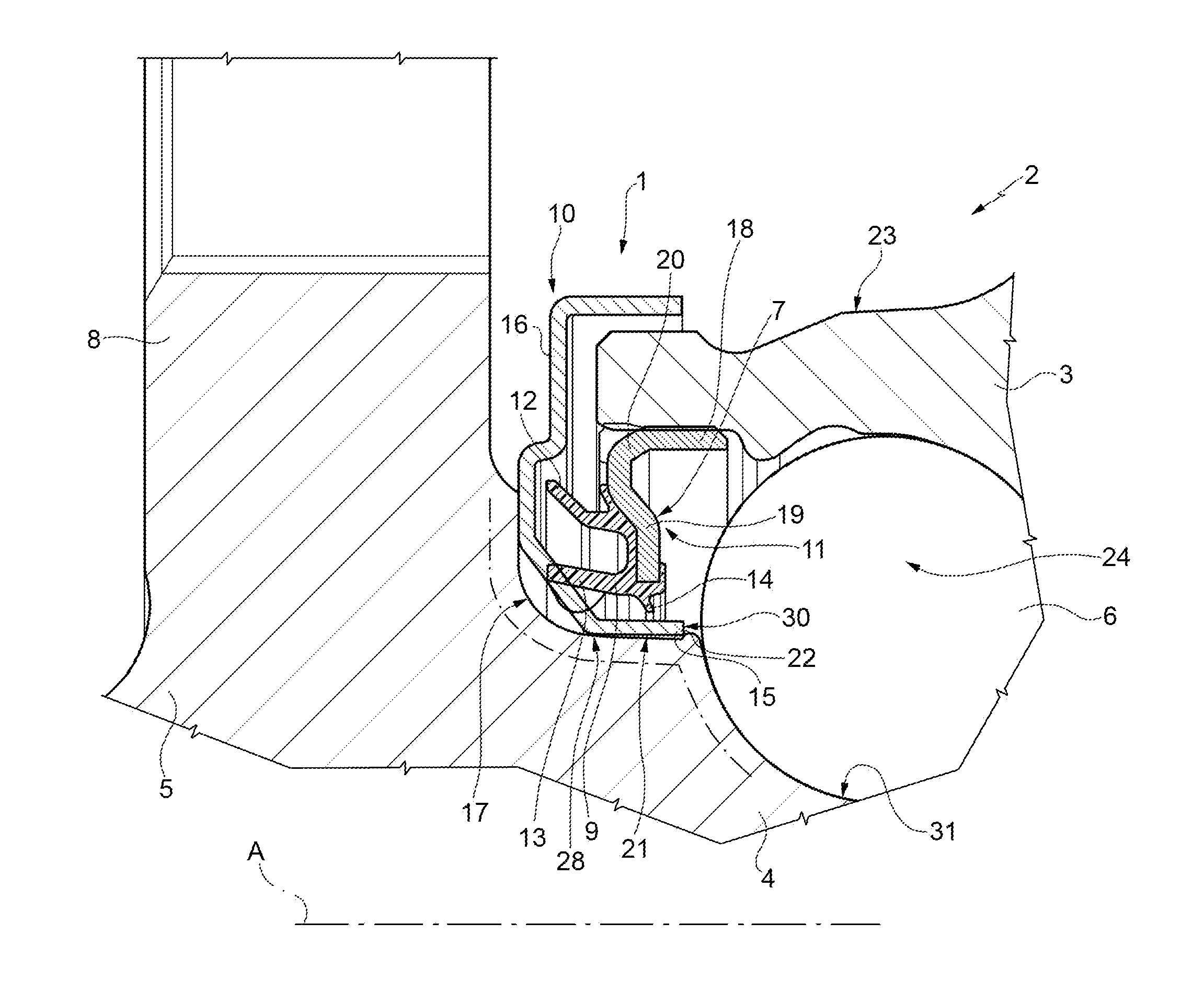

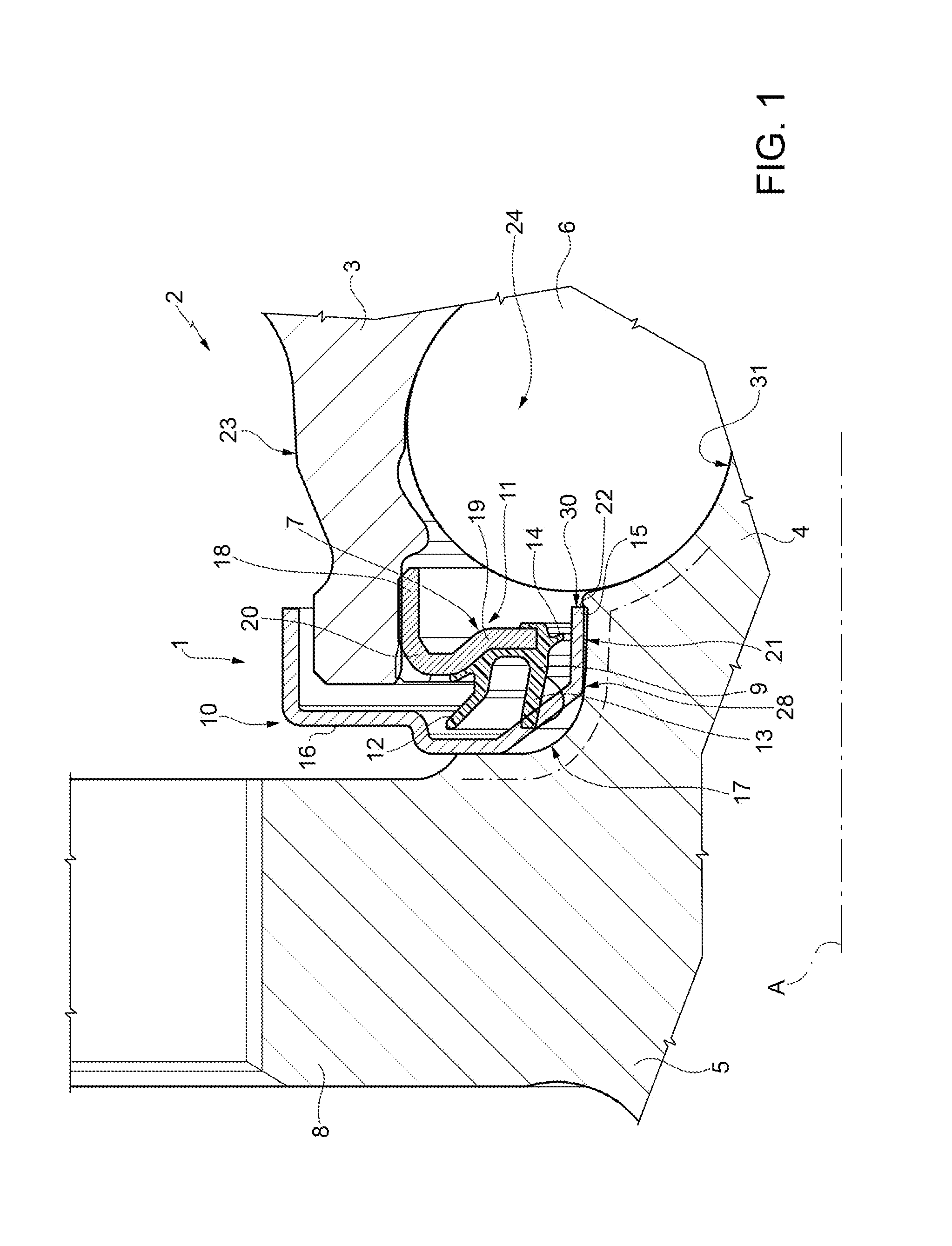

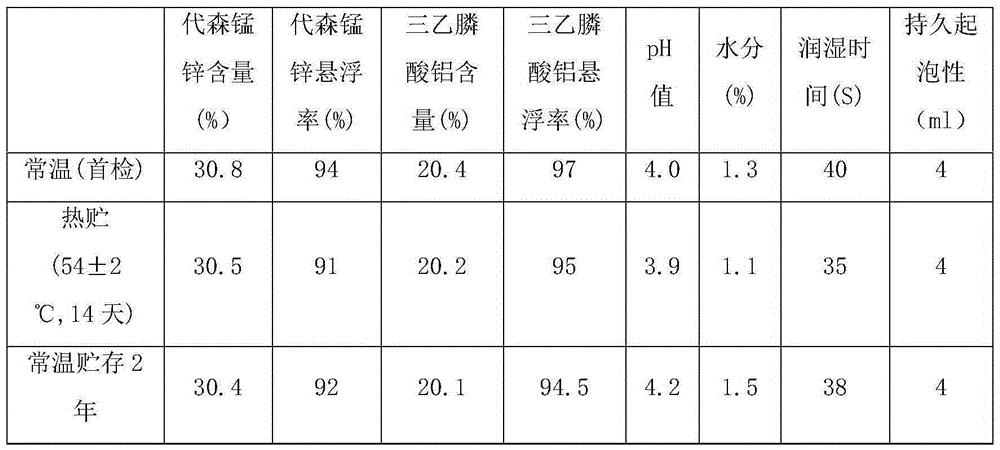

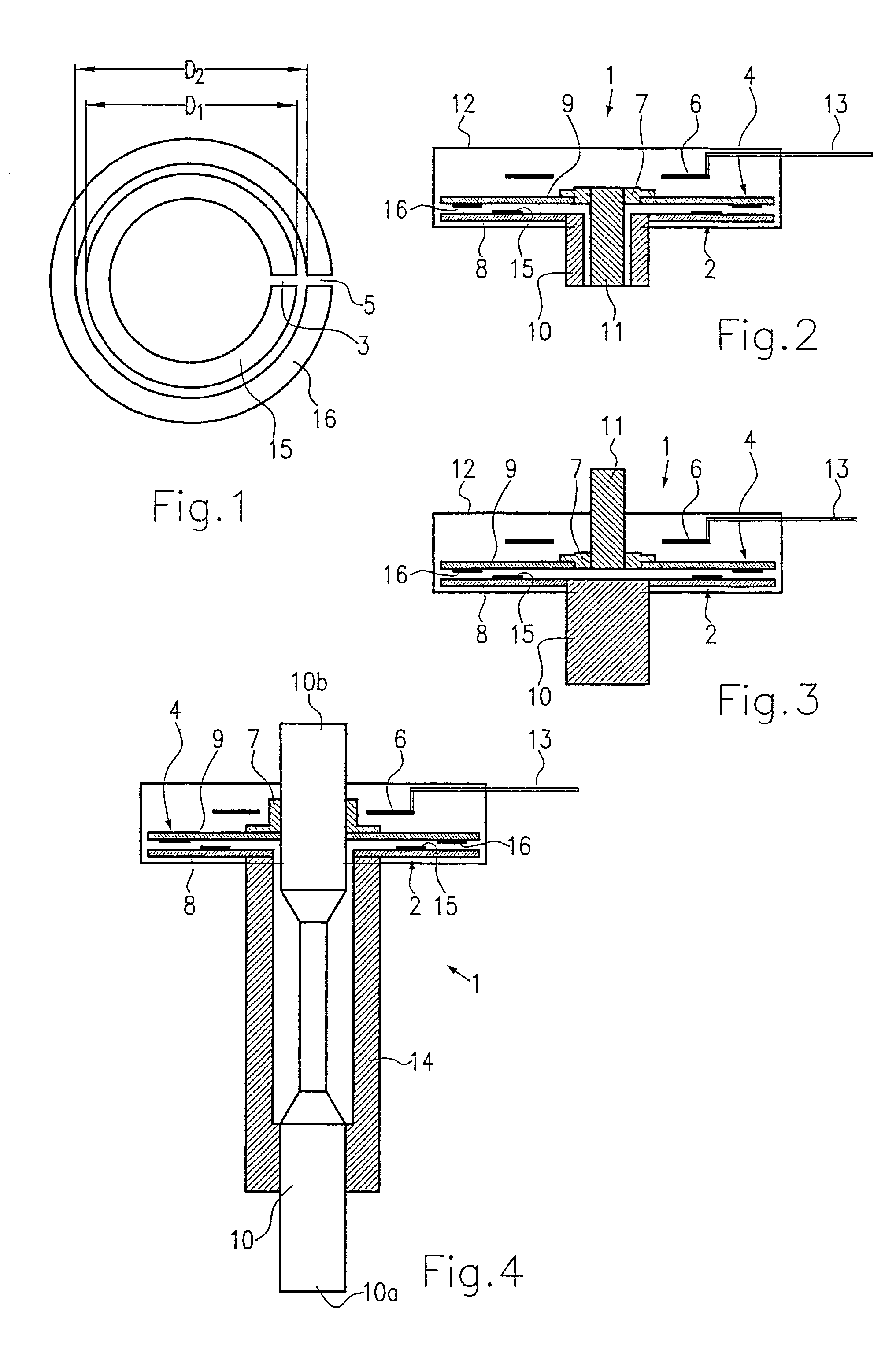

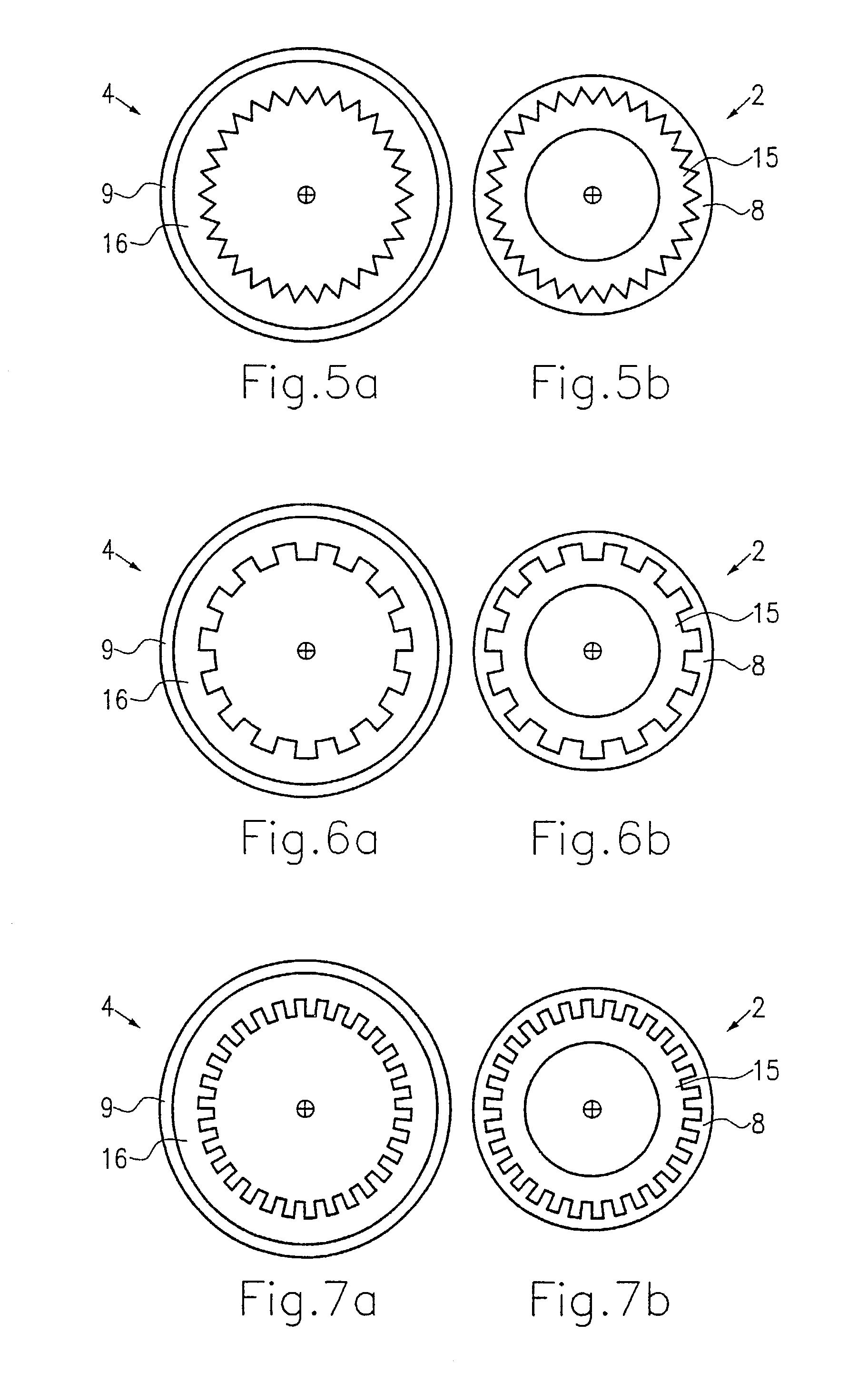

Coupling system of a low friction sealing assembly with a bearing ring and a hub bearing unit equipped with such a sealing assembly

ActiveUS20150151574A1Low costProduction delayEngine sealsRolling contact bearingsCoupling systemLow friction

A sealing assembly including at least one first annular shield having a sleeve portion integral in use with a rotating member and a flange portion, which radially and overhangingly extends from the sleeve portion. Preferably, a second annular shield is arranged in front of the first shield with the interposition of an annular seal; wherein the sleeve portion of the first shield is delimited by a conic-truncated lateral mounting surface having a tapering facing so as to have a greater diameter arranged on the side of the flange portion and intended to couple in use with a mounting seat of the rotating member formed by a shallow recess delimited by a conic-truncated bottom wall having the same tapering as the lateral mounting surface and by an axial shoulder which is arranged on the side opposite to the flange portion.

Owner:AB SKF

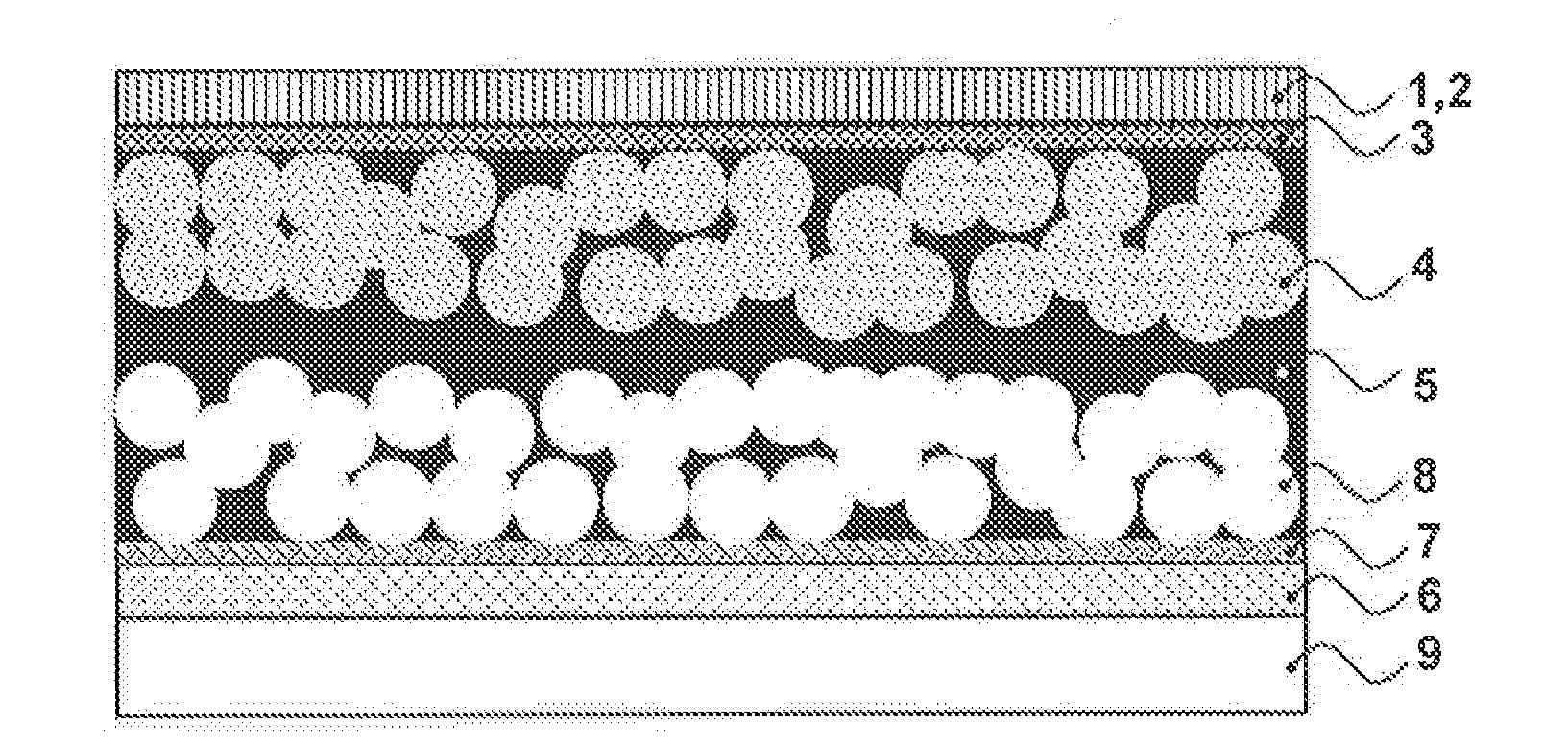

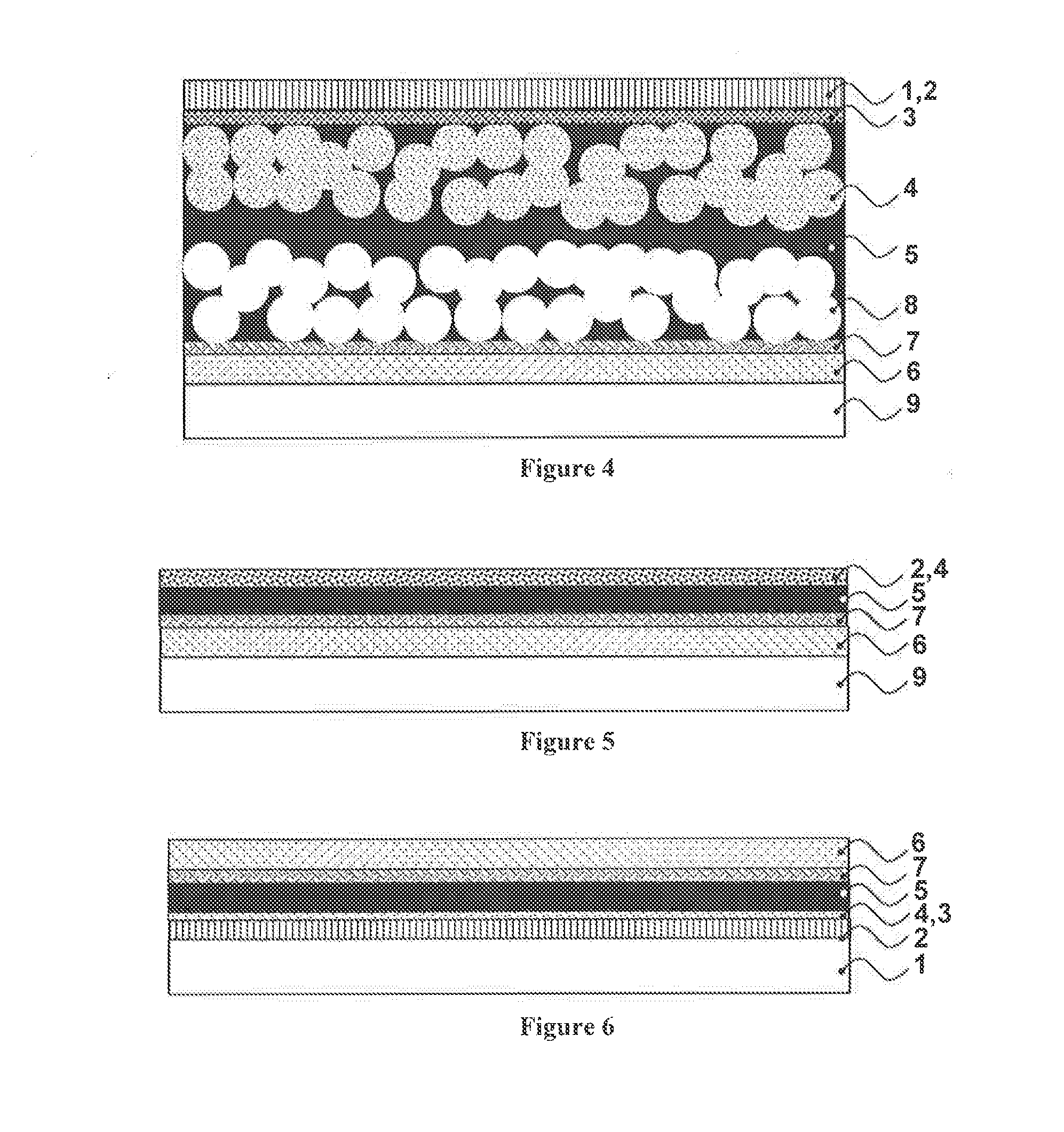

Photovoltaic device

InactiveUS20160218308A1Ease of productionHigh hole mobilityElectrolytic capacitorsFinal product manufactureElectricityMaterials science

Photovoltaic devices are described including: a region of perovskite material which is in electrical contact with a mesoporous region of hole transport material, wherein the hole transport material is at least partially comprised of an inorganic hole transport material.

Owner:DYESOL LTD

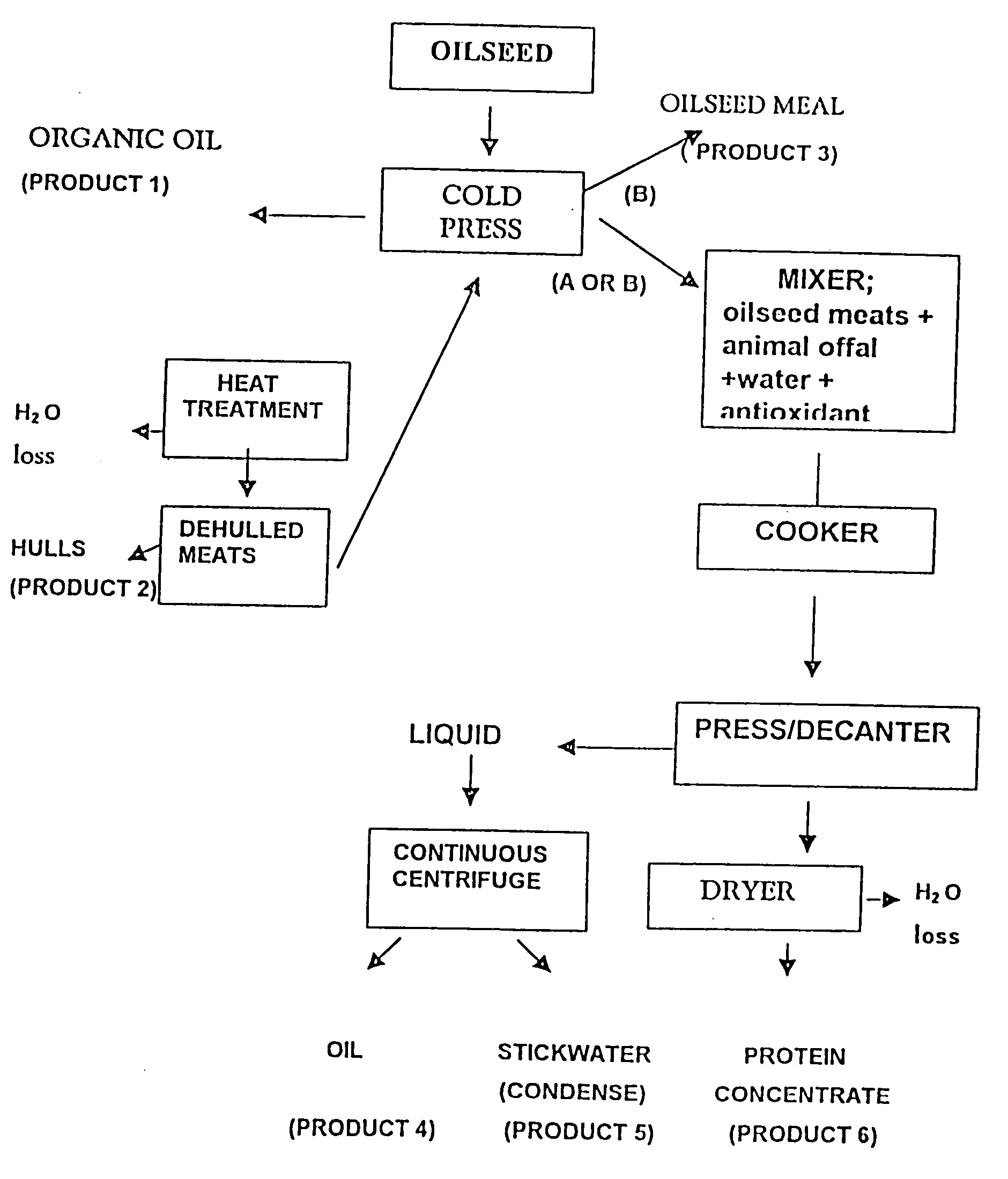

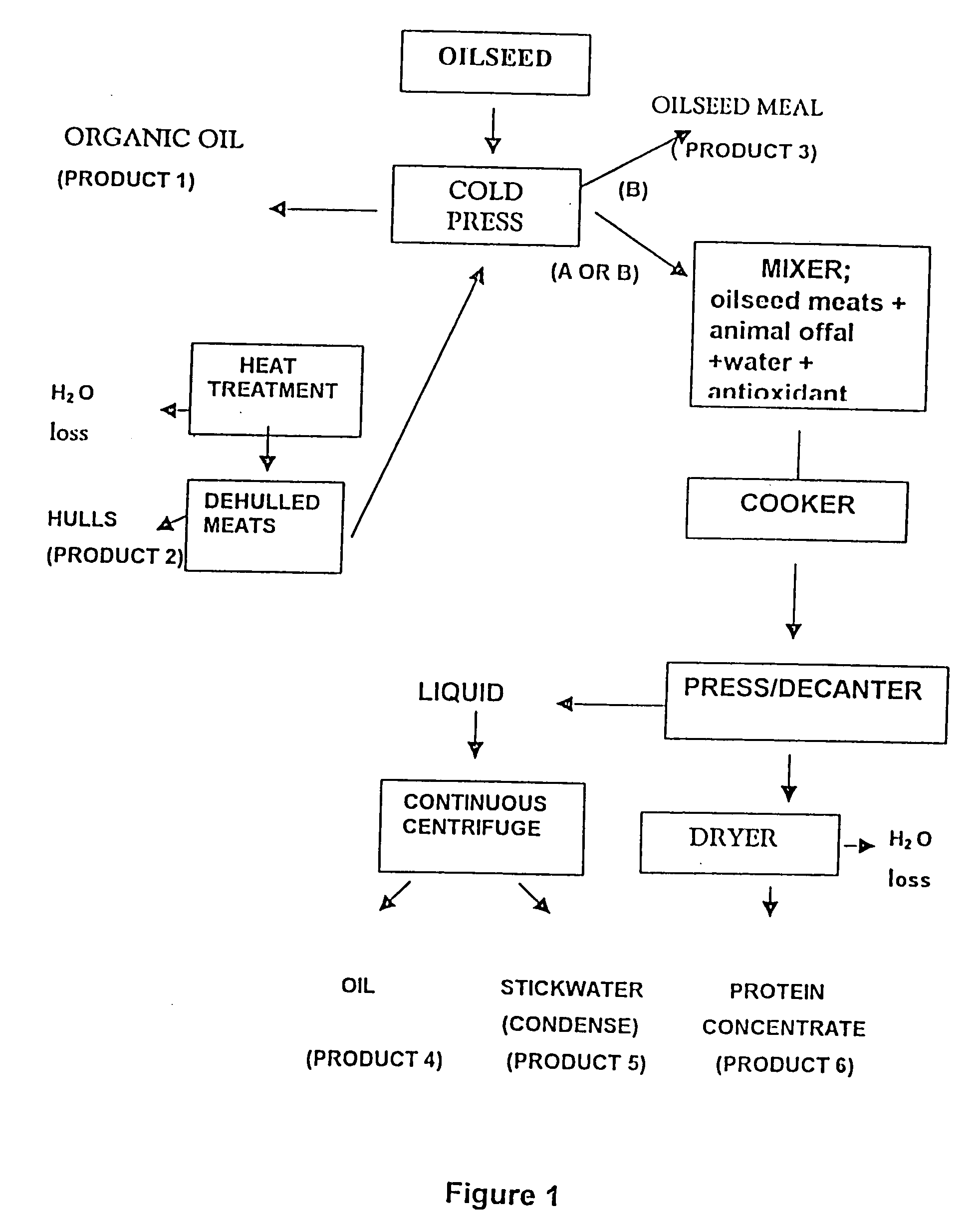

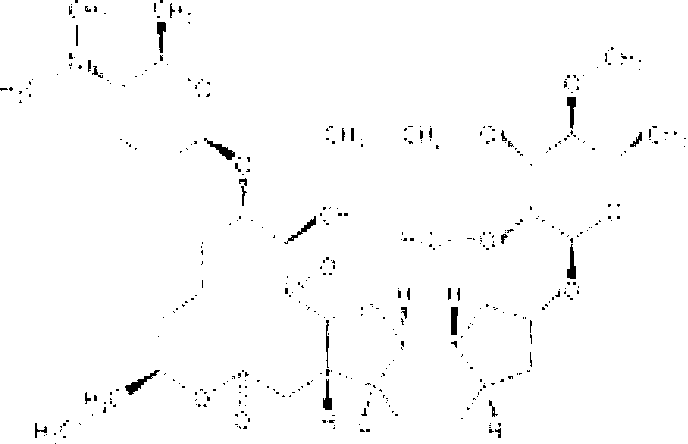

Protein and lipid sources for use in aquafeeds and animal feeds and a process for their preparation

InactiveUS20060051489A1Reduce concentrationProduction delayBioloigcal waste fertilisersEdible oils/fatsLipid formationWAS PROTEIN

A process for preparation of nutritionally upgraded oilseed meals which are protein and lipid-rich and have a reduced fibre content, and plant oils from oilseeds for use in fish or other non-human animal diets or human foods comprising the steps of: providing a source of oilseed; subjecting the oilseed to heat treatment to substantially reduce the concentration of at least some antinutritional components normally present in the oilseed to obtain heat-treated seed; dehulling the heat-treated seed to produce a meat fraction, a hull fraction or a mixture thereof; and cold pressing the meat fraction or the mixture to yeild the plant oils and the protein and lipid-rich meals.

Owner:HIGGS DAVID +2

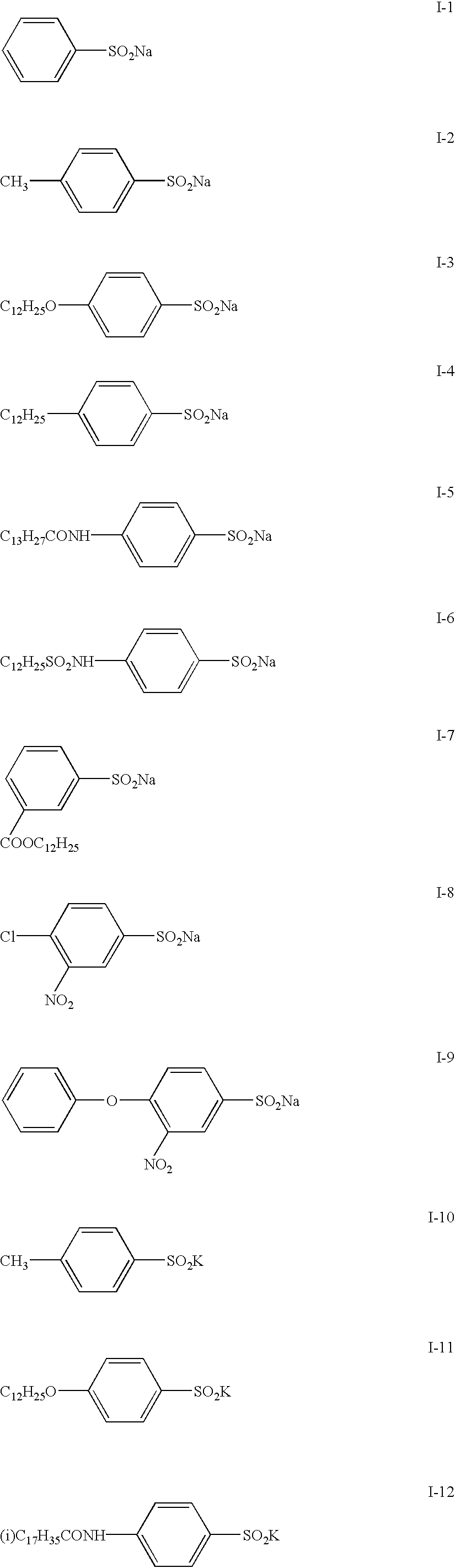

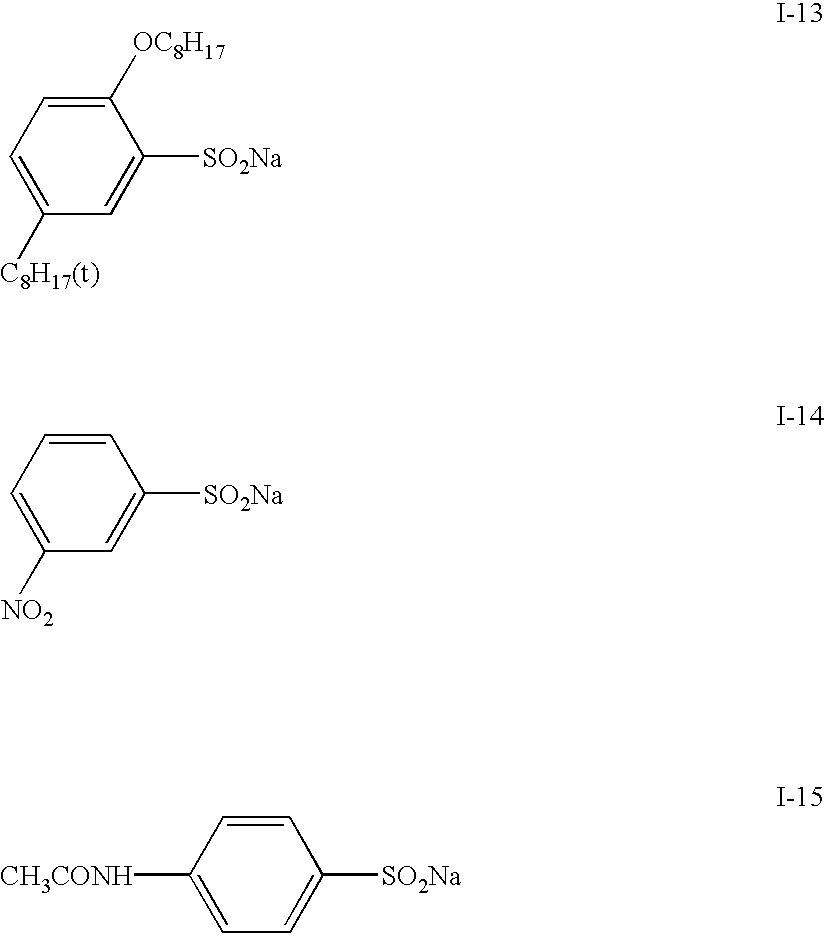

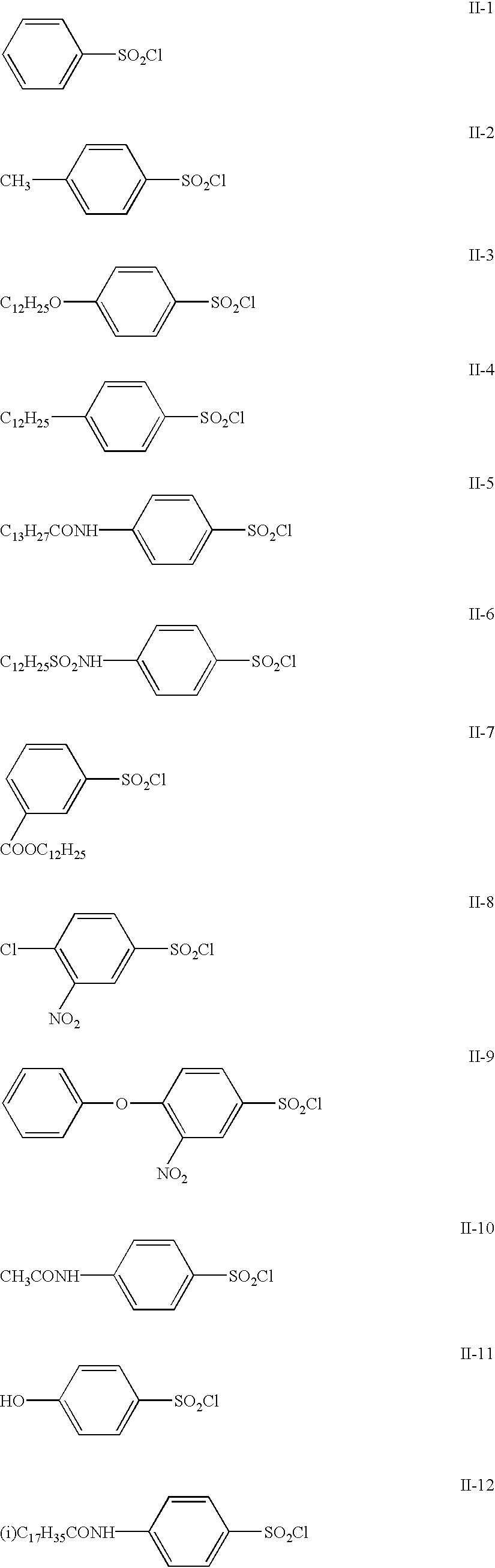

Process for preparing a sulfinate

InactiveUS6399815B2High yieldEase of productionPhysical/chemical process catalystsOrganic compound preparationSulfonyl chlorideOrganic compound

Disclosed is a process to prepare a sulfinate, which is useful for preparing a synthetic intermediate of an organic compound, especially for a color coupler, characterized by reducing a sulfonyl chloride with a sulfite or a hydrogensulfite in the presence of a hydrogenphosphate.

Owner:KONICA CORP

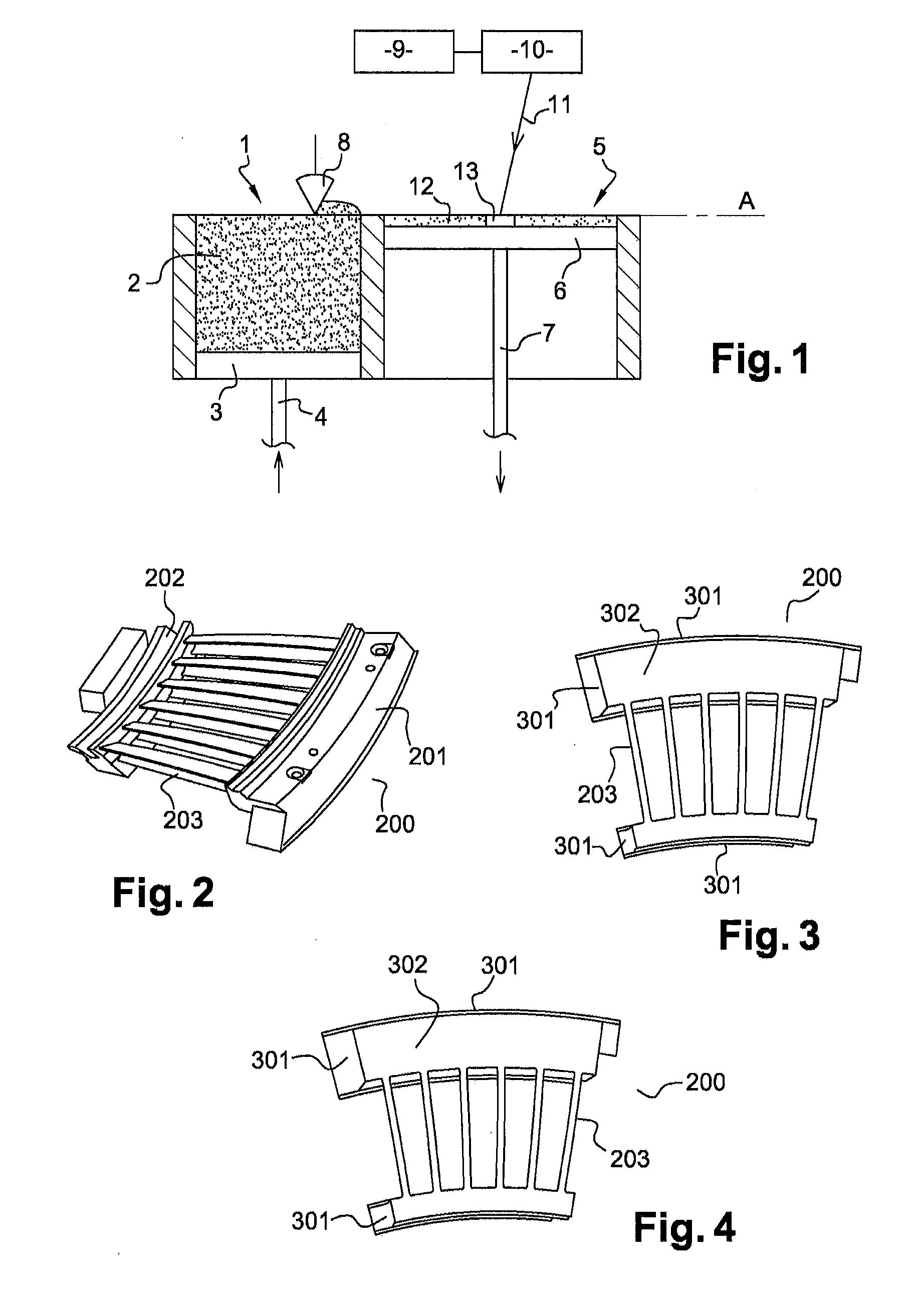

Method for producing a metal part for an aircraft turbo-engine

ActiveUS20140262124A1Ease of productionLow implementation costTurbinesAdditive manufacturing apparatusLiquid stateLiquid metal

A method for producing a metal part, the part including, in particular, a first set of elements having a small thickness, and a second set of elements having a large thickness, the method including: forming a peripheral portion of the elements of the second set of elements by selectively melting a powder by scanning the surface of the powder layer with a laser beam or with an electron beam; using the peripheral portion of the elements of the second set of elements as a mould by carrying out an operation of filling an inner area defined by the peripheral portion with liquid metal; cooling the metal part to solidify the inner area defined by the peripheral portion and filled with metal.

Owner:SN DETUDE & DE CONSTR DE MOTEURS DAVIATION S N E C M A

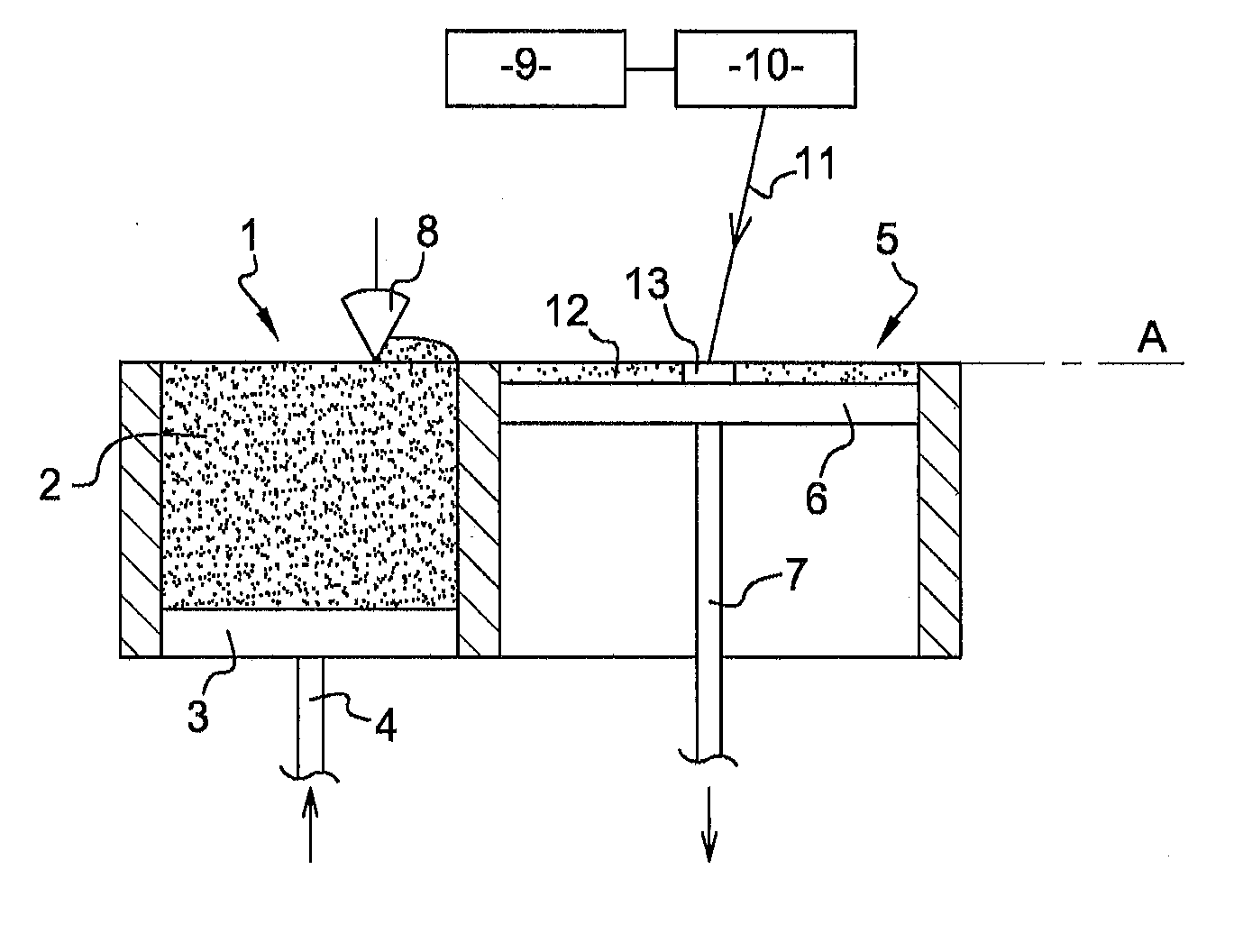

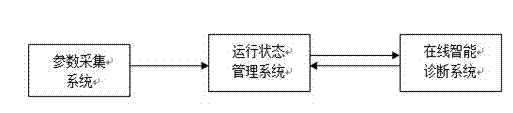

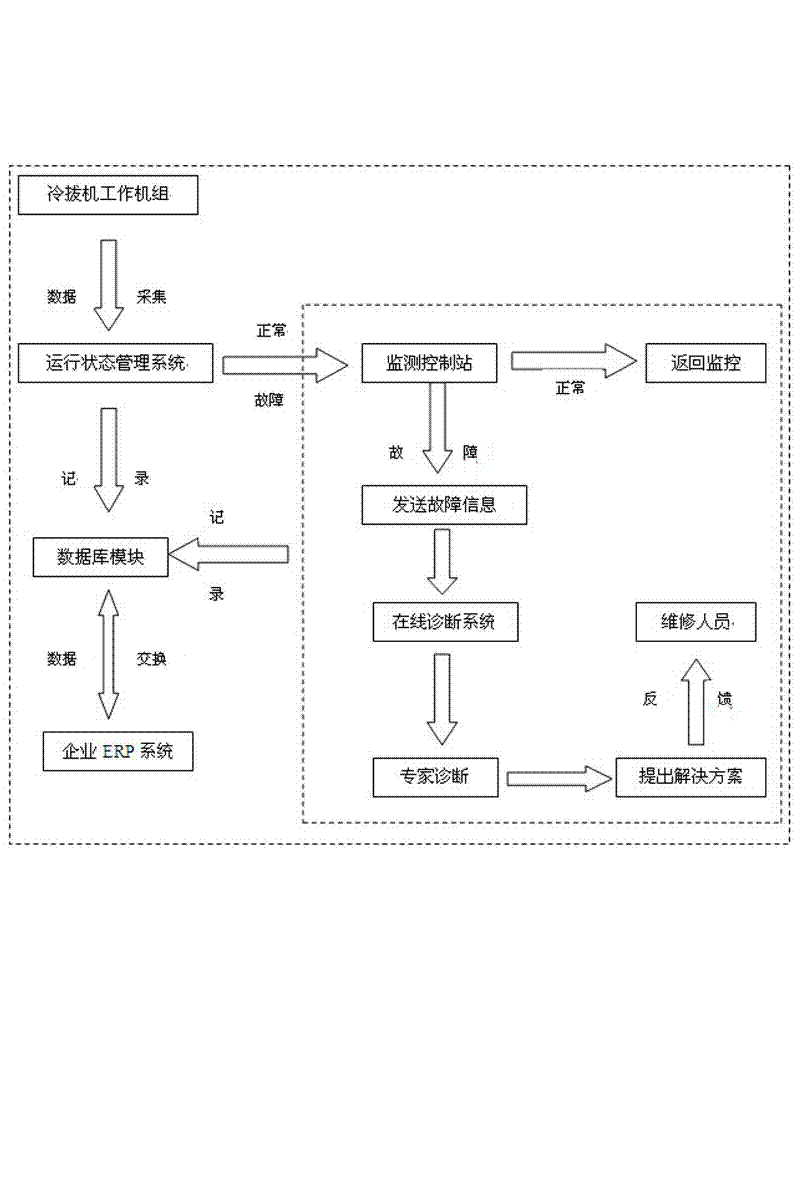

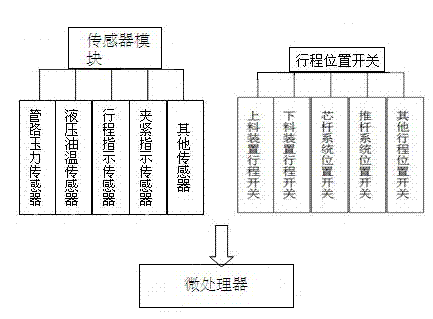

Online real-time diagnosis service system and method for hydraulic cold-drawing machine

InactiveCN102339030AAvoid Equipment DamageProduction delayProgramme controlComputer controlService systemResource planning

The invention discloses an online real-time diagnosis service system and an online real-time diagnosis service method for a hydraulic cold-drawing machine. The online real-time diagnosis service system for the hydraulic cold-drawing machine comprises a parameter acquisition system, a running state management system and an online diagnosis system, wherein by using an online monitoring mode, running management and fault maintenance of the hydraulic cold-drawing machine can be realized, and the online real-time diagnosis service system has the advantages of convenience for management, reliability and timeliness and high efficiency in maintenance; furthermore, a production delay phenomenon caused by equipment fault can be avoided effectively, historical data can be supplied to an optimized cold-drawing processing technology, and traceability and the like of the data can be realized; and data information exchange with an entrise resource planning (ERP) system of an enterprise can be realized, so online diagnosis service can be realized.

Owner:HOHAI UNIV CHANGZHOU

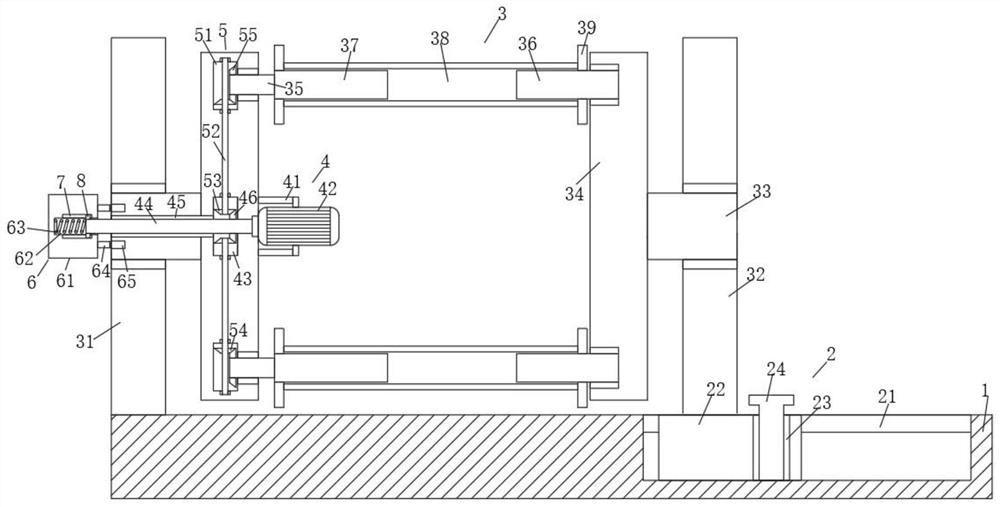

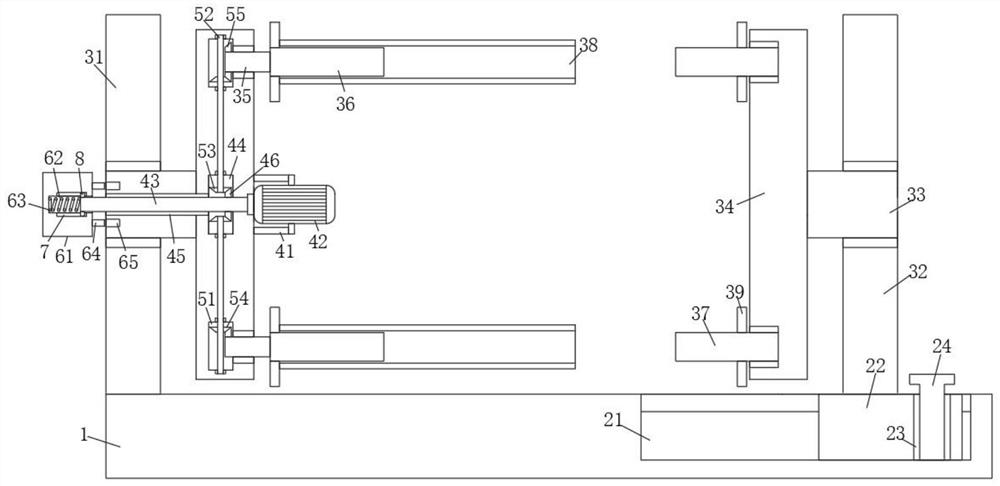

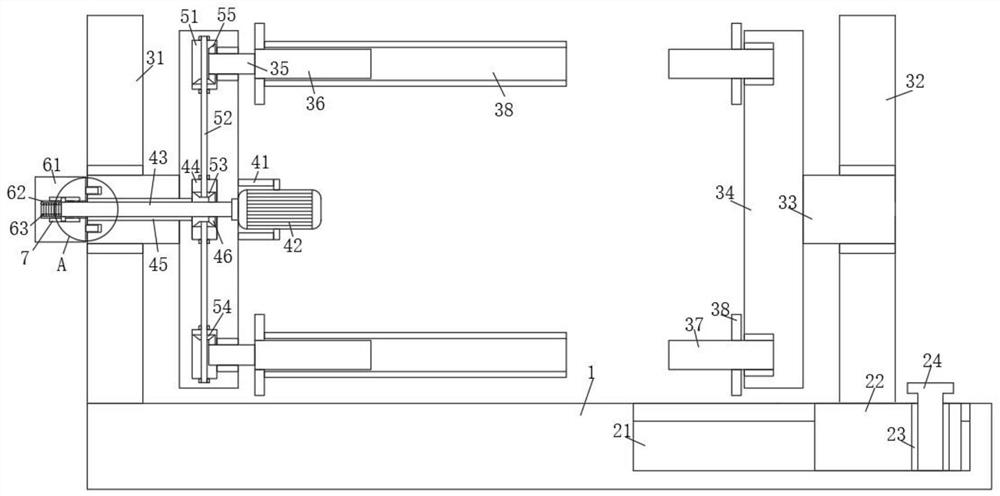

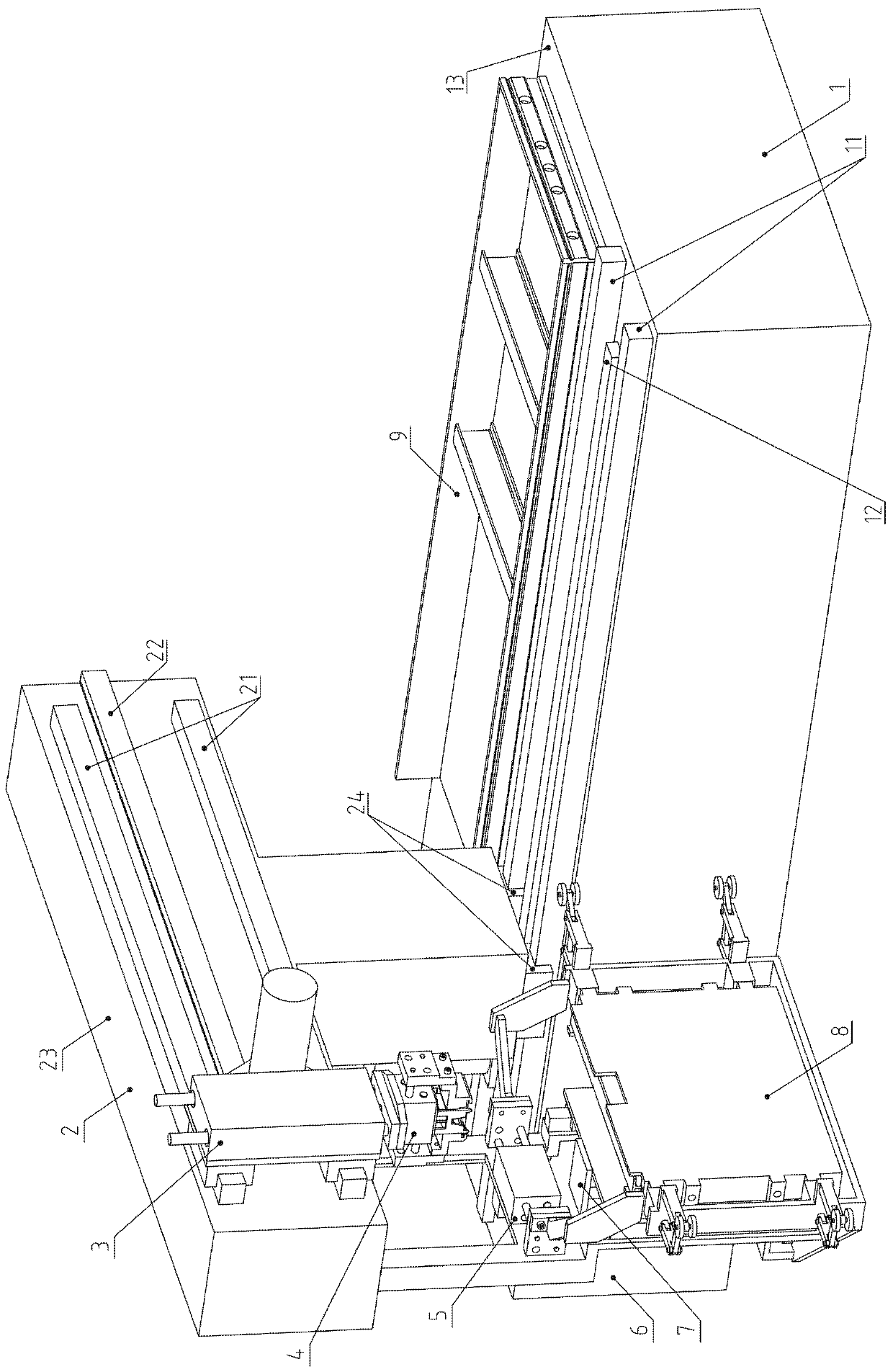

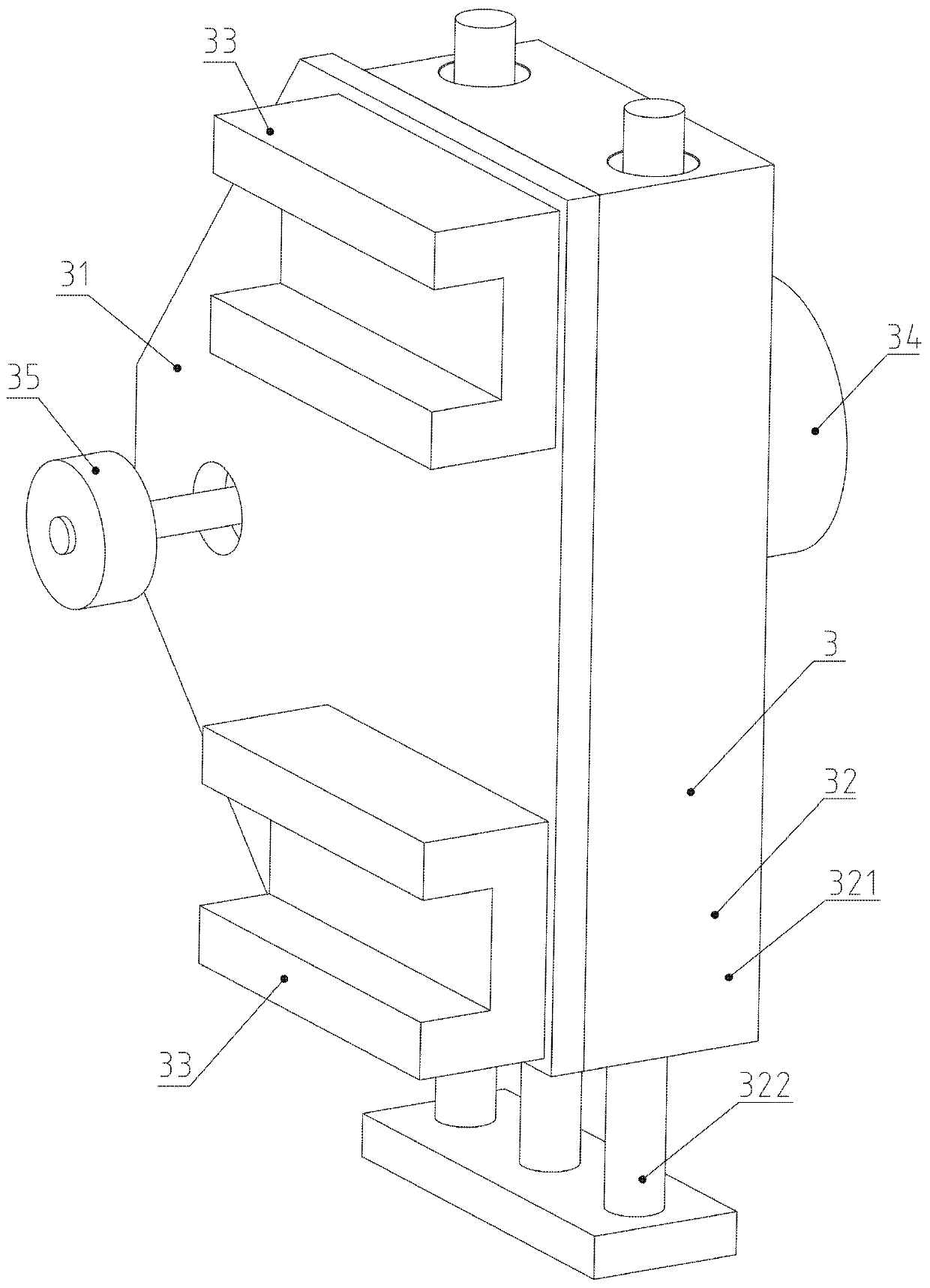

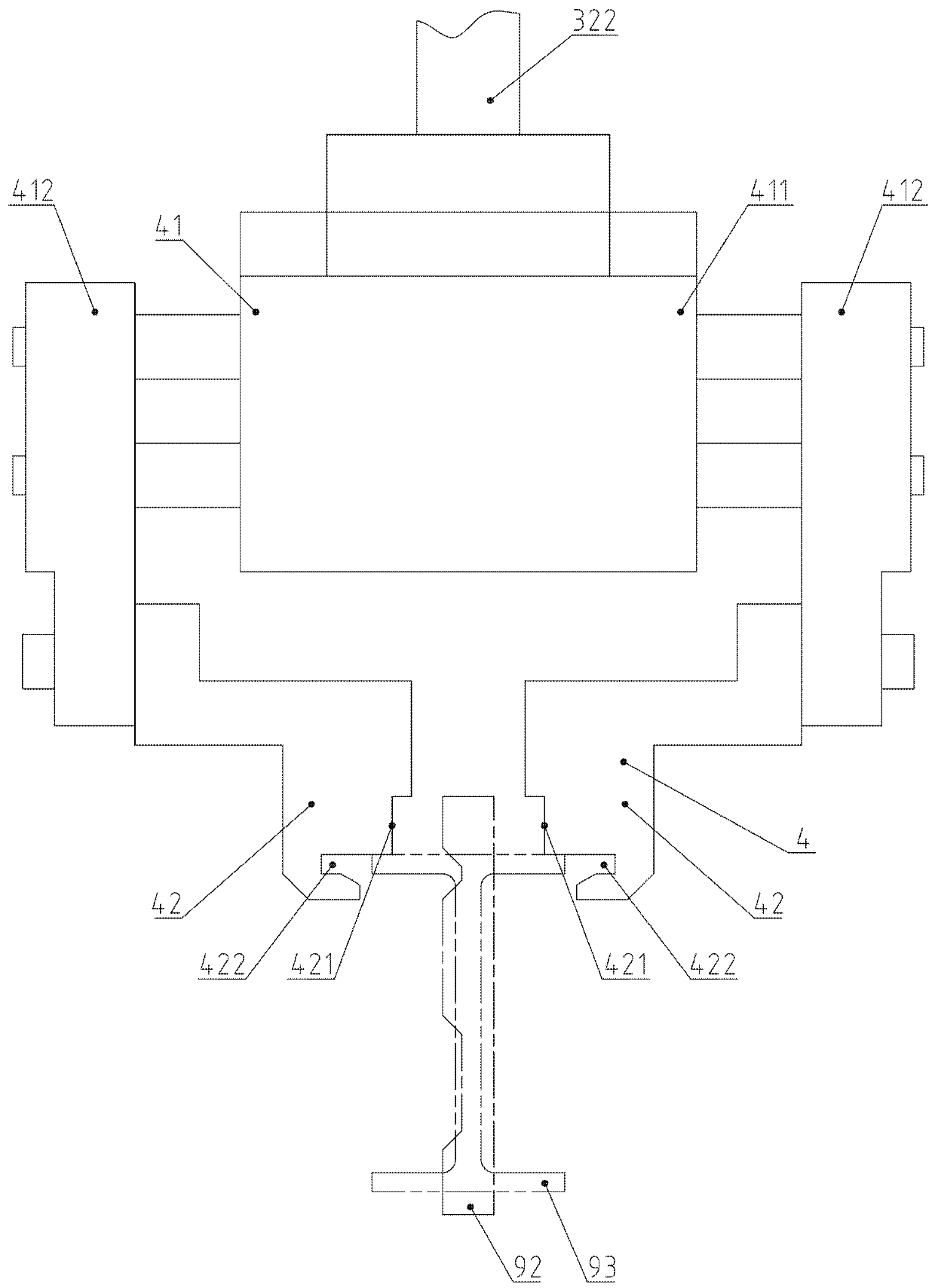

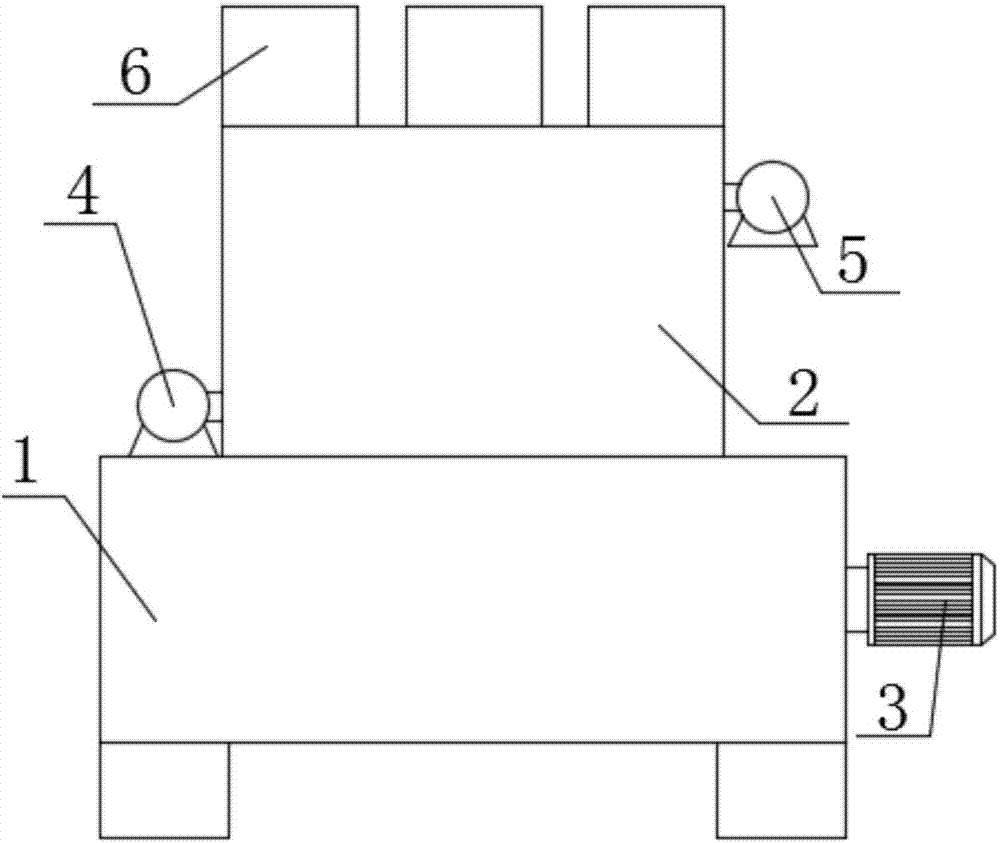

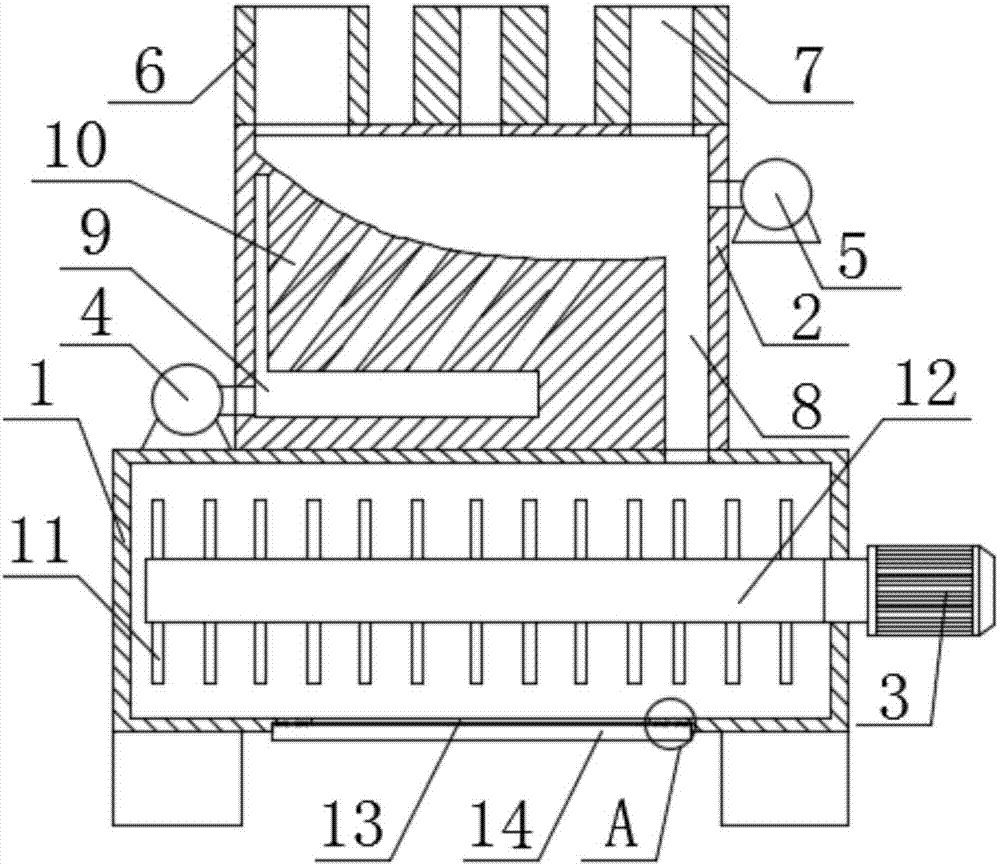

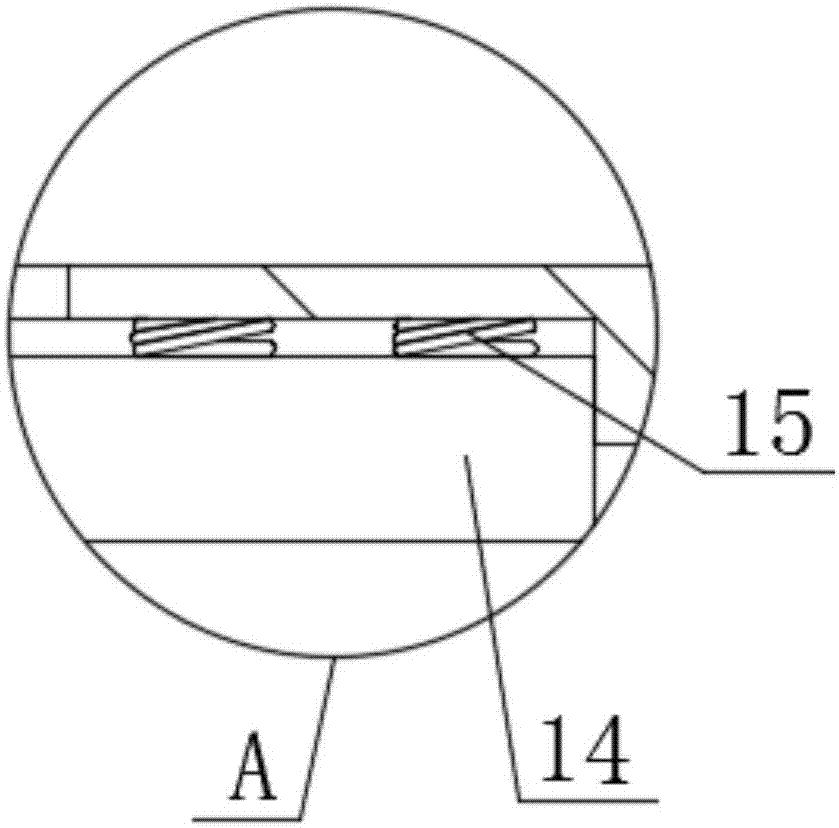

PVA film blow molding machine

InactiveCN112223732AProduction delayFor quick replacementWebs handlingBlow moldingMechanical engineering

The invention relates to the field of film production, in particular to a PVA film blow molding machine. The PVA film blow molding machine comprises a base, a moving mechanism is arranged on the edgeof one side of the upper surface of the base, the moving mechanism and the upper surface of the base are jointly and fixedly connected with a supporting mechanism, and a driving mechanism is arrangedinside the supporting mechanism. The PVA film blow molding machine has the beneficial effects that when one winding drum needs to be replaced, a film is wound on the other winding drum firstly, then aT-shaped sliding block drives a second supporting plate and a second rectangular rod to move, supporting of the second rectangular rod to the winding drum and limiting of a limiting ring to the winding drum are relieved, at the moment, the wound winding drum can be taken down from a first supporting rod and replaced with a new winding drum, the second supporting plate and the second rectangular rod are reset to support and limit the winding drum, overall replacement is simple and convenient, shutdown is not needed, and film production is prevented from being delayed.

Owner:邵振洋

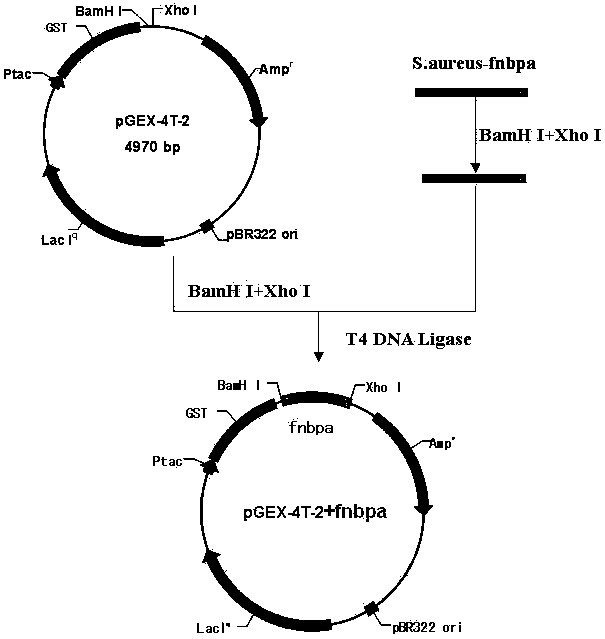

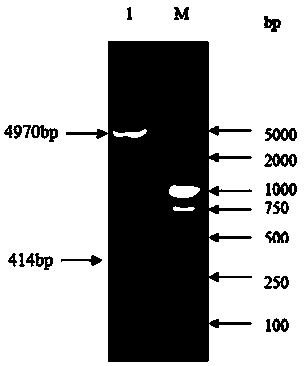

Chemically synthesized staphylococcus aureus surface protein FnBPA gene fragment and expression and application thereof

ActiveCN103725697AHigh titerIncrease the body's cellular immunityImmunoglobulins against bacteriaDepsipeptidesPolyclonal antibodiesGenetic engineering

The invention relates to a chemically synthesized staphylococcus aureus surface protein FnBPA gene fragment, as well as expression and application thereof, belonging to the fields of genetic engineering technologies, antibodies and kits. According to the chemically synthesized staphylococcus aureus surface protein FnBPA gene fragment provided by the invention, a strong antigen epitope, namely 133 amino acids in total from 745th amino acid to 877th amino acid in the staphylococcus aureus surface protein FnBPA are screened out through computer analysis, a codon preferred by prokaryotes is selected, a brand new gene sequence of the antigen epitope is chemically synthesized, the gene fragment is expressed by utilizing the genetic engineering technology, and the strong antigen epitope fragment of the staphylococcus aureus surface protein FnBPA is prepared. The expressed strong antigen epitope fragment of the staphylococcus aureus surface protein FnBPA can be used for detection of staphylococcus aureus antibodies and immune preparation of anti-staphylococcus aureus monoclonal antibodies, polyclonal antibodies and the like.

Owner:李越希

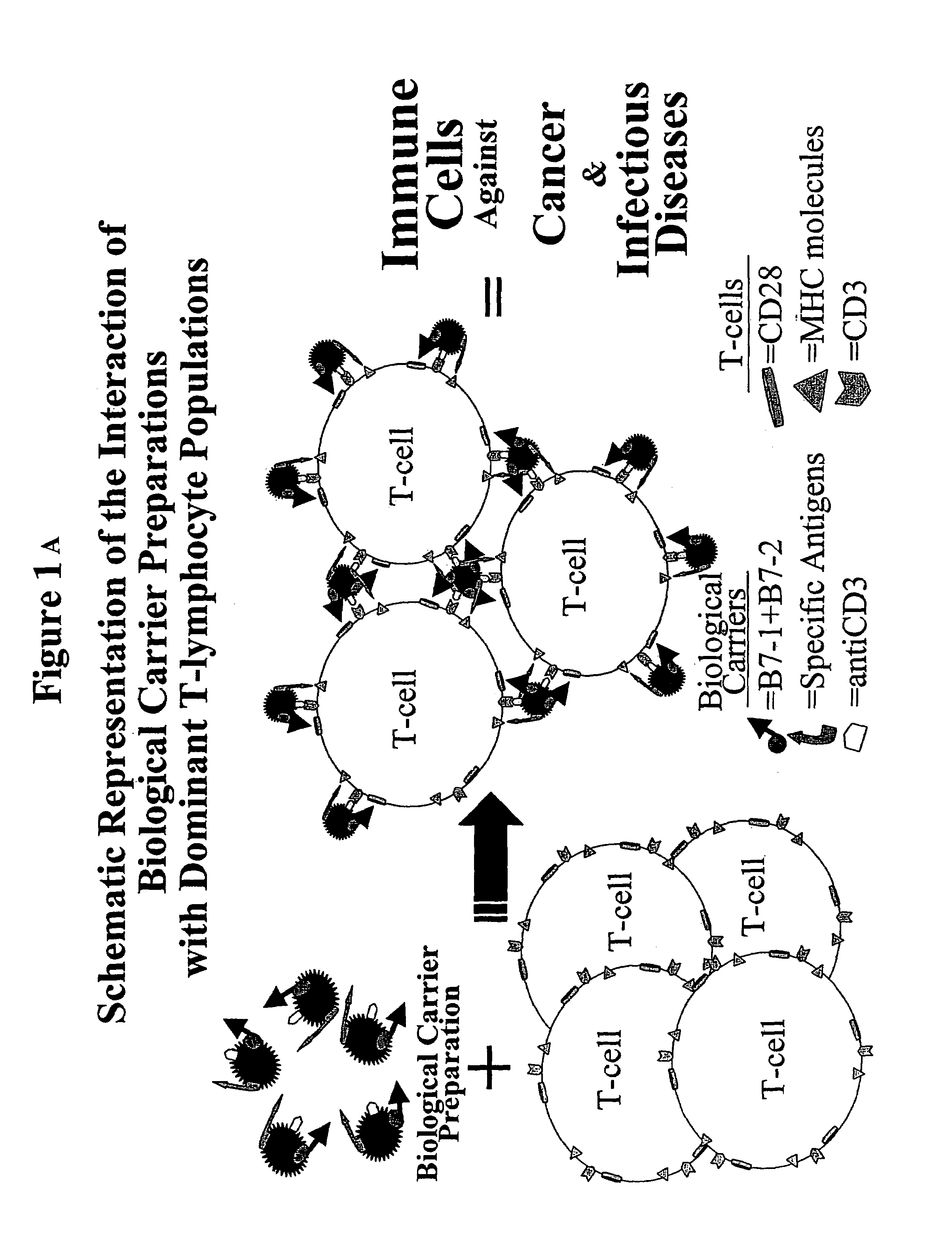

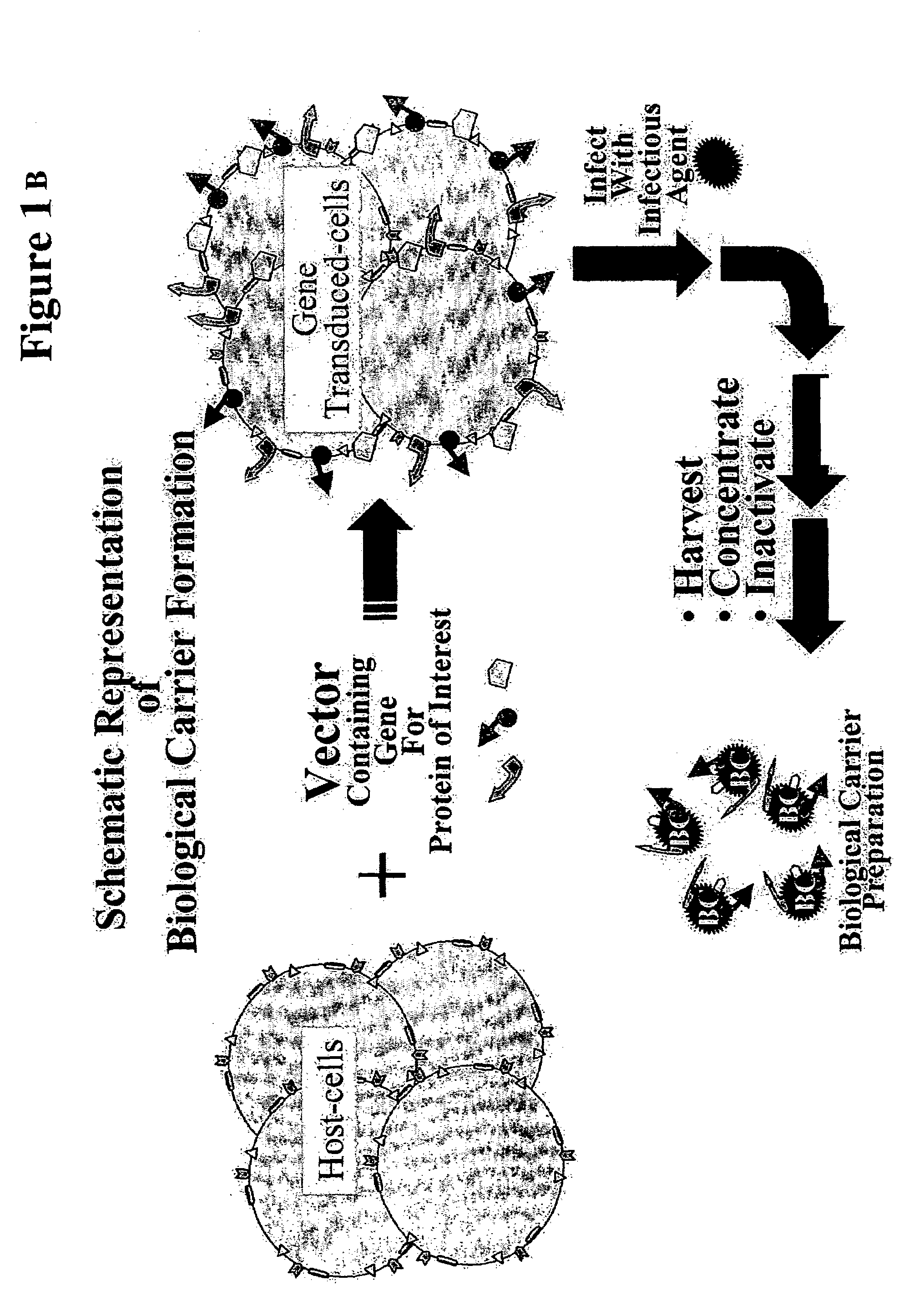

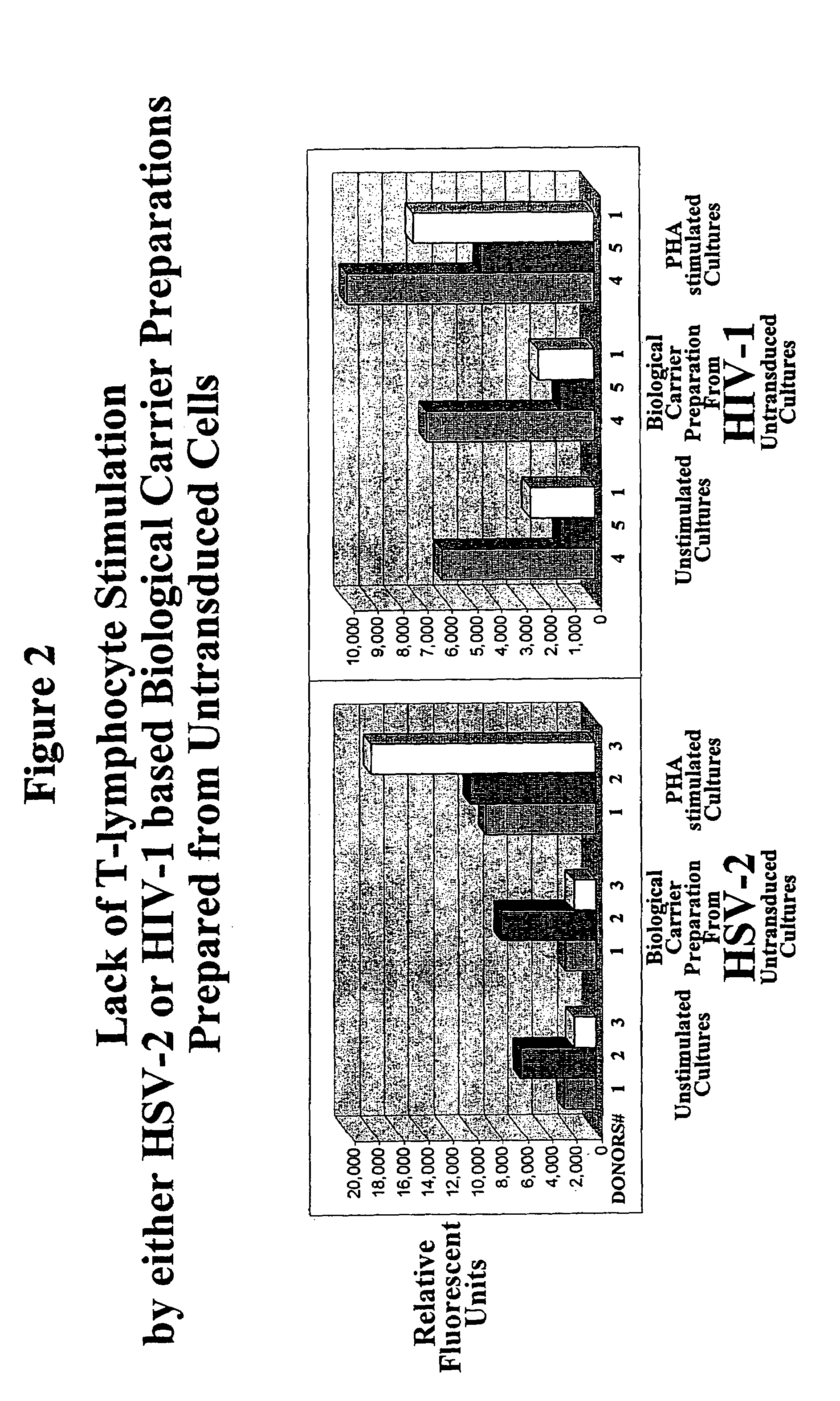

Production of "biological carriers" for induction of immune responses and inhibition of viral replication

InactiveUS7579007B2Production delaySimple processImmunoglobulins against cell receptors/antigens/surface-determinantsFermentationAntigenBiological property

This application provides a method to form non-infectious Biological Carrier that may be used to deliver signals to cells either in vitro or in vivo. The Biological Carriers are inactivated virus particles that have been specifically modified to give biological properties different from the virus particles deriving from an unmodified host cell that (i) expresses at least one co-stimulatory molecule and (iia) at least one antigen that can initiate an immune response, and / or (iib) express surface molecules that suppress viral replication.

Owner:JDM TECH +1

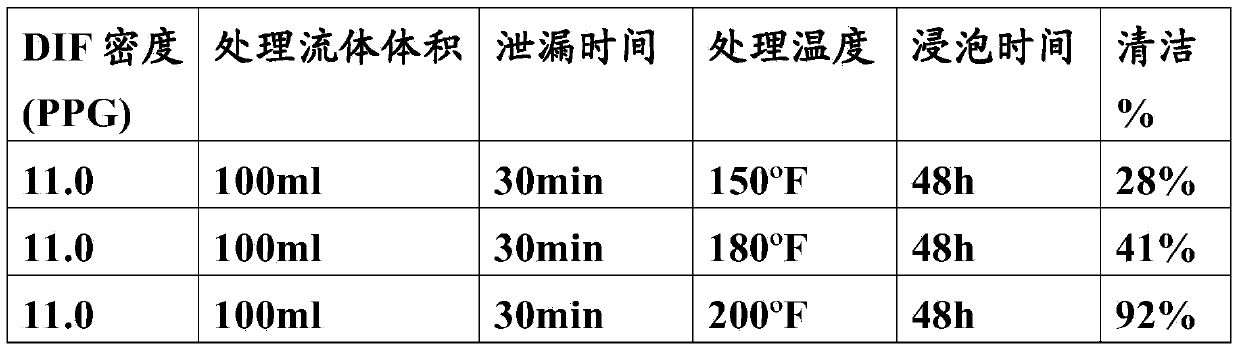

Composition and method for removing filter cake

An embodiment of the present disclosure is directed to a well servicing fluid emulsion. The well servicing fluid is formulated with components comprising an ester of an organic acid for which the pKa of the organic acid is less than 0; an aqueous based fluid and an emulsifier. The ester is dispersed in the aqueous based fluid to form the well servicing fluid emulsion.

Owner:BAKER HUGHES INC

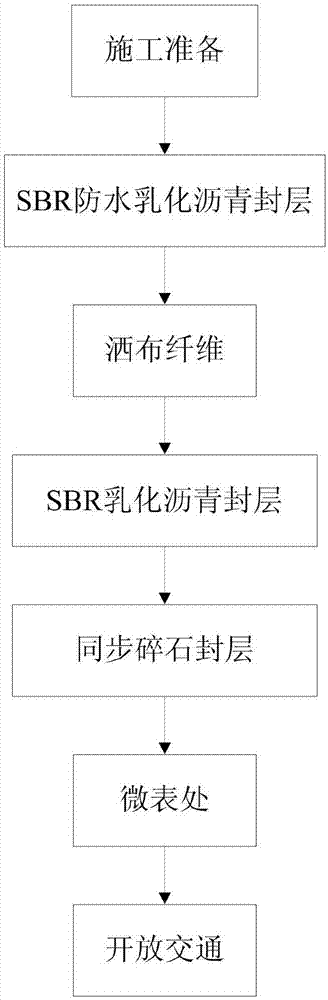

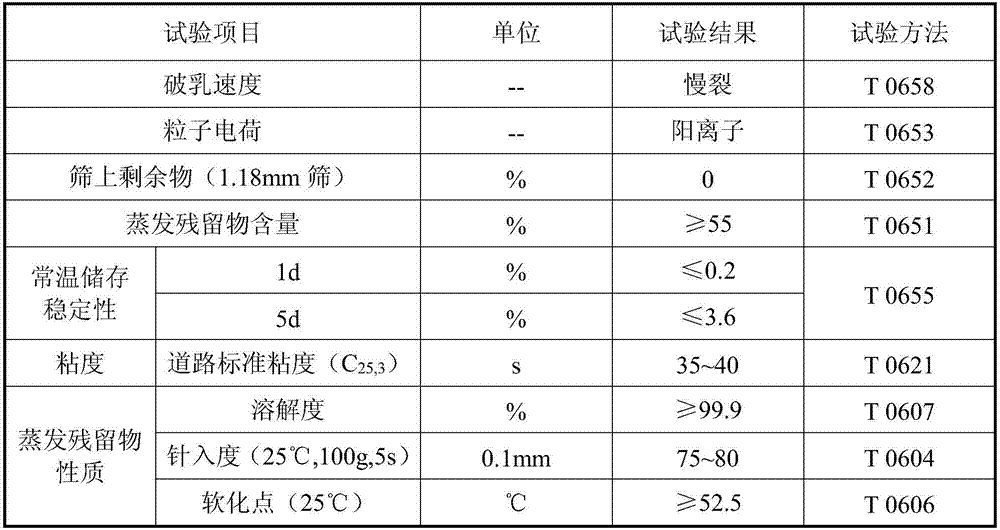

Composite pavement layer-sealing method

The invention provides a composite pavement layer-sealing method, and belongs to the technical field of highway pavement maintenance. The composite pavement layer-sealing method comprises the steps of construction preparing, SBR waterproof emulsified asphalt layer sealing, fiber spreading, SBR emulsified asphalt layer sealing, synchronous crushed stone layer sealing and micro surfacing. After treatment with the composite pavement layer-sealing method, pavement has good skid resistance and abrasion resistance, a net structure is formed by SBR emulsified asphalt with high viscosity, fiber and crushed stones, so that flowing of the asphalt is prevented effectively, high temperature stability is improved, the pavement is not flushing, load and abrasion can be effectively resisted at the same time, shear resistance and slip properties of the pavement is improved.

Owner:陕西国琳建设工程有限公司

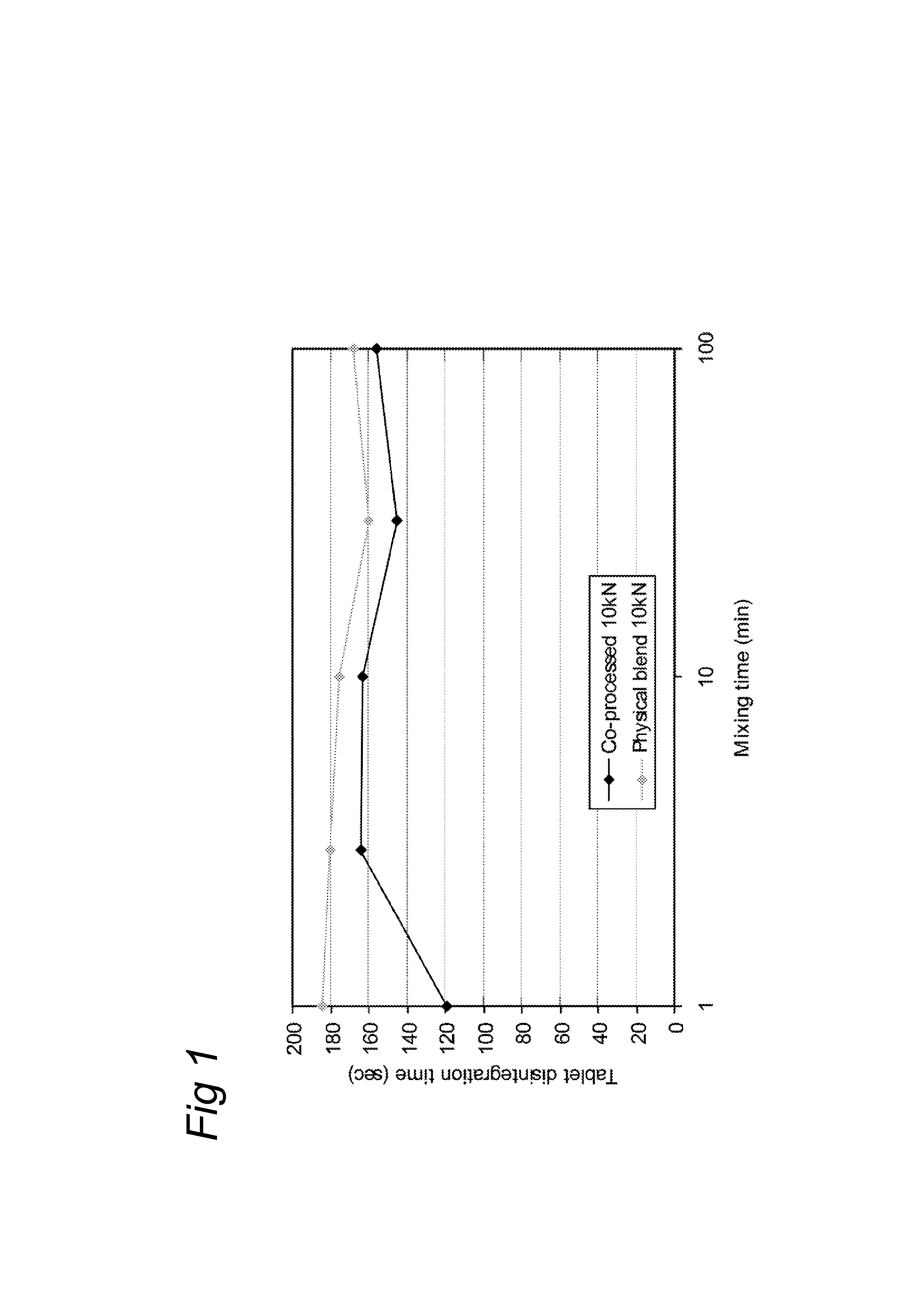

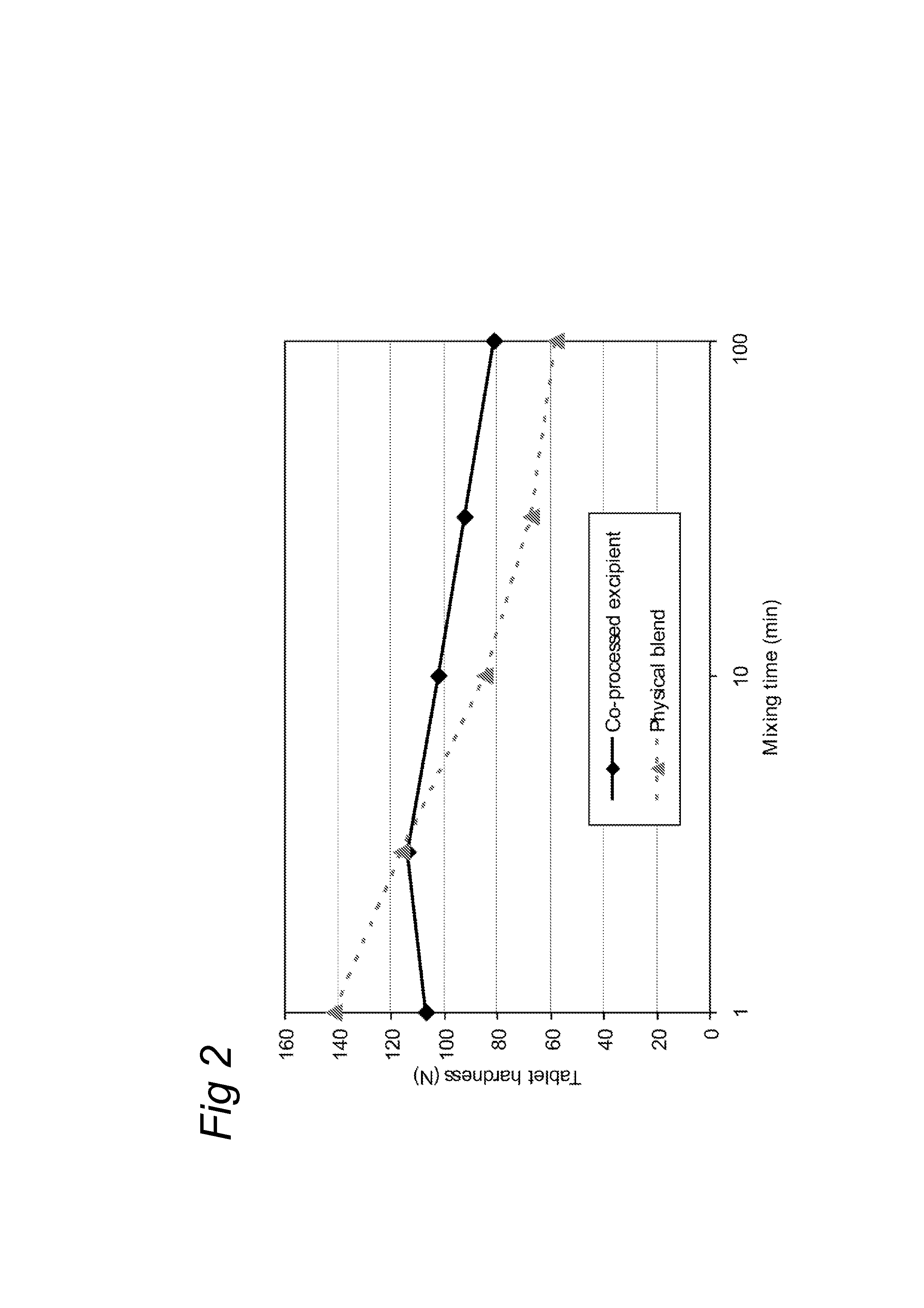

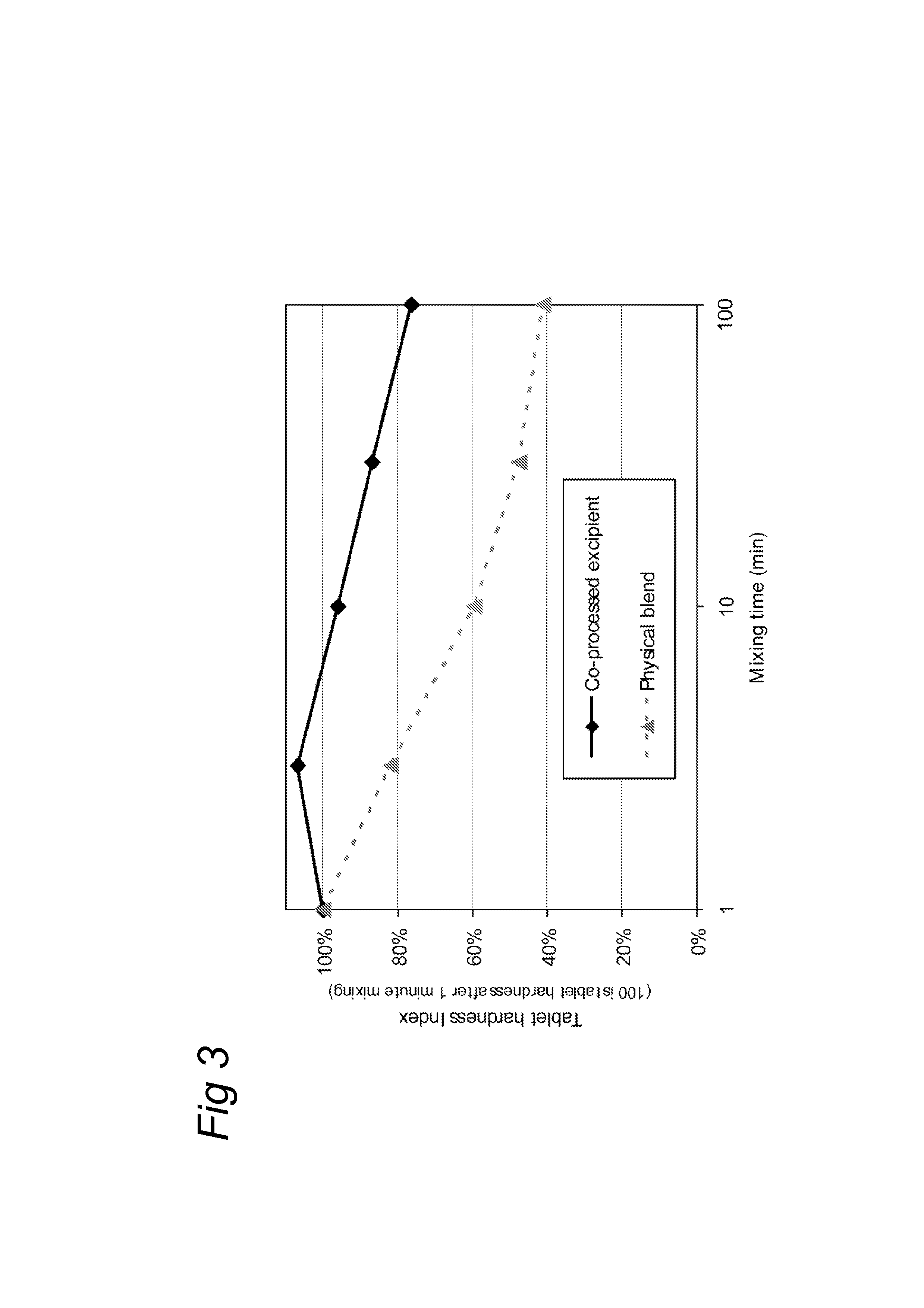

Co-processed tablet excipient composition its preparation and use

ActiveUS20130177649A1Excellent water solubility characteristicHigh densityPharmaceutical product form changePretreated surfacesLactoseTableting

The invention pertains to a co-processed excipient composition suitable for tableting, said composition comprising at least one filler-binder, at least one disintegrant, and at least one lubricant which have been subjected to granulation together, and said composition partially or completely coated with lactose, preferably in crystalline form. The inventors have overcome the prejudice against the use of lubricants in tableting excipient compositions early in the tableting process. It was found that the alleged detrimental affects of the lubricant in terms of binding and disintegration could readily be controlled in a excipient composition wherein the lubricant is co-processed in the matrix, and the composition is provided with a lactose coat.

Owner:FRIESLANDCAMPINA NEDERLAND HLDG

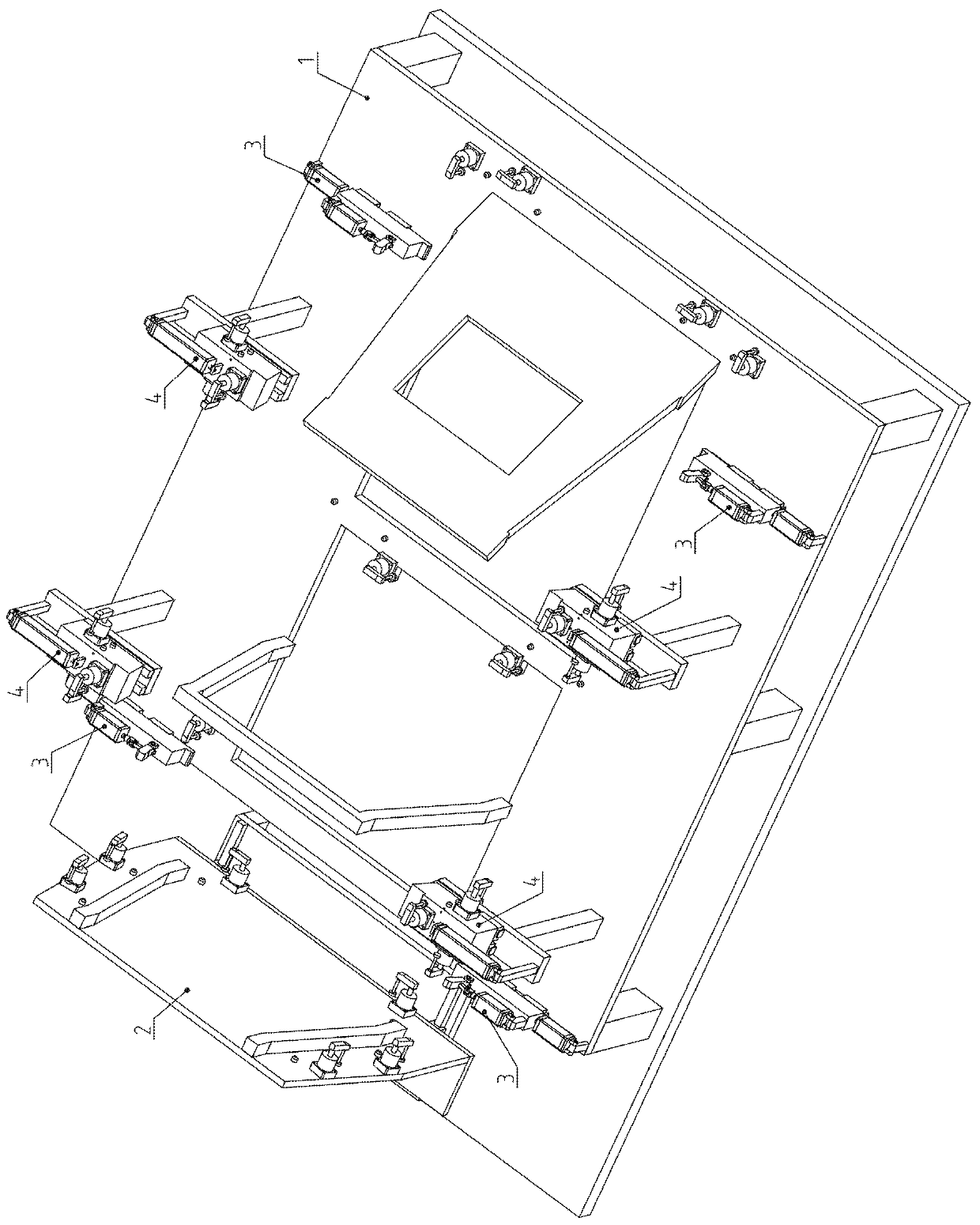

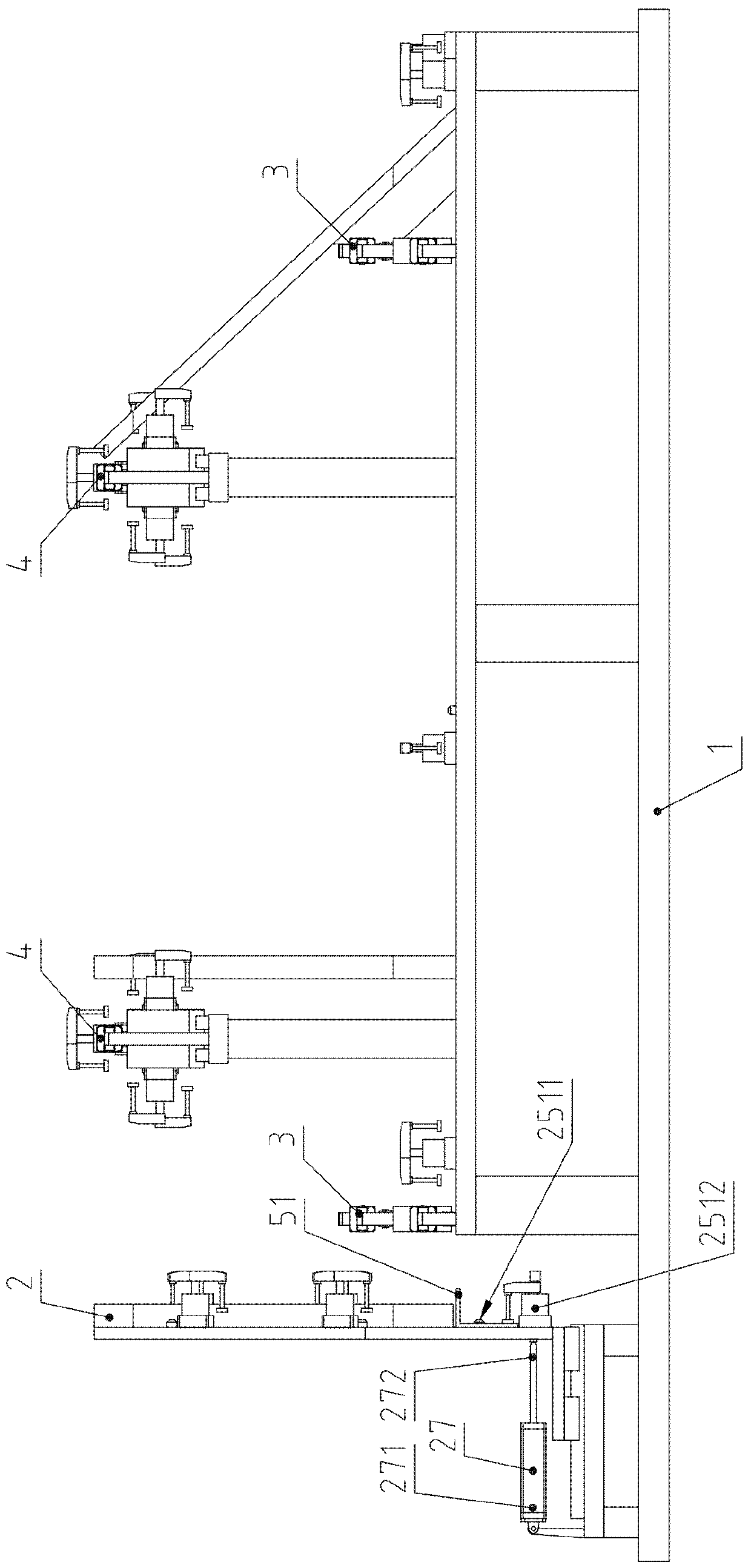

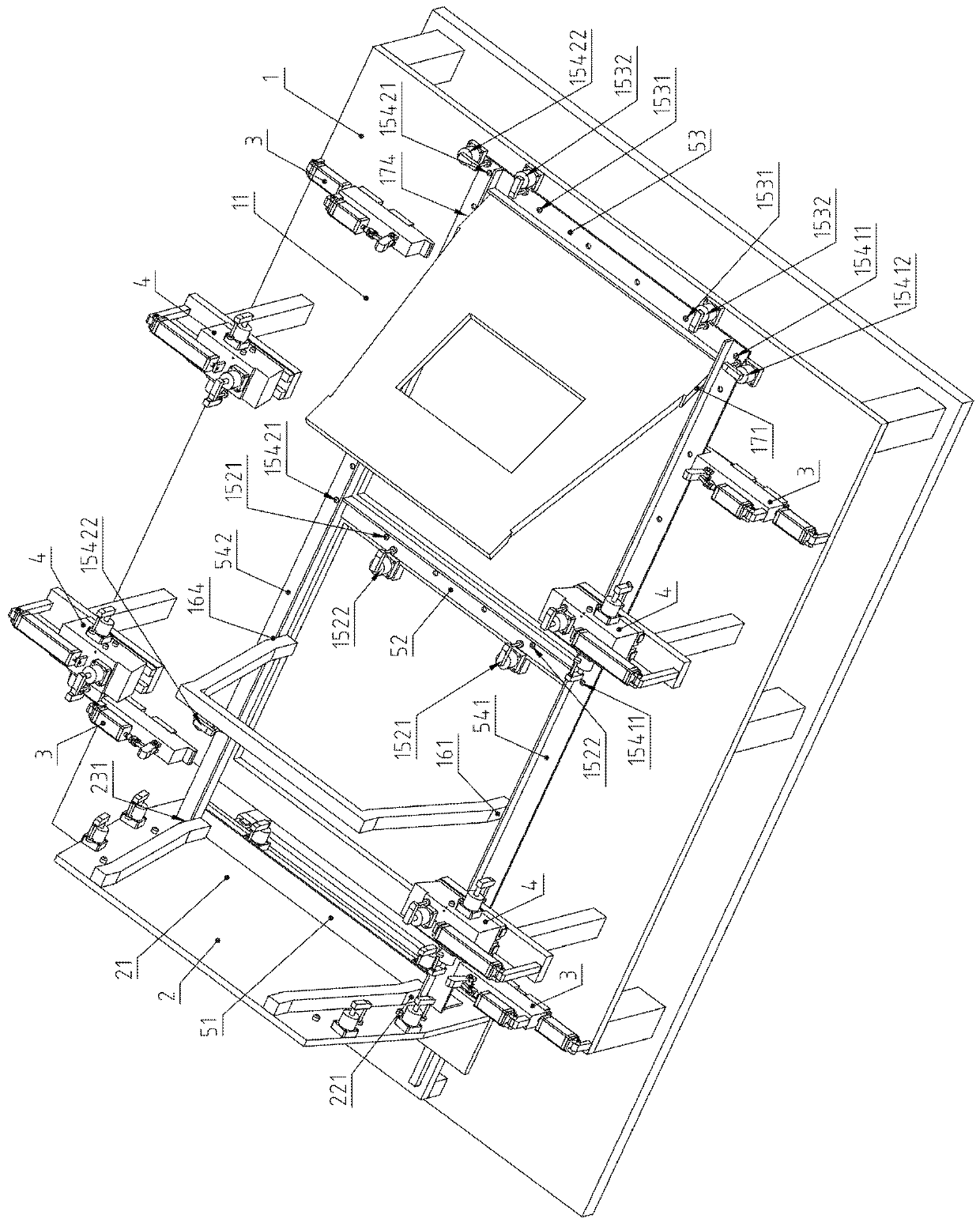

Efficient precise welding mold of belt type feeder guide groove

ActiveCN110695591AConsistent sizeSmall sizeWelding/cutting auxillary devicesAuxillary welding devicesEngineeringDrill

The invention belongs to the technical field of mine machine manufacturing, and relates to an efficient precise welding mold of a belt type feeder guide groove. Front upper angle steel positioning pins carry out positioning, a front upper angle steel corner oil cylinder presses front lower angle steel, and a front end positioning assembly transversely moves backwards to finish positioning; angularsteel positioning pins position lower middle angle steel, lower rear angle steel, lower left angle steel and lower right angle steel which are compressed by angle steel corner oil cylinders; a groovesteel clamping assembly positions and clamps left groove steel and right groove steel; a rib plate positioning assembly positions and clamps long ribs, short ribs and flat plates; a left front flangeplate positioning pin positions a left front flange plate, and a left front flange plate corner oil cylinder carries out pressing; a right front flange plate positioning pin positions a right front flange plate, and a right front flange plate corner oil cylinder carries out compressing; and a rib plate positioning assembly positions and clamps left upper angle steel and right upper angle steel, and an upper angle steel corner oil cylinder carries out pressing. The produced guide groove is consistent in size, good in interchangeability, simple in process, high in work efficiency and small in used bench drill specification.

Owner:HUNAN AOFENG HEAVY IND

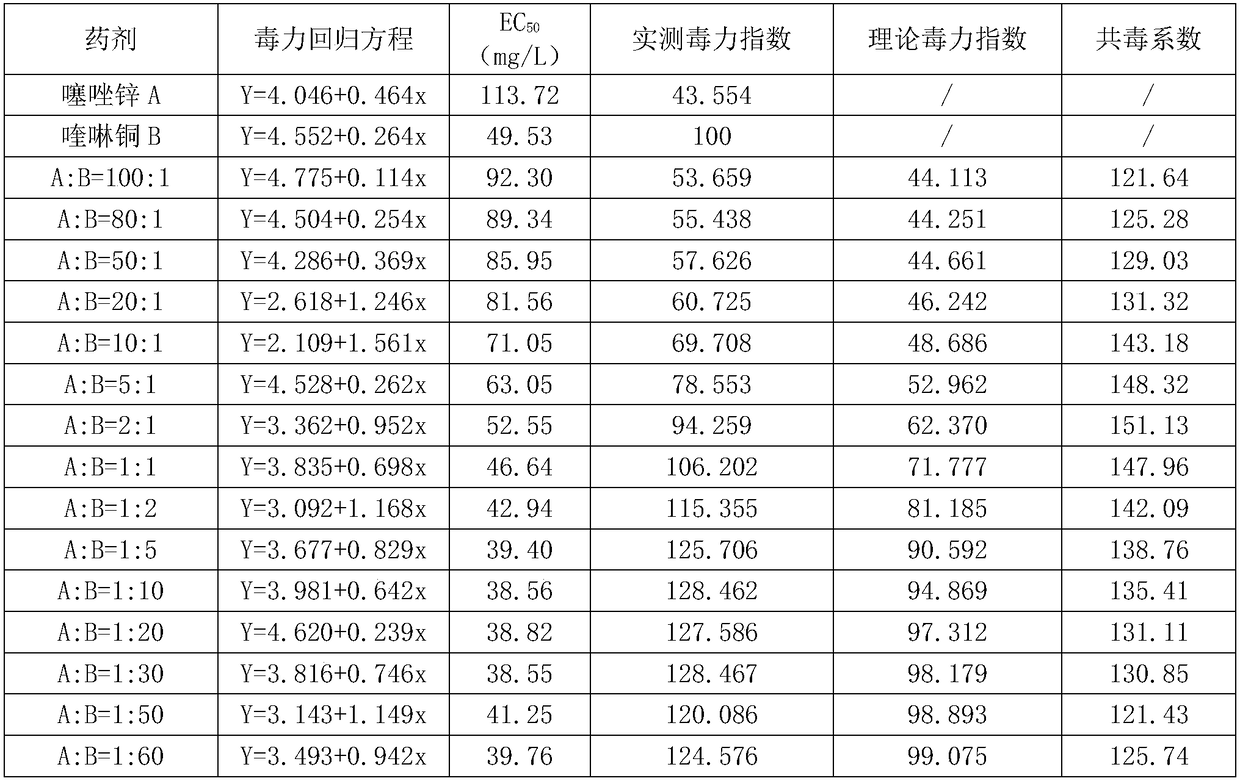

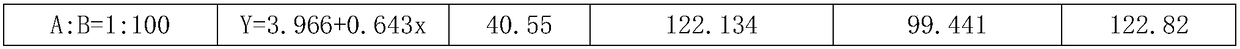

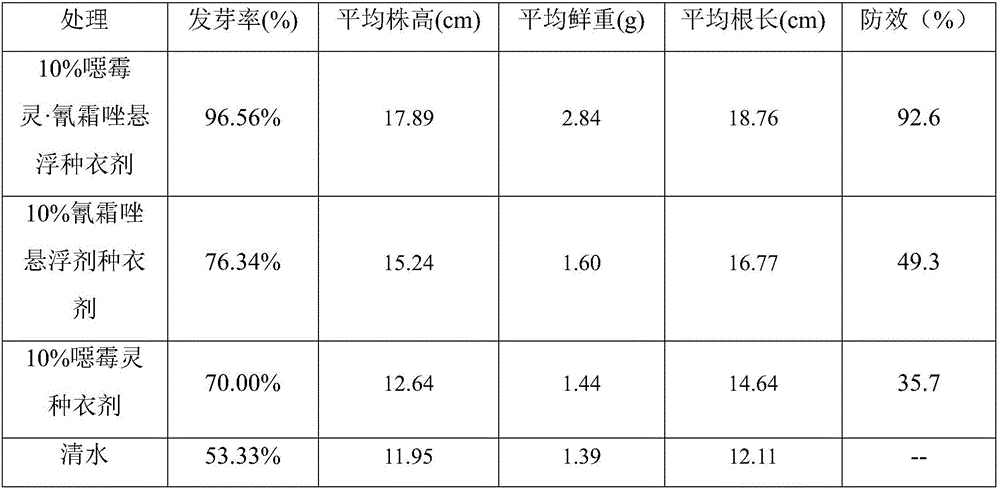

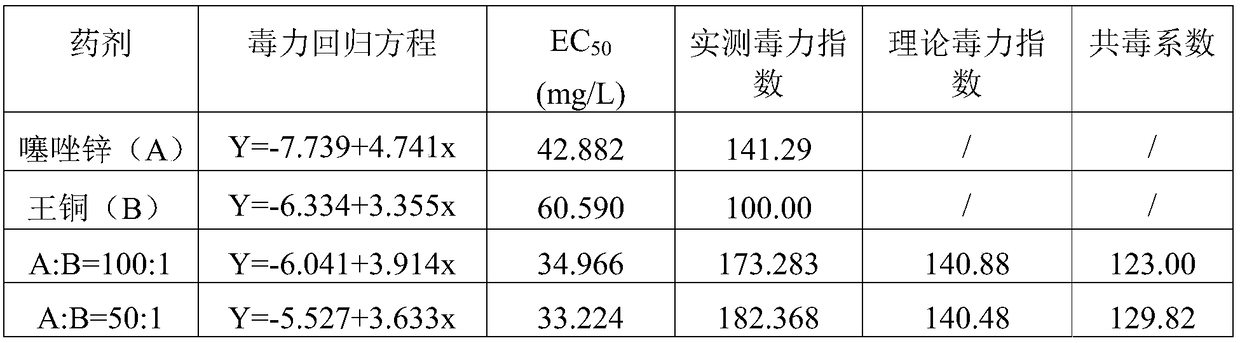

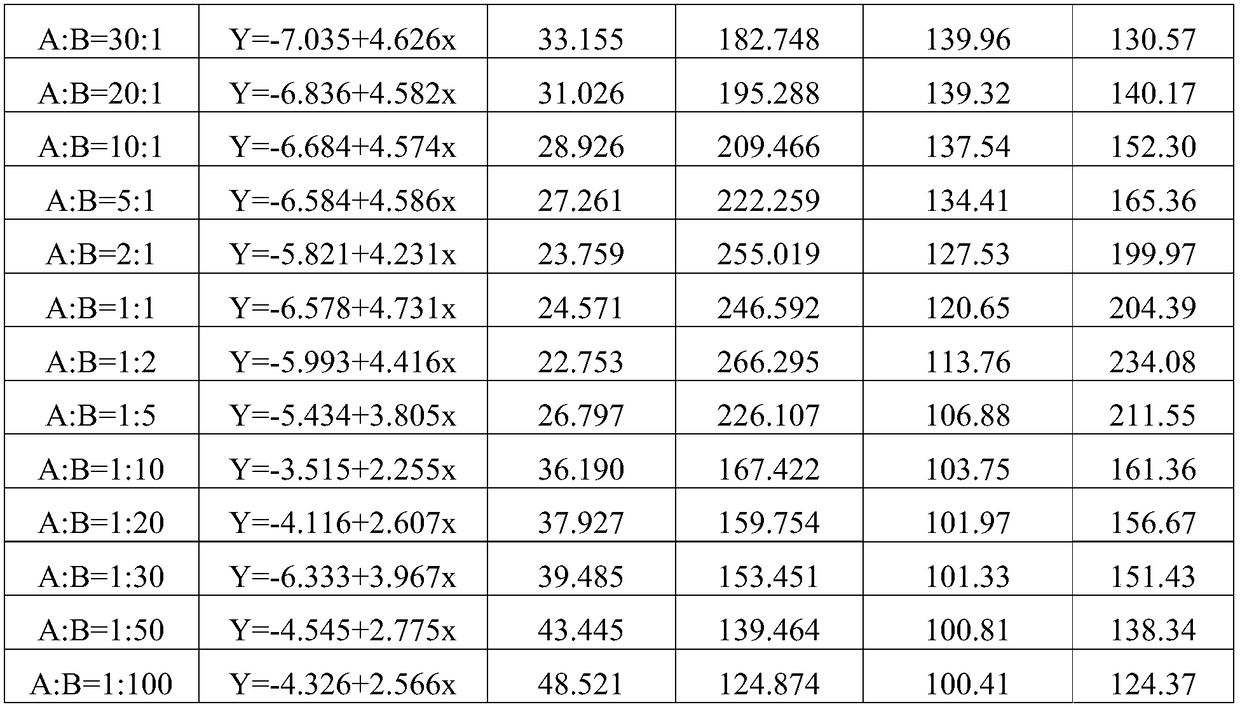

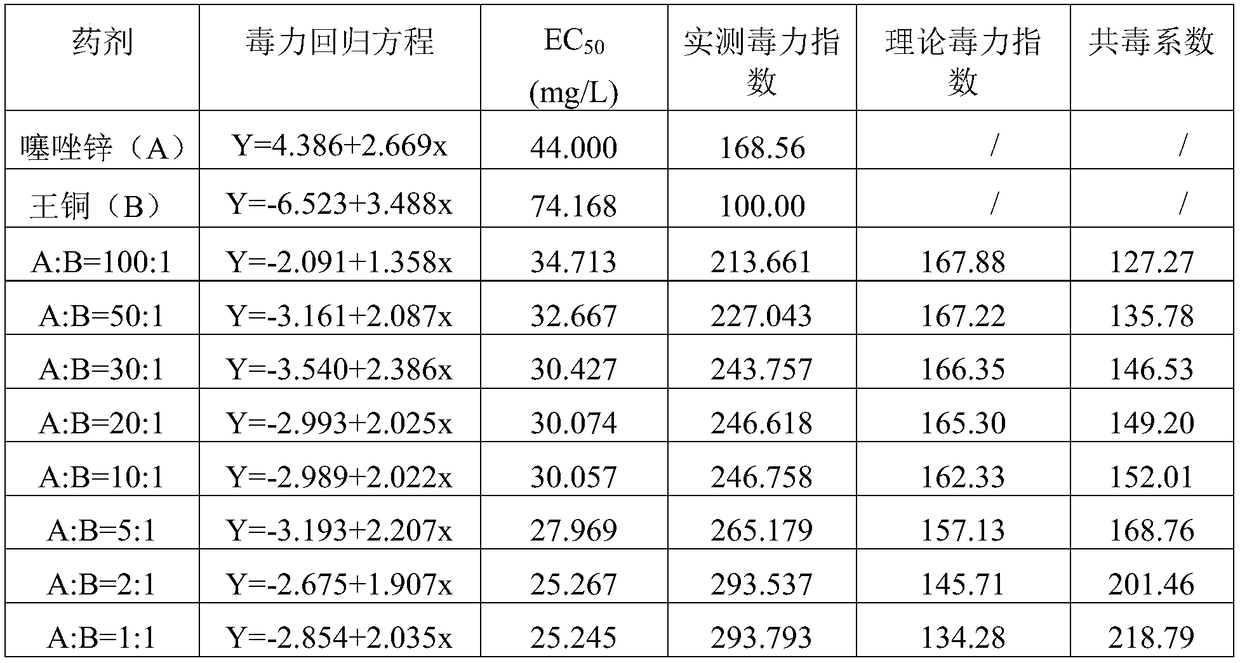

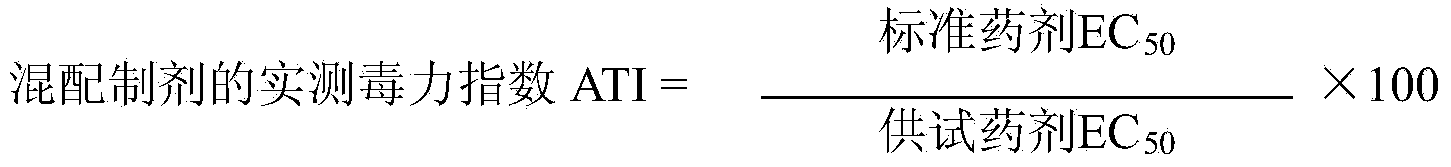

Application and preparation of composition containing zinc thiazole and organic copper fungicide

The invention discloses an application and preparation of a composition containing zinc thiazole and an organic copper fungicide. The composition is consist of the zinc thiazole and the organic copperfungicide, wherein the weight ratio of the zinc thiazole to the organic copper fungicide is 1:0.01-100). When the active ingredients of the zinc thiazole and the organic copper fungicide in the composition exist in a specific weight ratio, the bactericidal activity is greater than the total bactericidal activity of the zinc thiazole and the organic copper fungicide, and significant synergistic effect is achieved.

Owner:ZHEJIANG XINNONG CHEM CO LTD +1

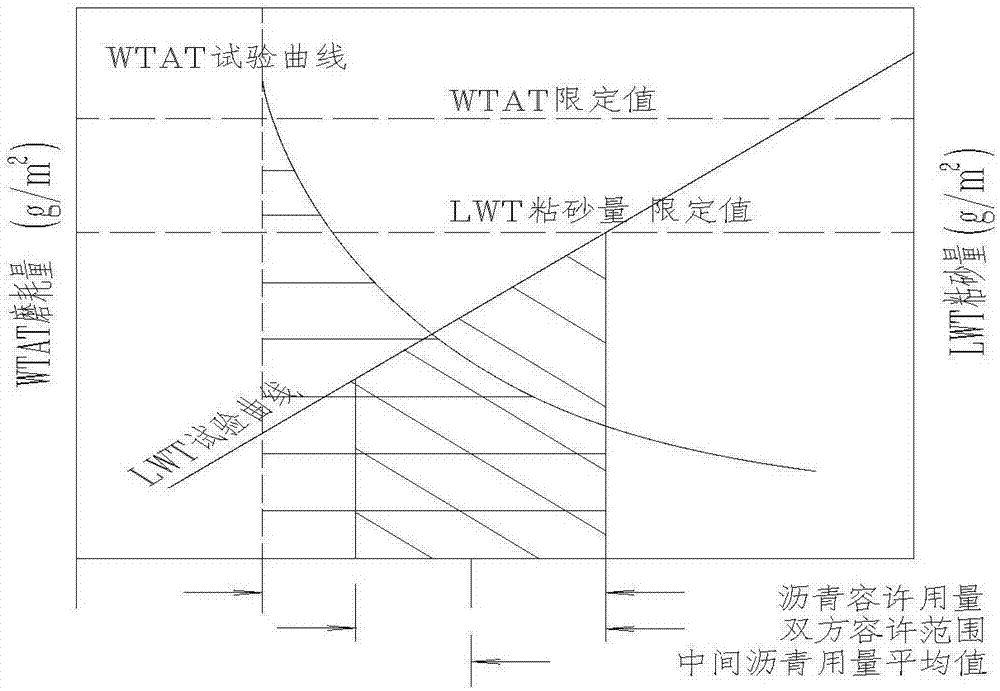

Frustule asphalt modifier, frustules asphalt modifier modified composite asphalt, and preparation method of frustule asphalt modifier

InactiveCN108342090ASmall particle sizeSmaller and more uniform particle sizeBuilding insulationsCrack resistanceWaste rubber

The invention relates to a frustule asphalt modifier, a frustules asphalt modifier modified composite asphalt, and a preparation method of the frustules asphalt modifier. The frustules asphalt modifier is prepared from, by weight, 5 to 20 parts of frustule, 10 to 25 parts of waste rubber powder, 0 to 5 parts of petroleum resin or low grade asphalt, and 0 to 3 parts of a stabilizing agent. The invention also discloses a frustules composite modified asphalt, and a preparation method thereof. The frustule asphalt modifier is capable of improving the high temperature performance, the low temperature performance, the fatigue resistance, and the water stability of asphalt mixtures; the obtained frustules composite modified asphalt possesses excellent heat storage stability, and low temperature crack resistance, and is capable of prolonging the service life of road. A part of expensive SBS is replaced by cheap frustule, compared with the pavement performance of modified asphalt prepared via using of only SBS, the pavement performance is improved, and modified asphalt cost is reduced.

Owner:深圳市海绵城市科学研究院

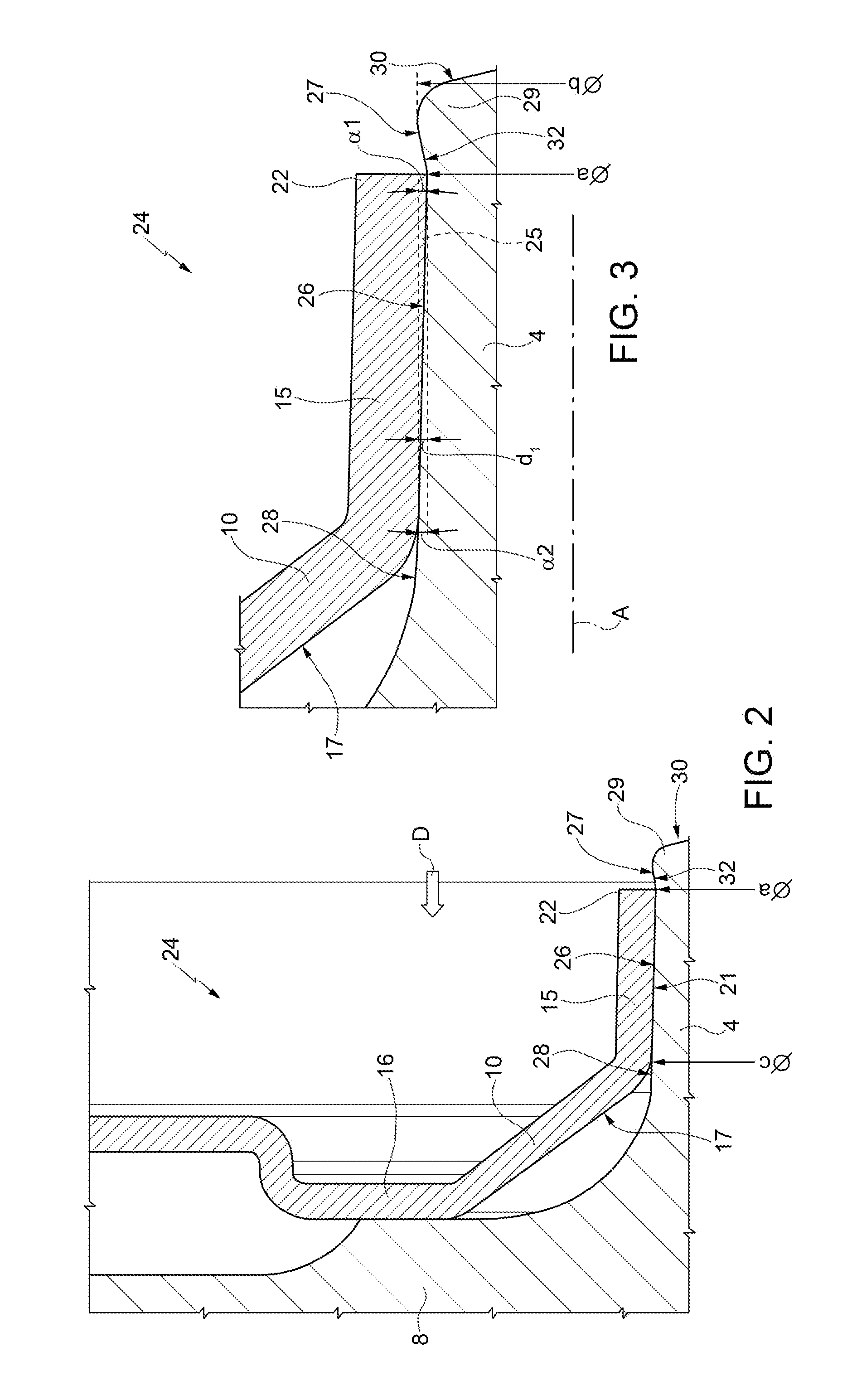

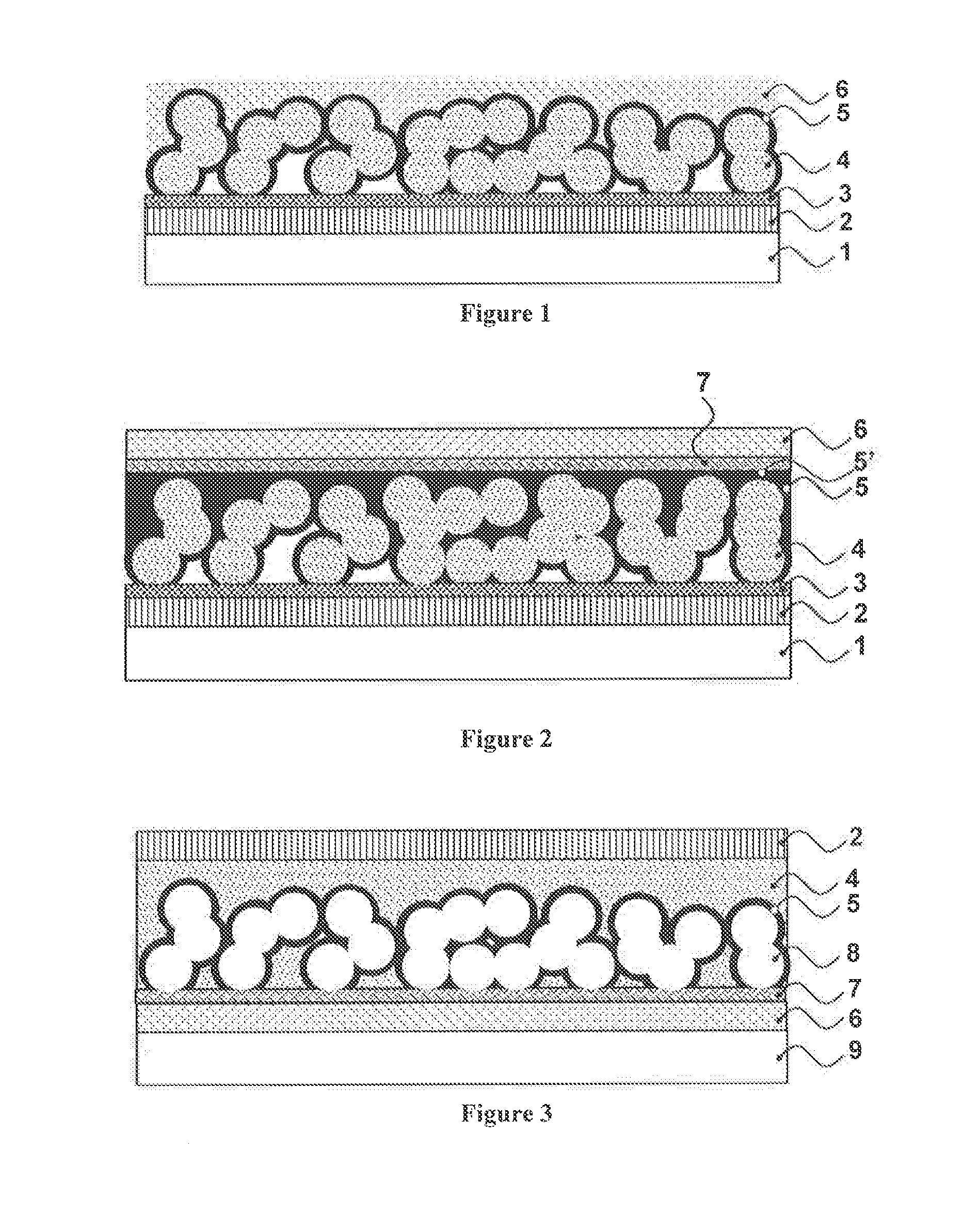

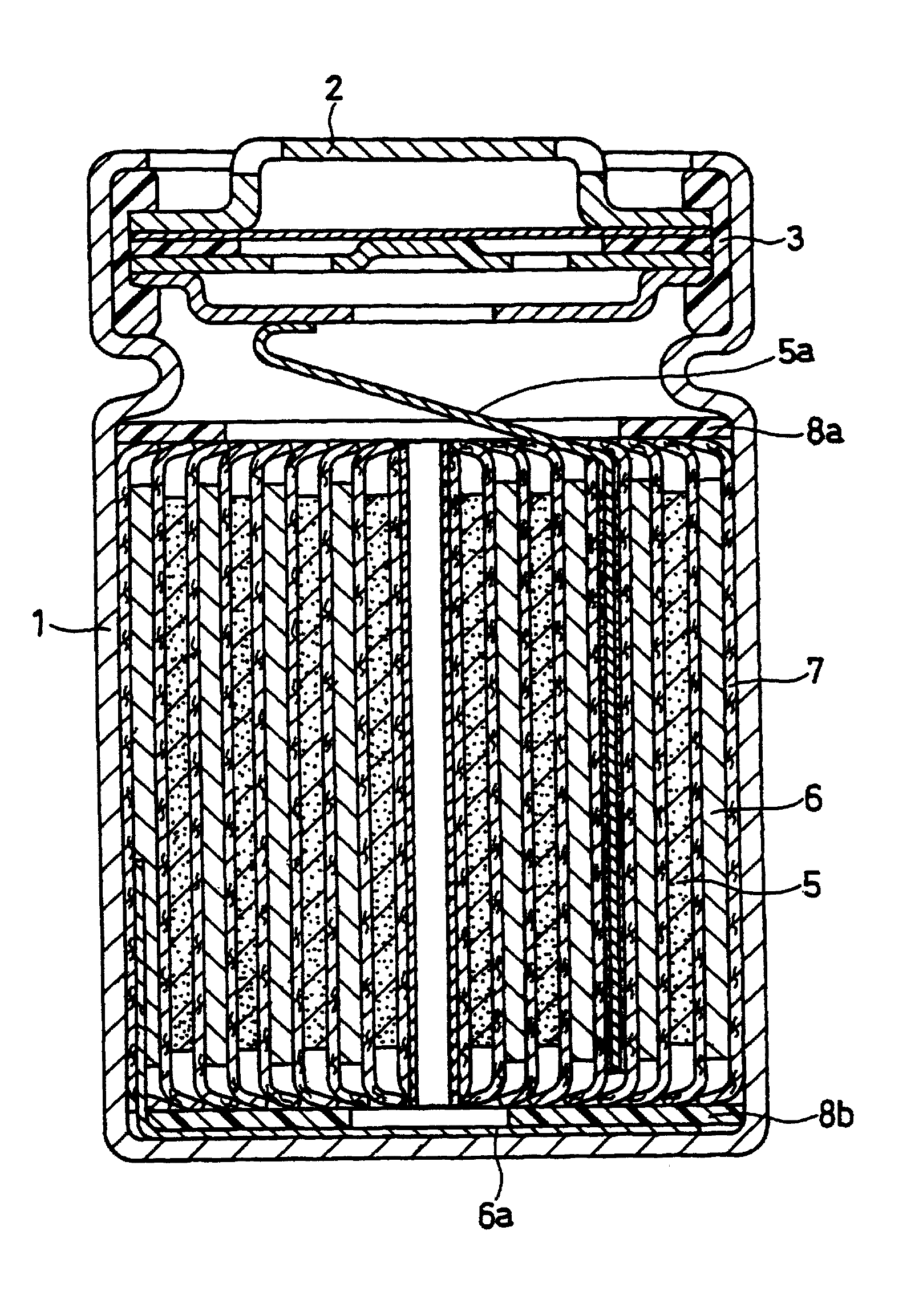

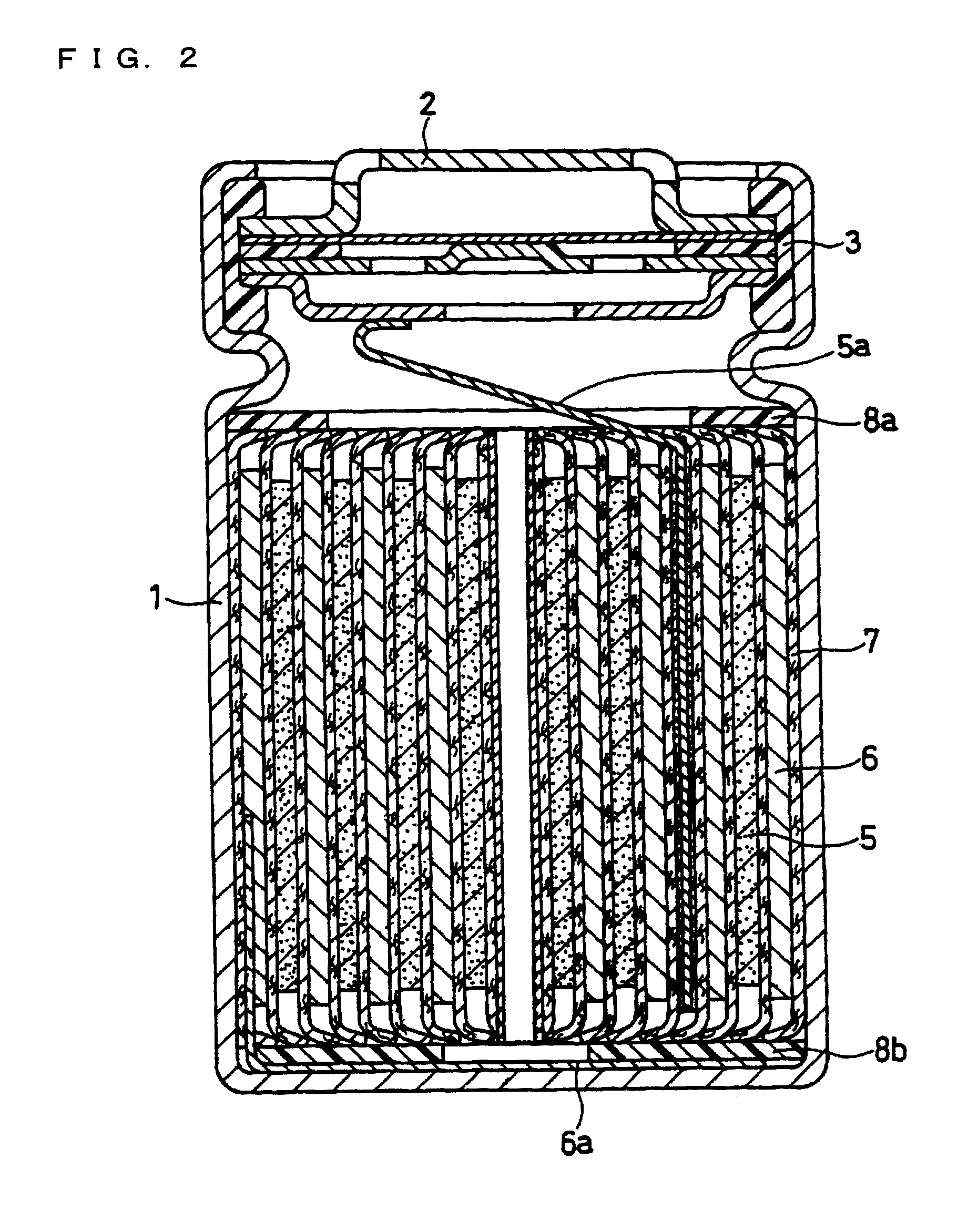

Positive electrode for non-aqueous electrolyte secondary batteries and non-aqueous electrolyte secondary battery

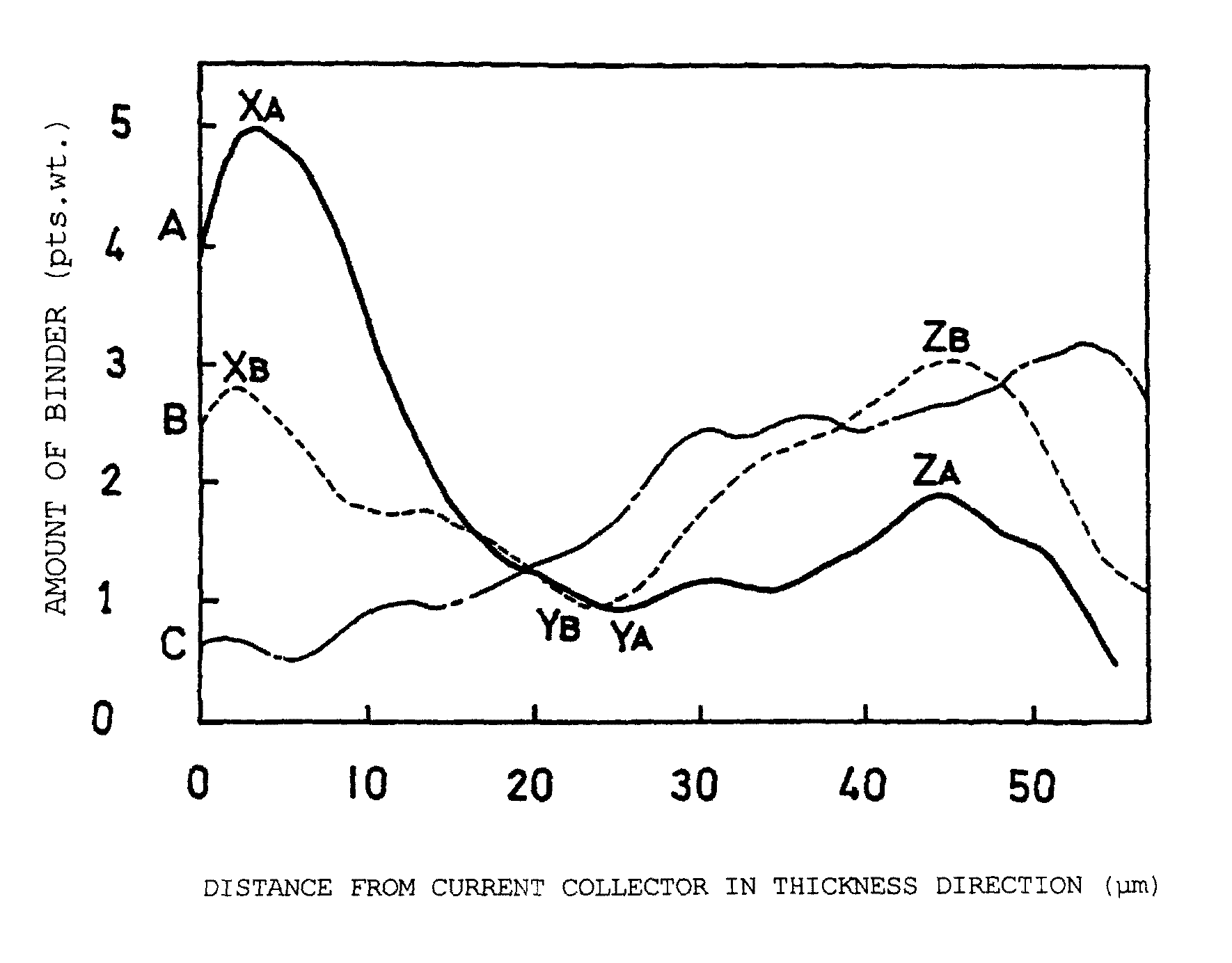

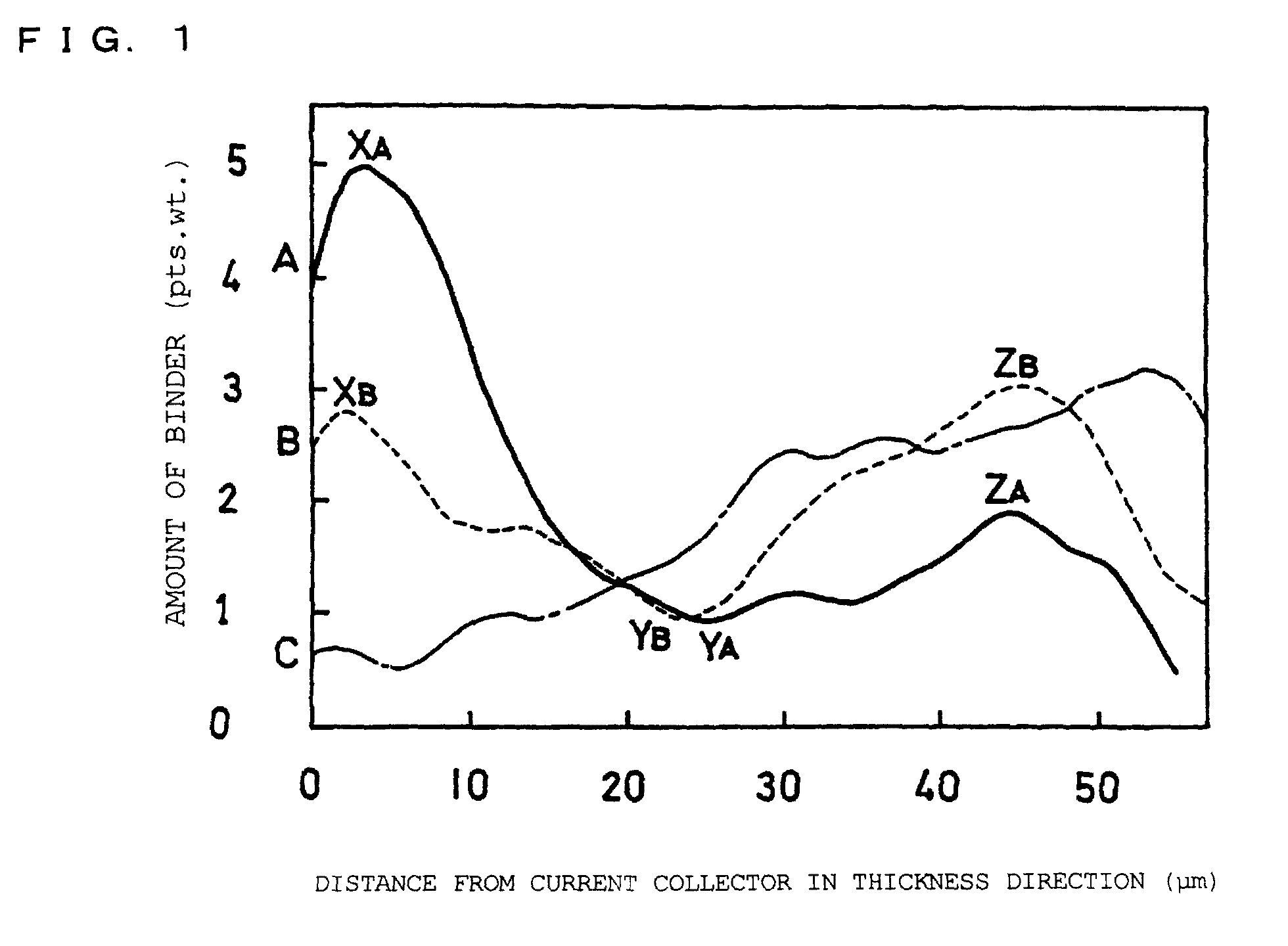

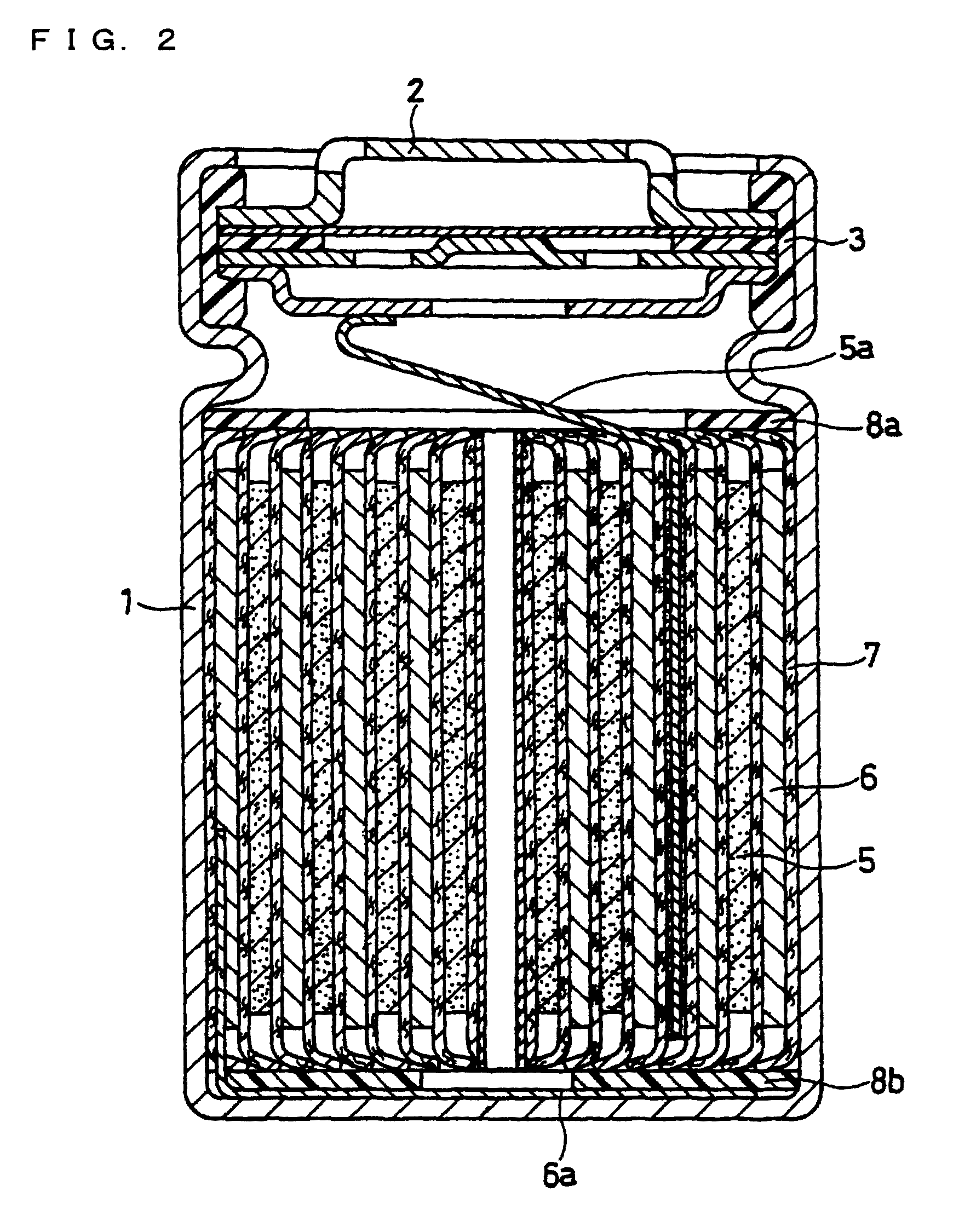

ActiveUS20120121955A1Ease of productionWell understandingNon-aqueous electrolyte accumulatorsFinal product manufactureCurrent collectorNon aqueous electrolytes

Disclosed is a positive electrode for non-aqueous electrolyte secondary batteries, the positive electrode including a positive electrode material mixture layer which includes positive electrode active material particles and a binder. A curve representing a correlation between a distance from a current collector in the thickness direction of the positive electrode material mixture layer and an amount of the binder has a first maximum point, a minimum point, and a second maximum point. The minimum point corresponds to a position in a center area of the positive electrode material mixture layer in a thickness direction thereof, and the first and second maximum points correspond to a position nearer the current collector and a position further away from the current collector than the position corresponding to the minimum point, respectively. A ratio W1 / W2 of an amount W1 at the first maximum point to an amount W2 at the minimum point of the binder per 100 parts by weight of the positive electrode active material particles is greater than 2.

Owner:PANASONIC INTELLECTUAL PROPERTY MANAGEMENT CO LTD

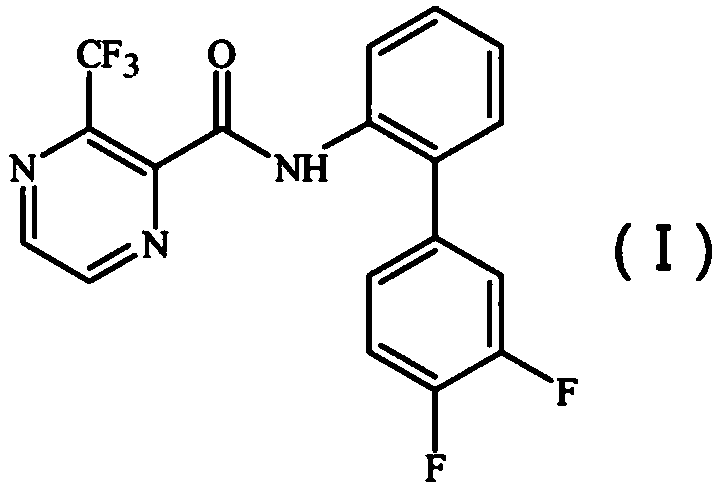

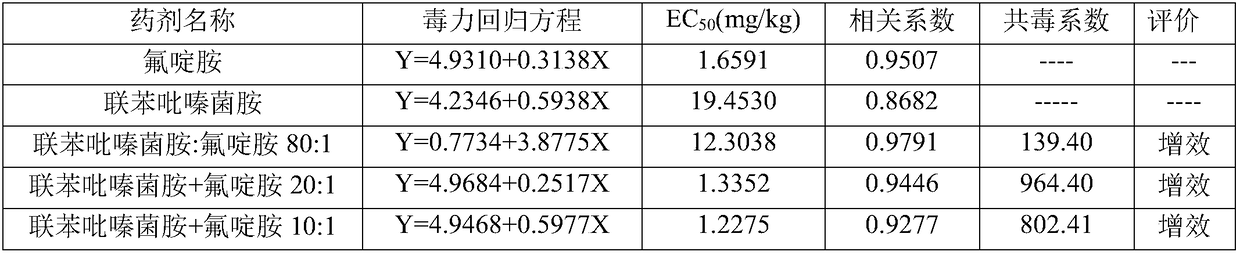

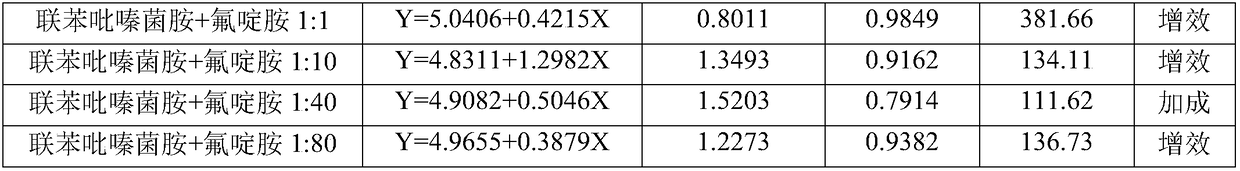

Composition containing pyraziflumid and usage thereof

The invention includes a composition containing pyraziflumid and usage thereof. Specifically, a bactericidal composition provided by the invention is characterized by containing a bactericidal activeingredient A and a bactericidal active ingredient B; the bactericidal active ingredient A is a compound as shown in a formula (I) and named as pyraziflumid; and the bactericidal active ingredient B isone of prothioconazole, boscalid and fluazinam. The bactericidal composition of the invention can achieve unexpected synergism in preventing and controlling ginseng sclerotinia disease, cabbage sclerotinia disease, strawberry gray mold, strawberry powdery mildew, cucumber powdery mildew, cucumber gray mold, cucumber sclerotinia disease, tomato gray mold, tomato sclerotinia disease, eggplant graymold, pepper gray mold, and capsicum sclerotinia disease.

Owner:JILIN AGRI SCI & TECH COLLEGE

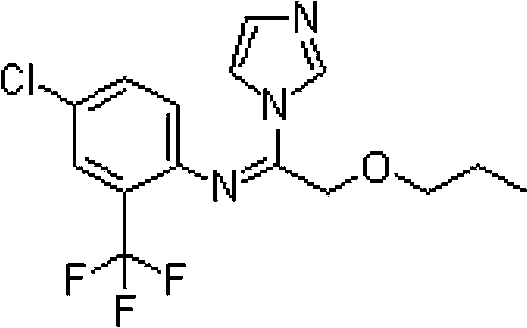

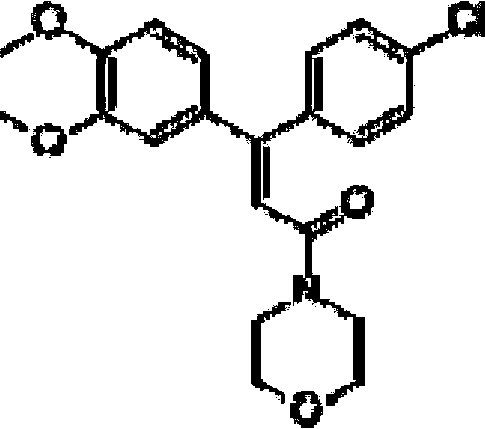

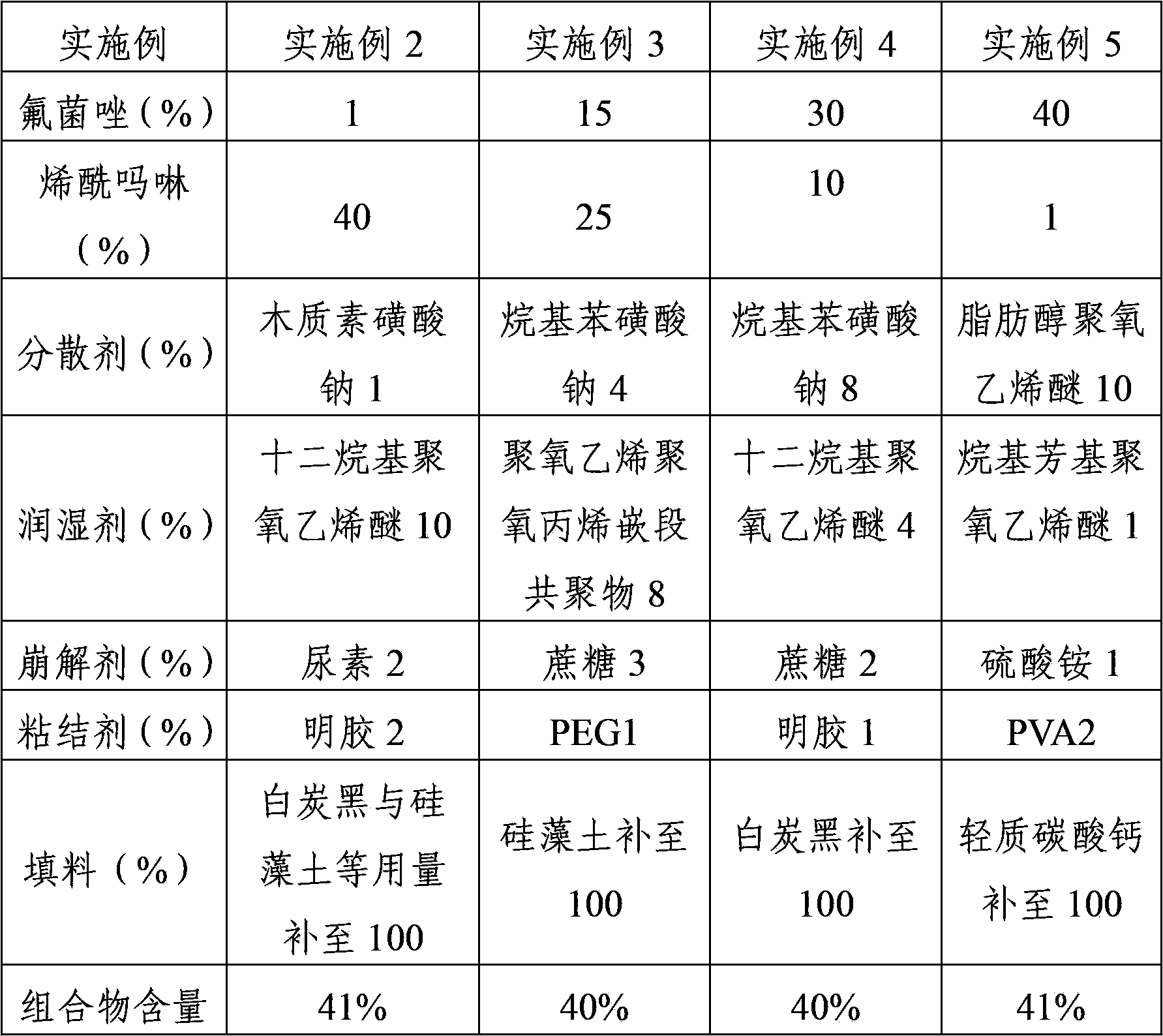

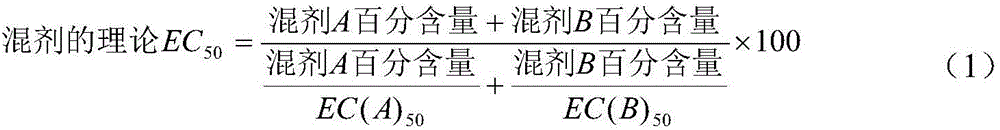

Sterilization composition containing triflumizole and dimethomorph and application thereof

ActiveCN102939975BHigh bactericidal activityExtended service lifeBiocideFungicidesBiotechnologySuspending Agents

The invention discloses a sterilization composition containing triflumizole and dimethomorph and the application thereof. The sterilization composition utilizes triflumizole and dimethomorph as main effective components with mass ratio of the triflumizole and the dimethomorph being (1-40): (40-1). Content sum of the triflumizole and the dimethomorph is 1-80% of total mass of the sterilization composition. The sterilization composition can be prepared into water dispersible granule, wettable powder or suspending agent which are allowable in agriculture and is mainly used for preventive treatment of powdery mildew, downy mildew, brown rot and the like.

Owner:上海沪联生物药业(夏邑)股份有限公司

Sterilizing composition with synergistic effect and use thereof

InactiveCN106797941AImprove the effect of prevention and controlReduce the use effectBiocideDead animal preservationSocial benefitsDisease

The invention discloses a sterilizing composition with a synergistic effect and use thereof. The sterilizing composition comprises the active ingredients of hymexazol and cyazofamid in a weight ratio of 1: 50 to 50: 1. The sterilizing composition can obviously improve the preventing and treating effect of soil-borne diseases and is obvious in synergic effect, so that the number of times of application is reduced, and therefore, the using cost is lowered, the time and labor are saved, and the sterilizing composition has obvious economical and social benefits, and meanwhile, pesticide resistance is delayed.

Owner:INST OF PLANT PROTECTION CHINESE ACAD OF AGRI SCI

Composition containing zinc thiazole and copper (II) busic chloride and preparation and application thereof

The invention discloses a composition containing zinc thiazole and copper (II) busic chloride and a preparation and application thereof, wherein the composition comprises the zinc thiazole and the copper (II) busic chloride, wherein the weight ratio of the zinc thiazole to the copper (II) busic chloride is 1: (0.01-100). When the active ingredients zinc thiazole and copper (II) busic chloride in the composition are present in a specific weight ratio, the bactericidal activity is greater than the sum of the bactericidal activities of the zinc thiazole and the copper (II) busic chloride when thezinc thiazole and the copper (II) busic chloride are used alone, and the synergistic effect is very remarkable.

Owner:ZHEJIANG XINNONG CHEM CO LTD +1

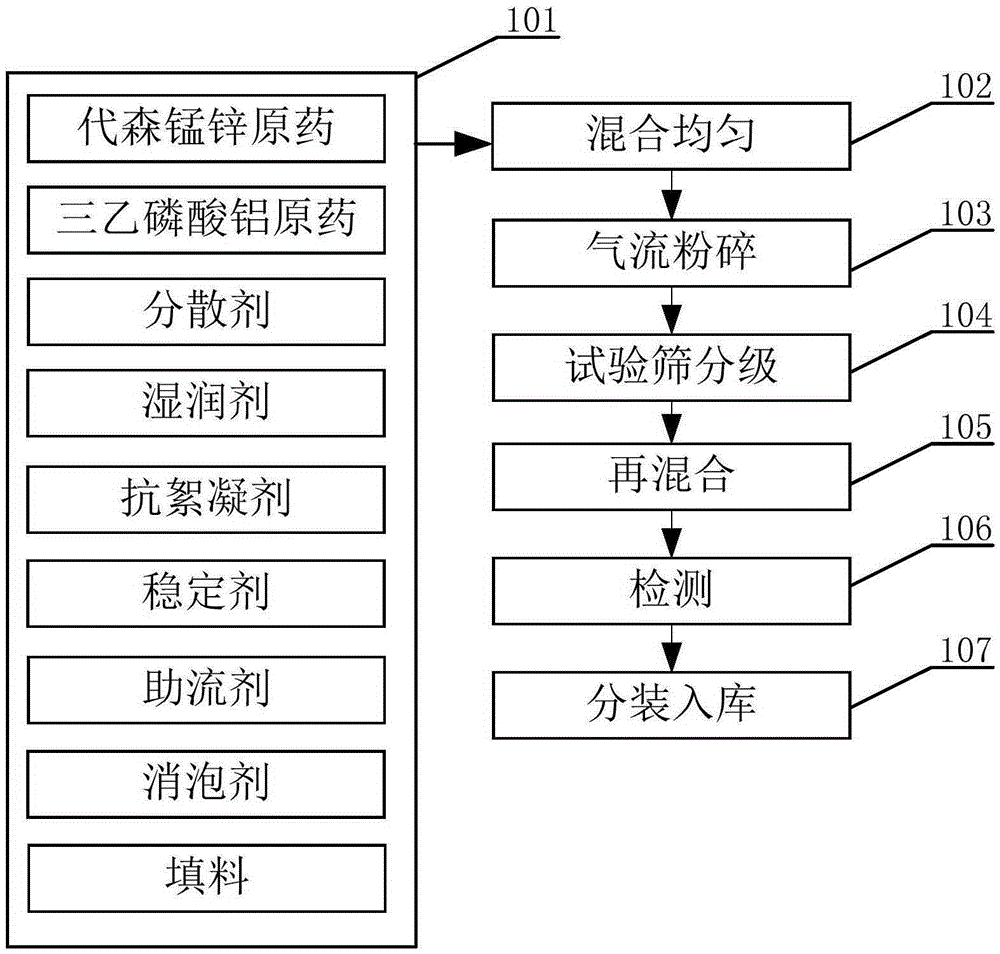

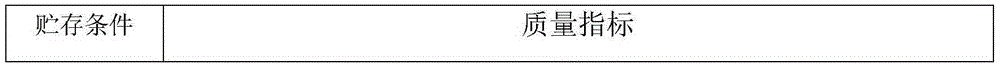

Wettable powder compounded of mancozeb and fosetyl-aluminium and preparation method of wettable powder

InactiveCN105284869ASimple processing methodReduce manufacturing costBiocideFungicidesMancozebMaterials science

Disclosed is wettable powder compounded of mancozeb and fosetyl-aluminium and a preparation method of the wettable powder. The wettable powder comprises, by mass percentage: original drugs of mancozeb and fosetyl-aluminium, a dispersant, a wetting agent, a deflocculant, a stabilizing agent, a glidant, an antifoaming agent, and a filler. The preparation method comprises: (1) weighing the following raw materials: the original drugs of mancozeb and fosetyl-aluminium, the dispersant, the wetting agent, the deflocculant, the stabilizing agent, the glidant, the antifoaming agent, and the filler, and uniformly mixing the raw materials; and (2) performing superfine grinding of the raw materials through a jet mill, grading the obtained product through a 45-micron test sieve, and uniformly mixing the obtained product. The wettable powder is simple in process, low in cost, convenient to store and transport, safe, and stable in property, has advantages of less application amount, wide bactericidal spectrum, quick effect, complete sterilization, low residue, and effective postponing of generation of a pathogen antibody, and is an excellent chemical bactericide.

Owner:LIMIN CHEM CO LTD

Measurement of angle rotation using microstrip resonators (2.4ghz,2 degree)

InactiveUS6969998B2Simple structureProduction delayResistance/reactance/impedenceConverting sensor ouput using wave/particle radiationClassical mechanicsMicrostrip resonators

Owner:ROBERT BOSCH GMBH

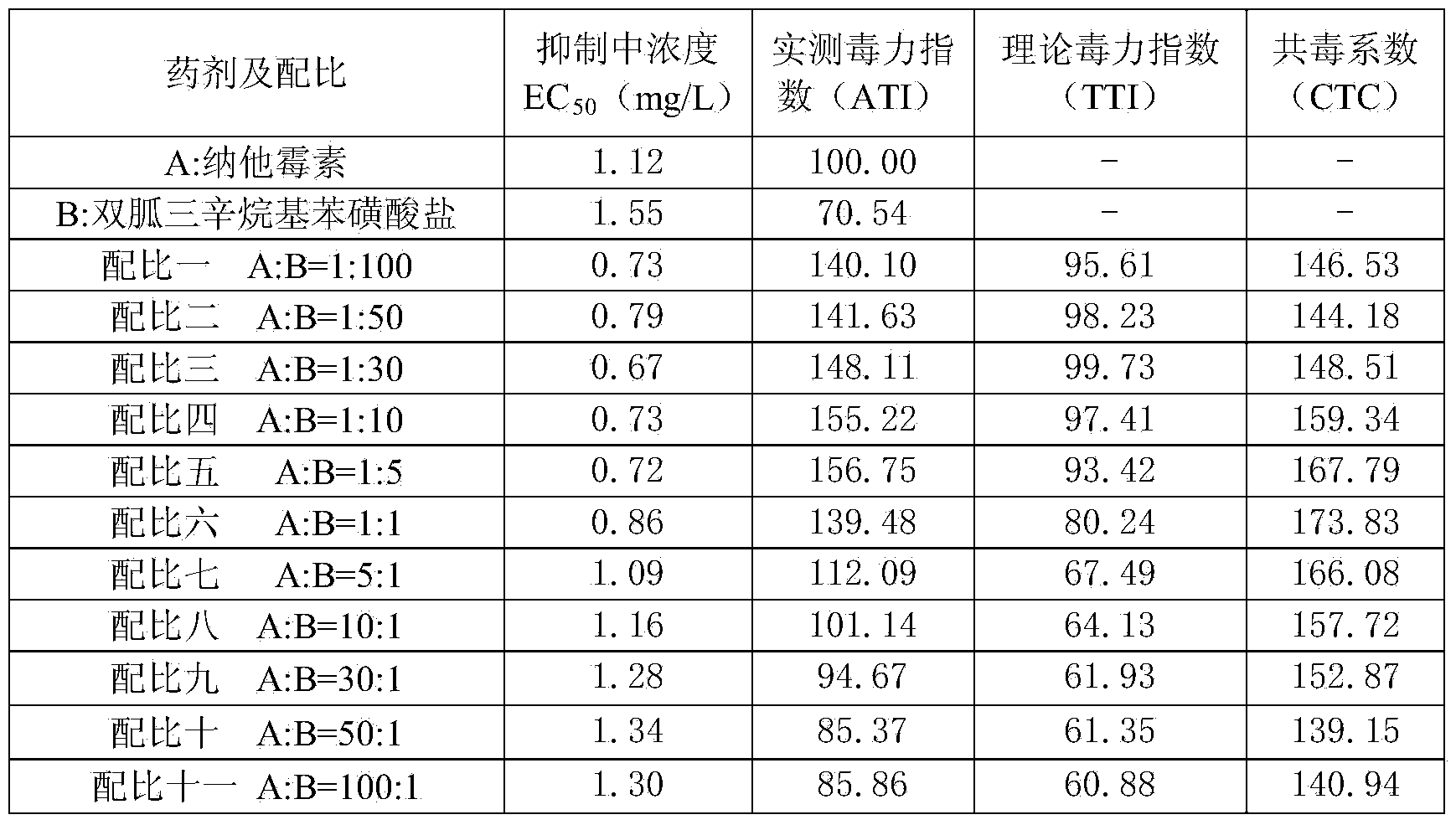

Compound bactericide

InactiveCN103636655AReduce labor costsNot easy to produceBiocideFungicidesSuspending AgentsBULK ACTIVE INGREDIENT

The invention belongs to the technical field of pesticides, and relates to a compound bactericide. The compound bactericide is characterized by containing two active ingredients, namely natamycin and iminoctadine tris. The compound bactericide can be prepared into a suspending agent and wettable powder, is used for preventing and controlling scutellum rot of oranges, has remarkable synergistic effects, and is safe and harmless.

Owner:BEIJING YOLOO BIO TECH CORP

Clip-type automatic small material carrying mechanism of intelligent welding equipment for aluminum formwork of building

ActiveCN110814591AReduce volumeReduce areaWelding/cutting auxillary devicesAuxillary welding devicesControl engineeringStructural engineering

The invention belongs to the technical field of manufacturing equipment for aluminum formworks of buildings, and relates to a clip-type automatic small material carrying mechanism of intelligent welding equipment for an aluminum formwork of a building. A touch inclined plane touches or leaves from a rolling wheel, the rolling wheel is close to or away from an inner location plane and drives a swing arm to swing around a hinge III, the swing arm pushes and pulls a location pin through a connection rod, and a location head locates a material clip assembly; a lifting servo motor drives a liftingassembly and a small material to ascend through the combination of thread pairs, an ascending-descending and clamping assembly transversely moves downwards and clamps the small material, and then ascends, a transverse movement servo motor drives a transverse movement assembly to transversely move to the left until a symmetrical middle surface in the left-right direction of the small material is superposed with a symmetrical middle surface in the left-right direction of a groove of a large plate, a longitudinal movement servo motor drives a longitudinal movement assembly to transversely move forwards and backwards until the small material is located above a position to be installed, and then the small material is put in place. An intelligent welding robot looks for a welding joint and carries out spot welding. According to the clip-type automatic small material carrying mechanism of the intelligent welding equipment for the aluminum formwork of the building, the material clip assembly is compact in structure and saves storage and carrying spaces, and the small material can be automatically aligned and does not move along with clamping fingers.

Owner:江苏天利成建筑科技有限公司

High-uniformity noodle raw material mixing mechanism

PendingCN107952380ASimple structureReduce usageRotary stirring mixersTransportation and packagingMechanical engineeringMixing chamber

The invention discloses a high-uniformity noodle raw material mixing mechanism. The high-uniformity noodle raw material mixing mechanism comprises a first mixing chamber and a second mixing chamber and is characterized in that a motor is mounted in the middle of one side surface of the first mixing chamber, the output end of the motor penetrates the side surface of the first mixing chamber, a stirring shaft is welded to the top end of the output end of the motor, stirring blades are welded to the side surface of the stirring shaft, a discharging port is formed in the middle of the bottom surface of the first mixing chamber, a baffle plate is arranged below the discharging port, the second mixing chamber is welded onto the upper surface of the first mixing chamber, a mixing cavity is formedin the second mixing chamber, a first fan and a second fan are mounted on two side surfaces of the second mixing chamber, an air distributing cavity and an air exhaust cavity are formed in the secondmixing chamber, the output end of the first fan is communicated with the air distributing cavity, and a feeding pipe is welded above the second mixing chamber. According to the raw material mixing mechanism for noodle production, raw materials are uniformly mixed, mixing time is shortened, and working efficiency is improved.

Owner:重庆盛青汇农业发展有限公司

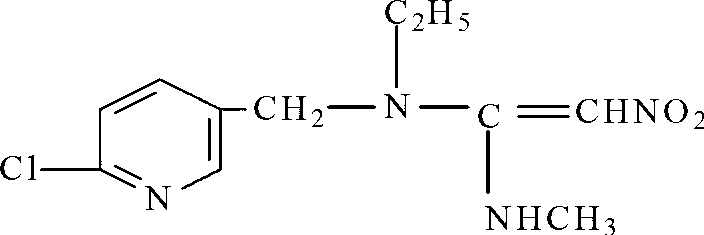

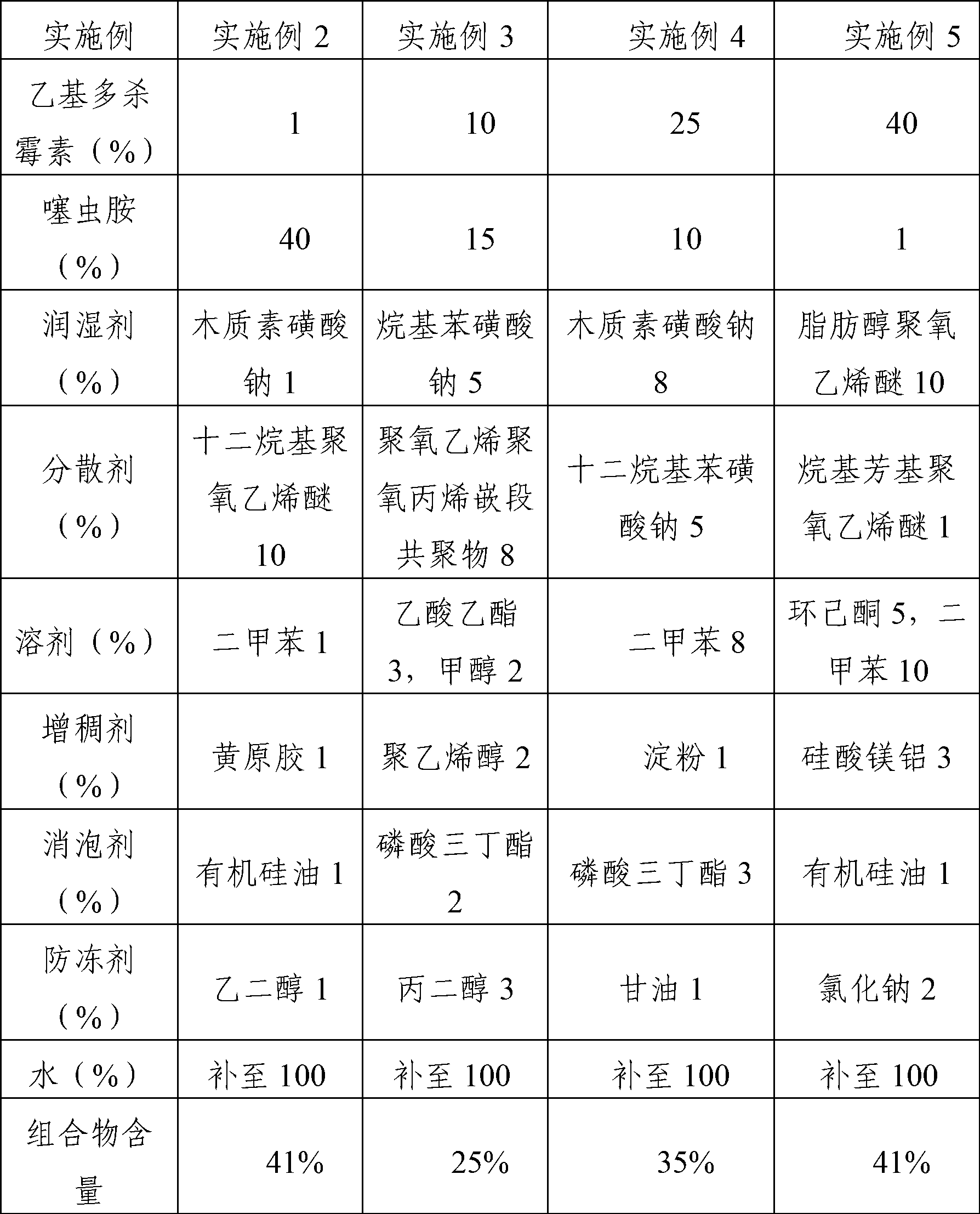

Pesticide composition containing ethyl spinosad and clothianidin and application thereof

InactiveCN102934638AHigh insecticidal activityExtended service lifeBiocideAnimal repellantsSpinosadClothianidin

The invention discloses a pesticide composition utilizing ethyl spinosad and clothianidin as effective ingredients and an application of the pesticide composition. The pesticide composition utilizes the ethyl spinosad and clothianidin as the effective ingredients, the mass ratio of the ethyl spinosad to the clothianidin is (1:40)-(40:1), and the content sum of the ethyl spinosad and the clothianidin accounts for 1-80% of the total mass percent of the pesticide composition. The pesticide composition disclosed by the invention has excellent synergism for killing insects and has such properties as extensive insecticidal spectrum, high efficiency, fast acting speed, low poison on mammals and natural enemy insects, low dosage and agricultural cost and non-cross resistance between drugs, and the like, and can be used for overcoming and delaying the generation of pest resistance to insecticides.

Owner:上海沪联生物药业(夏邑)股份有限公司

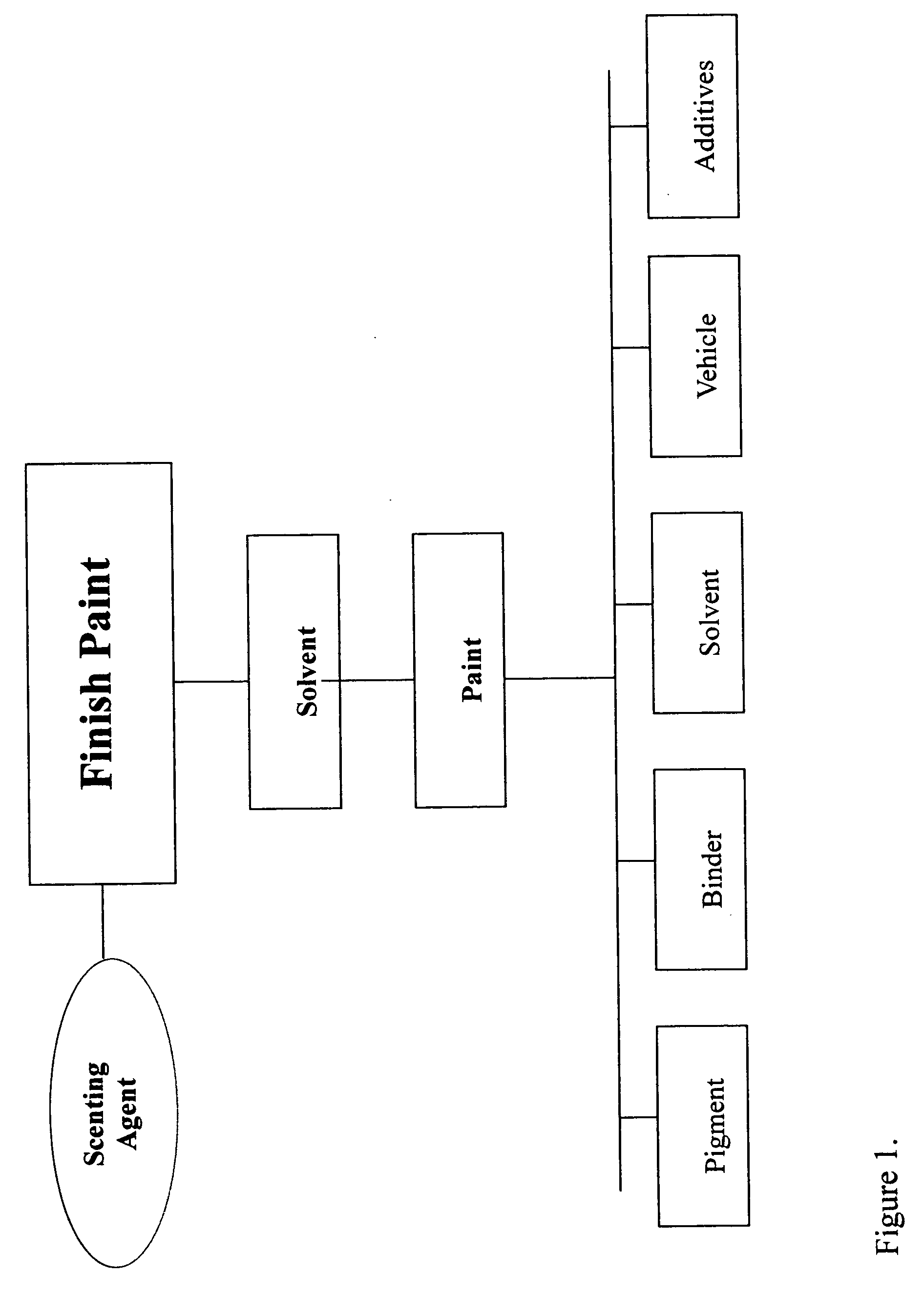

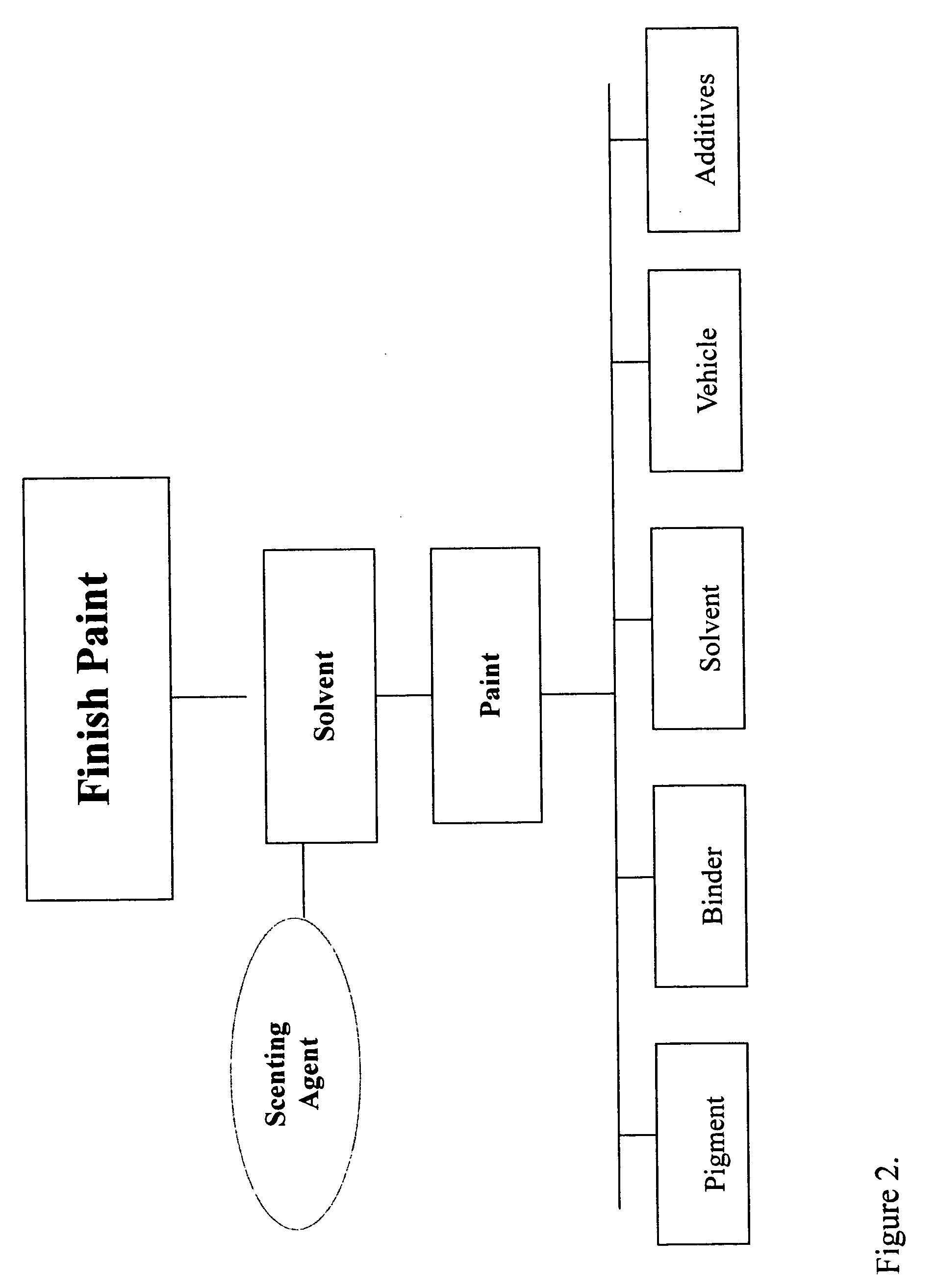

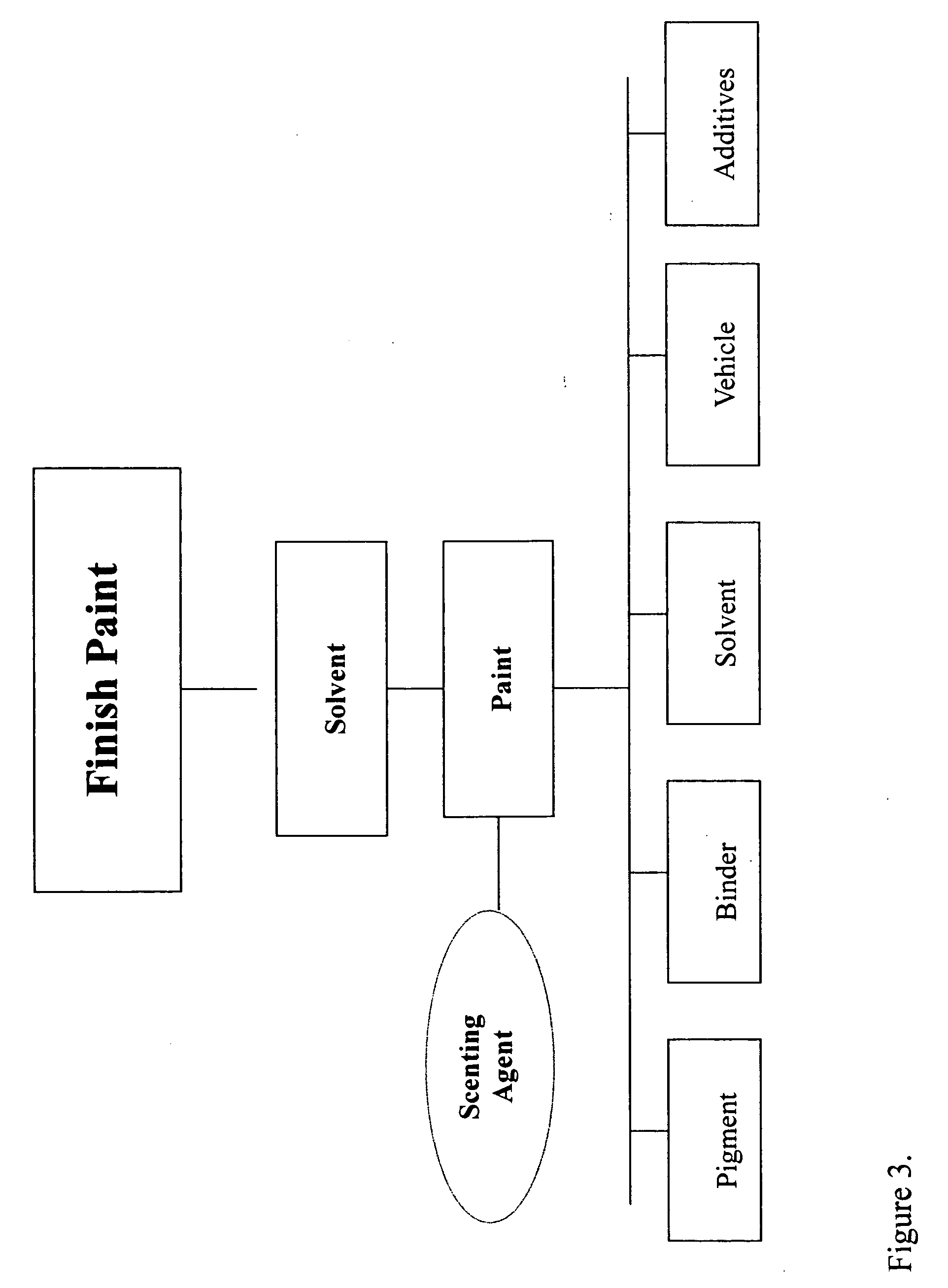

Long-lasting scented paint and method for making same

Owner:SANDLIN OSCAR D +1

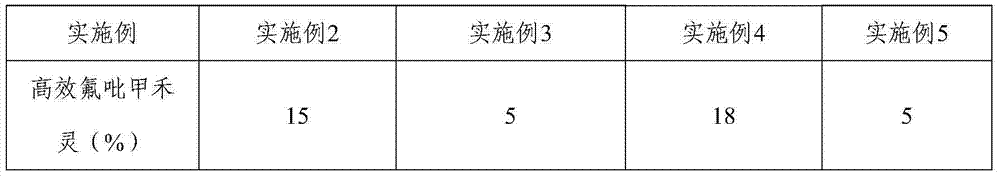

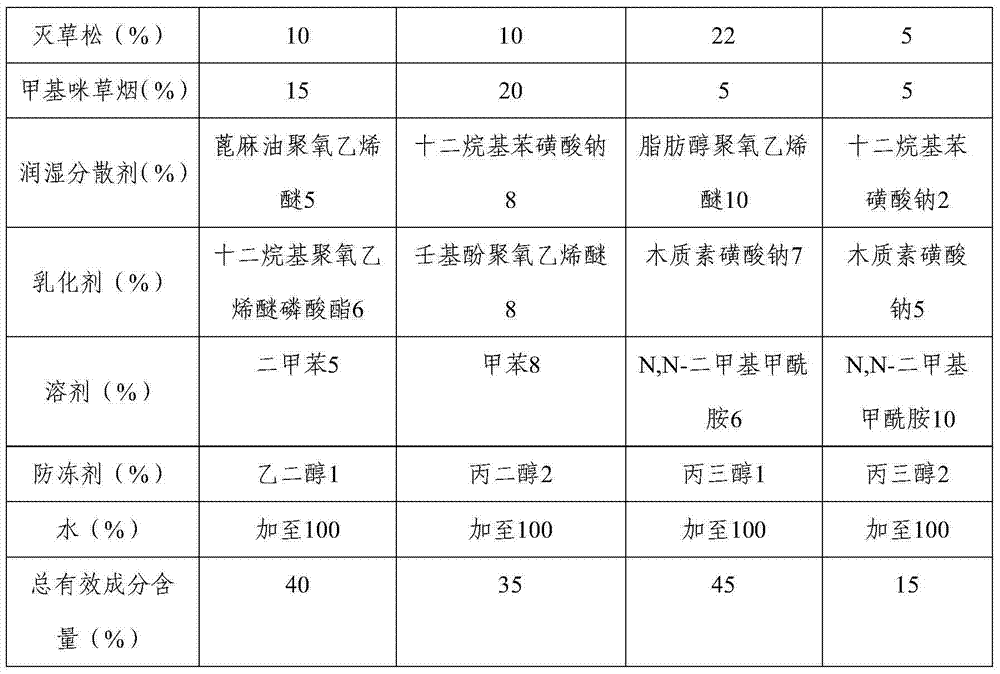

Compound herbicide containing haloxyfop-R-methyl, bentazone and imazapic and application of compound herbicide

InactiveCN104285995AImprove herbicidal activityBroad spectrum herbicideBiocideAnimal repellantsPesticideArachis hypogaea

The invention discloses a compound herbicide containing haloxyfop-R-methyl, bentazone and imazapic and application of the compound herbicide. The principle active ingredients of the compound herbicide are haloxyfop-R-methyl, bentazone and imazapic in the mass ratio of (1-18):(2-22):(3-5), and the mass percent contents of the three ingredients in the compound herbicide are 15-50%. The compound herbicide containing haloxyfop-R-methyl, bentazone and imazapic has a remarkable effect in application in peanut field weeding after seedling, in particular in application in prevention and weeding of various gramineous weeds and broadleaf weeds in the peanut field. Compared with single dosage, the compound herbicide containing haloxyfop-R-methyl, bentazone and imazapic has the advantages of weed resistance delaying, weeding spectrum expanding, both gramineous weed and broadleaf weed eliminating, long period of preserving heat, and reliable safety on either peanut or after-reap crops on the premise of improvement of pesticide effect.

Owner:河南中天恒信生物化学科技有限公司

Positive electrode for non-aqueous electrolyte secondary batteries and non-aqueous electrolyte secondary battery

ActiveUS9112209B2Production delayHigh densityNon-aqueous electrolyte accumulatorsFinal product manufactureMaterials scienceNon aqueous electrolytes

Owner:PANASONIC INTELLECTUAL PROPERTY MANAGEMENT CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com