Composite plate material of foam microcrystalline glass and pure microcrystalline glass and manufacturing method of composite plate material

A technology of foamed glass-ceramics and composite plates, which is applied in the field of engineering materials, can solve the problems of easy aging, flammability of organic thermal insulation materials, poor corrosion resistance, etc., achieve strong acid and alkali corrosion resistance, excellent sound insulation and thermal insulation performance, and improve The effect of load-bearing capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

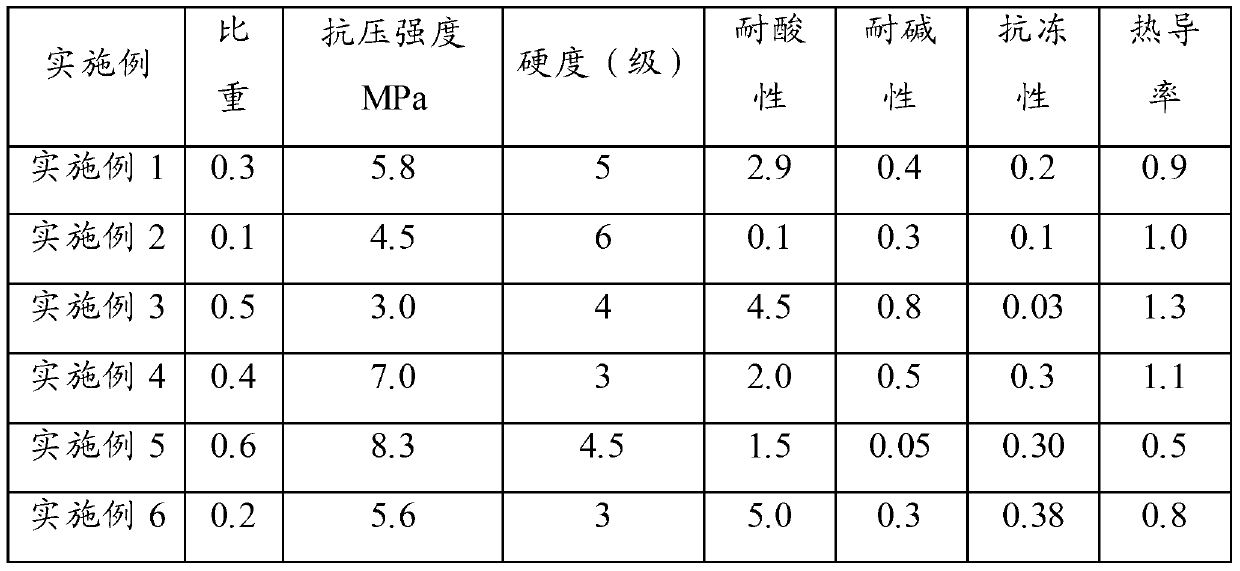

Examples

Embodiment 1

[0061] In terms of weight percentage, desert aeolian sand 50%, limestone 20%, feldspar 10%, soda ash 4%, barium carbonate 5%, spodumene 6%, alumina 2%, sodium nitrate 2%, borax 0.8%, Antimony oxide 0.2%, batching according to the above components and dosage, put the obtained mixture into a high-temperature furnace for heating, the temperature is controlled at 1480°C, and melt after 24 hours to obtain a glass-ceramic liquid. The glass-ceramic liquid flowing out of the high-temperature melting furnace is extruded into thin-faced pellets with a thickness of 0.3 mm by a twin-roller machine, and then ground on a ball mill to form glass-ceramic powder with a particle size of 320 mesh.

[0062] In terms of weight percentage, get 80% of the prepared glass-ceramic powder, graphite 3%, lime 2%, silicon carbide 5%, boric acid 2% and zinc oxide 8%, and mix uniformly to obtain the foamed glass-ceramic mixture. Use an automatic distributing machine to evenly spread and scrape the foamed gla...

Embodiment 2

[0064] In terms of weight percentage, Yellow River silt 50%, limestone 20%, feldspar 10%, soda ash 4%, barium carbonate 5%, spodumene 6%, alumina 2%, sodium nitrate 2%, borax 0.8%, oxide Antimony 0.2%, mix the ingredients according to the above components and dosage, put the obtained mixture into a high-temperature furnace for heating and melting, the temperature is controlled at 1500°C, and melt after 24 hours to obtain glass-ceramics. The glass-ceramic liquid flowing out of the high-temperature melting furnace is extruded into thin-faced pellets with a thickness of 0.5 mm by a twin-roller machine, and then ground into a glass-ceramic powder with a particle size of 250 mesh on a ball mill.

[0065] In terms of weight percentage, take 80% of the prepared glass-ceramic powder, 5% of high-altitude glass powder, 5% of silicon carbide, 5% of boric acid and 5% of zinc oxide, and mix them uniformly to obtain a foamed glass-ceramic mixture. Use an automatic distributing machine to ev...

Embodiment 3

[0067] In terms of weight percentage, iron tailings 60%, limestone 14%, feldspar 10%, soda ash 3%, barium carbonate 4%, spodumene 4%, sodium nitrate 3%, borax 0.8%, antimony oxide 0.2%, according to The above-mentioned components and dosages are mixed together, and the obtained mixture is put into a high-temperature furnace for heating and melting. The temperature is controlled at 1500° C., and after 24 hours, it is melted to obtain glass-ceramic liquid. The glass-ceramic liquid flowing out of the high-temperature melting furnace is extruded into thin-faced pellets with a thickness of 0.2 mm by a double-roller machine, and then ground into a glass-ceramic powder with a particle size of 100 mesh on a ball mill.

[0068] In terms of weight percentage, take 90% of the prepared glass-ceramic powder, 2% of gypsum, 2% of high-altitude glass powder, 3% of boric acid, 2.6% of zinc oxide and 0.4% of manganese dioxide, and mix them evenly to obtain foamed glass-ceramics. material. Use ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com