Composition and method for removing filter cake

A technology of filter cake and fluid, applied in the field of composition and method for removing filter cake, can solve the problems such as unsatisfactory filter cake cleaning effect, achieve the effect of improving filter cake dissolution and low corrosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

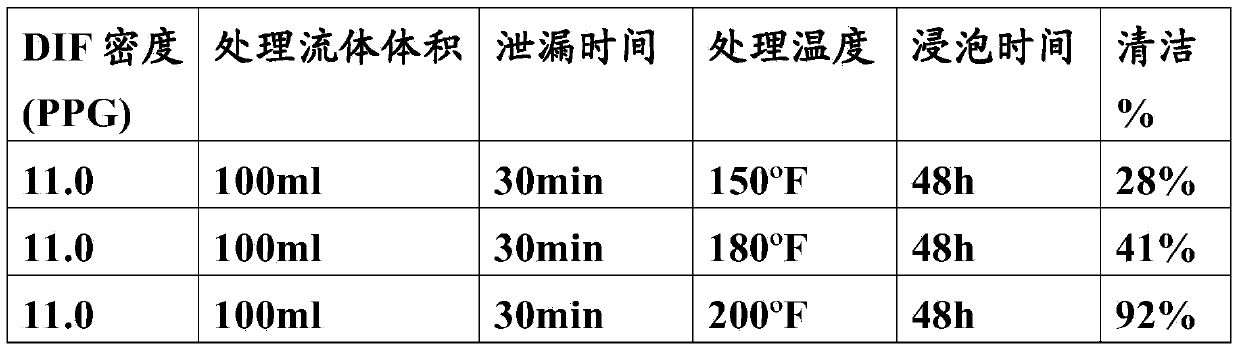

Method used

Image

Examples

Embodiment 1

[0061] Embodiment 1 formula

[0062] Emulsion of the present invention, it comprises the DA-1 (methyl tosylate) of 10 volume %, the S-400 (emulsifier) of 0.5 volume %, the GBW-14C (enzyme) of 5 volume %, the GBW of 1 volume % -16C (enzyme) and 0.1% by volume of BF-7L (buffer) were finally added to the HTHP pool at the target temperature (180°F) and 500 psi under static conditions for the indicated time. Fresh water was used as solvent. The method for forming the emulsion involved adding 0.5 ml of S-400 to 83.4 ml of fresh water in a Warring mixer under vigorous stirring. After 15 seconds, 10 ml of DA-1 was added to the blender. After mixing for 45 seconds, BF-7L (0.1 ml), GBW-14C (5 ml) and GBW-16C (1 ml) were added and stirring was maintained for 10 seconds.

Embodiment 2

[0063] Embodiment 2 formula

[0064] Example 2 was similar in composition to Example 1 except that Example 2 did not include a buffer. Similar to that described in Example 1, the composition of Example 2 was added to the HTHP cell at the target temperature (180°F) and 500 psi under static conditions for the indicated times.

Embodiment 3 and 4

[0065] Example 3 and 4 formulations

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com