Sliding loading machine

A skid steer loader and hinged technology, which is applied to earth movers/shovels, mechanically driven excavators/dredgers, construction, etc. problems, to achieve the effect of increasing the maintenance area, shortening the width of the machine, and reliable work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

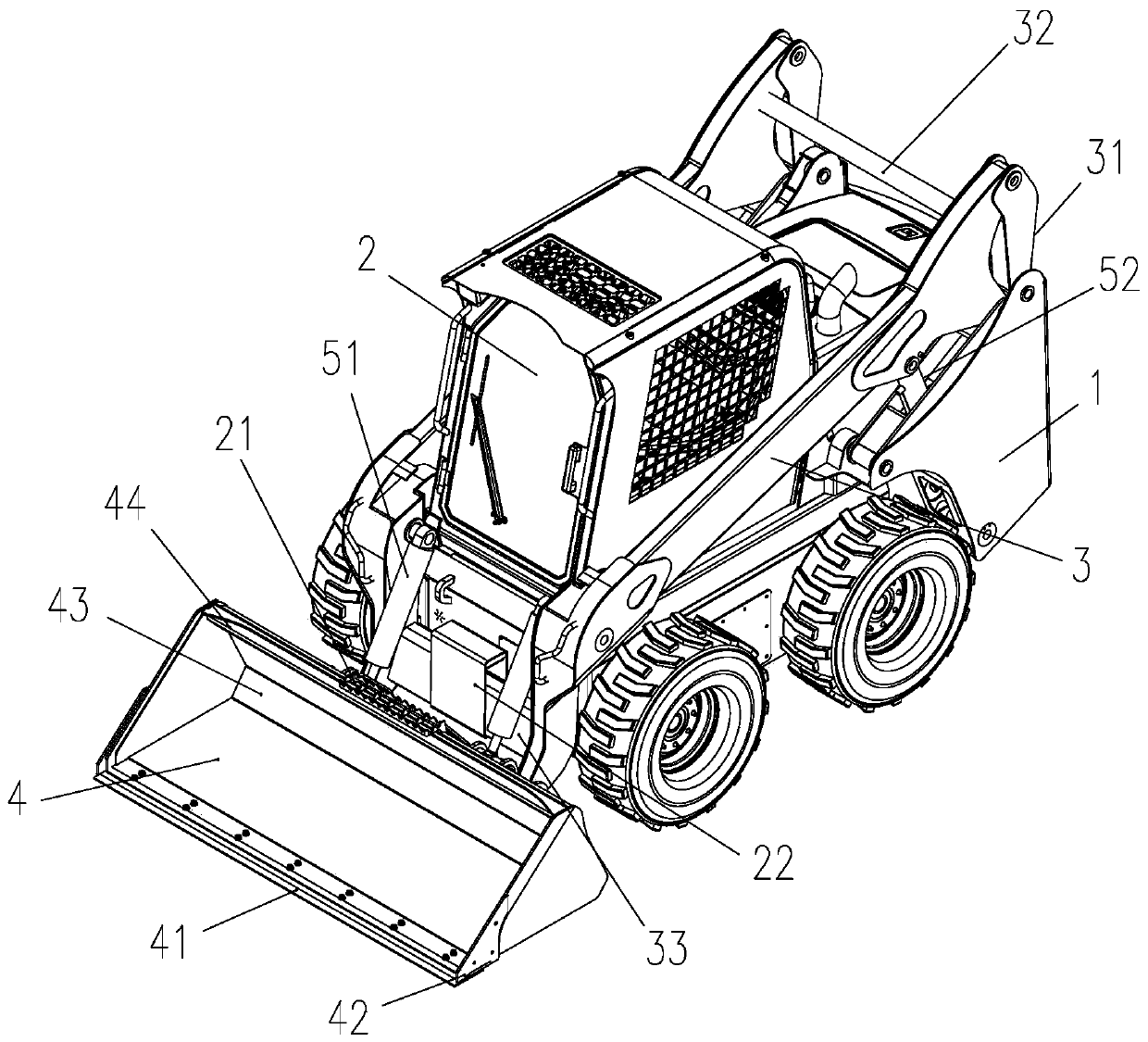

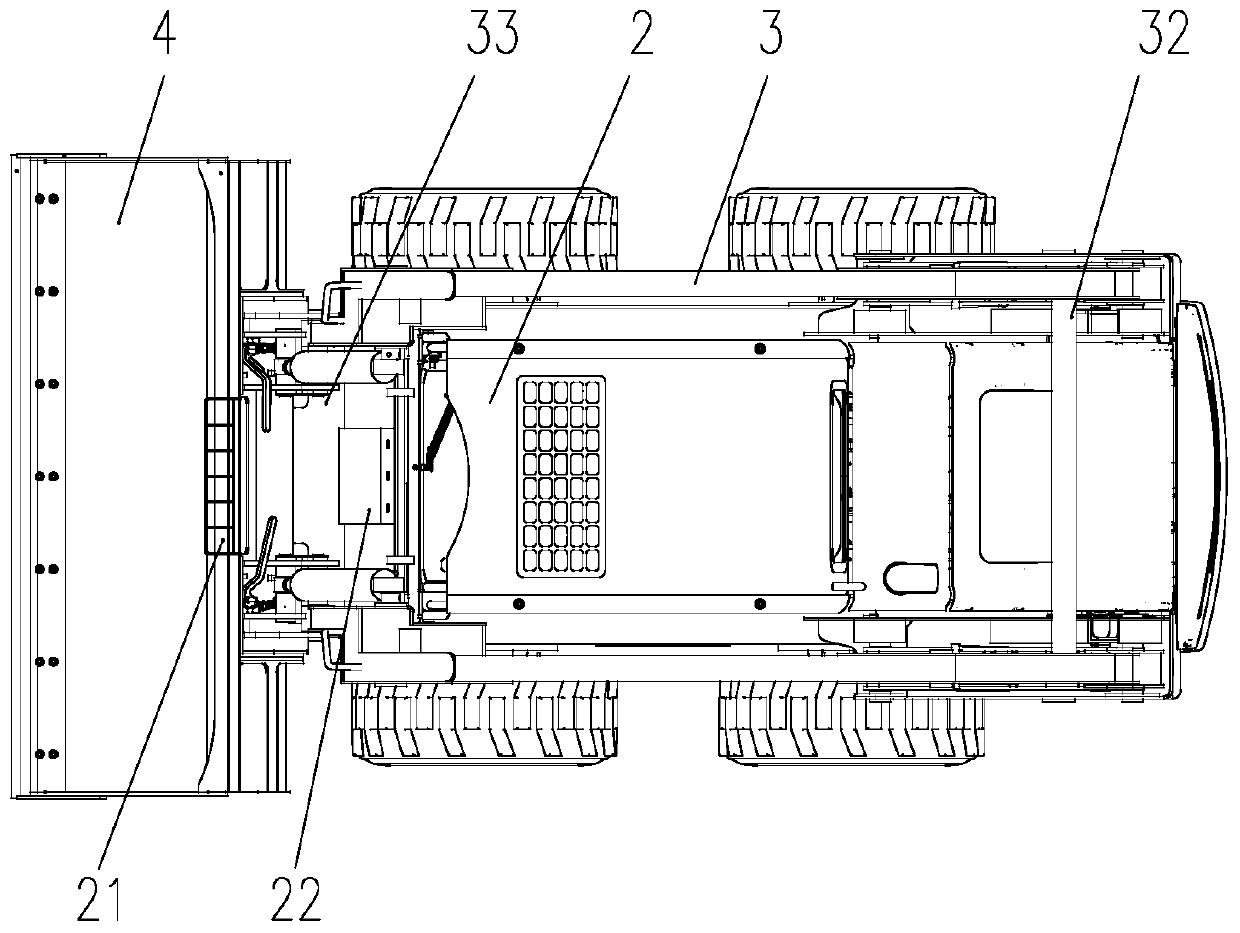

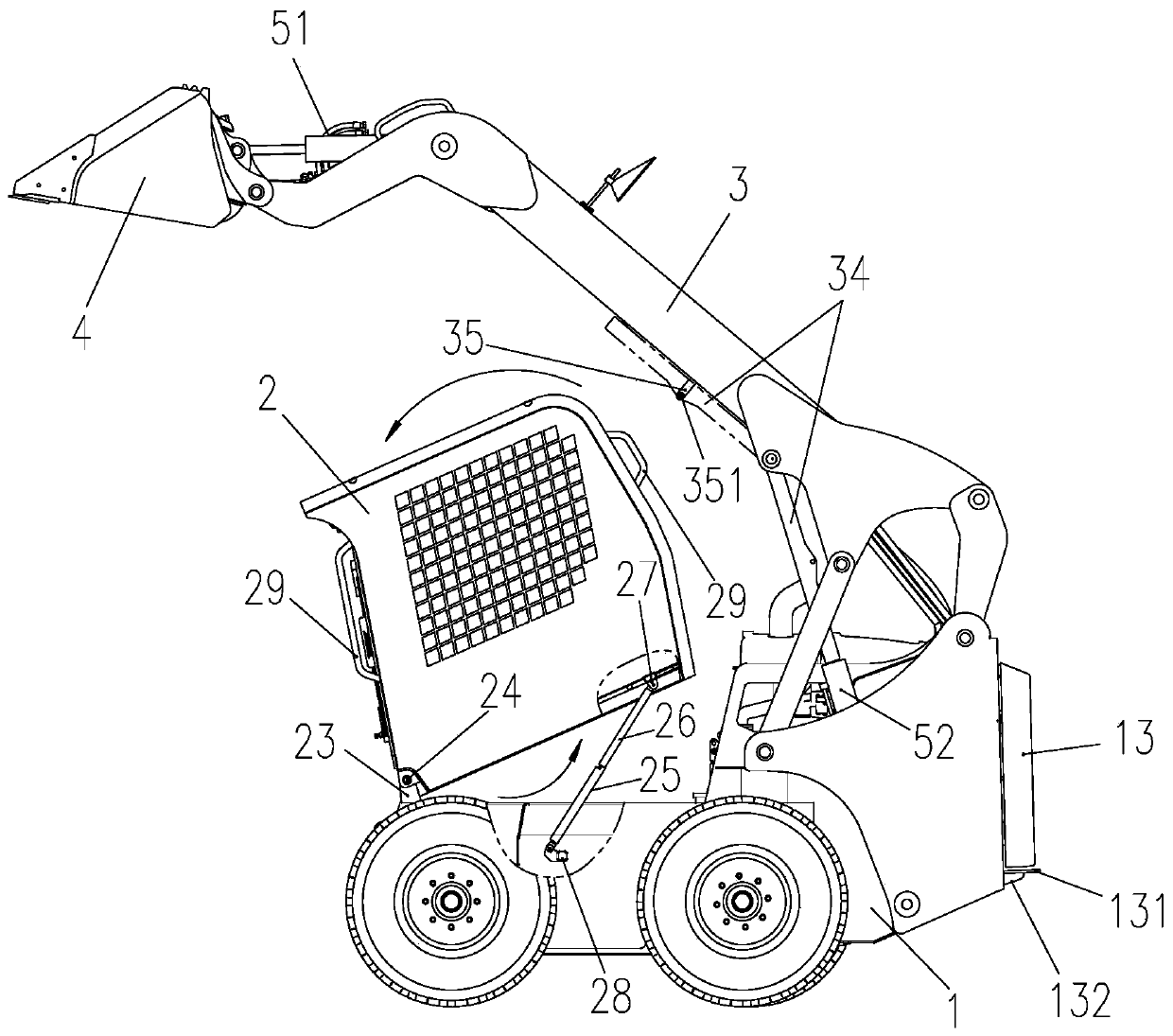

[0062] see Figure 1-3 , the skid steer loader in the illustration is a specific embodiment of the present invention, specifically including a chassis frame 1, a cab 2, a main beam 3, a bucket 4, a loading and unloading cylinder 51, a lifting cylinder 52 and the power system in the figure Not shown, etc., wherein, the chassis frame 1 is assembled with the wheeled walking system to form the mobile chassis of the skid steer loader. The hydraulic motor control can realize the walking and steering functions of the skid steer loader through the speed difference of the wheels on both sides. The power system includes the engine system and the hydraulic system, and the various action parts of the skid steer loader provide driving force. The driver's cab 2 is flipped and set at the front of the chassis frame 1 for the driver to operate the skid steer loader. The main beam 3 connects the bucket 4 and the chassis frame 1, and transmits the lifting power of the bucket 4 through the swing ...

Embodiment 2

[0083] see Figure 16 , the skid steer loader in the illustration is another specific embodiment of the present invention. The skid steer loader in the first embodiment uses a wheeled walking system. This embodiment is on the same chassis frame as the first embodiment Equipped with crawler walking system. According to the setting position of the crawler walking system, it can be completed by replacing the wheel axle bracket with the crawler frame. Compared with the wheel-type walking system, the crawler-type walking system has a more stable load balance in the loading and unloading movement of the vehicle, and a stronger cross-country driving ability.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com