Nickel hydroxide @ manganese dioxide core-shell hetero-structured nanosheet array material growing on carbon cloth, and preparation method and application of nickel hydroxide @ manganese dioxide core-shell hetero-structured nanosheet array material

A nanosheet array, nickel hydroxide technology, applied in the field of nanomaterials, can solve the problems of low capacitance, poor conductivity, low energy density and power density, etc., achieve long-term stability, improve energy density and power density, high energy Effects of Density and Power Density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] A preparation method based on nickel hydroxide@manganese dioxide core-shell heterostructure nanosheet array material grown on carbon cloth, comprising the following steps:

[0035] a. Put the nickel sheet with impurities on the surface into dilute sulfuric acid, water, and ethanol in sequence for ultrasonic cleaning for 15 minutes;

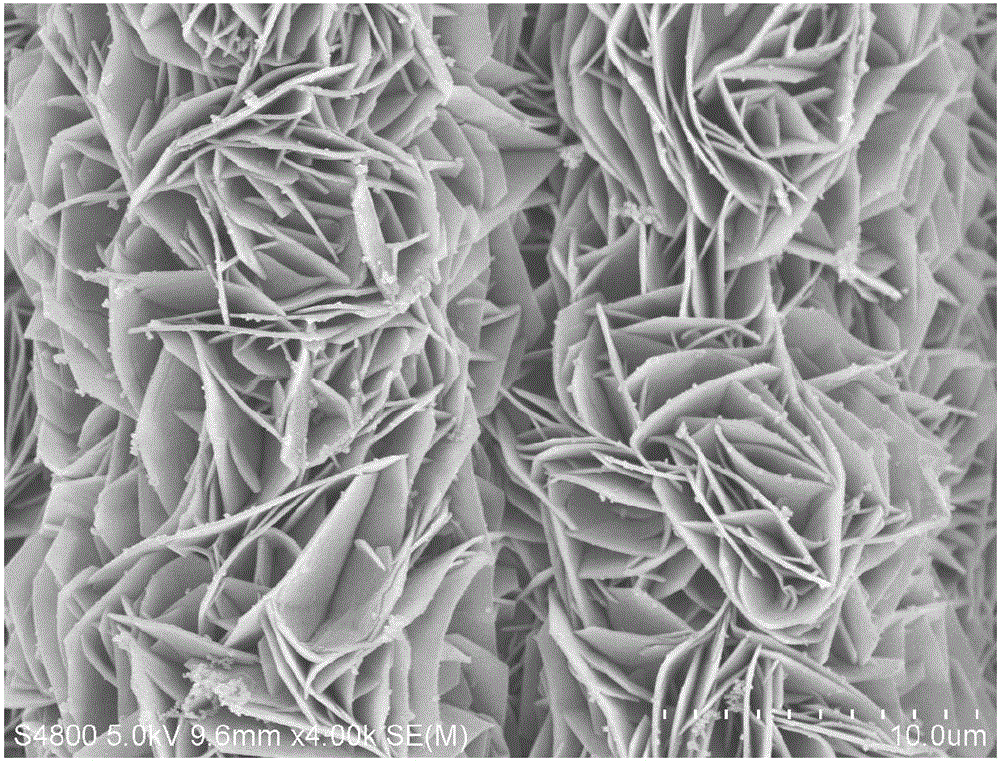

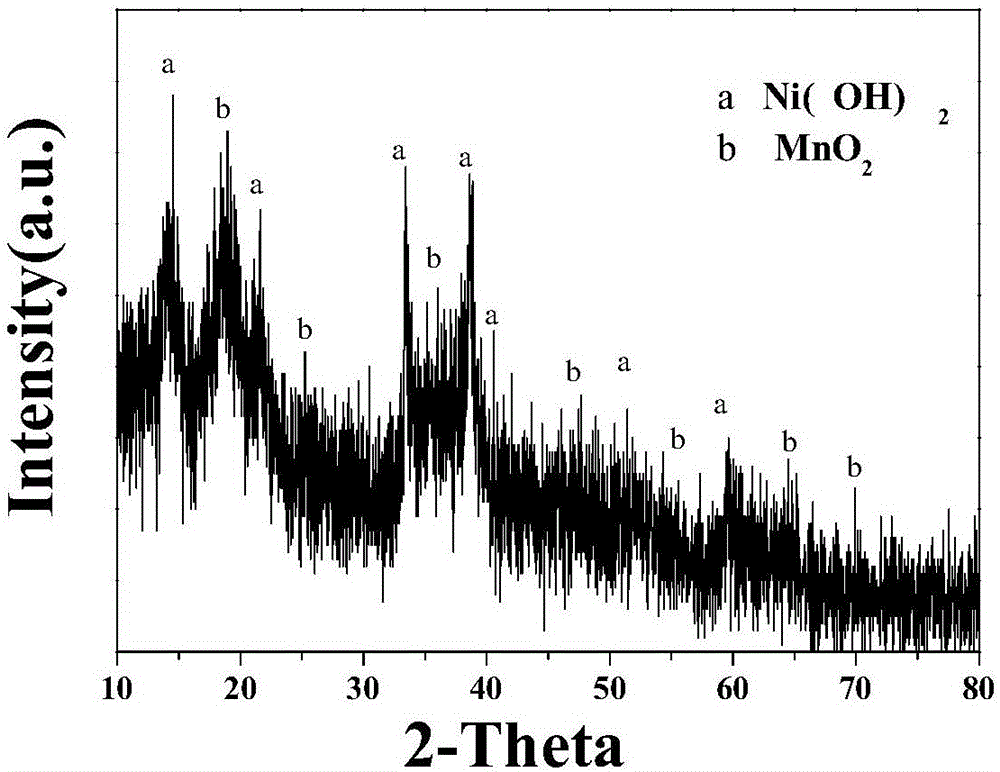

[0036] b. Mix 50mL double-distilled water, 4mmol nickel chloride hexahydrate, 20mmol ammonium fluoride and 80mmol urea evenly, then add it into a 60mL reaction kettle, soak the treated carbon cloth in the mixture, pour it into the reaction kettle, and tighten the kettle Cover, react at 110°C for 10h, take out the reactor and cool it down to room temperature naturally, wash with ethanol and double distilled water for 3-5 times, rinse well, and dry at 60°C for 2h to obtain nickel hydroxide nanosheet material.

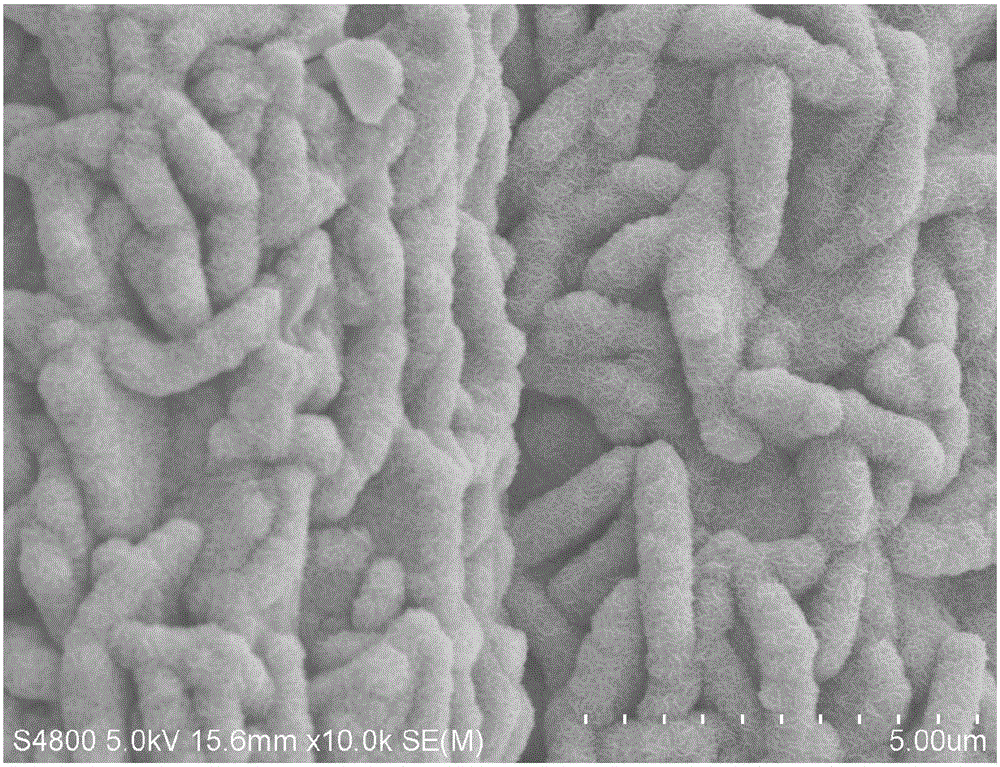

[0037] c. Dissolve 0.5mmol potassium permanganate in 50mL double-distilled water, stir magnetically for 20min to form a uniform solut...

Embodiment 2

[0045] A preparation method based on nickel hydroxide@manganese dioxide core-shell heterostructure nanosheet array material grown on carbon cloth, comprising the following steps:

[0046] a. Put the nickel sheet with impurities on the surface into dilute sulfuric acid, water, and ethanol in sequence for ultrasonic cleaning for 15 minutes;

[0047] b. Mix 50mL double-distilled water, 4mmol nickel chloride hexahydrate, 20mmol ammonium fluoride and 80mmol urea evenly, then add it into a 60mL reaction kettle, soak the treated carbon cloth in the mixture, pour it into the reaction kettle, and tighten the kettle Cover, react at 110°C for 3 hours, take out the reaction vessel and cool it down to room temperature naturally, rinse with ethanol and double distilled water in sequence, and dry at 60°C for 2 hours to obtain the nickel hydroxide nanosheet material.

[0048] c. Dissolve 0.5mmol potassium permanganate in 50mL double-distilled water, stir magnetically for 20min to form a unifo...

Embodiment 3

[0053] A preparation method based on nickel hydroxide@manganese dioxide core-shell heterostructure nanosheet array material grown on carbon cloth, comprising the following steps:

[0054] a. Put the nickel sheet with impurities on the surface into dilute sulfuric acid, water, and ethanol in sequence for ultrasonic cleaning for 15 minutes;

[0055] b. Mix 50mL double-distilled water, 4mmol nickel chloride hexahydrate, 20mmol ammonium fluoride and 80mmol urea evenly, then add it into a 60mL reaction kettle, soak the treated carbon cloth in the mixture, pour it into the reaction kettle, and tighten the kettle Cover, react at 110°C for 10h, take out the reactor and let it cool down to room temperature, rinse it with ethanol and double distilled water in sequence, and dry at 60°C for 2h, to obtain the nickel hydroxide nanosheet material.

[0056] c. Dissolve 0.5mmol potassium permanganate in 50mL double-distilled water, stir magnetically for 20min to form a uniform solution, immers...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com