Patents

Literature

245results about How to "Good crystal shape" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

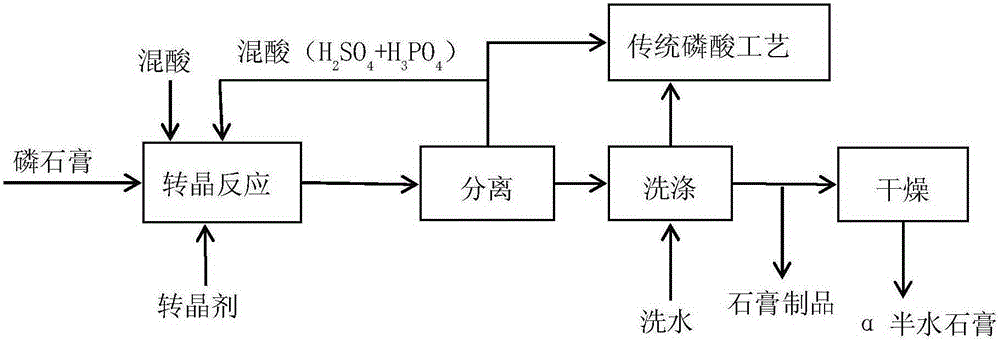

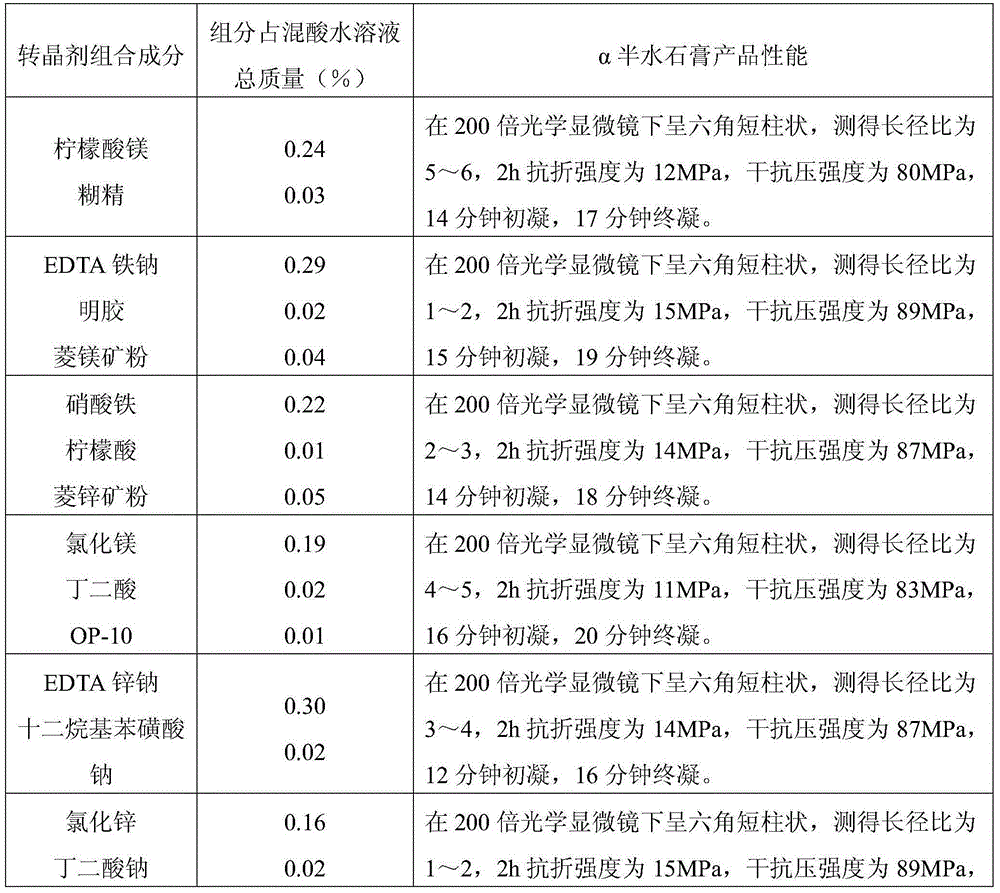

Method for preparing alpha semi-hydrated gypsum from dihydrate gypsum

The invention relates to a method for preparing alpha semi-hydrated gypsum from dihydrate gypsum. The method comprises the following steps: adding dihydrate gypsum and a crystal modifier into a mixed acid water solution containing sulfur acid and phosphoric acid to carry out crystal transformation, carrying out solid-liquid separation, returning a part of liquid phase into a crystal transformation tank for crystal transformation, and conveying another part of liquid phase to an acidolysis tank for use, wherein the acidolysis tank is used for preparing phosphoric acid by decomposing phosphorite by virtue of sulfuric acid; adding washing water to wash a solid phase, and introducing the washing water into the liquid phase for use. The washed solid phase can be prepared into alpha semi-hydrated gypsum powder through drying and can be prepared into gypsum products such as gypsum boards, gypsum blocks, gypsum components and the like by directly adding water without drying. According to the method, the alpha semi-hydrated gypsum is prepared in the mixed acid water solution containing sulfur acid and phosphoric acid, procedures including desulfuration, removal of impurity and the like on raw gypsum can be omitted, furthermore, mixed acid can be recycled, and the obtained alpha semi-hydrated gypsum product is high in strength and stable in quality.

Owner:贵州正磷科技有限公司

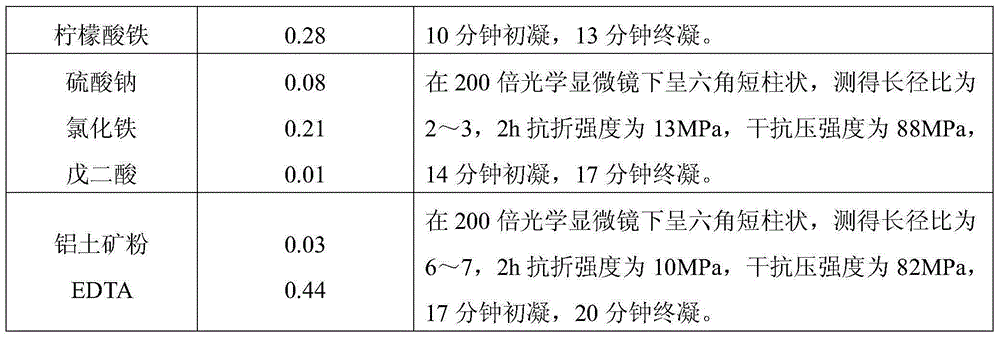

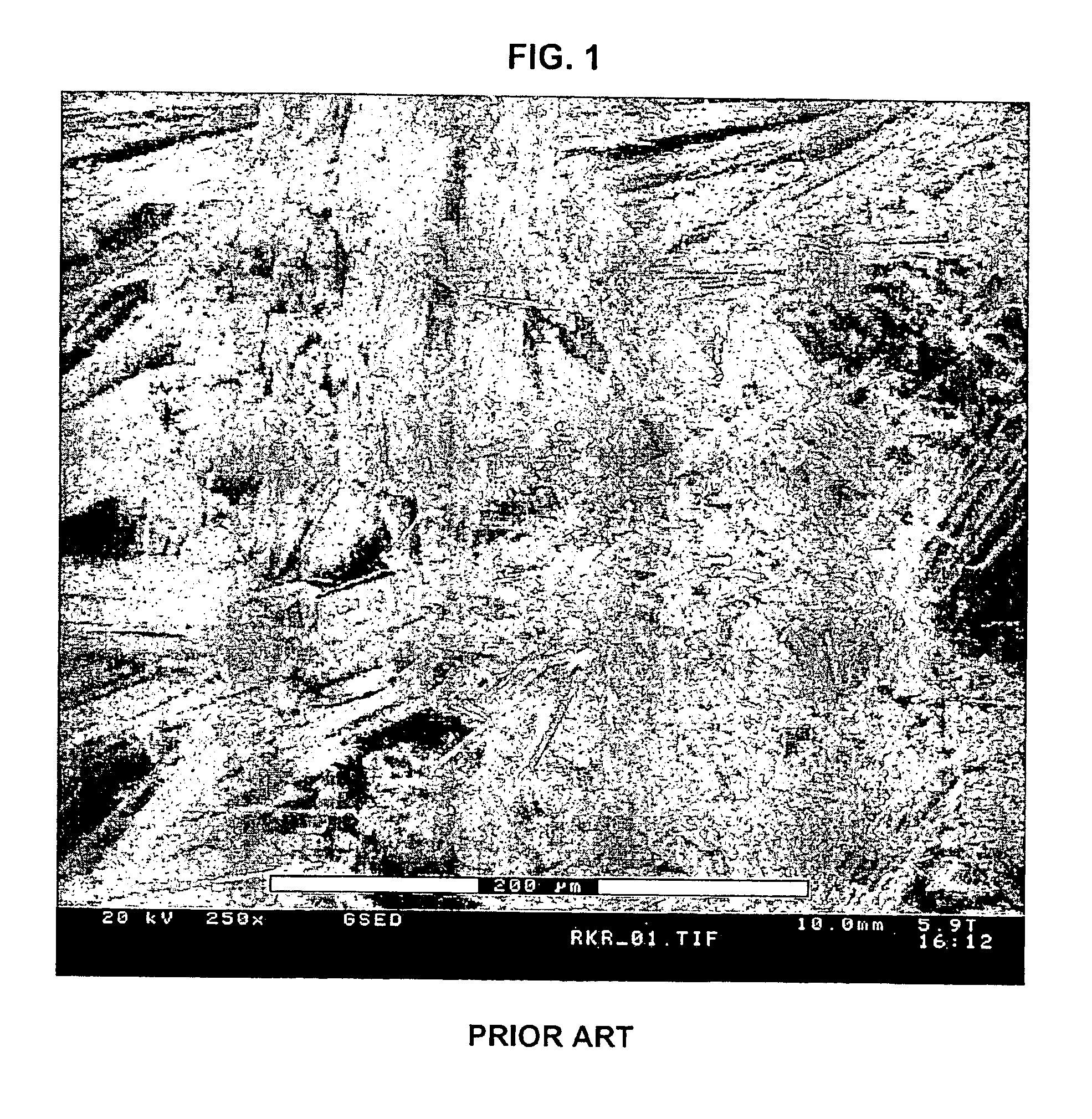

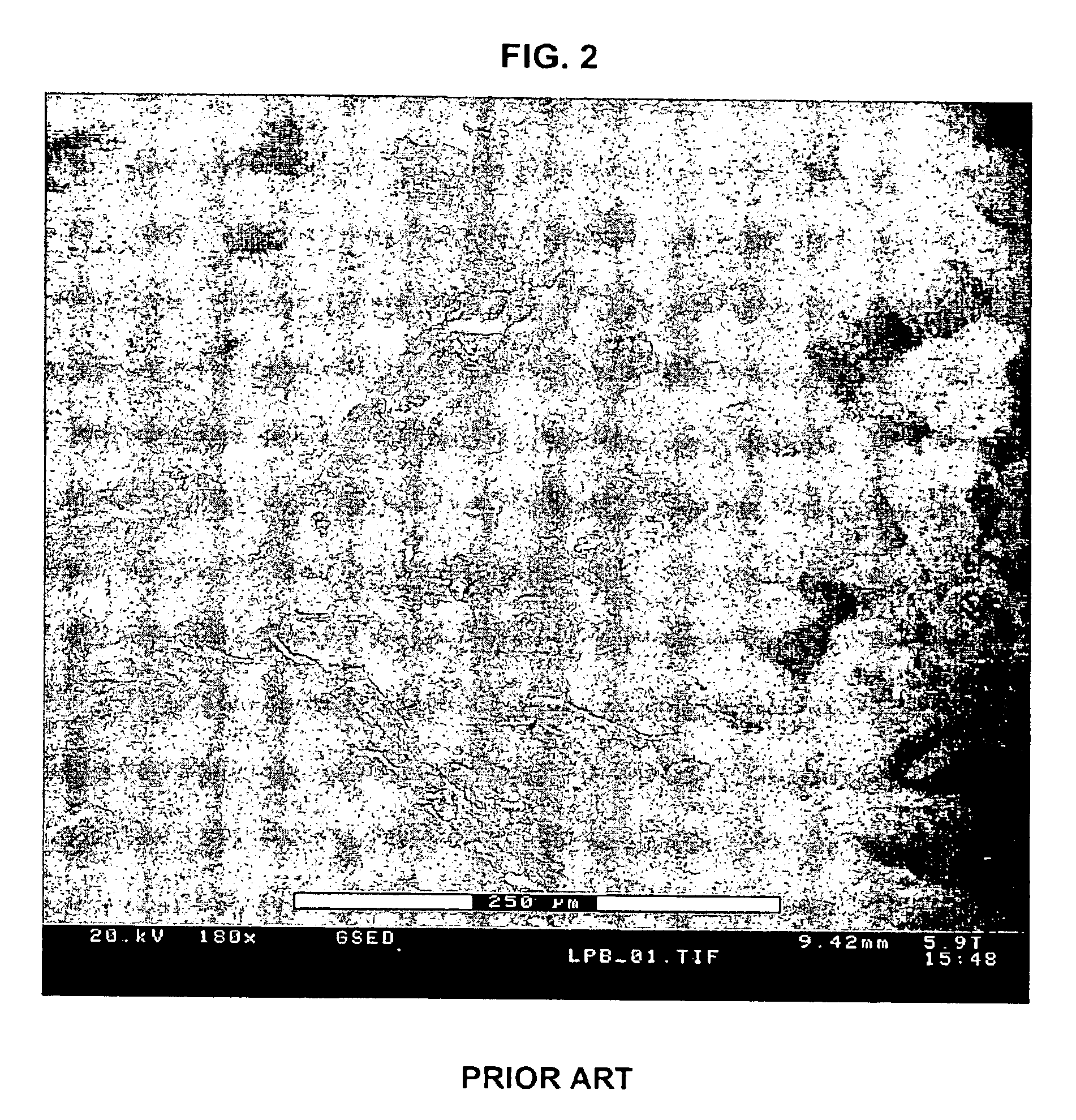

Calcium sulphate-based composition and methods of making same

InactiveUS6964704B2Good crystal shapeSolid waste managementCalcium/strontium/barium sulfatesHigh pressureBriquette

Owner:G B TECH LLC

Preparation method of memantine hydrochloride

InactiveCN1400205AGet stableOperational securityNervous disorderOrganic compound preparationMemantine HydrochlorideSolvent

The preparation method of medicine for curing dementia, N-methyl-D-aspartic acid (NMDA) receptor antagonist memantine hydrochloride includes the following steps: using polybasic alcohol as solvent; making 1-bromo-3,5-dimethyl adamantane and urea according to the mole ratio of 1:0.25-10 react for 0.5-48 hr. at 20-200 deg.C; after the reaction is completed, adding sodium hydroxide into the reactionsolution according to that the mole ratio of 1-bromo-3,5-dimethyl adamantane and sodium hydroxide is 1:0.1-10, making alcoholysis at 50-200 deg.C, chloroform extraction, concentration, acidification with hydrochloric acid and salt-forming so as to obtain the invented menantine hydrochloride. It features safe and simple operation and low cost, etc.

Owner:GUANGZHOU INST OF GEOCHEMISTRY - CHINESE ACAD OF SCI

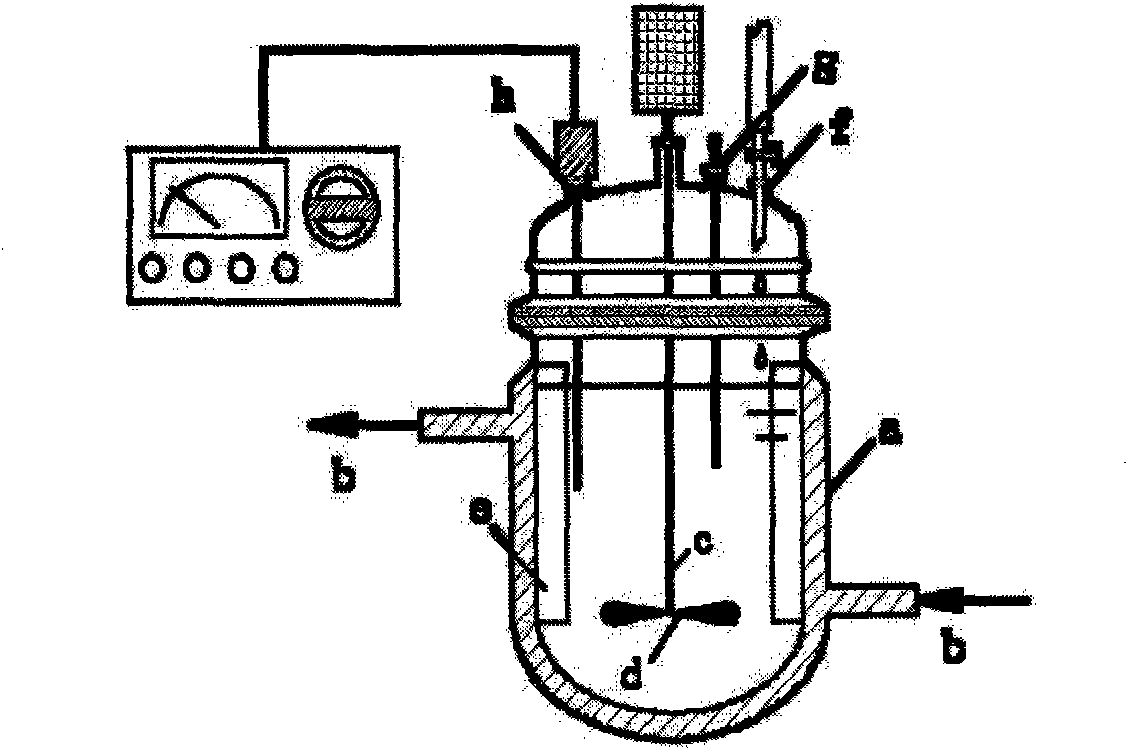

Nanometer material with nickel cobaltate@nickel molybdate core shell structure as well as preparation method and application of nanometer material

InactiveCN104282446AConvenient lightingImprove stabilityMaterial nanotechnologyHybrid capacitor electrodesCapacitanceHigh energy

The invention discloses a nanometer material with a nickel cobaltate@nickel molybdate core shell structure as well as a preparation method and application of the nanometer material. The nanometer material is prepared in a sealed high-temperature and high-pressure reaction kettle. Compared with the prior art, the preparation method has the advantages that the product has high purity, good dispersibility, and good and controllable crystalline form, production cost is low and reproducibility is good. The prepared nanometer material with the nickel cobaltate@nickel molybdate core shell structure grows on foamed nickel and can directly serve as an electrode material of a super capacitor, and thus the good circulation stability, large concrete capacitance, high energy density and high power density are realized and the potential application value in the aspect of energy storage is also realized.

Owner:ANHUI NORMAL UNIV

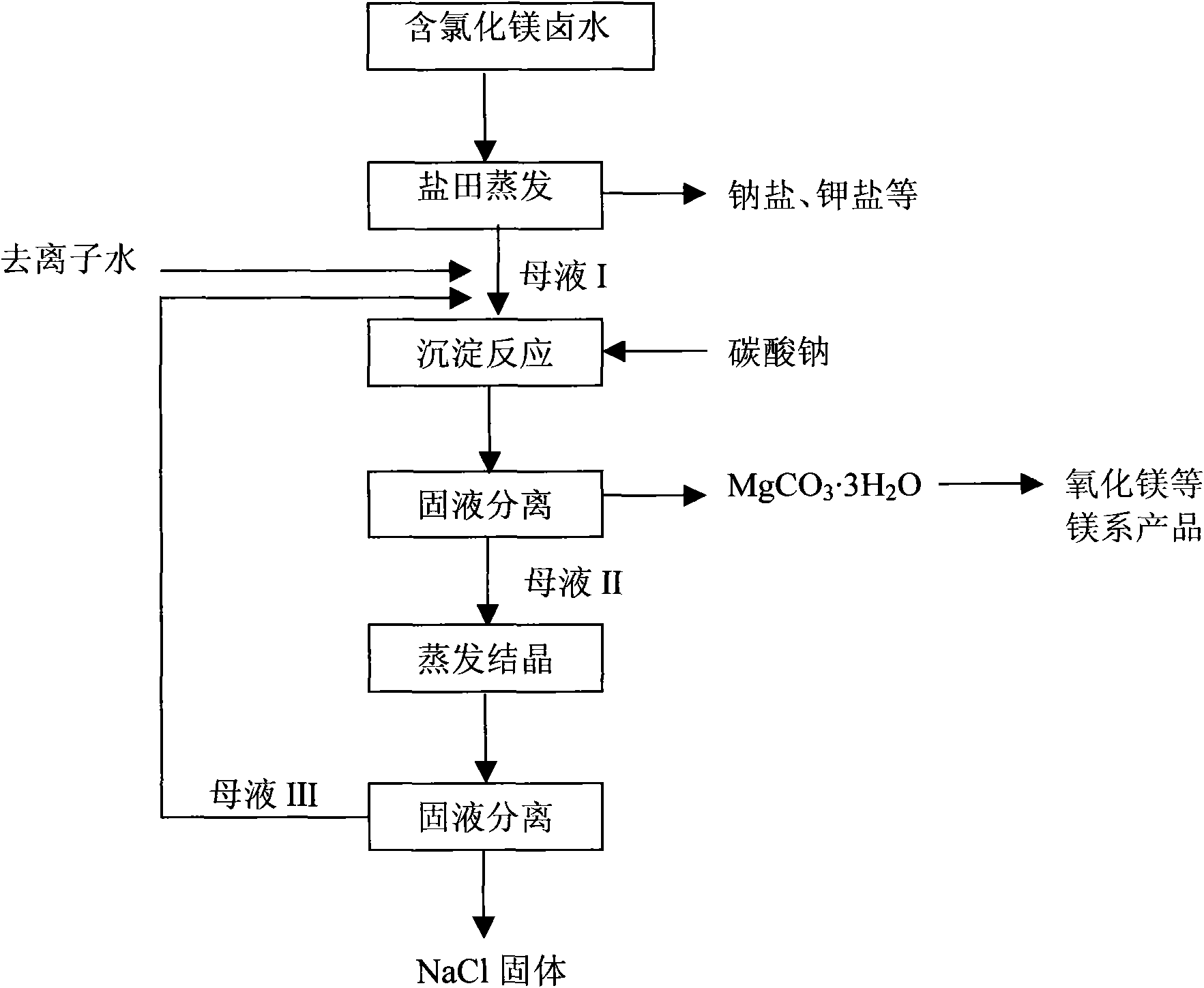

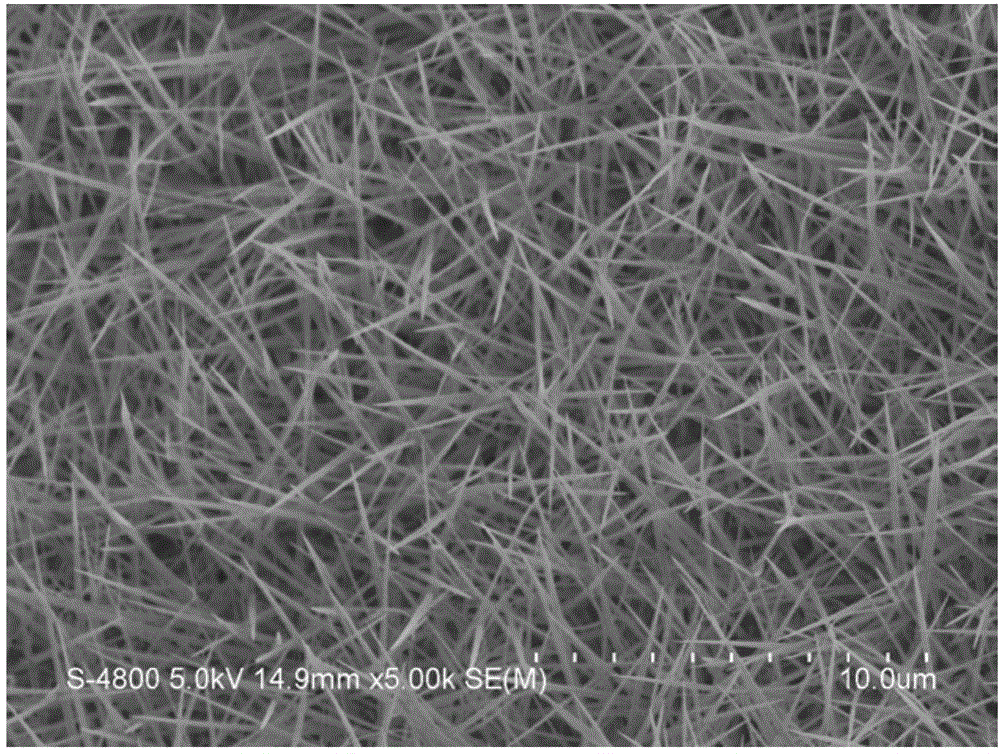

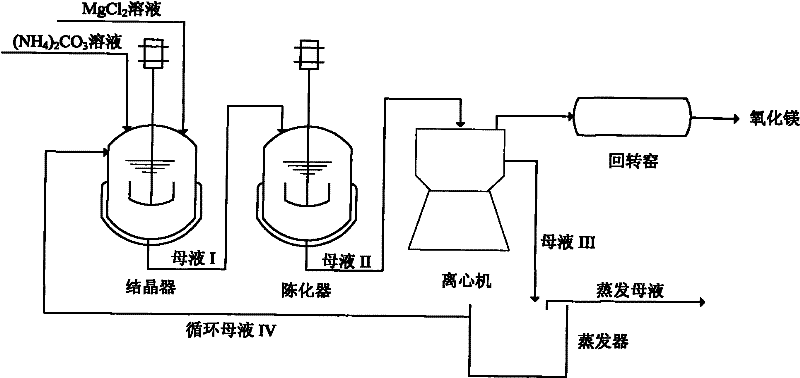

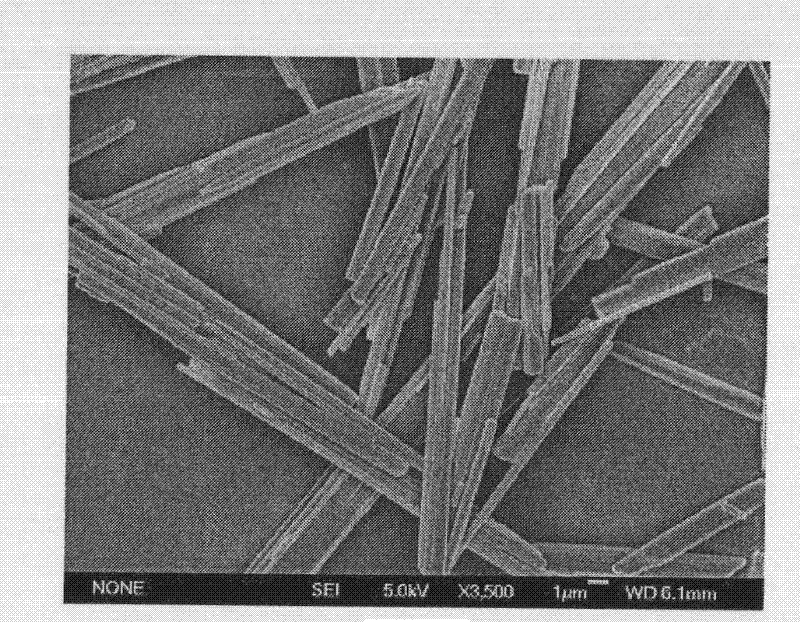

Method for preparing magnesia by taking magnesium chloride containing brine as raw material

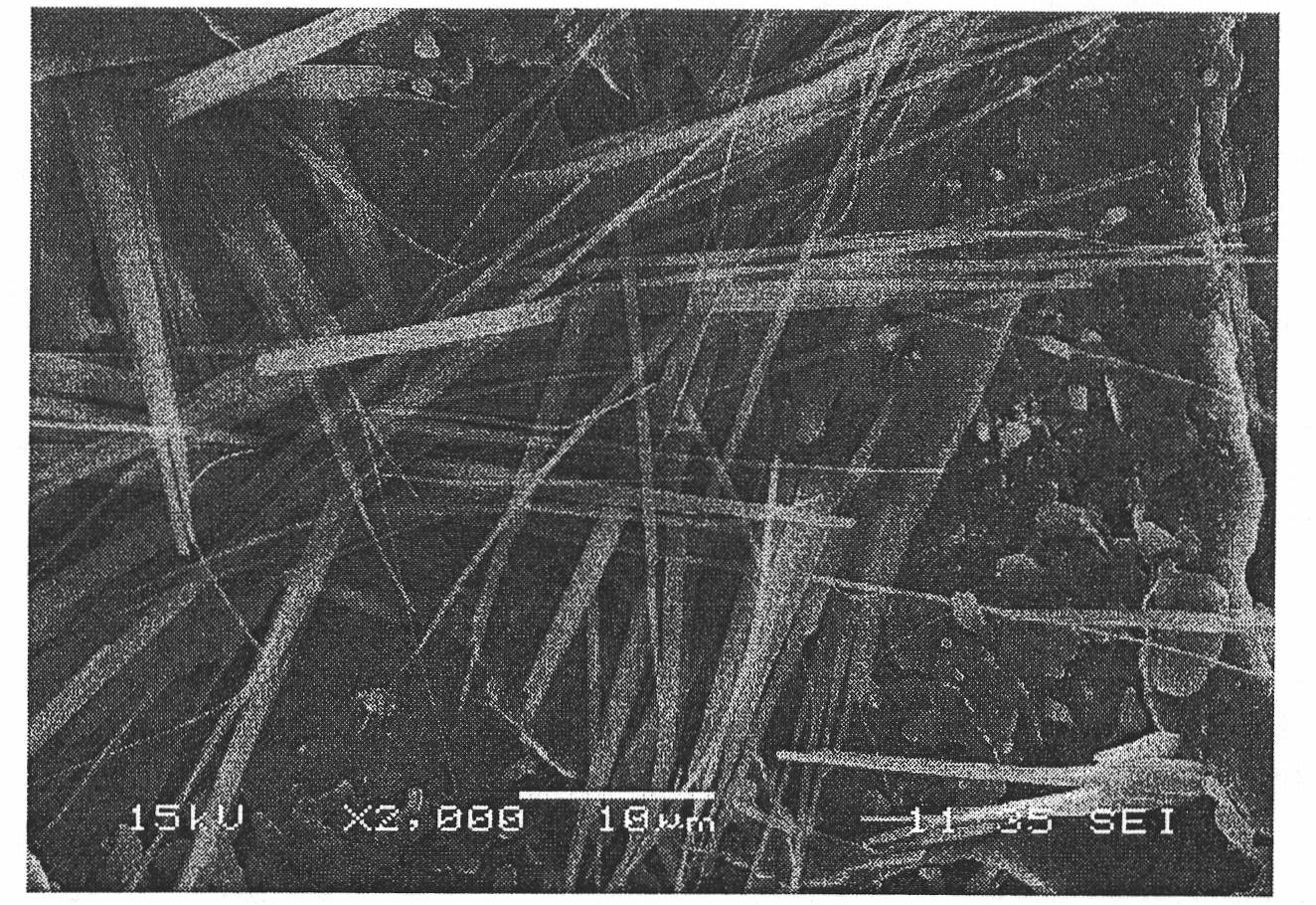

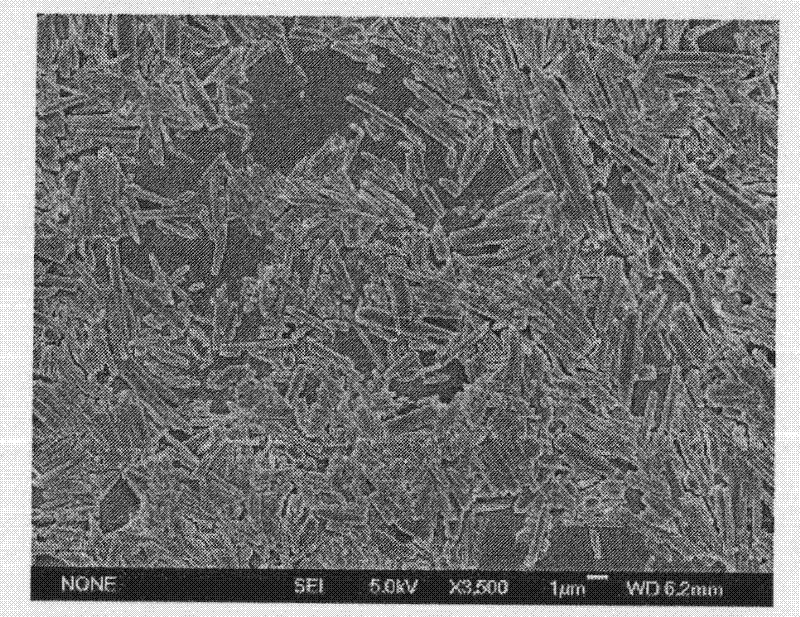

The invention belongs to the field of salt chemical engineering, in particular relates to a method for preparing magnesia by taking magnesium chloride containing brine as a raw material. The method comprises the following steps of: obtaining an intermediate (the purity is 99.0 percent) of magnesium carbonate trihydrate with good needle-shaped crystalline form by taking the magnesium chloride containing brine as the raw material and sodium carbonate as a precipitator and controlling the reaction conditions of reaction temperature, stirring rotary speed and charging speed of the sodium carbonate and the like; calcining the obtained intermediate of the needle-shaped magnesium carbonate trihydrate crystal at a high temperature to prepare high-purity magnesium oxide (the purity is 99.4 percent); after reaction, filtering a coarse product of the magnesium carbonate trihydrate to obtainsodium chloride containing crystalline mother liquor; by vaporizing, condensing and crystallizing the crystalline mother liquor, extracting a sodium chloride crystal; and filtering the sodium chloride crystal to obtain a sodium chloride crystal. The method aims to produce the intermediate of the needle-shaped magnesium carbonate trihydrate by rich brine from sea and salt lakes, and further prepares the high-purity magnesia. The method has the advantages of good economic benefits, no environmental pollution, strong operability and easy realization of industrialization.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

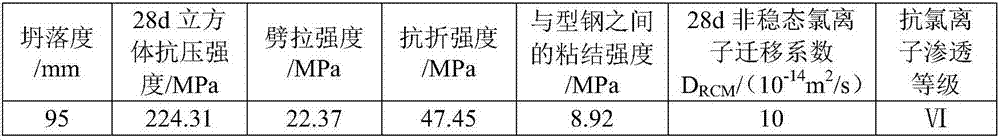

Coarse-aggregate-containing C220-strength-grade ultrahigh-performance fiber concrete and preparation method

ActiveCN107285707AImprove toughnessImprove deformation abilitySolid waste managementModified carbonCellulose fiber

The invention discloses coarse-aggregate-containing C220-strength-grade ultrahigh-performance fiber concrete and a preparation method. The concrete is composed of, by mass, 545 parts of cement, 63 parts of water, 900 parts of rubble, 750 parts of fine aggregate, 72 parts of coal ash, 65 parts of rice husk ash, 140 parts of silicon ash, 15.5 parts of water reducer, 11.5 parts of excitant, 1.7 parts of cellulosic fiber, 78 parts of steel fiber, 48 parts of hydroxyl modified carbon nanotube dispersion, 50 parts of oxidized graphene dispersion and 2.9 parts of defoamer. The concrete prepared by the method has high toughness and durability and has high binding strength with section steel, compressive strength reaches 224.31MPa, bending strength reaches 47.45MPa, splitting tensile strength reaches 22.37MPa, the binding strength with the section steel reaches 8.92MPa, and chlorion anti-permeation grade reaches VI grade. When the concrete is used in a section steel and concrete combined structure, cooperative working performance between the section steel and the concrete can be brought into play effectively, and the defects that the section steel and the concrete are poor in binding performance and respective mechanical performance of the section steel and the concrete cannot be brought into full play are made up.

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY

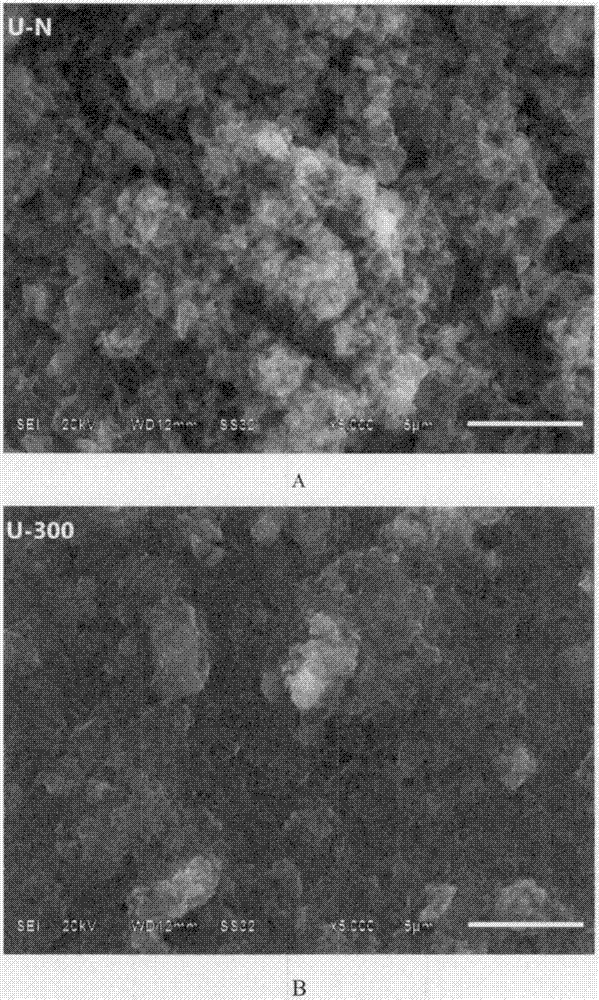

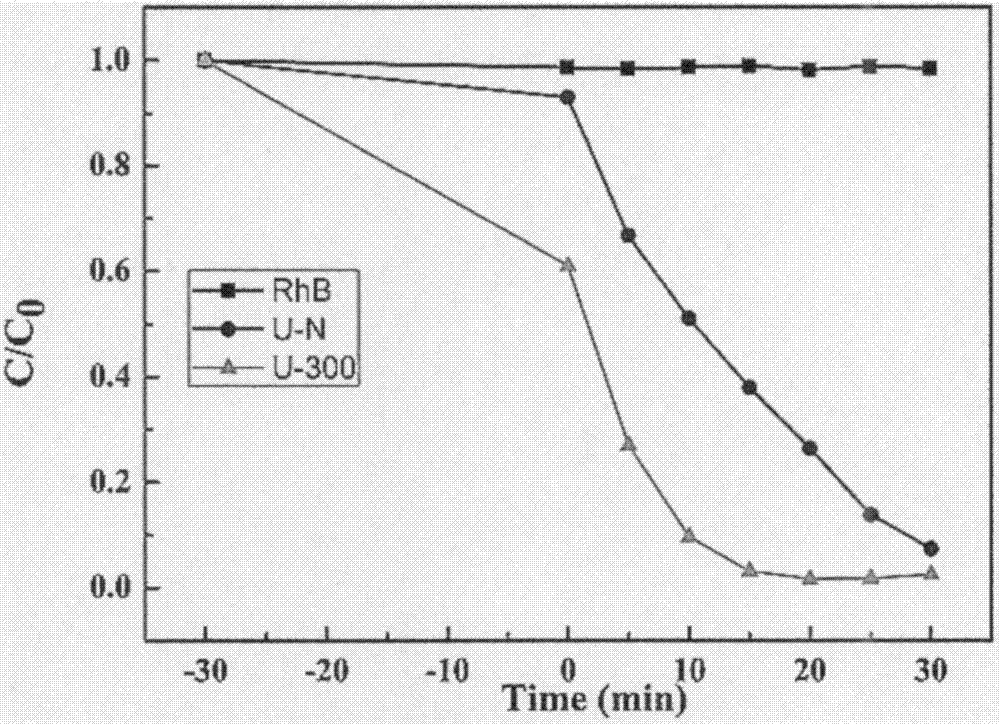

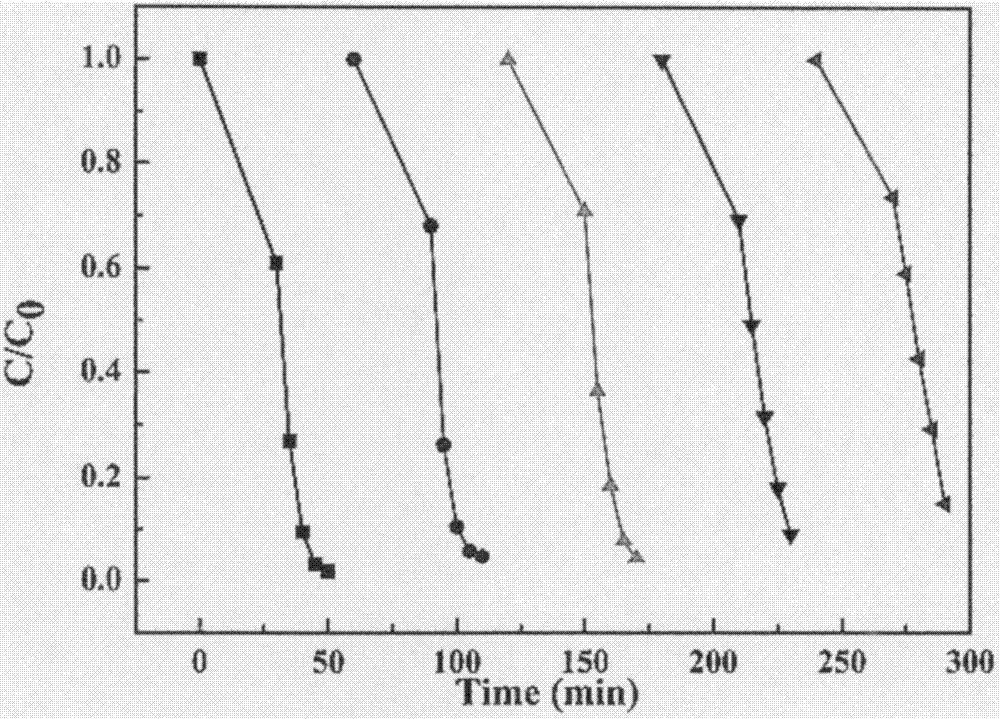

High-activity graphite-phase carbon nitride material and preparation method thereof

InactiveCN107252701AReduce compoundingImprove photocatalytic activityPhysical/chemical process catalystsWater/sewage treatment by irradiationMaterials preparationReactive site

The invention belongs to the technical field of material preparation and photocatalysis, and discloses a high-activity graphite-phase carbon nitride material and a preparation method thereof. The preparation method comprises the following steps: forming a self-generated gas atmosphere a gas generated from a precursor by pyrolysis in the high-temperature calcining process under the control on an inert gas, and guiding synthesis of a carbon nitride material, thereby obtaining a flaky porous graphite-phase carbon nitride material. According to the preparation method, after the inert gas is not introduced any longer, a self-generated gas generated from the precursor is relatively uniform at different parts, and the carbon nitride material prepared with the preparation method is uniform in morphology and relatively good in crystal form; due to the escape of the self-generated gas, the material is effectively pored, and thus the specific surface area and the active sites of the material are increased; due to the self-generated gas atmosphere, the polymerization degree of the precursor is reduced, and the obtained carbon nitride material has a relatively large amount of unpolymerized amino or imino groups. The preparation method disclosed by the invention is simple, efficient and low in cost, and the carbon nitride material prepared with the preparation method is excellent in photocatalysis activity and very good in practicability.

Owner:CHINA WEST NORMAL UNIVERSITY

Method for preparing A type zeolite by gangue

InactiveCN1631779AThe method is simple and easySmall deviceAluminosilicate zeolite type-ACoal gangueChemistry

The invention is a method of prepare A zeolite with coal gangue which is by burning the coal gangue and mixing it with alkaline fusion solution to react at high temperature, then extracting the alkaline fusion in the water to remove the Fe, adding aluminum salt and heating to crystallize, finally filtering, washing and drying the crystallization to obtain the high quality A zeolite. The invention has got advantages such as easy and simple techniques in the process, small reacting devices, low cost, exact repeatability. The obtained A zeolite is of narrower particle distribution, quite perfect crystal shape and high crystalline.

Owner:CHINA RES INST OF DAILY CHEM IND

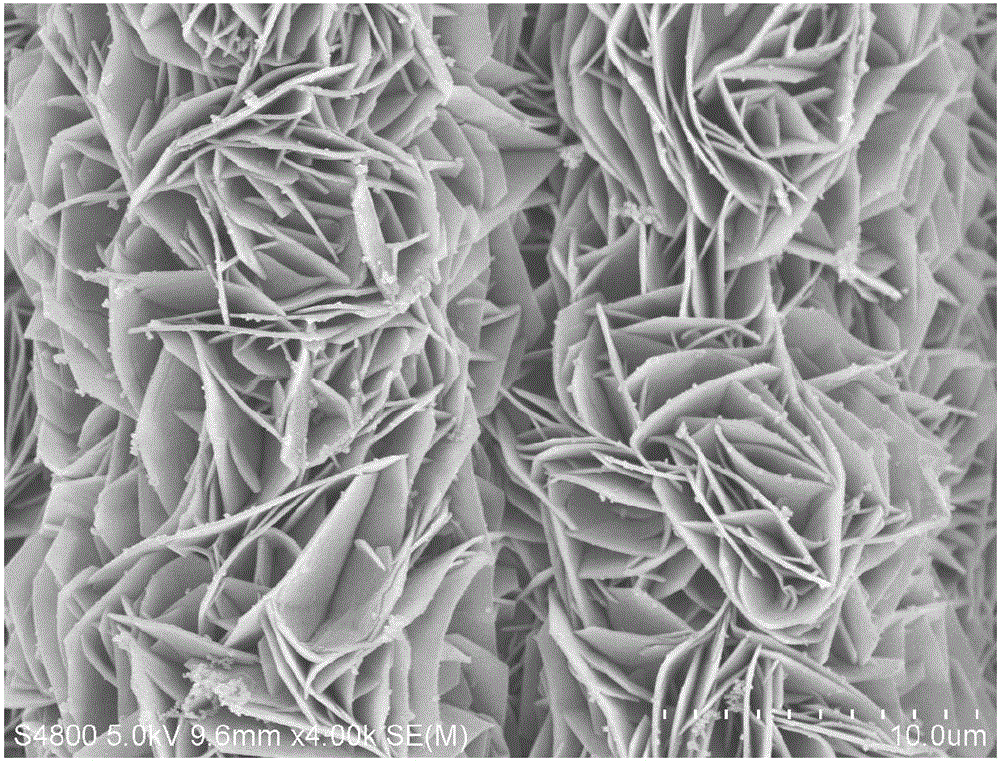

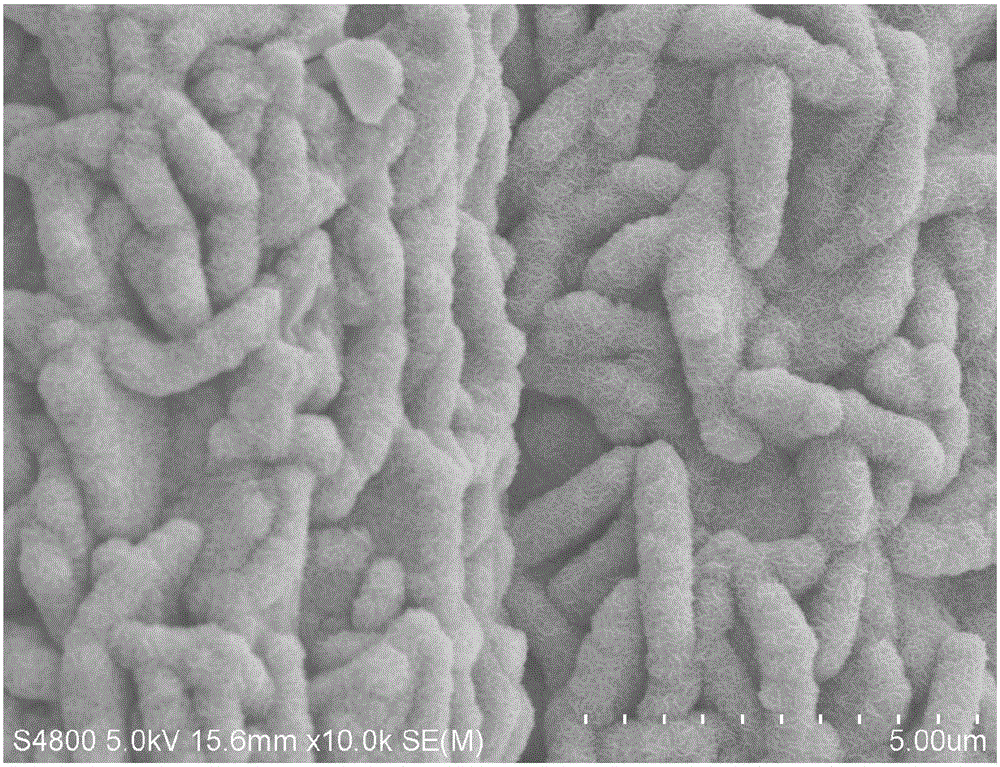

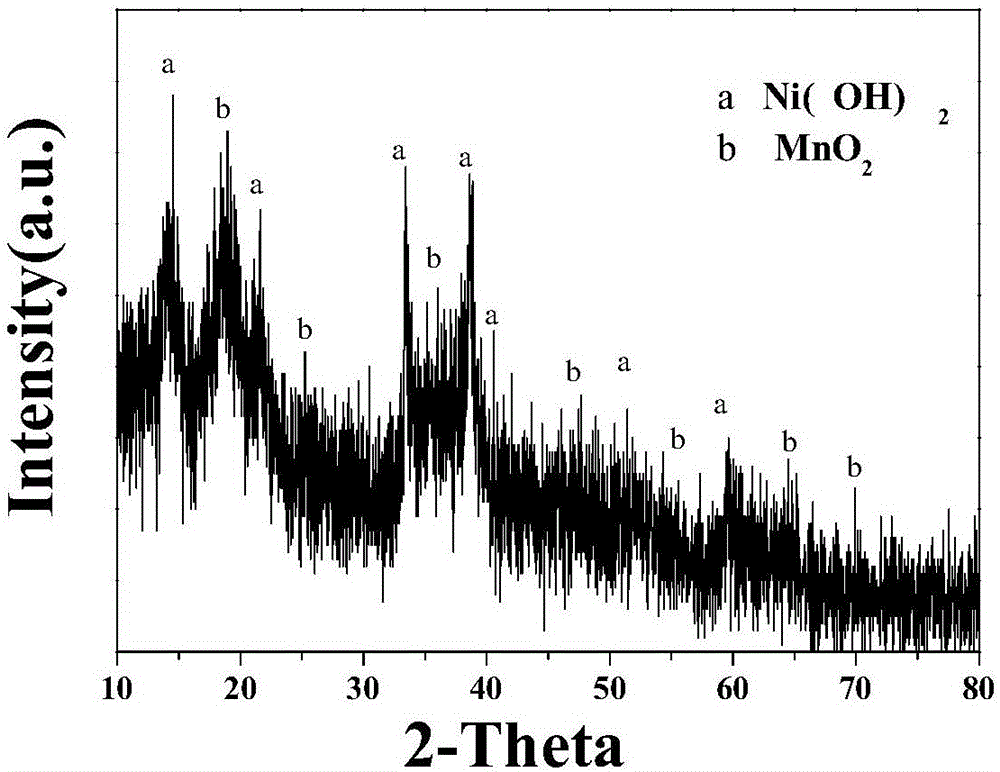

Nickel hydroxide @ manganese dioxide core-shell hetero-structured nanosheet array material growing on carbon cloth, and preparation method and application of nickel hydroxide @ manganese dioxide core-shell hetero-structured nanosheet array material

InactiveCN106298285AHigh purityIncrease energy densityMaterial nanotechnologyHybrid capacitor electrodesCapacitanceHigh energy

The invention provides a nickel hydroxide @ manganese dioxide core-shell hetero-structured nanosheet array material growing on carbon cloth, and a preparation method and application of the nickel hydroxide @ manganese dioxide core-shell hetero-structured nanosheet array material. Compared with the prior art, the nickel hydroxide @ manganese dioxide core-shell hetero-structured nanosheet array material has the advantages that when growing on the carbon cloth, a nickel hydroxide @ manganese dioxide core-shell hetero-structured nanosheet prepared by the nickel hydroxide @ manganese dioxide core-shell hetero-structured nanosheet array material can be directly used as an electrode material of a super capacitor, so that the flexibility, high stability, high specific capacitance and high energy density and power density of an electrode are realized; furthermore, when the material is assembled into a flexible symmetric super capacitor, the energy density and the power density are increased, and a micro motor is successfully operated.

Owner:ANHUI NORMAL UNIV

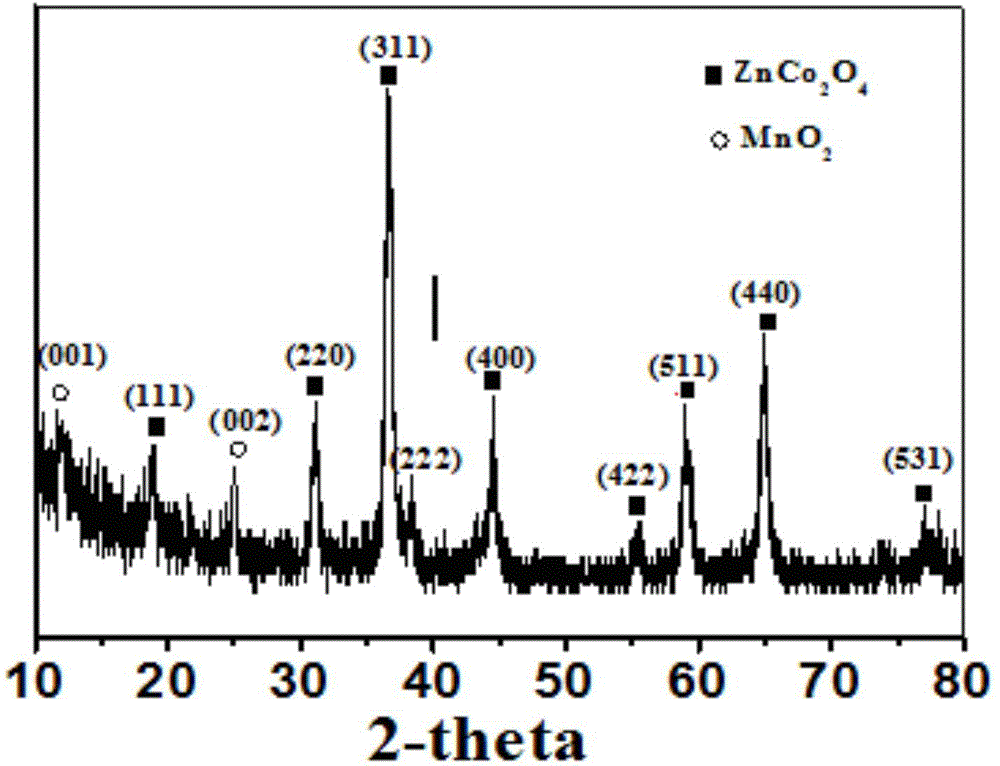

ZnCo2O4@MnO core-shell heterostructure nanotube array material, and preparation method and application thereof

InactiveCN104465117AHigh purityGood dispersionHybrid capacitor electrodesHybrid/EDL manufactureCapacitanceDispersity

The invention provides a preparation method and application of a ZnCo2O4@MnO core-shell heterostructure nanotube array material. According to the prepared product, a ZnCo2O4 nanowire serves as a framework and is wrapped with a MnO nanofilm material, and the product grows vertically, is arranged orderly and has a regular three-dimensional heterostructure. Compared with the prior art, the product prepared through the preparation method is high in purity, good in dispersity, good and controllable in crystalline form, low in production cost and good in reproducibility. The prepared tubular ZnCo2O4@MnO core-shell heterostructure nanotube array grows on nickel foam, can serve as an electrode material of a super capacitor directly, has long-term circulatory stability, large specific capacitance and high energy density and power density, and has great commercial value.

Owner:ANHUI NORMAL UNIV

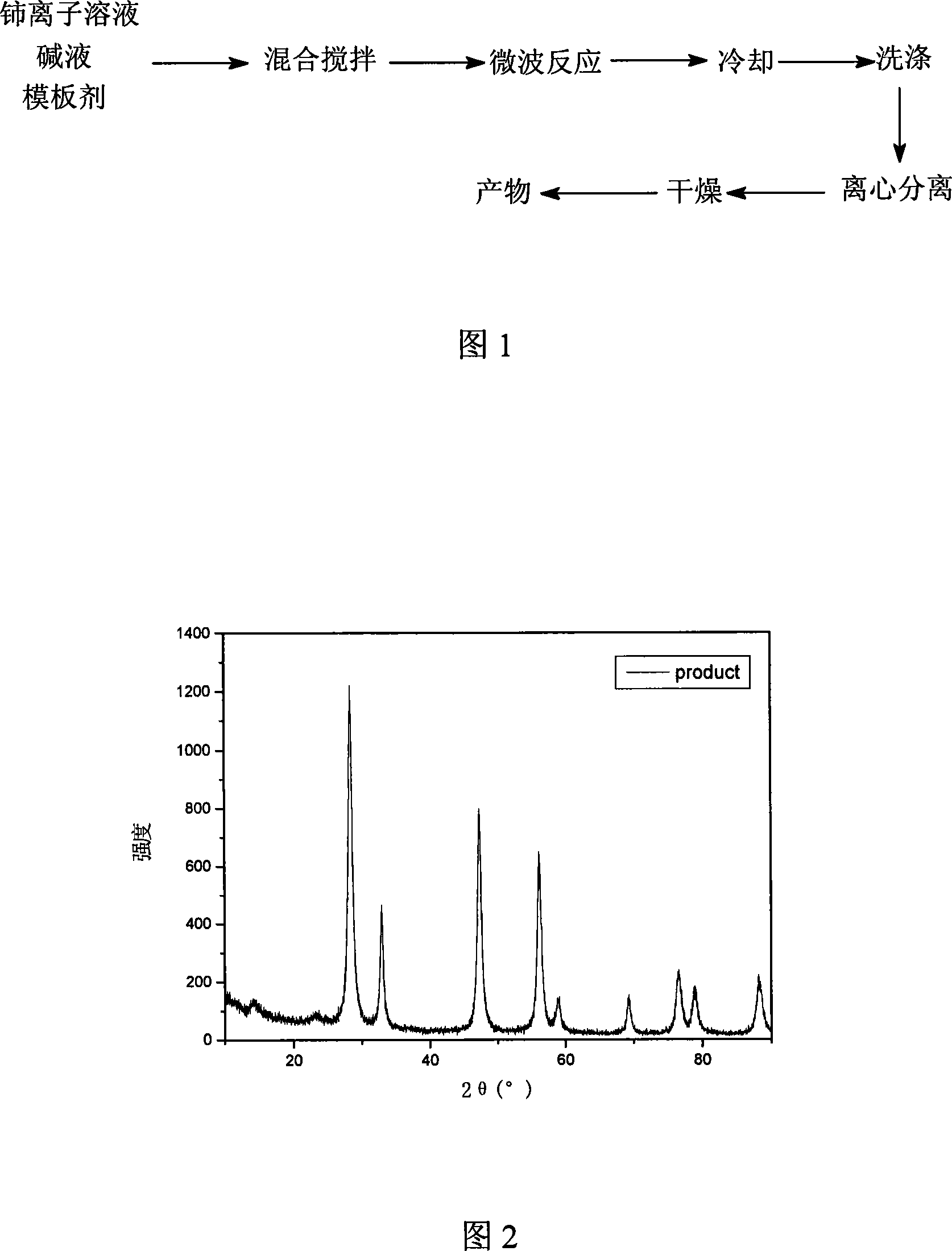

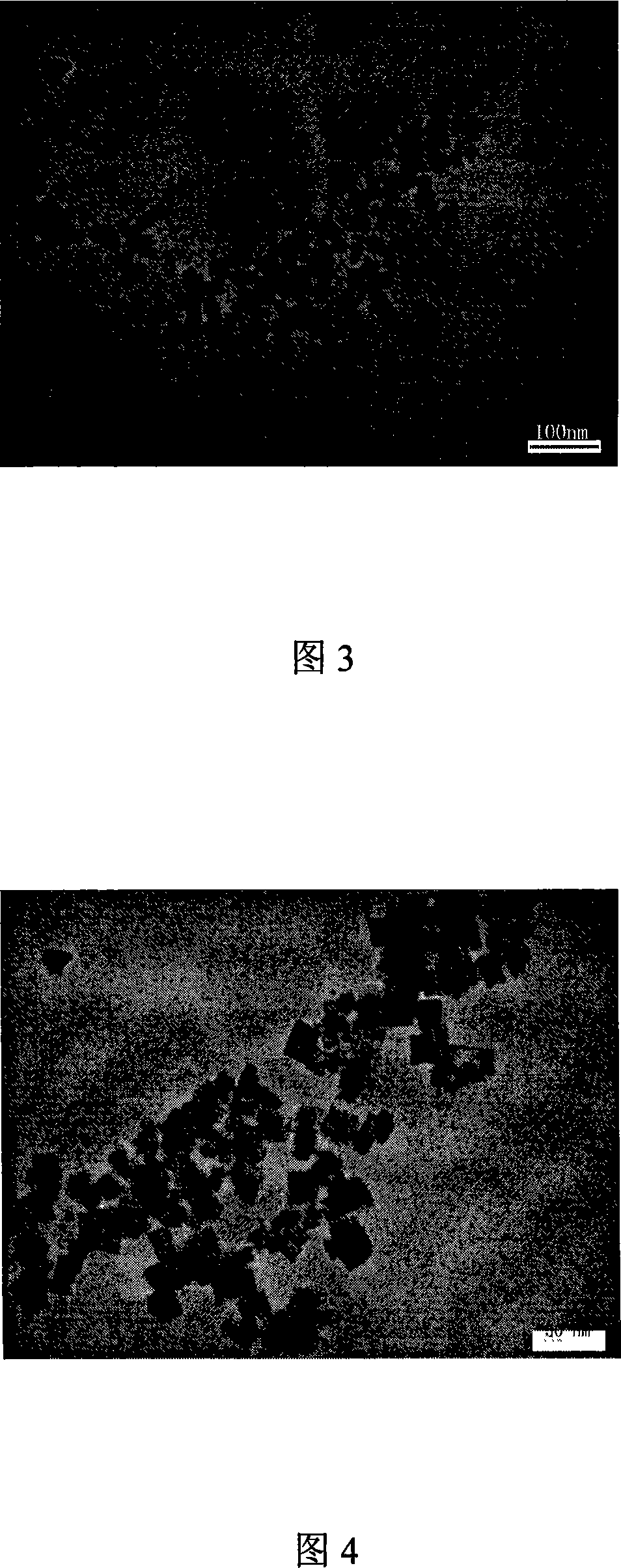

Method for preparing cerium oxide nano particle by auxiliary microwave

A method to microwave-assisted prepare ceria Nano particles pertains to the preparation technology field of the ceria Nano particles. First cerium ion solution and alkali liquor are mixed and then the mixture is put into a microwave high pressure reaction cylinder, at last the ceria Nano particles, chemical formula of which is CeO2, are obtained by microwave-assisted reaction. The invention has the advantages of simple preparation process, short reaction time, and energy conservation, small particle diameter of ceria Nano particles, good dispersion and structured appearance.

Owner:BEIJING UNIV OF CHEM TECH

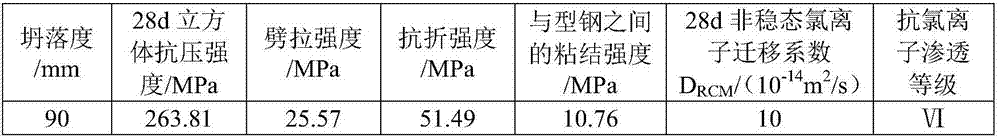

Coarse-aggregate-containing C250-strength-grade ultrahigh-performance fiber concrete and preparation method

ActiveCN107285711AImprove toughnessImprove deformation abilitySolid waste managementModified carbonCrushed stone

The invention discloses coarse-aggregate-containing C250-strength-grade ultrahigh-performance fiber concrete and a preparation method. The concrete is composed of, by mass, 596 parts of cement, 60 parts of water, 870 parts of rubble, 810 parts of fine aggregate, 70 parts of coal ash, 65 parts of rice husk ash, 168 parts of silicon ash, 17 parts of water reducer, 12 parts of excitant, 1.6 parts of cellulosic fiber, 85 parts of steel fiber, 55 parts of hydroxyl modified carbon nanotube dispersion, 58 parts of oxidized graphene dispersion and 3.0 parts of defoamer. The concrete prepared by the method has high toughness and durability and has high binding strength with section steel, compressive strength reaches 263.81MPa, bending strength reaches 51.49MPa, splitting tensile strength reaches 25.57MPa, the binding strength with the section steel reaches 10.76MPa, and chlorion anti-permeation grade reaches VI grade. When the concrete is used in a section steel and concrete combined structure, cooperative working performance between the section steel and the concrete can be brought into play effectively, and the defects that the section steel and the concrete are poor in binding performance and respective mechanical performance of the section steel and the concrete cannot be brought into full play are made up.

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY

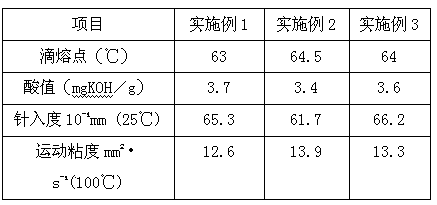

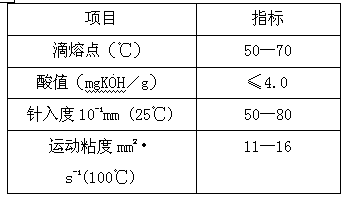

Plant type compound oil phase for emulsion explosive

ActiveCN103694068ASimple production processProduct quality is easy to controlNon-explosive/non-thermic compositionsWaxVegetable oil

The invention discloses a plant type compound oil phase for an emulsion explosive. The compound oil phase comprises main components of plant wax and plant oil, and is characterized by comprising the following materials by mass: 20%-50% of the plant wax, 10%-25% of the plant oil, 10%-25% of light dewaxing paste, 20%-35% of an emulsifier and 5%-15% of additives, wherein the total mass percentage of the materials is 100%. The compound oil phase prepared from the plant wax and the plant oil is applied to the industrial explosive production, so that a production process is simplified, and the production process quality is conveniently controlled; the compound oil phase is proper in drop melting point, acid value, needle penetration degree and kinematic viscosity, and is an ideal emulsion explosive oil phase material; the produced emulsion explosive is good in explosion performance; the plant oil phase material is clean, environment-friendly, low in price and highly available, and can effectively reduce the production cost; the compound oil phase used for producing the emulsion explosive has good economic and social benefits and is convenient for industrialization production and application.

Owner:FUZHOU GUOTAI COMPOSITE MATERIAL CO LTD

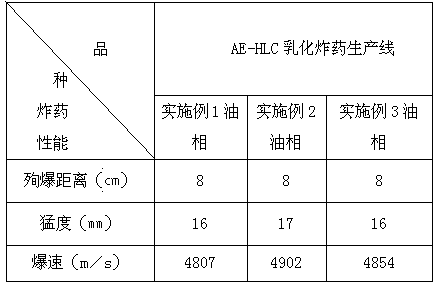

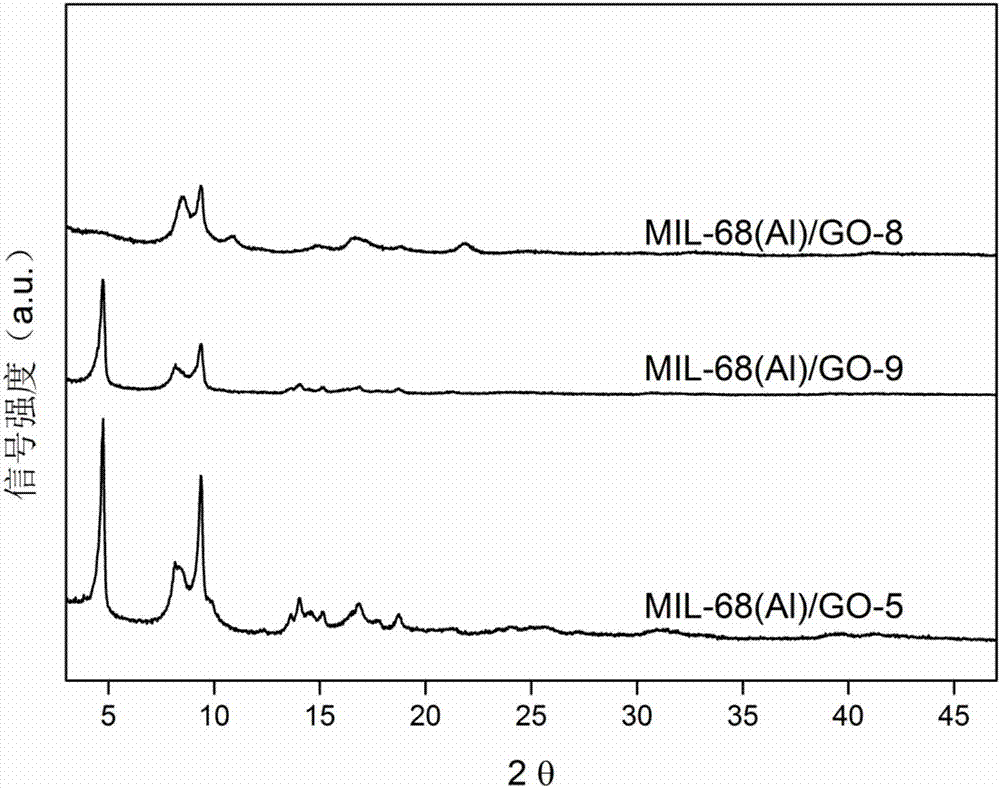

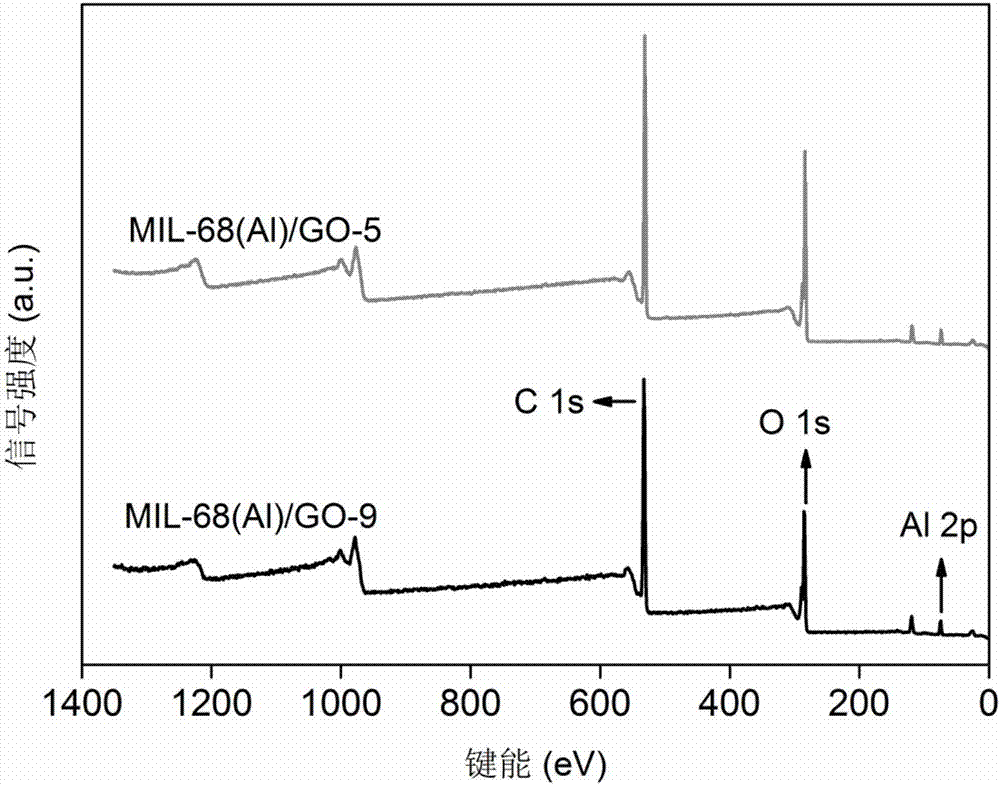

Aluminum base MOFs/oxidized graphene composite material and preparation method and application thereof

InactiveCN107029673AIncrease profitHigh crystallinityGas treatmentOther chemical processesOrganic solventBoiling point

The invention discloses an aluminum base MOFs / oxidized graphene composite material and a preparation method and application thereof. The preparation method comprises the following steps: (1) uniformly dispersing oxidized graphene in a low-boiling-point organic solvent to obtain oxidized graphene dispersion; (2) dissolving a soluble aluminum salt and an organic ligand in the oxidized graphene dispersion to obtain a reaction matrix solution after the dissolution is complete; (3) heating the reaction matrix solution, and allowing isothermal reaction under a high pressure condition for a period of time to obtain a primary product; and (4) filtering the primary product, washing, and activating to obtain a purified aluminum base organic framework / oxidized graphene composite material. The preparation method is simple, easy to operate, economic and environment-friendly, the reaction time is shortened, the usage of the organic solvent is reduced, and the obtained composite material has better crystal form and properties. Meanwhile, the effect of the composite material to adsorb toluene in the air is significantly effective, and the composite material has good application prospects in the aspect of air pollution treatment.

Owner:广东星帮尼科技股份有限公司

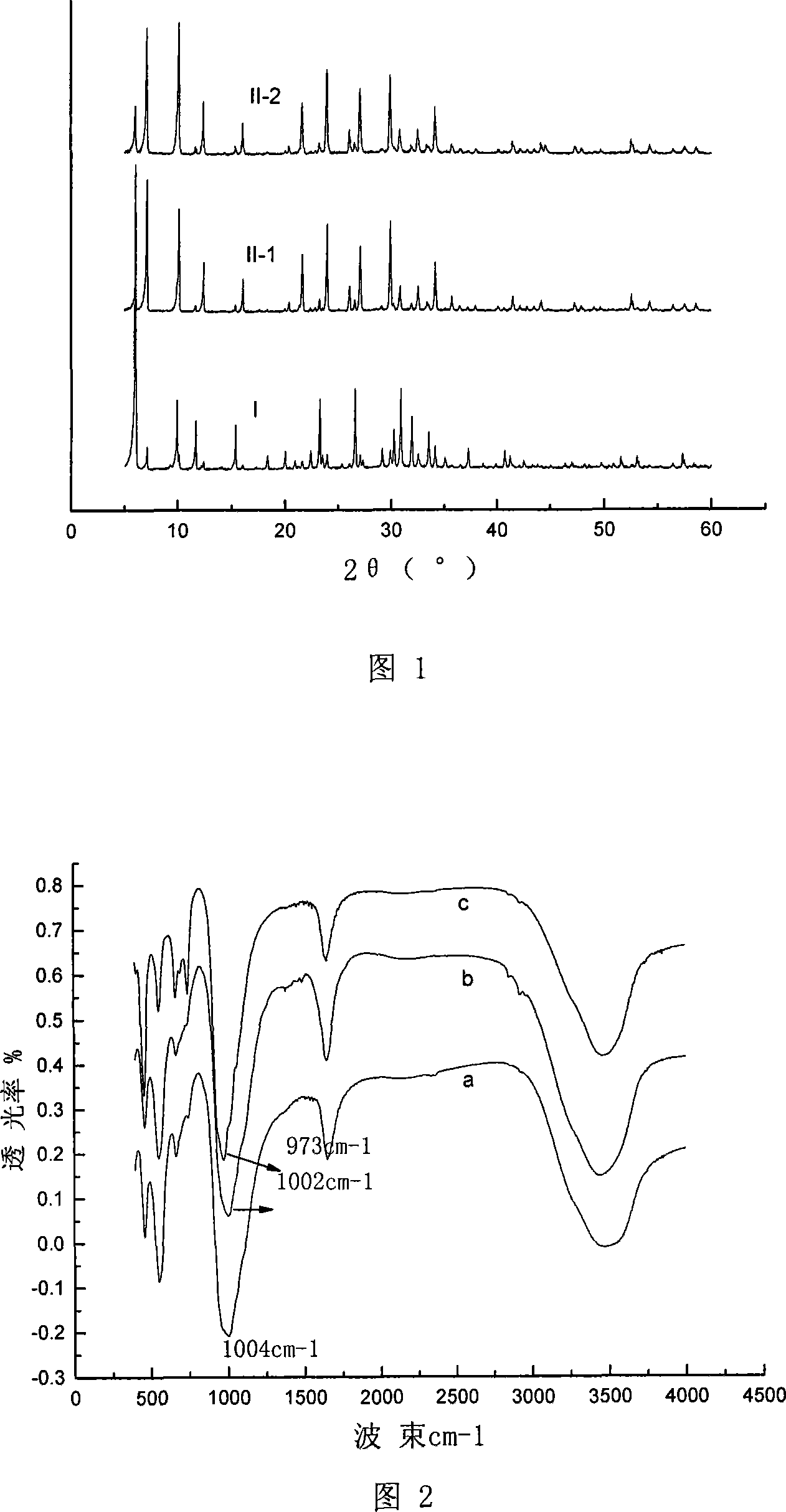

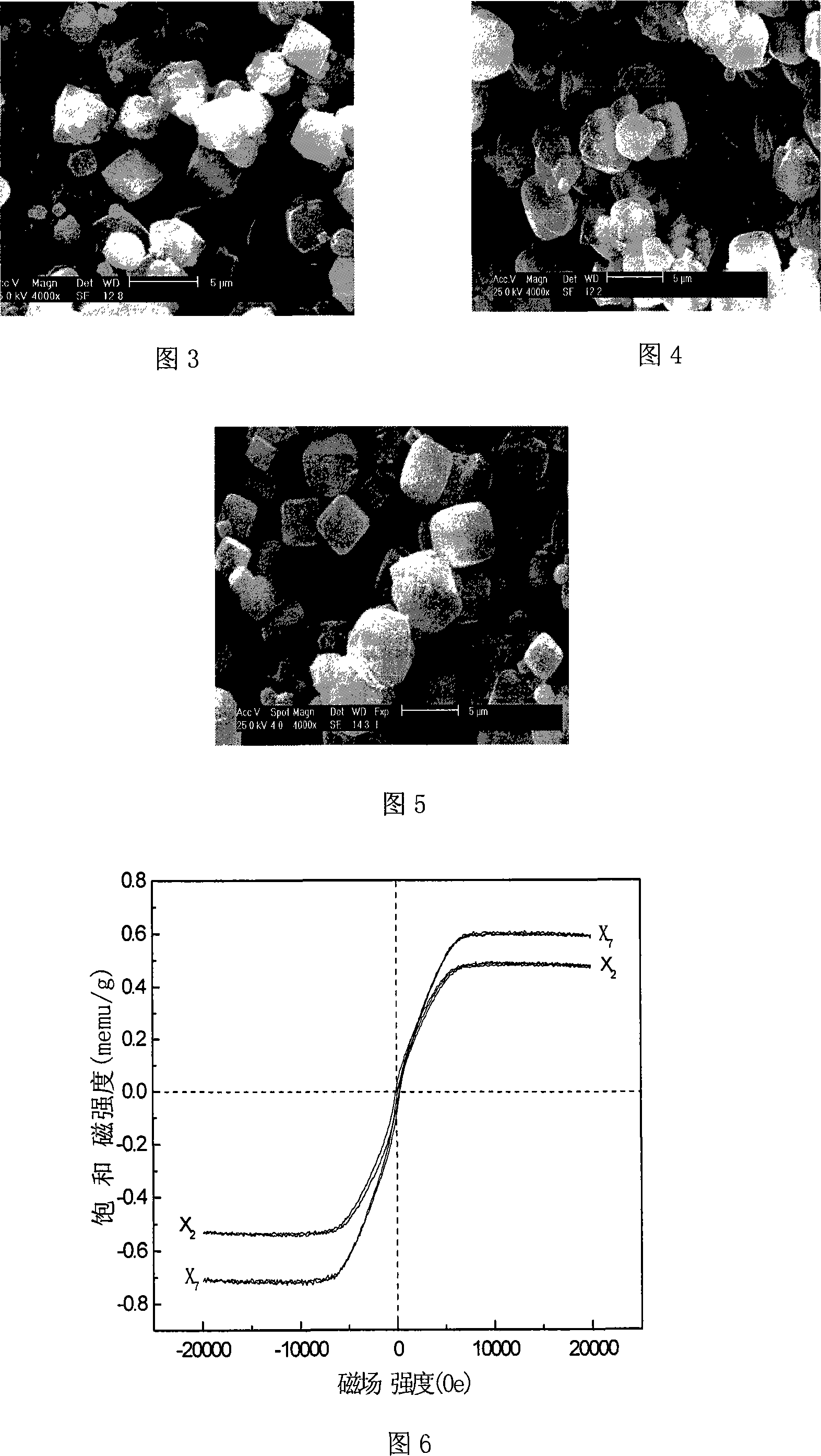

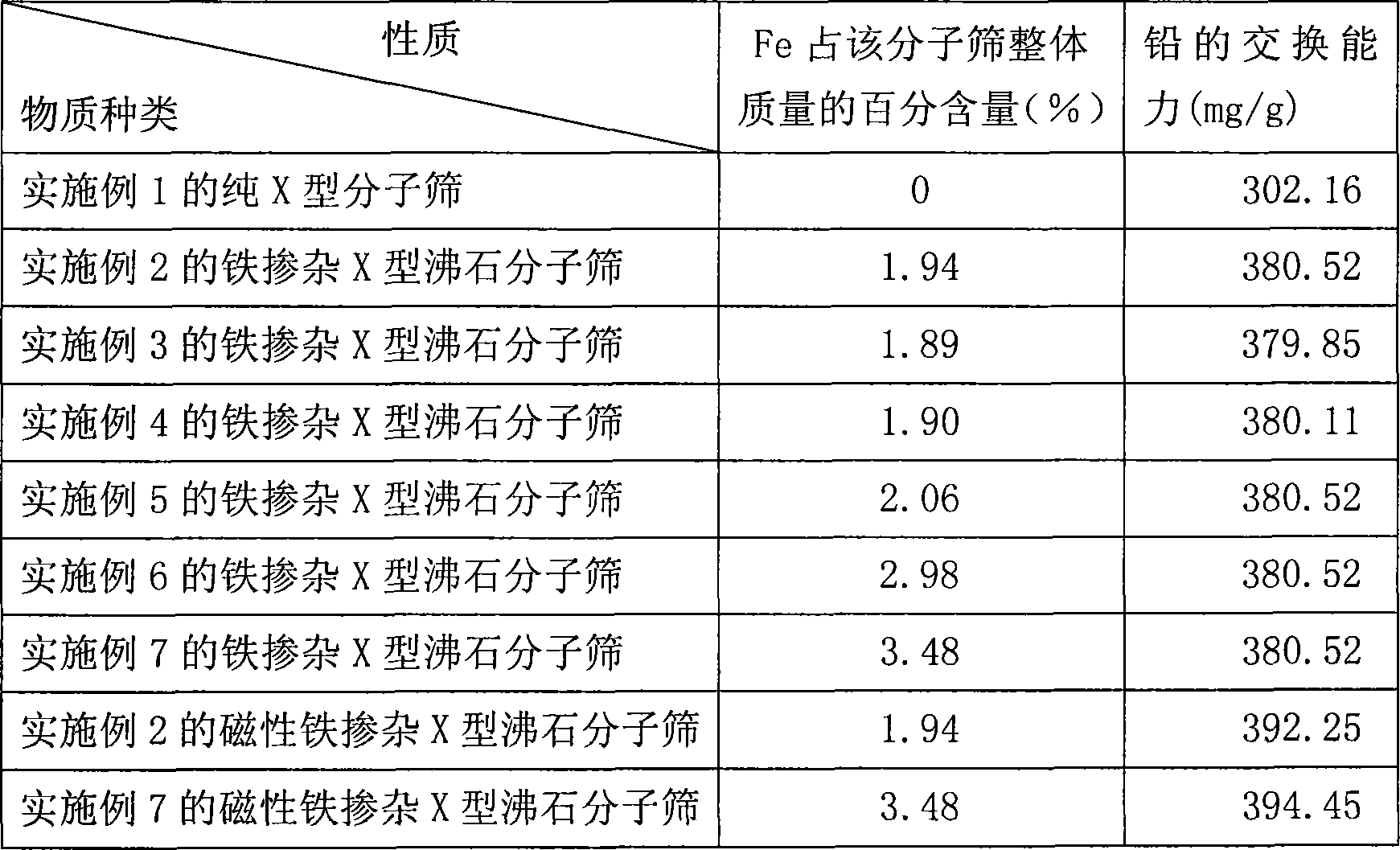

X type zeolite molecular sieve and method for producing the same

InactiveCN101219795AImprove performanceImprove adsorption capacityFaujasite aluminosilicate zeoliteMolecular sieveMagnetic stability

The invention relates to an X-shaped zeolite molecular sieve and a method for preparing thereof, relating to a field of zeolite molecular sieve material; The X-shaped zeolite molecular sieve is a magnetic iron-doped X-shaped zeolite molecular sieve; magnetic ferroferric oxide is formed in the zeolite lattice, wherein, quality percentage of Fe occupying the molecular sieve is 1.89 percent to 3.48 percent. The preparing method comprises the steps that, iron-doped X-shaped zeolite molecular sieve is firstly compounded and then the magnetized magnetic iron-doped X-shaped zeolite molecular sieve is prepared through hydrogen reduction; the method results in a structure of Fe3O4 formed in frame of the iron-doped X-shaped zeolite molecular sieve. The magnetic iron-doped X-shaped zeolite molecular sieve has strong magnetism and magnetic stability, which not only solves the problem that the existing powdery zeolite molecular sieve is difficult to be recycled in reaction solution, and further improves absorption property of the sieve, but also enlarge application range of the zeolite molecular sieve, thereby allowing the zeolite molecular sieve to be applied to catalytic reaction in which iron acts as the catalyst.

Owner:HEBEI UNIV OF TECH

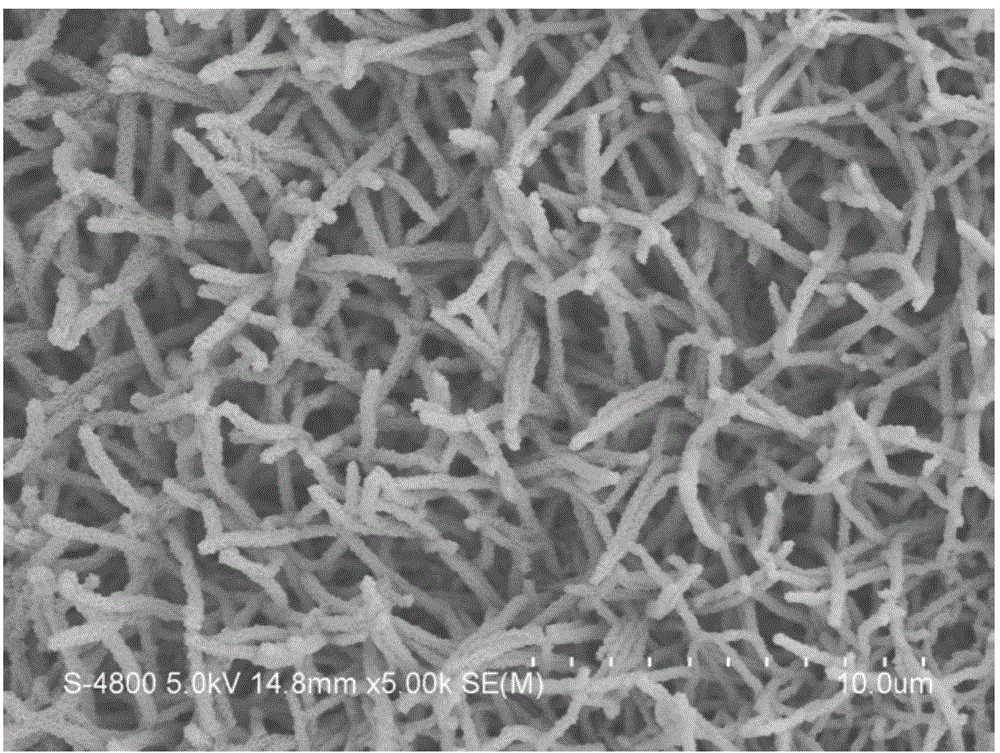

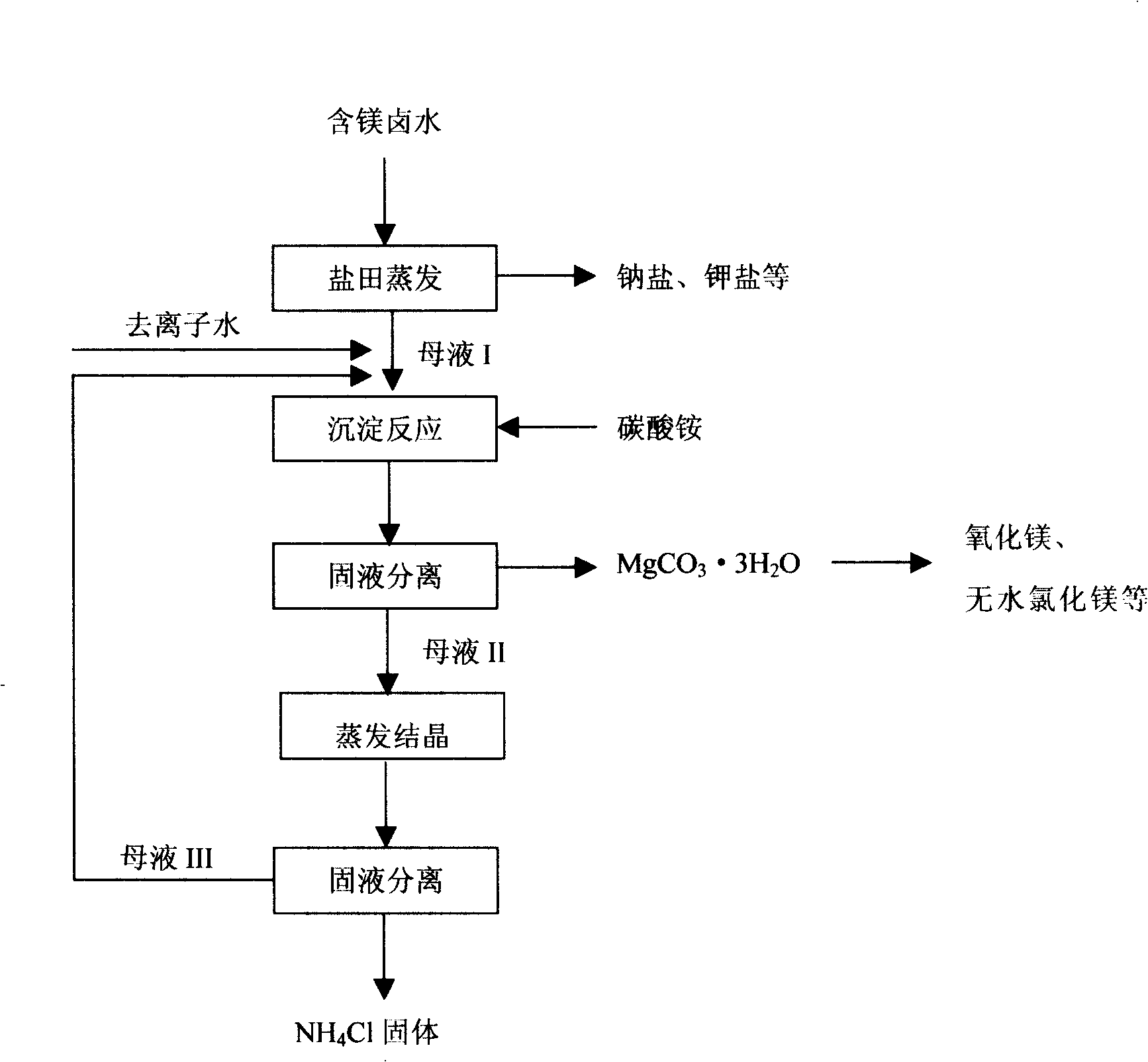

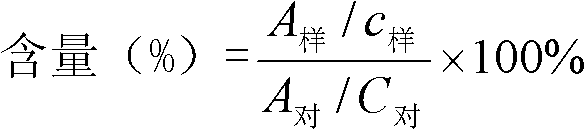

Method for preparing trihydrated magnesium carbonate from magnesium chloride-containing bittern by using ammonium carbonate

InactiveCN101259968AImprove the environmentSolve the use problemMagnesium carbonatesChemical industryHigh concentration

The invention belongs to the salt chemical industry technical field, in particular to a method for producing trihydrated magnesium carbonates and ammonium chlorides from magnesium chloride containing brine water by utilizing ammonium carbonates. The invention adopts the technical proposal that: the trihydrated magnesium carbonates are produced by taking the magnesium chloride containing brine water with high concentration as materials and the ammonium carbonates as precipitating agents. The trihydrated magnesium carbonate crystals with desirable shapes can be obtained by controlling technological conditions, so that the adsorption of impurities is reduced, and the products have relatively high purity; the trihydrated magnesium carbonate crystals obtained by reaction are big in volume and easy to filter, thereby lowering the energy consumption of filtering; moreover, the method of the invention has the advantages of strong operability, easy realization of industrialization, good economic benefits of byproducts and no environmental pollution, and realizes the comprehensive utilization of salt lake resources.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

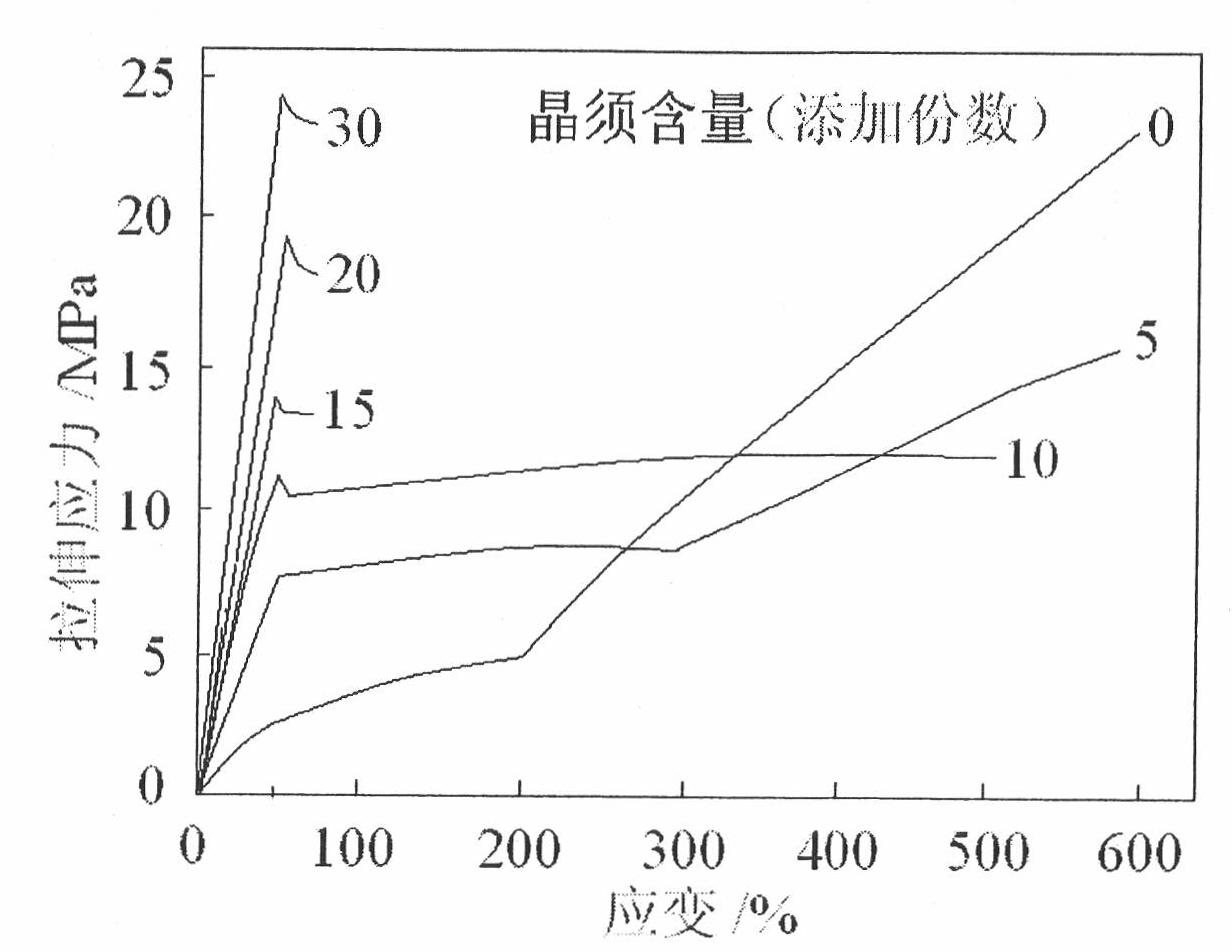

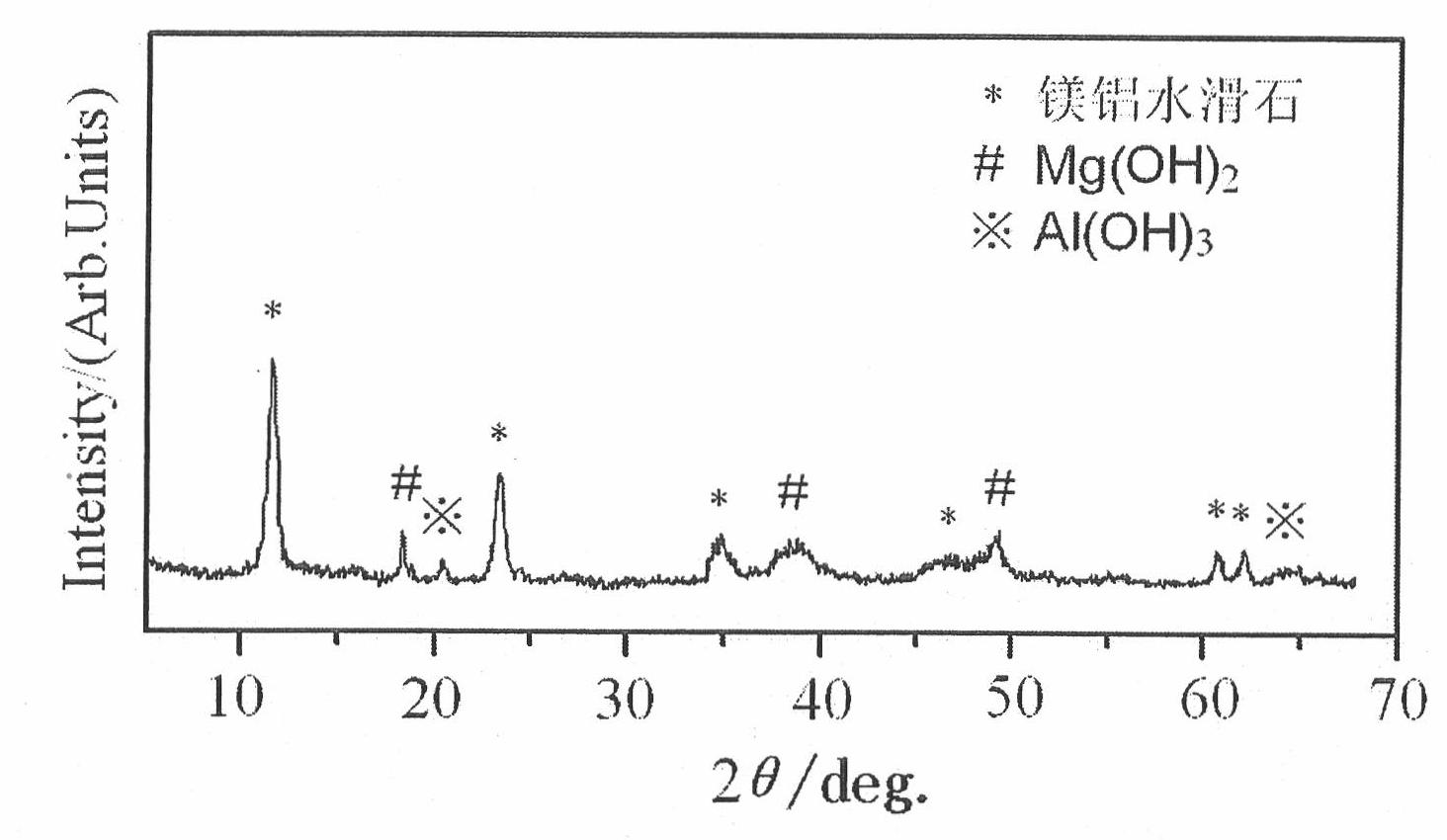

Aluminum hydroxide/magnesium-based hydrotalcite multiphase-based material and preparation method for crystal whiskers thereof

ActiveCN101880912AIncreased riskReduce complexityPolycrystalline material growthFrom normal temperature solutionsAluminum IonAluminium hydroxide

The invention discloses an aluminum hydroxide / magnesium-based hydrotalcite multiphase-based material and a preparation method for crystal whiskers thereof. The aluminum hydroxide / magnesium-based hydrotalcite multiphase-based material comprises magnesium ion solution prepared by mixing magnesium sulfate and magnesium nitrate in a molar ratio of 1:1, aluminum ion solution prepared by mixing aluminum chloride hexahydrate and sodium metaaluminate in a molar ratio of 1:1, sodium hydroxide and sodium carbonate. The preparation method comprises the following steps of: dissolving the magnesium sulfate and the magnesium nitrate into deionized water, dissolving the aluminum chloride hexahydrate and the sodium metaaluminate into the deionized water, and mixing to prepare aqueous solution of magnesium ions and aqueous solution of aluminum ions respectively; adding the sodium carbonate into the aqueous solution of magnesium ions and the aqueous solution of aluminum ions to obtain mixed solution; and adding sodium hydroxide solution into the mixed solution to obtain suspension of aluminum hydroxide / magnesium-based hydrotalcite, and precipitating, washing and aging the suspension to obtain white crystal whiskers of the aluminum hydroxide / magnesium-based hydrotalcite multiphase-based material. The preparation method has the characteristics of simple and reliable preparation process, no pollution, wide sources of raw materials and low preparation cost.

Owner:PLA SECOND ARTILLERY ENGINEERING UNIVERSITY +1

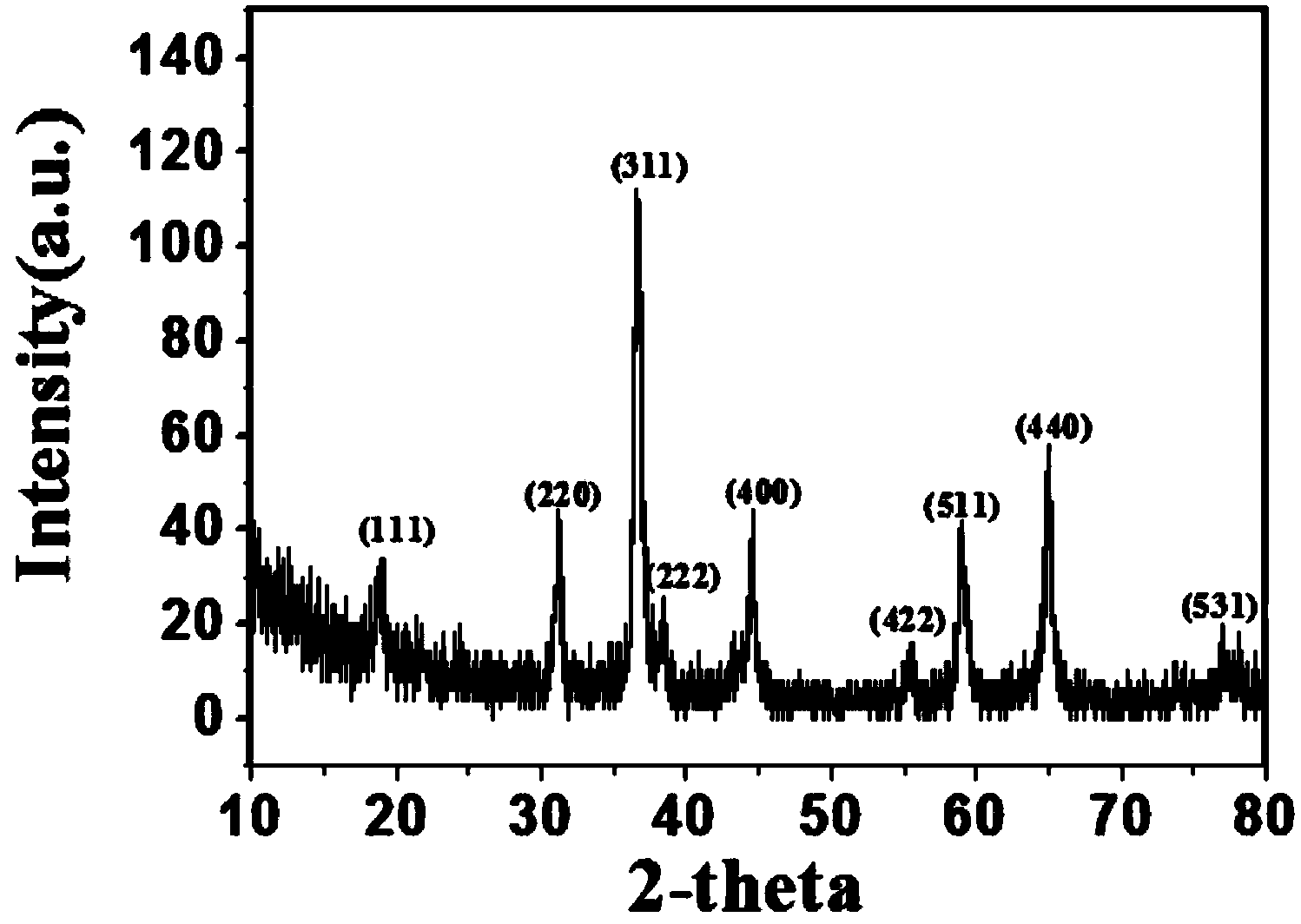

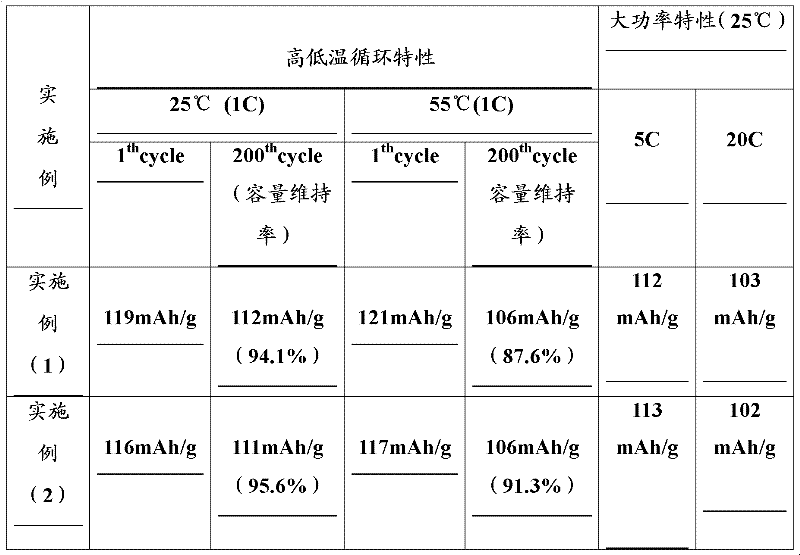

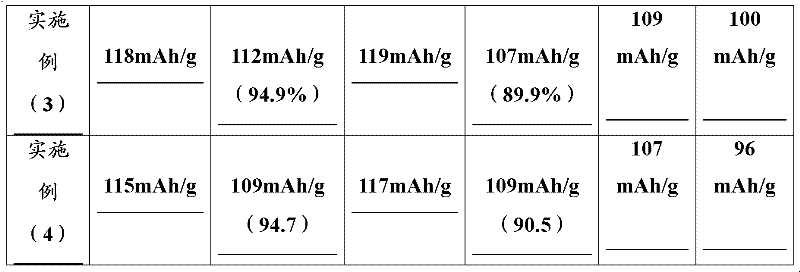

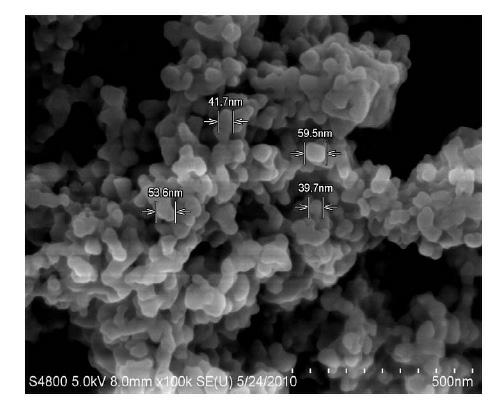

A kind of preparation method of lithium manganate battery material

InactiveCN102259931AAvoid reunionGood crystal shapeManganates/permanganatesSolid phasesManganese oxide

The invention discloses a method for preparing a lithium manganese oxide battery material, which comprises the following steps of: (1) dissolving a manganese source and a doped ion source into water, then adding an alkaline medium to form ion-doped manganese oxide precipitation, filling oxidizing gas into solution, finishing filling until a pH value of the solution reaches 6 to 7 and separating to obtain ion-doped manganese oxide; (2) mixing the ion-doped manganese oxide and aqueous solution of lithium hydroxide and performing a reaction under the hydrothermal condition of 150 to 500 DEG C to obtain the lithium manganese oxide; (3) pouring a mixture of a carbon source and water, a mixture of oxide and water or precursor salt solution of the oxide which is used for cladding into the obtained reaction solution, sufficiently stirring the obtained mixture, collecting the reaction solution and drying to obtain an intermediate product; and (4) in the protective atmosphere, sintering the intermediate product at a temperature of 500 to 800 DEG C to obtain a finished product. The lithium manganese oxide material prepared by the method has uniform particle size and the high and low temperature cycle performance and the high multiplying power discharge performance of the lithium manganese oxide material are both obviously superior to those of a like product synthetized by a conventional high-temperature solid-phase method.

Owner:姚金翰 +1

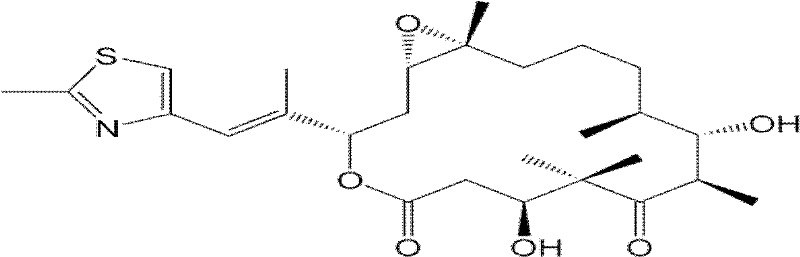

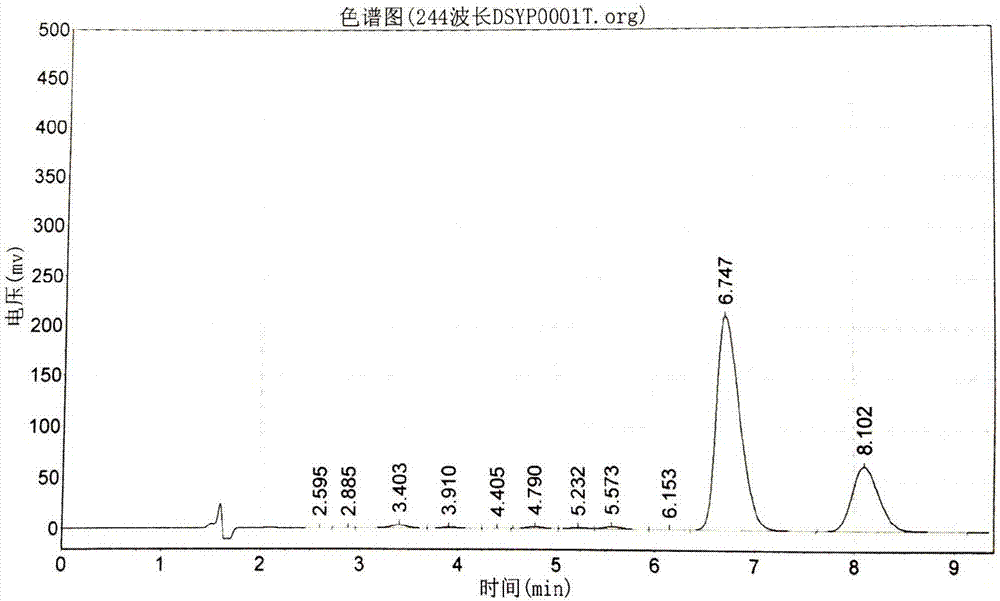

Biosynthesis method for improving yield of epothilone B

ActiveCN102586358AAvoid mutationPromote growthOrganic chemistryMicroorganism based processesEthyl acetateEthyl ester

The invention relates to a biosynthesis method for improving yield of epothilone B. The biosynthesis method comprises the following steps of: selecting robust strains for producing the epothilone B by using a centrifugal process, inoculating the strains into a sterilized seed medium, performing shaking culture at 30DEG C on a shaker, and fermenting; adding a precursor inductor phenylalanine into a fermentation medium; harvesting a culture solution after culturing at 30DEG C for 10 to 11 days; and collecting, adsorbing and saturating by using macroporous resin, eluting by using ethyl acetate, separating and purifying, performing vacuum concentration, extracting, crystalizing at low temperature, and performing vacuum drying. The purity of the epothilone B can be effectively improved by a liquid preparation column, and is over 99.5 percent; and methanol is adopted for extraction and separation, so that the epothilone B is crystallized in the methanol, and the finished product reaches thepharmaceutical grade. By the method, the yield of the epothilone B is greatly improved and is 30-45 percent, and the method has a good industrial production prospect.

Owner:HUBEI HONCH PHARMA

Method for preparing trihydrated magnesium carbonate by using continuous crystallization process

InactiveCN102190320ASimple reaction conditionsImprove the environmentMagnesium carbonatesSolution crystallizationHigh concentrationLithium

The invention belongs to the technical field of salt chemical industrial production, concretely, the invention relates to a method for preparing trihydrated magnesium carbonate by a using continuous crystallization process. The technical schemes of the present invention comprises: selecting high concentration magnesium chloride or high ratio of magnesium to lithium brine, ammonium carbonate as raw materials, adding into a continuous crystallizer for crystallizing, adding a crude product of trihydrated magnesium carbonate obtained by crystaling into an aging device for aging, obtaining a trihydrated magnesium carbonate crystal with good form and high purity for condition for providing conditions to produce high purity magnesium oxide. According to the method of the present invention, continuous crystallization in a process of producing trihydrated magnesium carbonate can be realized, the stability and automation degree of the crystallization in the process of producing trihydrated magnesium carbonate can be effectively raised, and the quality of products is increased as well as the production cost is reduced.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

Method for preparing cefazolin compounds

ActiveCN102617607ASimple recycling processHigh recovery rateAntibacterial agentsOrganic chemistryCefazolin SodiumMethyl carbonate

The invention belongs to the field of pharmacy and relates to a method for preparing cefazolin compounds. The method comprises the following steps that: 1, cefazolin sodium imidazo (toluene diamine TDA) is synthetized, thiadiazole and 7-ACA are obtained through reaction, dimethyl carbonate is used as solvents in the reaction, boron trifluoride-dimethyl carbonate is used as catalysts, and reagents used for regulating the pH of the reaction liquid are inorganic alkali after the reaction is completed; 2, anhydride is prepared, and the anhydride is obtained through the reaction between tetrazole acetic acid and pivaloyl chloride, and 3, the cefazolin is synthesized, TDA solution reacts with the anhydride, and the reaction solution is subjected to decoloration and purification through an aluminium oxide column.

Owner:哈药集团股份有限公司 +1

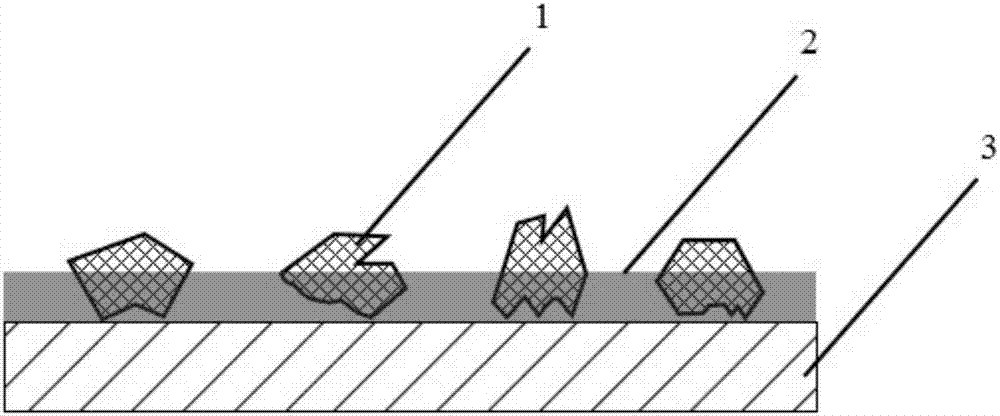

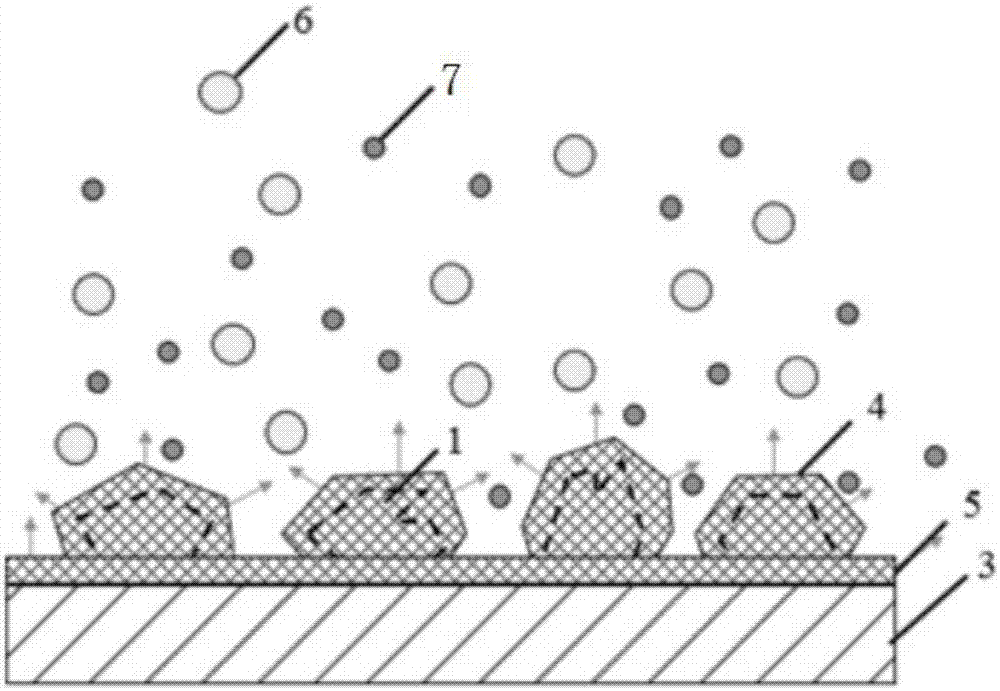

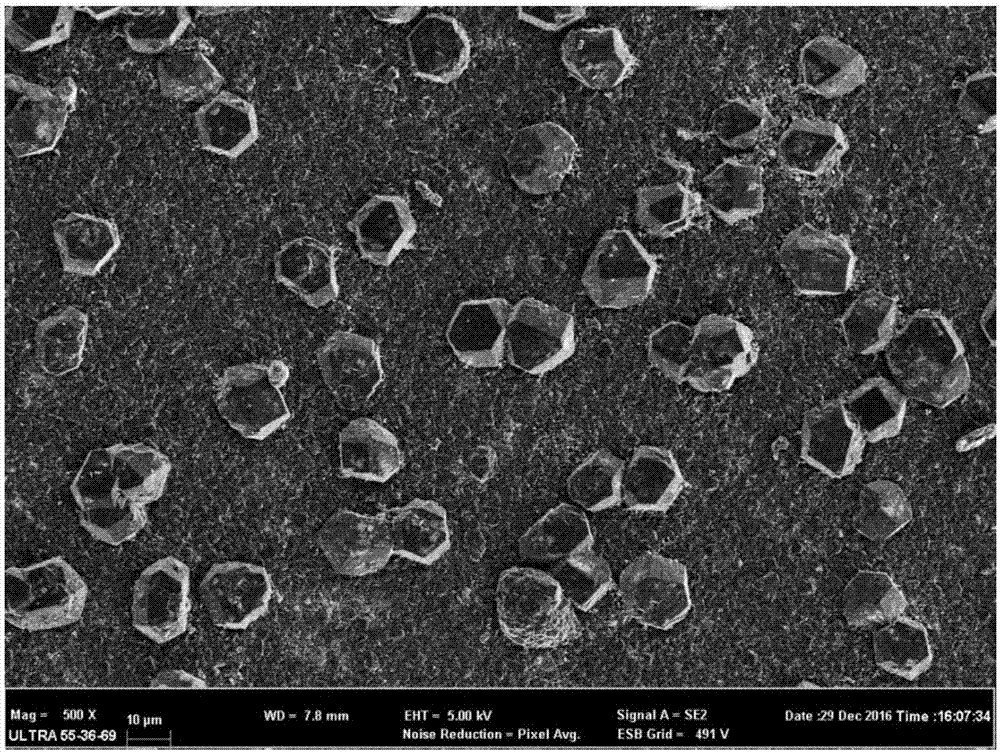

Method for preparing single-layer diamond abrasive tool through chemical vapor deposition

The invention discloses a method for preparing a single-layer diamond abrasive tool through chemical vapor deposition. According to a silicon carbide base body, a diamond abrasive material is mixed into a photoresist solution and is subject to ultrasonic vibration, rotating whirl coating is used for evenly dispersing diamond abrasive particles, uniform distribution of the particles on a base body substrate can be achieved, the CVD method is adopted to enable the diamond coating bonding agent to be subject to deposition between the diamond abrasive particles and the silicon carbide base body, the abrasive material and the base body are firmly connected together, and meanwhile, the abrasive particles grow to become high-grade cubic octahedral single-crystal particles. The prepared single-layer diamond abrasive tool is high in abrasive particle holding force, the exposure height is large, the chipping containing space is large, defects of electroplating and brazing single-layer diamond abrasive tools are overcome, and the method is suitable for preparing fine granularity (five micrometers to 100 micrometers) single-layer diamond abrasive tools. The prepared single-layer diamond abrasive tool has the wide application prospect in high-precise grinding fields of crisp and hard materials of semiconductors, optical crystals, artificial sapphire, glass and the like

Owner:SHANGHAI JIAO TONG UNIV +1

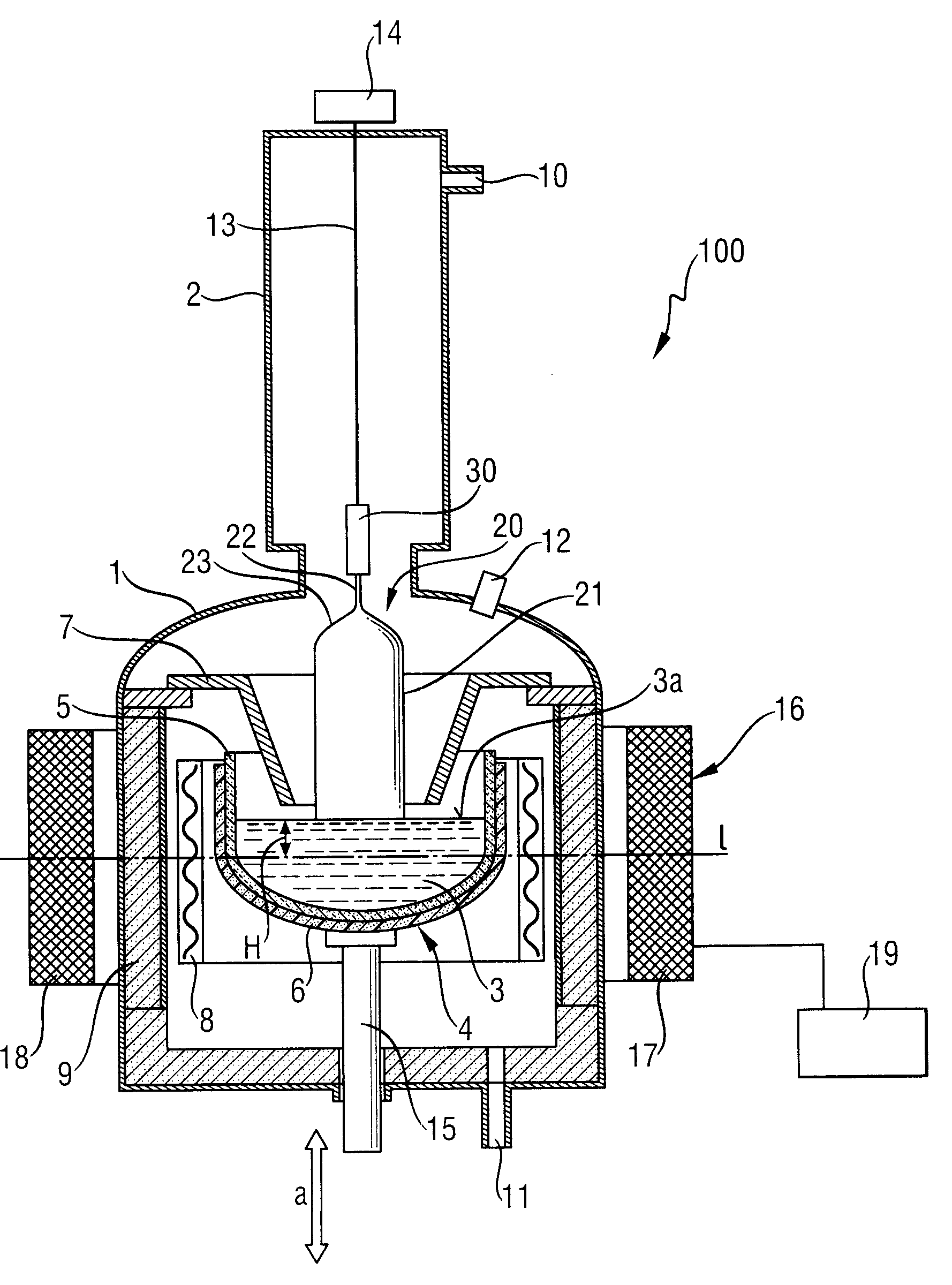

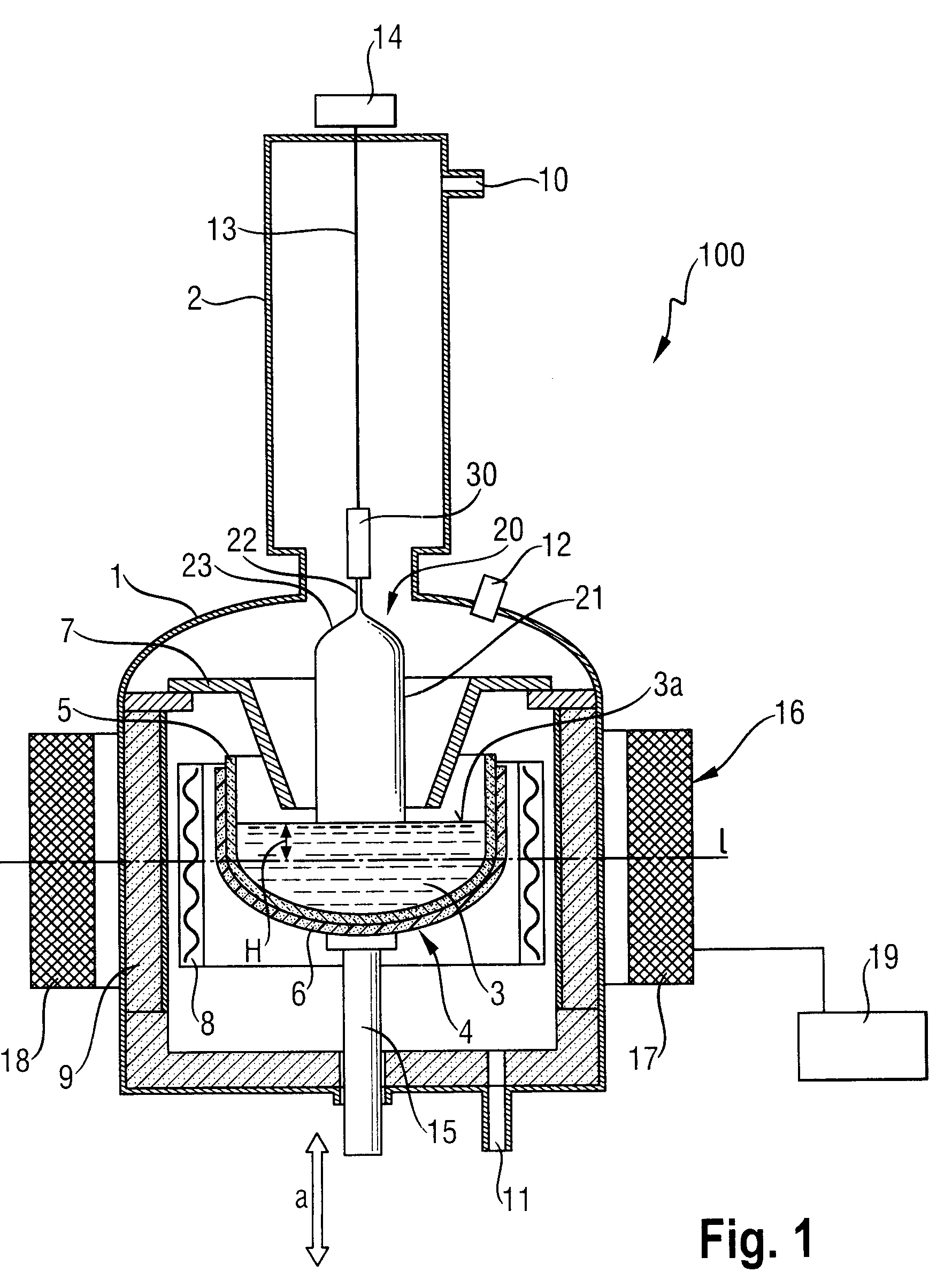

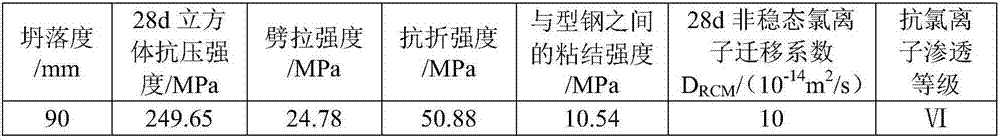

Single Crystal Manufacturing Method

ActiveUS20080302294A1Good crystal shapeSuppressing generation of dislocationPolycrystalline material growthBy pulling from meltEngineeringIngot

Single crystalline ingots can be stably pulled free from dislocation and with a good crystal shape by actuating a crystal driving unit so as to immerse a seed crystal in a silicon melt, and controlling the crystal driving unit and a crucible driving unit under predetermined conditions so as to pull the seed crystal. During pulling, a horizontal magnetic field positioning device applies a magnetic field in the horizontal direction to the inside of the silicon melt, fixing the magnetic field axis at a constant position from the liquid surface of the melt. Positional adjustment of the vertical position of the horizontal magnetic field is performed in advance by a magnetic field position adjusting device, and the magnetic field axis of the applied field is fixed at a constant distance lower than the liquid surface of the melt by more than 50 mm and at the same level or higher than a depth L from the melt surface at the point of tail-in.

Owner:SILTRONIC AG

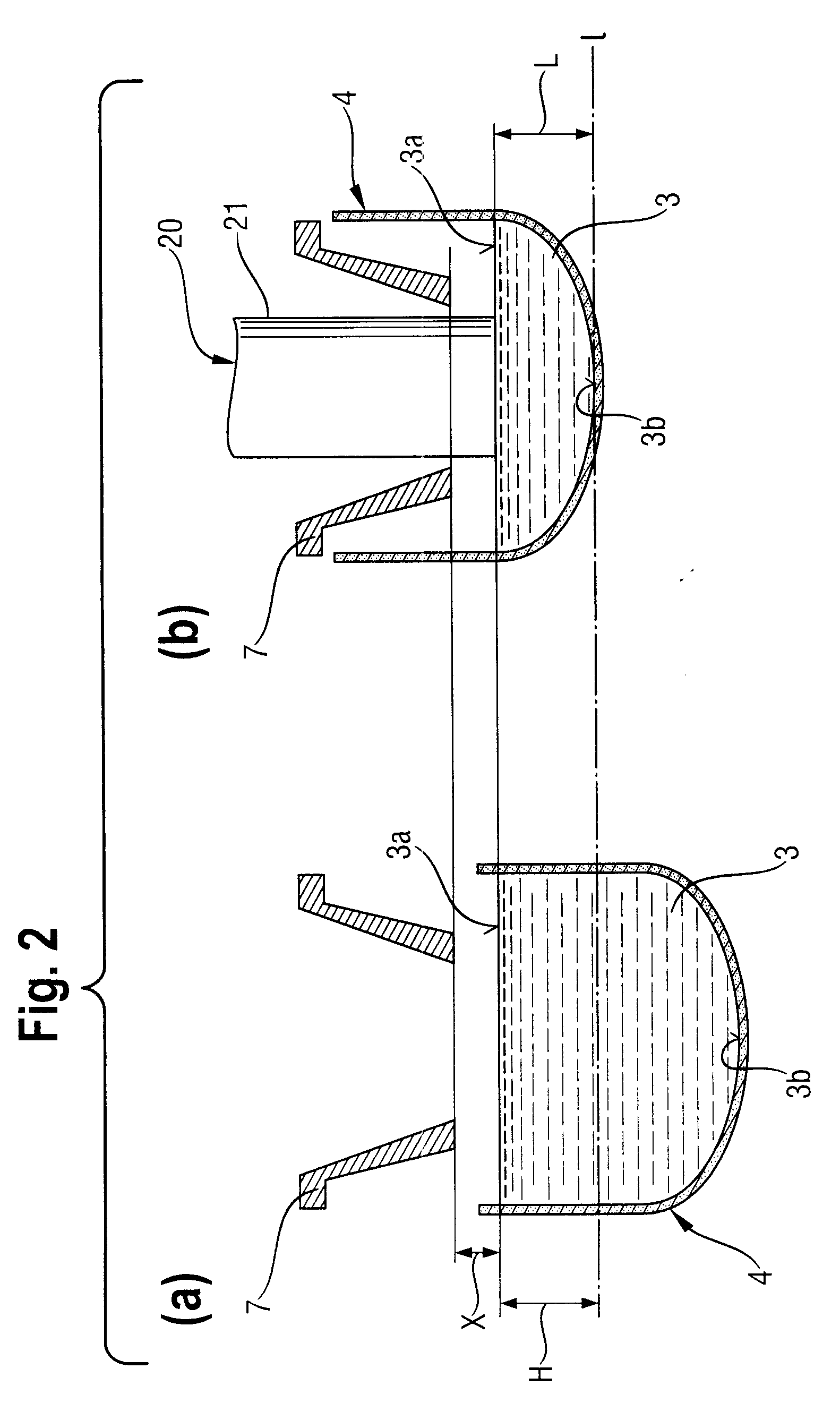

Coarse-aggregate-containing C240-strength-grade ultrahigh-performance fiber concrete and preparation method

ActiveCN107285708AImprove toughnessImprove deformation abilitySolid waste managementModified carbonCellulose fiber

The invention discloses coarse-aggregate-containing C240-strength-grade ultrahigh-performance fiber concrete and a preparation method. The concrete is composed of, by mass, 578 parts of cement, 62 parts of water, 880 parts of rubble, 800 parts of fine aggregate, 70 parts of coal ash, 60 parts of rice husk ash, 154 parts of silicon ash, 16.5 parts of water reducer, 11.5 parts of excitant, 1.7 parts of cellulosic fiber, 90 parts of steel fiber, 51 parts of hydroxyl modified carbon nanotube dispersion, 54 parts of oxidized graphene dispersion and 2.9 parts of defoamer. The concrete prepared by the method has high toughness and durability and has high binding strength with section steel, compressive strength reaches 249.65MPa, bending strength reaches 50.88MPa, splitting tensile strength reaches 24.78MPa, the binding strength with the section steel reaches 10.54MPa, and chlorion anti-permeation grade reaches VI grade. When the concrete is used in a section steel and concrete combined structure, cooperative working performance between the section steel and the concrete can be brought into play effectively, and the defects that the section steel and the concrete are poor in binding performance and respective mechanical performance of the section steel and the concrete cannot be brought into full play are made up.

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY

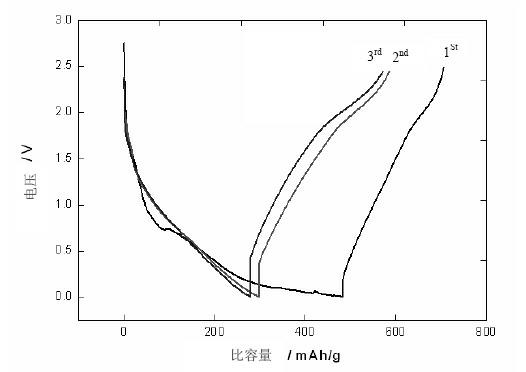

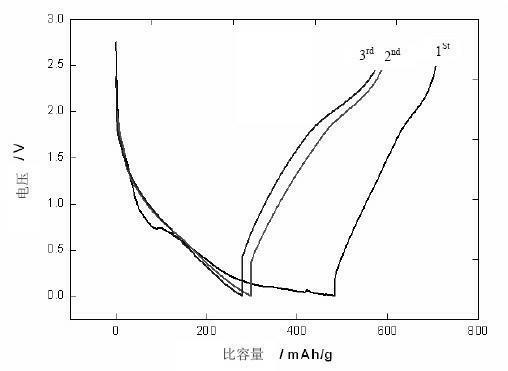

Lithium ion battery anode material and preparation method thereof, and lithium ion battery

ActiveCN102569788AStable structureExcellent performanceCell electrodesSecondary cellsCharge and dischargeLithium electrode

The invention provides a lithium ion battery anode material, which comprises a silicate material and a carbon material, wherein the content of the silicate material is 85 wt percent to 97 wt percent, and the content of the carbon material is 3 wt percent to 15 wt percent; and the structural formula of the silicate material is Li2MSiO4, and M is selected from Mn, Fe and Mn(1-x)Fe(x), wherein x is more than 0 and less than 1. Furthermore, the invention also provides a preparation method for the anode material and a lithium ion battery adopting the anode material. The process of the preparation method of the invention is simple; and the prepared anode material has high performance and a stable structure, is applied to the lithium ion battery, has high initial charging efficiency and relatively high specific capacity, and can bear high-rate charge and discharge.

Owner:BYD CO LTD

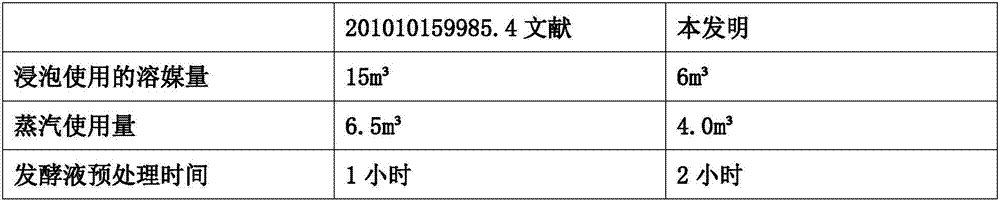

Extraction process for industrial mass production of spinosad

ActiveCN107474088AReduce usageImprove leaching efficiencySugar derivativesSugar derivatives preparationFiltrationSolvent

The invention relates to an extraction process for industrial mass production of spinosad. The process includes the steps of: fermentation broth pretreatment, frame and plate filtration, and flash drying; mycelium soaking in methanol; concentration of extract liquid, phase inversion washing; back extraction with tartaric acid; adjustment of pH and centrifugation to obtain a spinosad crude product; and recrystallization with methanol to obtain a spinosad fine product. The process provided by the invention extracts spinosad by means of mycelium separation, drying and extraction, and has the characteristics of high extraction efficiency, small solvent dosage, which is only half of that of fermentation broth direct solvent extraction, relatively low energy consumption, and shortened production cycle. In addition, the equipment needed by frame and plate filtration, flash drying, extraction, concentration, washing, back extraction and refining is general, therefore industrial production can be realized easily. The obtained product has high yield up to 85%-90%, after purification of spinosad coarse crystals by solvent recrystallization, the quality of spinosad is improved, and the product content reaches 95%-98%.

Owner:QILU PHARMA INNER MONGOLIA

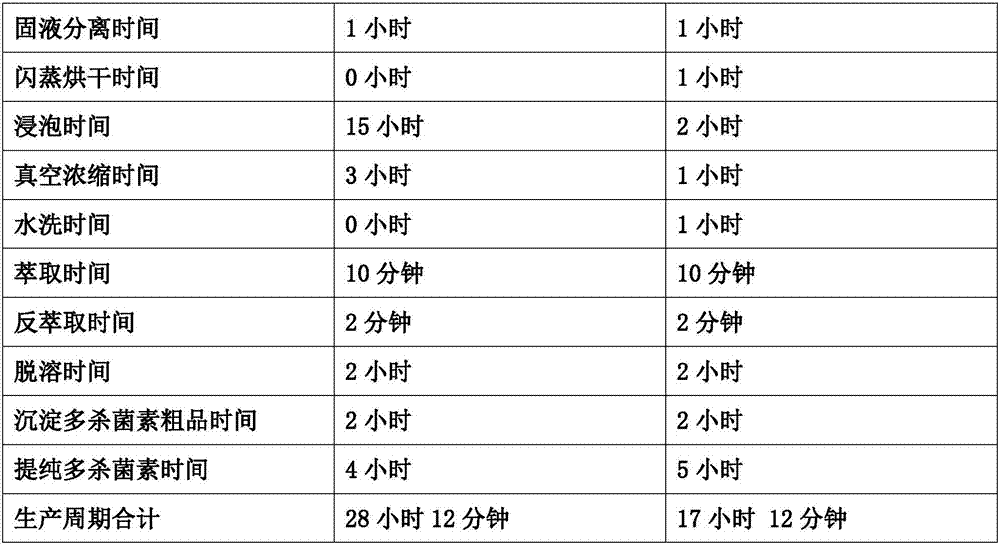

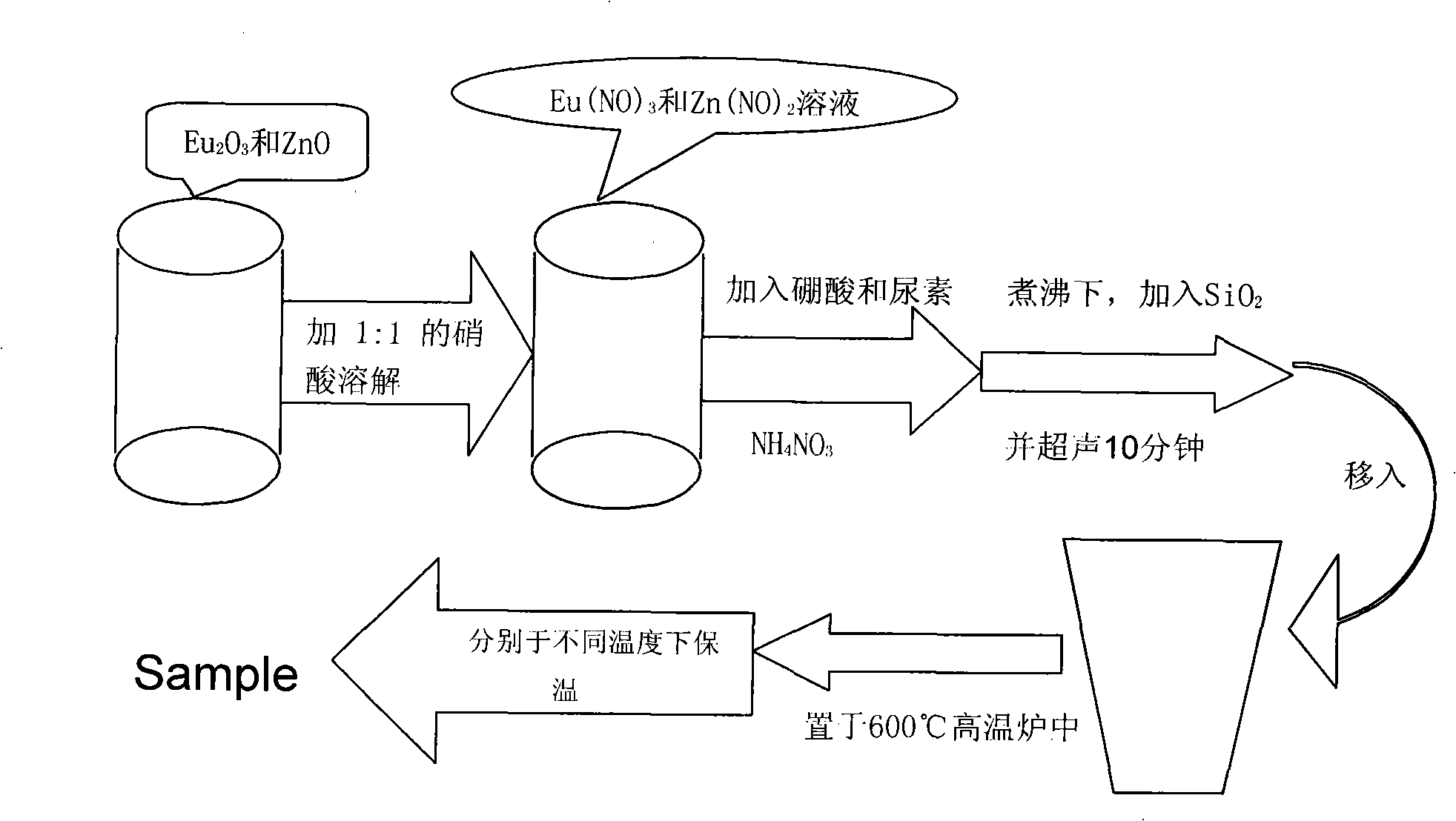

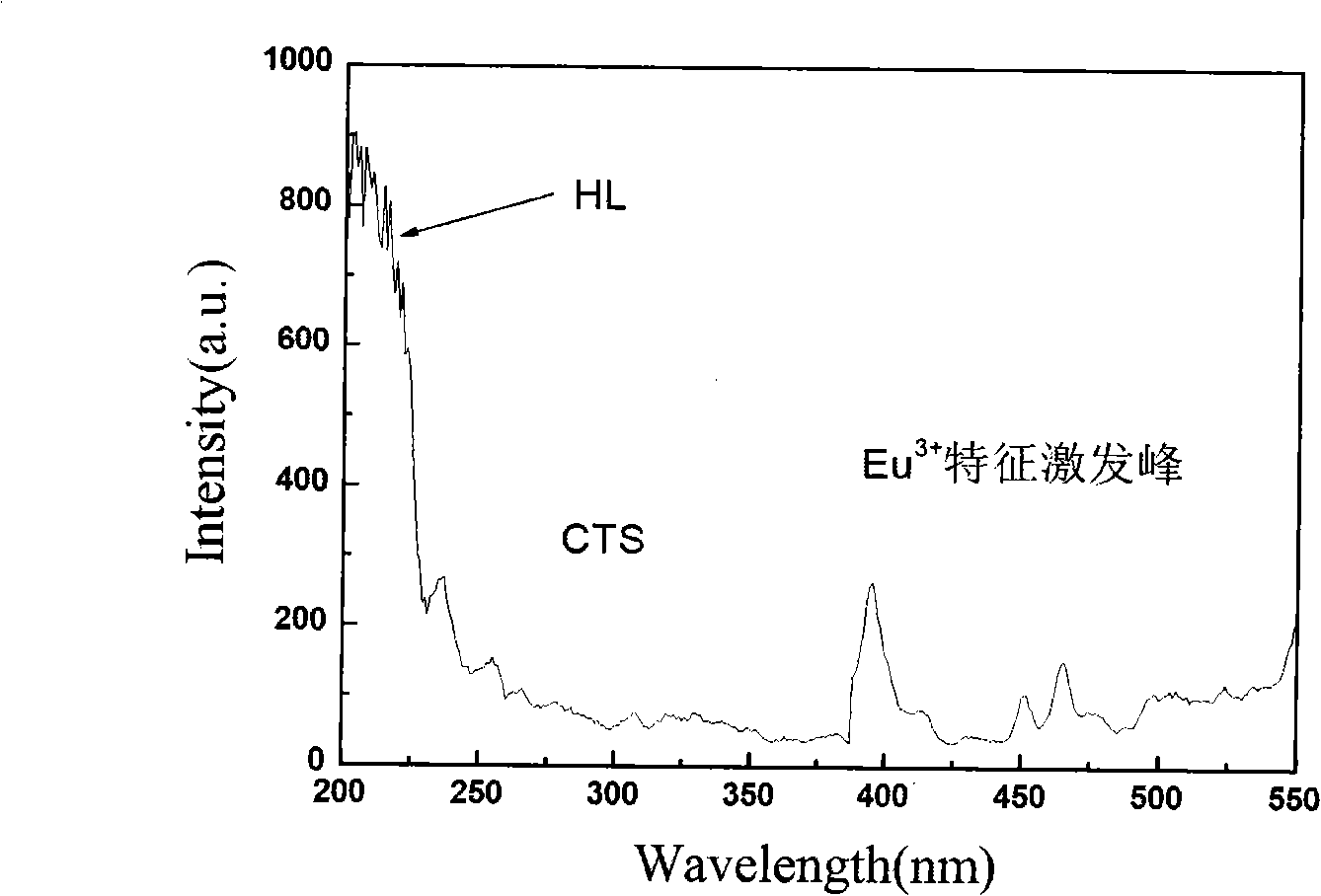

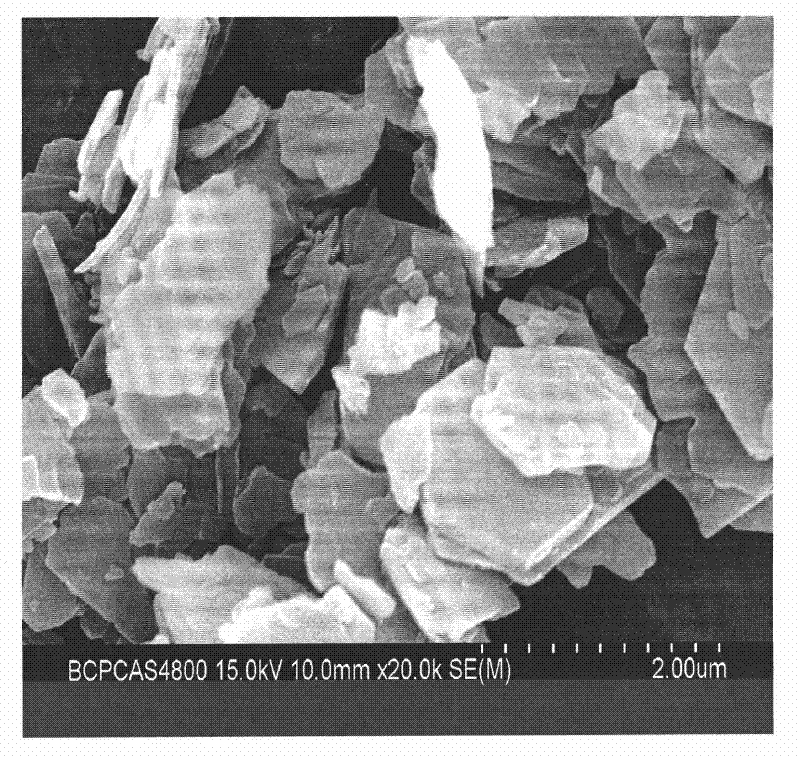

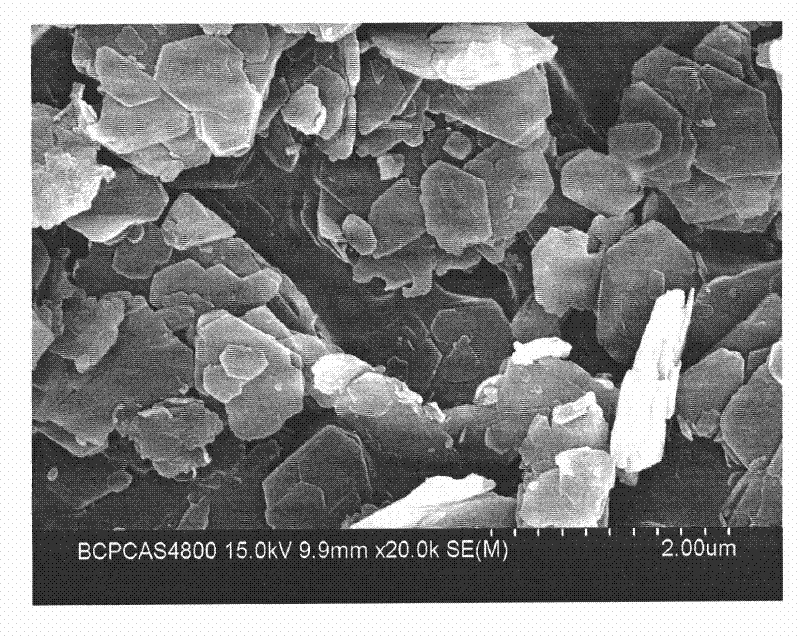

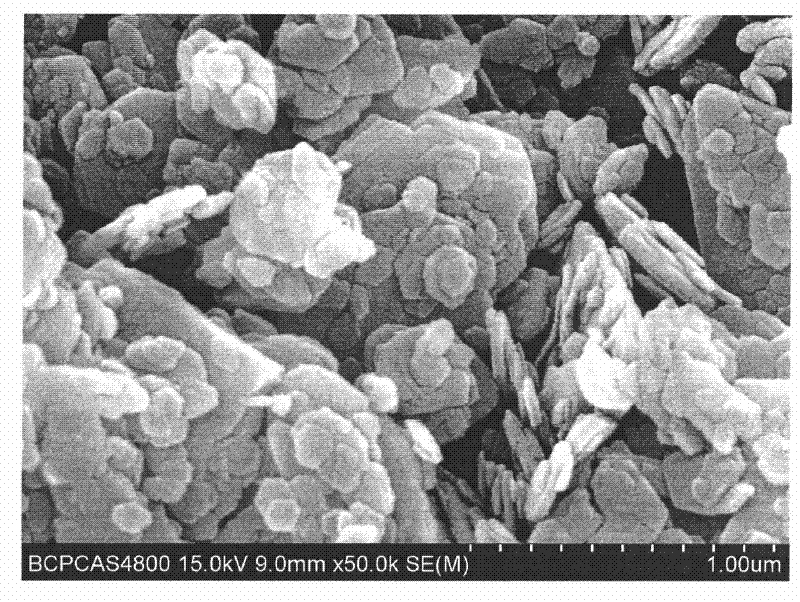

Preparation of red fluorescent powder Zn2SiO4:Eu3+

InactiveCN101280189AIncrease the heat of combustionGood crystal shapeLuminescent compositionsPhosphorBiological activation

The invention discloses the preparation method of red phosphor Zn2SiO4:Eu3+, which adopts the combustion method as the novel preparation method; Urea is used as the incendiary agent to synthesize the red phosphor Zn2SiO4:Eu3+ successfully; the combustion thermal discharge is improved and excessive combustion gas is generated through the addition of a small quantity of combustion auxiliary agent ammonium nitrate so that the combustion product is ensured to be looser; the combustion auxiliary agent is combusted in the interior of the mixture to catalyze the whole combustion reaction, facilitating the system to overcome high reaction activation potential barrier; the raw product is combusted within the temperature range of the experiment; after the continuous heat preservation; the product has small morphological changes; the crystal formation of the product is good, avoiding the decreasing of the luminescent property caused by the damage of the crystal lattice after grinding and crushing.

Owner:SHANGHAI NORMAL UNIVERSITY

Coal-series hard kaolinite stripping method capable of keeping crystal form of kaolinite

The invention discloses a coal-series hard kaolinite stripping method. The method comprises the following steps of: crushing the coal-series hard kaolinite, mixing the crushed coal-series hard kaolinite with water and an intercalator to obtain intercalated compound pulp, striping the intercalated compound pulp by using medium spheres of three types grain sizes, and performing filtration washing and spray-drying to obtain the finished product. By the method, the hexagonal sheet-shaped crystal form of the kaolinite is kept relatively complete, and the content of hexagonal sheet-shaped kaolinite crystals is 30 to 60 percent.

Owner:CHINA UNIV OF MINING & TECH (BEIJING)

Catalyst for synthesizing isophorone

InactiveCN103691416AHigh purityGood crystal shapePhysical/chemical process catalystsOrganic compound preparationAluminium nitratePtru catalyst

The invention relates to a method for preparing isophorone, and belongs to the technical field of chemical material preparation. The method comprises the steps of: compounding the nitrate of metal magnesium, metal aluminum and metal zirconium into a mixed salt solution, dripping an aluminium nitrate solution and a zirconium nitrate solution into a magnesium nitrate solution at the same time under the condition of stirring, stirring for 1 to 1.5h, aging the obtained deposit for 0.5 to 1h under 50 to 60 DEG C, pumping, filtering and washing the deposit to be neutral, drying the deposit under 60 to 80 DEG C to obtain magnesium-aluminum-zirconium hydrotalcite samples, putting the hydrotalcite samples obtained by drying in a muffle furnace, calcining the hydrotalcite samples for 3 to 4h under 300 to 400 DEG C to prepare the needed catalyst, and cooling, grinding and sieving the catalyst. The hydrotalcite catalyst which is prepared in the method not only has high purity, good crystal form and the characteristic of hydrotalcite-like compounds but also has a porous structure, a large specific surface area and an alkaline site which are required for catalyzing the reaction; the catalytic reaction with mild condition and no pollution can be repeatedly used, thereby greatly lowering production cost.

Owner:张锦碧

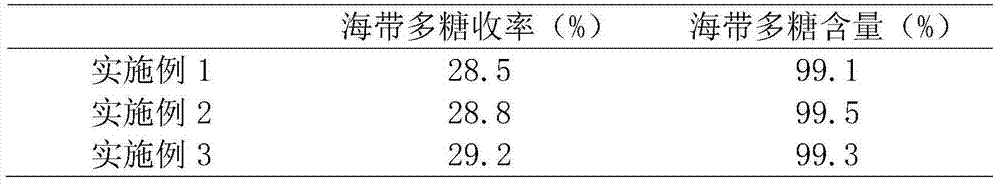

Method for preparing laminarin from kelp

InactiveCN104710541AUniform particle size distributionEasy to operateHigh pressureTrichloroacetic acid

The invention discloses a method for preparing laminarin from kelp, which comprises the following steps: raw material treatment, high-pressure microjet pulverization treatment, fermentation, enzymolysis, decolorization, protein removal and drying to obtain the finished product. Compared with the existing trichloroacetic acid precipitation process, savage process or the like, the method disclosed by the invention has the advantages of high laminarin yield and high content.

Owner:广西还珠海洋生物科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com