Rolling type automatic tipping cargo box

An automatic flipping and rolling technology, which is applied in the direction of tilting and carrying vehicles, can solve the problems of tricycle power consumption, slow unloading speed, and low work efficiency, and achieve high work efficiency, stable speed, and fast speed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

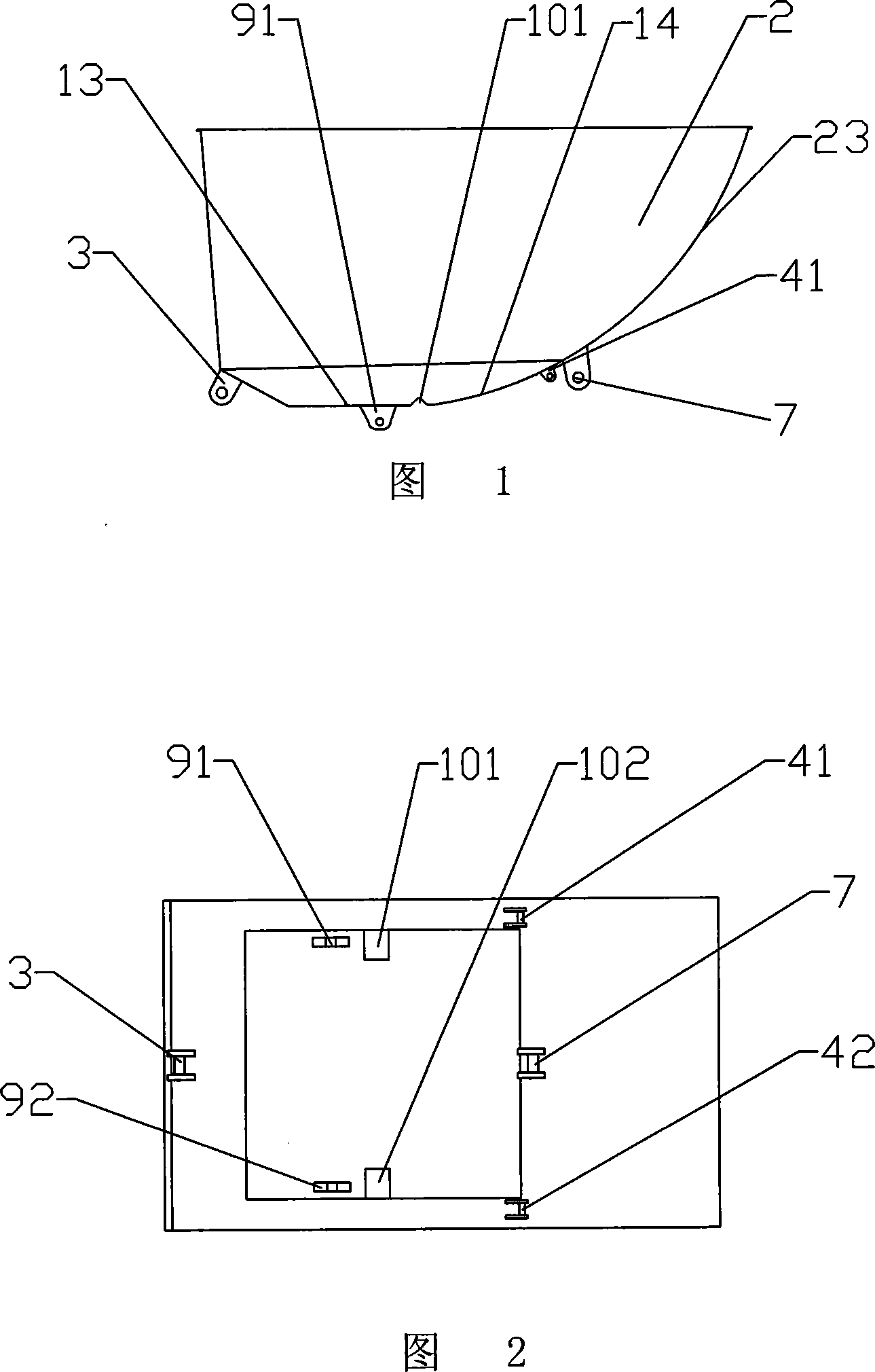

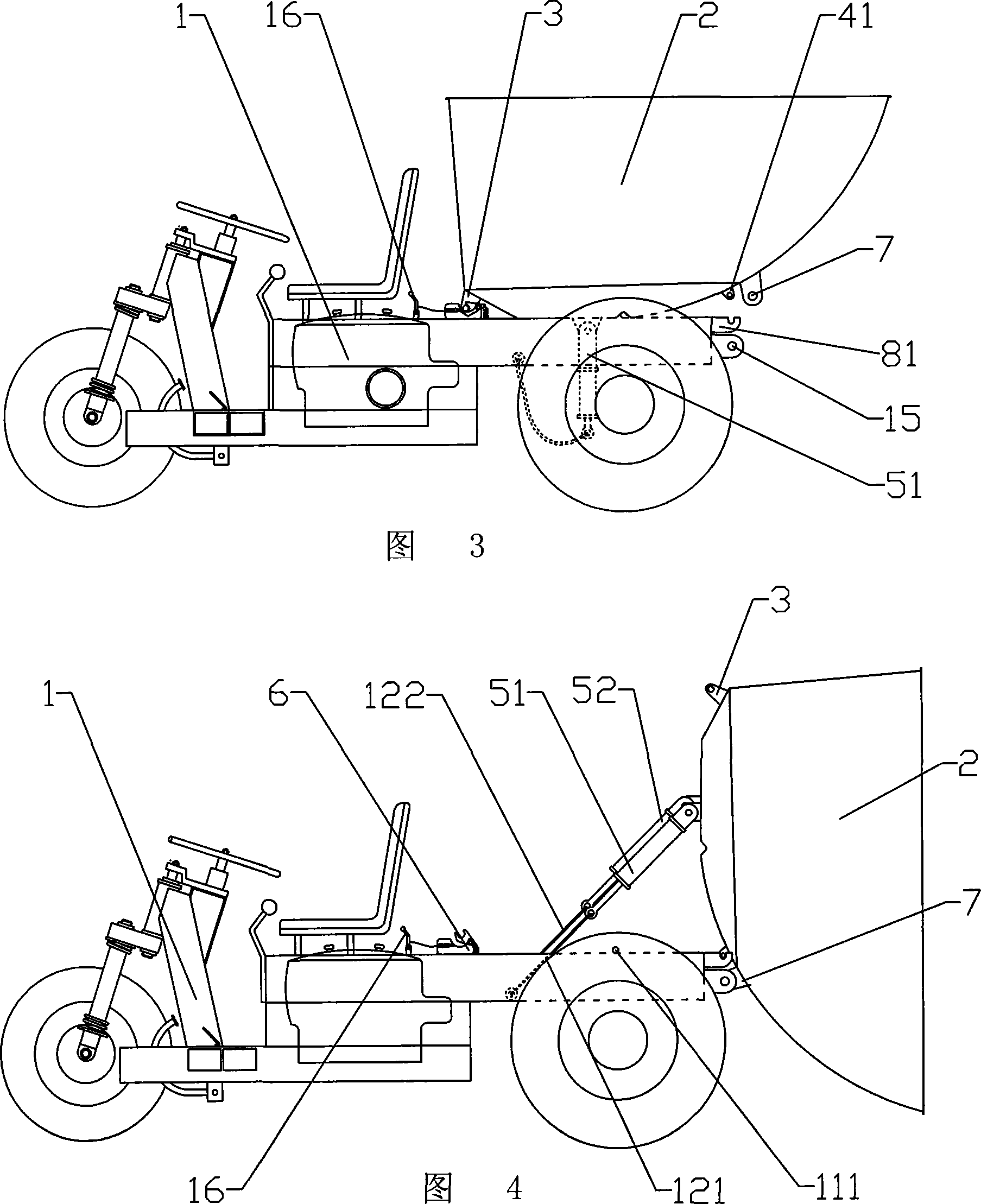

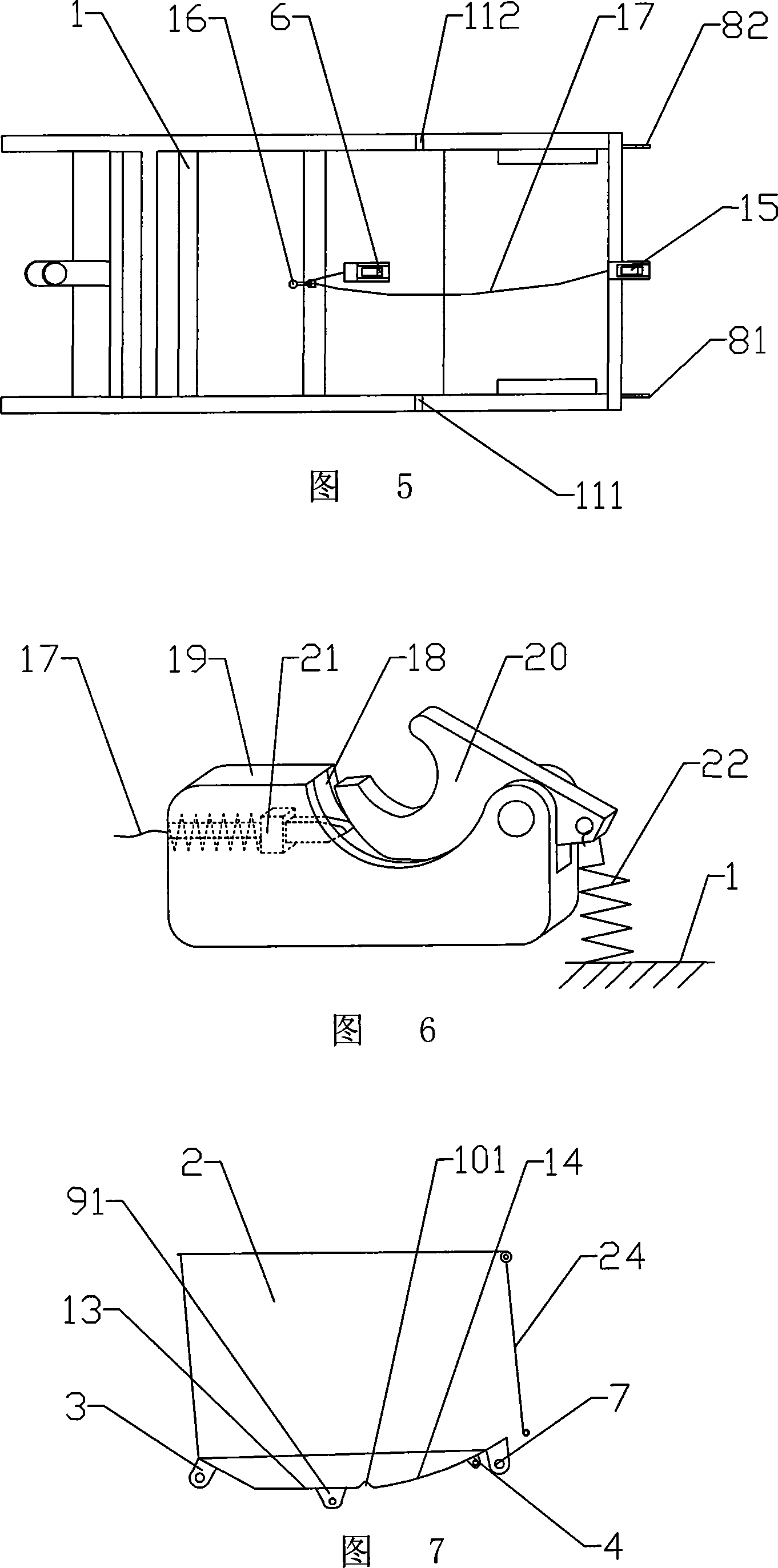

[0025] Embodiment 1, as shown in Figure 1 and Figure 2, the rolling type automatically turns over the cargo compartment, the cargo compartment 2 is composed of a front baffle, a rear baffle, a left baffle, a right baffle, and a base plate, and the base plate of the cargo compartment 2 is provided with Groove 101, groove 102 perpendicular to the driving direction, the bottom plate in front of groove 101, groove 102 is flat bottom plate 13, the bottom plate behind groove 101, 102 is curved bottom plate 14, and the center of gravity of cargo compartment 2 is positioned at The rear portion of the groove 101 and the groove 102, the tailgate 23 of the cargo compartment 2 is an arc-shaped baffle plate, and the arc-shaped bottom plate 14 at the rear portion of the cargo compartment 2 is provided with a support rod 41, a support rod 42, and the front end of the cargo compartment 2 The front locking nose 3 is provided, the rear locking nose 7 is provided at the rear, and the flat bottom ...

Embodiment 2

[0029] Embodiment 2, as shown in Figure 7, the upper part of the tailgate 24 of the cargo compartment 2 is hingedly connected with the left and right baffles respectively, and the lower part of the tailgate is movably connected with the left and right baffles respectively, and the rest of the structure is the same as that of embodiment 1. same.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com