Fermentation method for producing epothilone B by sorangium cellulosum and fermentation medium

A technology of C. celluliformis and a fermentation medium, which is applied to the field of fermentation and fermentation medium for the production of Epothilone B by C. cellulosum, and can solve the problems of difficulty in culturing, low yield, and mutagenesis screening of Myxobacter celluliformis Difficulty and other problems, to achieve the effect of stable strain performance, increased yield and significant effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-4

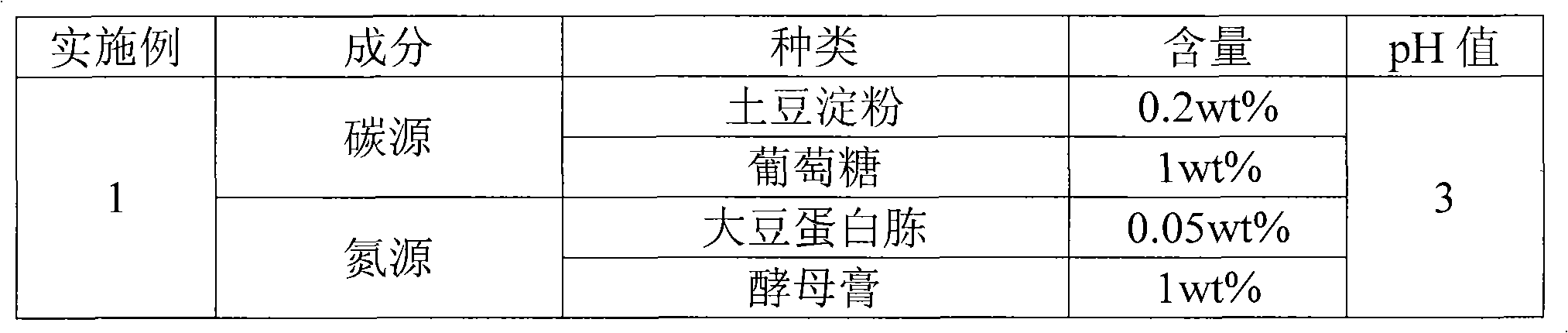

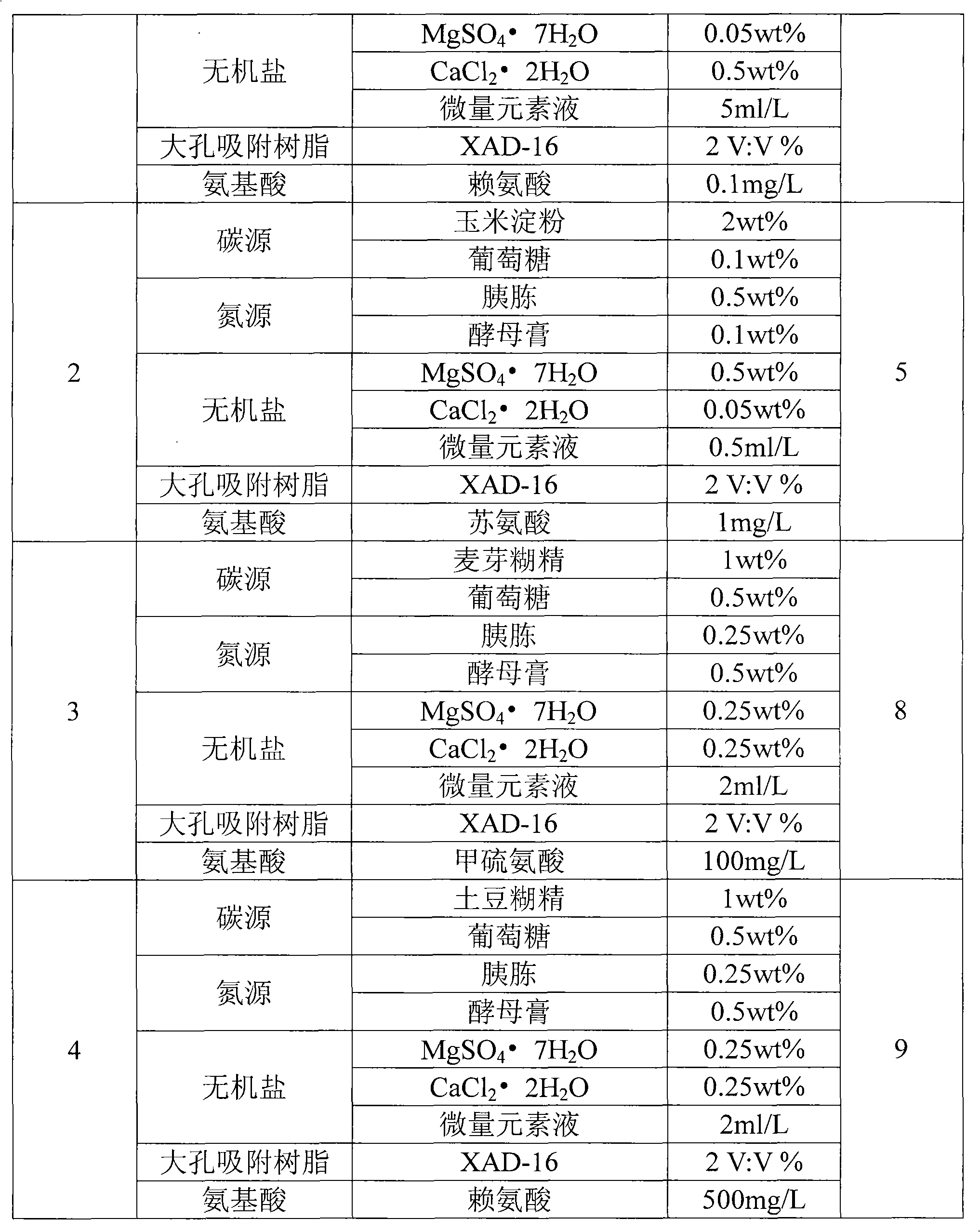

[0031] Table 1 has provided the formula of fermentation medium embodiment 1~4 of the present invention, according to listed component and its content in Table 1 and its content (percentage is mass percentage), simply mix uniformly, make up content to mass percentage with deionized water 100%, sterilized and sterilized, that is, each fermentation medium is prepared.

[0032] Among them, trace element solution preparation (1L system): MnCl 2 4H 2 O 100mg, CoCl 2 20mg, CuSO 4 10 mg, Na 2 MoO 4 2H 2 O 10mg, ZnCl 2 20mg, LiCl 5mg, SnCl 2 2H 2 O5mg, H 3 BO 3 10mg, KBr 20mg, KI 20mg, EDTA Na-Fe 3+ 8g.

[0033]

[0034]

Embodiment 5

[0036]Myxobacterium cellulosus seeds: purchased from the American Type Culture Collection ATCC, the storage number is ATCC15384, and the seeds can be stored in glycerol tubes or freeze-dried tubes.

[0037] Trace element solution preparation (1L system): MnCl 2 4H 2 O 100mg, CoCl 2 20mg, CuSO 4 10 mg, Na 2 MoO 4 2H 2 O 10mg, ZnCl 2 20mg, LiCl 5mg, SnCl 2 2H 2 O 5 mg, H 3 BO 3 10mg, KBr 20mg, KI 20mg, EDTANa-Fe 3+ 8g.

[0038] 1. Spore culture: connect the myxobacterium Somatella cellulosus to the VY / 2 solid slant medium and cultivate it for 5-7 days. After forming a diffuse colony, use it as a seed. The composition of VY / 2 medium is: 0.5wt% fresh yeast, 0.1wt% CaCl 2 2H 2 O, 0.5mg / L VB 12 , 1.5wt% agar, adjust the pH to 7.2 with KOH, and sterilize at 121°C for 20min.

[0039] 2. Seed cultivation:

[0040] i. Use an inoculation needle to scrape a few colonies on the slant of Myxobacterium cellulosus VY / 2 and connect them to the M7 liquid seed medium. The bott...

Embodiment 6

[0046] Except for the fermentation medium used, the operating steps and conditions of spore culture, seed culture, and result analysis are the same as in Example 5.

[0047] Wherein, the composition of fermentation medium is: 0.8wt% potato starch, 0.2wt% soybean peptone, 0.2wt% glucose, 0.2wt% yeast extract, 0.1wt% MgSO 4 ·7H 2 O, 0.1wt% CaCl 2 2H 2 O, 1ml / L trace element solution, 2% (V:V) XAD-16 resin and 2-10mg / L threonine; the pH value is 7.0.

[0048] Result analysis The output of epothilone B is shown in the following table:

[0049] Threonine (mg / L)

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com