Epothilone B separating and extracting method based on molecularly imprinted membrane filtering technology

A molecularly imprinted membrane and epothilone technology, applied in organic chemistry, fermentation, etc., to achieve good application prospects, facilitate industrialized large-scale production, and good selectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

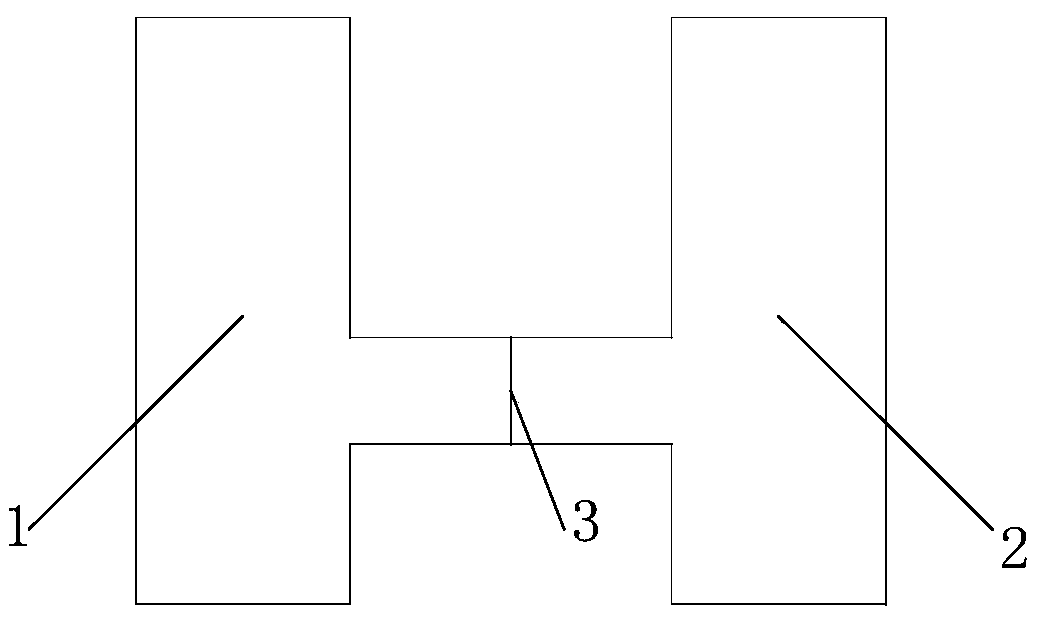

Image

Examples

Embodiment 1

[0026] (1) Adsorption of the resin to the fermentation broth: Ferment S. cellulosus ATCC25532 in the liquid medium, and add the treated macroporous resin XAD-16 to the liquid medium. The macroporous resin XAD-16 exists in the whole In the fermentation process, the adsorption resin is obtained by filtering after 120 hours of fermentation;

[0027] Wherein, the addition amount of macroporous resin XAD-16 is 2% of the volume of liquid medium;

[0028] The macroporous resin XAD-16 is processed by the following method: First, soak the macroporous resin XAD-16 with 3 times the volume of the macroporous resin XAD-16 in methanol, shake the shaker for 12 hours, remove the methanol solution, and wash the macroporous resin with pure water XAD-16 until there is no smell of methanol; after soaking in methanol for 12 hours, wash with pure water until there is no smell of methanol;

[0029] The composition of the liquid medium is potato starch 2.5-3.0g / L, sucrose 0.7-1.0g / L, glucose 0.2-0.5...

Embodiment 2

[0038] (1) Adsorption of the resin to the fermentation broth: ferment S. cellulosus ATCC25569 in a liquid medium, and add the treated macroporous resin XAD-16 to the liquid medium, and the macroporous resin XAD-16 exists in the whole In the fermentation process, after 150 hours of fermentation, the adsorption resin is obtained by filtration.

[0039] Wherein, the addition amount of macroporous resin XAD-16 is 3% of the volume of liquid medium;

[0040] The macroporous resin XAD-16 is processed by the following method: First, soak the macroporous resin XAD-16 with 3 times the volume of the macroporous resin XAD-16 in methanol, shake the shaker for 12 hours, remove the methanol solution, and wash the macroporous resin with pure water XAD-16 until there is no smell of methanol; after soaking in methanol for 12 hours, wash with pure water until there is no smell of methanol;

[0041] The composition of the liquid medium is potato starch 2.5-3.0g / L, sucrose 0.7-1.0g / L, glucose 0.2...

Embodiment 3

[0050] (1) Adsorption of the resin to the fermentation broth: Ferment S. cellulosus ATCC25532 in a liquid medium, and add the treated macroporous resin XAD-16 to the liquid medium. The macroporous resin XAD-16 exists throughout the fermentation In the flow process, the adsorption resin is obtained by filtering after 130 hours of fermentation;

[0051] Wherein, the addition of macroporous resin XAD-16 is 5% of the volume of liquid medium;

[0052] The macroporous resin XAD-16 is processed by the following method: First, soak the macroporous resin XAD-16 with 3 times the volume of the macroporous resin XAD-16 in methanol, shake the shaker for 12 hours, remove the methanol solution, and wash the macroporous resin with pure water XAD-16 until there is no smell of methanol; after soaking in methanol for 12 hours, wash with pure water until there is no smell of methanol;

[0053] The composition of the liquid medium is potato starch 2.5-3.0g / L, sucrose 0.7-1.0g / L, glucose 0.2-0.5g / ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com