Patents

Literature

285 results about "Spinosad" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

This medication is used to treat head lice, tiny insects that infest and irritate your scalp.

Synergistic insecticidal mixtures

The invention relates to insecticidal mixtures of spinosyns and agonists or antagonists of nicotinic acetylcholine receptors for protecting plants against attack by pests.

Owner:DOW AGROSCIENCES LLC

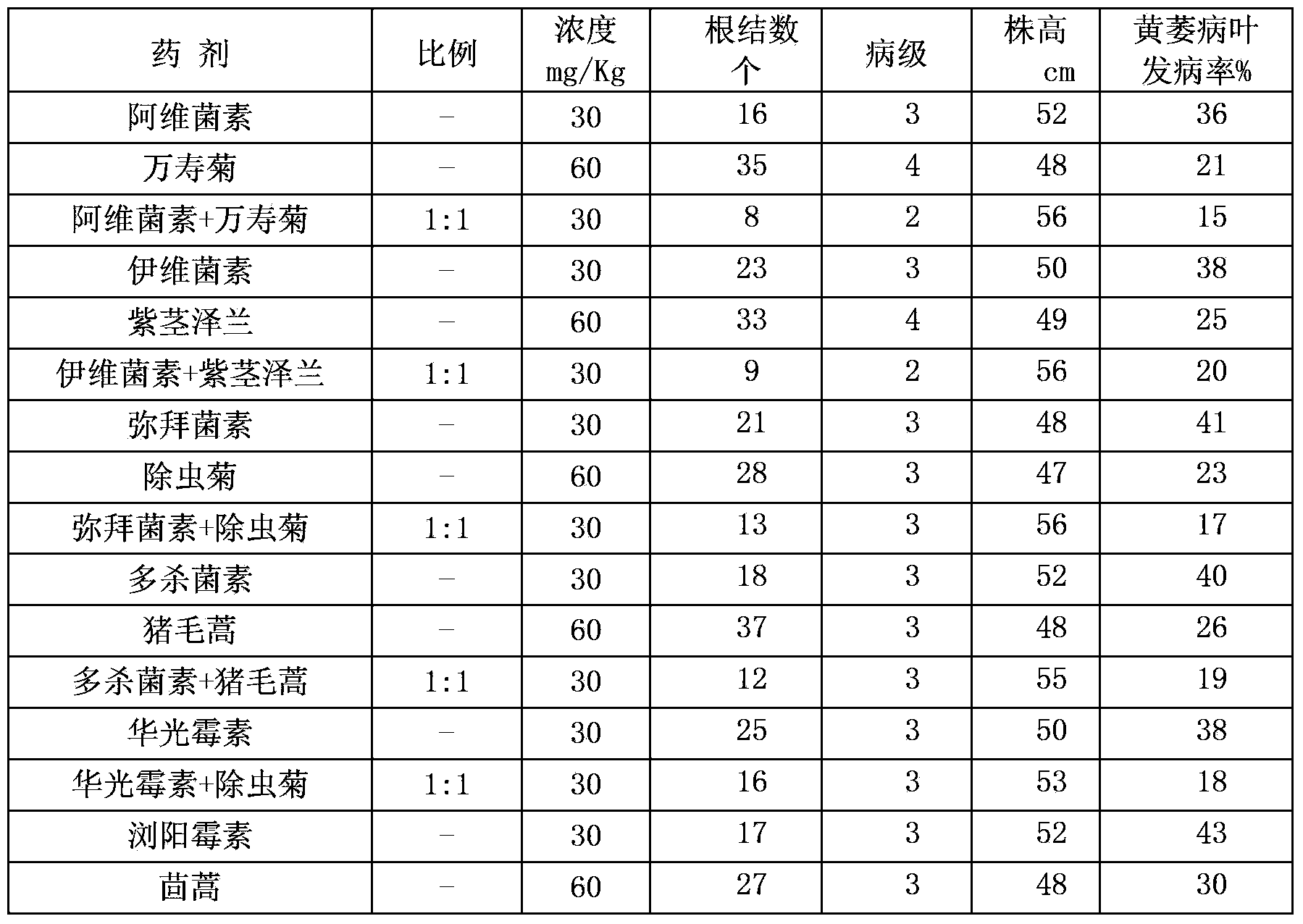

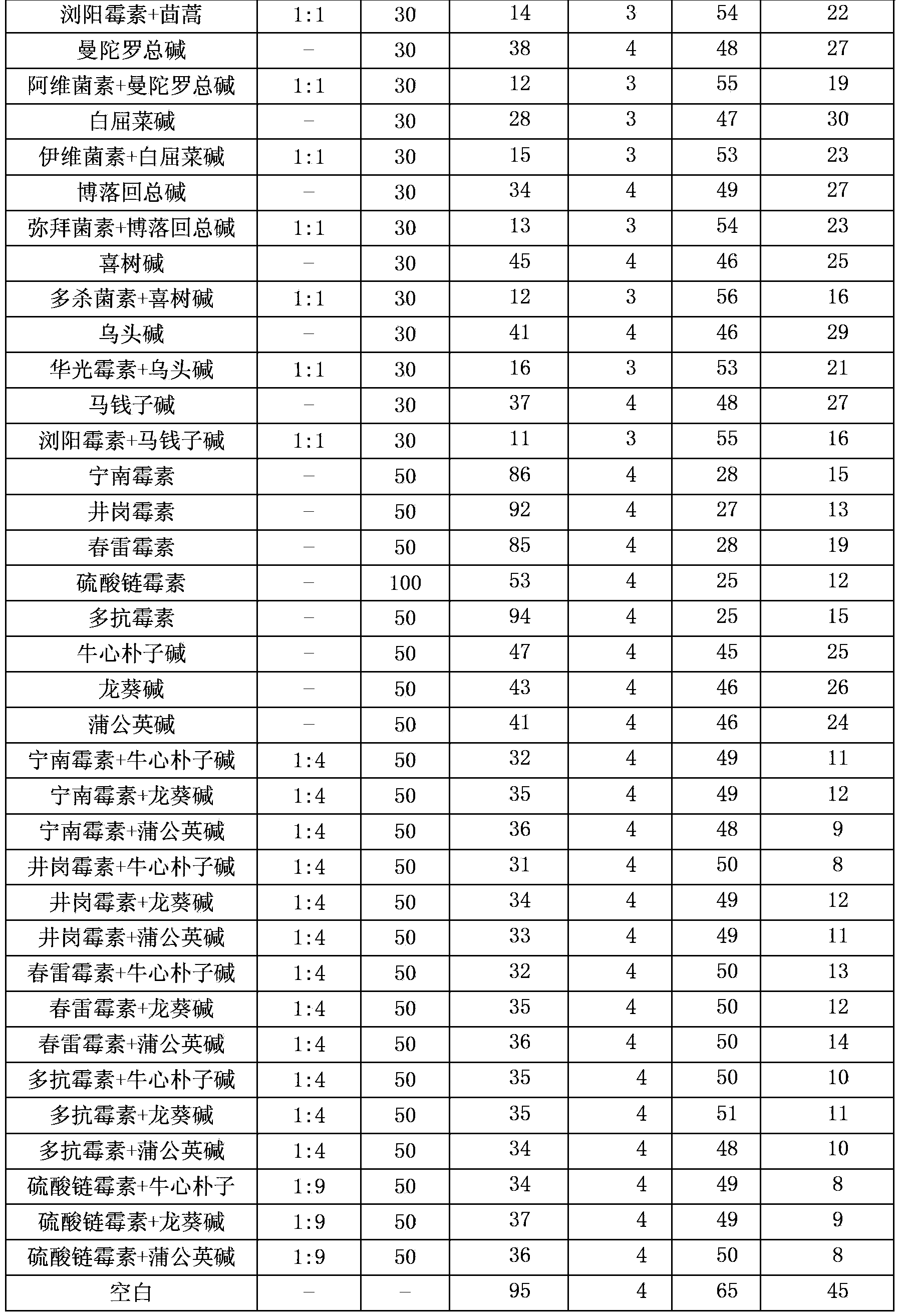

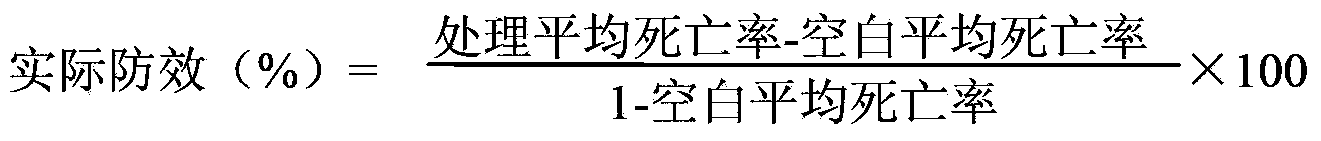

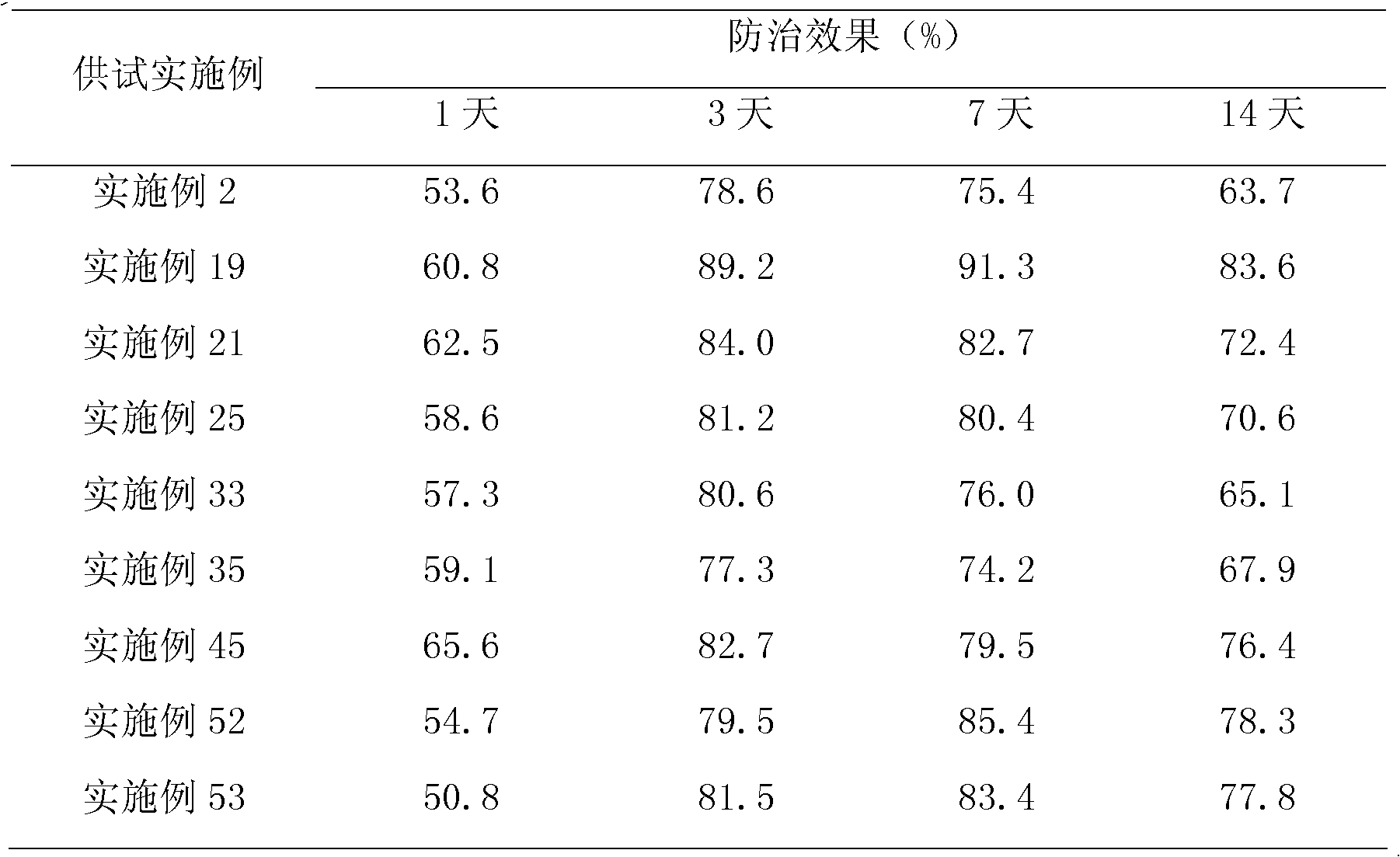

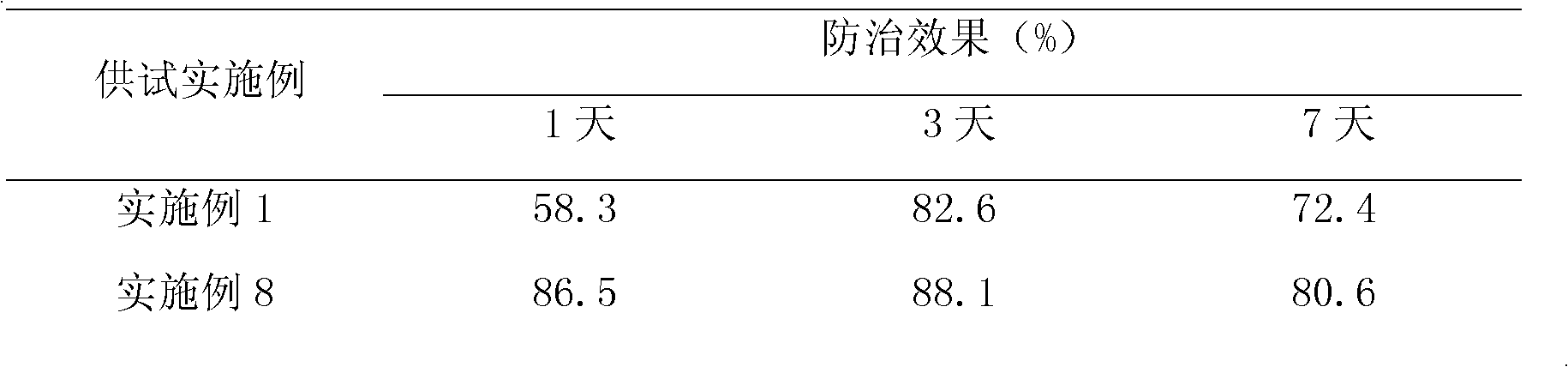

Agricultural composition containing antibiotics and plant source materials and application thereof

ActiveCN103349007AIncrease useImprove efficiencyBiocideDead animal preservationPlant SourcesAntibiotic Y

The invention belongs to the field of plant protection, and relates to an agricultural composition containing antibiotics and plant source materials, wherein antibiotic is one or several selected from abamectin, ivermectin, milbemectin, pleocidin, nikkomycin, liuyangmycin, streptomycin, polyoxins, chunleimeisu, jinggangmeisu, ningnanmycin and the like; the plant source material is one or several of smashing material, crude extract, or active ingredient of derris, thunder god vine, tobacco, pyrethrum, tagetes, crofton weed, radix stemonae, cayenne, macleaya cordata, radix sophorae flavescentis and the like. The composition provided by the invention expresses well synergism in a certain matching range, and has excellent control efficiency for crop diseases and pests.

Owner:HAINAN ZHENGYE ZHONGNONG HIGH TECH

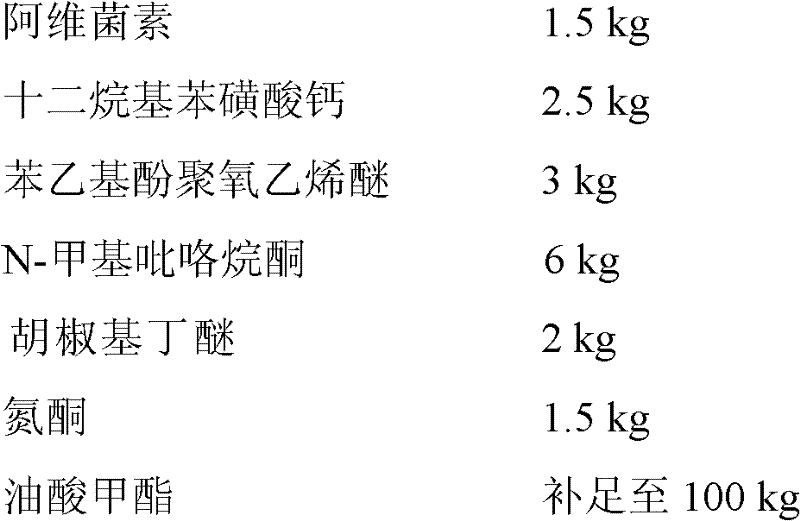

Ultralow-volume solvent containing pleocidin or spinetoram

ActiveCN102349502AImprove ergonomicsConserve waterBiocideAnimal repellantsAdditive ingredientCnaphalocrocis medinalis

The invention belongs to the field of pesticide, which mainly relates to an ultralow-volume solvent containing pleocidin or spinetoram. The ultralow-volume solvent is an active component I or an active ingredient compounded by the active component I or an active component II, and the balance is solvent and accessory ingredient, wherein the active component I is pleocidin or spinetoram; and the active component II is insecticide of the other type of action mechanism. The ultralow volume solvent is simple to process and has the advantages of water conservation, high work efficiency, long efficacy continuing period, small possibility of generating resistance to drug for a target, small environment pollution, synergy and the like. Ultralow volume spraying, low-volume spraying or low-volume electrostatic spraying is applied to effectively prevent and control various pests, such as Cnaphalocrocis medinalis, Chilo suppressalis, rice planthopper, Ostrinia nubilalis, plutella xylostella, cabbage caterpillar, Spodoptera litura, Spodoptera exigua, aphids, Lesser green leaf hopper, Icerya purchase, aleyrodid, Thrip, stinkbug, acridid, flea beetle, leafminer, looper and the like.

Owner:GAUNGXI TIANYUAN BIOCHEM

Insect killing compound containing chlorantraniliprole

ActiveCN102113516AReduce dosageSynergistic effect is obviousBiocideAnimal repellantsAdditive ingredientChlorfenapyr

The invention discloses an insect killing compound containing chlorantraniliprole, which is prepared by two effective ingredients A and B. The ingredient A is chlorantraniliprole, the ingredient B is one of high-efficiency cypermethrin, trifluoro-cypermethrin, dursban, profenofos, dipterex, diafenthiuron, chlorfenapyr, emamectin benzoate, pleocidin, tebufenozide, hexaf lumuron, chlorfenapyr, pyridaben, acetamiprid, isoprocarb, dimehypo and cartap, and the composed mass ratio of the effective ingredient A to the ingredient B is 1:60-60:1. The accumulated mass percent of the two ingredients A and B accounts 1%-85% of the total mass of the compound. In the invention, the blending of the two active ingredients is utilized, so that the effect is improved obviously, the dosage of effective ingredients is reduced, and the drug resistance of insects and mites on the chlorantraniliprole is delayed. The insect killing compound can be used controlling various insects on rice, cotton, vegetables, fruit trees and the like.

Owner:HAINAN ZHENGYE ZHONGNONG HIGH TECH

Insecticide composition containing chlorantraniliprole, preparation method and application thereof

The invention relates to a pesticide composition, in particular to an insecticide composition. The composition comprises chlorantraniliprole with synergistic effective dose, abamectin or emamectin benzoate, and one of cyhalothrin, dursban, diazinon, acetamiprid, cypermethrin, alpha cypermethrin, thiamethoxam, thiacloprid, fenvalerate, propargite, diafenthiuron, benfuracarb, azocyclotin, buprofezin, ethofenprox, phonamiphos, fipronil, flufenoxuron, monosultap, dimehypo, imidacloprid, flufenoxuron, chlorfluazuron, pleocidin and tebufenozide, wherein the mass percentage of the three compositions is that: the chlorantraniliprole is 1 to 35 percent, the abamectin or the emamectin benzoate is 1 to 10 percent, and any one of the insecticides is 1 to 50 percent. The invention discloses a process for processing the compositions and application of the compositions in preparing insecticides for controlling agricultural, forestry and gardening insect pests.

Owner:NANKAI UNIV

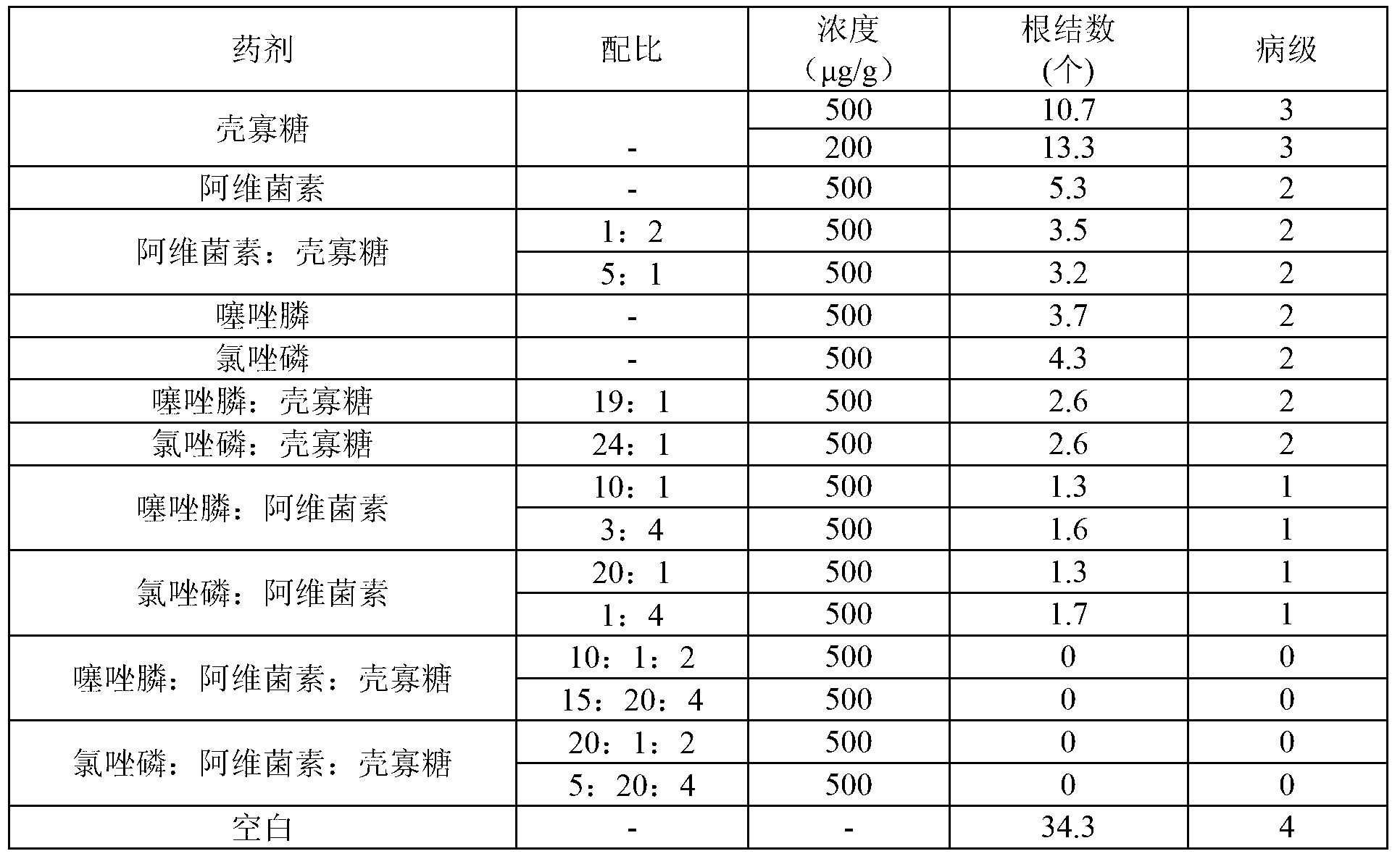

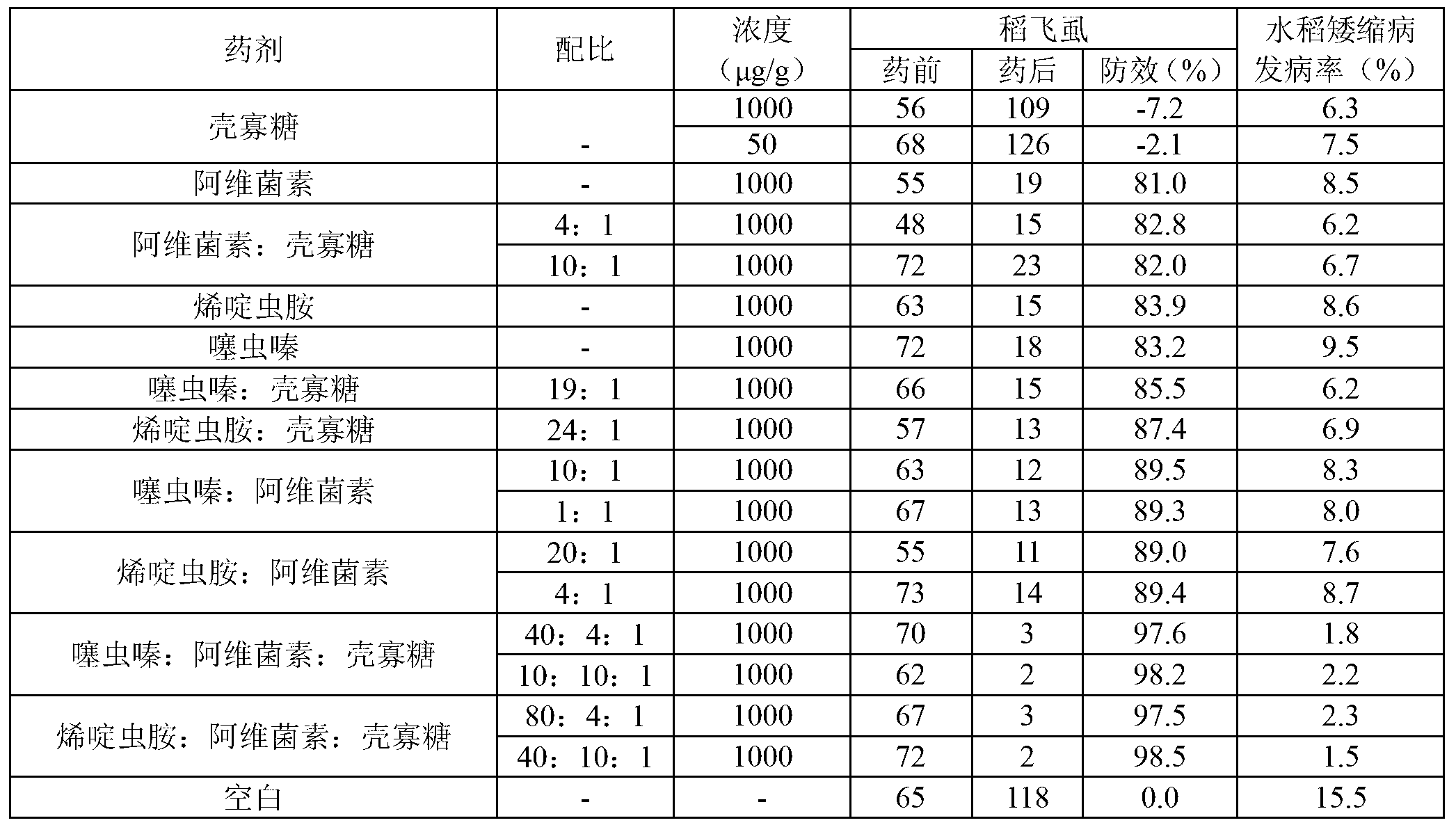

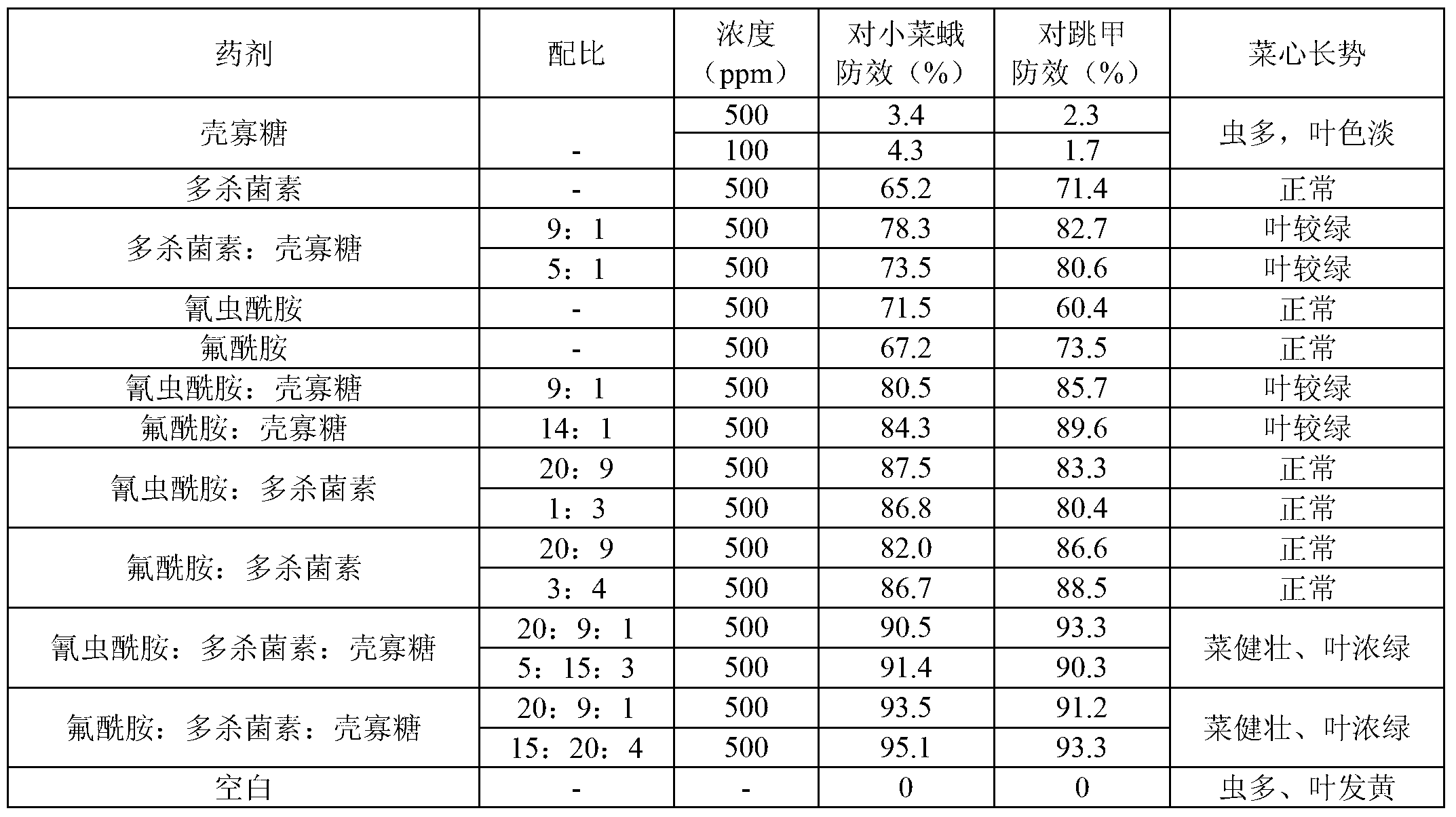

Insecticide acaricide taking oligose and macrolides composition as synergist and application of insecticide acaricide

The invention discloses an insecticide acaricide taking an oligose and macrolides composition as a synergist, and in particular relates to a synergism composition capable of enhancing the insecticiding effect of the insecticide acaricide. The composition comprises oligose and a macrolides insecticide; the macrolides insecticide is abamectin, pleocidin, emamectin benzoate or ivermectin; the oligose is pectic oligosaccharide, sodium alginate oligosaccharides or chitosan oligosaccharide; the mass part ratio of the oligose to the macrolides insecticide is (1-30):(1-10). The synergism composition can enhance the insecticidal efficacy of the insecticide acaricide and realize the synergism effect with other insecticide acaricides.

Owner:HAINAN ZHENGYE ZHONGNONG HIGH TECH

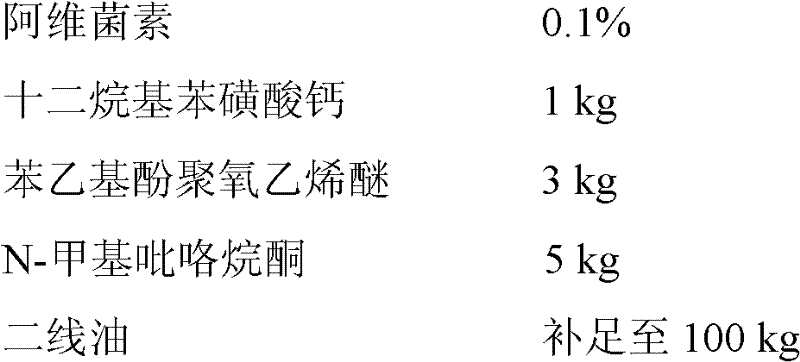

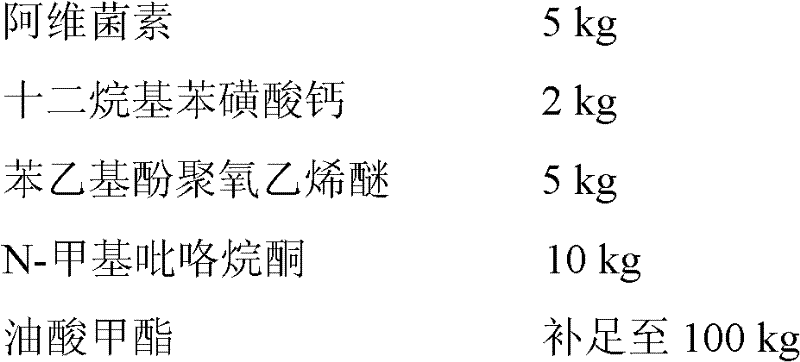

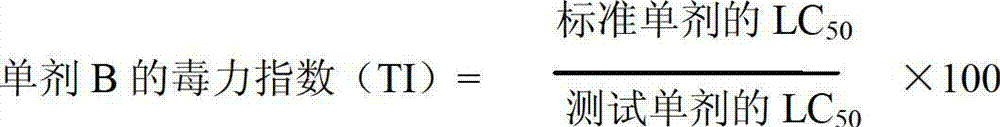

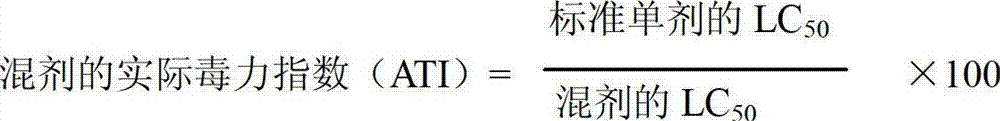

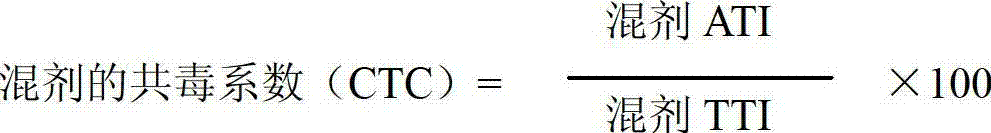

Macrolide compound ultralow volume formulation

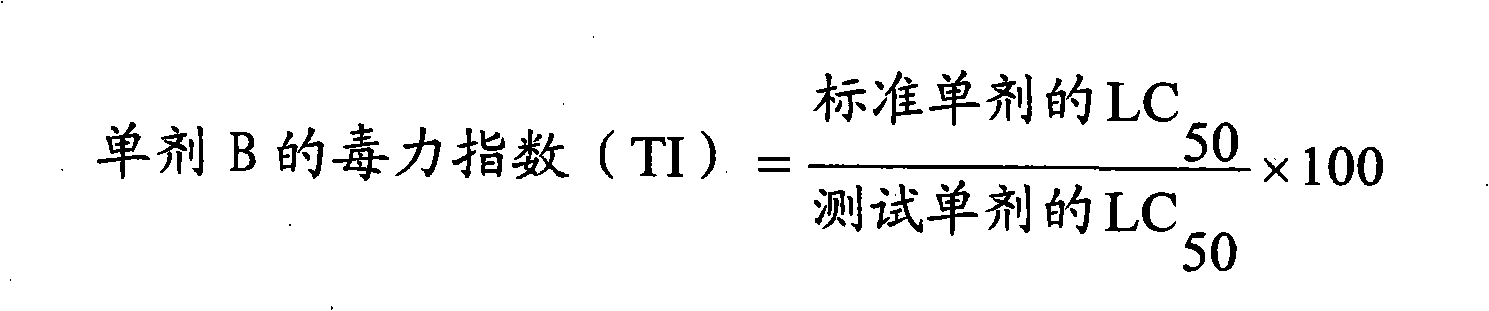

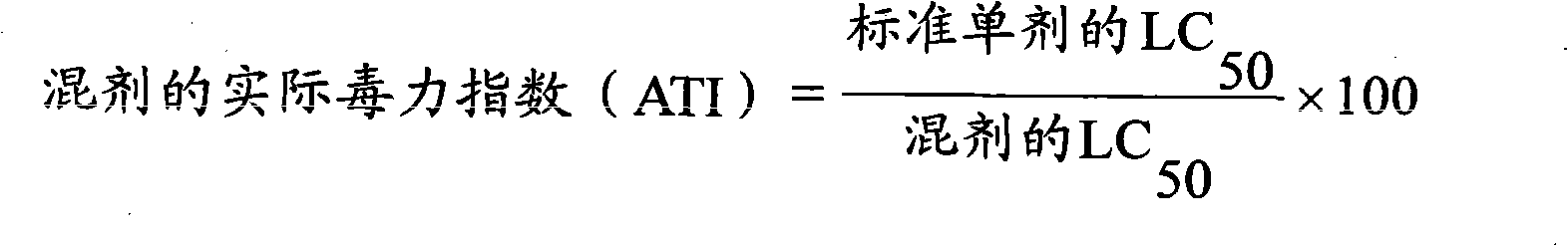

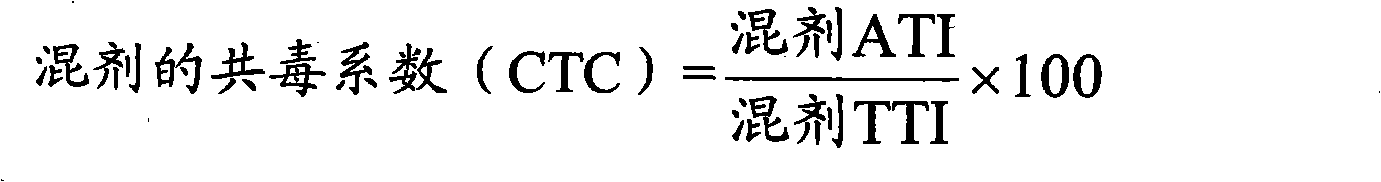

The invention relates to a macrolide compound ultralow volume formulation. An active component I and an active component II are used as active components with the addition of a solvent and an auxiliary agent to prepare the ultralow volume liquid formulation, Wherein the active component I contains one or more ingredients selected from the group consisting of a macrolide compound avermectin, emamectin benzoate and ivermectin; the active component II contains one or more ingredients selected from the group consisting of chlorantraniliprole, flubendiamide, metaflumizone, ethiprole, indoxacarb, spinosad, spinetoram, guinalphos and basudin; the content of the active component I is 0.1-5% and the content of the active component II is 0.1-20%; and the cotoxicity coefficient calculated according to Sunyunpei method. The invention is suitable for ultralow volume spraying, low volume spraying and electrostatic spraying, and has advantages of high work efficiency, fast effectiveness, long persistent period, water saving, cooperative synergism and the like.

Owner:GAUNGXI TIANYUAN BIOCHEM

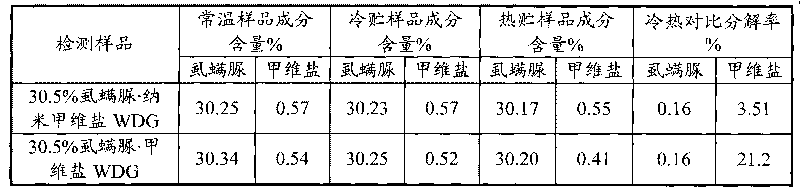

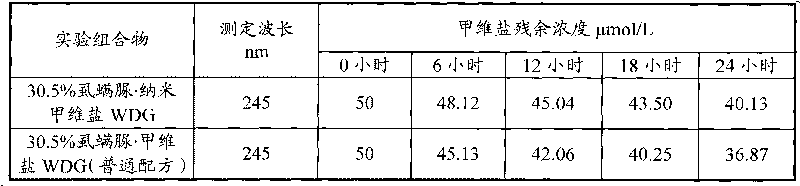

Emamectin benzoate solid lipid nanoparticle and preparation method and application thereof in pesticide formulation

InactiveCN101692808AHigh affinityDelayed photolysisBiocideAnimal repellantsWater dispersibleChlorfenapyr

The invention discloses an emamectin benzoate solid lipid nanoparticle and a preparation method for a water dispersible granule, a suspension concentrate and wettable powder of the composition of the emamectin benzoate solid lipid nanoparticle with lufenuron, indoxacarb, pleocidin, chlorfenapyr and chlorantraniliprole. Compared with the composition preparation which is prepared by directly adopting the emamectin benzoate raw pesticide as raw material, the emamectin benzoate solid lipid nanoparticle has the advantages of improving the chemical stability of hot and cold storage, reducing the photolysis rate, prolonging efficacy time, reducing dosage, and significantly improving insecticidal effect.

Owner:SHENZHEN NOPOSION AGROCHEM

Water emulsion containing pleocidin and preparation method thereof

The invention discloses a water emulsion containing pleocidin and a preparation method thereof. The water emulsion comprises the following components: A) the pleocidin; and B) abamectin, methylamino-abamectin benzoate, efficient bifenthrin, lufenuron, efficient cypermethrin, chlorfenapyr, chlorfluazuron, diafenthiuron, thiamethoxam or fipronil. The stable water emulsion is prepared by adding a proper amount of auxiliary agents such as an emulsifying agent, a thickening agent, an antifreezing agent, a UV-protecting agent, a defoaming agent and the like and the balance of water through a certain processing technique. A nuisanceless solvent is used for preparing the water emulsion to avoid adverse effects on the environment, a user and the health of a producer caused by a harmful solvent. The water emulsion has board-spectrum and efficient insecticidal properties, can be applied to the comprehensive control and resistance control on pests, and is suitable to be used on nuisanceless vegetables, fruit trees, grains and cotton.

Owner:SHENZHEN NOPOSION AGROCHEM

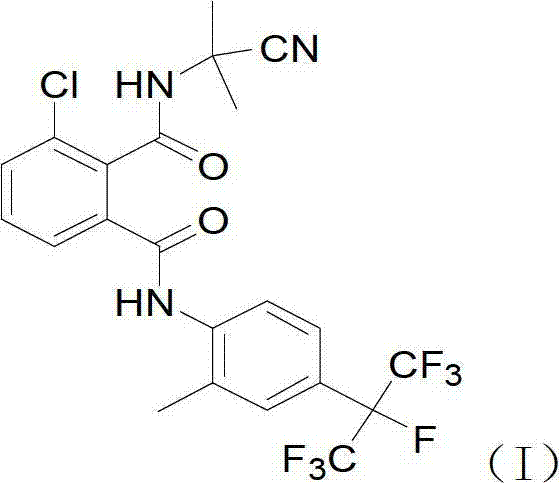

Agricultural insecticidal composition containing spinosad and ZJ4042

ActiveCN103039450AImprove insecticidal effectGood quick effectBiocideAnimal repellantsSpinosadOrder Lepidoptera

The invention discloses an insecticidal composition for agricultural insects, which contains two active ingredients: the first active ingredient is spinosad, the second active ingredient is 3-chlorine-N<1>-(2-methyl-4-heptafluoroisopropyl phenyl)-N<2>-(1-methyl-1-cyano ethyl) phthalic diamide, and the weight ratio of the first active ingredient to the second active ingredient is (1-50):(20-1). The insecticidal composition is suitable for controlling lepidoptera insects, and superior to a single insecticide in quick-acting property and persistent-acting property, the use cost of the insecticide is low, and environmental protection and comprehensive control of the agricultural insects are facilitated.

Owner:SINOCHEM LANTIAN +2

Synergistic insect-killing composition

Owner:RES CENT FOR ECO ENVIRONMENTAL SCI THE CHINESE ACAD OF SCI

Insecticidal composition containing thiodicarb and spinosad

InactiveCN103004821AObvious synergyObvious sustained control effectBiocideAnimal repellantsSpinosadOrder Lepidoptera

The invention discloses an insecticidal composition containing thiodicarb and spinosad. The mass ratio of the thiodicarb to the spinosad is (1-40) to (0.1-20). The total weight of the active ingredients accounts for 1%-90% of that of the composition. The insecticidal composition provided by the invention comprises wettable powder, water dispersible granules, suspending agent, suspoemulsion and microcapsule suspension. The insecticidal composition has remarkable synergism and a lasting preventing effect when being used for preventing insects of agriculture, expands an insecticidal spectrum, and has high activity to a plurality of insects such as lepidoptera and coleopteran. Moreover, the dosage of pesticides is reduced, and the residual quantity of the pesticides in crops and soil is reduced. The insecticidal composition can alleviate environment pollution, is safe to human and livestock, and can delay insecticide resistance of insects.

Owner:海利贵溪新材料科技有限公司

Agricultural composition containing chitosan oligosaccharide and fipronil

The invention relates to an agricultural composition containing chitosan oligosaccharide and fipronil, the agricultural composition is characterized by also containing one or a plurality of component from an insecticidal component, a sterilization component, a plant growth regulator and a fertilizer component, the insecticidal component is selected from one or a plurality of component of abamectin, chlorpyrifos, fosthiazate, thiamethoxam, phoxim, spinosad, isazofos, ivermectin, profenofos, thiodicarb and imidacloprid, the sterilization component is selected from one or a plurality of component of ethylicin, azoxystrobin, fludioxonil, hymexazol, difenoconazole and propiconazole, the plant growth regulator is selected from one or a plurality of component of mepiquat chloride, naphthylacetic acid, chlormequat chloride, uniconazole, paclobutrazol and indolebutyric acid, and the fertilizer component is selected from one or a plurality of component of nitrogen, phosphorus, potassium, calcium, magnesium, boron, zinc and amino acids. The agricultural composition can be one of a granule agent, a microcapsule agent, an absorbent product, a water agent, a water emulsion agent, a suspending agent, a water dispersible granule agent, a wettable powder agent and a microemulsion agent, and is used for root irrigation, sprinkling and pouring, furrow application pesticide-clay mixture or hole application, and the agricultural composition is used for the control of plant diseases and insect pests and regulation of plant growth.

Owner:HAINAN ZHENGYE ZHONGNONG HIGH TECH

Insecticidal composition of tea saponin and pleocidin

InactiveCN101720766ASynergistic effect is obviousEasy to prepareBiocideAnimal repellantsSpinosadBiology

The invention discloses an insecticidal composition of tea saponin and pleocidin, which comprises the following components by weight percentage: 0.10-50% of tea saponin, 0.01-30% of pleocidin and 20-95% of auxiliary agents. The invention also discloses various formulations of the insecticidal composition and a preparation method thereof. In the invention, the composition can be applied to the prevention and control of common pests in the agricultural production and provides a safe and efficient new variety of pesticides for the productions of export-oriented agriculture, green foods and pollution-free fruits and vegetables.

Owner:SOUTH CHINA AGRI UNIV

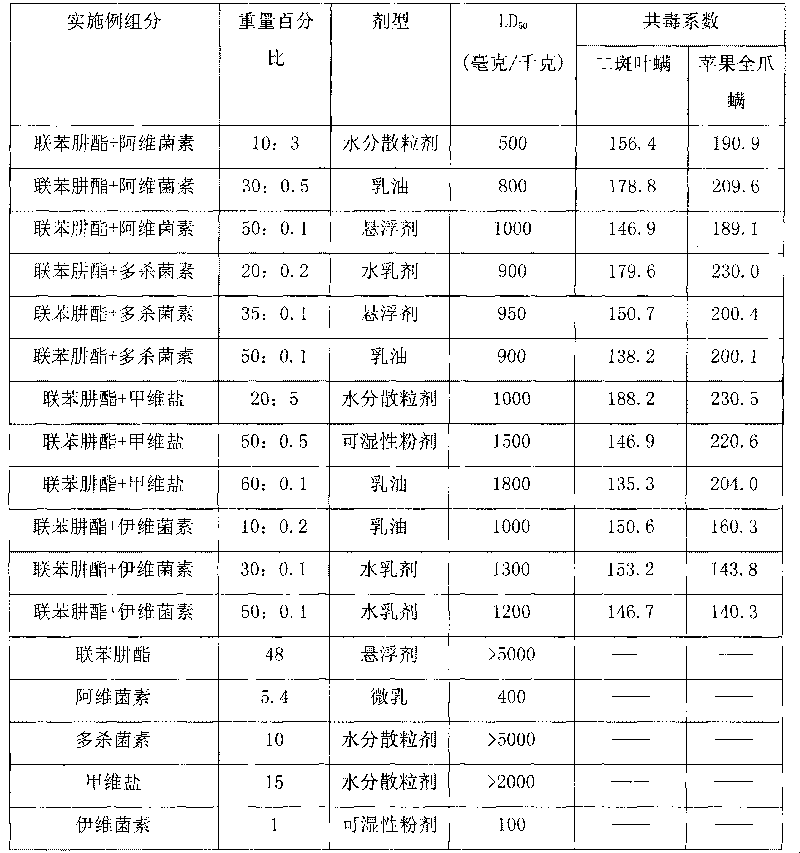

Acaricidal composition containing bifenazate and application thereof

InactiveCN101708005ANot easy to develop resistanceSynergistic effect is obviousBiocideAnimal repellantsOil emulsionSuspending Agents

The invention discloses an acaricidal composition which comprises a synergic effective dose of acaricidal material bifenazate A and at least one macrolide acaricidal compound B as active components, wherein the macrolide acaricidal compound B is selected from avermectin, pleocidin, emamectin benzoate and invermectin, and based on the active components, the proportion of A to B according to parts by weight is 5-70:0.1-10. The composition can be prepared into oil emulsion, suspending agents, aqueous emulsion, micellar emulsion, wettable powder, microcapsule agents and other formulations for controlling acarid of various crops such as fruit trees, tea trees, vegetables and the like.

Owner:HAILIR PESTICIDES & CHEM GRP

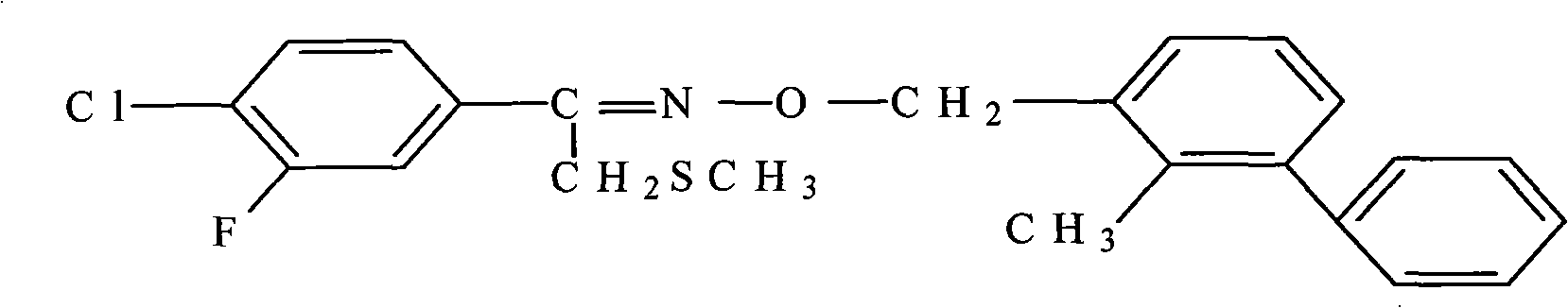

Insecticidal composition of sufluoxime

The present invention discloses a combination of macrolides insecticide and insecticide of Sufluoxime, wherein the macrolides insecticide is spinosad, avermectin, the derivative thereof, etc., and the Sufluoxime is 1-(3-fluoro-4-chlorophenyl)-2-methylthioethanone-O-(2-hydroxymethyl-3-methyl) aether. The various surfactants and additives such as carrier, thickening agent, stabilizing agent, antifreeze agent, antifoaming agent, adhesive and the like are added to prepare an insecticidal composition in dosage forms of missible oil, aqueous emulsion, microemulsion, suspending agent, granular formulation, water dispersible powder or dispersible granula, etc. The insecticidal composition has characteristics of evident synergism, resistance delay, widening the spectrum of insect disinfestation, etc., and has disinfestation effect to the destructive insect in the disinfestation range of two normal insecticides.

Owner:HUNAN CHEM RES INST

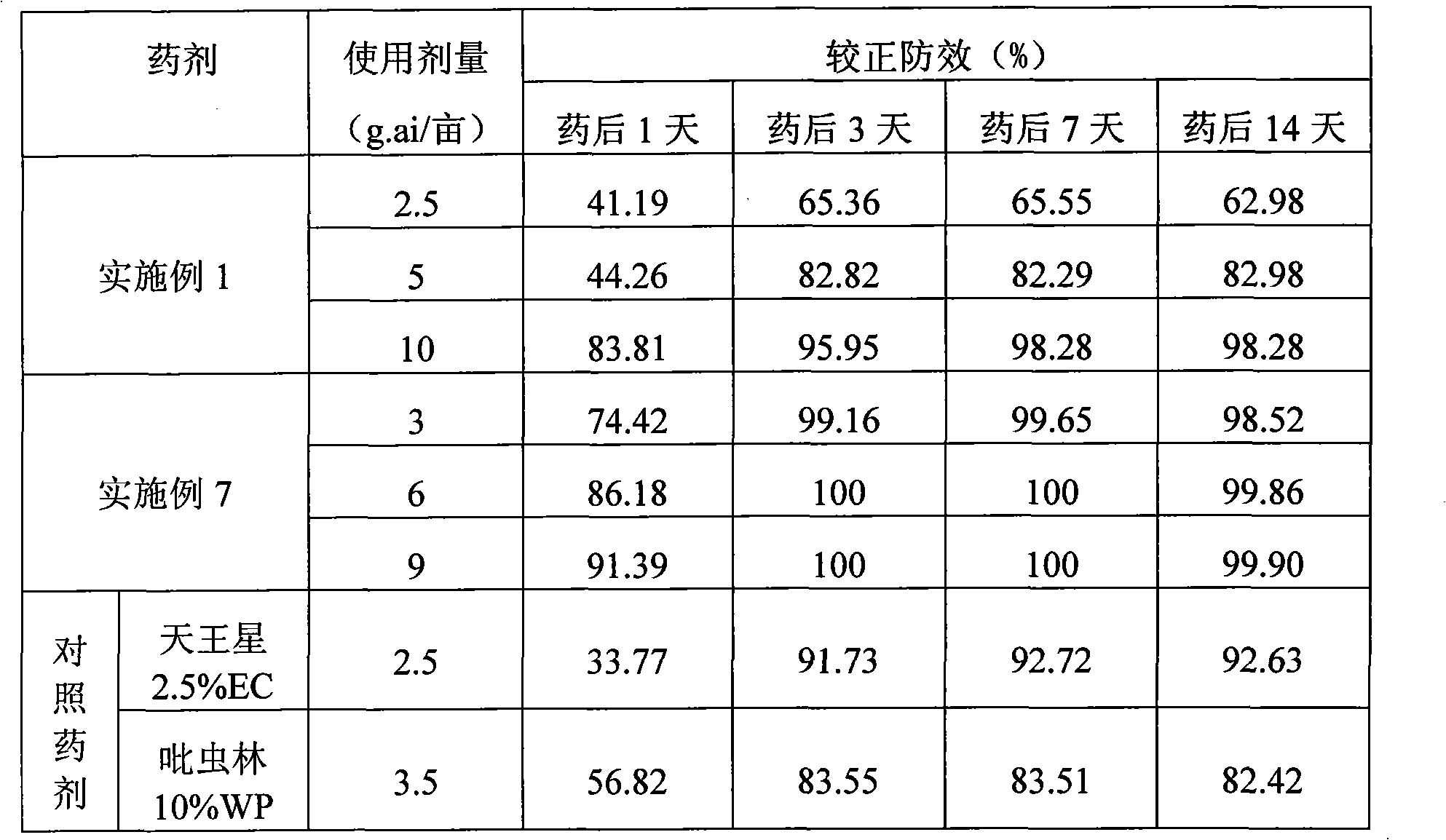

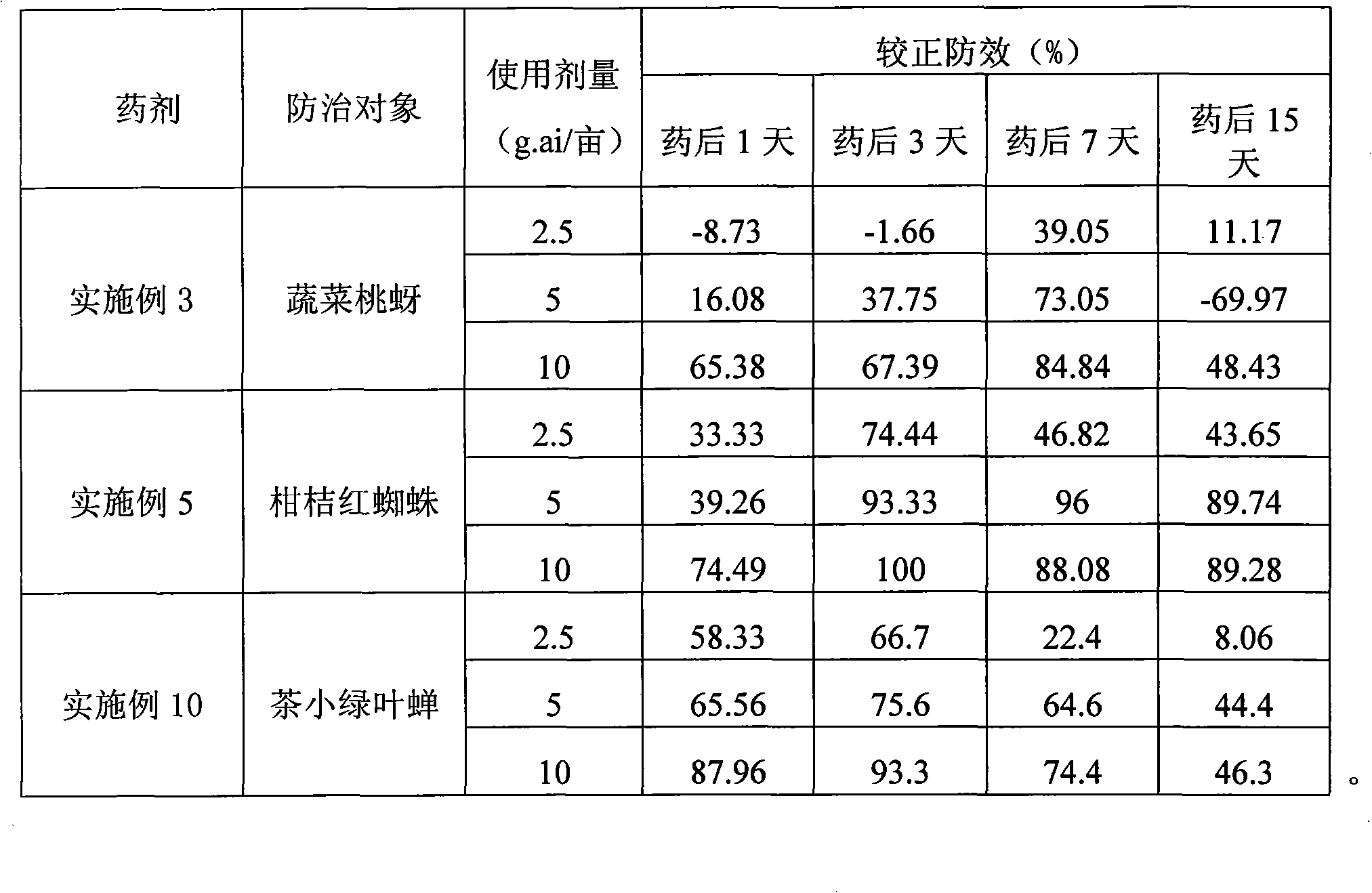

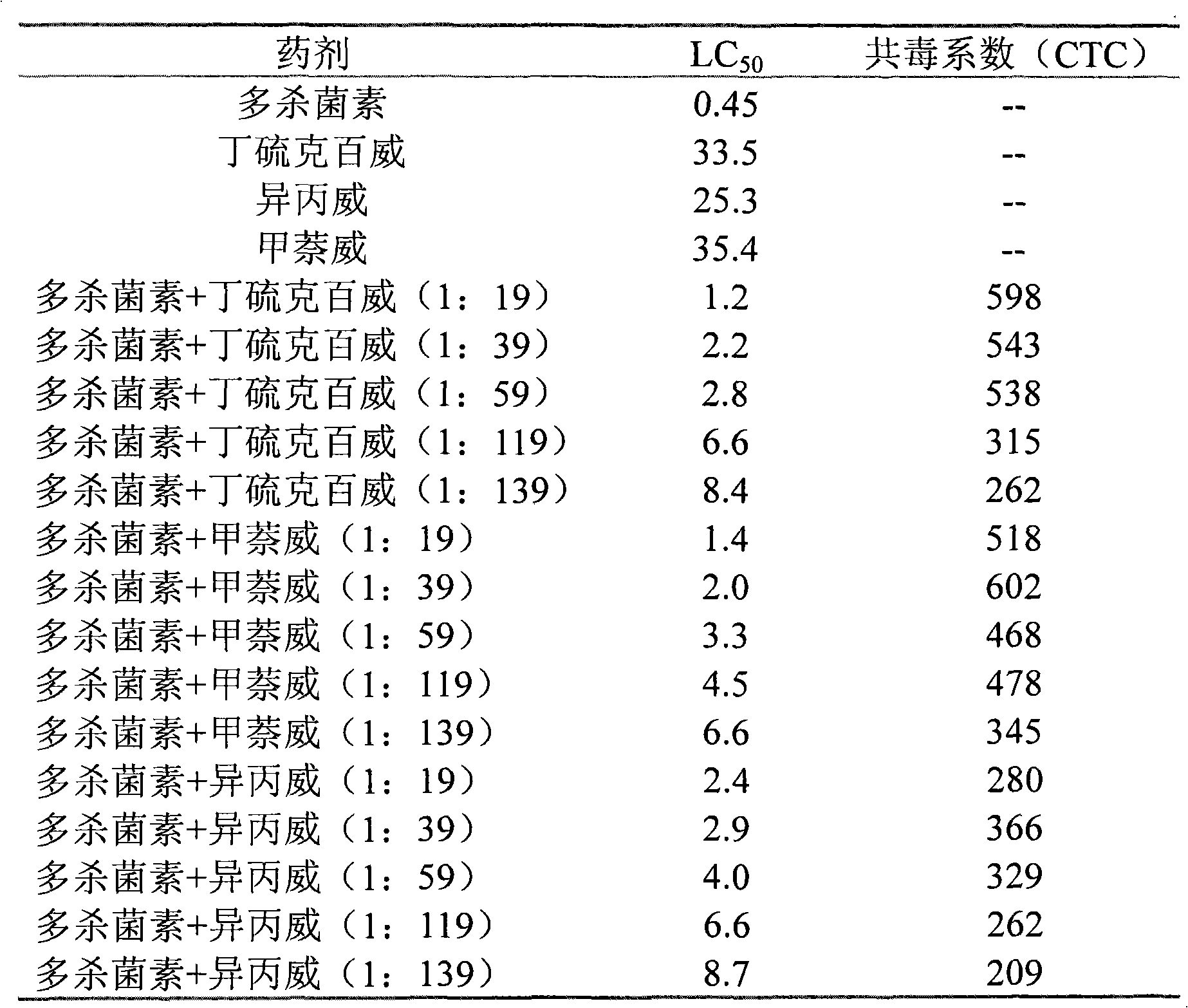

Agricultural chemical composition containing multiple bactericidins and carbamate inecticides

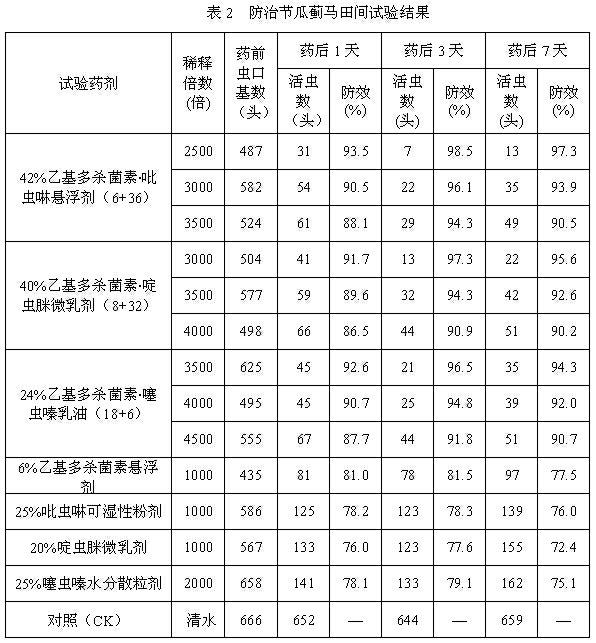

The invention relates to a pesticide composition, in particular to a pesticide composition containing dosis efficax synergism pesticide of pleocidin and carbamates, wherein the weight ratio of the pleocidin and the carbamates is selected preferably (1:0.1)-(1:200), more preferably (1:1)-(1:150) and most preferably (1:19)-(1:139).

Owner:CHINA AGRI UNIV

Pesticide composition containing spinetoram and neonicotinoid insecticide

ActiveCN102578132AImprove insecticidal effectImprove securityBiocideAnimal repellantsSpinosadActive component

The invention discloses a pesticide composition containing spinetoram and neonicotinoid insecticide, which comprises active components composed of a first active component and a second active component, wherein the first active component includes spinetoram and the second active component includes neonicotinoid insecticide selected from imidaclprid, acetamiprid and thiamethoxam, the weight ratio between the first active component and the second active component is (1:20) : (30: 1). The composition can be prepared to be formulations allowed in agriculture such as a water dispersible granule, wettable powder, a suspending agent, an emulsifiable concentrate or a microemulsion. According to the pesticide composition containing spinetoram and neonicotinoid insecticide, the components are reasonable, the insecticidal effect is good, the pesticide cost is low, and the activity and insecticidal effect are not a simple composition of each component activity, compared with the existing single preparation, the pesticide composition containing spinetoram and neonicotinoid insecticide has the advantages of remarkable insecticidal effect, and also prominent synergistic effect, good security, accordance with the safe requirement of pesticide preparations, and good preventing effect for vegetable thrips.

Owner:SHAANXI SUNGER ROAD BIO SCI

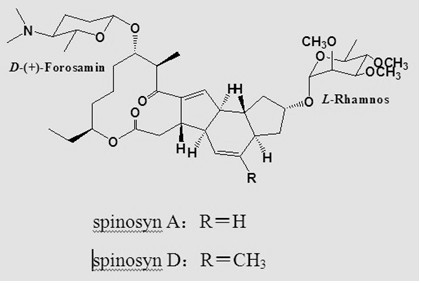

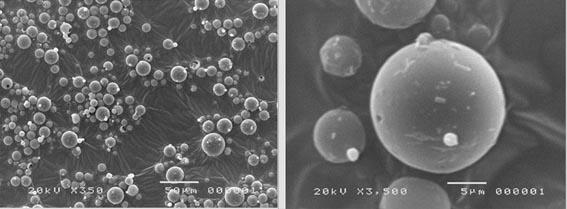

Spinosad microcapsule suspending agent

The invention relates to a microcapsule suspending agent which takes spinosad as an active ingredient. Capsule-core spinosad is coated with a polyurethane type semipermeable envelope so as to form a microcapsule which is stably dispersed and suspended in water and is milk-white homogeneous-phase suspension liquid. A pesticide composition has good prevention and control effects on plutella xylostella. The occurrence of medicament resistance is delayed, environmental pollution is reduced and lasting period is prolonged.

Owner:BEIJING YOLOO BIO TECH CORP

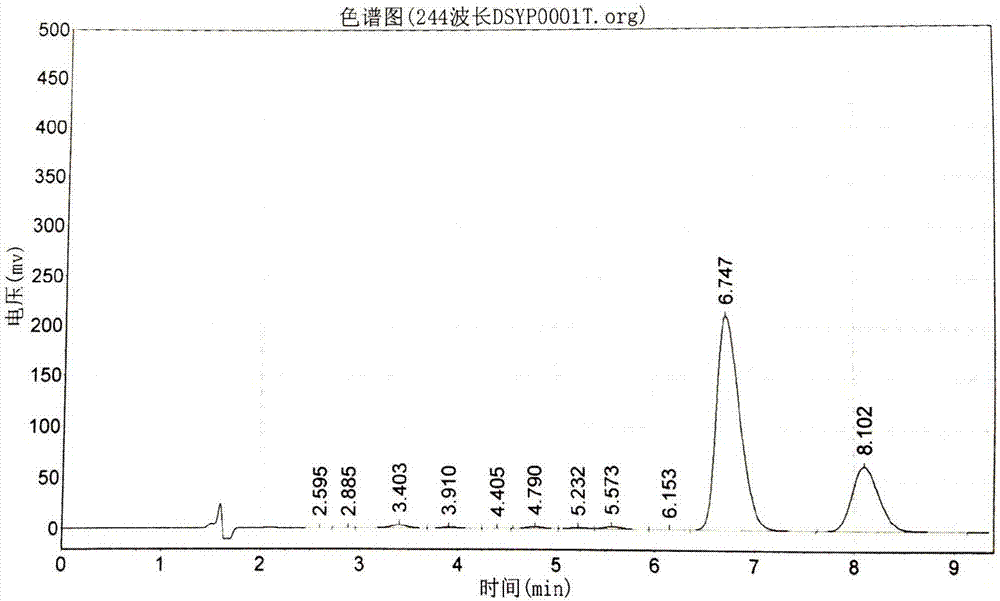

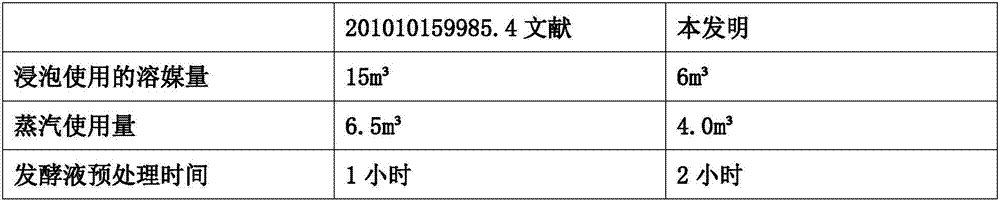

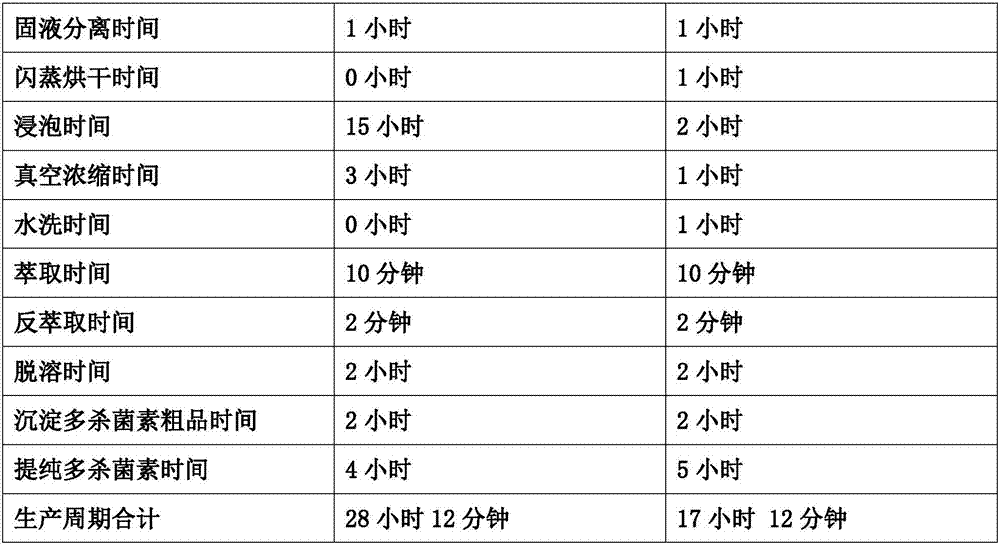

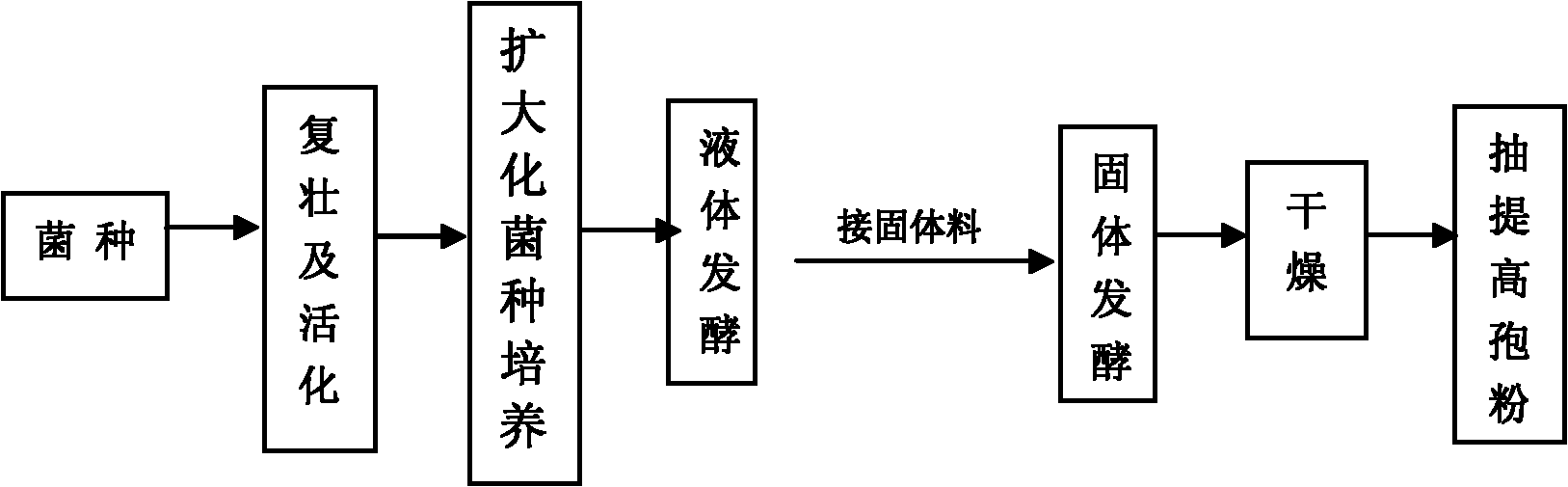

Extraction process for industrial mass production of spinosad

ActiveCN107474088AReduce usageImprove leaching efficiencySugar derivativesSugar derivatives preparationFiltrationSolvent

The invention relates to an extraction process for industrial mass production of spinosad. The process includes the steps of: fermentation broth pretreatment, frame and plate filtration, and flash drying; mycelium soaking in methanol; concentration of extract liquid, phase inversion washing; back extraction with tartaric acid; adjustment of pH and centrifugation to obtain a spinosad crude product; and recrystallization with methanol to obtain a spinosad fine product. The process provided by the invention extracts spinosad by means of mycelium separation, drying and extraction, and has the characteristics of high extraction efficiency, small solvent dosage, which is only half of that of fermentation broth direct solvent extraction, relatively low energy consumption, and shortened production cycle. In addition, the equipment needed by frame and plate filtration, flash drying, extraction, concentration, washing, back extraction and refining is general, therefore industrial production can be realized easily. The obtained product has high yield up to 85%-90%, after purification of spinosad coarse crystals by solvent recrystallization, the quality of spinosad is improved, and the product content reaches 95%-98%.

Owner:QILU PHARMA INNER MONGOLIA

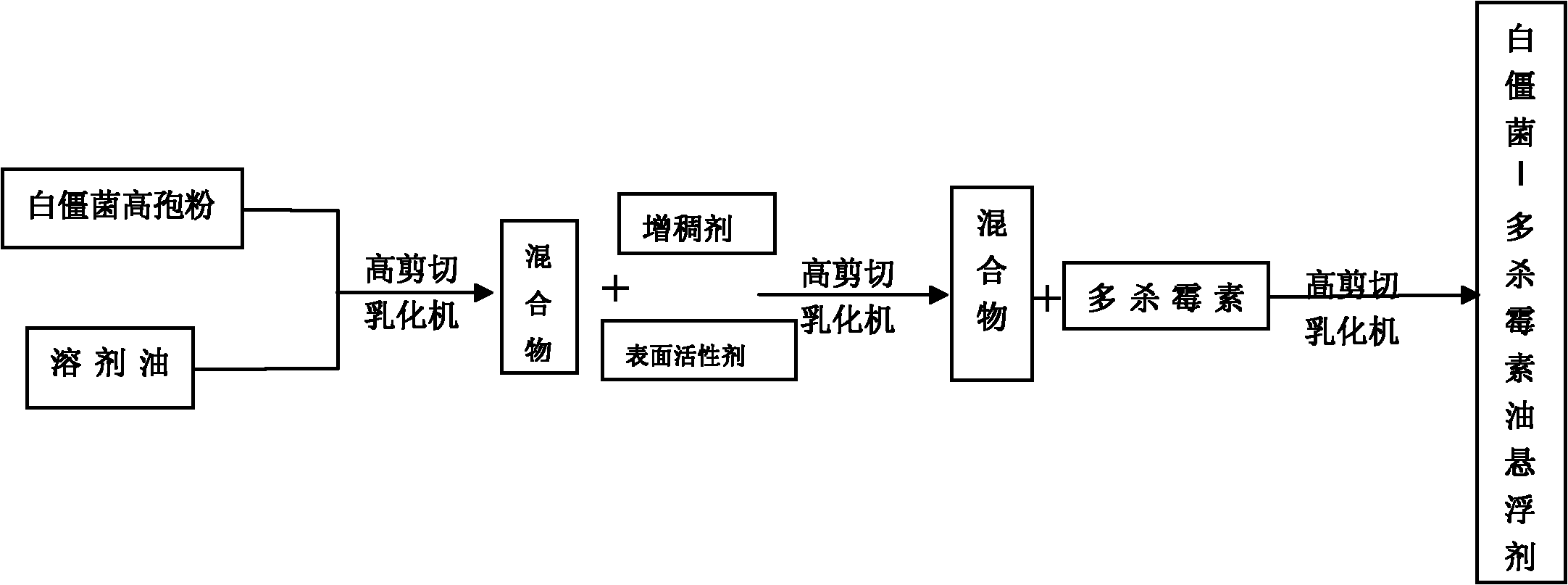

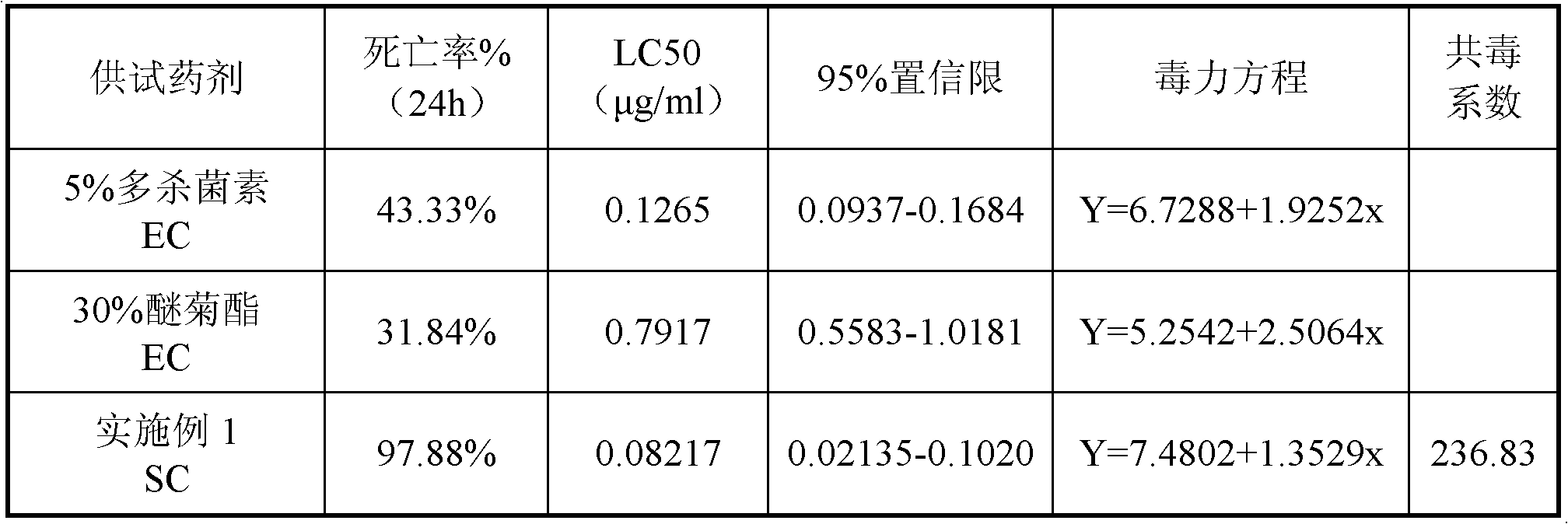

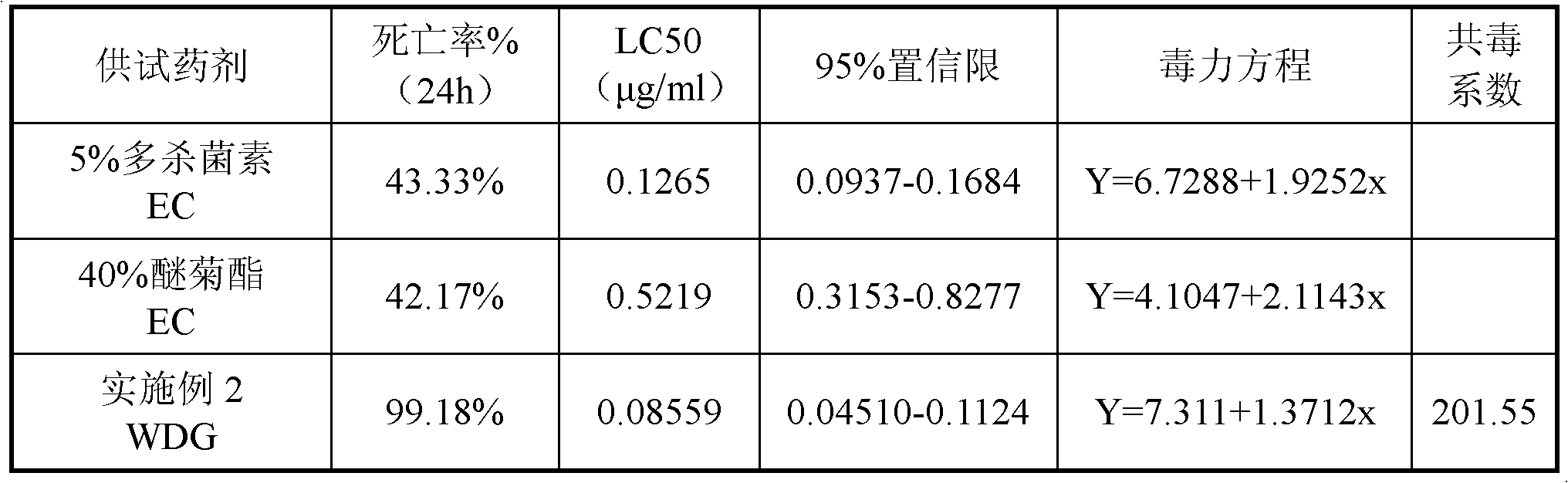

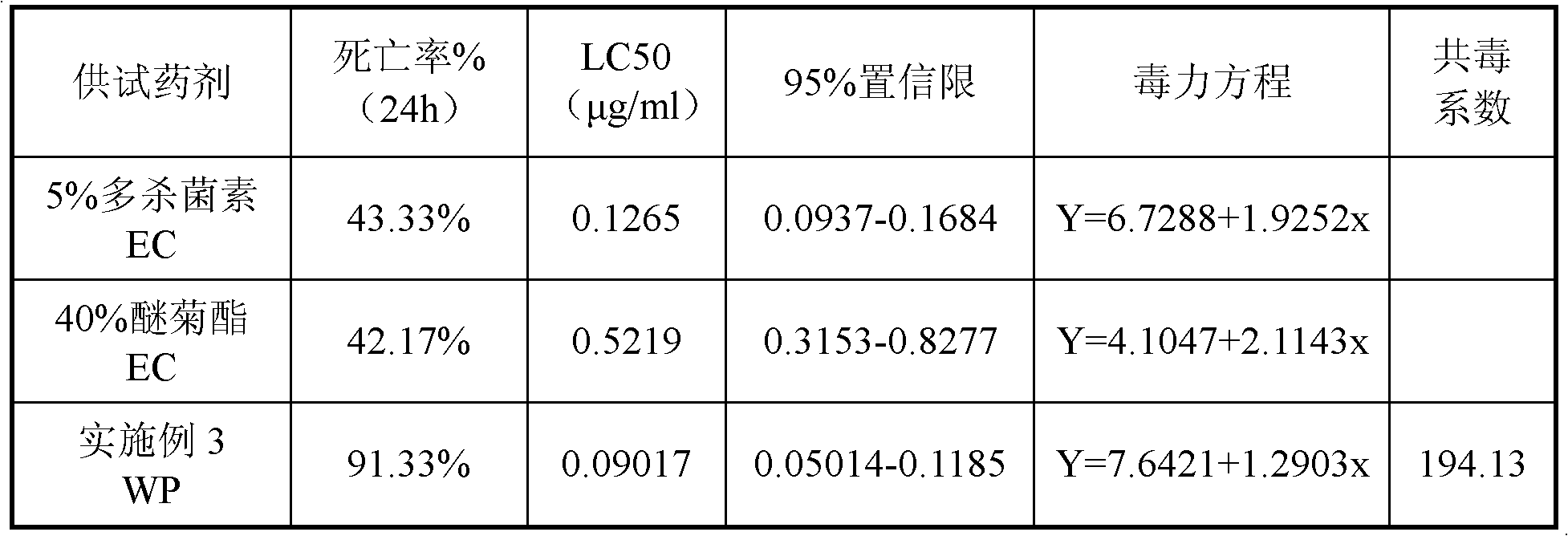

Preparation method and application of eauveria-spinosad suspending agent

InactiveCN102172250AOvercome the disadvantage of slow drug effectObvious synergism of toxicityBiocideAnimal repellantsSpinosadHas active ingredient

The invention relates to a preparation method and application of q beauveria-spinosad suspending agent. Beauveryia bassiana and spinosad are the active ingredients of the suspending agent which is used for preventing and treating agriculture and forestry injurious insects, such as leptinotarsa decemlineata and acridid and the like. The invention is characterized in that (1) the suspending agent comprises active ingredients, namely the beauveryia bassiana and the spinosad; and (2) the mass ratio of the beauveryia bassiana and the spinosad is (30:1)-(30:2), and the mass percent of the effective components in the preparation is 3.1-10%. The preparation method has the advantages that the product can be dissolved with oil or water; the effective duration of the beauveria vuillemin and the relative quick action of spinosad have complementary advantages, and injurious insects of various crops are treated; and the suspending agent prepared by the method has the advantages of good synergism and permeability, strong adhesivity and evaporation resistance and the like.

Owner:INST OF ENVIRONMENT & SUSTAINABLE DEV IN AGRI CHINESE ACADEMY OF AGRI SCI

Insecticide composition containing spinosad and etofenprox

The invention relates to an agricultural insecticide composition, and in particular discloses an insecticide composition containing spinosad and etofenprox. When the insecticide composition is a suspending agent, a wettable powder or a water dispersible granule and has a formula comprising the following components: 1-70 percent of active component, 1-20 percent of compound auxiliary agent and 10-98 percent of stuffing; when the insecticide composition is an aqueous emulsion or a microemulsion, the formula of the insecticide composition comprises the following components: 1-40 percent of active component, 1-19 percent of compound auxiliary agent, 5-40 percent of solvent and 1-93 percent of water; and the active component comprises spinosad and etofenprox in the mass ratio of 1:(0.045-500). The insecticide composition has the advantages of good insecticidal effect, long pest control time, difficult generation of resistance for pests, safety for crops, environmental protection, wide insecticidal range, low cost and the like.

Owner:湖南大方农化股份有限公司

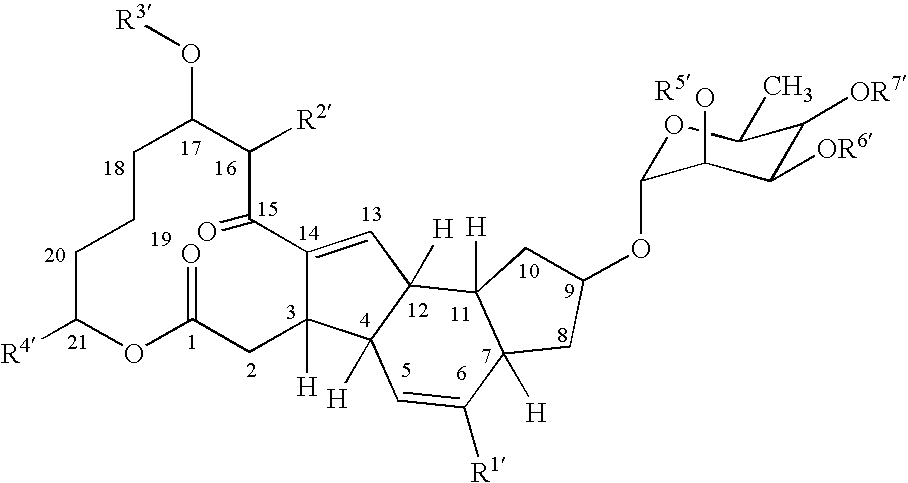

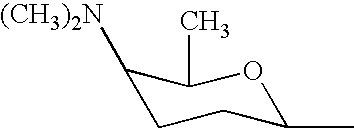

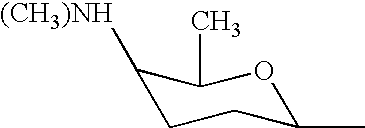

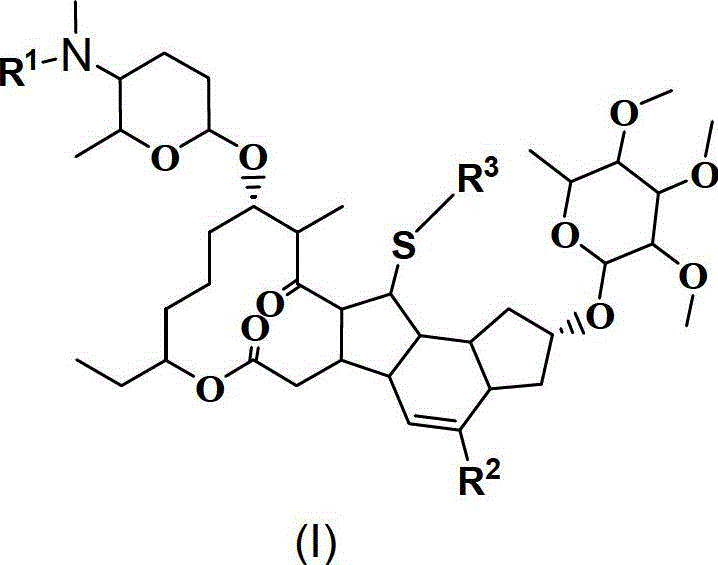

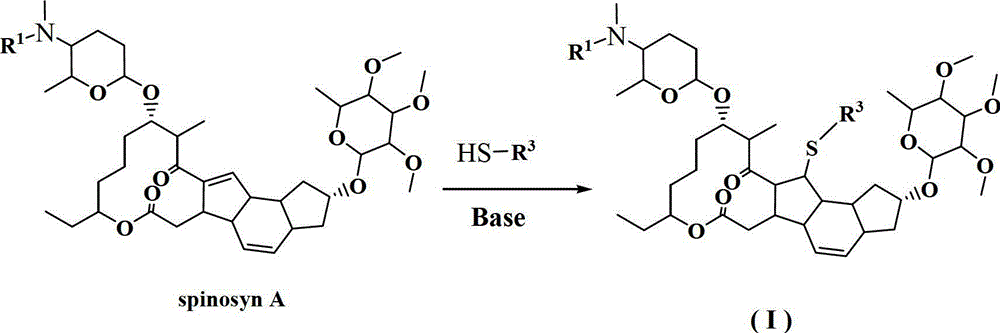

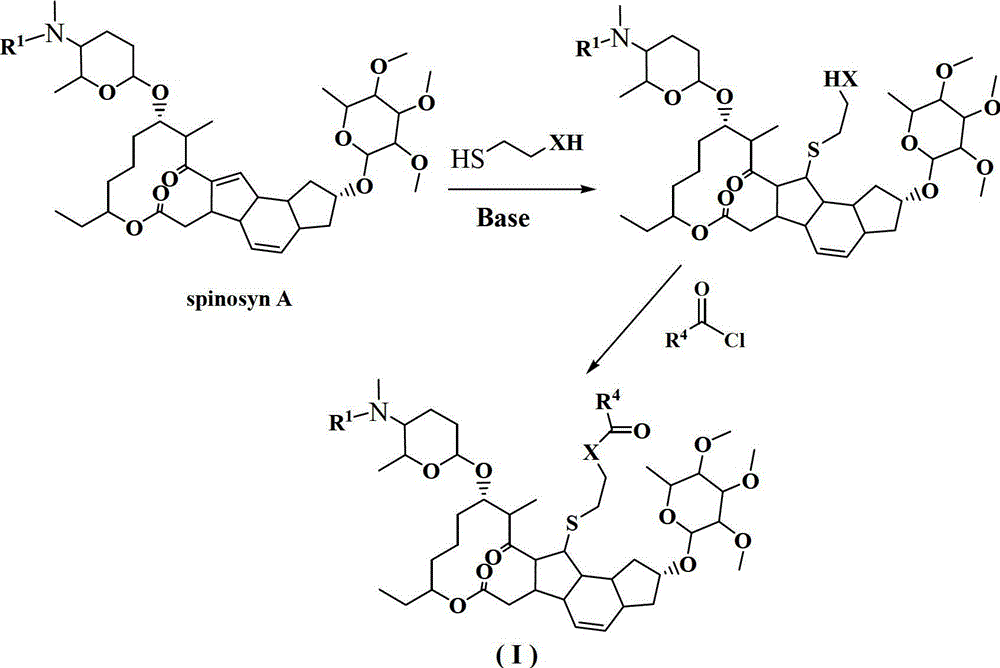

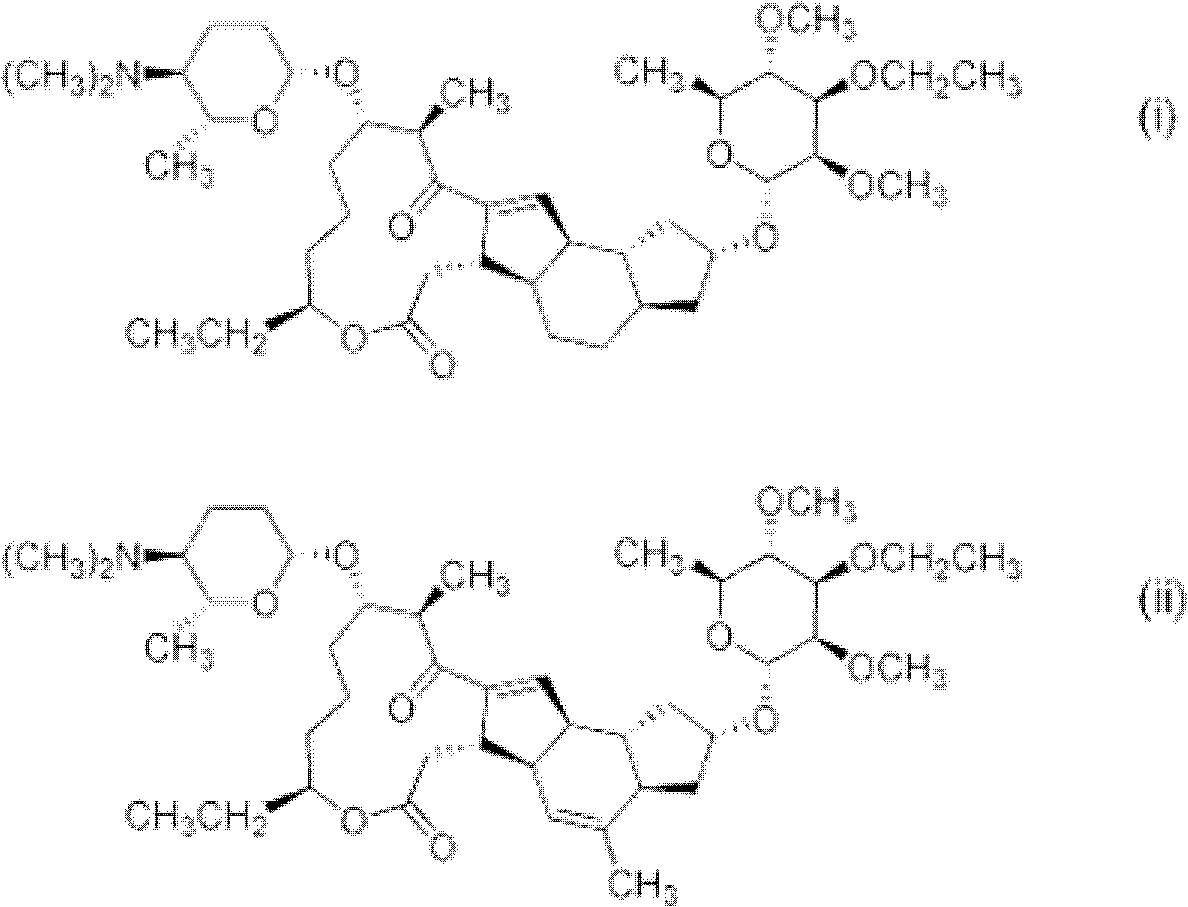

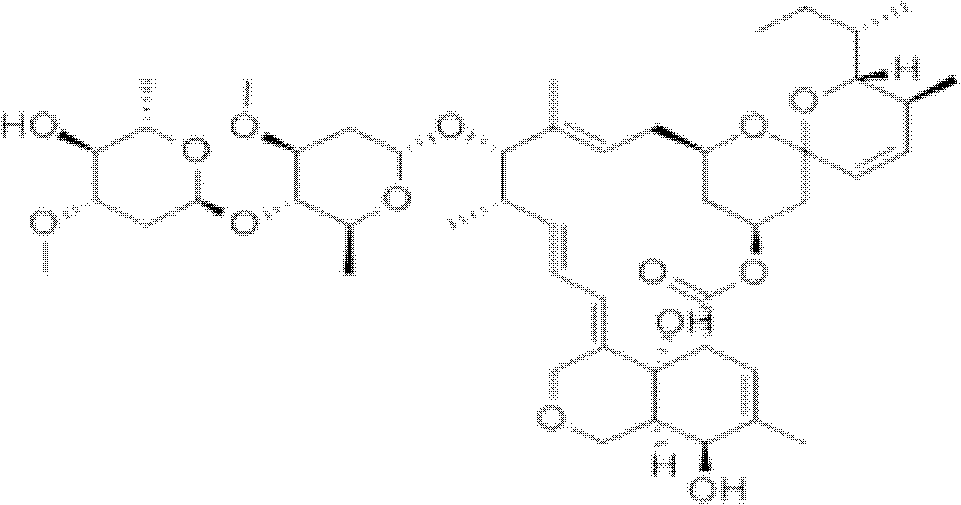

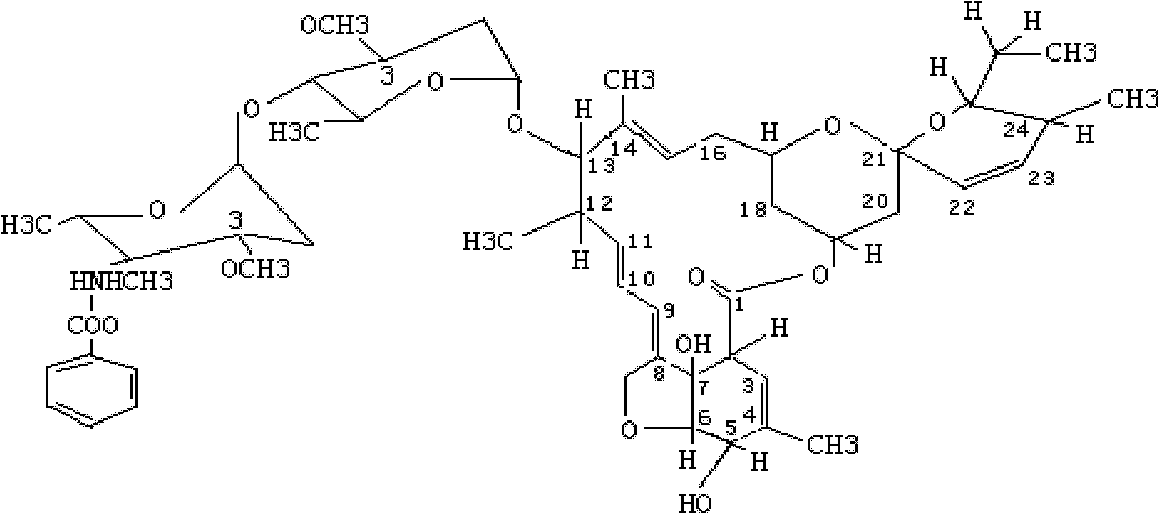

13-thioether substituted pleocidin derivative and preparation method thereof

ActiveCN102977166AHigh reaction yieldMild reaction conditionsBiocideSugar derivativesChemical synthesisSpinosad

The invention discloses a 13-thioether substituted pleocidin derivative which is represented by a general formula (I) shown in the specification and has an insecticide and acarid-killing activity, and a preparation method thereof. The compound with the general formula (I) is obtained by a chemical synthesis method from natural pleocidin or a pleocidin derivative prepared by a semi-synthesis method as a raw material. The synthesis method disclosed by the invention comprises a 13-Michael reaction, an acylation reaction and an esterification reaction. The compound with the general formula (I) has good activity on various pests and acarids on crops. The compound with the general formula (I) is prepared into an acid addition salt by using a standard salt preparation technology to be used for crop protection.

Owner:HUNAN CHEM RES INST

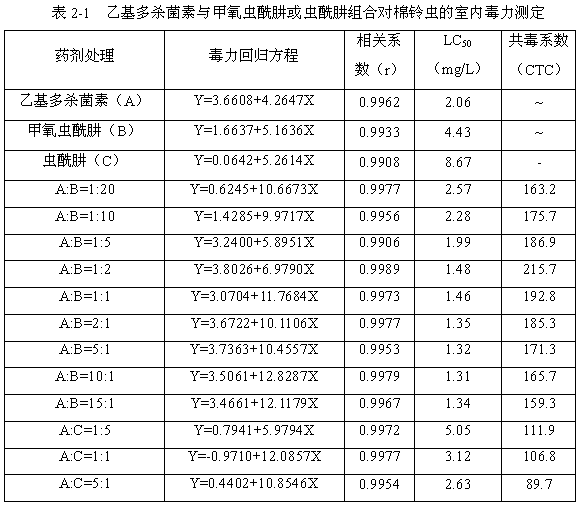

Insecticidal composition containing spinetoram

InactiveCN102696603AImprove securityMeet security requirementsBiocideAnimal repellantsSpinosadOil emulsion

The invention discloses an insecticidal composition containing spinetoram. The insecticidal composition comprises a first active ingredient of spinetoram and a second active ingredient of methoxyfenozide or ZJ0967, wherein the weight ratio of the first active ingredient to the second active ingredient is 1:20-15:1. The insecticidal composition can be prepared into agriculturally accepted water dispersible granules, suspending agents, oil emulsion, micellar emulsion or aqueous emulsion; the insecticidal composition has reasonable components and a good insecticidal effect and is low in cost, and the activity and the insecticidal effect of the insecticidal composition is not equal to the simple superposition of the activity of all components; and compared with the presently used single preparation, the insecticidal composition achieves an obvious insecticidal effect as well as obvious synergistic action, has high safety and meets the safety requirements of pesticide formulations. The insecticidal composition has quite high insecticidal activity on cnaphalocrocis medinalis guenee, cotton bollworms, prodenia litura and mythimna separate.

Owner:DOW AGROSCIENCES LLC

A spinosad-polylactic acid microsphere suspension and preparation method thereof

InactiveCN102293203AImprove stabilityImprove utilization efficiencyBiocideAnimal repellantsSpinosadOrganic solvent

The invention discloses a spinosad-polylactic acid microsphere suspension and a preparation method thereof. composition. The preparation has good stability, high pesticide utilization efficiency, and environmental friendliness, and the preparation product basically does not contain organic solvents, and has significant economic and social benefits.

Owner:FUJIAN AGRI & FORESTRY UNIV

Compound pesticide

The invention relates to a compound pesticide which belongs to the technical field of pesticides. The effective components of the compound pesticide are chlorantraniliprole and spinosad, and the compound pesticide is characterized in that the proportion of the chlorantraniliprole to the spinosad is 1:5-5:1. The compound pesticide has good insecticidal effect, high titer, low toxicity and safe use; and the compound pesticide is not easy to lead pests to produce immunity to the compound pesticide.

Owner:浙江拜克生物科技有限公司

Composition of dithiocyano-methane and macrolide insecticide component

ActiveCN102960359ASignificant synergy of activityHave an unexpected effectBiocideNematocidesSpinosadAvermectin

The invention relates to a composition of dithiocyano-methane and macrolide insecticide component. The macrolide insecticide component is one of abamectin, ivermectin, emamectin benzoate and pleocidin. The mass ratio of the dithiocyano-methane to the macrolide insecticide component is (0.05-50):1, and the mass sum of the dithiocyano-methane and the macrolide insecticide components accounts for 0.1-60 percent of the total mass of the composition. The composition is used for controlling nematode, is applied to crops suffering from nematode pest invasion or soil in which the crops grow, and the application dosage of the composition is 50-2000mg / Kg.

Owner:HAINAN ZHENGYE ZHONGNONG HIGH TECH

Pesticide composition containing spinetoram and biogenic pesticide

ActiveCN102396474AReasonable compositionMultiple pest action sitesBiocideAnimal repellantsBenzoic acidAbamectin

The invention discloses a pesticide composition containing spinetoram and biogenic pesticide. The biogenic pesticide may be abamectin, emamectin benzoate or ivermectin; the weight ratio of spinetoram to biogenic pesticide is 1:60 to 60:1; and the spinetoram and biogenic pesticide account for 1 to 60 percent of the weight of the pesticide composition in total. The pesticide composition can be used for preventing and controlling rice stem borers, plutella xylostella in vegetables, beet armyworms and cotton bollworm in cotton. The pesticide composition not only expands the application range of pesticides, but also reduces the dosage of pesticides, namely dosage per mu of the pesticides under the conditions of obvious synergistic effect and optical prevention and control effects, and therefore the cost and environmental harms are reduced.

Owner:GAUNGXI TIANYUAN BIOCHEM

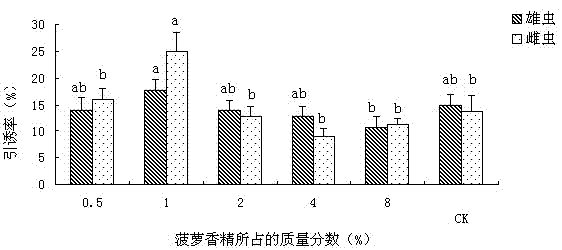

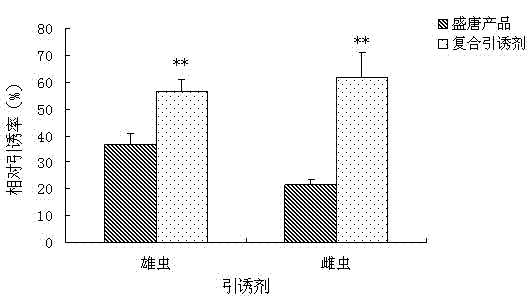

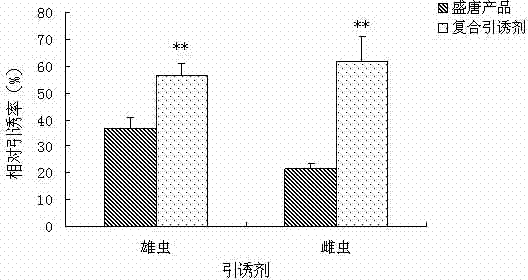

Composite attractant of bactrocera dorsalis hendel

InactiveCN102499269ASimple recipeRaw materials are cheap and easy to getBiocidePest attractantsBiotechnologyHydrolysate

The invention discloses a composite attractant of bactrocera dorsalis hendel, which comprises aqueous solution of a molasses, aqueous solution of a complex protein hydrolyzate and a fruit flavor. The mass ratio of the aqueous solution of the molasses to the aqueous solution of the complex protein hydrolyzate is 4:1; the complex protein hydrolyzate is the hydrolysate which is obtained by mixing soy protein and brewer's yeast protein at the weight ratio of 1:1-9, adding 5,000U / g of acidic protease, 0.5-5.0 parts by weight of preservative and 0.01-0.1 part by weight of spinosad, and hydrolyzing at 50 DEG C for 2hours. The formula of the composite attractant of the bactrocera dorsalis hendel is simple, and the raw materials are cheap and easy to obtain. The composite attractant has good effect of attracting the male and female adult bactrocera dorsalis hendel, and particularly, the composite attractant can attract more than 25% of bactrocera dorsalis hendel of 10-11 days old. The raw materials used for preparing the composite attractant do not contain any harmful chemical substances, have no toxic effects on people and animals and meet the environmental protection requirements.

Owner:SOUTH CHINA AGRI UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com