Patents

Literature

410results about How to "Has hardness" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Environment friendly antibacterial waterborne paint and preparation thereof

InactiveCN101486861AImprove adhesionFull paint filmAntifouling/underwater paintsPaints with biocidesChemistryEmulsion

The invention provides an environment-friendly antibacterial water paint and a preparation method thereof. The components include deionized water, germicide, assistant for film forming, defoaming agent, wetting agent, dispersant, nanometer TiO2, emulsion or water dispersoid resin, filler, anti-settling agent, flatting agent, thickener, pH regulator, scratch resistance agent or slipping agent, pigment or coloring agent, additive with special function and the like. The preparation method includes the steps of: A. preparing the water dispersoid; B. adding the water dispersoid obtained in the step A into the stirred emulsion, then adding the assistant for film forming, the flatting agent, the thickener, the anti-settling agent, and the pH regulator and uniformly stirring and dispersing the components; C. adding the pigment or the coloring agent; and D. charging water and adjusting the Stormer viscosity at the temperature of 25 DEG C to be 65-90KU, thus obtaining the water paint. The water paint provided in the invention has good adhesion to wood materials, full paint films with certain hardness, low VOC, no heavy metal, and the antibacterial and mildewproof functions, and belongs to the environment-friendly and safe children woodwork water paint.

Owner:SHENZHEN OCEANPOWER NEW MATERIALS TECH

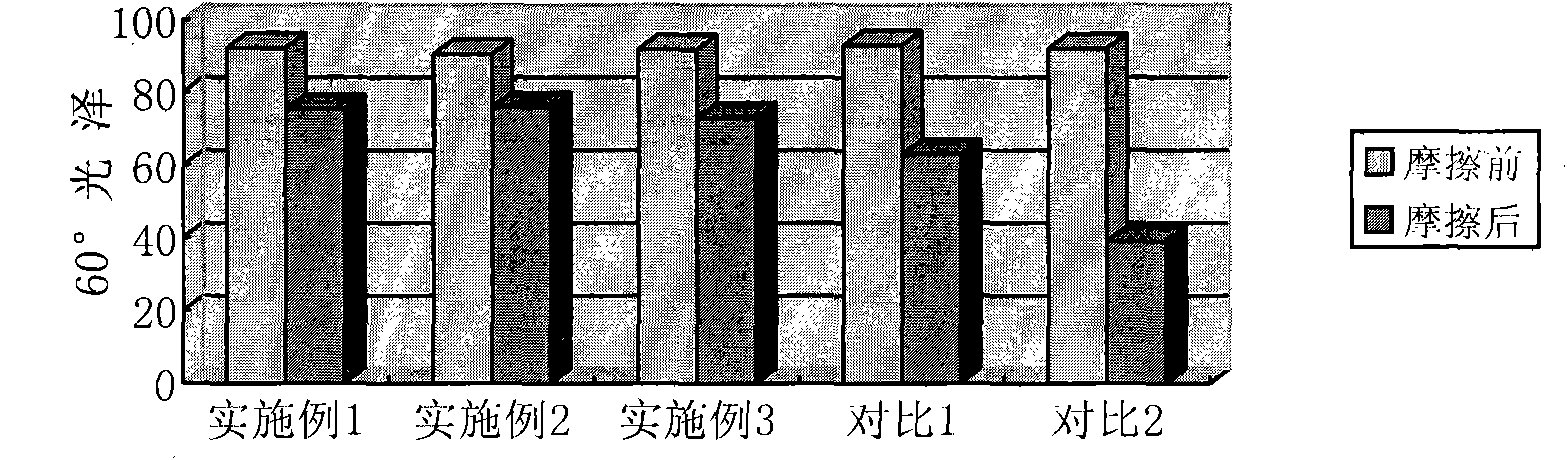

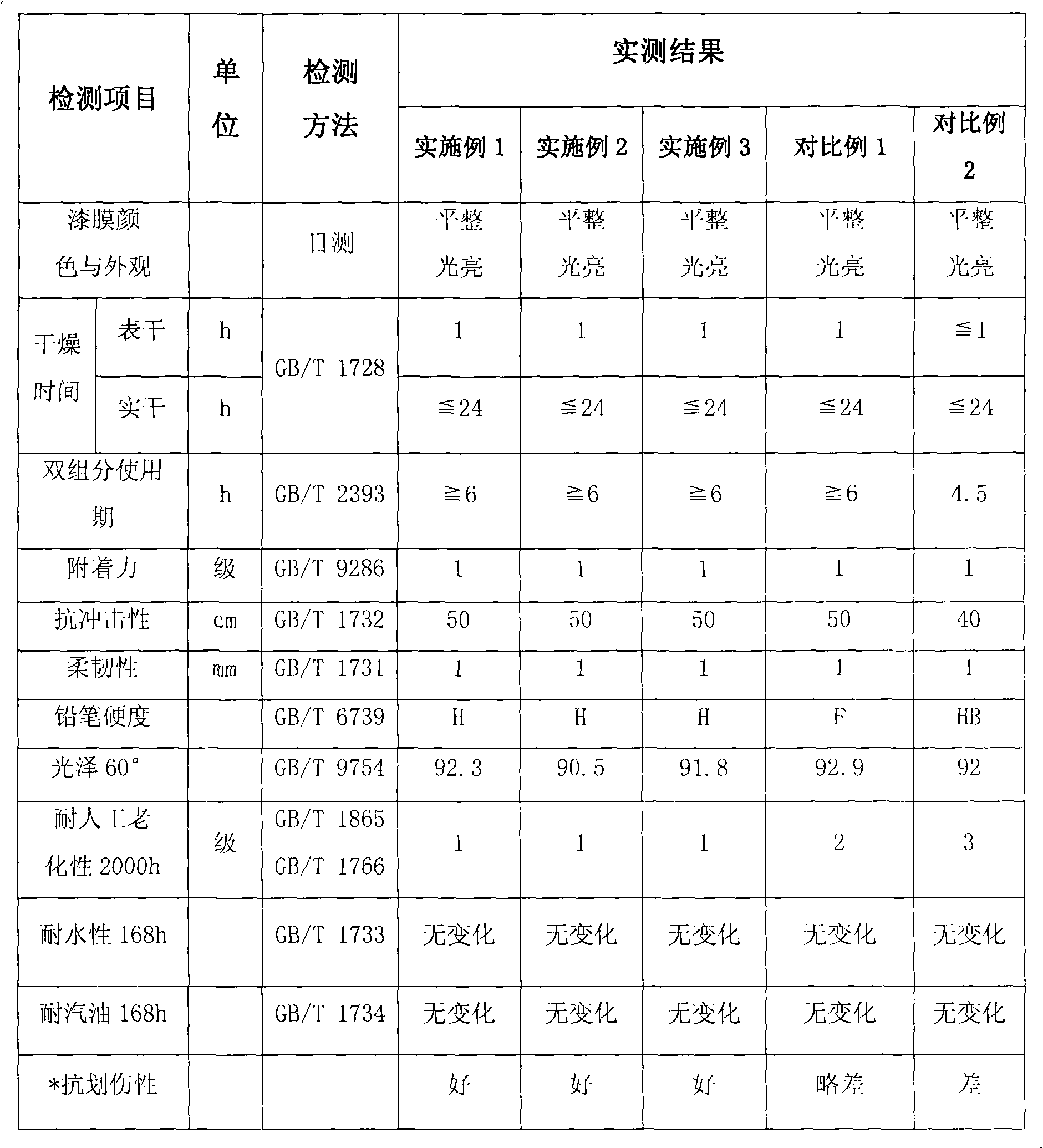

Wear-resisting scratch-resisting weather-proof polyurethane coating and preparation method thereof

ActiveCN101792639AImprove scratch resistanceGood weather resistancePolyurea/polyurethane coatingsPolyester coatingsScavengerAcrylic resin

The invention relates to a double-component polyurethane coating and a preparation method thereof. The coating comprises a component A and a component B, wherein the component A comprises hydroxyl-containing acrylic resin, fluorocarbon resin, polyester resin, non-nanoscale titanium white, nanometer titanium dioxide, nanometer silicon dioxide and various auxiliary agents; and the component B comprises polyisocyanate curing agent, solvent and moisture scavenger. The component A and the component B are mixed at the weight ratio of 4:1-5:1 to obtain the polyurethane coating. The coating has excellent wear resistance, scratch resistance and weather proofness, has favorable decoration, and is suitable for coating the surfaces of rapid trains, automobiles and the like which have higher requirements on decoration and physiochemical performance.

Owner:DE LAITTERN ENVIRONMENTAL COATING BEIJING

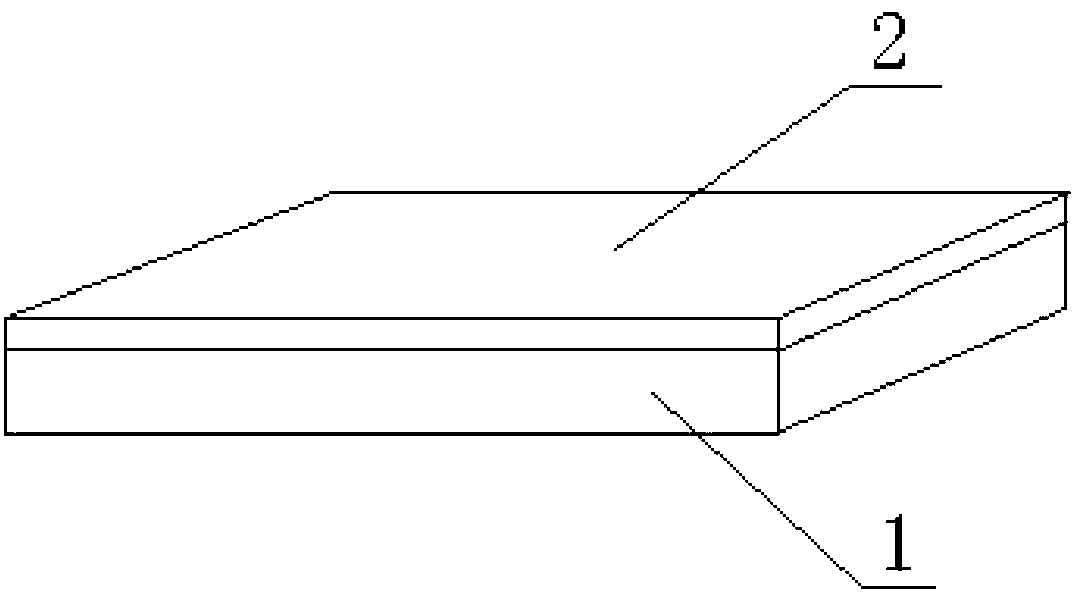

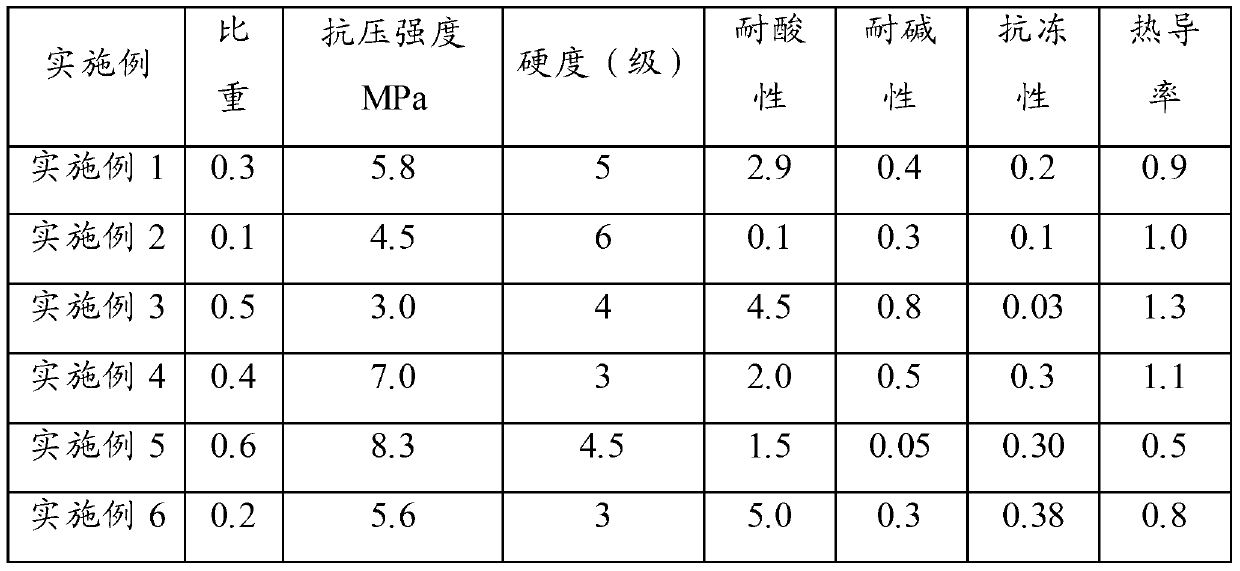

Composite plate material of foam microcrystalline glass and pure microcrystalline glass and manufacturing method of composite plate material

The invention provides a composite plate material of foam microcrystalline glass and pure microcrystalline glass. The composite plate material comprises a base body and a decoration surface, wherein the base body is made of a foam microcrystalline glass mixed material; the thickness of the base body is 50mm to 500mm; the decoration surface covers the surface of the base body and is made of pure microcrystalline glass granules; the thickness of the decoration surface is 3mm to 30mm. The invention also provides a manufacturing method of the composite plate material. The composite plate material of the foam microcrystalline glass and the pure microcrystalline glass, provided by the invention, can simultaneously replace a building material and a decoration material, and is small in specific gravity, high in strength, fireproof and corrosion-resistant; environment products which are difficultly handled in a natural environment and industrial wastes which are difficultly treated currently can be consumed; the environment stress is reduced.

Owner:北京晶雅石科技有限公司

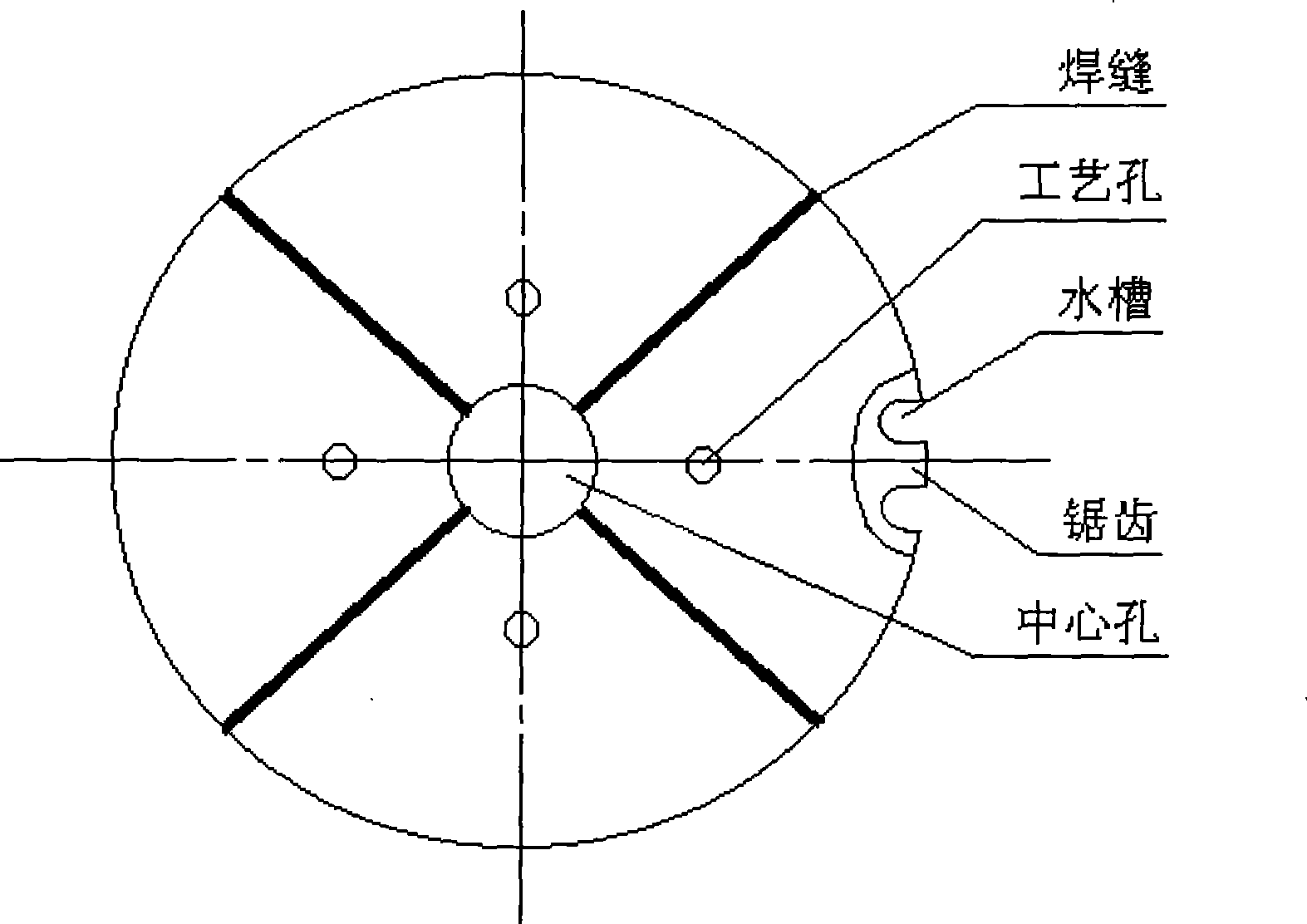

Electric welding rod for hand welding X80 grade steel oil, gas transmission pipe

ActiveCN101362257AHas tensile strengthHas a shock valueWelding/cutting media/materialsSoldering mediaManganeseFerrosilicon

The invention relates to an electric welding rod used for manual welding. The electric welding rod comprises core welding-wires containing the following chemical compositions (wt%): 0.020-0.100 of C, 0.350-0.550 of Mn, 0.015-0.030 of Si, 0.005-0.015 of P, 0.002-0.005 of S, 0.01-0.20 of Cr, 0.01-0.30 of Ni, 0.01-0.20 of Cu, 98.675-99.47 of Fe, and the residue of impurity; the electrode coating comprises the following compositions: 28-38 of marble powder, 16-28 of fluorite powder, 2-8 of feldspar powder, 2-7 of white titanium pigment, 4-8 of electrolytic manganese, 3-7 of ferrosilicon powder, 6-9 of ferrotitanium powder, 0.5-2 of ferromolybdenum powder, 3-8 of nickel powder, 10-25 of iron power and 5-8 of other elements. The chemical compositions, the performance and the structure of the welding seam of a grade X80 steel pipe welded by using the electric welding rod are closer to the pipe body, and without heat treatment, the welding seam can meet the requirements on technical indicators such as high strength, high toughness, low hardness and the like of the grade X80 steel pipe used for oil and natural gas transferring; the electric welding rod overcomes the defaults in the prior art that the welding seam is required to be heat-treated after welding, the quality is poor, and engineering accidents are easy to happen when in use and the like.

Owner:ATLANTIC CHINA WELDING CONSUMABLES +1

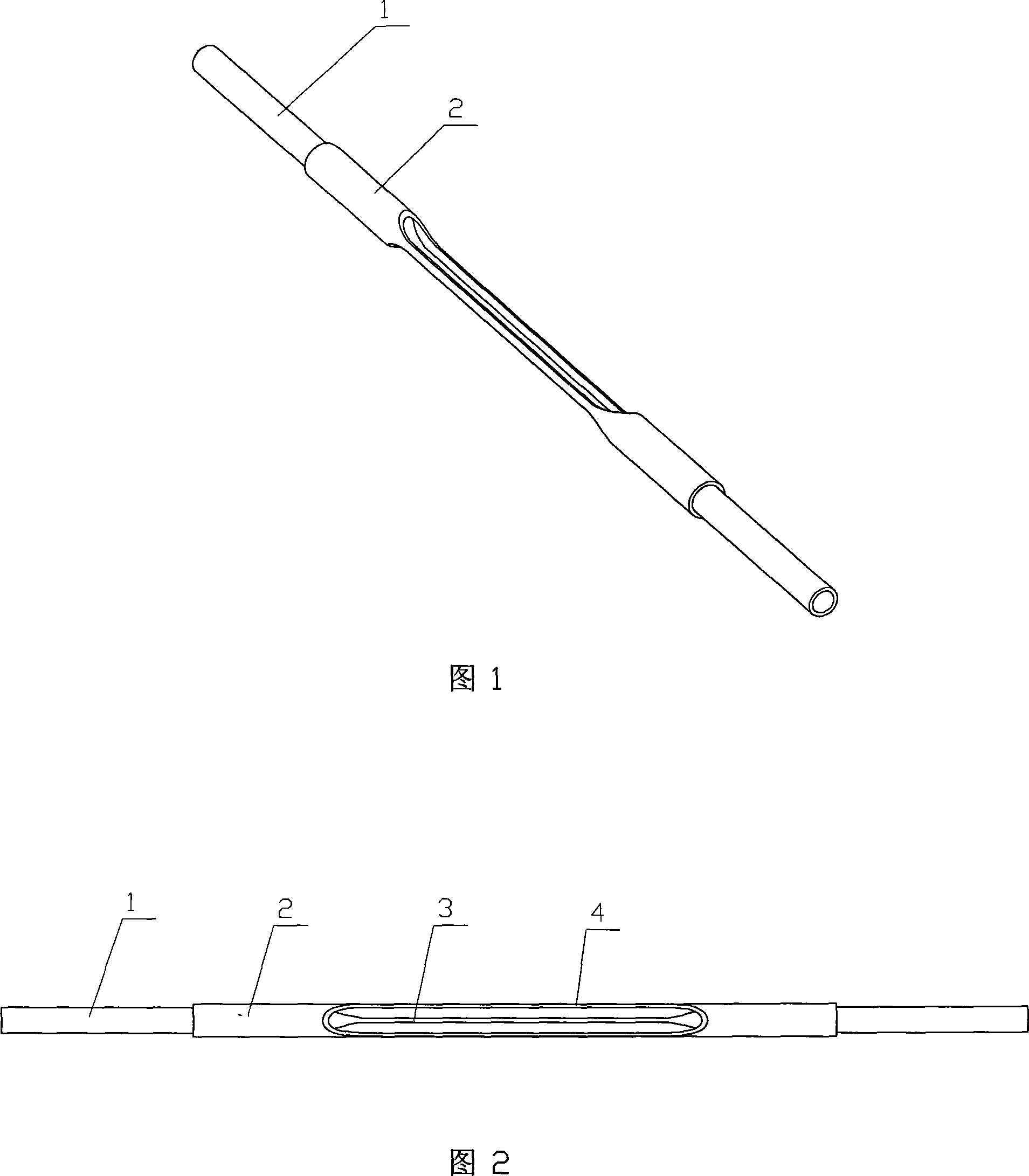

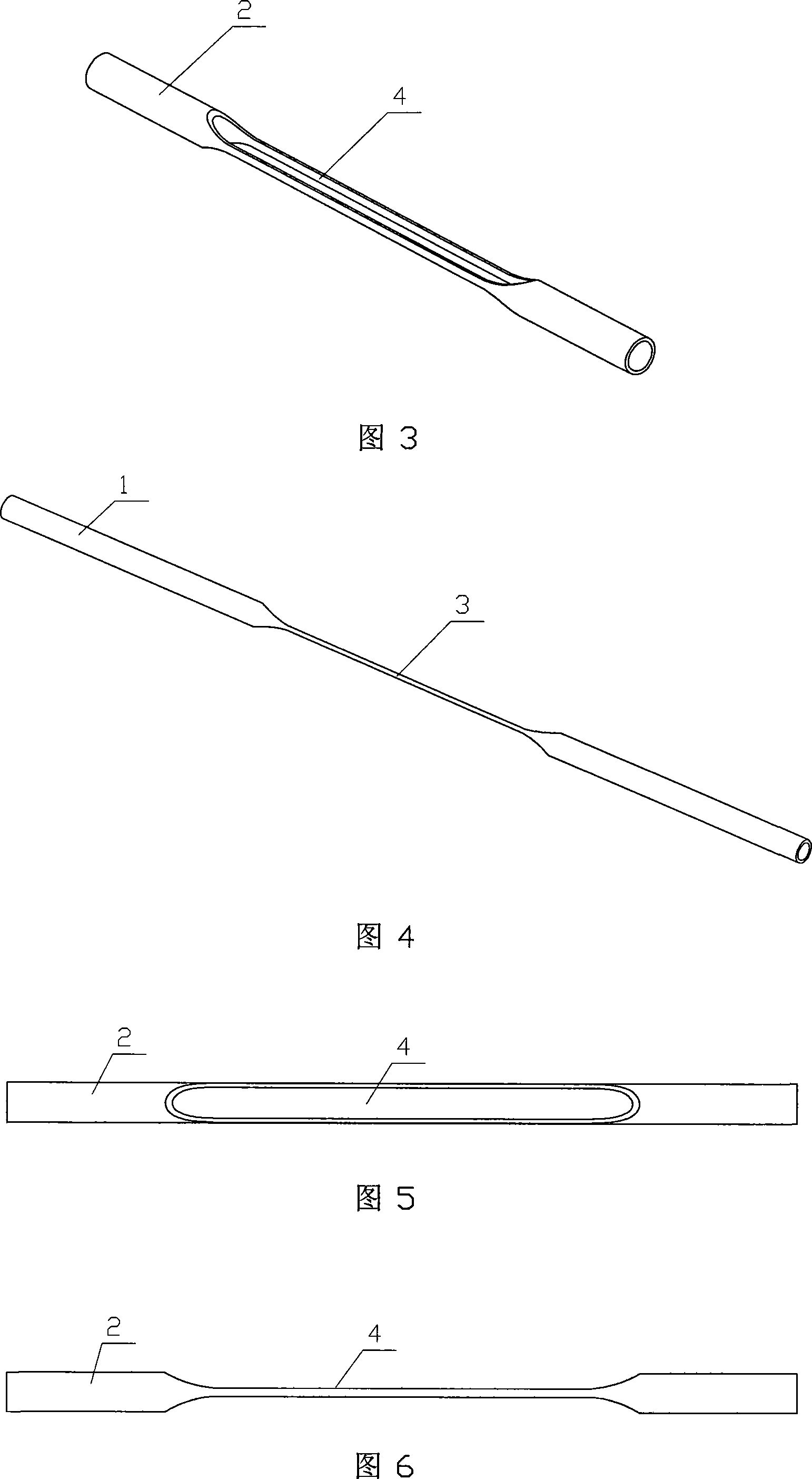

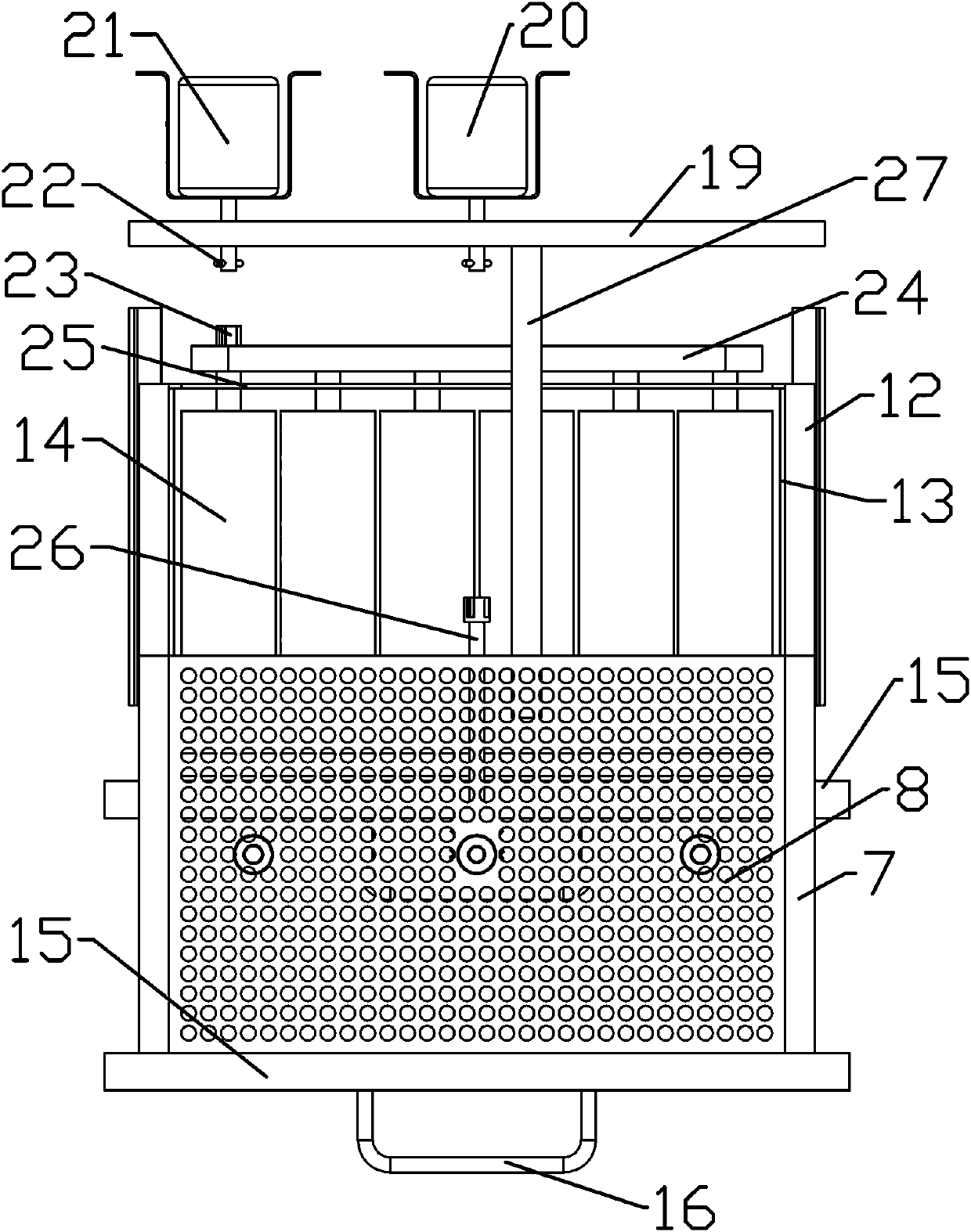

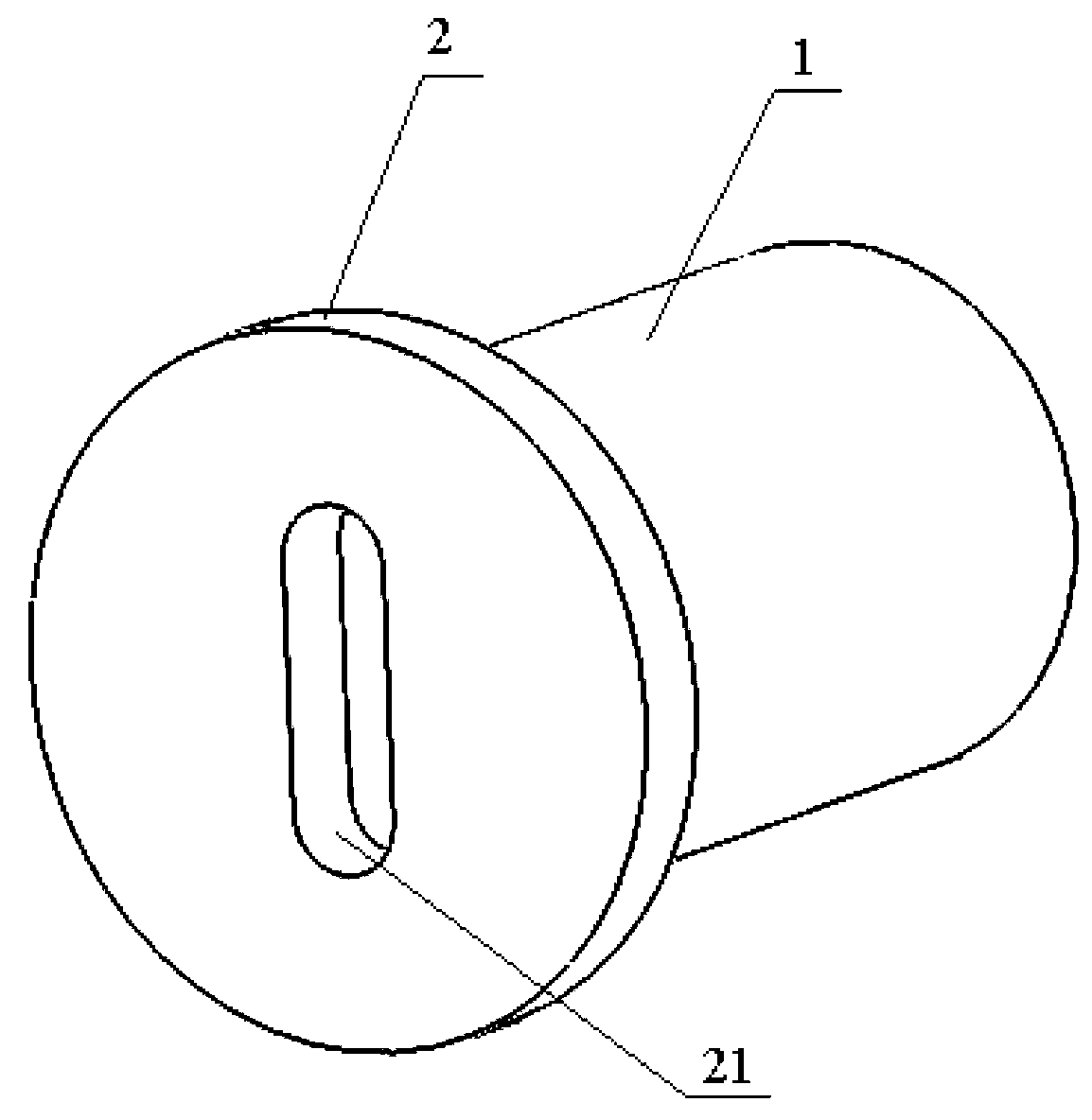

Biological sample glass freezing and conserving appliance

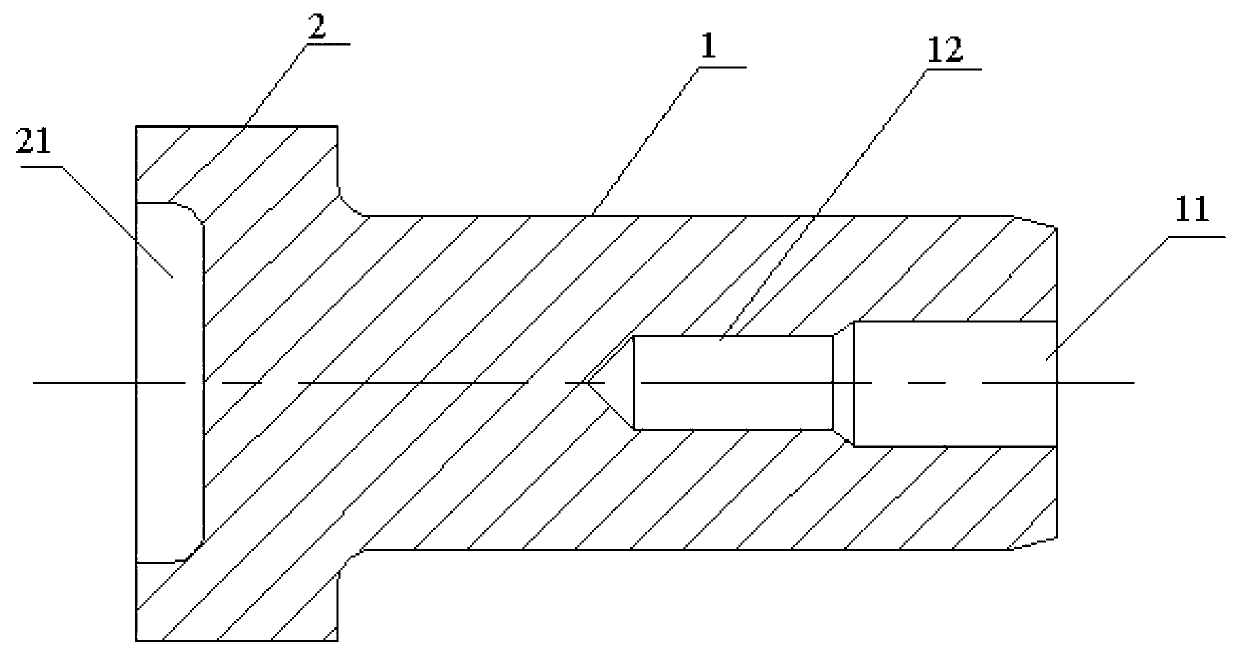

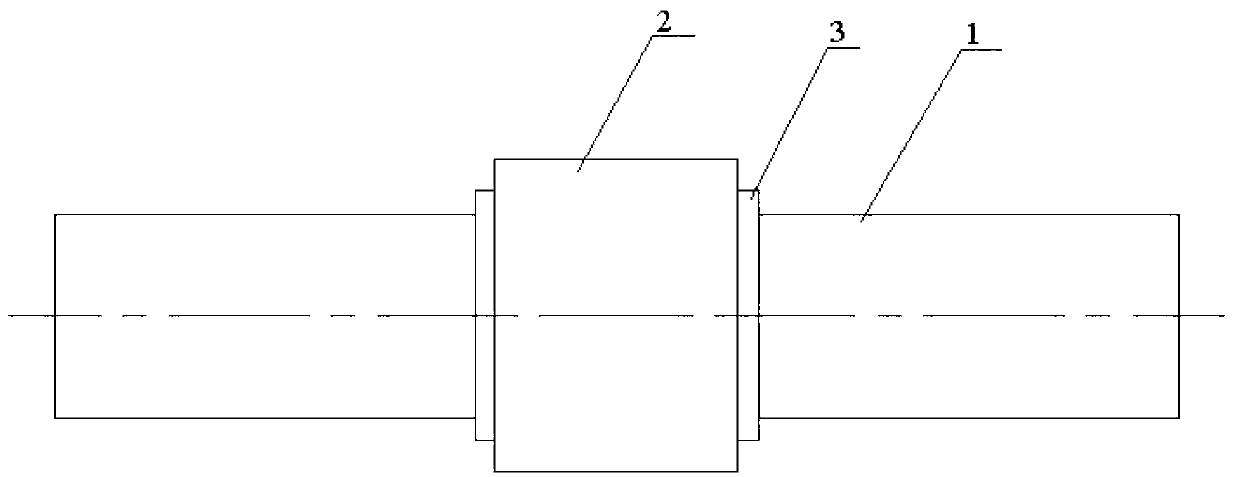

InactiveCN101200706AVitrificationfastProtection against biocontamination hazardsDead animal preservationTissue cultureVitrificationEmbryo

The present invention relates to a tool for vitrification freezing and storing biological samples of ovum, embryo, etc. The present invention solves the problem that the biological sample is frozen promptly but is not exposed to liquid nitrogen directly, so as to prevent the potential biological pollution danger. The tool for vitrification freezing and storing biological sample comprises a straw and a protecting pipe which is mounted at the straw. The middle part of the straw is a fine thin-wall tube, the length of which is 20 to 30mm, and the diameter is 0.3 to 0.35mm. The two sides at the middle part of the protecting pipe are symmetrically provided with concave windows. The straw tool of the present invention is used for vitrification freezing and storing the ovum or the embryo and other cells, which can ensure that the biological sample is vitrified and frozen fast and also can ensure that the biological sample is not exposed to the liquid nitrogen directly to prevent the potential biological pollution danger.

Owner:ANHUI MEDICAL UNIV

Preparation method of alkyd resin

InactiveCN102408551AImprove adhesionFullnessCosmetic preparationsToilet preparationsPolymer scienceNitrocellulose

The invention relates to a preparation method of alkyd resin. The preparation method comprises the following specific steps: (1) adding neopentyl glycol, trihydroxymethyl propane, phthalic anhydride, hydrogenated phthalic anhydride and antioxidant to a reaction container, and heating to carry out melt esterification on the materials at the temperature of 200-240 DEG C; (2) when esterification is carried out to an acid value being 40-45 mgKOH / g, cooling to 120-160 DEG C, and adding short-chain synthetic fatty acid and an aliphatic hydrocarbon solvent; (3) heating to carry out reflux esterification at the temperature of 180-200 DEG C, and diluting with acetic acid ester organic solvent when the acid value is smaller than or equal to 8 mgKOH / g; and (4) cooling to 100 DEG C and filtering to obtain alkyd resin. The paint prepared from the alkyd resin obtained in the invention and nitrocellulose has the characteristics of rapid drying, high hardness, good fullness, good adhesion force, and good water resistance.

Owner:JIANGSU SANMU GROUP CORPORATION

Production process of yellow peach can

InactiveCN102422878APreserve fruit flavorFirm peach fleshFruits/vegetable preservation using sugarsHardnessFruit Flavor

The invention discloses a production process of a yellow peach can, which particularly comprises the following steps: 1. cleaning; 2. cutting into pieces; 3. digging kernels; 4. sprinkling alkali and peeling; 5. cleaning; 6. finishing and grading; 7. weighing; 8. preparing a sugar solution; 9. filling in a pot, and performing vacuum sealing; 10. performing sterilization and cooling; 11. performing transportation and drying. The yellow peach can produced by the process has completely-maintained specific fruit flavor of yellow peaches, maintained solid peach flesh, certain hardness and good taste. The product can not only be eaten directly by consumers, but also be used as an excellent auxiliary material for baked products.

Owner:宿迁市罐头食品有限责任公司

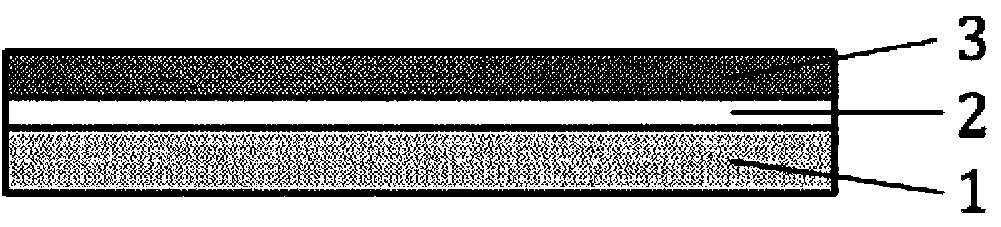

Novel electric welding rod

InactiveCN101362258AGuaranteed welding strengthLow diffusible hydrogen contentWelding/cutting media/materialsSoldering mediaFerrosiliconMetallic Nickel

The invention provides an electric welding rod with ultra low hydrogen and high toughness. The electric welding rod comprises core welding-wires and electrode coating composition. The electrode coating composition comprises the following components (weight percentage): 38-42 percent of marble, 21-28 percent of fluorspar, 1-3 percent of white titanium pigment, 6-10 percent of ferrotitanium, 0.5-1.5 percent of low-carbon ferromanganese, 3-7 percent of ferrosilicon, 3-6 percent of manganese metal, 2-4 percent of metallic chromium, 1-3 percent of mica, 1-3 percent of ferromolybdenum, 1.5-3.5 percent of ferrovanadium, 1-4 percent of nickel powder and 2-4 percent of rare earth metal. H08A is adopted as the core welding-wires, and water glass is used as the cementing agent. The electric welding rod fills the blank of electric welding rod needed for an ultra-thin large diameter circular saw blade, and simultaneously the electric welding rod can also be used for the welding of products in structures of carbon tool steel, alloy tool steel and spring steel material. The electric welding rod has good welding processing property and crack resistance, and simultaneously has very high welding strength, rigidity, plasticity and toughness, and the color of the welding seam is identical with the color of the base material.

Owner:HARBIN INST OF TECH

Water-based mold release and preparation method thereof and release paper prepared by utilizing water-based mold release

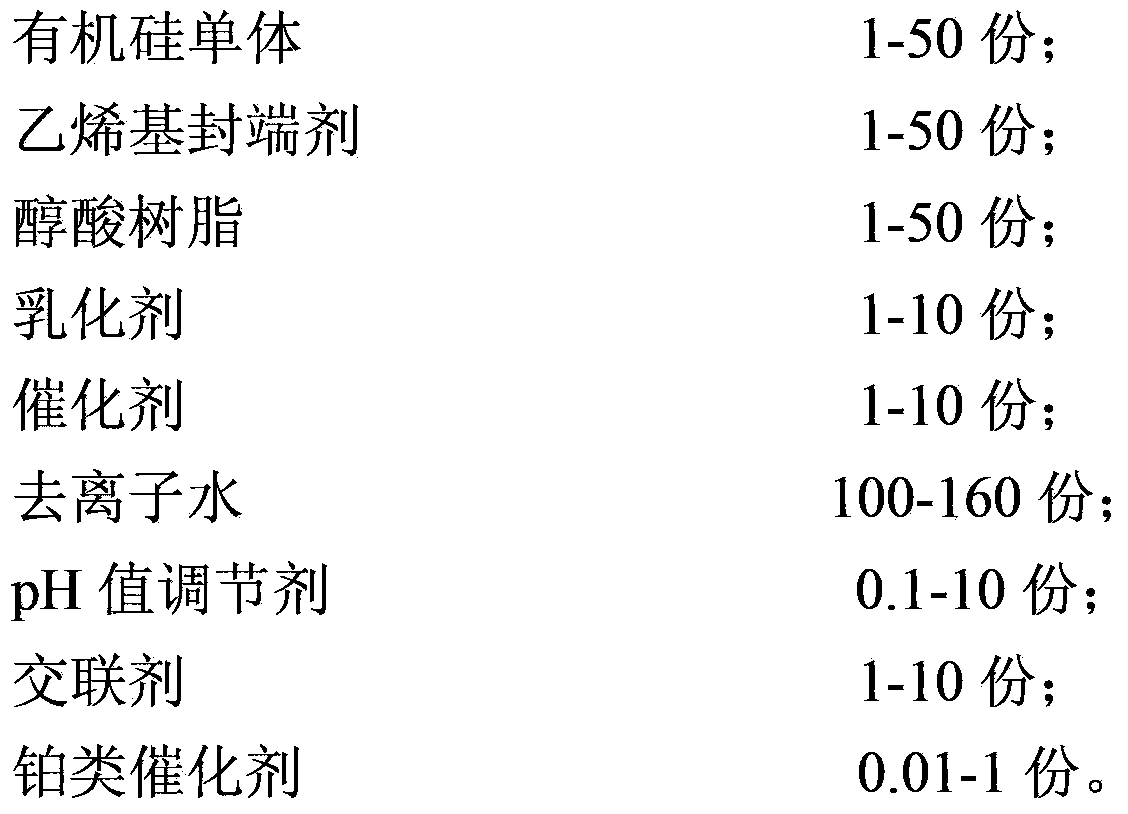

The invention discloses a water-based mold release and a preparation method thereof and release paper prepared by utilizing the water-based mold release. The mold release comprises the following raw materials by weight: 1 to 50 parts of organosilicone monomer, 1 to 50 parts of vinyl end-capping agent, 1 to 50 parts of alkyd resin, 1 to 10 parts of emulsifying agent, 1 to 10 parts of catalytic agent, 100 to 160 parts of deionized water, 0.1 to 10 parts of pH value conditioning agent, 1 to 10 parts of cross-linking agent and 0.01 to 1 part of platinum-based catalytic agent. The mold release has the advantages that the raw materials are cheap and easy to get; the preparation method is simple; the used mold release layer takes water as a dispersing agent; no organic solvent is released; the mold release is safe and environment-friendly; the release paper prepared by utilizing the mold release is short in thermosetting time, and is suitable for industrialized production; the prepared release paper is good in property.

Owner:浙江池河科技有限公司

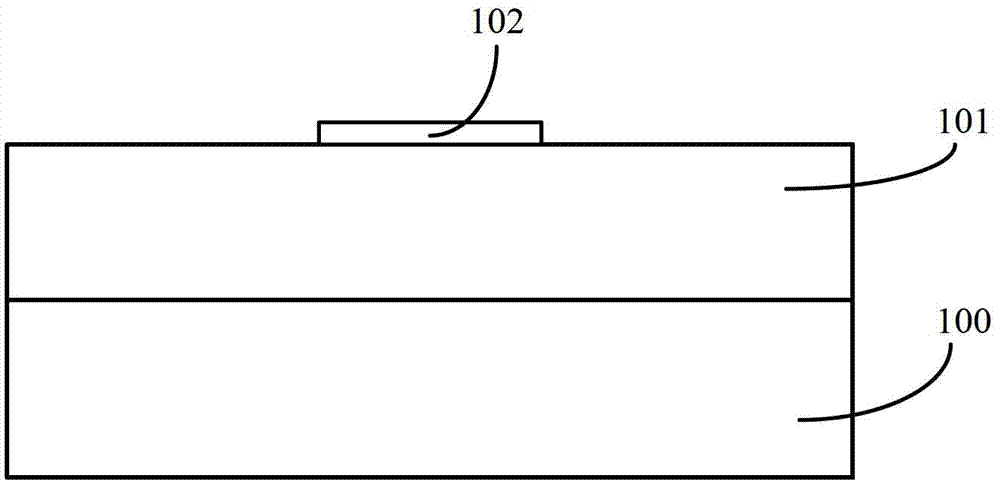

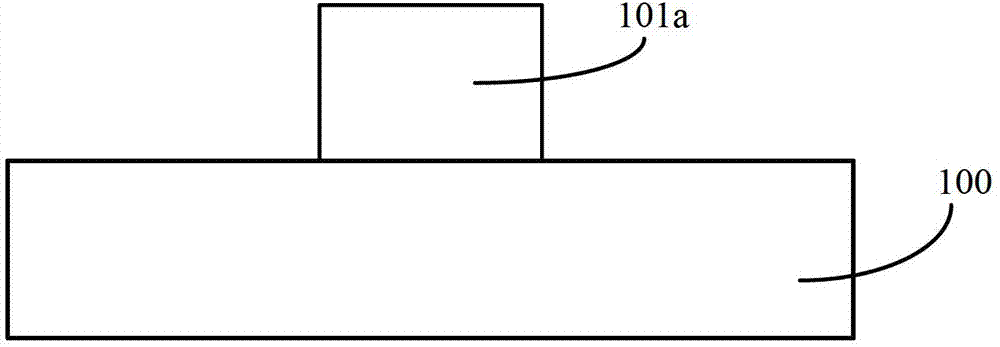

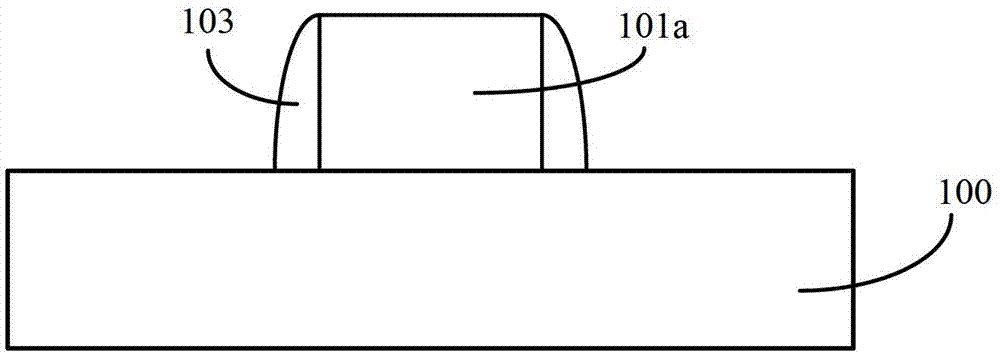

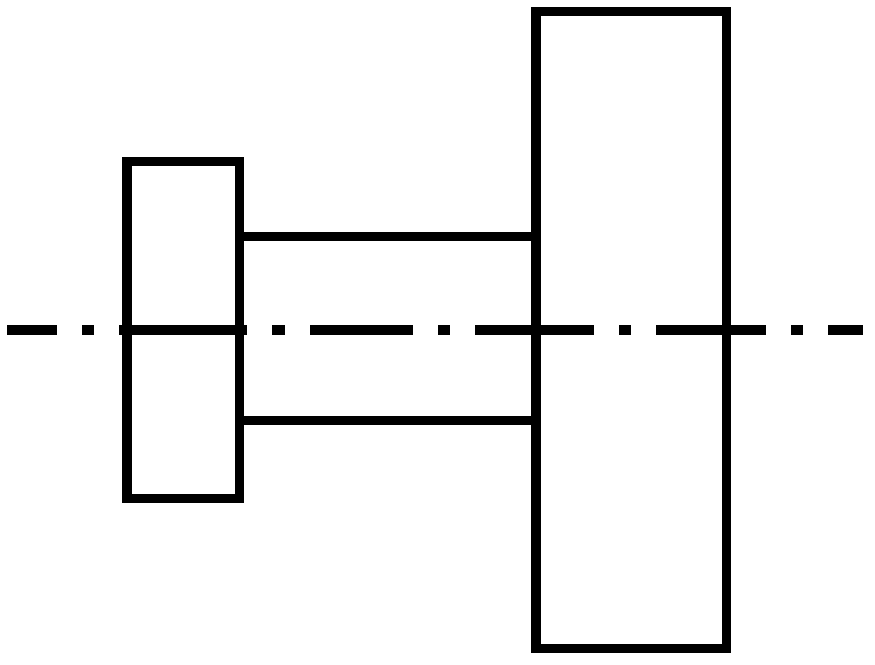

Forming method of self-aligned double pattern

ActiveCN103715080AConsistent sizeConsistent feature sizeSemiconductor/solid-state device manufacturingEngineeringElectrical and Electronics engineering

The invention relates to a forming method of a self-aligned double pattern. The provided forming method comprises the following steps that: a to-be-etched layer is provided, wherein first sacrificial layers are arranged at the surface of the to-be-etched layer and the width of one first sacrificial layer is identical with the distance between the two adjacent first sacrificial layers; first mask side walls are formed at the surface of the to-be-etched layer at the two sides of the first sacrificial layers; second sacrificial layers covering the surfaces of the first mask side walls are formed at the surface of the to-be-etched layer, wherein the surfaces of the second sacrificial layers are flush with the surfaces of the first sacrificial layer; after the forming of the second sacrificial layers, the first sacrificial layers are removed and the surface of the to-be-etched layer is exposed; after removing of the first sacrificial layers, second mask side walls are formed at the second sacrificial layers and the etched layer surface at the two sides of the first mask side walls, wherein the profile shapes of the second mask side walls are symmetrical with those of the first mask side walls; and after the forming of the second mask side walls, the second sacrificial layers are removed. According to the invention, the pattern that is formed by using the formed double pattern as the mask for etching has the unified dimension and morphology.

Owner:SEMICON MFG INT (SHANGHAI) CORP

Preparation method of non-woven fabric for shoe linings

InactiveCN105019143AEasy extractionIncrease relative volatilityInsolesNon-woven fabricsActivated charcoal powderAfter treatment

The invention relates to the field of preparation of non-woven fabrics for shoe linings and discloses a preparation method of non-woven fabric for shoe linings. The preparation method comprises following steps of: (1) taking and adding natural perfume to water, adding sea-foam stone powder to a solution, allowing mixed liquor to stand and obtaining sea-foam stone powder loaded with natural perfume by centrifugal and drying treatment; (2) additionally taking activated charcoal powder, aluminum chloride, polyoxyethylene, carboxymethylcellulose, dispersants, silane coupling agents and sea-foam stone powder loaded with natural perfume in order to obtain a mixture; (3) fusing isotatic polypropylene slices and the mixture and performing spinning, drawing, web-forming and hot-rolling operation in order to obtain base cloth of the non-woven fabric; (4) utilizing finishing liquor to process one of surfaces of the base cloth of the non-woven fabric and performing roll-pressing operation on the base cloth after treatment; (5) drying the base cloth of the non-woven fabric subjected to roll-pressing operation and thus obtaining the non-woven fabric for shoe linings. The preparation method of non-woven fabric for shoes is good in deodorization function and breathability and high in hardness so that the shape of a vamp can be kept for a long time.

Owner:LANXI YIMING WEAVING

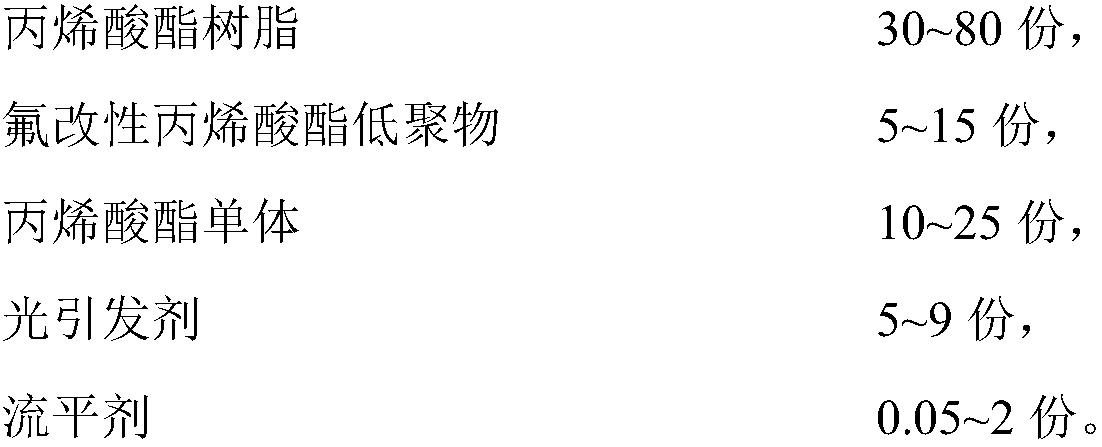

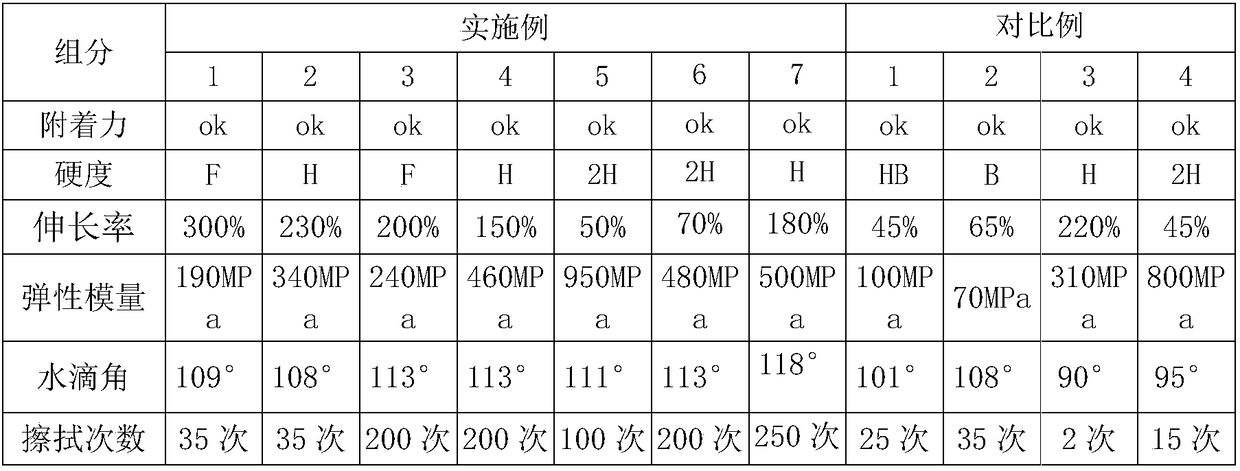

Flexible and stain-resistant ultraviolet curable coating composition and preparation method thereof

InactiveCN108264838AHas hardnessWith highlightsAntifouling/underwater paintsPaints with biocidesOligomerHardness

The invention provides a flexible and stain-resistant ultraviolet curable coating composition. The composition comprises, by weight, 30-80 parts of acrylate resin, 5-15 parts of a fluorine-modified acrylate oligomer, 10-25 parts of an acrylate monomer, 5-9 parts of a photoinitiator and 0.05-2 parts of a leveling agent. Compared with coatings in the prior art, the coating composition in the invention has a higher flexibility, and has the advantages of certain hardness, wear resistance, stain resistance, suitableness for bendable and crimped substrates, excellent comprehensive performances and wide applicability .

Owner:SHANGHAI CHENGYING NEW MATERIALS +1

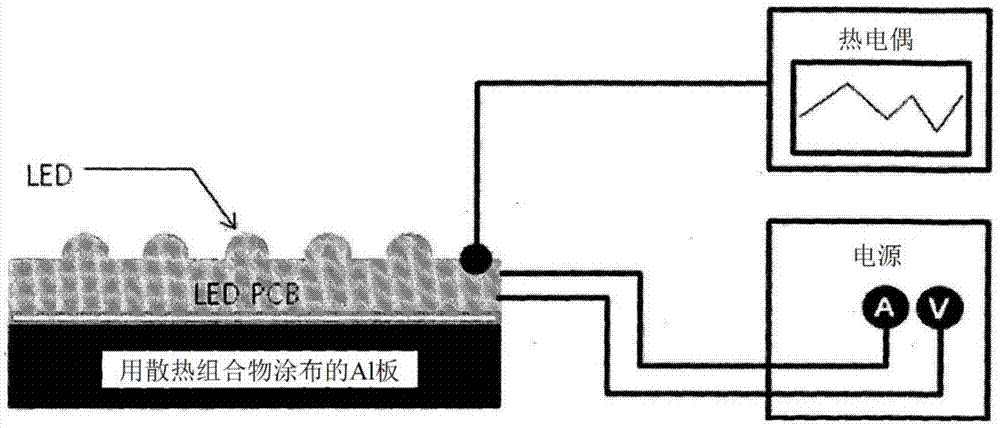

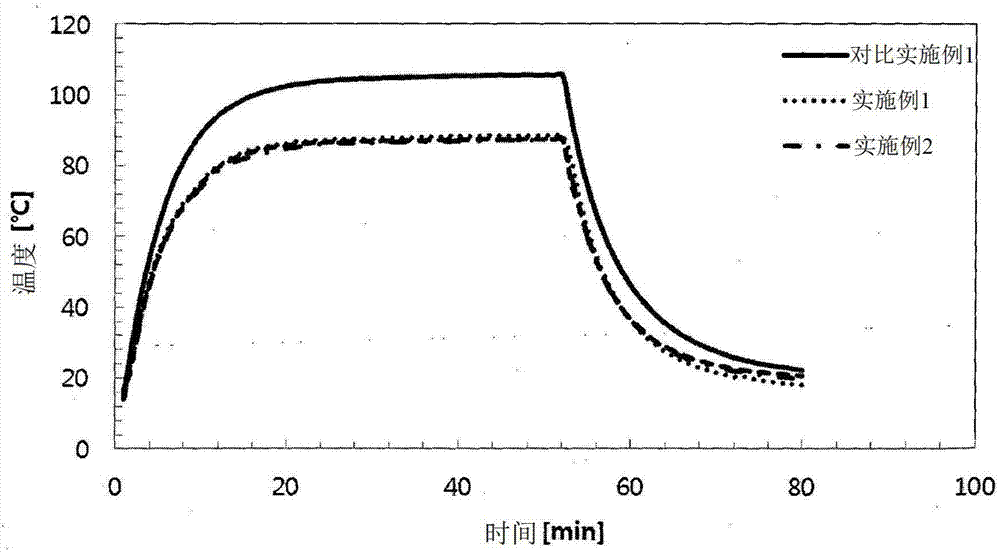

Radiation paint composition and radiation structure

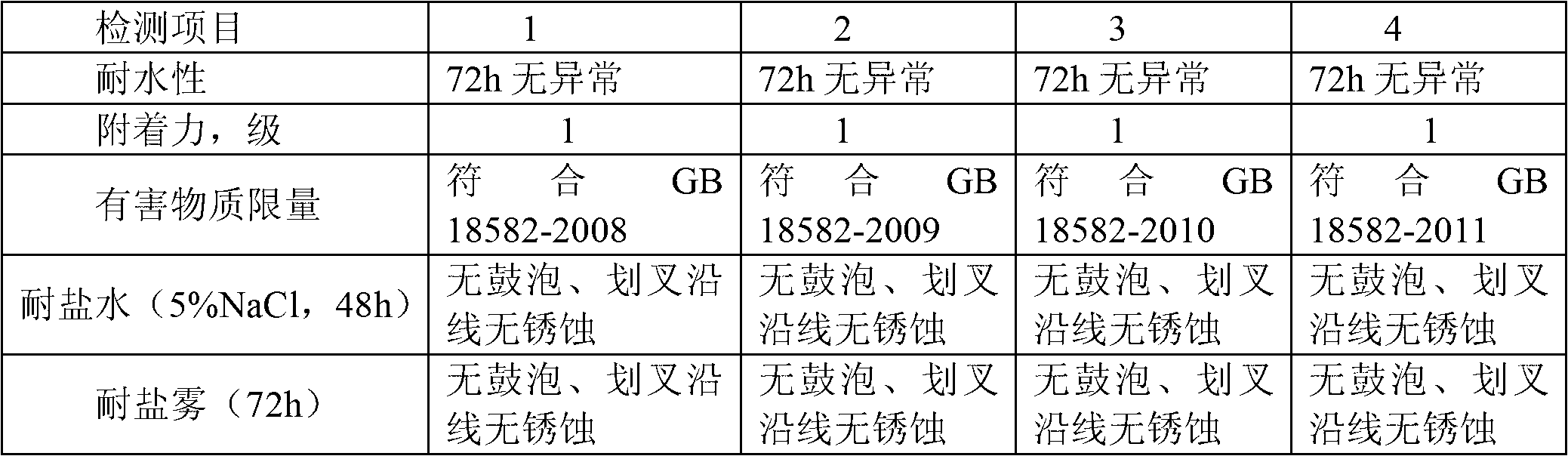

InactiveCN104769057ASalt water resistantAdhesiveHeat-exchange elementsEpoxy resin coatingsEpoxySalt water

There are provided a heat dissipation paint composition capable of forming a heat dissipation layer having excellent salt water resistance, coating film strength, adherence property, scratch resistance, and the like, together with excellent heat dissipation property, in various products, and a heat dissipation structure. The heat dissipation paint composition includes: an epoxy resin; a curing agent; a carbon-based filler having a functional group including at least one selected from the group consisting of an amine group, an amide group, a carboxyl group and a hydroxyl group bound thereto; and a solvent.

Owner:HANWHA CHEMICAL CORPORATION

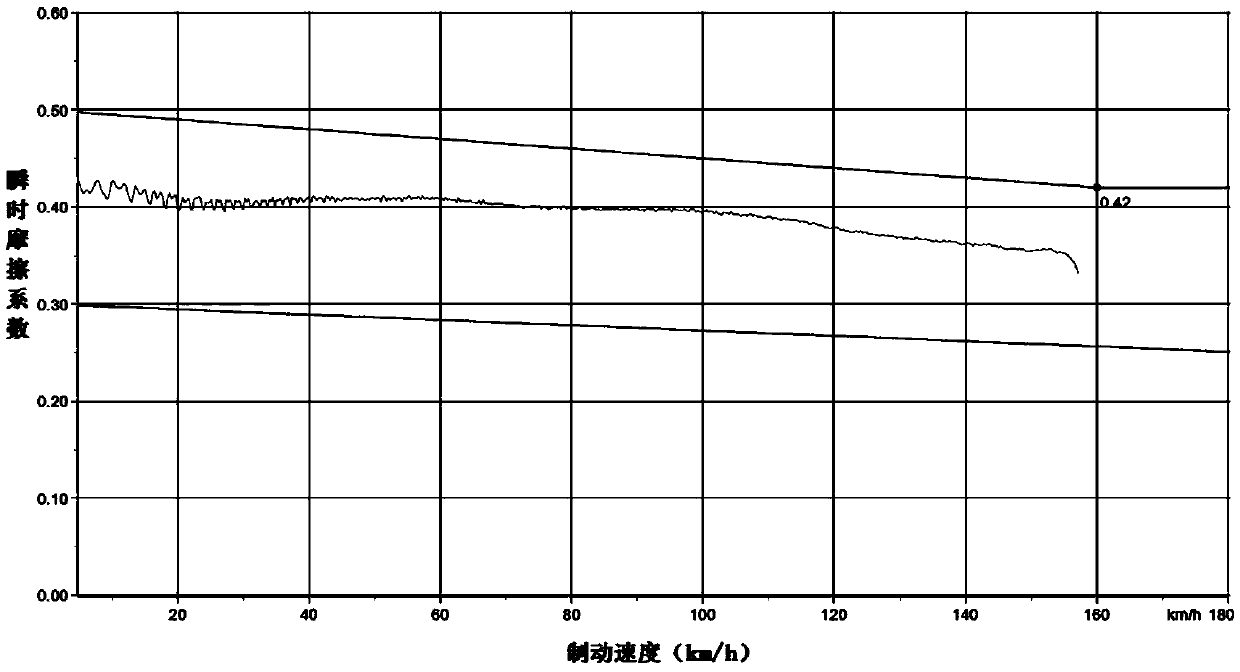

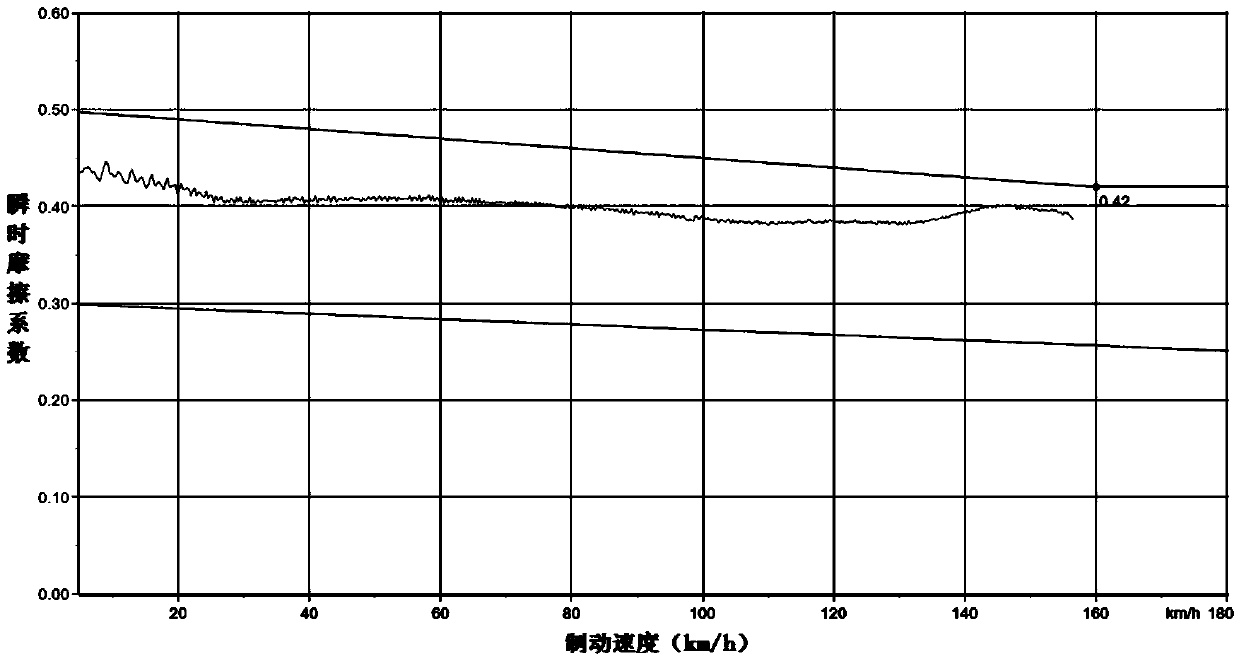

Powder metallurgy brake pad friction material and preparation method thereof

The invention relates to a powder metallurgy brake pad friction material and a preparation method thereof. The preparation method comprises the following specific steps: (A) raw materials are weighed, and include the following components in percentage by mass: 46-56% of copper, 25-35% of ferrochrome, 8-18% of graphite and 4-7% of silicon carbide; (B) the raw materials are fully mixed; (C) the raw materials are molded by pressing; and the pressing pressure is 15-20 MPa; and (D) the pressurization and the sintering are performed; the sintering temperature is 950-1050 DEG C; the sintering time is 7-15 h; and the sintering pressure is 0.5-3 MPa. The prepared powder metallurgy brake pad friction material is high in purity, excellent in friction performance and lower in cost.

Owner:CRRC CHANGZHOU TECH MARK IND CO LTD +1

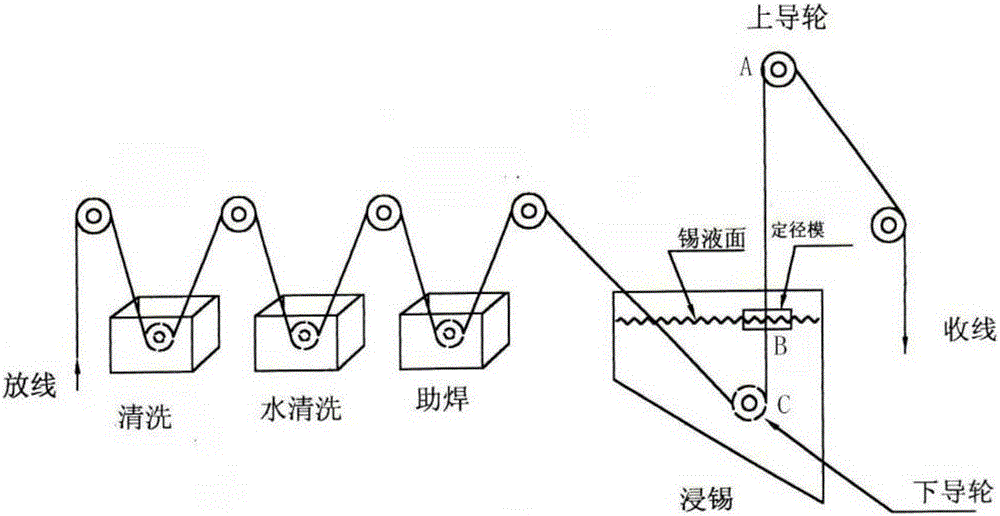

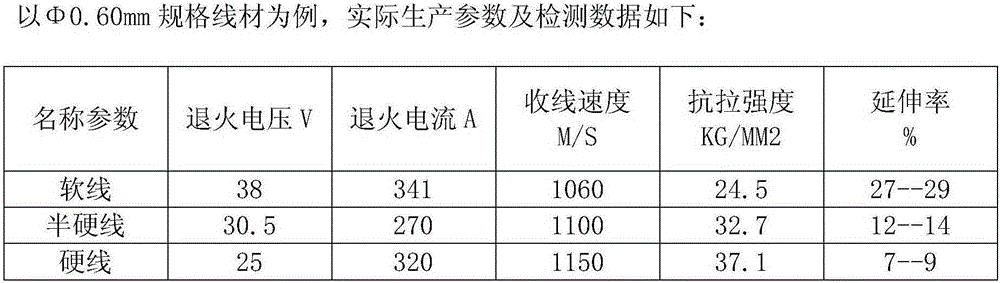

Hard and semi-hard tin-coated copper wire manufacturing method

InactiveCN105304221AEasy plugging and rivetingHas hardnessHot-dipping/immersion processesCable/conductor manufactureCopper wireVoltage

The invention provides a hard and semi-hard tin-coated copper wire manufacturing method. The method comprises the following steps: heavy-duty drawing: using a copper drawing stock for electrical purposes to make a bare copper wire; medium drawing: sending the qualified bare copper wire to a wire release support, enabling the bare copper wire to be stretched through hole mold drawing, preparing a copper wire with a required wire diameter, conducting annealing softening on the copper wire through a certain annealing voltage, and enabling the copper wire to be a circular soft copper wire with a required external diameter; and tinning: detecting the qualified copper wire and sending the copper wire to a wire feed support, cleaning oil stains, oxides and impurities on the surface of the wire by a cleaning agent, sending the cleaned copper wire to a tinning pan for tinning, scraping superfluous tin off the tinned wire through a specification hole mold, ensuring that a surface coating on the copper wire is smooth and even, cleaning the surface of the tin-coated copper wire after cooling, and making a finished product with a required specification by reeling the wire. The beneficial effects of the method are that tin-coated copper wires manufactured by the method exhibit certain hardness, meet the hardness requirement for some special industries, and are convenient to plug, unplug and rivet.

Owner:天津市宏远电子有限公司

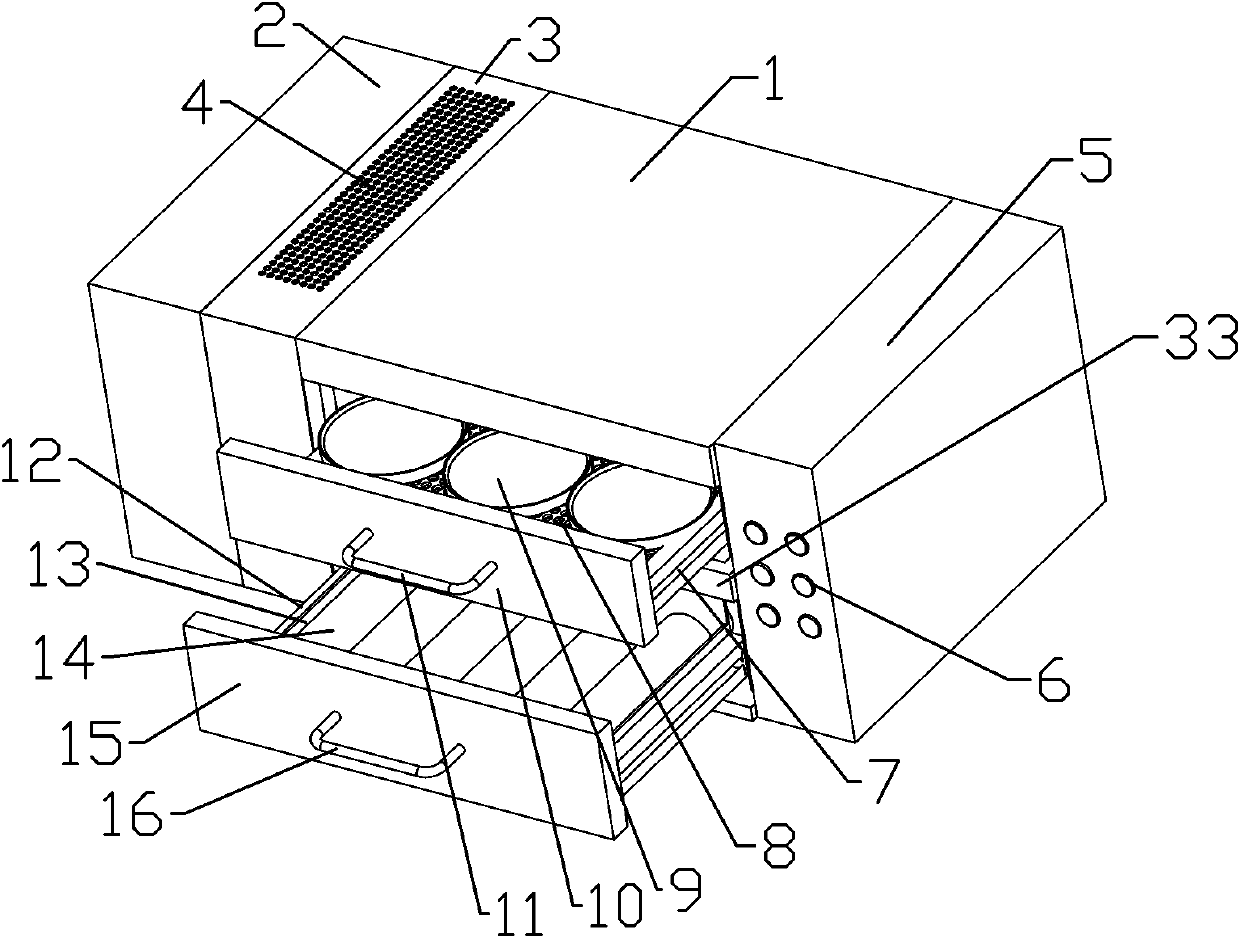

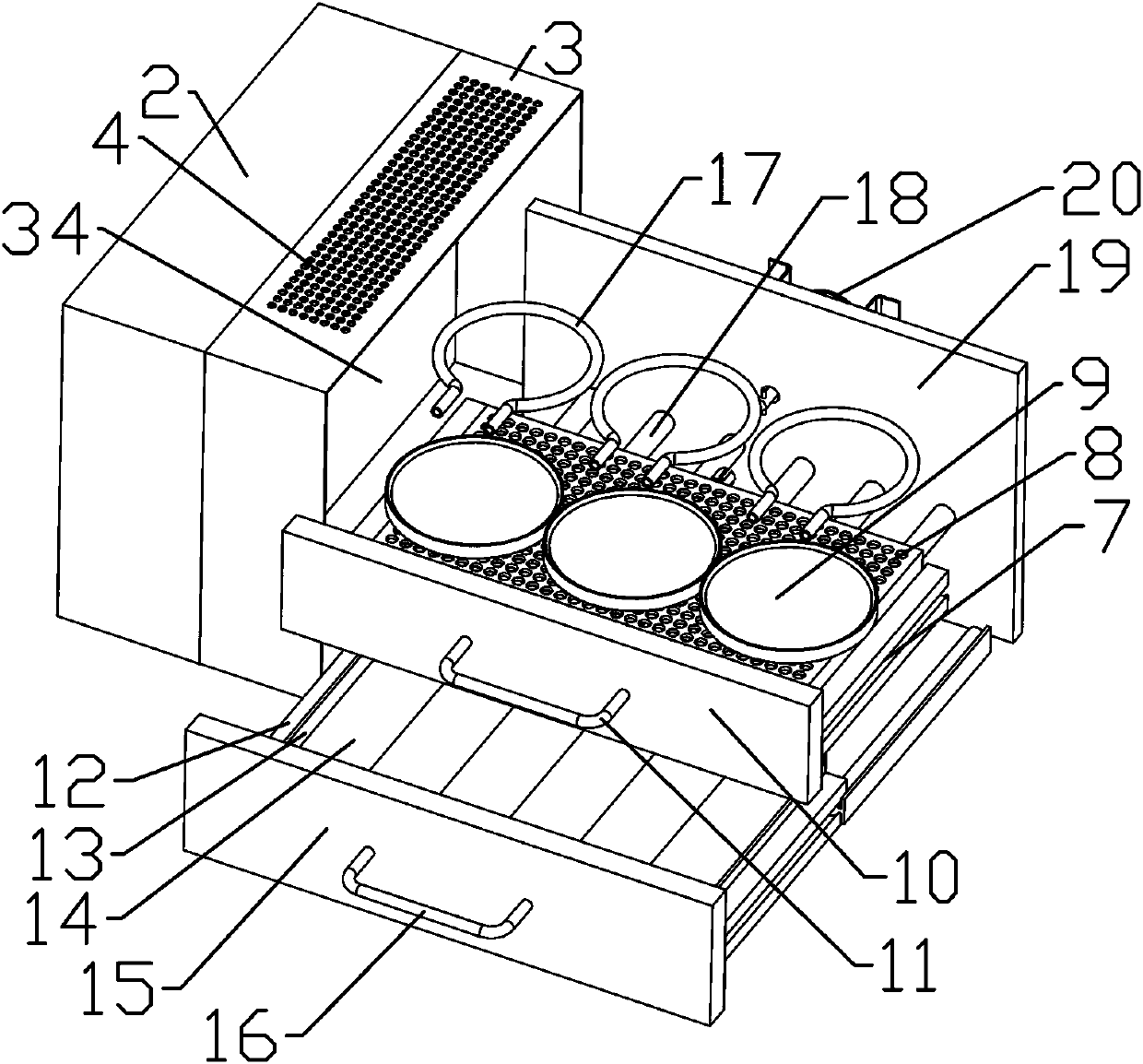

Multifunctional quick roasting oven

The invention relates to an oven, in particular to a multifunctional quick roasting oven. The multifunctional quick roasting oven comprises a box body. The front side of the box body is opened, a magnetron mounting box is arranged on the left side of the box body, a magnetron appointed to the box body is arranged in the magnetron mounting box, a heat isolating box is arranged between the magnetronmounting box and the box body, a columnar food bracket and a cake-shaped food bracket are arranged in the box body, the magnetron and a tubular electric heating component can be started at the same time, food is cooked quickly from inside to outside by means of microwaves generated by the magnetron, and food is roasted from outside to inside by means of heat radiated by the tubular electric heating component, and the magnetron and the tubular electric heating component improve the food processing efficiency. Meanwhile, the surface of the food forms hard scabs, so that heat of the food is prevented from being diffused, the food is crispy and sharp in taste, has certain hardness and is convenient to fetch and place. The oven is high in processing speed to quick-frozen food which needs not to be unfrozen. The processing step is simple. The multifunctional quick roasting oven can promote development of the quick-frozen food industry greatly and has relatively great promotion action to improve the living level of people.

Owner:郑州哆味哆客智能科技有限公司

Zinc alloy mold rapid manufacture process based on rapid prototyping and zinc alloy mold material

InactiveCN103372763AShorten production timeReduce manufacturing costFoundry mouldsFoundry coresComputer Aided DesignZinc alloys

Provided are a zinc alloy mold rapid manufacture process based on rapid prototyping and a zinc alloy mold material. The method includes the steps of manufacturing of a computer aided design (CAD) model, rapid prototyping, manufacturing of a silicone rubber mold, casting, pre-burying of a cooling water channel, zinc alloy pouring, cleaning, machining, polishing and embedding to obtain the zinc alloy mold. The zinc alloy mold material comprises, by weight, 2.0-15.0% of Al, 2.0-10% of Cu, 0.01-0.05% of Mg, 0-0.1% of Re and the balance Zn.

Owner:LANZHOU UNIVERSITY OF TECHNOLOGY

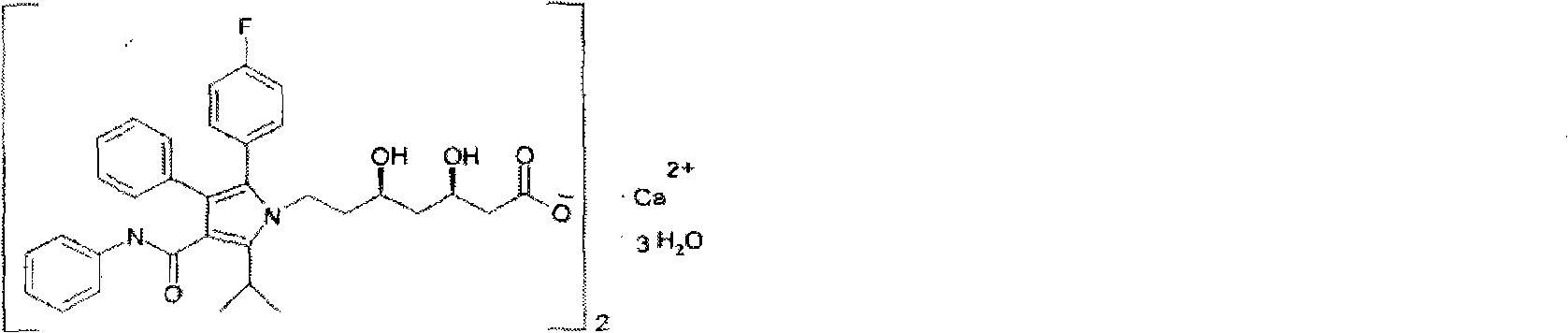

Atorvastatin calcium oral disintegrating tablet and preparation method thereof

InactiveCN101791297AEasy to takeHas hardnessMetabolism disorderPill deliveryMicroparticleMedical prescription

The invention provides an atorvastatin calcium oral disintegrating tablet prescription and a preparation method thereof. The atorvastatin calcium oral disintegrating tablet prescription comprises atorvastatin calcium, a bitter covering agent, a filling agent, a disintegrant, a lubricant, and the like. The invention is technically characterized by providing a particle preparing technology which not only can effectively cover the bitter of the atorvastatin calcium, but also can lead the atorvastatin calcium oral disintegrating tablet to be disintegrated in the mouth. The atorvastatin calcium oral disintegrating tablet with pressure of above 4kg and disintegrating time within 30 seconds can be prepared by adding normal supplementary materials of filling agents, disintegrants, lubricants, and the like of oral disintegrating tablets and is easy to realize industrial scale production.

Owner:CHINA PHARM UNIV

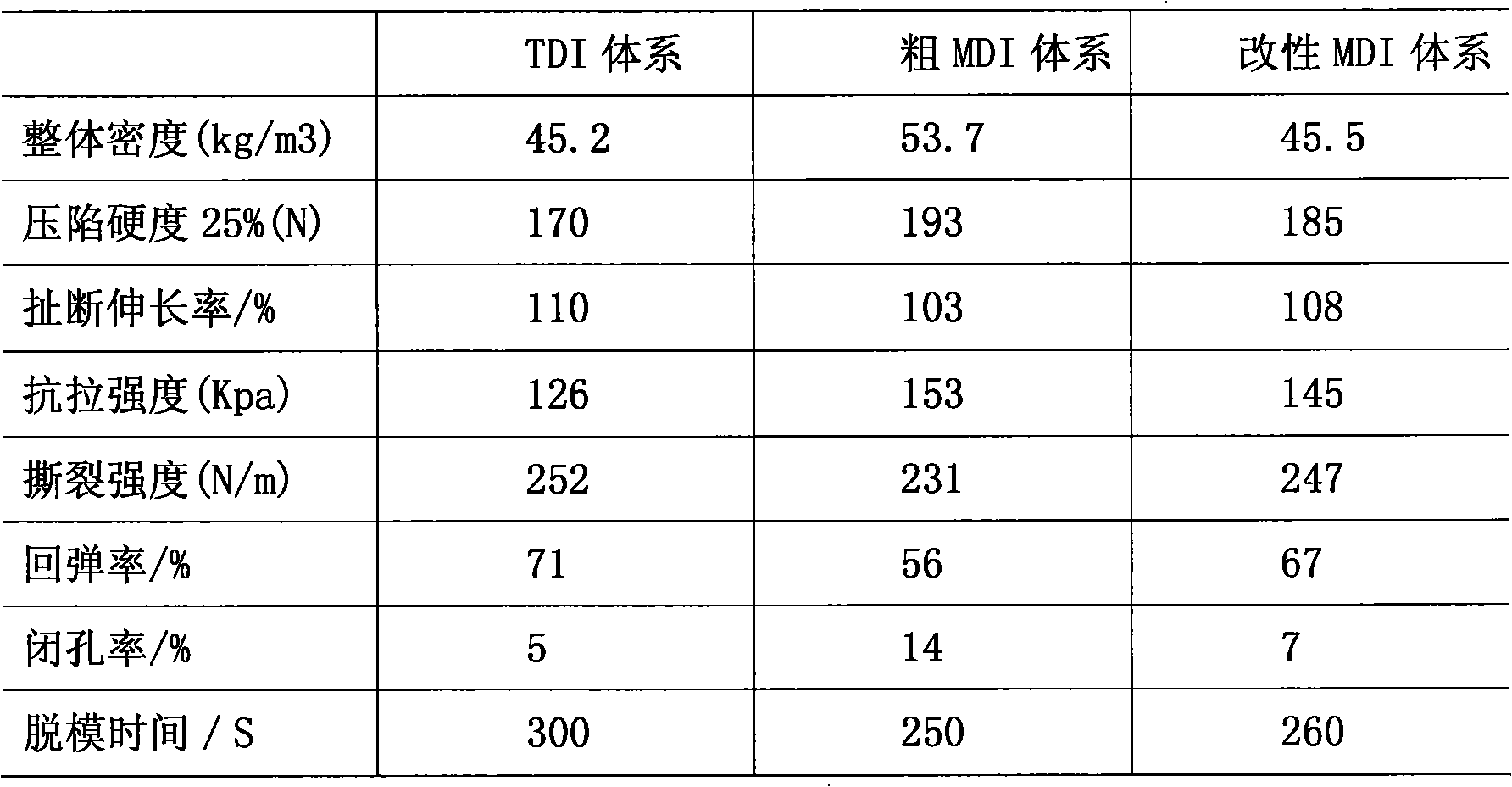

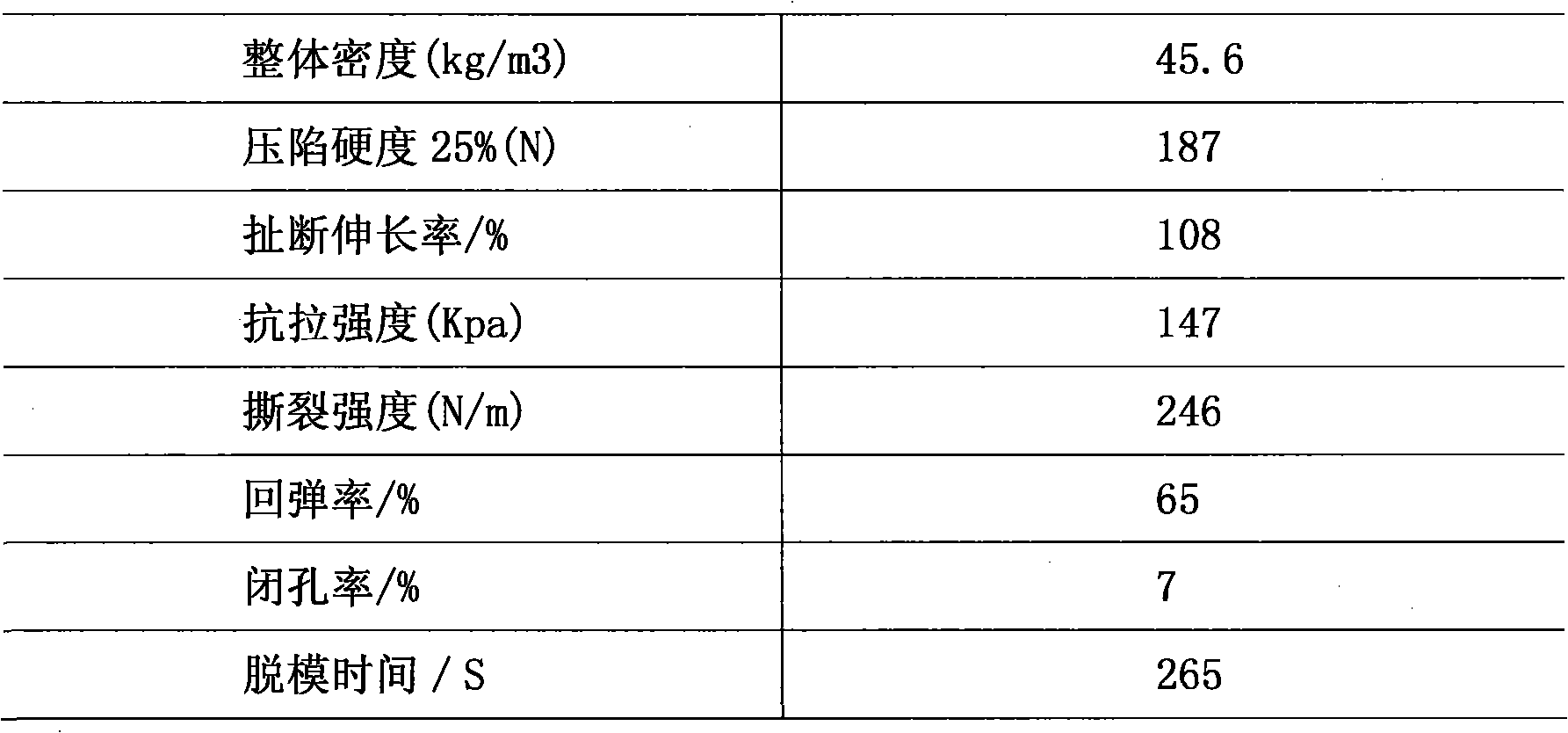

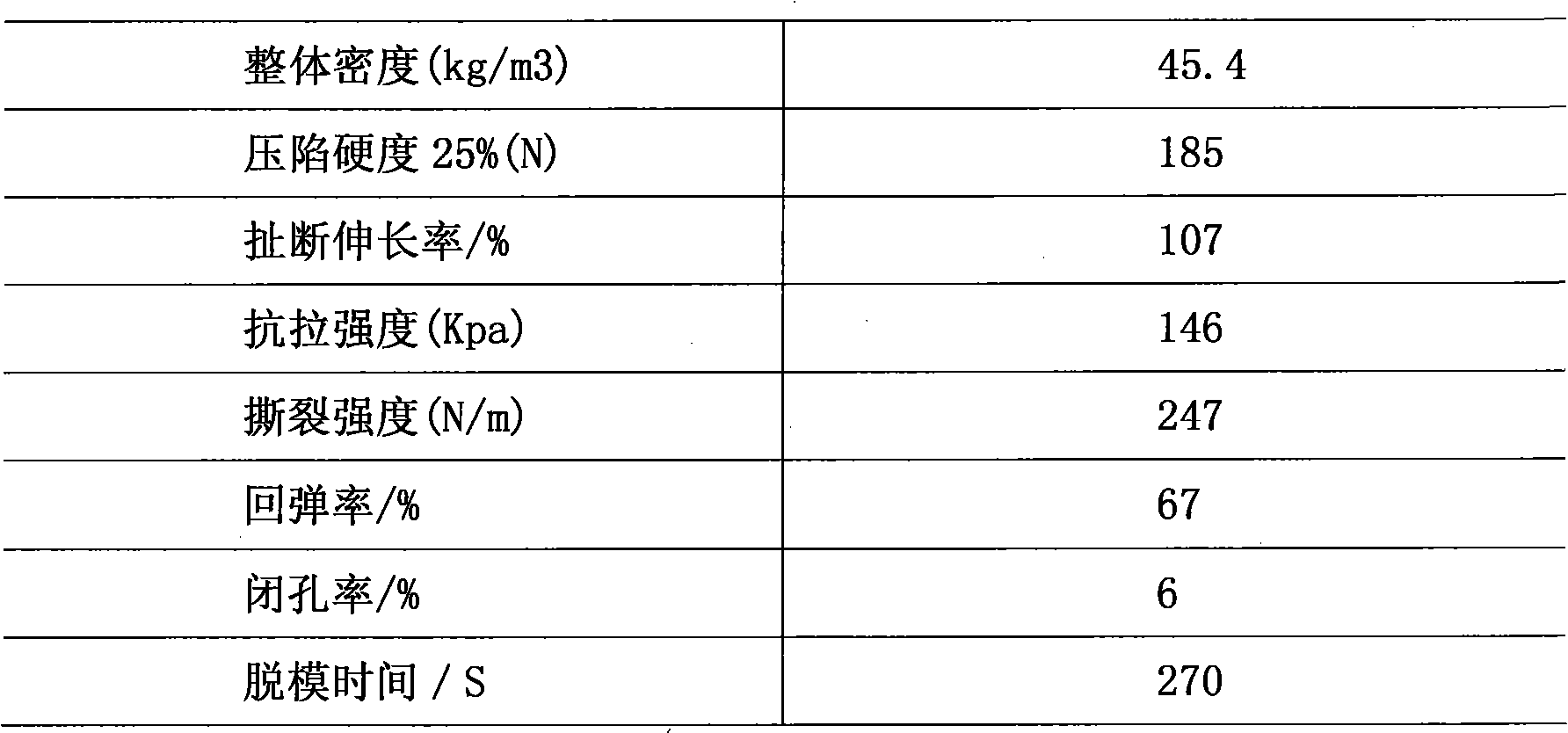

Modified isocyanate for cold curing high resilience foam plastic and preparation thereof

The invention relates to a modified MDI used for a cold curing high resilience foaming plastic. Isocyanate, PDG, a modifying agent and a polymerization inhibitor are taken as the materials, wherein, the isocyanate is a mixture of MDI and PAPI; the PDG has a functionality of three and the number average molecular weight of 5000 to 7000 as well as the weight content of hydroxyl stroma of 65 to 80 percent; glycerin is used as an initiator; the end of ethylene epoxide is sealed by PPOX trihydric alcohol; the modifying agent is modifiedsilicone PDG with a number average molecular weight of 2000 to 3000. When in use, the high resilience combined materials and the modified MDI are weighed according to an index that the index of isocyanic acid is 1.0, stirred and injected into a mold. Compared with a TDI system, the modified MDI of the invention has the advantages of lower cost, good hand feeling and similar elasticity. Compared with a coarse MDI system, the modified MDI has the advantages of better elasticity, better hand feeling, lower density and good opening performance.

Owner:SHANDONG INOV POLYURETHANE

Novel alloy tool steel welding electrode

InactiveCN101920407AGuaranteed welding strengthLow diffusible hydrogen contentWelding/cutting media/materialsSoldering mediaManganeseRare earth

The invention provides a superlow-hydrogen, high-strength and high-toughness alloy tool steel welding electrode with outstanding anticracking performance, which comprises a core wire and a welding electrode covering composition, wherein the electrode covering composition comprises the following components in percentage by weight: 35 to 45 percent of marble, 20 to 30 percent of fluorite, 2 to 4 percent of titanium white, 8 to 13 percent of ferrotitanium, 0.5 to 1.5 percent of alkali, 3 to 6 percent of metal chromium, 4 to 8 percent of metal manganese, 4 to 8 percent of nickel powder, 3 to 6 percent of ferromolybdenum, 2 to 6 percent of rare earth silicon, 2 to 6 percent of quartz and 2 to 6 percent of feldspar. The core wire is made of H08A steel or H08E steel, and potassium sodium mixed water glass is used as a bonder. The alloy tool steel welding electrode can be used as a superlarge-section alloy tool steel (5CrNiMo) structure welding electrode which used to lack and can be used for welding other high-strength alloy steel structure products. The welding electrode has an excellent welding process property, high welding strength, rigidity, plasticity and ductility.

Owner:SHIYAN JINKE CHEM

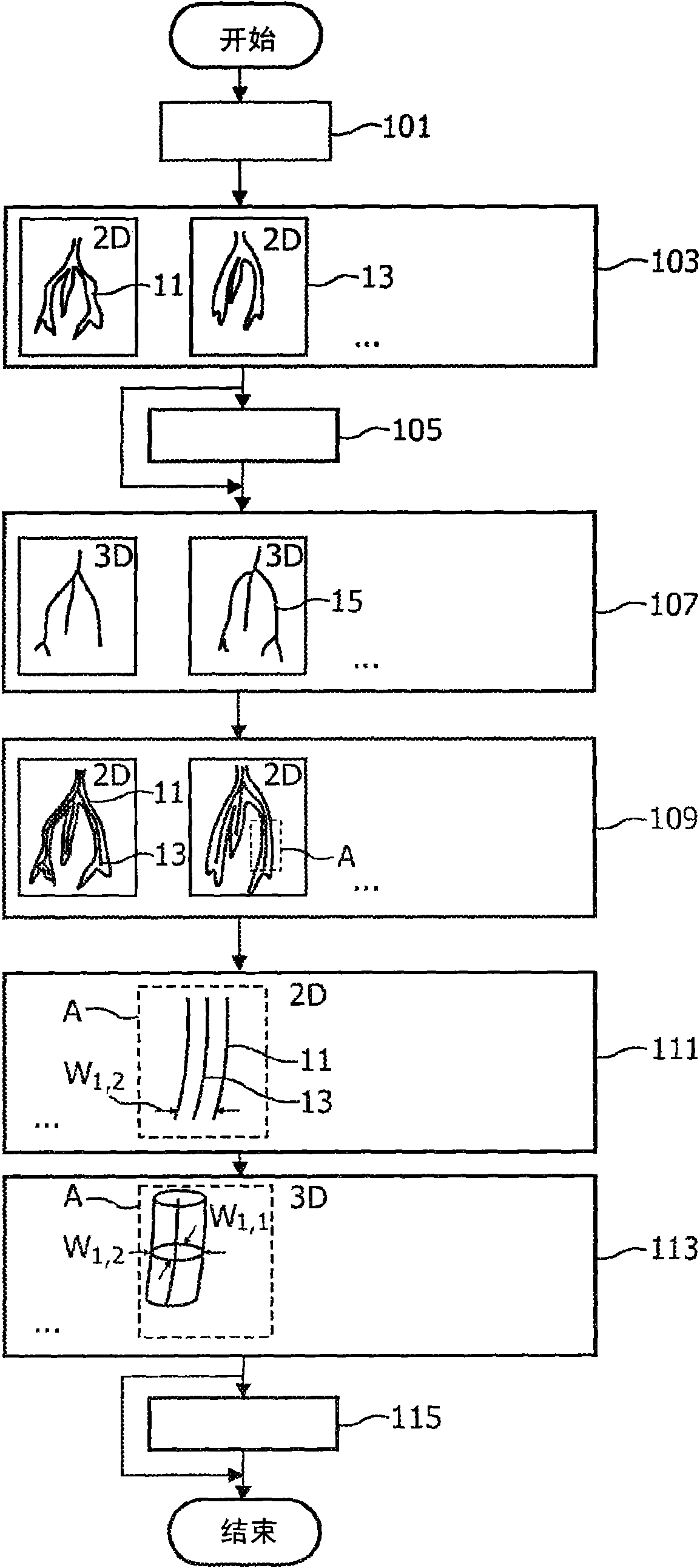

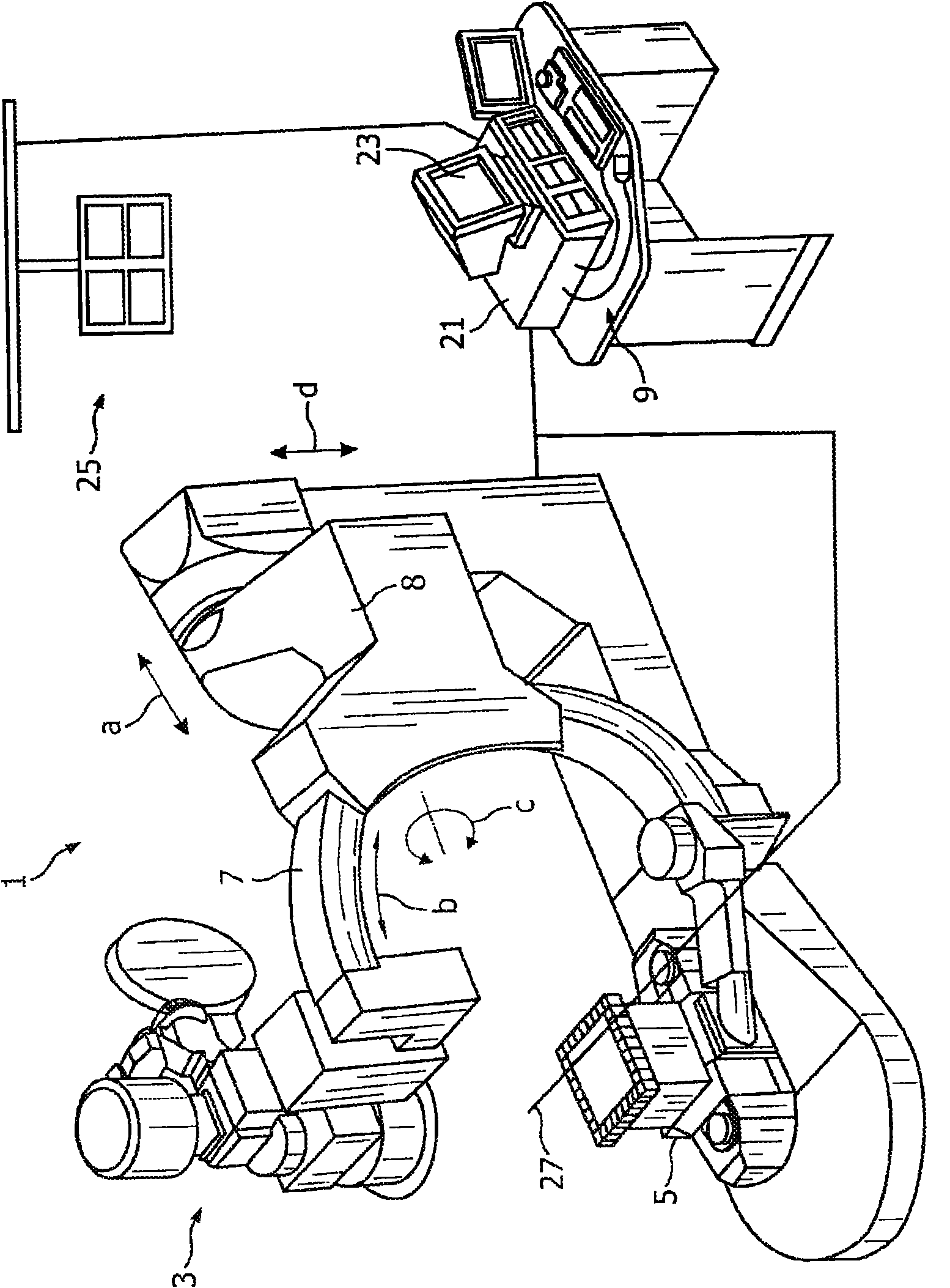

Method for acquiring 3-dimensional images of coronary vessels, particularly of coronary veins

A method and an apparatus for acquiring 3-dimensional images of coronary vessels (11), particularly of coronary veins, is proposed. 2-dimensional X-ray images (13) are acquired within a same phase ofa cardiac motion. Then, a 3- dimensional centerline model (15) is generated based on these 2-dimensional images. From 2-dimensional projections of the centerline model into respective projection planes, the local diameters (w) of the vessels in the projection plane can be derived. Having the diameters, a 3-dimensional hull model of the vessel system can be generated and, optionally, 4-dimensionalinformation about the vessel movement can be derived.

Owner:KONINK PHILIPS ELECTRONICS NV

Asphalt pavement net-shaped crack treatment regeneration sealing layer material and preparation method thereof

The invention relates to an asphalt pavement net-shaped crack treatment regeneration sealing layer material and a preparation method thereof. The asphalt pavement net-shaped crack treatment regeneration sealing layer material is characterized by being composed of the raw materials in parts by weight: 70-100 parts of a composite emulsion and 200-400 parts of a fine aggregate; the composite emulsion is prepared by mixing the raw materials in pars by weight: 20-50 parts of an inorganic solution and 200-600 parts of an organic emulsion; the inorganic solution is an acidic silicon solution or a neutral silicon solution, the silica content is 10-30% (mass), the pH value is 3-7, the sodium oxide content is less than 0.5% (mass), and the average particle size is 10-20 nm; the organic emulsion comprises the raw materials by weight: 100 parts of a regeneration agent emulsion and 100-500 parts of modified emulsified asphalt. The asphalt pavement net-shaped crack treatment regeneration sealing layer material has strong permeability, plays good seam-sealing and waterproof roles in cracks, and has remarkable regeneration and reduction improvement effects on aged asphalt.

Owner:上海乐辛新材料科技有限公司

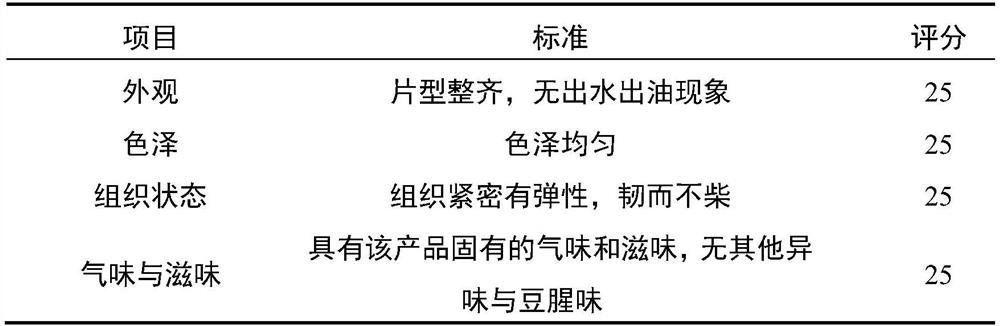

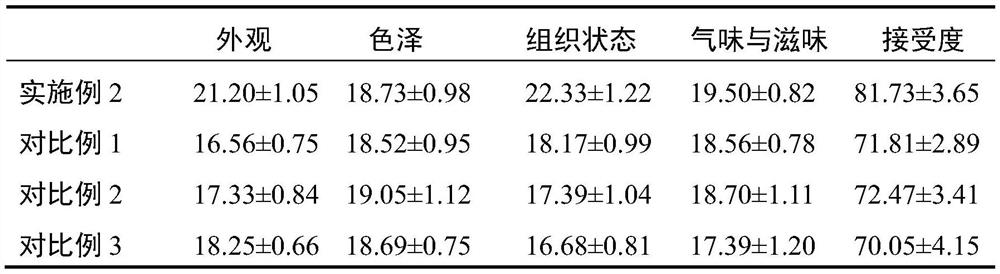

Dried vegetarian meat slice and processing method thereof

InactiveCN112167424AEfficient removalHas hardnessProteins working-up by texturisingFood ingredientsBiotechnologyVegetable oil

The embodiment of the invention provides a dried vegetarian meat slice and a processing method thereof. The dried vegetarian meat slice comprises the following raw materials of, in parts by weight, 20-40 parts of vegetarian meat blank, 8-15 parts of soybean isolate protein powder, 8-15 parts of wheat protein powder, 1-5 parts of starch, 0.1-3 part of sodium alginate, 0.5-1.5 parts of monascus red,10-18 parts of vegetable oil, 5-15 parts of seasonings and 20-45 parts of water, the vegetarian meat blank is prepared by uniformly mixing 30-50 parts of soybean protein, 20-40 parts of wheat protein, 5-10 parts of potato starch, 3-5 parts of white granulated sugar, 1-2 parts of salt, 1-2 parts of light soy sauce, 3-5 parts of spice powder and 10-20 parts of water, and carrying out twin-screw extrusion treatment at 80-160 DEG C. According to the embodiment of the dried vegetarian meat slice and the processing method thereof, the dried vegetarian meat slice which has elasticity and chewiness similar to those of meat, is nutritional and delicious is obtained, and the dried vegetarian meat slice conforms to the current high-protein low-fat diet pursuit of people, and has favorable market prospects.

Owner:CHINA MEAT RES CENT

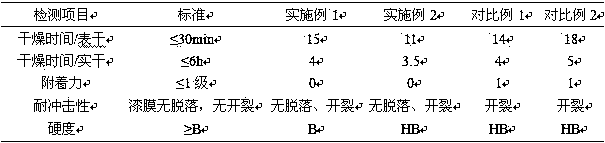

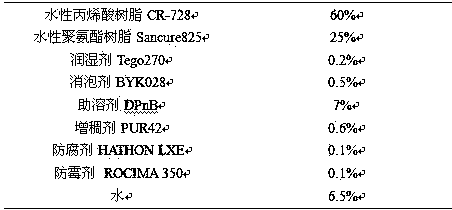

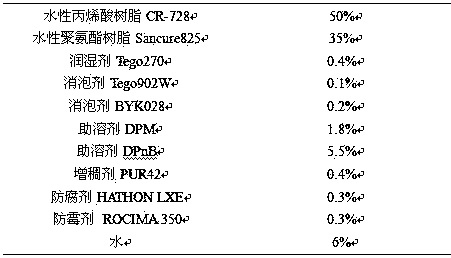

Single-component waterborne finishing coat and preparation method thereof

The invention provides single-component waterborne finishing coat and a preparation method thereof. According to coating performance requirements of existing soft wood and rattan wood products, technical problems that a coating material is poor in flexibility, poor in elasticity and easy to crack are solved by utilizing performances of waterborne acrylic resin and waterborne polyurethane resin, and adjusting a use ratio, so that technical requirements of a client for coating the soft material are satisfied. The single-component waterborne finishing coat comprises the following main components in percentage by weight: 50%-60% of waterborne acrylic resin, 25%-35% of waterborne polyurethane resin, 0.2%-0.5% of a wetting agent, 0.3%-0.5% of a defoaming agent, 6%-8% of a cosolvent, 0.4%-0.6% of a thickener, 0.1%-0.3% of a preservative, 0.1%-0.3% of a mildew preventive and 6%-8% of water.

Owner:GUANGDONG BADESE CHEM

Anti-cracking machining method of small axial surface carburizing and hardening stepped shaft with end face provided with groove

The invention discloses an anti-cracking machining method of a small axial surface carburizing and hardening stepped shaft with an end face provided with a groove. The groove is arranged in an end face of a shaft section B of the stepped shaft, a shaft section A and a side face, close to the shaft section A, of the shaft section B have carburizing and hardening requirements, other parts have no hardness requirements, 20Cr steel serves as blanks of the stepped shaft, the procedures of blanking, rough machining, carburizing treatment, semi finish machining, hardening, fine machining, cutting and groove milling are sequentially carried out on the blanks, and then the stepped shaft with different shaft sections having different mechanical properties are machined. The anti-cracking machining method is simple in structure and convenient to achieve; a protective step is arranged before carburizing, the protective step before the hardening is machined to be a fillet, and cracking caused by oversize stress when the carburizing and hardening are carried out on the root portion of the step can be effectively avoided; a shaft section B carburized layer is milled off before the hardening, the hardness of the shaft section B after the hardening is reduced, and machining efficiency of following steps is improved.

Owner:HEBEI HUABEI DIESEL ENGINE

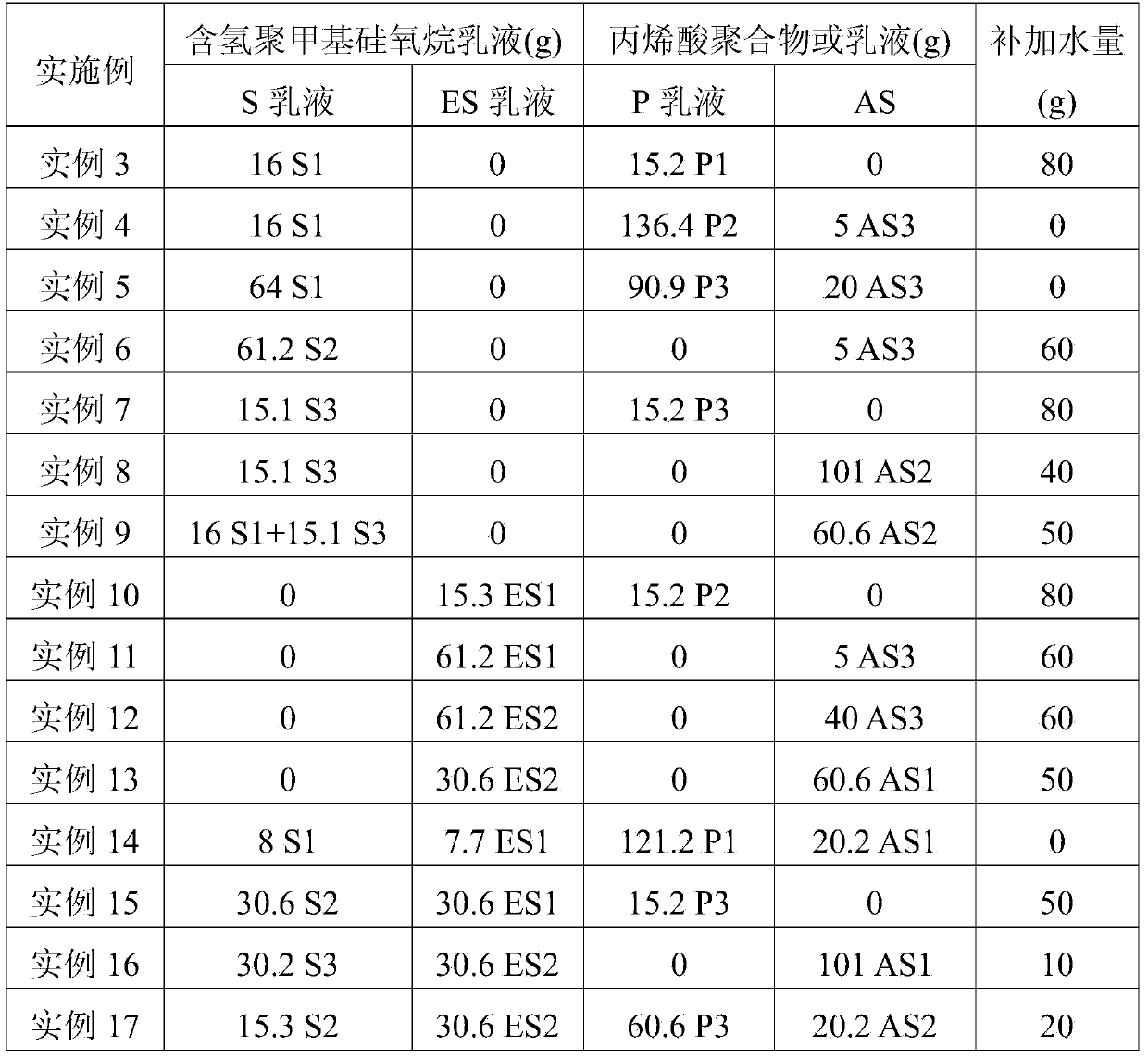

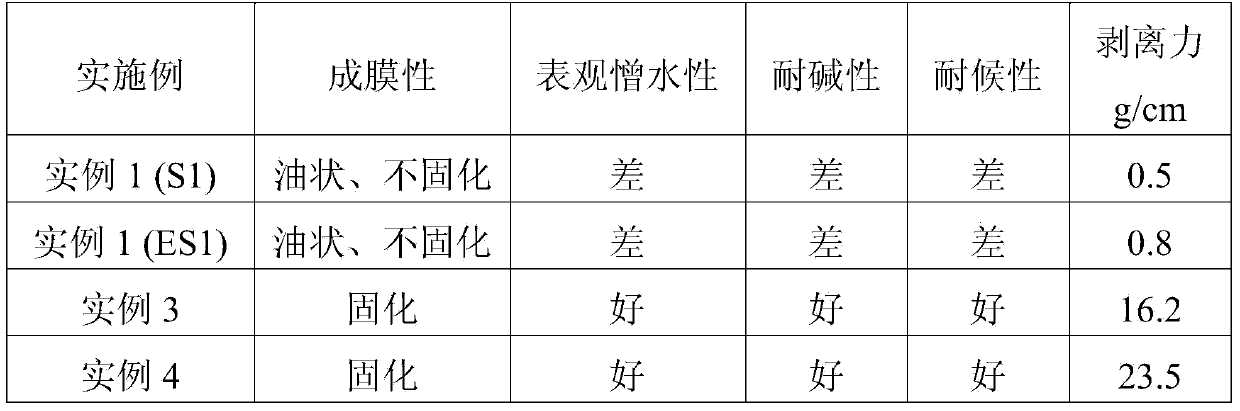

Acrylic organosilicone water-emulsion coating as well as preparation method and application for same

The invention belongs to the technical field of acrylic coatings, and discloses an acrylic organosilicone water-emulsion coating as well as a preparation method and an application for the same. The acrylic organosilicone water-emulsion coating comprises the following components in the following parts by weight: 100 parts of water, 0.1-4 parts of an emulsifier, 5-20 parts of liquid hydrogen-containing polymethyl siloxane, and 5-50 parts of acrylic polymers. The organosilicone content of the acrylic organosilicone water-emulsion coating disclosed by the invention is up to more than 10% in the polymers, organosilicone and the acrylic polymers are compounded in a wide range, and curing film-forming is performed at a room temperature. The preparation process disclosed by the invention is simple, and the obtained emulsion is good in stability; and after curing film-forming, the acrylic organosilicone water-emulsion coating is good in mechanical performance (wherein the hardness can be up to 3 H), excellent in waterproof and hydrophobic performances, acid-base resistance, weather resistance, and adhesive force (which can be up to 2.5 MPa), and proper in peel strength (which can be up to 23 g / cm).

Owner:GUANGZHOU CHEM CO LTD CHINESE ACADEMY OF SCI

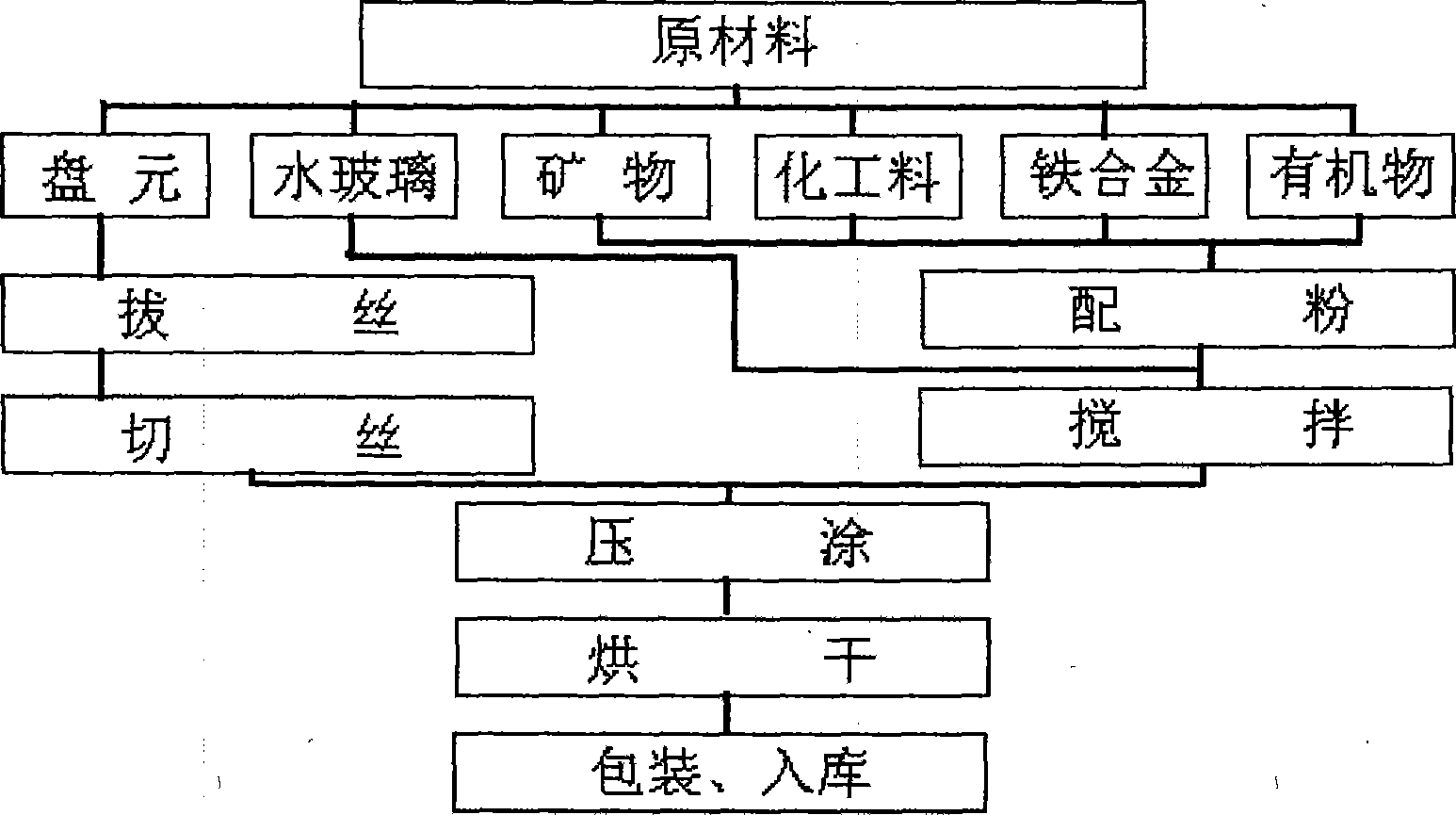

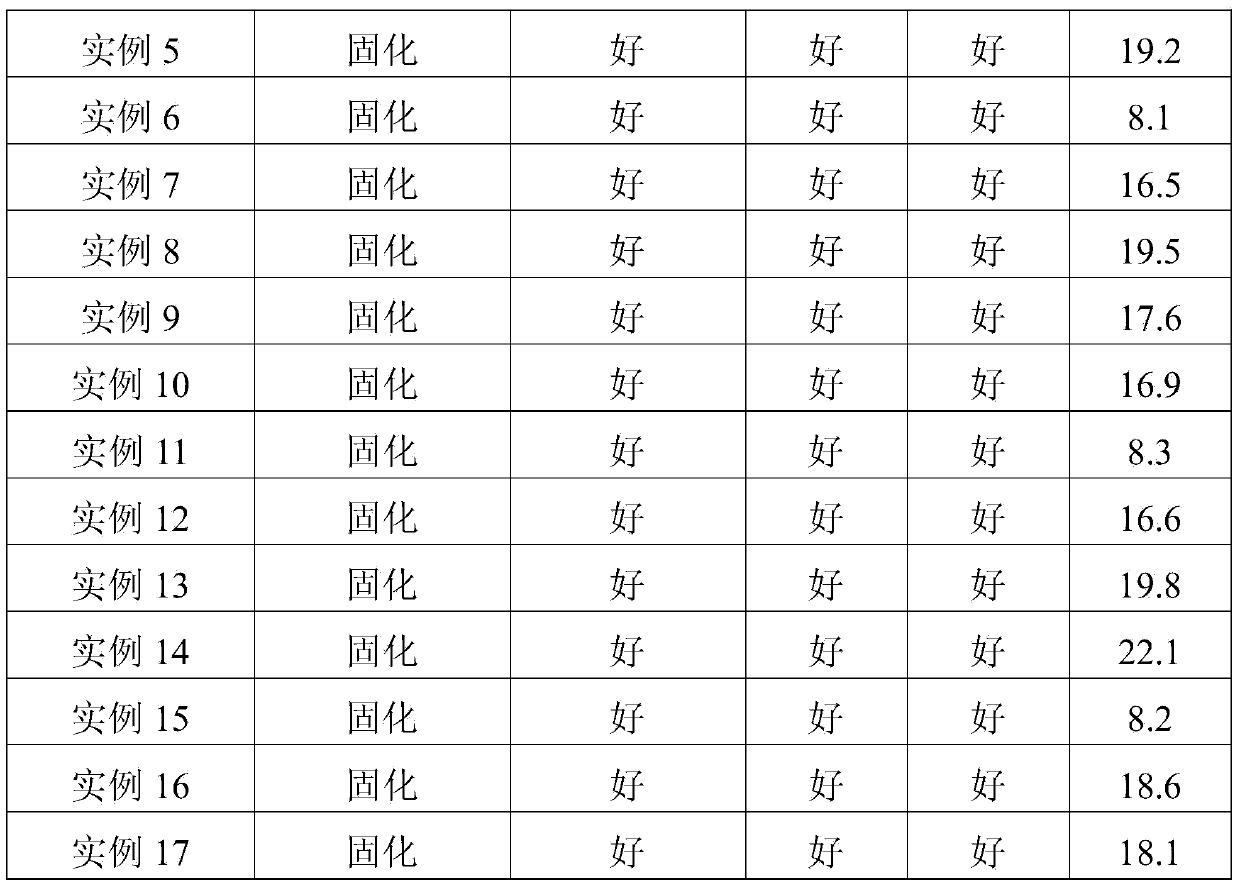

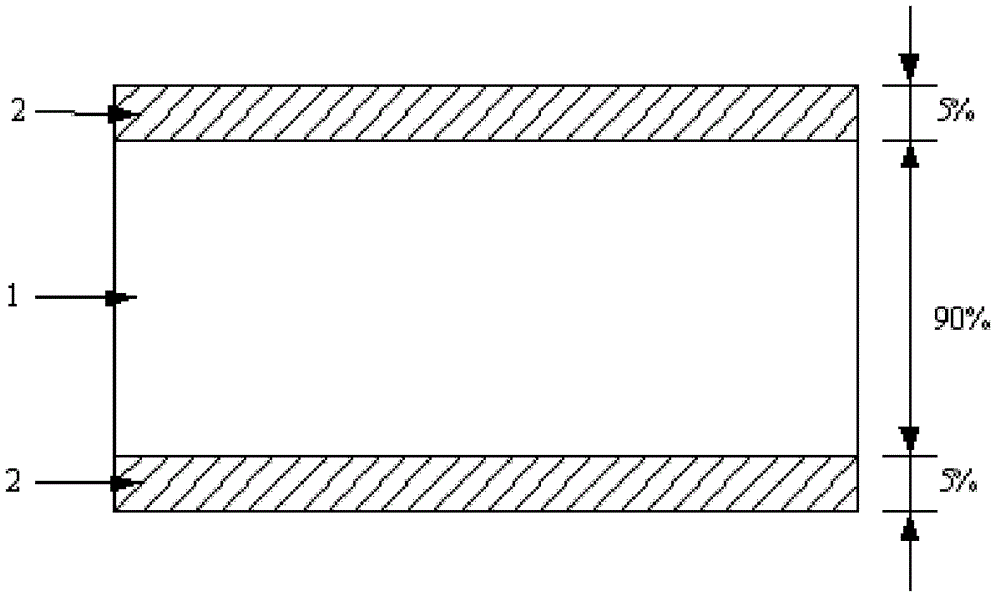

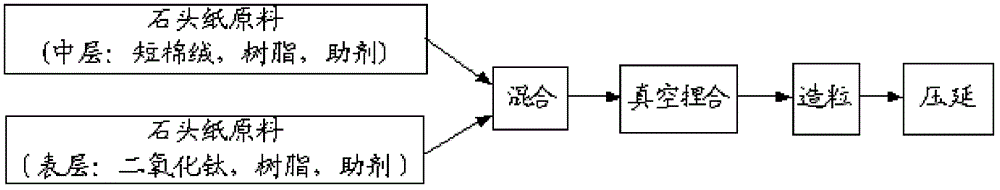

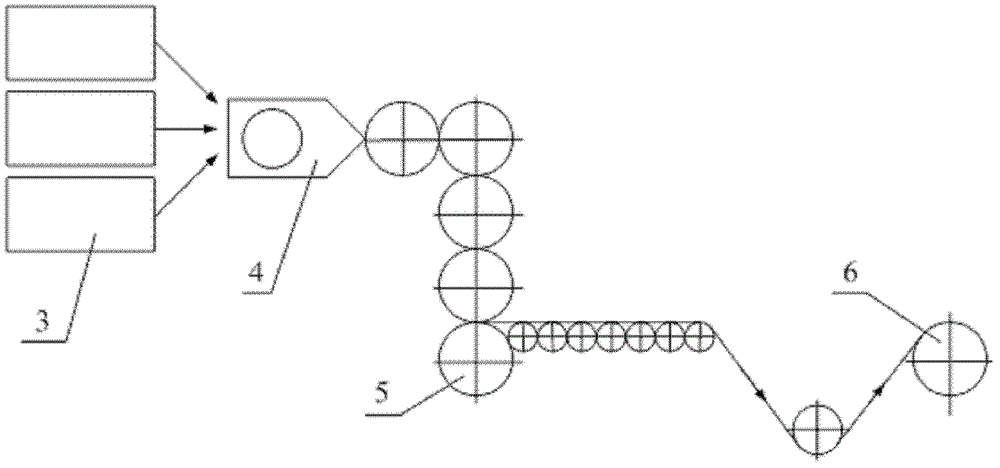

Novel environment-friendly stone paper and preparation method thereof

InactiveCN103061200ALight weightImprove rigiditySurface covering paperNon-fibrous pulp additionFiberSurface layer

The invention relates to the field of papermaking, and discloses a novel environment-friendly stone paper and a preparation method thereof. The invention provides a novel environment-friendly stone paper using short fiber to substitute a main component calcium carbonate in a traditional stone paper. The invention further provides a three-layer coextrusion environment-friendly stone paper. The environment-friendly stone paper is composed of a three-layer structure comprising a surface layer-a middle layer-a surface layer; the middle layer comprises main components of short fiber and resin; and the surface layer comprises main components of titanium dioxide and resin. Compared with performance of the traditional stone paper, the novel environment-friendly stone paper, prepared from processes comprising mixing, kneading, granulation and calendering, gains reduced specific gravity, improved physical and mechanical properties and increased size, and qualitatively changes definition, characteristics, advantages and application fields of stone paper, and has extensive application value.

Owner:HONG KONG GREEN ANGEL TECH

Water-based paint and preparation method thereof

InactiveCN102702871AAntibacterialMildew proofPolyurea/polyurethane coatingsEpoxy resin coatingsSodium acetateWater based

The invention relates to water-based paint, which comprises the following raw materials by part by weight: 52 to 55 parts of water, 0.5 to 0.7 part of sodium dodecyl sulfate, 30 to 70 parts of emulsion or aqueous dispersoid resin, 0.8 to 1 part of ammonia water, 0.1 to 0.2 part of defoamer, 0.05 to 0.1 part of sodium acetate, 0.5 to 5 parts of germicide, 0.1 to 1 part of corrosion inhibitor and 0.1 to 0.2 part of potassium peroxydisulfate. The invention further provides a preparation method for the water-based paint. The water-based paint is non-poisonous and harmless and causes little pollution to the environment. A coating formed by applying the water-based paint has high brightness and excellent firmness and resistance to crack, is hard to a certain extent, contains few VOCs and no heavy metal and have the functions of antibiosis and both mold and rust prevention. Therefore, the water-based paint is environmentally friendly and safe.

Owner:ANHUI JINDUN PAINT

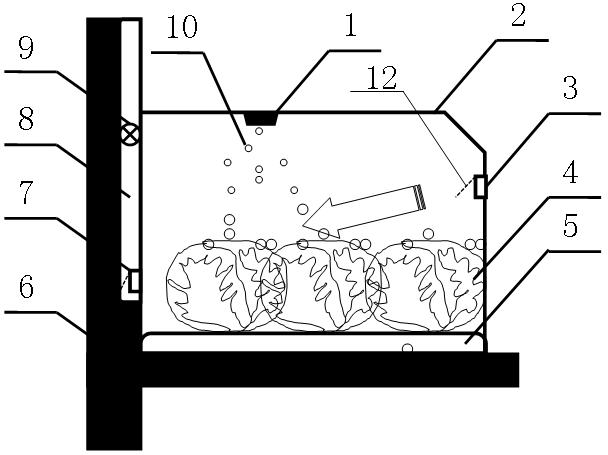

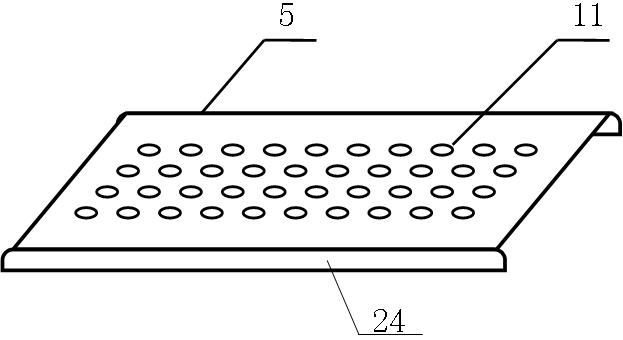

Fruit-vegetable box applicable to air-cooling refrigerator and rapid-cooling and moisturizing method of fruit-vegetable box

InactiveCN102620509AAggravate frostingFrosting remainsLighting and heating apparatusUltrasonic humidifiersHigh humidityEvaporation

The invention discloses a fruit-vegetable box applicable to an air-cooling refrigerator. The fruit-vegetable box comprises a box body, wherein a spraying device is arranged at the top in the box body; an air inlet is arranged at the upper part of the front side of the box body; an air outlet is backwards and convexly arranged at the lower part of the rear side of the box body and is communicated with an air duct of the refrigerator; the tops of the rear ends of the air inlet and the air outlet are respectively hinged with a wind board; and the wind boards are used for blocking the air inlet and the air outlet. The invention also discloses a rapid-cooling and moisturizing method of the fruit-vegetable box applicable to the air-cooling refrigerator. The fruit-vegetable box is provided with the air outlet connected with the air duct of the refrigerator, so that high-humidity gas in the fruit-vegetable box is directly conveyed out by the air duct of the refrigerator, and is prevented from entering a refrigerating chamber and further promoting the frosting phenomenon in the refrigerating chamber. The spraying device can carry out spraying and over-humidifying treatment on fruits and vegetables in advance, the circulating air of the refrigerator can carry out evaporation and cooling on the fruits and the vegetables, so that not only is rapid cooling of the fruits and the vegetables realized, but also high humidity of the fruits and the vegetables is maintained, and simultaneously, the frosting phenomenon in the refrigerating room can not be promoted.

Owner:HENAN XINFEI ELECTRICAL EQUIP

Organic and inorganic complex finishing varnish

InactiveCN105001728AHas hardnessHas densityAntifouling/underwater paintsPaints with biocidesDispersityEmulsion

The invention provides an organic and inorganic complex finishing varnish. An inorganic photocatalysis material is added into a complex organic liquid of silica sol and an elastic acrylic emulsion so as to form an organic and inorganic complex finishing varnish main-body material. The silica sol is added into the emulsion-formed film. Through compounding of the silica sol and the self-crosslinking emulsion, an organic and inorganic complex paint film is formed. The organic and inorganic complex paint film has hardness and density of silica sol and will not generate static charge. No pollutants will adhere to the paint film. Meanwhile, the elastic emulsion endows the paint film with flexibility, and the whole paint film is soft. Thus, the finishing varnish with good dispersity, high surface hardness and excellent anti-pollution performance is obtained.

Owner:上海贝塔建筑科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com