Extraction process for industrial mass production of spinosad

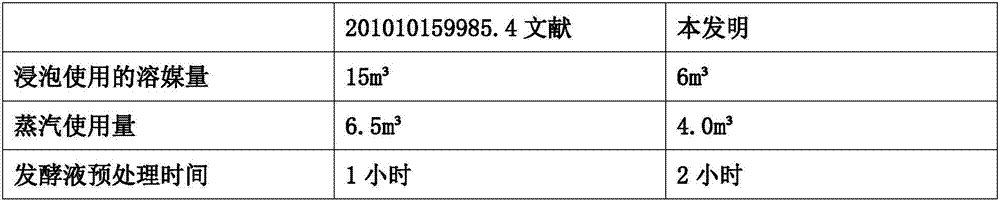

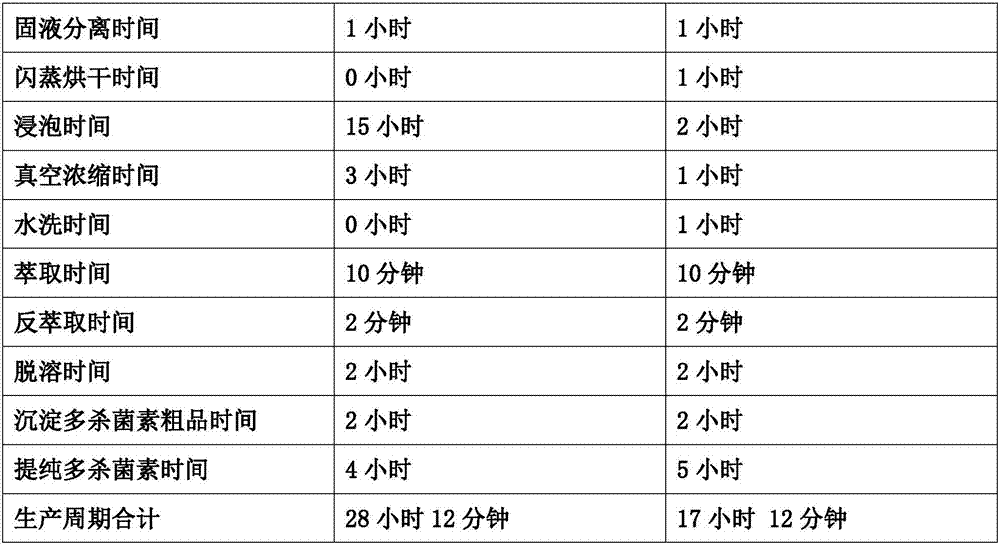

A technology of spinosyn and extraction method, applied in the direction of sugar derivatives, sugar derivatives, organic chemistry, etc., can solve the problems of poor product quality, large amount of solvent used, long production cycle, etc. High extraction efficiency and low solvent usage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

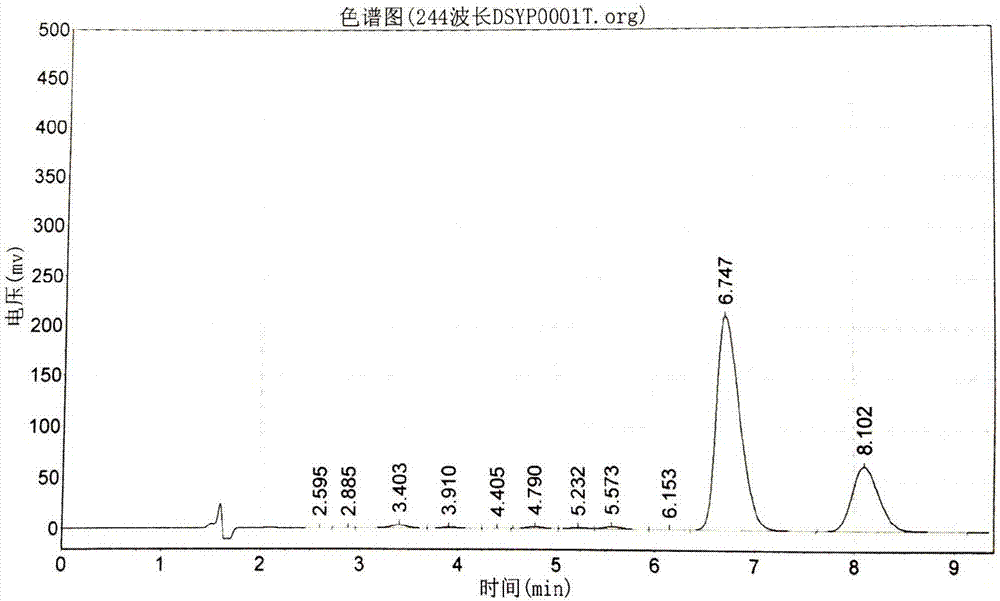

Image

Examples

Embodiment 1

[0038] A low-solvent, high-yield industrial extraction method of spinosad, the specific steps are as follows:

[0039] (1) 10m 3 Pretreatment tank access 4.95m 3 Add 99kg of perlite, 24.75kg of yellow blood salt, and 49.5kg of zinc sulfate into the fermented liquid (1201u / ml), heat up to 90°C with direct steam, and keep stirring for 2 hours.

[0040] (2) Utilize the plate and frame filter press to filter the fermented liquid that has been pretreated, after press filtration, collect filter cake, wet filter cake weight 592kg.

[0041] (3) Use flash drying to dry the wet filter cake. The temperature of the flash inlet air is controlled at 80°C to 100°C. The moisture content of the dried mycelia is controlled at 8.1%. The weight of mycocin dry powder is 305kg and the potency is 19277u / mg, the yield was 98.9%.

[0042] (4) Put 305kg of spinosad mycelia with a potency of 19277u / mg into the extraction column after drying, and use 1.5m 3 Soak in methanol for 1-2 hours, then pass ...

Embodiment 2

[0048] A low-solvent, high-yield industrial extraction method of spinosad, the specific steps are as follows:

[0049] (1) 10m 3 Pretreatment tank access 5.5m 3 Add 110kg of perlite, 27.5kg of yellow blood salt, and 55kg of zinc sulfate into the fermented liquid (1355u / ml), and heat up to 90°C with direct steam, and keep stirring for 2 hours.

[0050] (2) Utilize plate and frame filter press to filter the pretreated fermented liquid, after press filtration, collect filter cake, wet filter cake weight 642kg

[0051] (3) Use flash drying to dry the wet filter cake, the temperature of the flash inlet air is controlled at 80°C to 100°C, the moisture content of the dried mycelia is 8.3%, the weight of mycocin dry powder is 330kg, and the potency is 22245u / mg , the yield was 98.5%.

[0052] (4) 330kg of spinosad mycelia with a potency of 22245u / mg after drying are put into the extraction column, and the 1.65m 3 Soak in methanol for 1-2 hours, then pass nitrogen gas from the top ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com