Patents

Literature

86 results about "Epothilone B" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

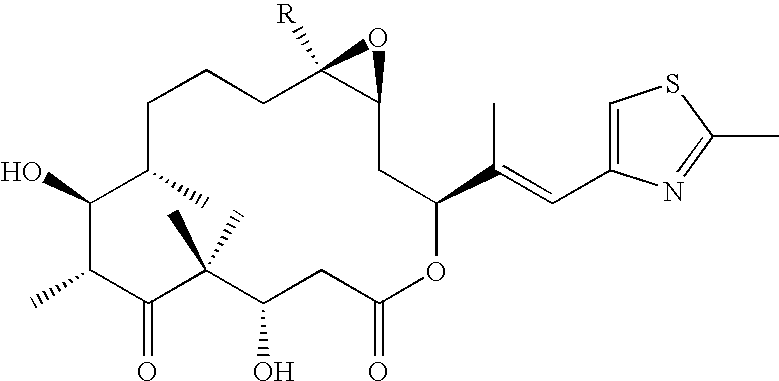

Fermentative preparation process for and crystal forms of cytostatics

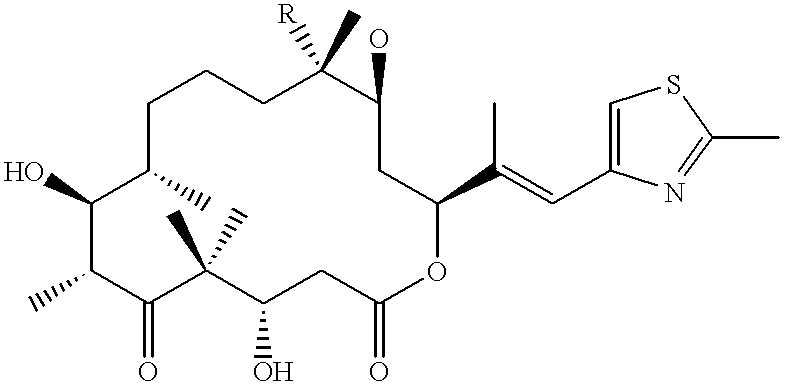

The invention relates to a new process for concentrating epothilones in culture media, a new process for the production of epothilones, a new process for separating epothilones A and B and a new strain obtained by mutagenesis for the production of epothilones, as well as aspects related thereto. New crystal forms of epothilone B are also described.

Owner:NOVARTIS AG

Methods for the preparation, isolation and purification of epothilone B, and x-ray crystal structures of epothilone B

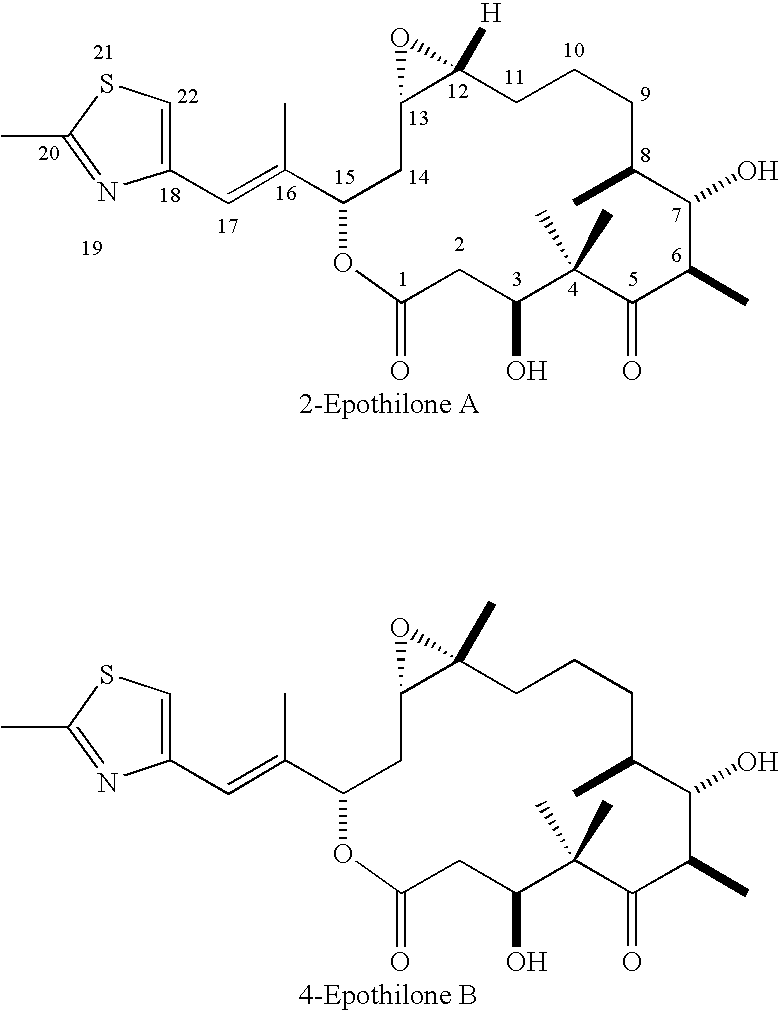

ActiveUS20040132146A1Improve epothilone titerQuality improvementOrganic active ingredientsBiocidePurification methodsEpothilone B

The present invention relates to improved methods for the production, isolation and purification of epothilone B. These methods include, for example, a fermentation process for the production of epothilone B, isolation via adsorption onto a resin, and subsequent purification.

Owner:GESELLSCHAFT FUR BIOTECHNOLOGISCHE FORSCHUNG MBH GBF +1

Anticancer sustained release agent containing epothilone

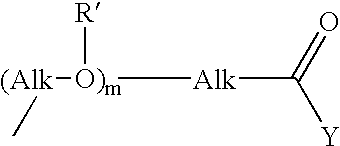

InactiveCN1969816AEasy injectionIncrease drug concentrationOrganic active ingredientsPharmaceutical delivery mechanismPolyethylene glycolDepressant

Disclosed is an anti-cancer drugs slow release agent containing Epothilone which comprises slow release microspheres and dissolvent, wherein the slow release microballoons comprise anti-cancer active constituents and slow release auxiliary materials, the dissolvent being specific dissolvent containing suspension adjuvant. The anticancer active constituents include Epothilone, Epothilone derivatives, Epothilone B, Epothilone D and combination of anti-cancer drugs selected from phosphoinositide-3-kinase inhibitor, of pyrimidine analogues and / or DNA restoring enzyme inhibitor, the slow release auxiliary materials include polylactic acid and its copolymer, polyethylene glycol, PLA-COOH copolymer, di-aliphatic acid and sebacylic acid copolymer, poly(erucic aciddipolymer-sebacylic acid), poly(fumaric acid-sebacylic acid), Polifeprosan, polylactic acid and other biocompatible high polymers, the viscosity of the suspension adjuvant is 100-3000cp (at 20-30 deg C), and is selected from sodium carboxymethylcellulose. The anticancer active constituents and the slow release microspheres can also be prepared into slow release implanting agent for intra-tumor or around-tumor injection or placement for the effective suppression of tumor growth and for the appreciable enhancement for curative effects of non-operative treatments such as chemotherapy.

Owner:JINAN SHUAIHUA PHARMA TECH

Anti-cancer sustained-released injection containing epothilone derivate

InactiveCN101396342AEasy to operateGood repeatabilityOrganic active ingredientsSolution deliveryPoly dl lactidePolyethylene glycol

The invention relates to an anti-cancer sustained release injection containing epothilone derivative, consisting of sustained microspheres and menstruum. The sustained microspheres comprise anti-cancer drugs selected from taxane, alkylating agent and / or plant alkaloid and the like, the epothilone derivative and sustained release auxiliary material. The menstruum is a special menstruum containing suspending agent. The epothilone derivative is selected from epothilone B, epothilone D, iso-epothilone D, BMS-247550, azaepothilone B, furan epothilone D or BMS-310705. The sustained release auxiliary material is selected from poly-dl-lactide, the glycolic acid copolymer of the poly-dl-lactide, polyethyleneglycol, the polylactide copolymer of the polyethyleneglycol, carboxyl terminated polylactide copolymer, fatty acid and decanedioic acid copolymer, etc. The suspending agent is selected from carboxymethyl cellulose and the like with the viscosity of 100cp to 3000cp (under the temperature of 25 DEG C to 30 DEG C). The sustained release microsphere can also be made into a sustained release implant. The sustained release injection is injected or arranged in or around the tumour and can release drug at partial position for 40 days approximately, therefore, the sustained release injection improves the local drug concentration selectively and enhances the treatment effect of non-operative treatments, such as radiotherapy, chemotherapy and the like at the same time.

Owner:JINAN SHUAIHUA PHARMA TECH

Anticancer sustained release injection containing epothilone derivatives

InactiveCN1969818AEasy to operateGood repeatabilityOrganic active ingredientsPharmaceutical delivery mechanismAdjuvantMicrosphere

Disclosed is an anti-cancer slow release injection containing Epothilone derivatives which comprises slow release microspheres and dissolvent, the slow release micro-balloons include anticancer drugs selected from Paclitaxel, alkyl agent and / or plant alkaloids, Epothilone derivatives and slow release auxiliary materials, the dissolvent being specific dissolvent containing suspension adjuvant. The Epothilone derivatives are selected from Epothilone B, Epothilone D, Isoepothilone D, BMS-247550, azaepothilone B, furaepothilone D or BMS-310705. The slow release auxiliary material is selected from poly-D, L-lactic acid and its glycolic copolymer, polyethylene glycol and polylactic acid copolymer, PLA-COOH copolymer, aliphatic acid and sebacylic acid copolymer, the viscosity of the suspension adjuvant is 100-3000cp (at 25-30 deg C), and is selected from sodium carboxymethylcellulose, The slow release microspheres can also be prepared into slow release implanting agent, for injection or placement in or around tumor with the period of local drug release can be about 40-50 days, as a result, the local medicinal concentration can be increased selectively, and the treatment effect of the non-operative treatment methods such as chemotherapy can be improved substancially.

Owner:JINAN SHUAIHUA PHARMA TECH

Anti-cancer sustained-released injection containing epothilone derivate

InactiveCN101396340AEasy to operateGood repeatabilityOrganic active ingredientsSolution deliveryPoly dl lactidePolyethylene glycol

The invention relates to an anti-cancer sustained release injection containing epothilone derivative, consisting of sustained microspheres and menstruum. The sustained microspheres comprise anti-cancer drugs selected from taxane, alkylating agent and / or plant alkaloid and the like, the epothilone derivative and sustained release auxiliary material. The menstruum is a special menstruum containing suspending agent. The epothilone derivative is selected from epothilone B, epothilone D, iso-epothilone D, BMS-247550, azaepothilone B, furan epothilone D or BMS-310705. The sustained release auxiliary material is selected from poly-dl-lactide, the glycolic acid copolymer of the poly-dl-lactide, polyethyleneglycol, the polylactide copolymer of the polyethyleneglycol, carboxyl terminated polylactide copolymer, fatty acid and decanedioic acid copolymer, etc. The suspending agent is selected from carboxymethyl cellulose and the like with the viscosity of 100cp to 3000cp (under the temperature of 25 DEG C to 30 DEG C). The sustained release microsphere can also be made into a sustained release implant. The sustained release injection is injected or arranged in or around the tumour and can release drug at partial position for 40 days approximately, therefore, the sustained release injection improves the local drug concentration selectively and enhances the treatment effect of non-operative treatments, such as radiotherapy, chemotherapy and the like at the same time.

Owner:JINAN SHUAIHUA PHARMA TECH

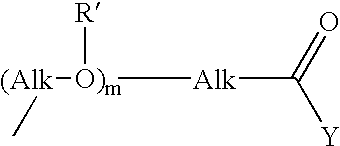

Fermentation production method based on epothilone B metabolic pathways

InactiveCN103243134ARaise the level of fermentationReduce fermentation costsMicroorganism based processesFermentationBiotechnologyAlcohol

The invention discloses a fermentation production method based on epothilone B metabolic pathways and belongs to the technical field of fermentation engineering. The method comprises the following steps of: 1) inoculating Sorangium cellulosum into an M26 culture medium, carrying out shake cultivation to obtain a seed solution; 2) inoculating the seed solution into fermentation liquor containing resin, carrying out shake culturing for 72-120 hours at 25-35 DEG C, adding a precursor and small molecular substances into the fermentation liquor containing resin; and 3) filtering the fermentation liquor after the culture is finished, collecting the resin, washing the resin and oscillating and extracting with methyl alcohol to obtain extract liquor containing the epothilone B. According to the invention, the precursor and small molecular substances related to the biosynthetic pathways obtained by screening are added into the fermentation liquor, and the constructive metabolism pathways of the epothilone B are disturbed, so that the excellent bacterial strain gives full play to the ability of anabolism and the fermentation level of the epothilone B is improved greatly, thus the fermentation cost is reduced and the commercial process of the anti-cancer drug is promoted.

Owner:SHAANXI UNIV OF SCI & TECH

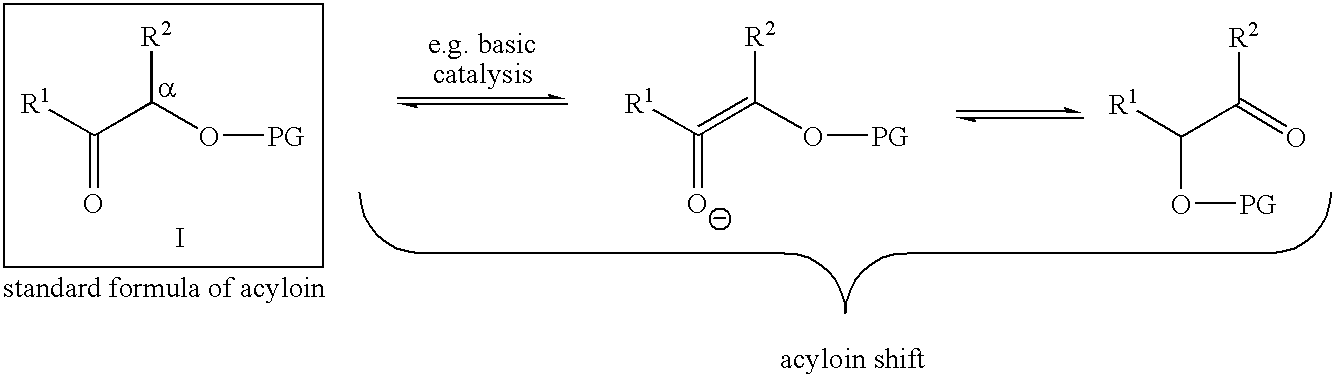

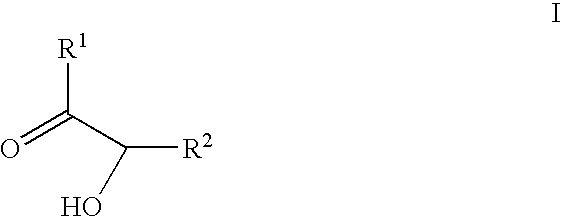

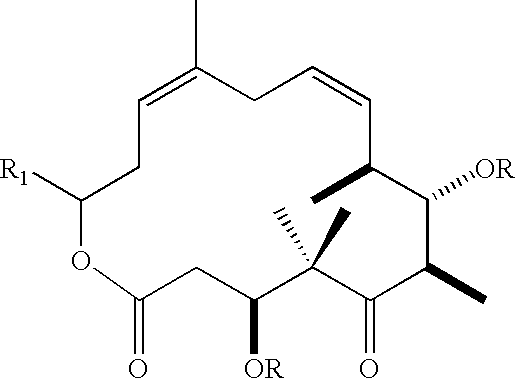

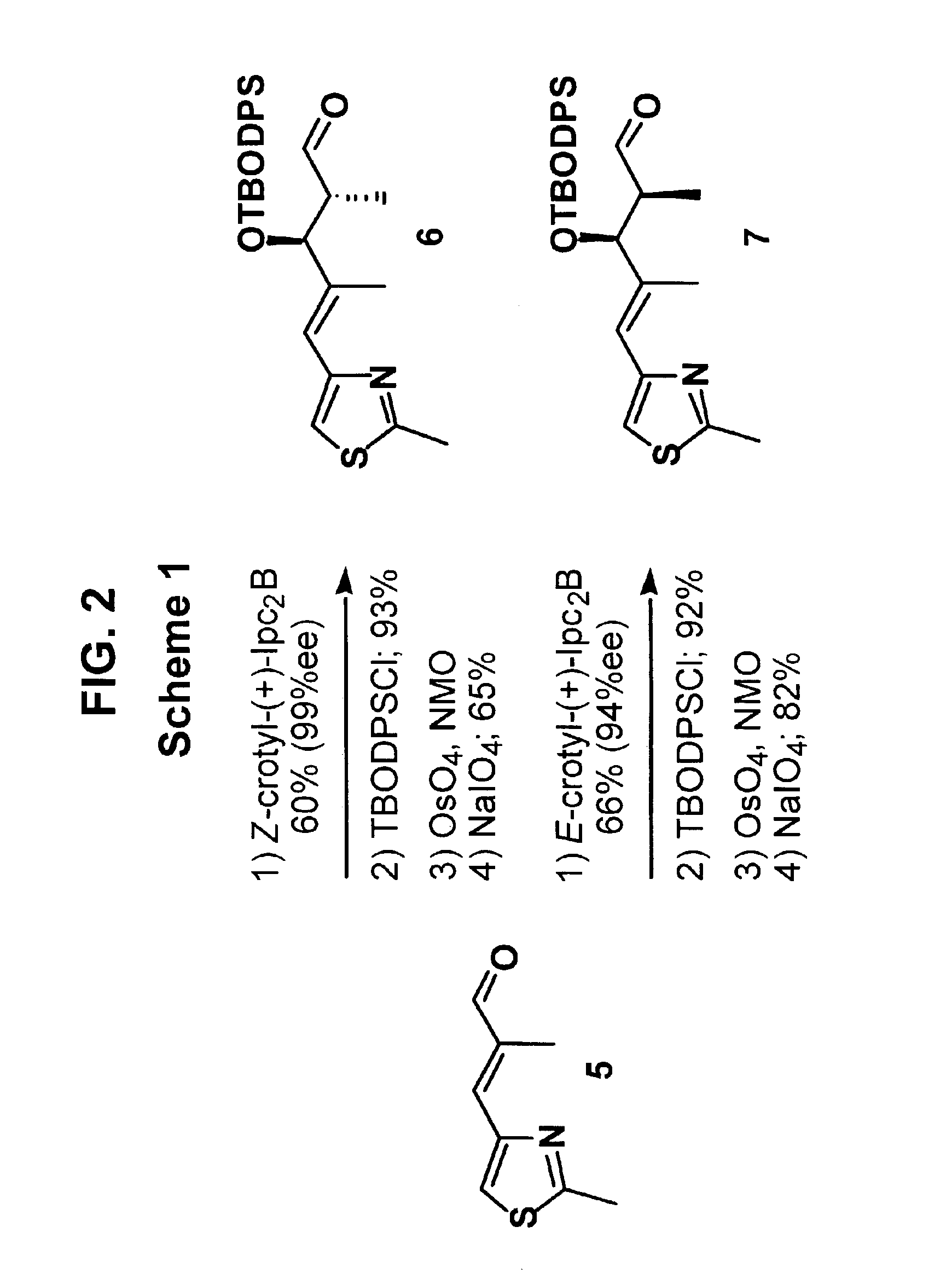

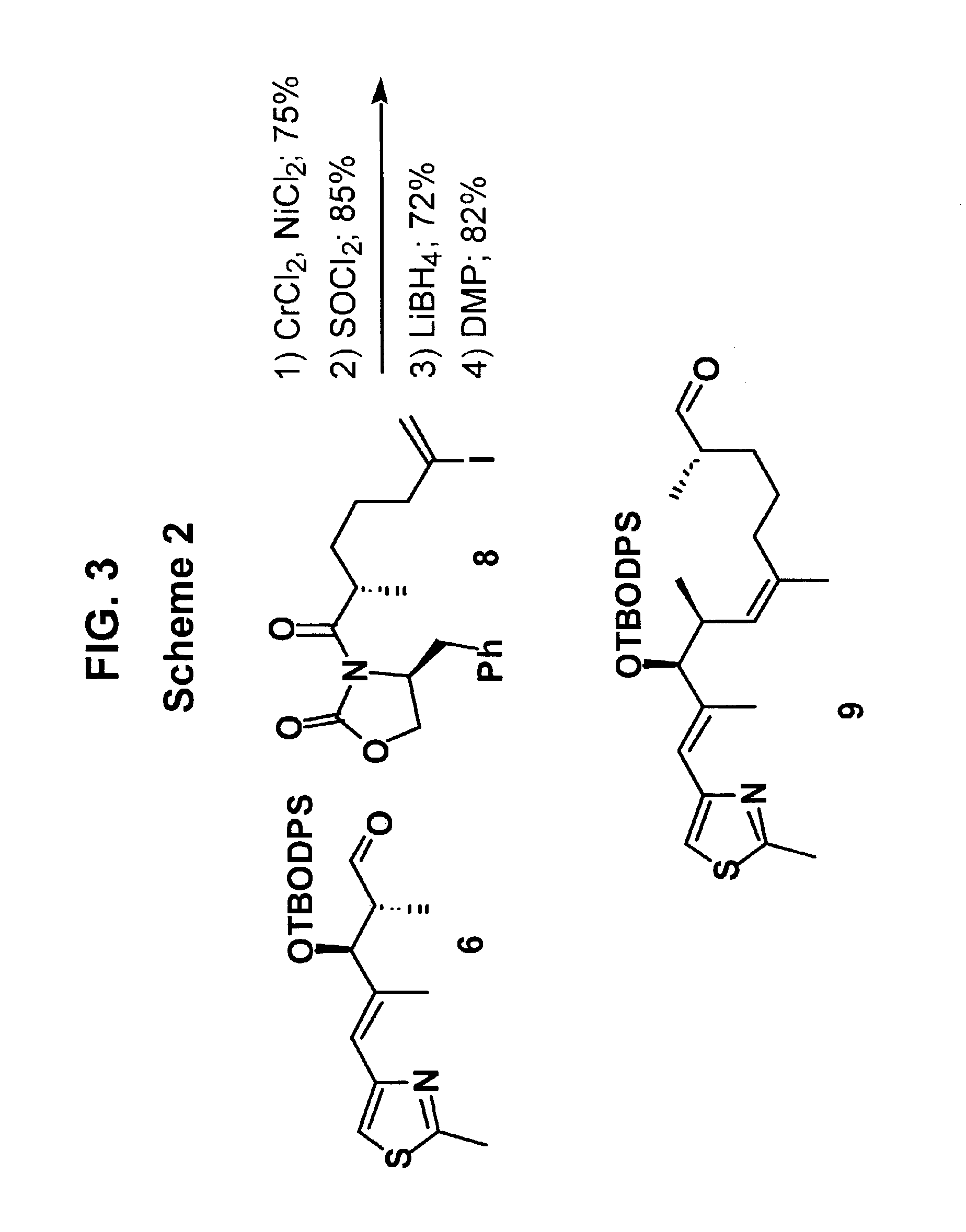

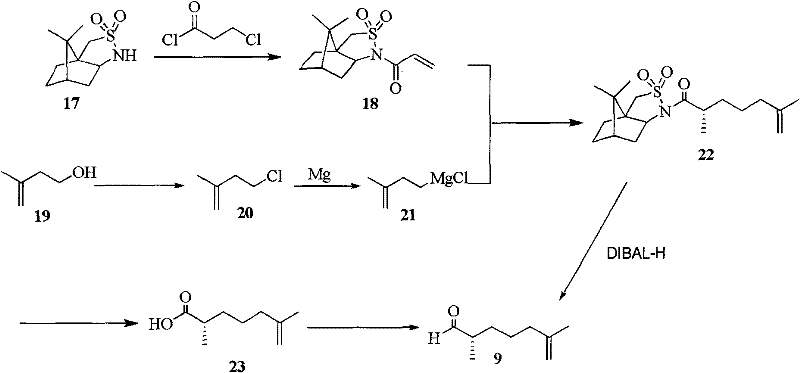

Epothilone synthesis building blocks iii and iv: asymmetrically substituted acyloins and acyloin derivatives, methods for their production and methods for the production of epothilones b, d and epothilone derivatives

InactiveUS6867333B2Lower requirementHigh yieldBiocideGroup 4/14 element organic compoundsEpothilone BEpothilone synthesis

Owner:R&D BIOPHARMLS

Method for preparing epothilones B and use thereof

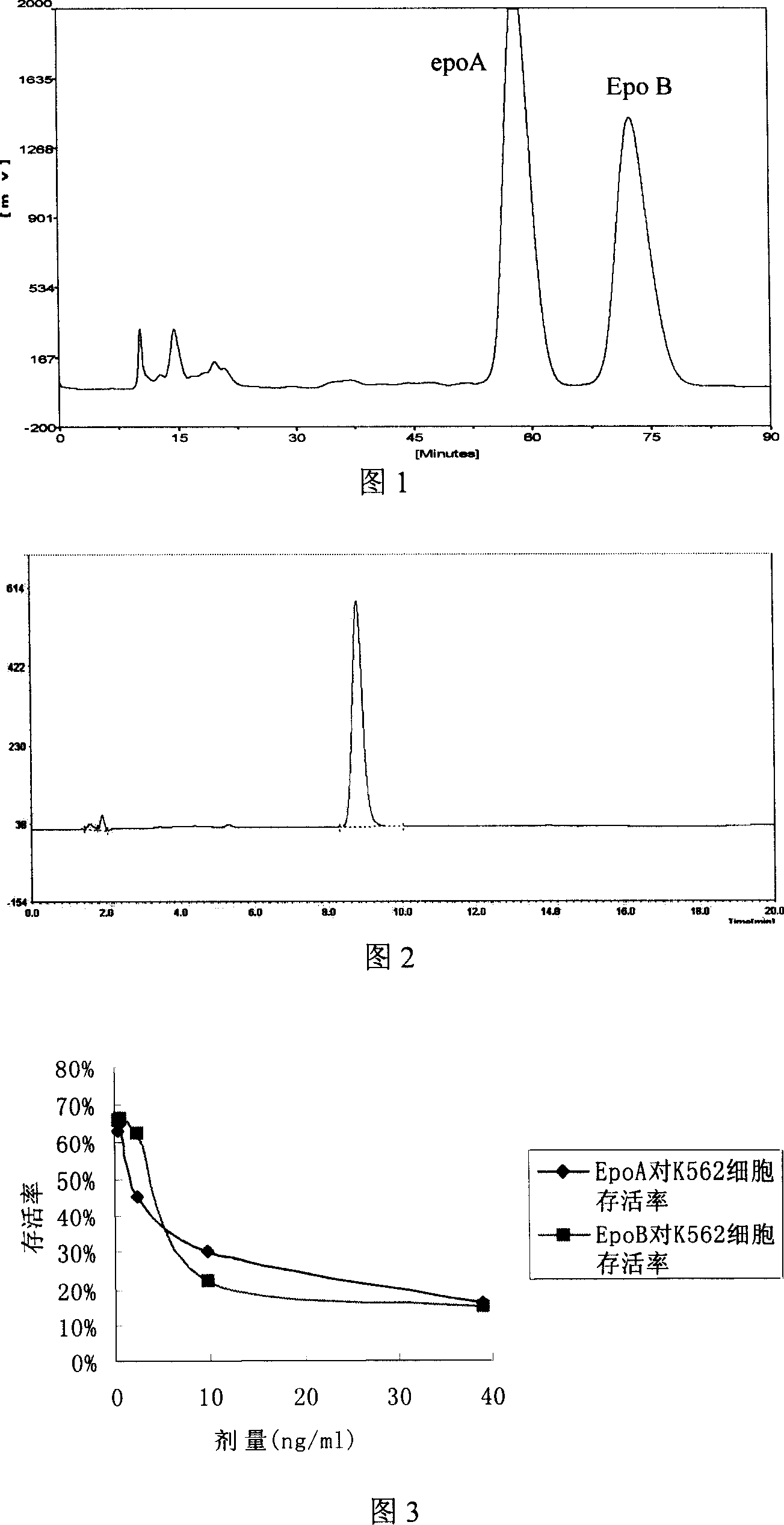

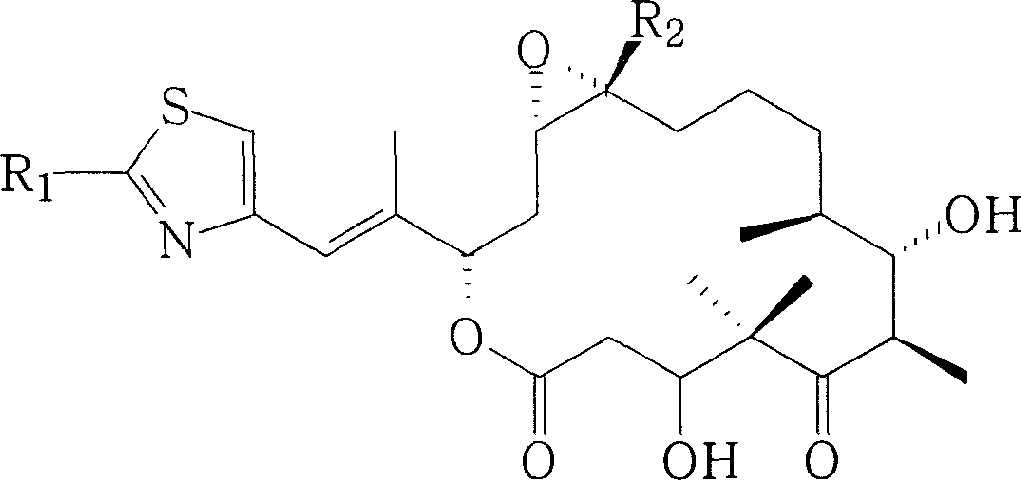

ActiveCN101104864AImprove applicabilityRealize localizationMicroorganism based processesFermentationEpothilone BMyeloid leukemia

The invention relates to a preparation method of epothilones B. In particularly, the invention provides a technique method to prepare epothilones B through adopting 100 to 500 liters fermentor to ferment and to separate epothilones B in large scale. The invention also relates to the preparation and application of epothilones B in preparation of gleevec resistance chronic myeloid leukemia treatment drug.

Owner:HUNAN DINUO PHARMA

Fermentative preparation process for and crystal forms of cytostatics

The invention relates to a new process for concentrating epothilones in culture media, a new process for the production of epothilones, a new process for separating epothilones A and B and a new strain obtained by mutagenesis for the production of epothilones, as well as aspects related thereto. New crystal forms of epothilone B are also described.

Owner:NOVARTIS AG

Fermentation production process of Epothilone B

InactiveCN102373252AIncrease productionElimination of inhibitory effectsOther chemical processesMicroorganism based processesFiberPolymer adsorbent

The invention discloses a fermentation production process of Epothilone B, i.e. a process for increasing the fermentation output of Epothilone B of Epothilone B production bacterial strain sprangium cellulosum. The process comprises the following steps: 1) adding a molecular imprinting polymer adsorbent of the Epothilone B in the fermentation process; 2) selecting soybean meal, corn starch and the like suitable for sprangium cellulosum production; and 3) adding glucose pulses in the fermentation process and the like. So the fermentation production output of the sprangium cellulosum of the epothilone B achieves 50mg / L.

Owner:SHAANXI UNIV OF SCI & TECH

Method for preparing epothilone molecularly imprinted polymer film by adopting mixed template

ActiveCN103724655AOvercome timeOvercomes the disadvantage of needing to sieveSemi-permeable membranesOrganic chemistryCross-linkFunctional monomer

The invention discloses a method for preparing an epothilone molecularly imprinted polymer film by adopting a mixed template and belongs to the technical field of molecular imprinting. The method comprises the following steps: 1, after mixing template molecule epothilone B and epothilone D, adding a functional monomer and a cross-linking agent, sufficiently and uniformly mixing to obtain a mixture, adding the mixture into a pore-foaming agent, uniformly mixing under the ultrasonic condition, standing at room temperature, then adding an initiator and uniformly mixing to obtain mixed liquid; 2, after soaking a matrix film in the mixed liquid, taking out the matrix film, placing the matrix film between two glass sheets, removing air bubbles, placing the glass sheets in a sealed bag, filling nitrogen, sealing up the bag, irradiating the bag by an ultraviolet lamp, separating the glass sheets to obtain the epothilone molecularly imprinted polymer film. The method is easy to operate; the reaction conditions are easy to control; the preparation cost is low; the film is easy to carry out readsorption and elution and has a high repeated utilization rate; not only are the defects of long polymerization time and requirement for screening of a rodlike molecularly imprinted polymer overcome, but also elution time is shortened.

Owner:SHAANXI UNIV OF SCI & TECH

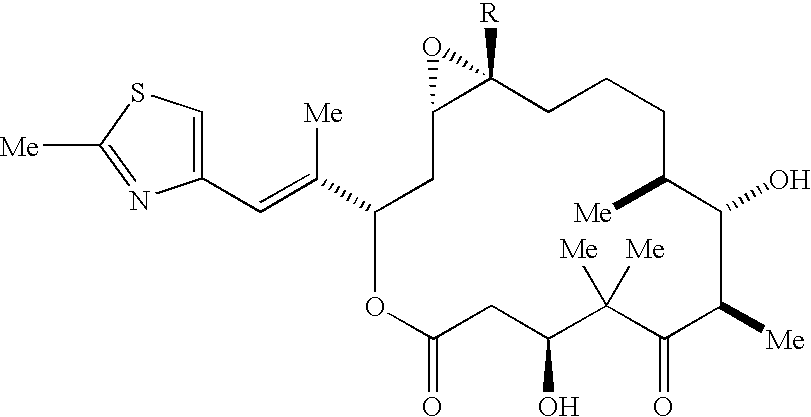

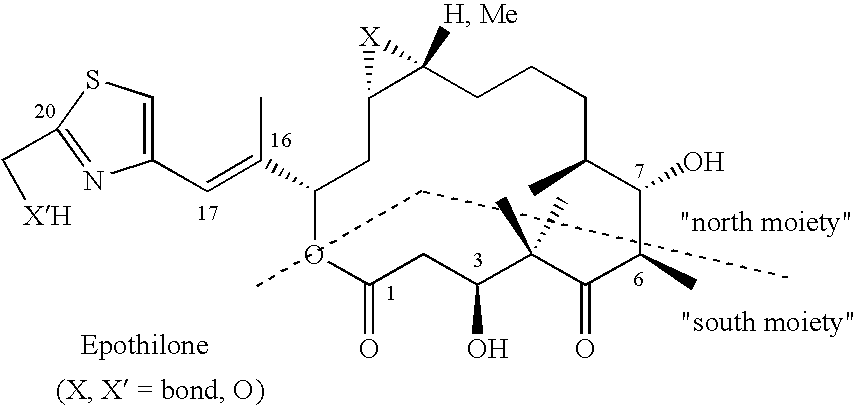

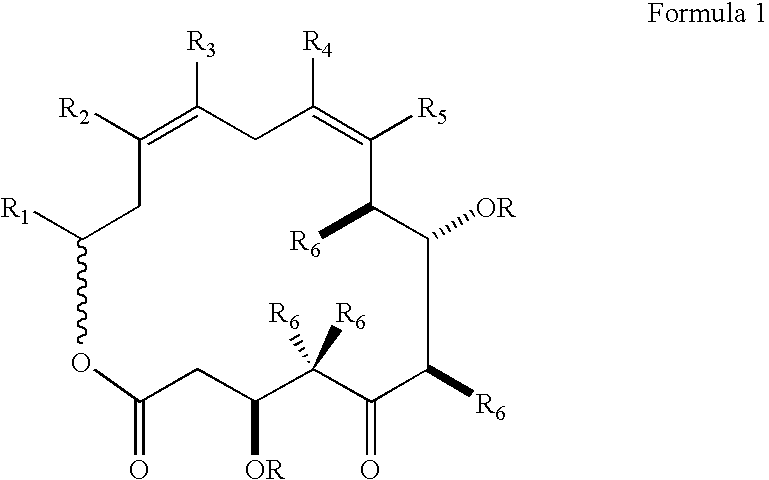

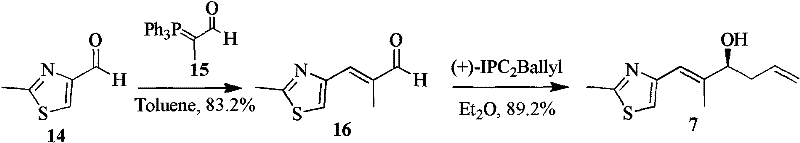

Method for synthesizing epothilones and epothilone analogs

InactiveUS20050192440A1Cell division is not possibleInhibits Nitric Oxide ProductionOrganic chemistryAntineoplastic agentsPhosphoniumEpothilone B

A method for making epothilones and epothilone analogs is described, as are novel compounds made by the method. One embodiment of the method was used to synthesize epothilone B by a convergent approach that entailed Wittig coupling of an ylide derived from phosphonium bromide with an aldehyde. The former was prepared from propargyl alcohol by a nine-step pathway which installed both trisubstituted double bonds with clean Z configuration. Macrolactonization of a resulting seco acid provided the following intermediate diene epothilone analog. Selective saturation of the 9,10-olefin and subsequent epoxidation provided epothilone B.

Owner:THE STATE OF OREGON ACTING BY & THROUGH THE OREGON STATE BOARD OF HIGHER EDUCATION ON BEHALF OF OREGON STATE UNIV

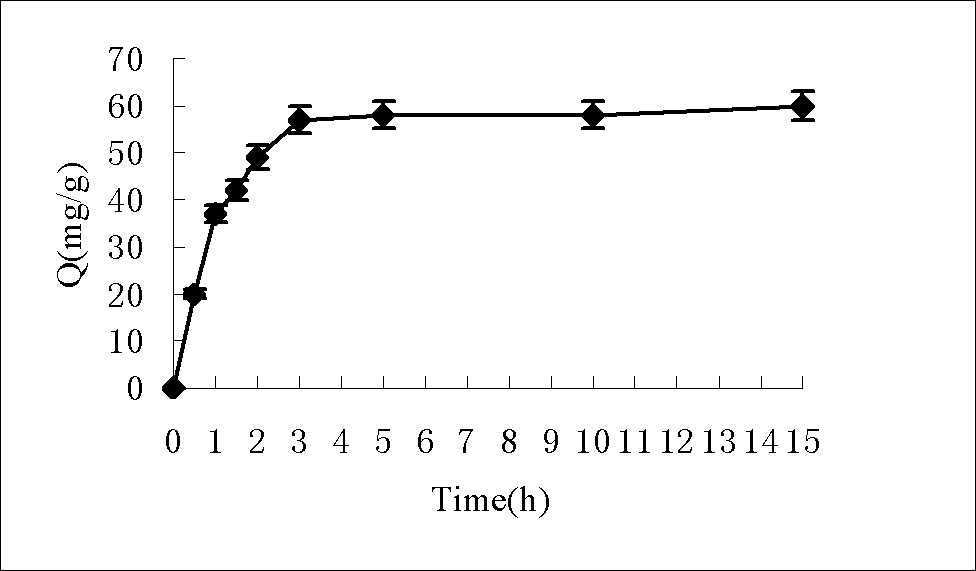

Preparation method of epothilone B molecularly imprinted polymer

InactiveCN102432753ARealize separation and purificationReduce manufacturing costCross-linkAcetic acid

The invention discloses a preparation method of an epothilone B molecularly imprinted polymer and belongs to the technical field of chemical engineering. The preparation method comprises the following specific steps of: dissolving a template molecule (epothilone B), a functional monomer, a cross-linking agent and an initiator into a pore-foaming agent according to a certain mol ratio, wherein the pore-foaming agent can be a mixed solution of methanol and acetonitrile; after reaction, grinding and sieving the obtained product to obtain particles with the particle size being about 40-60mum; fully washing the obtained particles in a mixed solution of acetic acid and methanol according to the ratio being (1: 9)-(3:7) (v:v) so as to remove the template molecule; and freezing and drying to obtain the epothilone B molecularly imprinted polymer. The epothilone B molecularly imprinted polymer prepared by the preparation method disclosed by the invention can be used for specifically and selectively adsorbing the epothilone B and has greater application value in the production process of the epothilone B by adopting a liquid fermenting method.

Owner:SHAANXI UNIV OF SCI & TECH

Method for preparing epothilone molecularly imprinted polymer by adopting mixed template

The invention discloses a method for preparing an epothilone molecularly imprinted polymer by adopting a mixed template and belongs to the technical field of molecular imprinting. The method comprises the following steps: 1, uniformly mixing epothilone B and epothilone D according to a certain proportion to obtain template molecules, adding a functional monomer and a cross-linking agent into the template molecules, uniformly mixing to form a mixture, adding the mixture into a pore-foaming agent, uniformly mixing under the ultrasonic condition, standing at room temperature, then adding an initiator and uniformly mixing to obtain mixed liquid; 2, performing the polymerization reaction on the mixed liquid at a temperature of 40 to 60 DEG C to obtain a blocky polymer, then crushing, grinding, sieving, repeatedly carrying out sedimentation by acetone, drying to obtain polymer particles, repeatedly carrying out Soxhlet extraction on the polymer particles and drying to obtain the epothilone molecularly imprinted polymer. The epothilone molecularly imprinted polymer prepared by the method has higher affinity on epothilone, has a better adsorption effect and has wide application value and market prospect.

Owner:SHAANXI UNIV OF SCI & TECH

Process for the isolation and purification of epothilones

InactiveUS6946561B2Increase volumeHigh purityOrganic active ingredientsOrganic chemistryPurification methodsEpothilone B

The invention relates to a desorption process for epothilones, especially epothilone A and / or epothilone B, from resins and new production, work-up or purification processes or manufacturing methods for epothilones comprising said desorption process, as well as the use of certain solvents for the desorption of epothilones from resins.

Owner:NOVARTIS AG

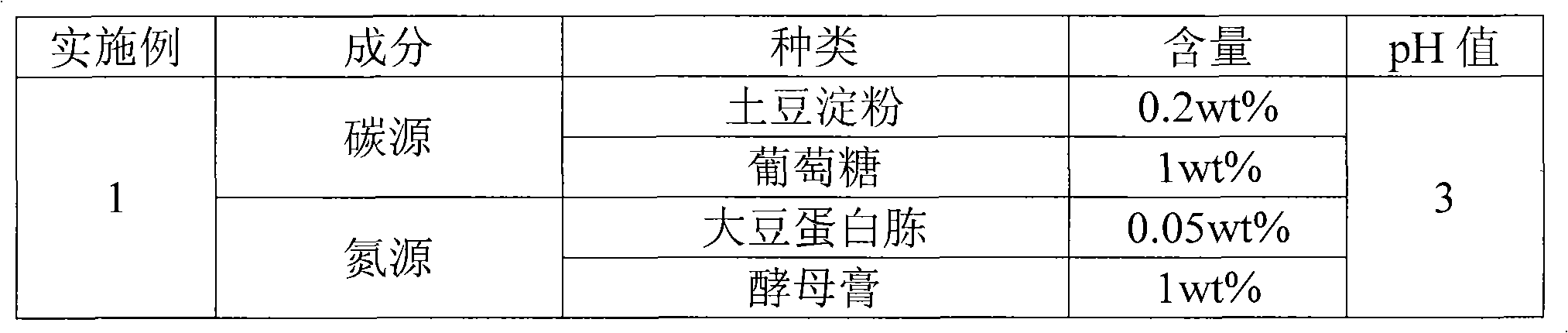

Fermentation method for producing epothilone B by sorangium cellulosum and fermentation medium

InactiveCN101851591AImprove performanceGrow fastBacteriaMicroorganism based processesInorganic saltsEpothilone B

The invention discloses a sorangium cellulosum fermentation medium, which comprises a carbon source, a nitrogen source, inorganic salts, a macroporous absorption resin, and water. The fermentation medium also comprises amino acid. When the fermentation medium is used for preparing the epothilone B by fermentation culture of sorangium cellulosum, the performance of strains is stable, the growth is rapid, and the yield of the product epothilone B is obviously improved. The invention also provides a fermentation method for producing the epothilone B by the fermentation culture of the sorangium cellulosum by using the sorangium cellulosum fermentation medium.

Owner:SHANGHAI INST OF PHARMA IND

Method for separation and extraction of epothilone B from sorangium cellulosum fermentation liquid

ActiveCN103667387APromote growthIncrease productionOrganic chemistryMicroorganism based processesDesorptionEthyl acetate

The invention provides a method for separation and extraction of epothilone B from a sorangium cellulosum fermentation liquid, and belongs to the microbial fermentation pharmacy field. The method comprises the steps: after shake-flask cultivation of sorangium cellulosum strains, amplifying step by step, fermenting sorangium cellulosum, followed by carrying out macroporous resin adsorption, ethyl acetate desorption and methanol redissolution, and thus obtaining a crude product; carrying out column chromatography and HPLC analysis of the crude product to obtain a preliminary component of epothilone B, then adding a molecularly imprinted polymer for specific adsorption of epothilone B, and finally carrying out methanol elution and crystallization to obtain epothilone B. Sorangium cellulosum is produced by step-by-step fermentation, and at the same time, the molecularly imprinted polymer with the specific targeted adsorption capacity is adopted in the separation and extraction process, not only has a strong adsorption capacity on epothilone B, but also can easily extract epothilone B, so as to reduce the extraction cost of separation and extraction of epothilone drugs, and have more wide industrialized application prospects and economic benefits.

Owner:SHAANXI UNIV OF SCI & TECH

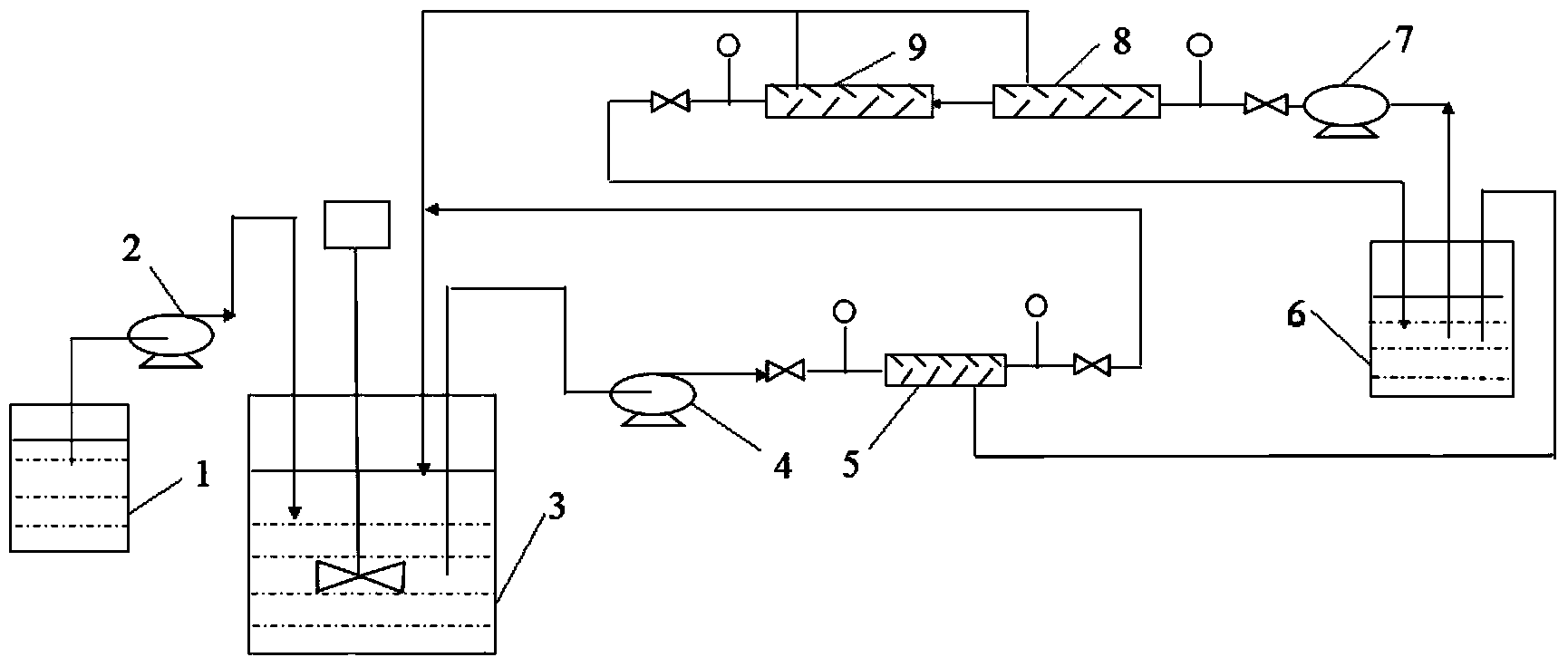

Method for producing epothilone B based on coupling of microbial fermentation and membrane separation techniques

InactiveCN103937851AImprove fermentation yieldReduce inhibitionOrganic chemistryMicroorganism based processesFiltration membraneSeparation technology

The invention discloses a method for producing epothilone B based on coupling of microbial fermentation and membrane separation techniques. The invention proposes a separation and fermentation coupling method mainly aiming at the problems that toxicity and feedback inhibition on cells are generated due to increase of a product epothilone B in the fermentation process, and bacteria growth in the fermentation process is affected. The method comprises the following steps: fermenting and cultivating, filtering by a micro-filtration membrane, carrying out ultrafiltration and nanofiltration, feeding materials, concentrating and extracting. The concentration of the fermentation liquor product epothilone B is reduced to a lower level, the growth inhibition action on the strain is relieved, the yield of the epothilone B is improved, the production cost is reduced, post-treatment of a fermentation liquor and refining of the product are facilitated, and large-scale production becomes possible, so that the method has a good industrial production prospect.

Owner:SHAANXI UNIV OF SCI & TECH

A method for producing epothilone b

ActiveCN106834377BQuality improvementPromote growthBacteriaMicroorganism based processesBiotechnologyPropanoic acid

The invention concretely discloses a fermentation method for producing epothilone B, and belongs to the field of biological fermentation. According to the method, during culturing of a seeding tank, ammonia hydroxide is added in a flowing mode to adjust the pH value, so that a lot of seed thalli are obtained; during fermentation, ammonia hydroxide or propanoic acid is added in a flowing mode to regulate the pH value, in this way, the yield of the epothilone B is increased, the regulation procedures are simplified, production cost is lowered, industrialized production is easy, and application prospects are good.

Owner:LUNAN BETTER PHARMA

Epothilone B separating and extracting method based on membrane filtration technology

The invention relates to an epothilone B separating and extracting method based on a membrane filtration technology. The method comprises the following steps: adsorbing a fermentation liquid by using a macroporous resin; then leaching the absorbed macroporous resin by using ethyl acetate and collecting a leaching liquid; filtering the leaching liquid by using an ultrafiltration membrane; washing and filtering the leaching liquid by using the ethyl acetate; combining filtrates; concentrating; performing detection through preparative HPLC (High Performance Liquid Chromatography); and crystallizing the epothilone B component obtained in a separating manner, thereby obtaining the epothilone B. The method is moderate in condition, simple and convenient to operate, few in separating steps and good in selectivity, and can be used for obviously increasing the yield of the epothilone B, thereby providing conditions more favorable for industrial production. The method with combination of membrane filtration and crystallization is adopted, so that a part of macromolecular impurities can be effectively removed; meanwhile, the application of an organic reagent is avoided, so that the industrial production pollution is reduced. Thus, the loss of the epothilone B in other complicated preparation processes is avoided. The epothilone B prepared in a crystallization manner has relatively high purity. Thus, the epothilone B is broad in application prospect and economic benefit.

Owner:SHAANXI UNIV OF SCI & TECH

Method for producing epothilone B

ActiveCN106834377AIncrease contentEasy to operateBacteriaMicroorganism based processesEpothilone BPropynoic acid

The invention concretely discloses a fermentation method for producing epothilone B, and belongs to the field of biological fermentation. According to the method, during culturing of a seeding tank, ammonia hydroxide is added in a flowing mode to adjust the pH value, so that a lot of seed thalli are obtained; during fermentation, ammonia hydroxide or propanoic acid is added in a flowing mode to regulate the pH value, in this way, the yield of the epothilone B is increased, the regulation procedures are simplified, production cost is lowered, industrialized production is easy, and application prospects are good.

Owner:LUNAN BETTER PHARMA

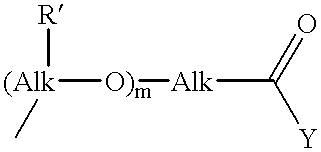

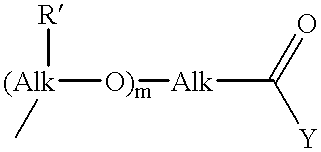

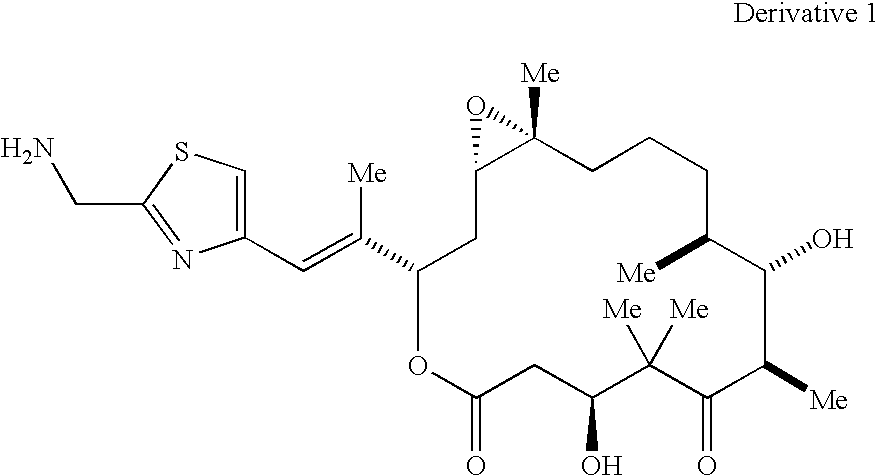

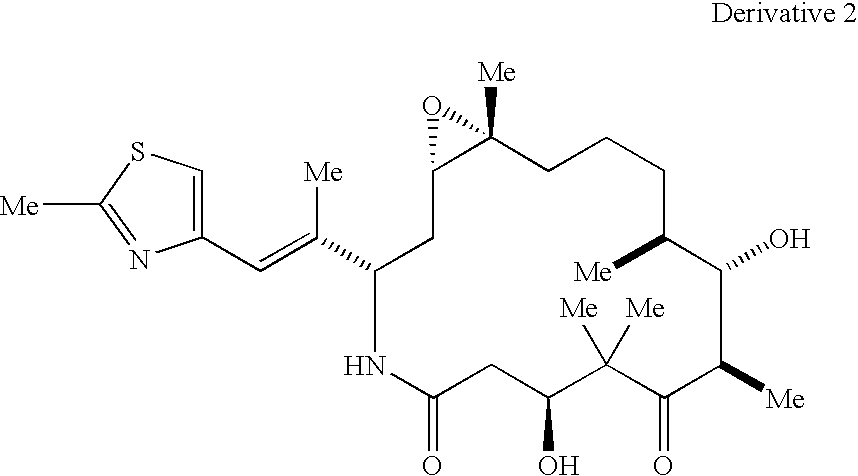

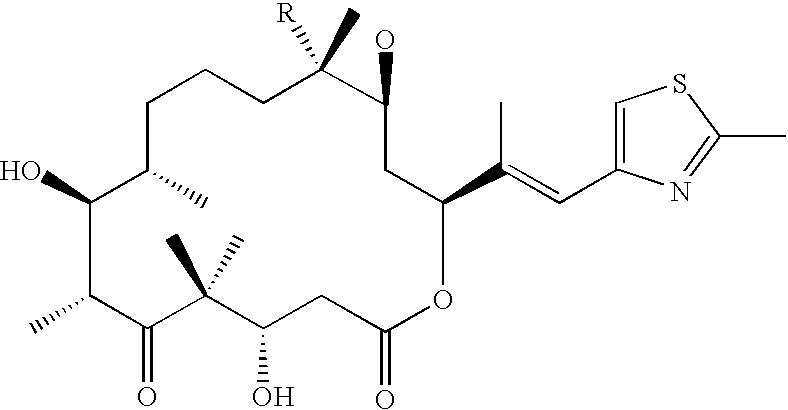

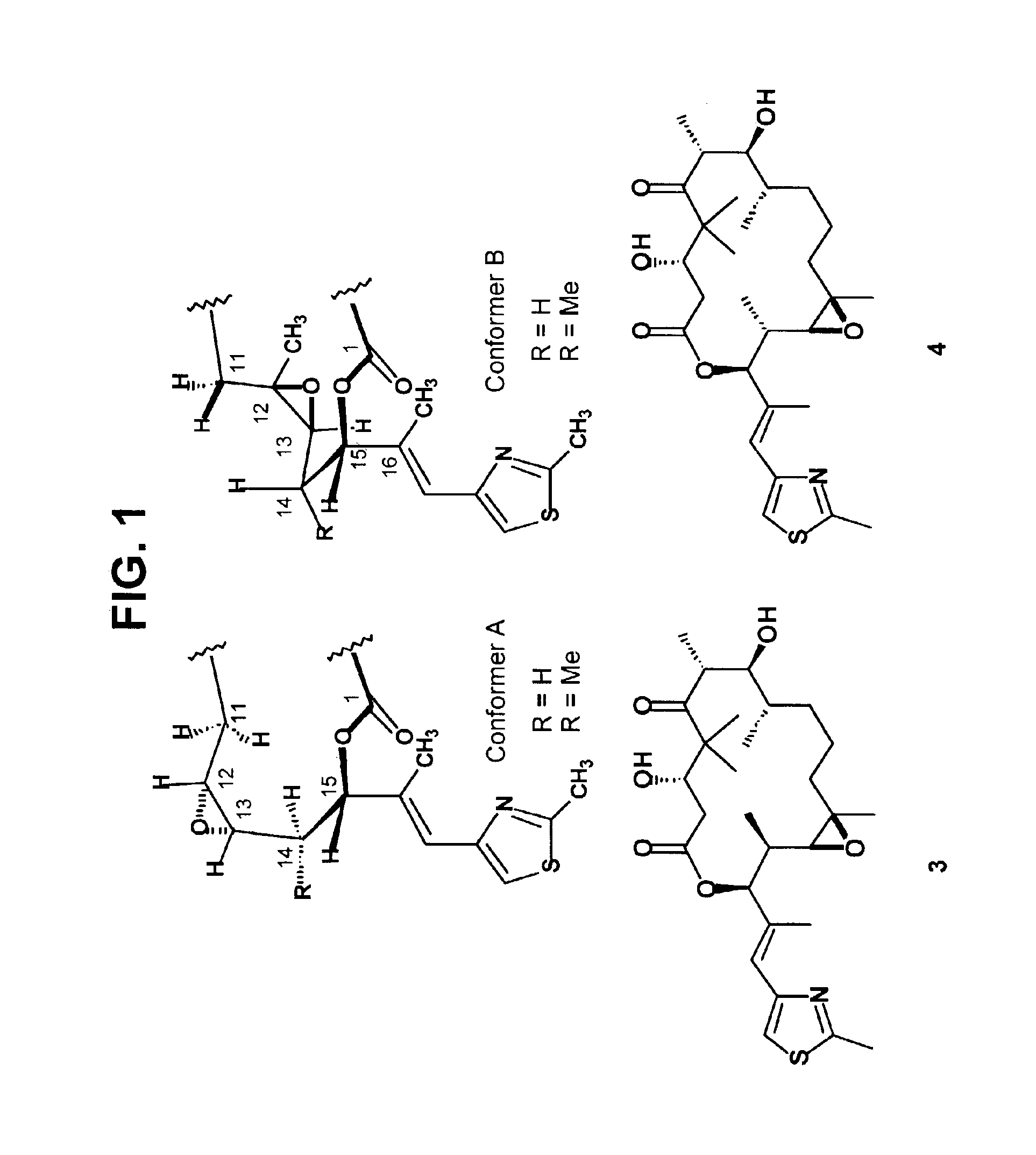

Derivatives of epothilone B and D and synthesis thereof

The present invention provides the following new compounds: (R)-C14-methyl-epothilone B, (S)-C14-methyl-epothilone B, (S)-C14-methyl-epothilone D, and (R)-C14-methyl-epothilone D and methods for synthesizing these compounds.

Owner:UNIV OF NOTRE DAME DU LAC

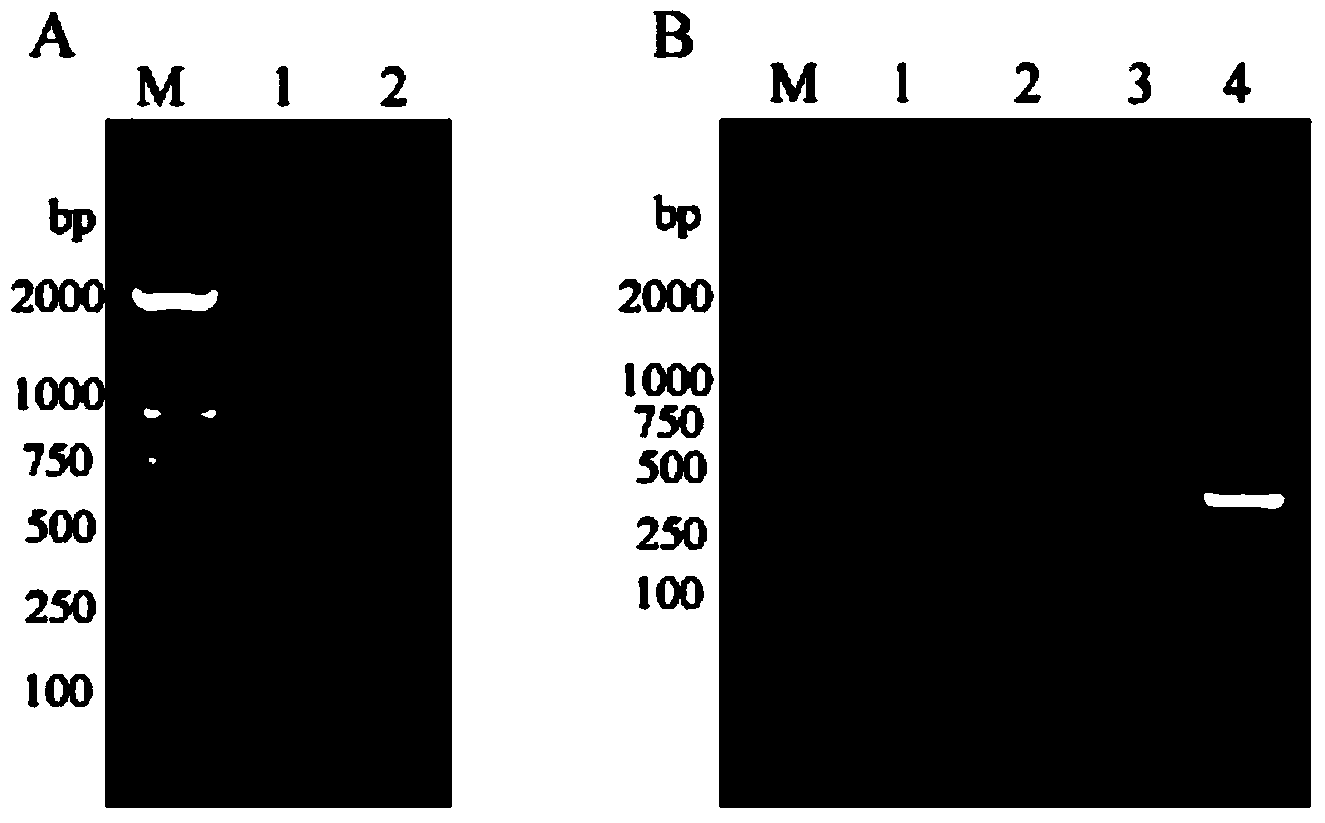

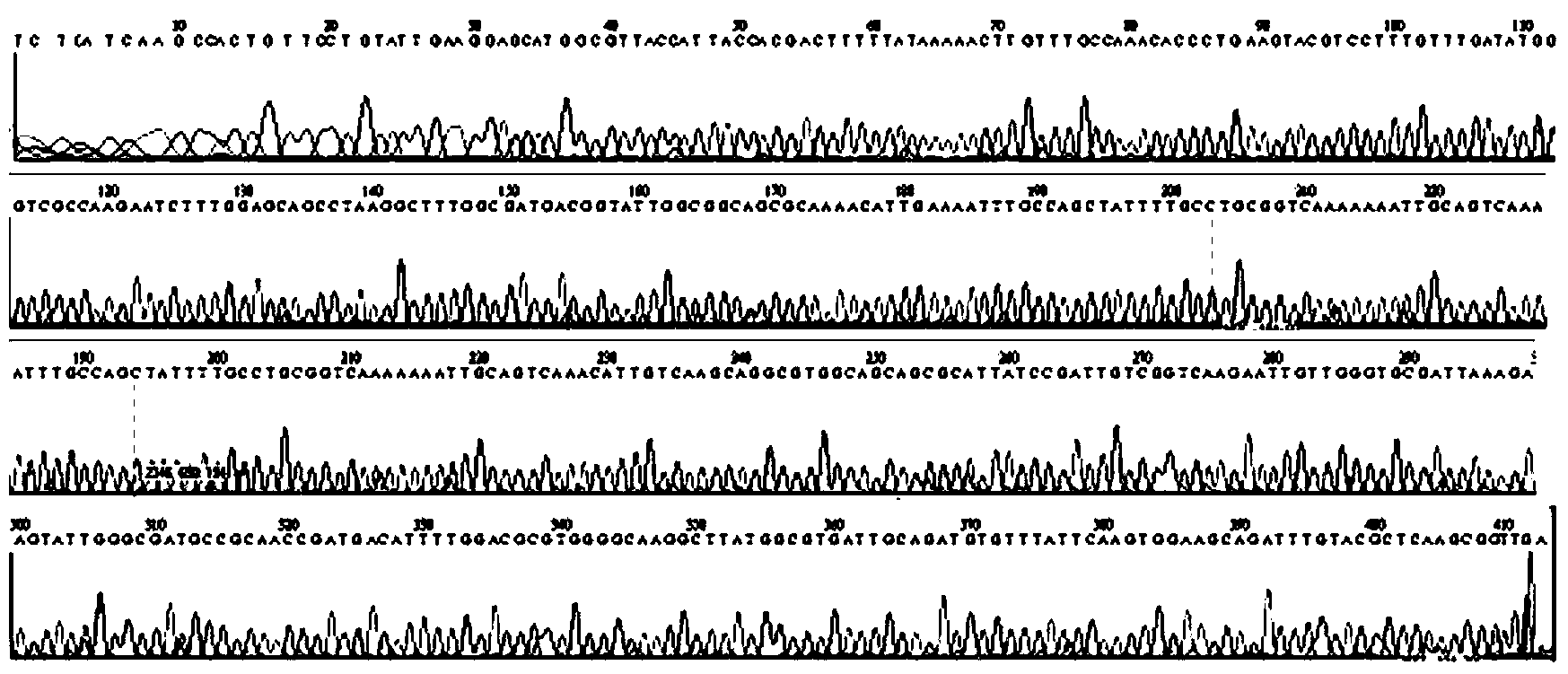

Method for improving sorangium cellulosum's epothilone B yield by genetic engineering

InactiveCN103834707AIncrease productionMicroorganism based processesFermentationBiotechnologyEpothilone B

The invention discloses a method for improving sorangium cellulosum's epothilone B yield by genetic engineering. The method includes: introducing a Vitreoscilla hemoglobin gene vgb into an expression vector PBEP43 to obtain a recombinant plasmid PBEP43-vgb, and then subjecting the recombinant plasmid PBEP43-vgb to electrotransformation into sorangium cellulosum So ce M4, thus obtaining a sorangium cellulosum So ce M4 recombinant strain, and realizing improving the sorangium cellulosum So ce M4's epothilone B yield. According to the invention, the electrotransformation method is employed to transform the gene of sorangium cellulosum So ce M4, thereby greatly improving the yield of epothilone B. The method provided by the invention has broad application prospects, and research in the aspect is not reported to date.

Owner:GUANGDONG INST OF MICROORGANISM

Epothilone B purification method

The invention relates to an improved method for epothilone B extraction and purification, and belongs to the technical field of biological separation. According to the method, most of impurities are removed by a low-temperature refrigeration method, solid-liquid separation is achieved by changing density, the purity of finished products is further improved by a two-time crystal method, rate-limiting steps such as silica-gel column chromatography are decreased, an epothilone B extraction process is simplified, operation cost is reduced, and the method has a wider application prospect.

Owner:LUNAN PHARMA GROUP CORPORATION

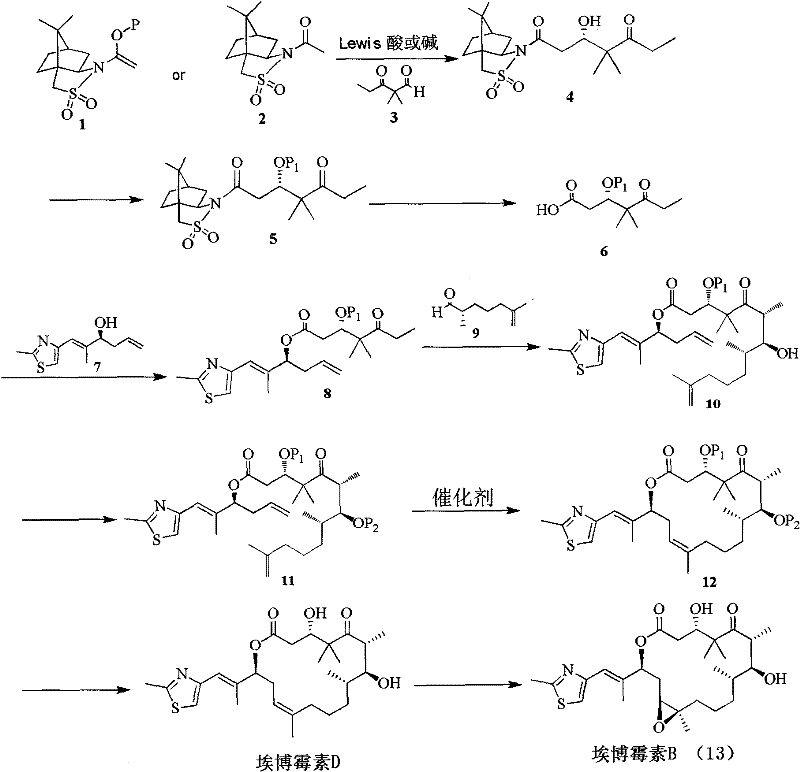

Method for preparing epothilone D and B

InactiveCN102633792AHigh reaction yieldEasy to operateOrganic compound preparationCarboxylic compound preparationEpothilone BCarboxylic acid

The invention relates to a preparation method of epothilone D and B, which comprises the following steps: reacting carboxylic acid (6) and hydroxyl compound (7) to obtain an ester (8), reacting with a key intermediate (9) in an Aldol mode to obtain a compound (10), carrying out hydroxy protection with proper protective group to obtain a compound (11), carrying out RCM reaction to close the cycle to obtain a compound (12), removing the hydroxy protective group to obtain the compound epothilone D, and epoxidating to obtain the epothilone B.

Owner:ACCENDATECH

Epothilone B separating and extracting method based on molecularly imprinted membrane filtering technology

ActiveCN103772406ASmooth and fastEfficient removalOrganic chemistryFermentationFiltration membraneUltrafiltration

The invention discloses an epothilone B separating and extracting method based on the molecularly imprinted membrane filtering technology. The method comprises the following steps: fermentation liquid is adsorbed by macroporous resin and resolved by ethyl acetate to obtain a crude product; the crude product is filtered by a micro-filtration membrane and an ultrafiltration membrane to remove macromolecules and other impurities; filtrate is filtered by the epothilone B molecularly imprinted membrane to obtain pure epothilone B liquid; and finally, the pure epothilone B liquid is obtained through crystallization. The method is convenient for continuous operation, is easy to enlarge, simple to operate, low in cost and high in selectivity, can rapidly separate the epothilone B molecules from a mixture of structural analogues, and can be put into industrial production easily.

Owner:SHAANXI UNIV OF SCI & TECH

A method based on porous ceramic adsorption and immobilization of S. cellulosus fermentation

InactiveCN103045675BHelps relieve feedback inhibitionReduce manufacturing costMicroorganism based processesFermentationFiberMicroorganism

The invention discloses a method for absorbing and fixing sorangium cellulosum for fermentation based on porous ceramics and belongs to the field of microbial fermentation pharmacy. The method comprises the steps that the prepared porous ceramics are processed by fermentation liquid to be dried for stand-by application; after sorangium cellulosum is cultivated through an M26 solid and a liquid medium respectively, bacterium suspension is formed; and after dilution, the bacterium suspension is inoculated in the fermentation liquid, the processed porous ceramics are added into the fermentation liquid, and shake cultivation is performed. The method for absorbing and fixing an epothilone production bacterial strain based on kieselguhr-based porous ceramics is provided by the invention, when epothilone B is in the fermentation production, sorangium cellulosum, which is the production bacterial strain of the epothilone B, is fixed, so that a solid attachment surface can be provided for a slime bacteria cell growing in a liquid environment, the method has the advantages that the fermentation production yield can be increased, the production cost of epothilone which is an anti-tumor medicine is lowered, and the operation steps are simple and easy to implement, therefore, the method can be amplified to the industrial production and establishes an experimental basis for the industrial production of epothilone.

Owner:SHAANXI UNIV OF SCI & TECH

A method for separating and extracting epothilone b based on membrane filtration technology

The invention relates to an epothilone B separating and extracting method based on a membrane filtration technology. The method comprises the following steps: adsorbing a fermentation liquid by using a macroporous resin; then leaching the absorbed macroporous resin by using ethyl acetate and collecting a leaching liquid; filtering the leaching liquid by using an ultrafiltration membrane; washing and filtering the leaching liquid by using the ethyl acetate; combining filtrates; concentrating; performing detection through preparative HPLC (High Performance Liquid Chromatography); and crystallizing the epothilone B component obtained in a separating manner, thereby obtaining the epothilone B. The method is moderate in condition, simple and convenient to operate, few in separating steps and good in selectivity, and can be used for obviously increasing the yield of the epothilone B, thereby providing conditions more favorable for industrial production. The method with combination of membrane filtration and crystallization is adopted, so that a part of macromolecular impurities can be effectively removed; meanwhile, the application of an organic reagent is avoided, so that the industrial production pollution is reduced. Thus, the loss of the epothilone B in other complicated preparation processes is avoided. The epothilone B prepared in a crystallization manner has relatively high purity. Thus, the epothilone B is broad in application prospect and economic benefit.

Owner:SHAANXI UNIV OF SCI & TECH

A method for the separation and extraction of epothilone b based on molecular imprinting adsorption technology

ActiveCN103788105BAchieve the purpose of separationSimple and fast operationOrganic chemistryFermentationEthyl acetateMacroporous resin

The invention provides a separation and extraction method for epothilone B based on a molecular imprinting adsorption technology. The separation and extraction method comprises the following steps: adopting macroporous resin to adsorb fermented liquid; then extracting the adsorbed macroporous resin by using ethyl acetate; filtering extracting liquid by using an ultra-filtering membrane to obtain a crude extract; adding an epothilone B molecular imprinting polymer into the crude extract to specifically adsorb the epothilone B; vibrating on a shaking table, and centrifuging and collecting lower-layer sediment; eluting the sediment by using methanol for a plurality of times and collecting eluting liquid; re-crystallizing to obtain the epothilone B. The separation and extraction method has the characteristics of simplicity and convenience in operation, good selectivity, low pollution and the like. The separation and extraction method is simple and feasible in operation steps, few in separation steps, low in cost and high in yield; the loss of the epothilone B in other complicated preparation flows is avoided; more importantly, the separation and extraction method is convenient for industrial large-scale production and has very wide application prospect and economic benefits.

Owner:SHAANXI UNIV OF SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com