Patents

Literature

124results about How to "Improve the sound insulation effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Composite plate material of foam microcrystalline glass and pure microcrystalline glass and manufacturing method of composite plate material

The invention provides a composite plate material of foam microcrystalline glass and pure microcrystalline glass. The composite plate material comprises a base body and a decoration surface, wherein the base body is made of a foam microcrystalline glass mixed material; the thickness of the base body is 50mm to 500mm; the decoration surface covers the surface of the base body and is made of pure microcrystalline glass granules; the thickness of the decoration surface is 3mm to 30mm. The invention also provides a manufacturing method of the composite plate material. The composite plate material of the foam microcrystalline glass and the pure microcrystalline glass, provided by the invention, can simultaneously replace a building material and a decoration material, and is small in specific gravity, high in strength, fireproof and corrosion-resistant; environment products which are difficultly handled in a natural environment and industrial wastes which are difficultly treated currently can be consumed; the environment stress is reduced.

Owner:北京晶雅石科技有限公司

Phosphogypsum light-weight partition wall board and building block and manufacturing method thereof

The invention discloses a phosphogypsum light-weight partition wall board and a building block and a manufacturing method thereof, which are characterized in that the phosphogypsum light-weight partition wall board and the building block consist essentially of raw materials according to the following weight percentages: 10-50% of phosphogypsum, 10-50% of magnesium oxide, 5-20% of magnesium chloride, 10-50% of water, 10-50% of packing, 0.1-3% of foaming agent and 0-5% of short fiber reinforced material. The phosphogypsum foamed building block or foamed wall board are light in weight, and good in sound insulation and heat preservation effects, thus being ideal energy-saving and environment-protective building materials; and main raw materials of phosphogypsum concrete can be obtained locally, the phosphogypsum concrete is simple and convenient in production, low in cost and pollution-free, and phosphogypsum concrete products not only can be widely used in mined-out areas of mines or tunnel backfilling, but also can be comprehensively utilized as surface layers, base layers and under layers of roads, and the like, thus having very broad application prospect.

Owner:杜庆贵

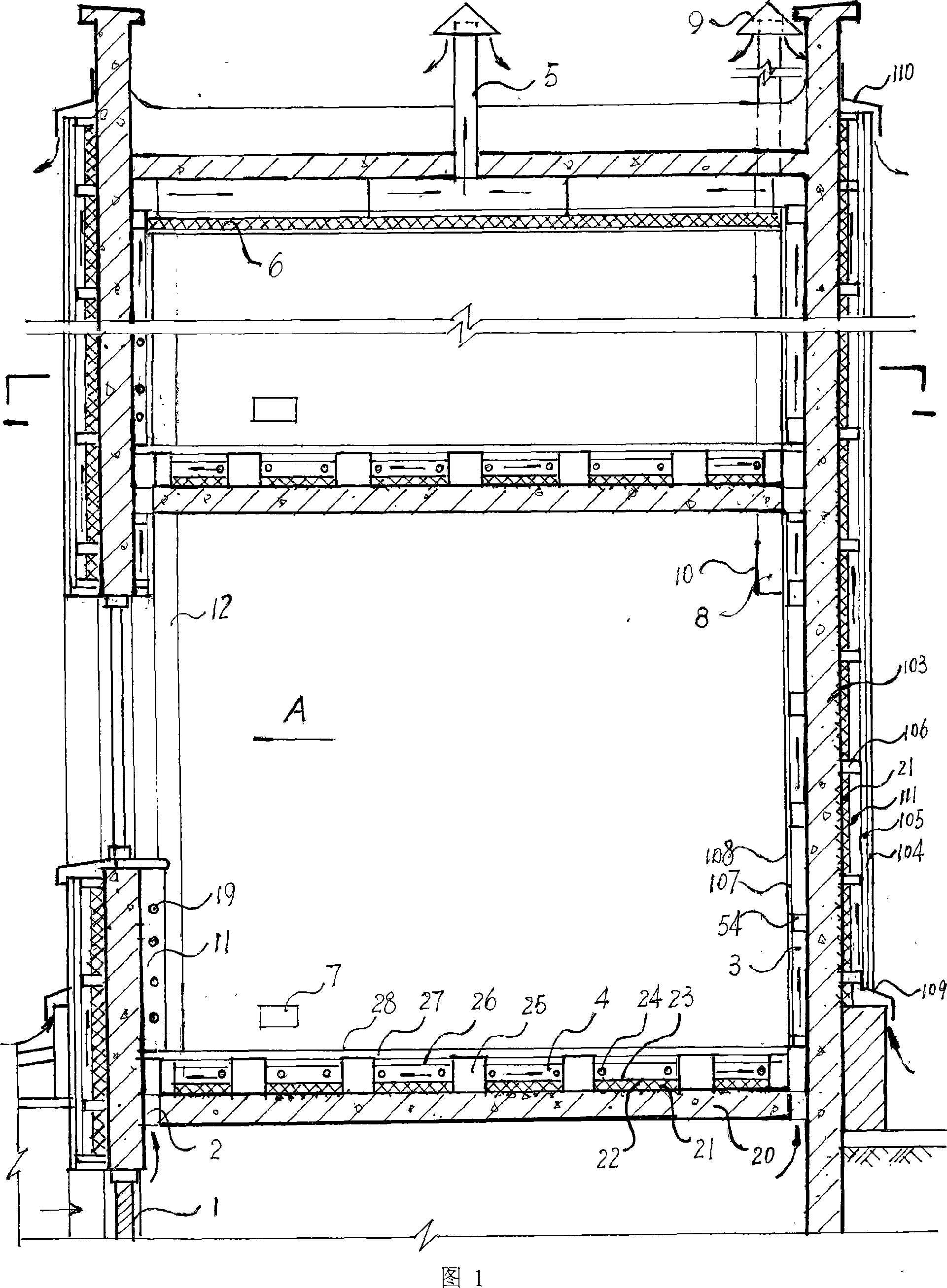

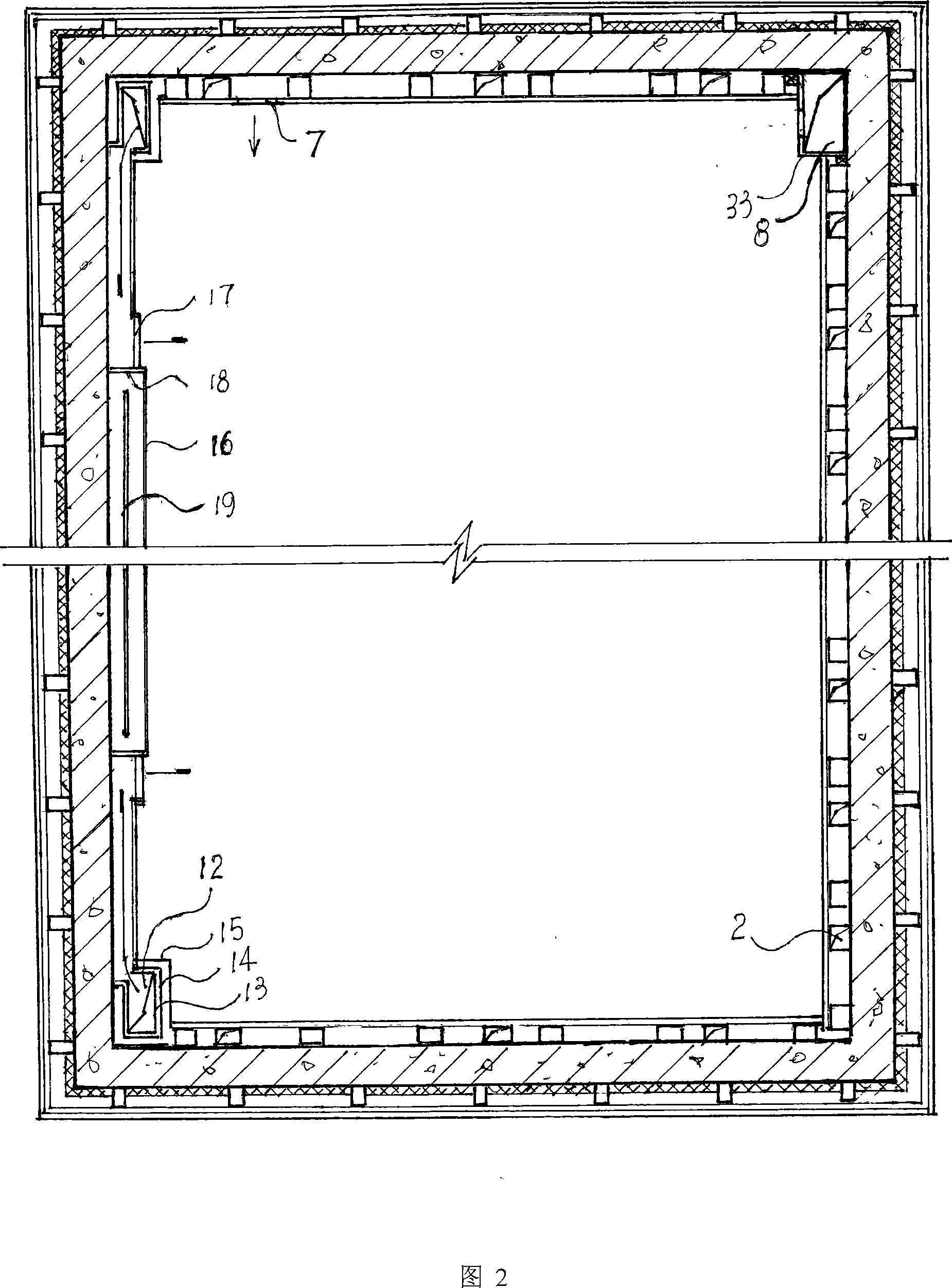

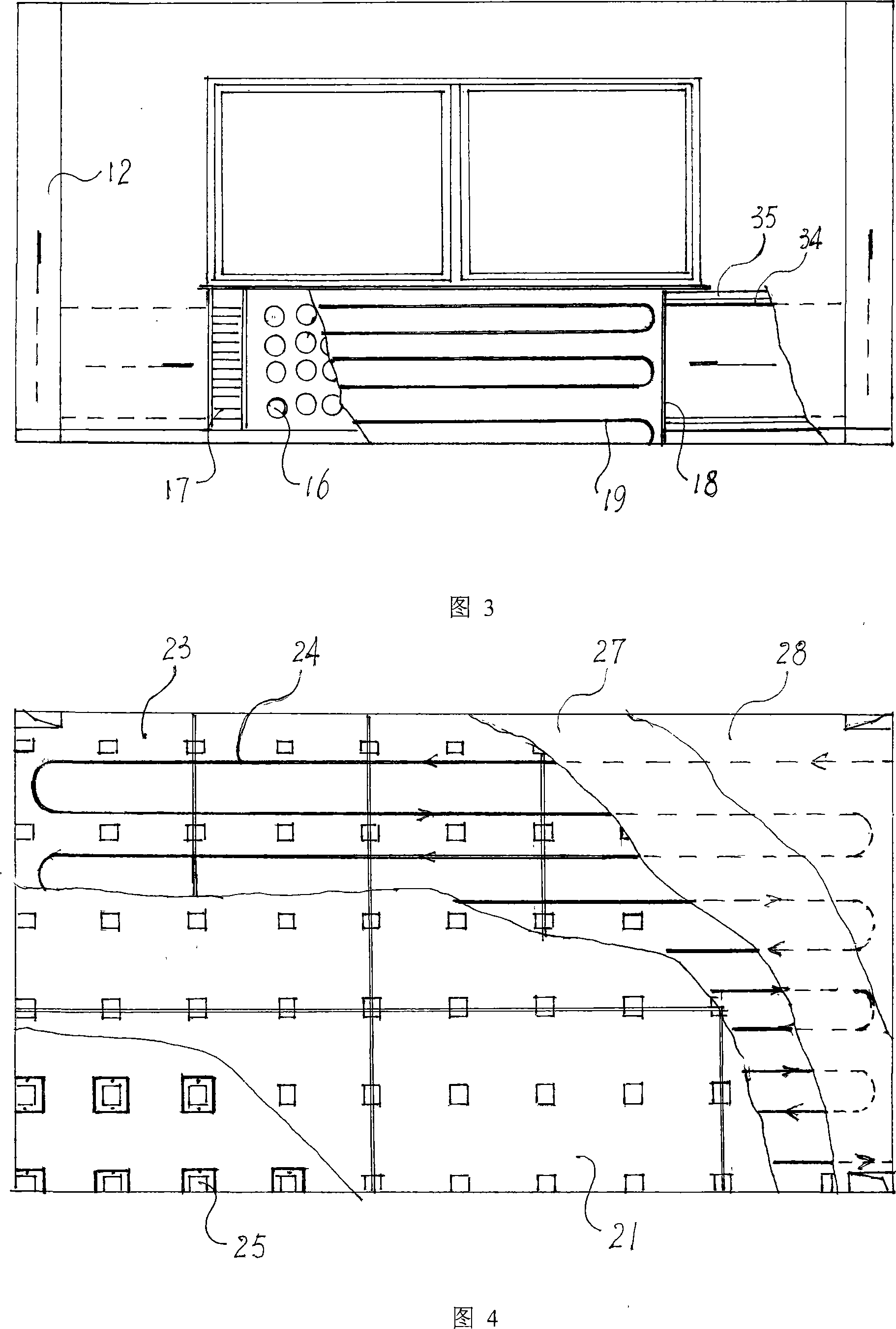

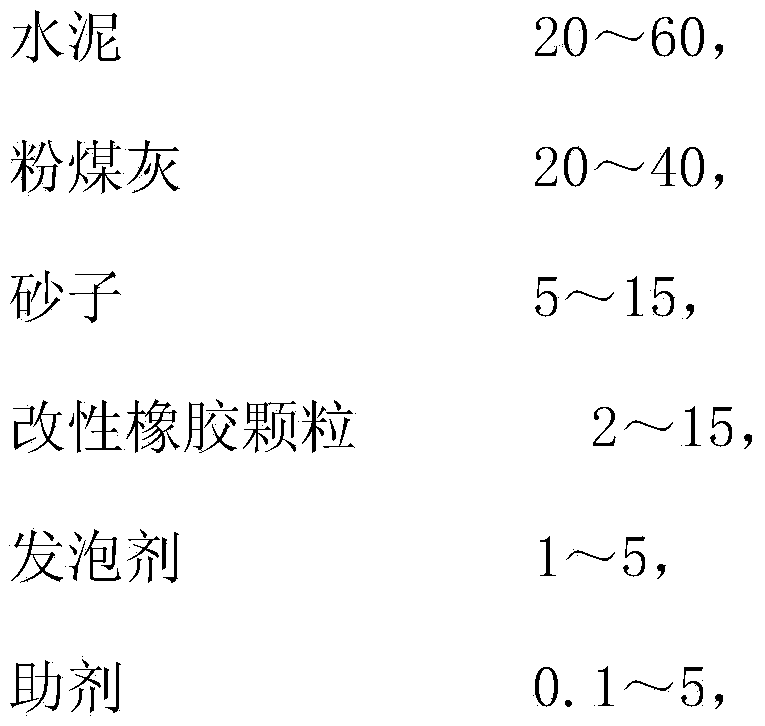

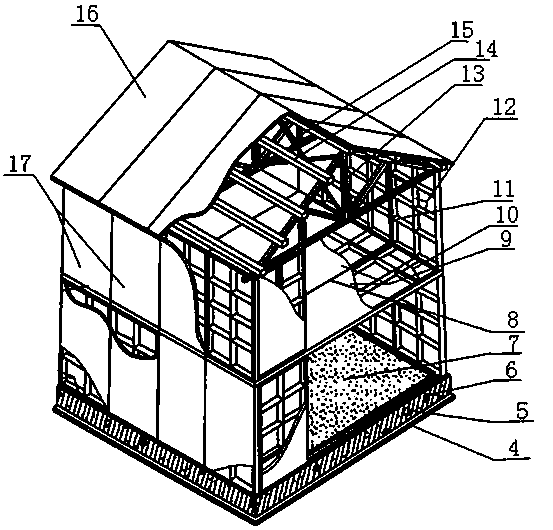

Environment-protection energy-saving ventilating air-conditioning sound-insulating novel building and construction method

InactiveCN101070713ATo achieve the purpose of auxiliary regulationReduce consumptionCovering/liningsLighting and heating apparatusNatural ventilationRoom temperature

The invention relates to a new construction and its methods for environmental protection, energy conservation, natural ventilation, air conditioning, noise insulation and heat preservation. It is applicable to all kinds of industrial and civil buildings. Its character is that it adopts the rationale of air-control to natural draft by cavities. In order to natrurally control the room-temperature and natural draft , it needs many cavities around the house to prepare for the natrural draft, soundproofing air-control circulate system work in the cavities formed by the intercommunication of the wall and ground ,using some special methods such as airy-control the ground and sound isolation control the wall by the wind cavities. Besides,it also recommends a manufactural erectional construction way which is suitable for the sustaining system between the earth-cavity and wall- cavity .The invention eliminates disadvantage of traditional out-of-date technique in resource-saving and environment protesting,with great worth of soundproofing, and improves noise insulation of buildings and natural ventilation permeability effect of environmental protection, energy saving and economy.

Owner:冯刚克

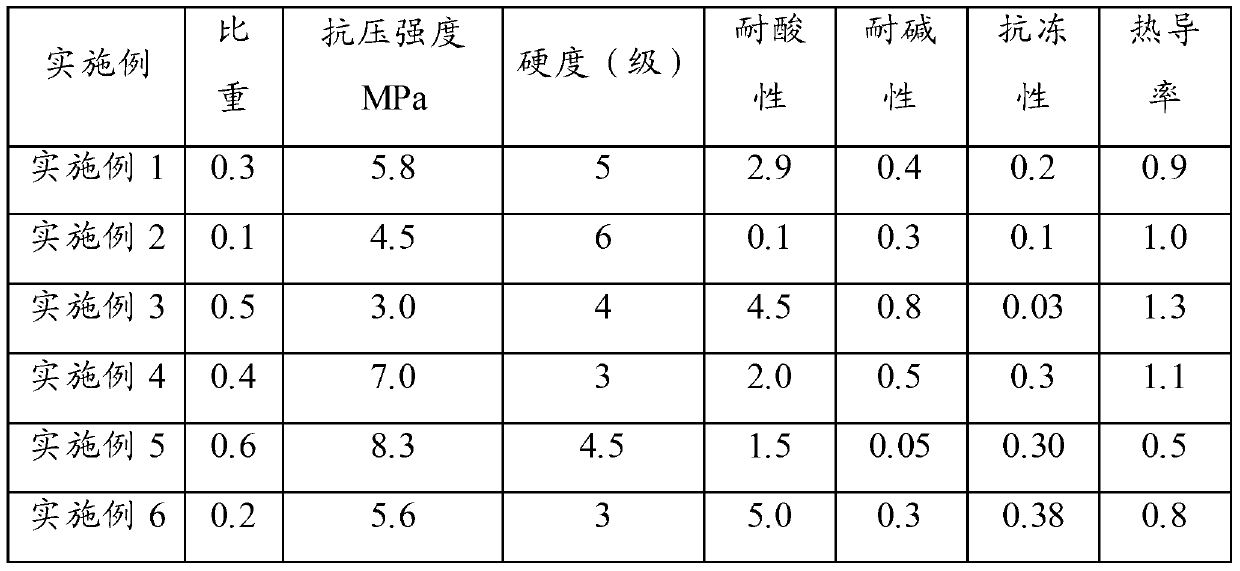

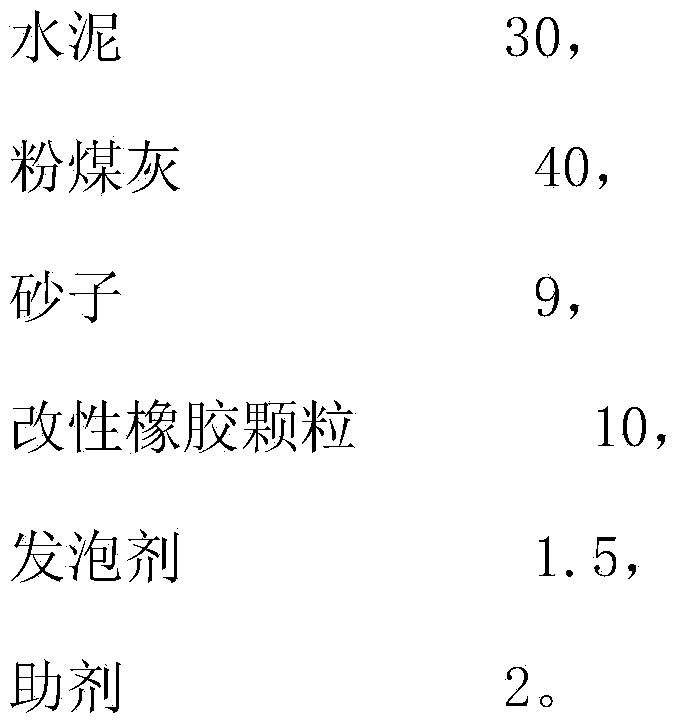

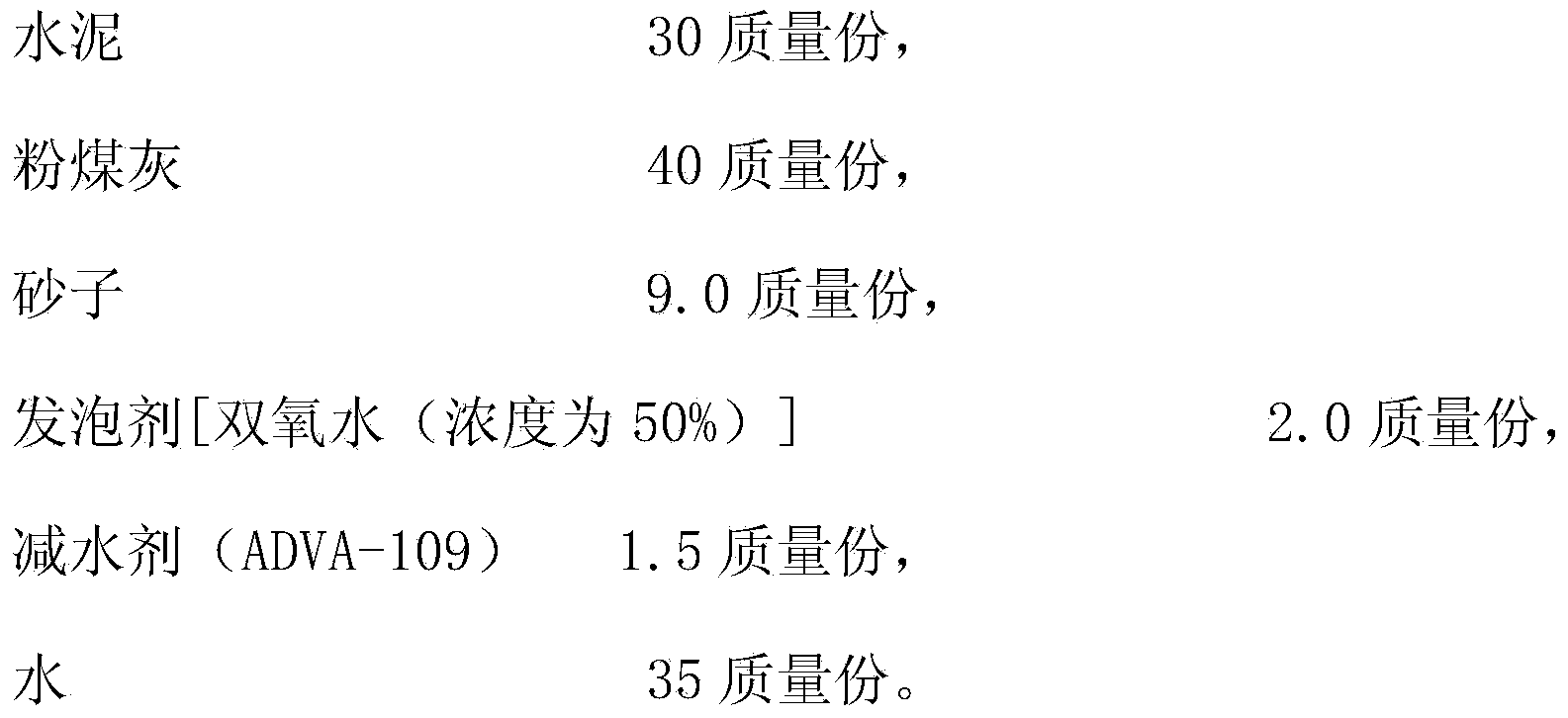

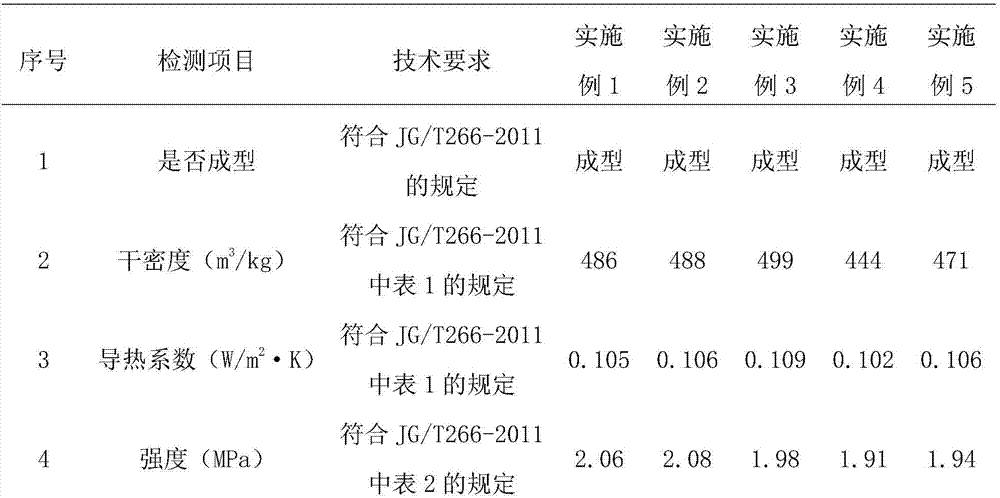

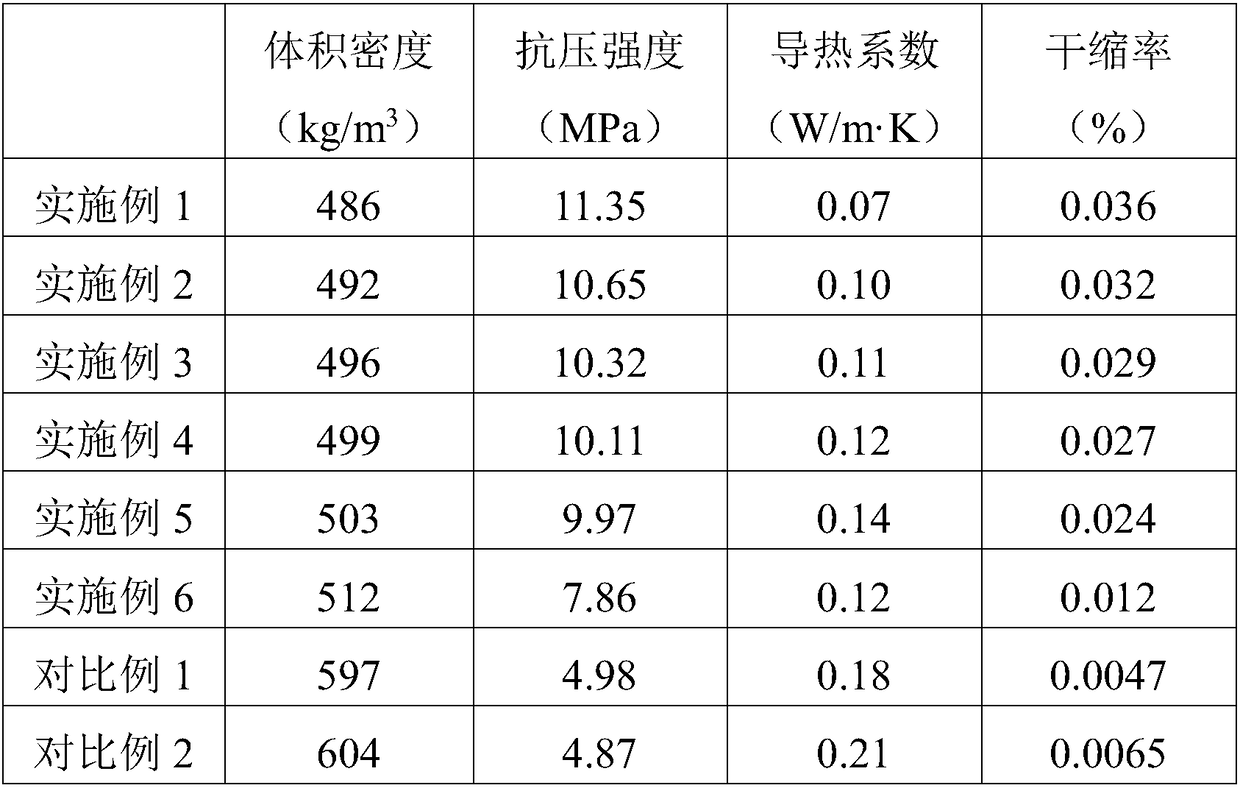

Heat-insulating and sound-isolating light foamed concrete material and preparation method thereof

InactiveCN103864382AGood insulation and sound insulationImprove thermal insulation and sound insulationSolid waste managementCeramicwareSocial benefitsFoam concrete

The invention relates to the technical field of preparation of concrete materials, and particularly relates to a heat-insulating and sound-isolating light foamed concrete material and a preparation method thereof. The concrete material comprises the following components in parts by weight: 20-60 parts of cement, 20-40 parts of coal ash, 5-15 parts of sands, 2-15 parts of modified rubber particles, 1-5 parts of foamer and 0.1-5 parts of assistant. Compared with the prior art, the heat-insulating and sound-isolating light foamed concrete material prepared by adopting the technical scheme of the invention is excellent in sound-isolating performance, heat-insulating performance, impervious performance and toughness, can realize the performance indexes of the construction industry standard of PRC: foamed concrete (JG / T266-2011), and is low in production cost and environment-friendly, so that the social benefit can be effectively improved and the social resources are effectively saved. Therefore, the material is suitable for being popularized and applied on a large scale.

Owner:江西鑫盛混凝土有限公司

Magnesium phosphate cement foamed lightweight wall building block

InactiveCN102344277AImprove stabilityReduce weightBuilding componentsCeramicwareMagnesium orthophosphateMagnesium phosphate

The invention provides a magnesium phosphate cement foamed lightweight wall building block. The building block comprises components of, by weight: 1 part of magnesium oxide, 0.4 to 0.6 parts of magnesium sulfate, 0.3 to 1 part of fly ash or other industrial slag, and 0.2 to 2 parts of ammonium dihydrogen phosphate. According to the invention, magnesium oxide and ammonium dihydrogen phosphate are added into a container; water is added into the container, and the materials are stirred; magnesium sulfate is added into the container, and the solution is regulated to 15-30 Baume degree; fly ash or other slag is added into the container, and the mixture is well mixed; the slurry is poured into a building block mold, foamed, demolded, and cured, such that the building block is produced. With long-term tests, the building block provided by the invention is stable in a long term, and does not scumming. During the production process, air gaps are formed by the foaming agent, such that the weight of the building block is reduced, and better acoustic insulation and thermal insulation effects are provided.

Owner:卞智铨

Construction method for assembling light energy-saving composite wallboards on separation wall

InactiveCN102777045ALight in massQuality improvementWallsBuilding material handlingLight energyChisel

The invention discloses a construction method for assembling light energy-saving composite wallboards on a separation wall, wherein the light energy-saving composite wallboards have the advantages of high strength, stable seismic performance and reliable quality. The construction method comprises the following steps: firstly laying side lines of the wall body of the separation wall and fixing the positions of openings of doors and windows; drilling holes in a main structure at a mounting face of the separation wall and implanting reinforcing steel bars; drilling holes in side vertical faces of the composite wallboards; after sizing, erecting the composite wallboards in a way of being aligned to mounting lines on the floor, splicing the composite wallboards orderly according to a splicing sequence, driving wooden wedges into the lower part of battens, wherein the wooden wedges are used for adjusting position so that the battens are arranged in place; fixing the composite wallboards firmly and then driving each composite wallboard into a building surface slantwise at the angle of 45 degrees by using a steel chisel, so as to achieving an anchoring effect; applying mortar for flattening; and finally carrying out maintenance.

Owner:LONGXIN CONSTR GRP

Foaming concrete lightweight wall material in situ production method

InactiveCN1769609AEasy constructionRaw materials are easy to getWallsFoam concreteUltimate tensile strength

The invention discloses a preparing method of on-site foaming concrete lightweight wall material in the architecture wall material preparing technique domain, which comprises the following steps: mixing the hydroperoxide of 5-10 percent water weight and water evenly; blending the aluminum powder of 2-7 percent cement, cement, sand and stone uniformly; pouring two mixtures in the built mould; foaming the concrete in the mould to form strength after 4 hours at 20 deg.c; demoulding to obtain the wall of 1900kg / m3 density.

Owner:SHENYANG JIANZHU UNIVERSITY

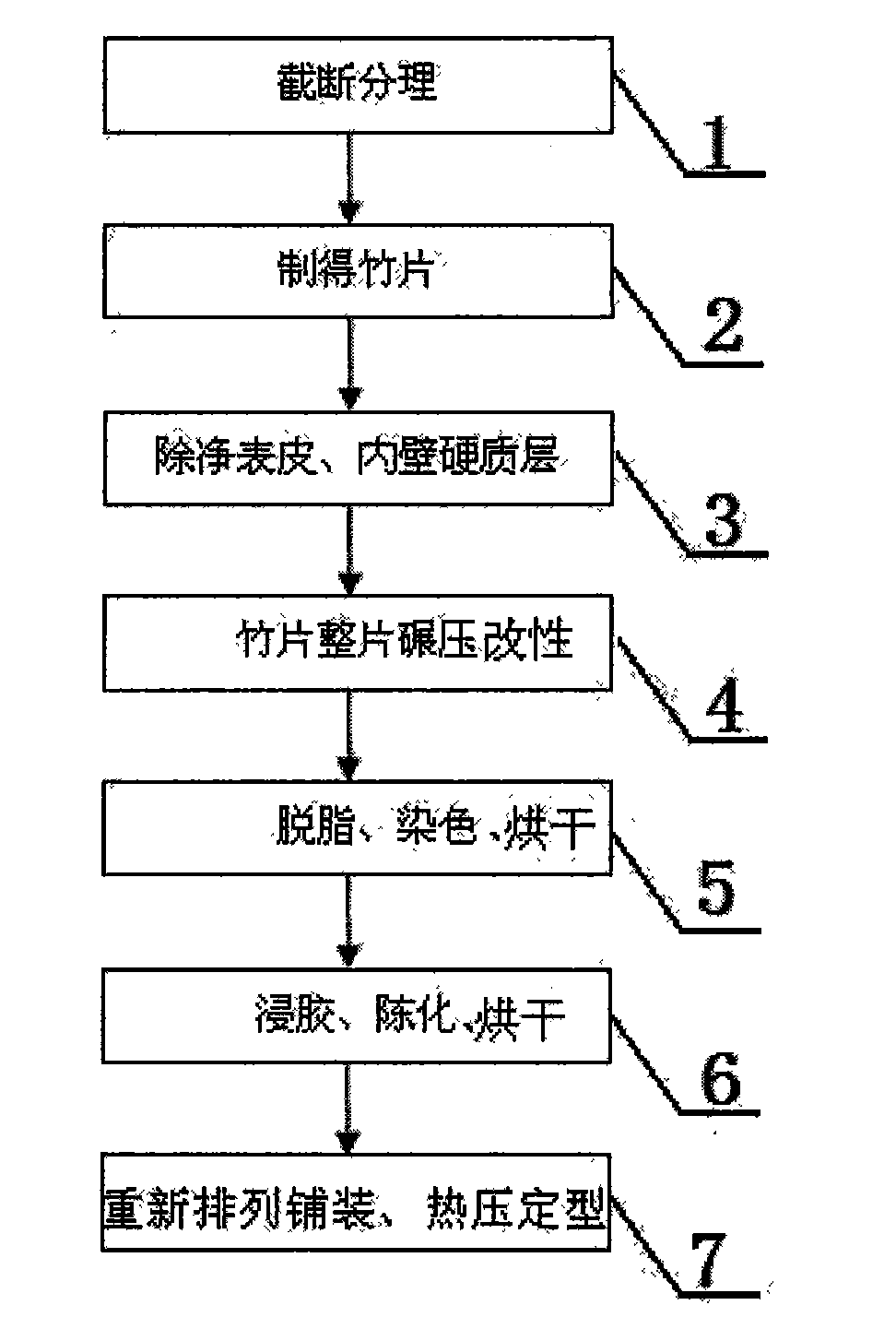

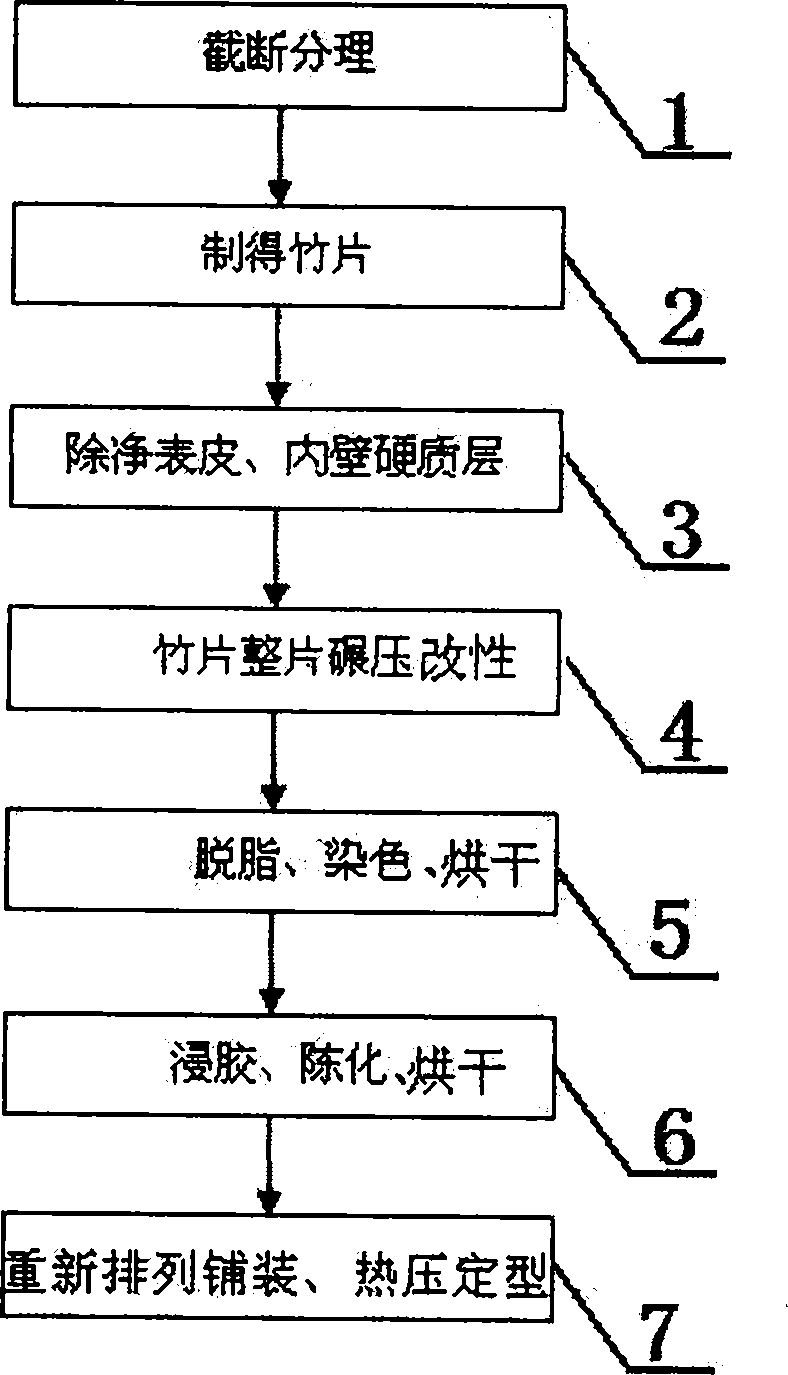

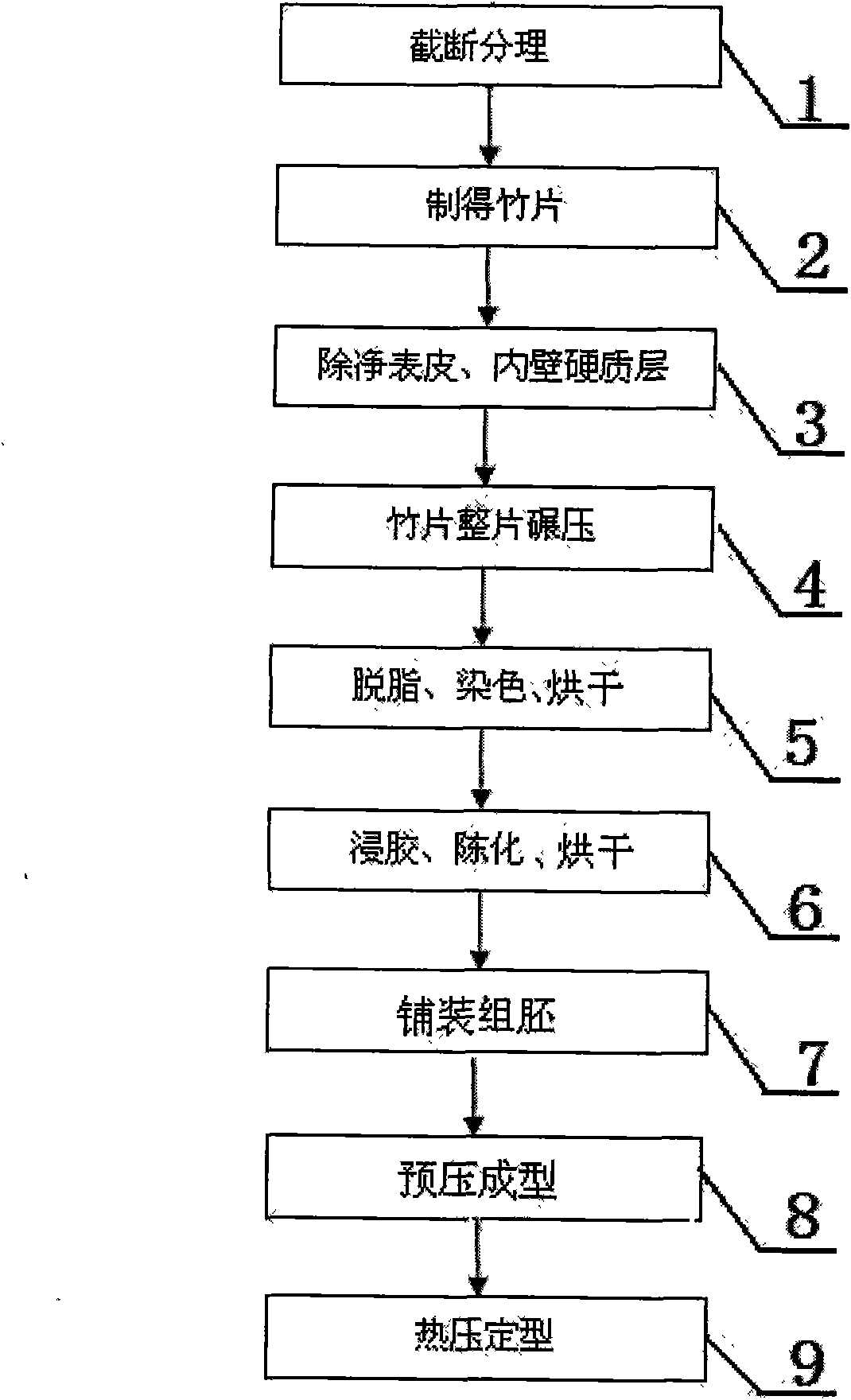

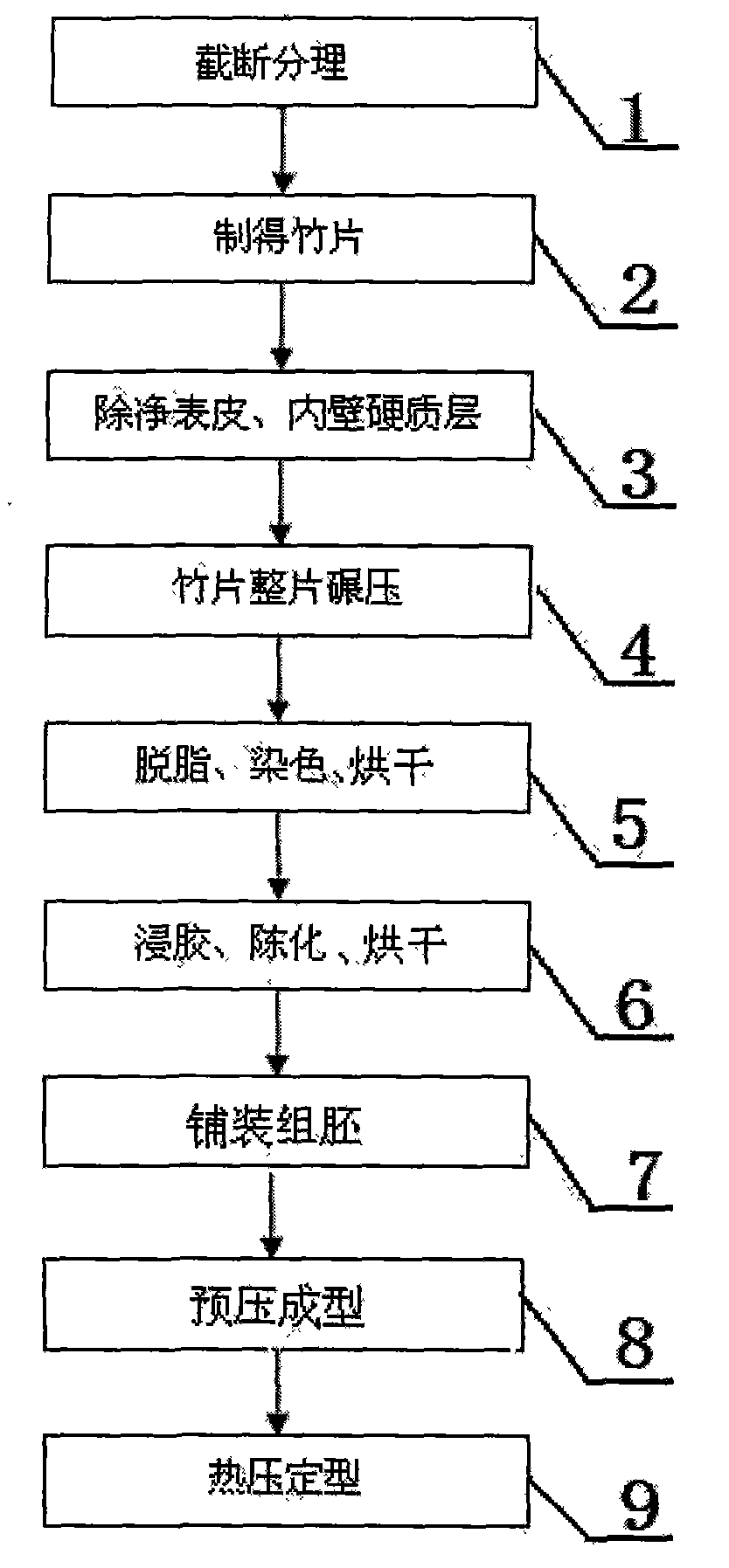

Process for manufacturing large-breadth plates by using all-bamboo modified material

The invention discloses a process for manufacturing large-breadth plates by using an all-bamboo modified material, which comprises the following steps of: (1), fully clearing way a surface wax layer and an inner hard layer; (2), modifying and laminating bamboo sheets into sheet bamboo materials which are in strips, filaments and fibres and are cracked but not fragile; (3), degreasing, dying and drying the bamboo material; (4), impregnating, ageing and drying the bamboo material; and (5), rearranging and laying the bamboo material to form blanks, and performing hot pressing on the blanks to mold the blanks into the large-breadth plates of the all-bamboo modified material. The large-breadth plates of the all-bamboo modified material are fine and smooth in vein and compact in structure and are applied to the application field of manufacturing all-bamboo furniture, floors, decoration materials and engineering, construction and military materials, and can effectively and greatly save raw materials, energy, labour cost, production field and storage field. At the same time, because the bamboo material is modified, 10 kinds of bamboos can be selected as processing raw materials.

Owner:上海缘竹实业有限公司 +2

Non-autoclaved foam concrete material and preparation method thereof

The invention relates to a non-autoclaved foam concrete material and a preparation method of the material. The non-autoclaved foam concrete material is characterized by comprising the following raw material ingredients in parts by weight: 85-96 parts of cement, 2-8 parts of fine sand, 2-10 parts of slag powder, 1.4-2.2 parts of chemical foaming agent, 0.7-1.5 parts of additive, 0.5-1.0 part of fiber and 1-1.5 parts of assistant, wherein the additive is a foam stabilizer, a water reducer and an early strength agent, and a water-material mass ratio is 0.55-0.6. The prepared foam concrete material can reach various performance indexes (foam concrete JG / T 266-2011); various performance is excellent; and the method is simple and practicable, low in cost, obvious in energy conservation effect and appropriate for large-scale popularization and application.

Owner:NANJING UNIV OF TECH

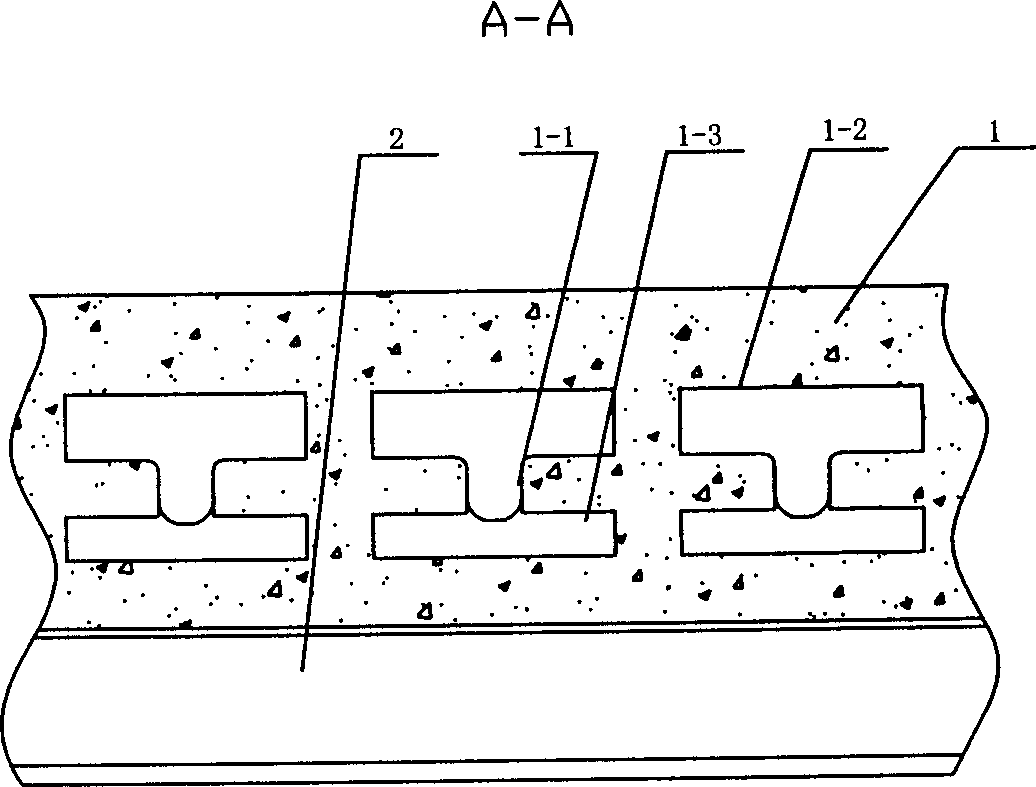

Heat-insulated sound-insulated building block and building method

InactiveCN101086181AImprove sound insulationImprove the sound insulation effectConstruction materialWallsSlagEngineering

The invention discloses a insulation sound-proof blocks, it is equipped with partition groove; the width, component of blocks and the number of partition groove are determined by the geographical building structure and the energy-saving requirements; the partition grooves are equipped in the blocks from up to down transparently in the separated mode and cross laying; the component of the block (weight percentage)is 15 - 21% bonding agent and the residue of aggregate; said bonding agent is gypsum, lime and cement; the aggregate is the fly ash, slag, construction waste or furnace cinder. The masonry method is: the bondings between blocks are rigid adhesion without grey mouth; the mine thrower dry powder uses the mixed component of same aggregate and cement, the mixing rate is the weight rate which can make the compression strength of mine thrower >=10-15MPa, then the mine thrower dry powder is mixed with water in the amount of collapse degree is 80-100cm, only the slot and the carvel joint of blocks are plastered. The wall body using the invention can be realized no forced cracks and no distortion cracks after the wall body is treated by the invention, the invention hash the characteristics of high combined strength of blocks, energy-saving, low consumption and swift operation.

Owner:王福山

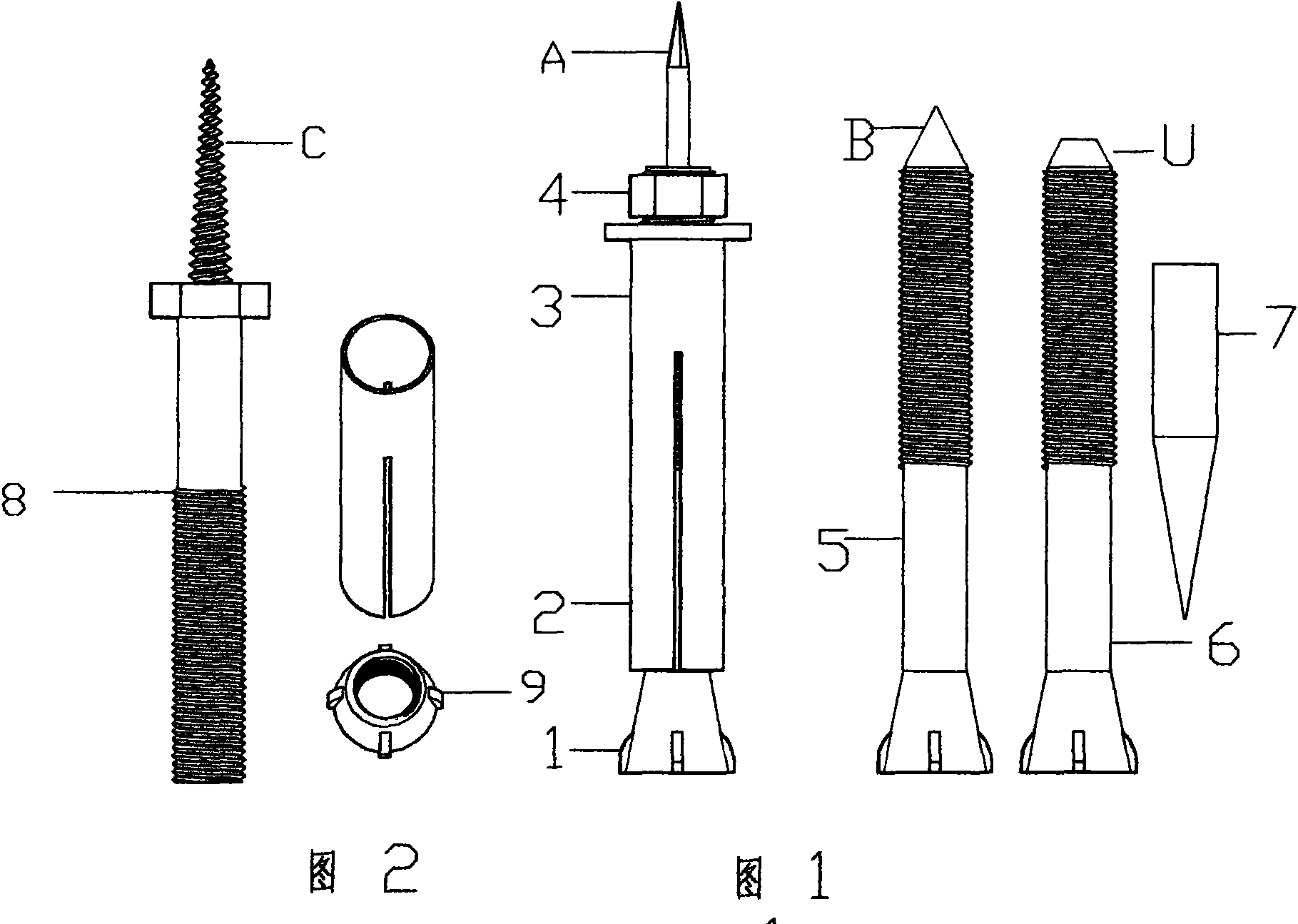

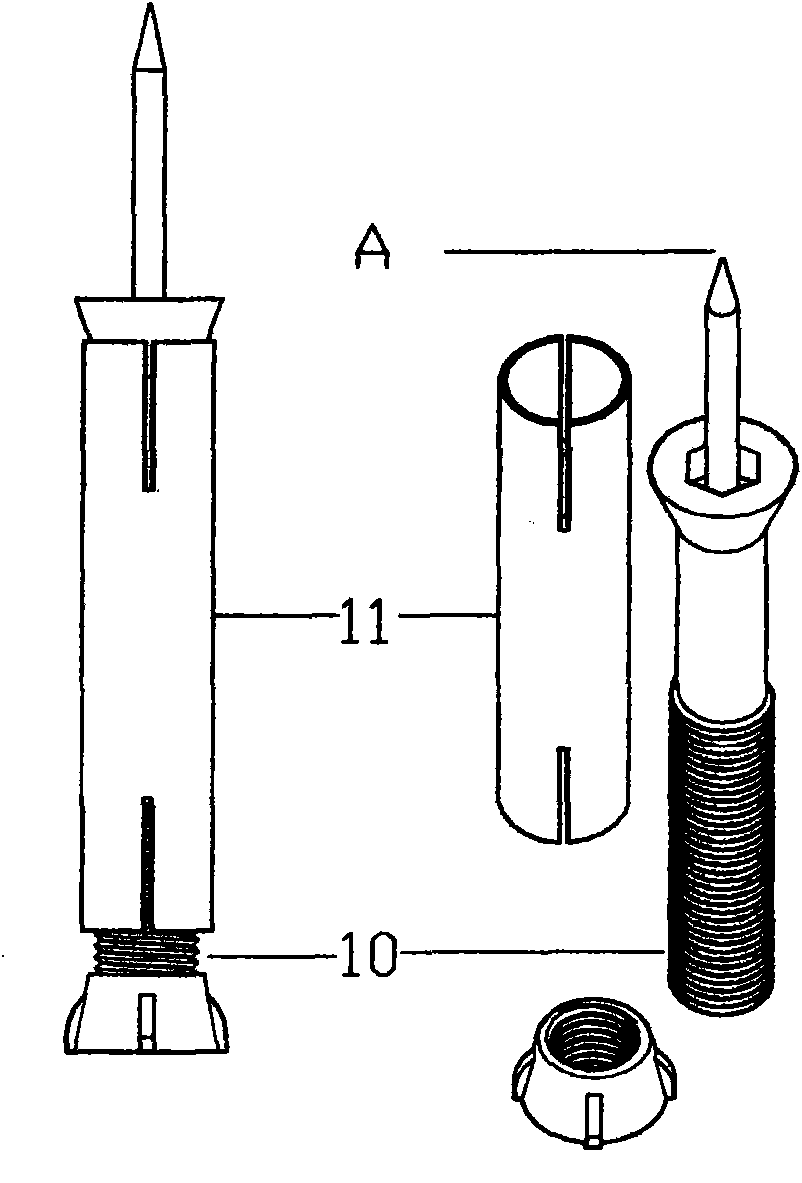

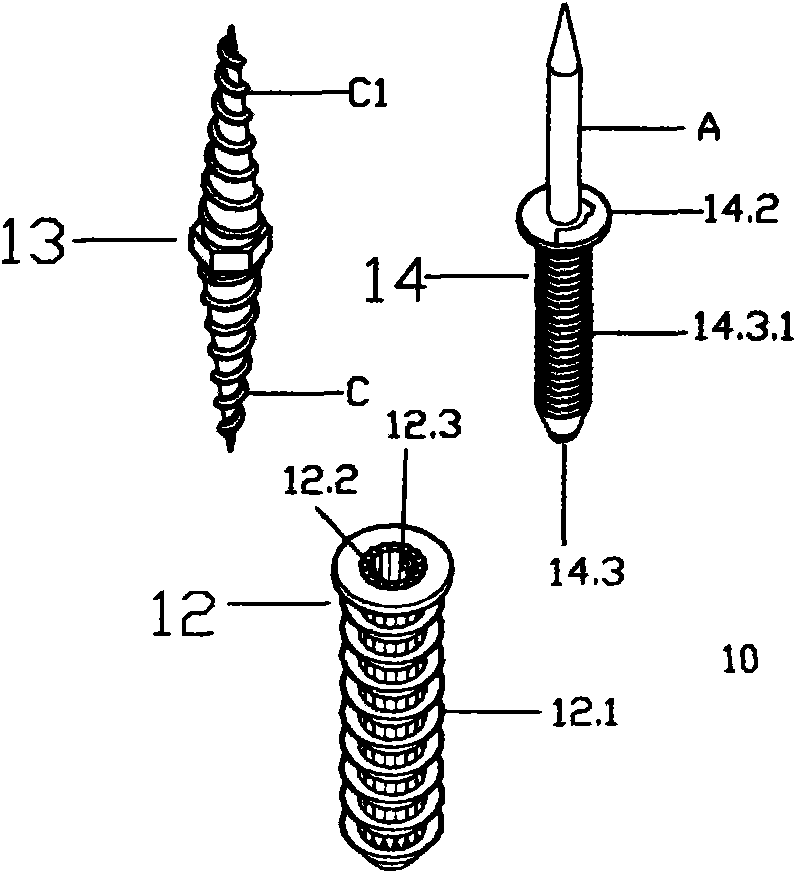

Method for installing door/window cover, matched tool, fitting and door/window cover

The invention provides a method for installing a door / window cover, a matched tool, a fitting and the door / window cover. The invention is characterized in that the method adopts an expansion bolt with a nail or a screw nail, a dowel and a connecting piece component, and comprises the steps of arranging a support bar and a glue groove on the door / window cover and a wall, tightly blocking by a wedge, injecting foaming glue and the like; and the invention provides the door / window frame cover with a support bracket, a perpendicularity disc, a chamfer clamp, an expansion bolt with a nail or a screw nail, a dowel, a support bar, a glue groove, a wedge, a connecting piece, a hasp with a connecting piece, a glue groove and a support bar. The invention has the advantages of being firm in installation, improving the work efficiency, saving the glue, improving moisture-proof, sound-proof and heat-preserving effects, and prolonging the service life of the door / window cover.

Owner:徐一鸣

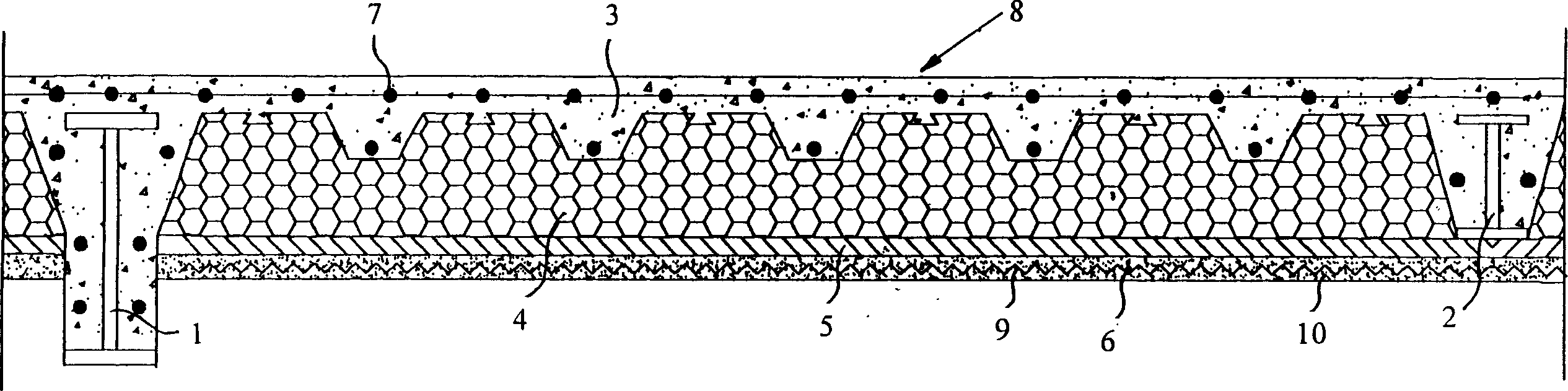

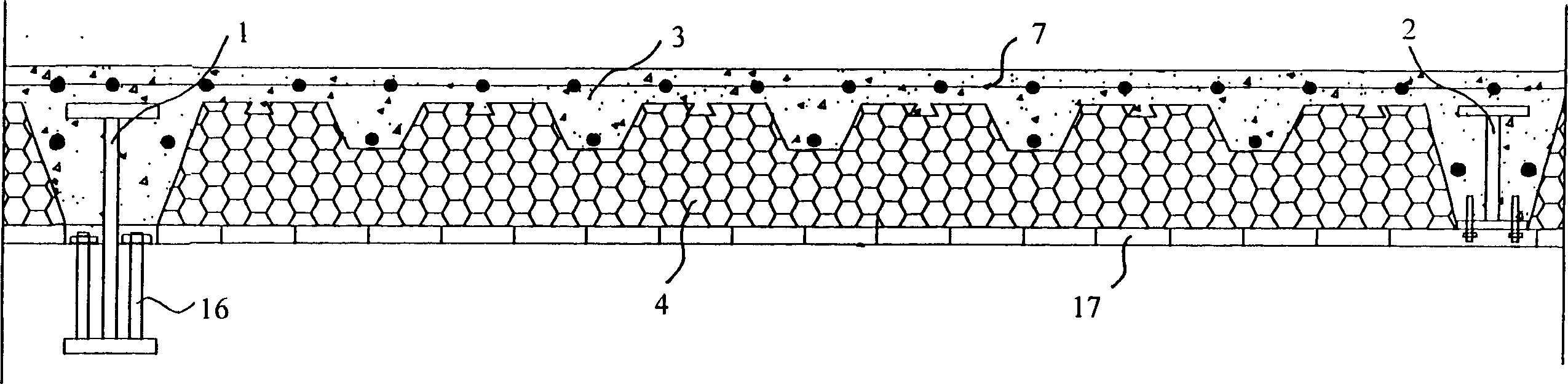

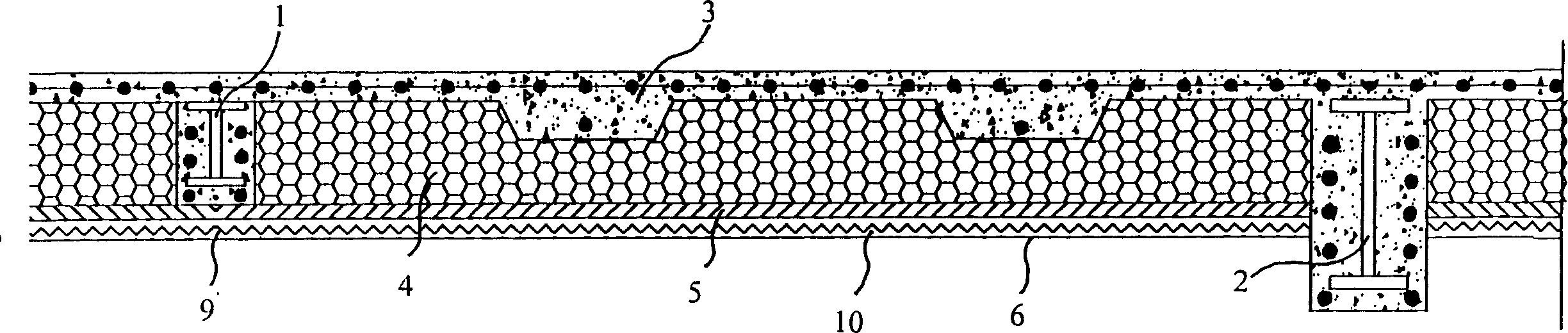

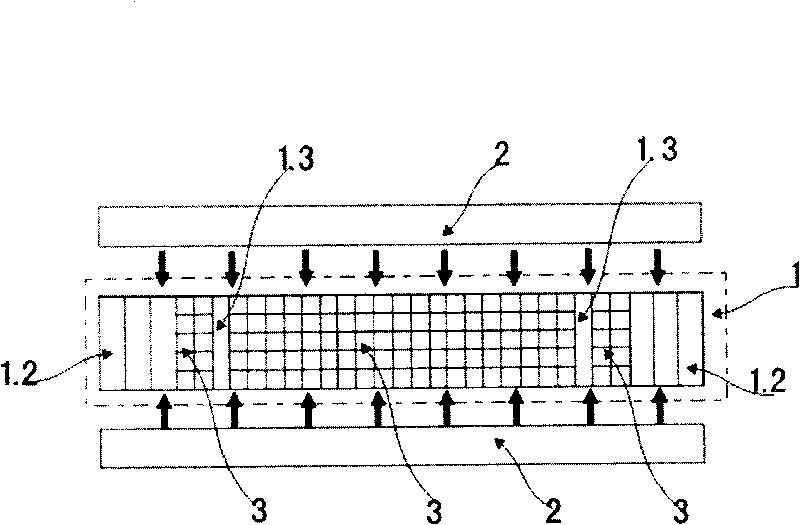

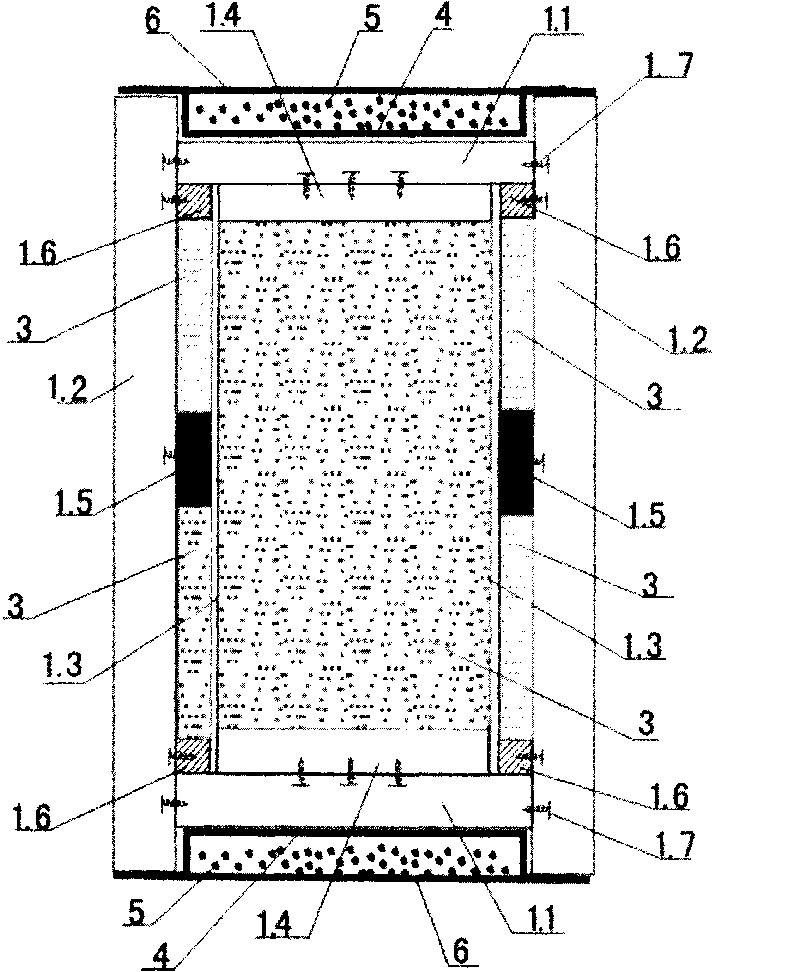

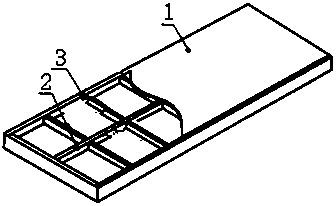

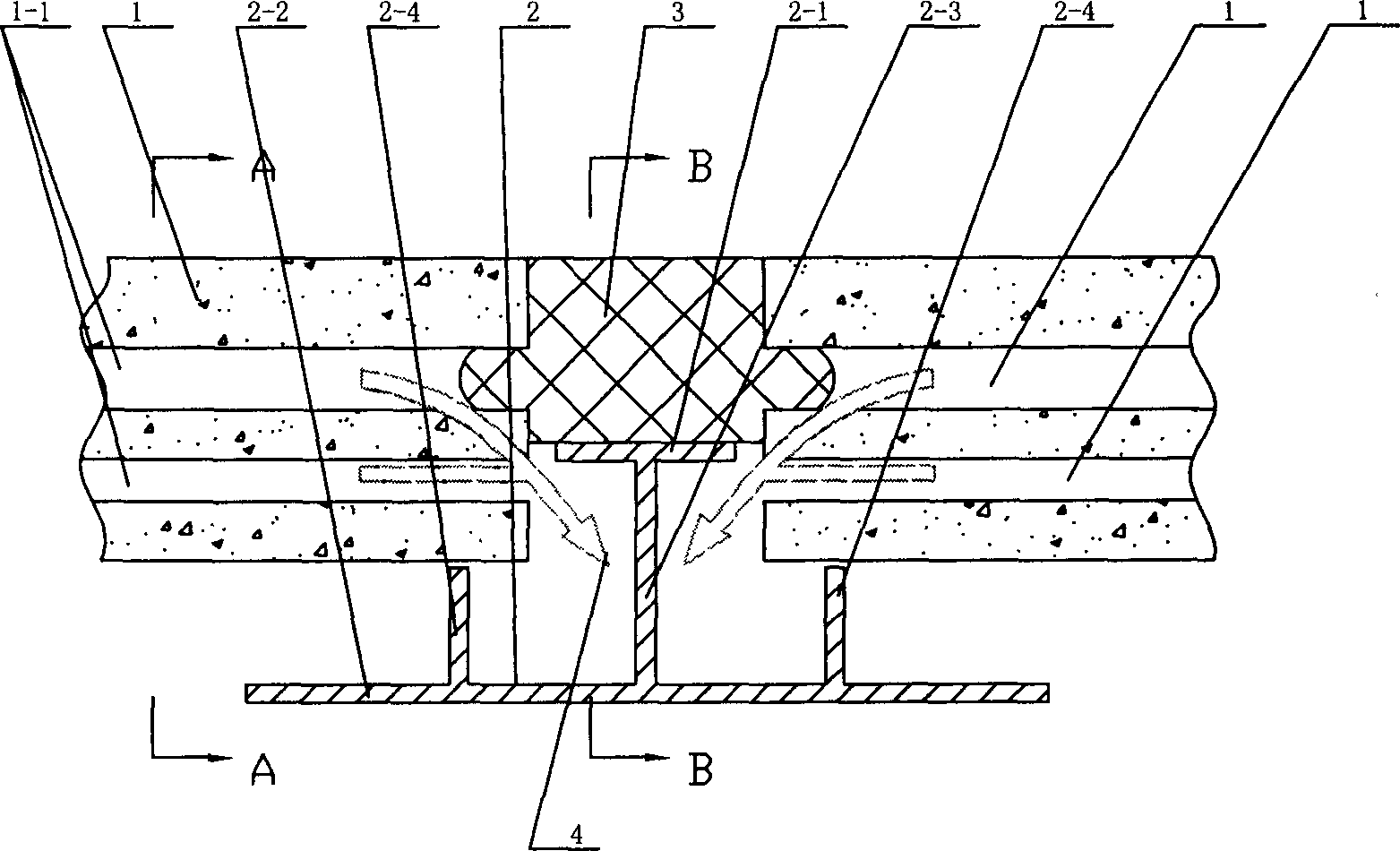

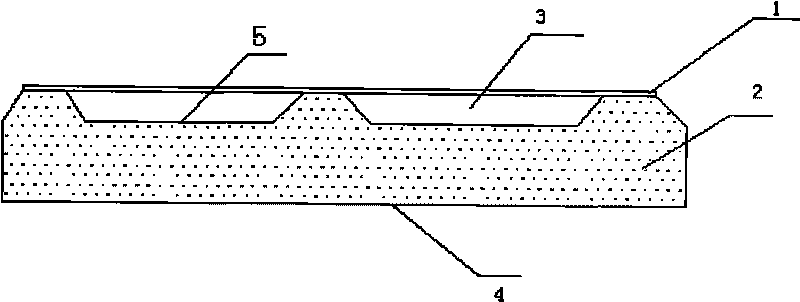

Assembled floor cover

A combined floor of building consists of several spaced bearing beams and composite plates. The composite plates include acoustic and thermal insulating parts with grooves on their top between the bearing beams, corrugated concrete cast in site and laid on them, fireproof and break resistant layers below the said acoustic and thermal insulating parts orderly. The floor can be cast with bearing beams uniformly in site reduce beam height so as to increase net height of room and acoustic and thermal insulating abilities, to enlarge effective space in use, to reduce sum of sub-beams and fireproof area of steel beams, with longer span length, no need of pressed steel plates and hanging roof so as to reduce cost with quality and high speed.

Owner:张英保

Magnesium silicate fiber blanket and production method thereof

ActiveCN101706030AWith insulationWith sound-absorbing functionMagnesium silicatesThermal insulationFiberThermal insulation

The invention relates to a magnesium silicate fiber blanket belonging to the technical field of fire-proof heat preservation and insulation materials. The magnesium silicate fiber blanket is characterized by comprising the following materials with oxides in percentage by weight: 40%-85% of SiO2, 3%-40% of MgO, 2%-30% of CaO, and the balance of one or the any combination of B2O3, Al2O3, Fe2O3, Na2O and K2O, wherein the total amount of the SiO2, the MgO and the CaO is more than or equal to 85%. The magnesium silicate fiber blanket is processed through the procedures of material melt, centrifugal thread throwing or blowing fiber forming, cotton collection, pinprick, heat treatment, cutting, and the like. The magnesium silicate fiber blanket has functions of non-inflammation, heat insulation, sound absorption and fire prevention and is a fire-resistant heat-preserving heat-insulating fire-proof material which is widely suitable for various heat engineering equipment and pipelines.

Owner:LUYANG ENERGY SAVING MATERIALS CO LTD

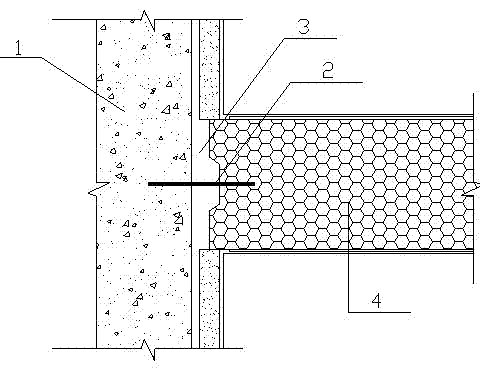

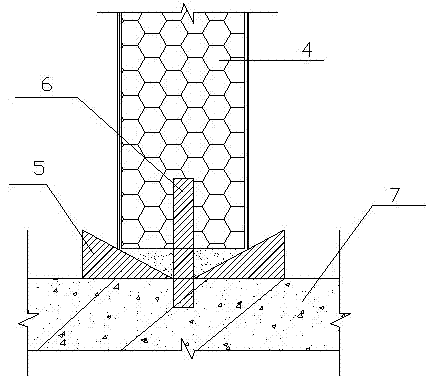

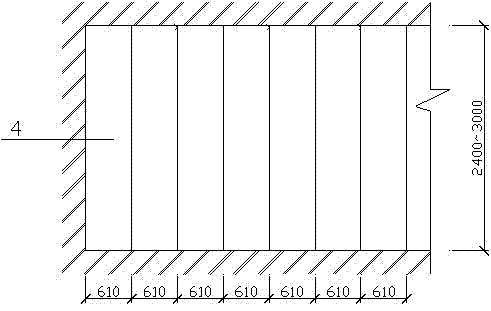

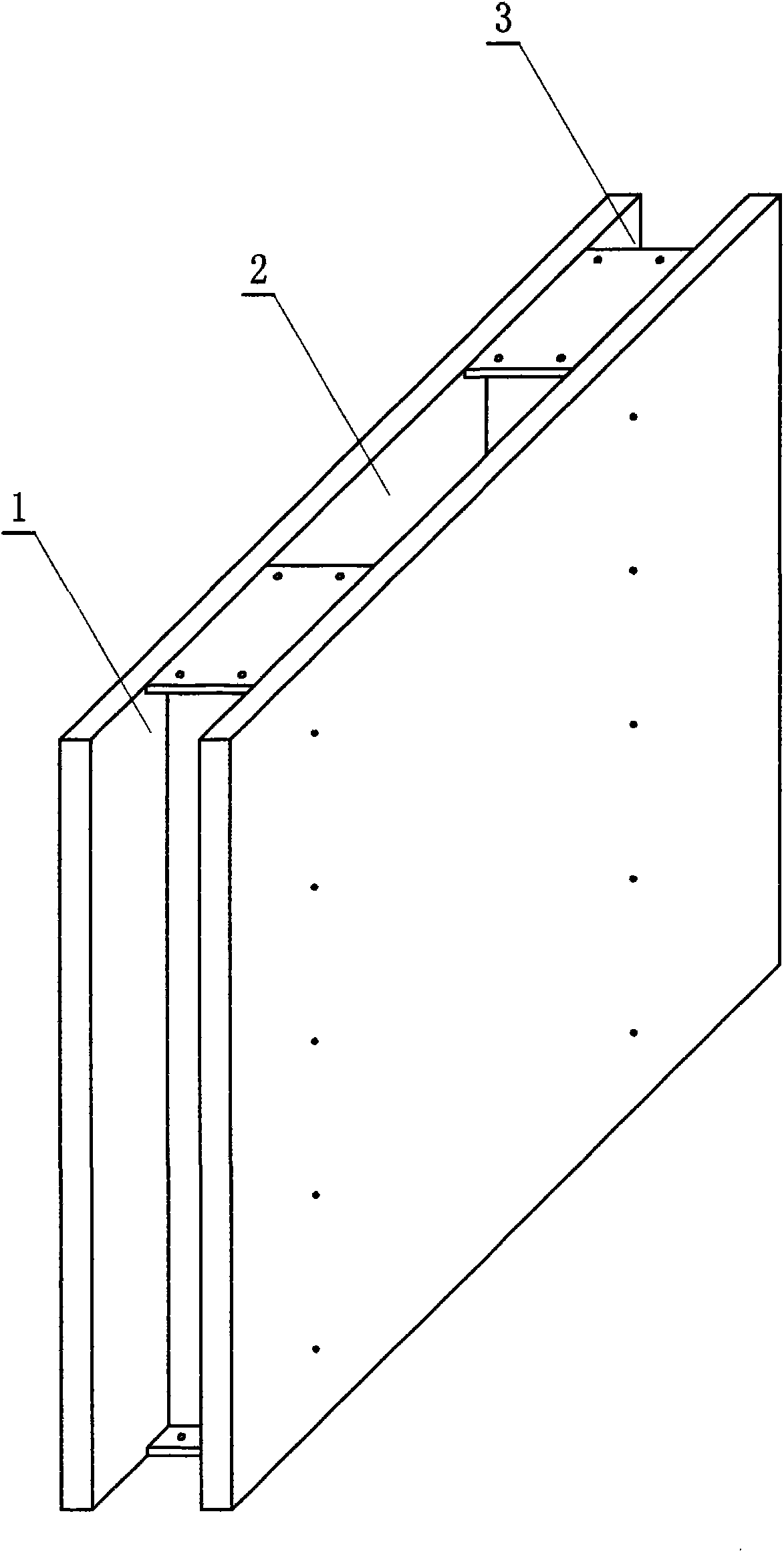

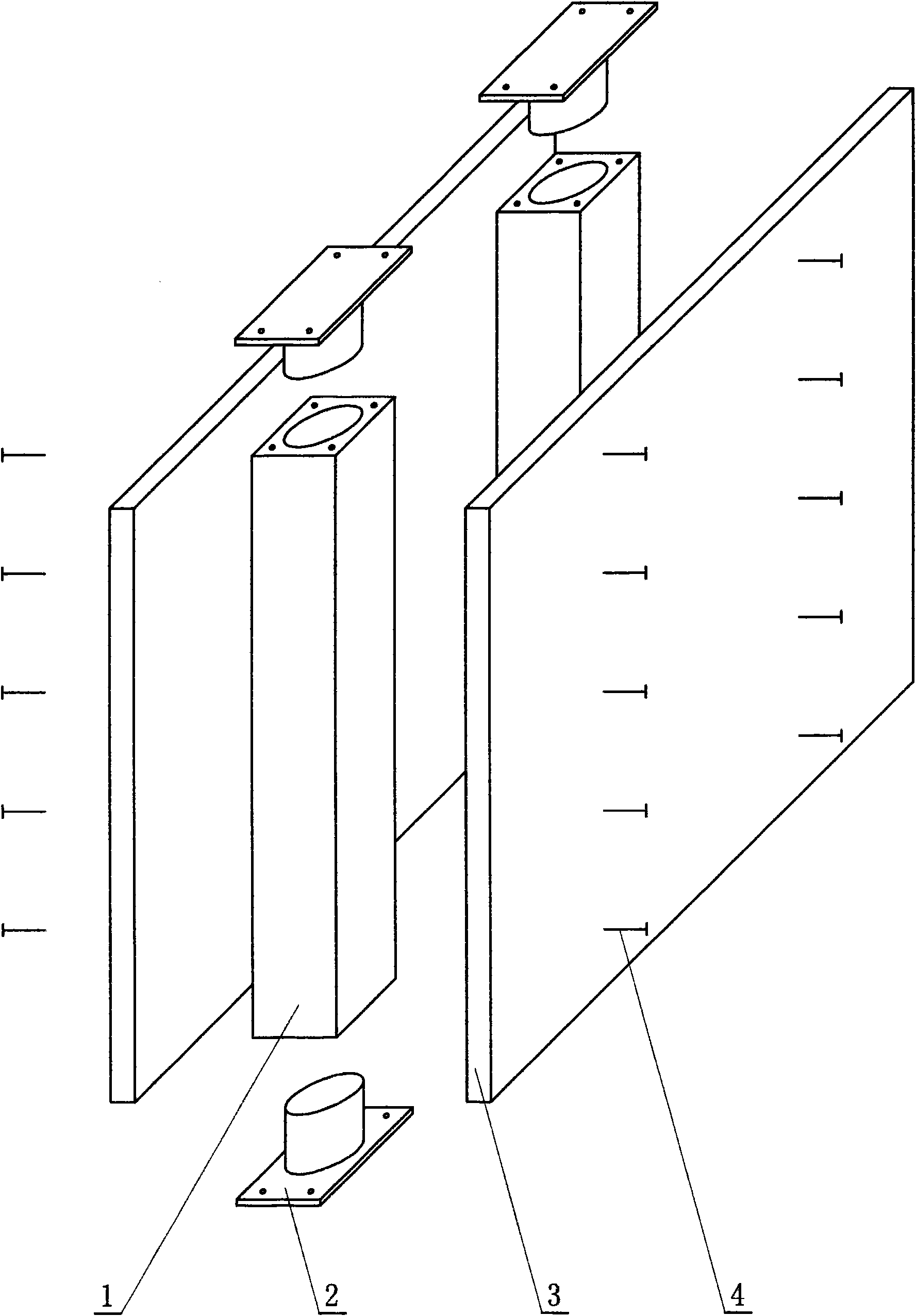

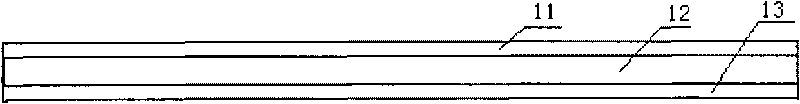

Assembled light wall plate and mounting process

InactiveCN101570995AImprove construction flexibilityEasy to carryWallsHeat proofingWall plateEngineering

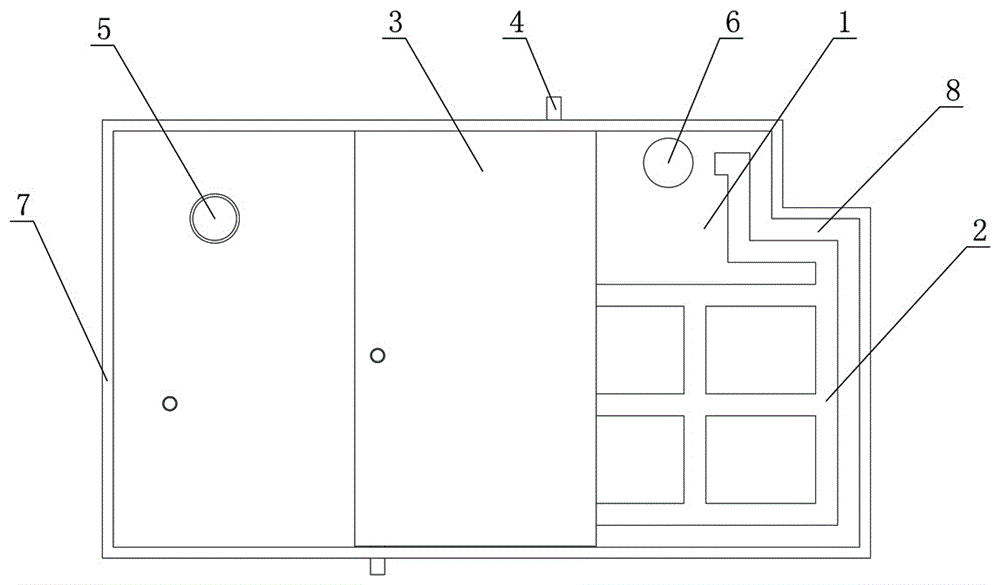

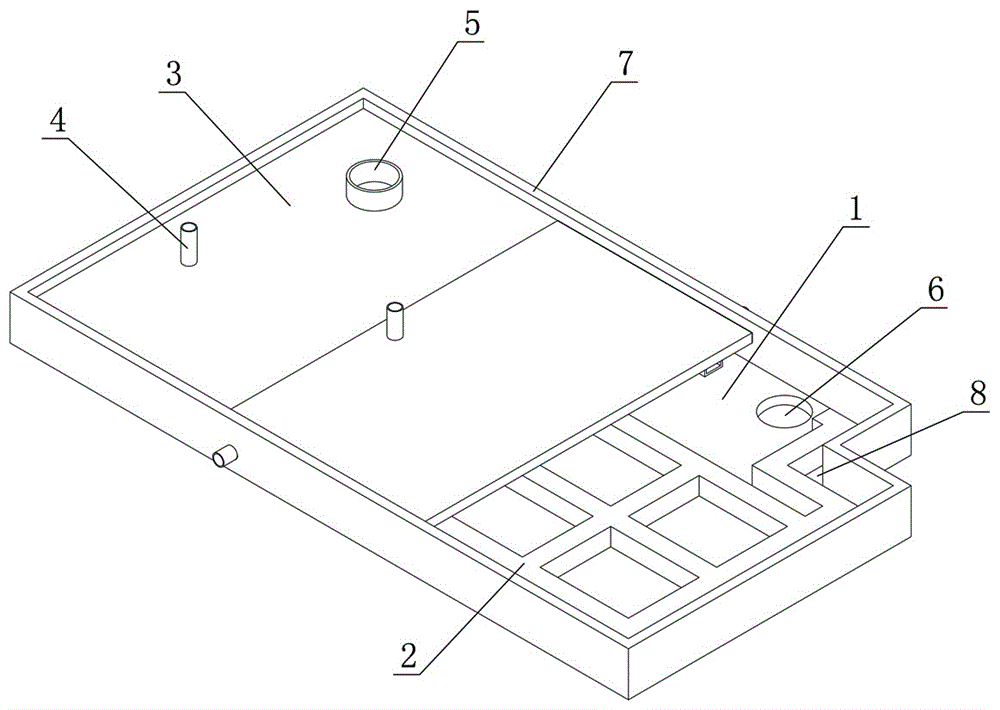

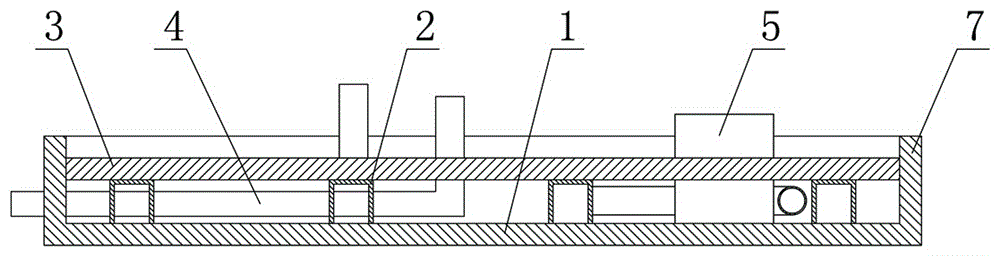

The invention introduces an assembled light wall plate and a mounting process. The wall plate has the following structures shown as figures 1, 2, 3 and 4, wherein in the figure 1, a keel has a strip square column structure, the keel is compounded by taking cement as a main raw material and adding auxiliary materials, the center of the keel is a cylindrical (or quadrate) hollow hole, and the keel is provided with a plurality of tiny reinforcement steel bars inside to improve the firm stability of the keel; in the figure 2, connecting clamps are made of galvanized steel sheets, the connecting clamps have a center protruding cylindrical structure, and the periphery of each connecting clamp is provided with a plurality of screw holes for fixing the keel; in the figure 3, a plaster flat plate is compounded by taking a fiber plaster as a main raw material; and in the figure 4, gun nails are used for fixing the plaster flat plate and the keel. In the mounting process, the keel and the connecting clamps are firstly assembled , the upper connecting clamp and the lower connecting clamp are fixed with a roof and a ground surface of a building by screws respectively, and the plaster flat plate is fixed with the keel by the gun nails. The mounting process is quick and simple, and walls are firm and durable.

Owner:罗国军

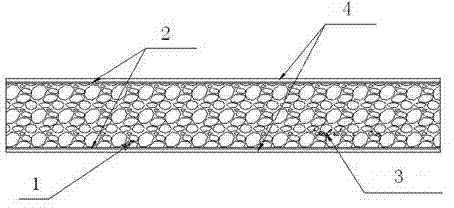

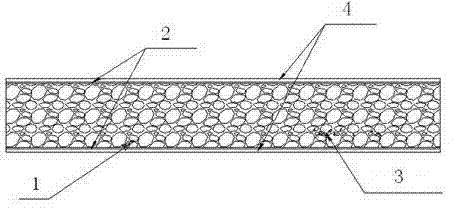

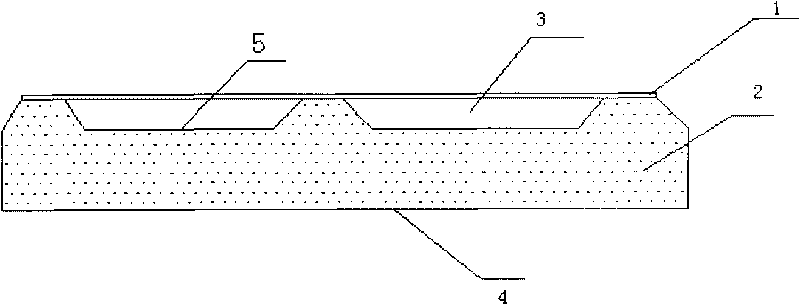

Foamed composite board and manufacturing method thereof

ActiveCN102350826AQuality improvementLight in massSynthetic resin layered productsLaminationFoaming agentComposite plate

The invention discloses a foamed composite board, which comprises a foamed core layer (1), wherein the foamed core layer consists of a composite material (2) and a foamed core plate (3), the foamed core layer (1) is a foamed-pass structure, the upper part of the composite material is provided with a color steel plate (4), and the pass structure of the foamed core layer (1) is respectively compounded with the color steel plate (4) and the composite material (2) through the hot melting way so as to form a foamed pass-structure composite board. The manufacturing method of the foamed composite board is characterized in that: under the situation that a certain foaming quality is realized, the entire compounding process is completed by utilizing the high temperature of the foamed core plate while the thickness of the composite board is increased, so the cost for manufacturing the composite board can be reduced; and the foaming quantity required for the production can be controlled according to the usage amount of the foaming agent and the stability of an extruding machine, so the sound insulation, the heat insulation and the light-weight effect of the foamed composite board can be improved.

Owner:JIANGSU XIECHENG SCI & TECH DEV

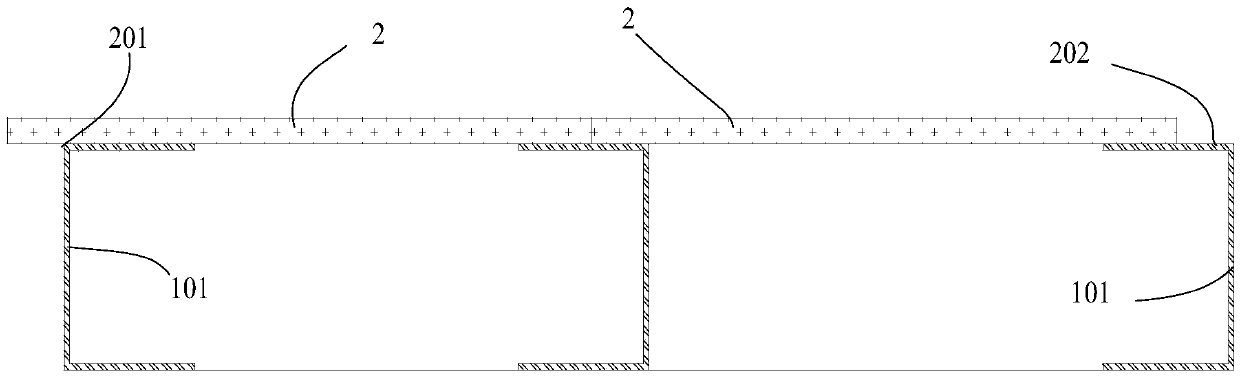

Waterproof undercarriage for bathroom

The invention provides a waterproof undercarriage for a bathroom. The waterproof undercarriage comprises a waterproof base plate provided with a circle of vertical retaining side, a supporting keel laid on the waterproof base plate, and a decorative layer which is laid on upper end face of the supporting keel, wherein the upper edge of the retaining side is not lower than the top face of the decorative layer; a pipe is mounted on the waterproof base plate; a penetrating hole corresponding to the pipe is formed in the supporting keel; communicated grooves are formed between the supporting keel and the retaining side; a water catchment hopper communicated with the grooves and a penetrating bushing vertically penetrating the waterproof base plate are arranged on the waterproof base plate respectively; the periphery of the water catchment hopper and the periphery of the penetrating bushing are both in sealed connection with the waterproof base plate. The waterproof undercarriage for the bathroom has the advantages that the design is scientific, modular production is achieved, mounting and maintenance are convenient, and the quality is guaranteed.

Owner:王凤蕊

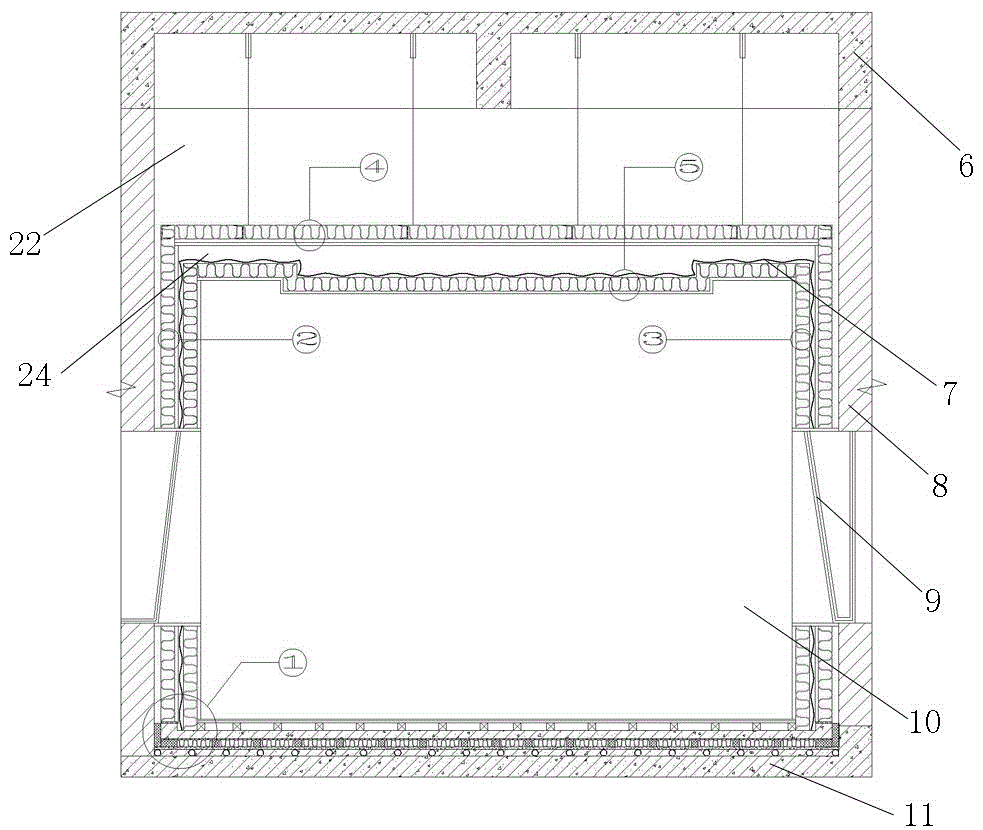

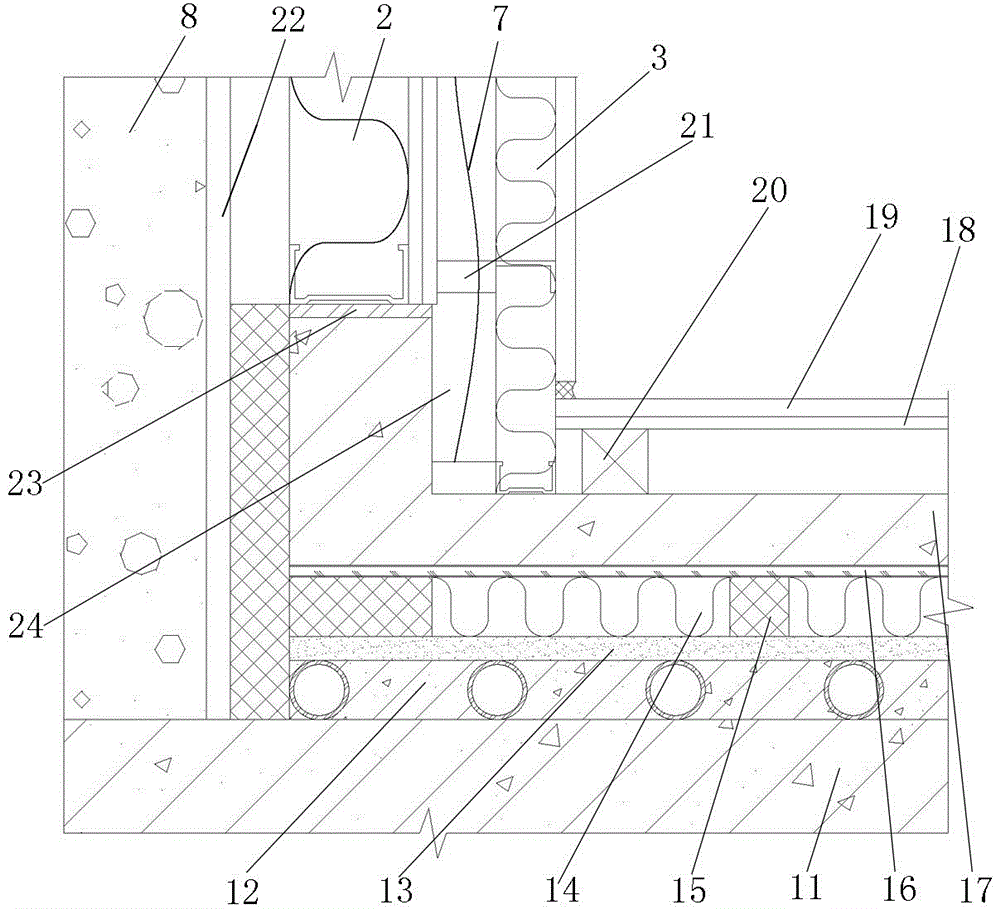

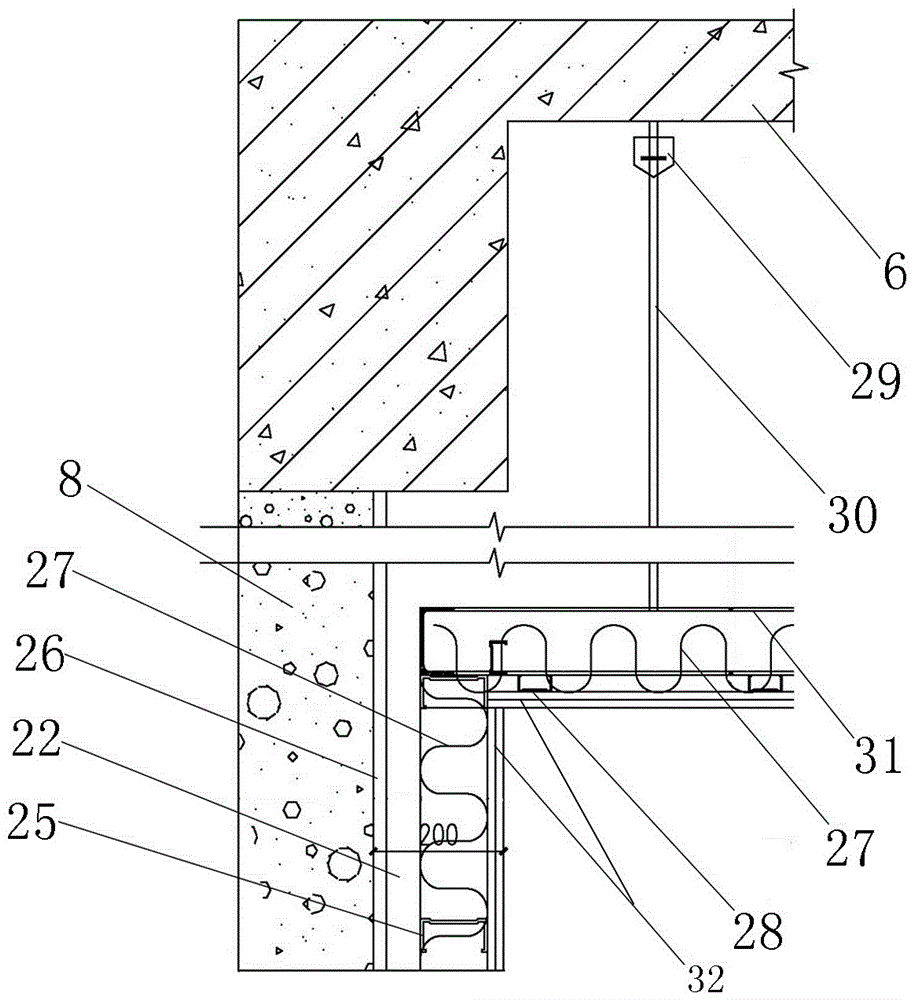

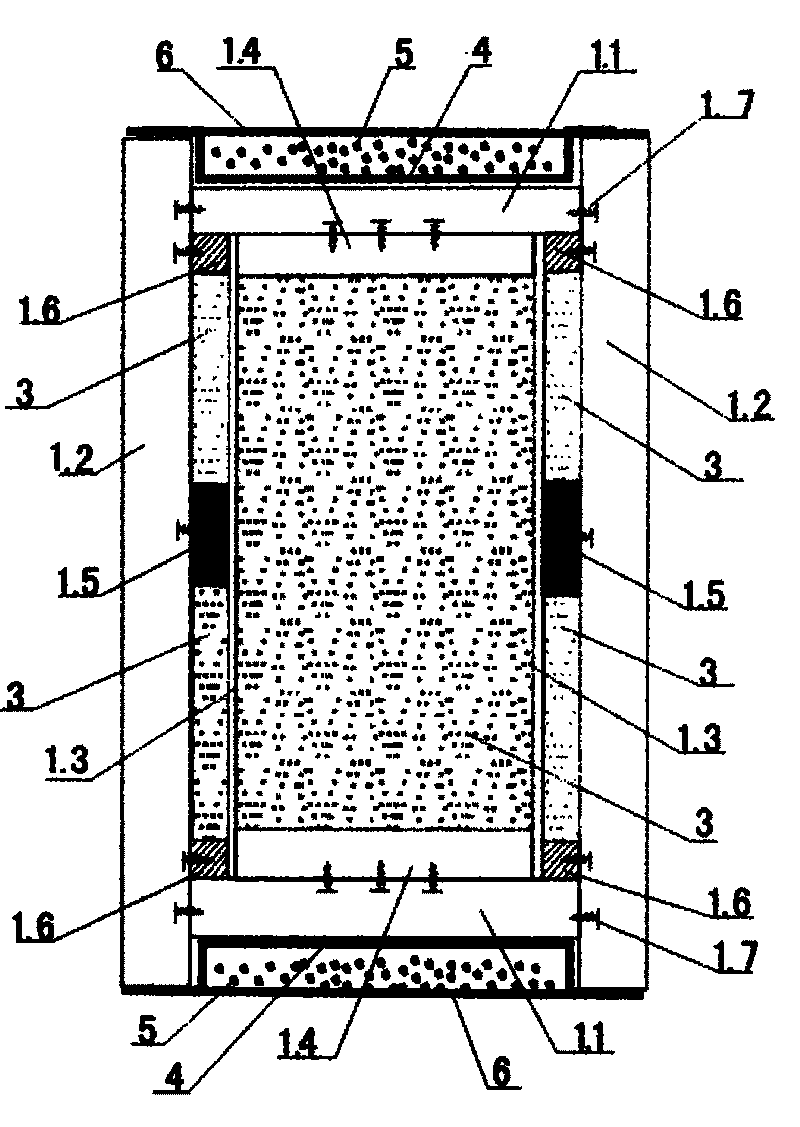

Room-in-room sound-insulation and shock-absorption system and construction method thereof

InactiveCN106522392AImprove sound insulationStructurally feasibleCeilingsCovering/liningsInsulation layerStructural engineering

The invention belongs to a room-in-room sound-insulation and shock-absorption system and a construction method thereof. The system comprises a sound-insulation and shock-absorption floor, a sound-insulation wall body structure, a sound-insulation ceiling structure, a sound-absorption wall body structure and a sound-absorption ceiling structure, wherein the sound-insulation and shock-absorption floor forms the ground of a sound-insulation and shock-absorption room; the sound-insulation wall body structure and the sound-absorption wall body structure form a double-layer wall body of the sound-insulation and shock-absorption room; or the sound-insulation wall body structure, the sound-absorption wall body structure and a soft body sound-absorption and shock-absorption layer between the sound-insulation wall body structure and the sound-absorption wall body structure form the double-layer wall body of the sound-insulation and shock-absorption room, an outer air sound-insulation layer is arranged in a distance space between a wall body base layer and the sound-insulation wall body structure, and an inner air sound-insulation layer is arranged in a distance space between the sound-insulation wall body structure and the sound-absorption wall body structure. According to the room-in-room sound-insulation and shock-absorption system, an ideal sound-insulation effect is achieved by virtue of reasonable structure and method. The room-in-room sound-insulation and shock-absorption system has the advantages that the method is feasible, the structure is simple, the cost is low, the sound-insulation effect is good, and the system is firm and durable.

Owner:BEIJING HONG KONG YUAN CONSTR DECORATION ENG

Ecological aluminium oxide melamine wood door and preparation method thereof

InactiveCN101733807AAdequate gluing propertiesEnough durabilityWood working apparatusPolystyreneEngineering

The invention discloses an ecological aluminium oxide melamine wood door, which is formed by an interlayer door frame and decorating plates which are pressed on the front and rear sides of the interlayer door frame. The ecological aluminium oxide melamine wood door is characterized in that: the decorating plates adopt melamine plates; an anti-wear agent prepared from aluminium oxide is laminated on the sides of the melamine plates; and the front and rear sides of the interlayer door frame are coated with polystyrene foams and then the melamine plates are pressed on the two sides by a hot press or a cold press. The ecological aluminium oxide melamine wood door and the preparation method thereof can not only solve the problem of wasting timber resources and simplify the production process, but also overcome the shortcoming of complicated process of the production method. The product cost is greatly reduced and the production cycle is shortened.

Owner:成都市科创巴赛科技有限公司

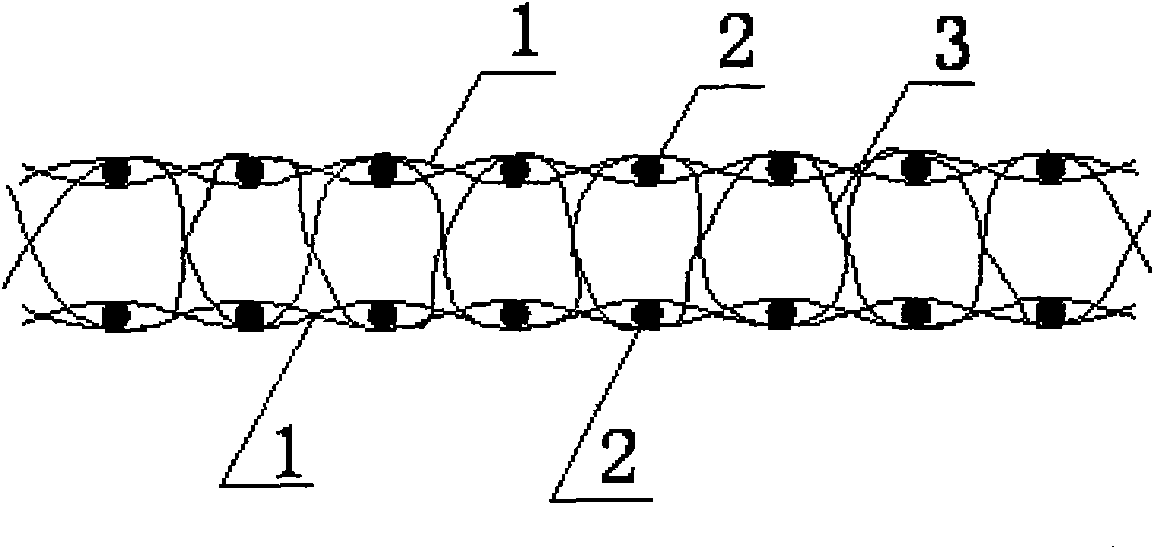

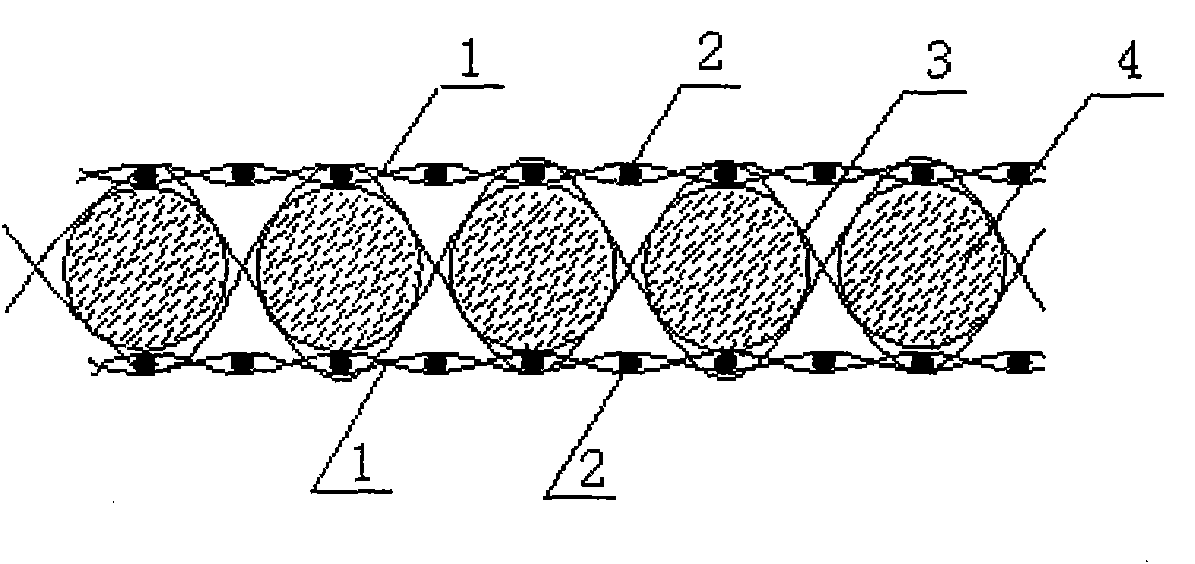

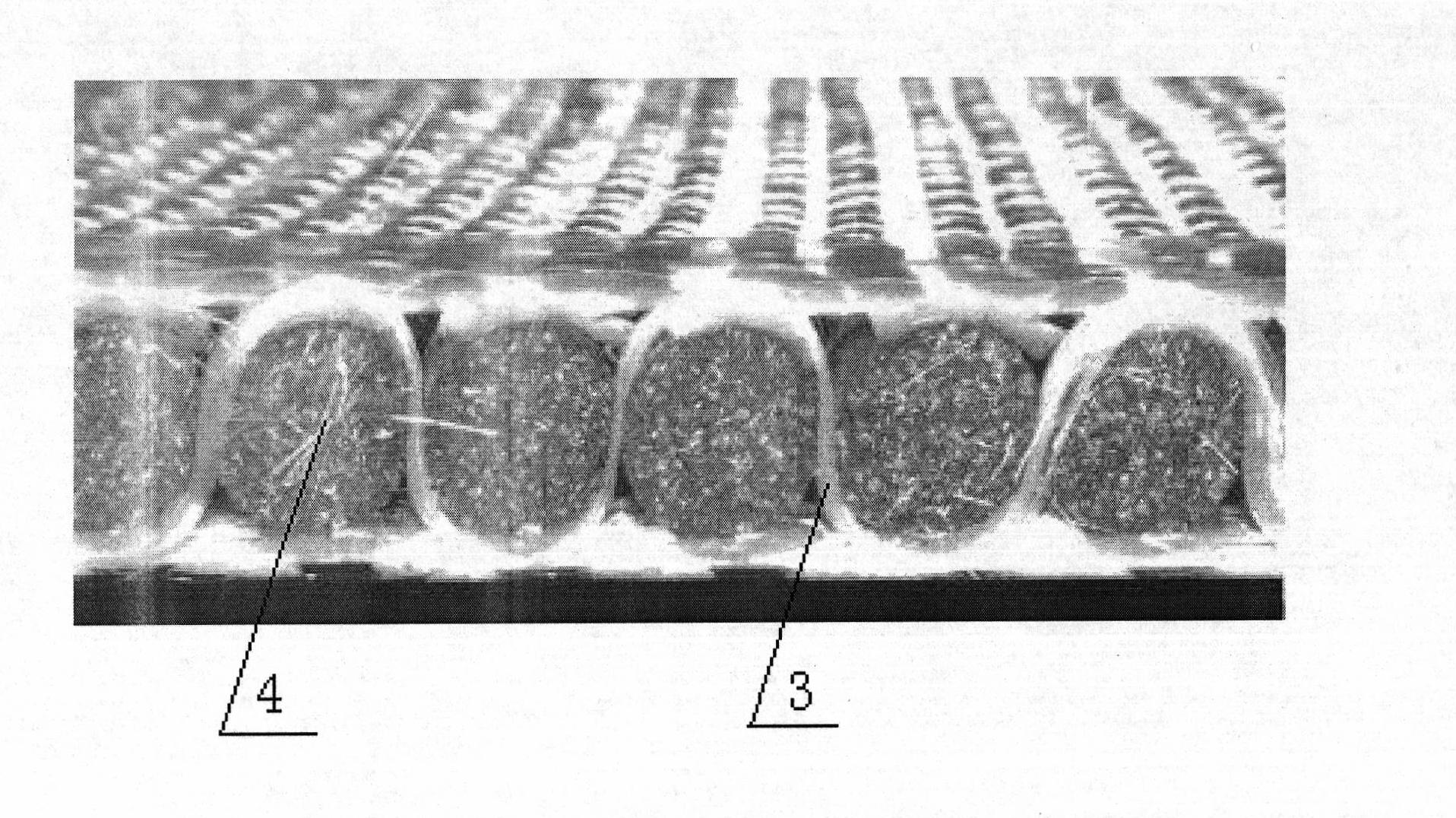

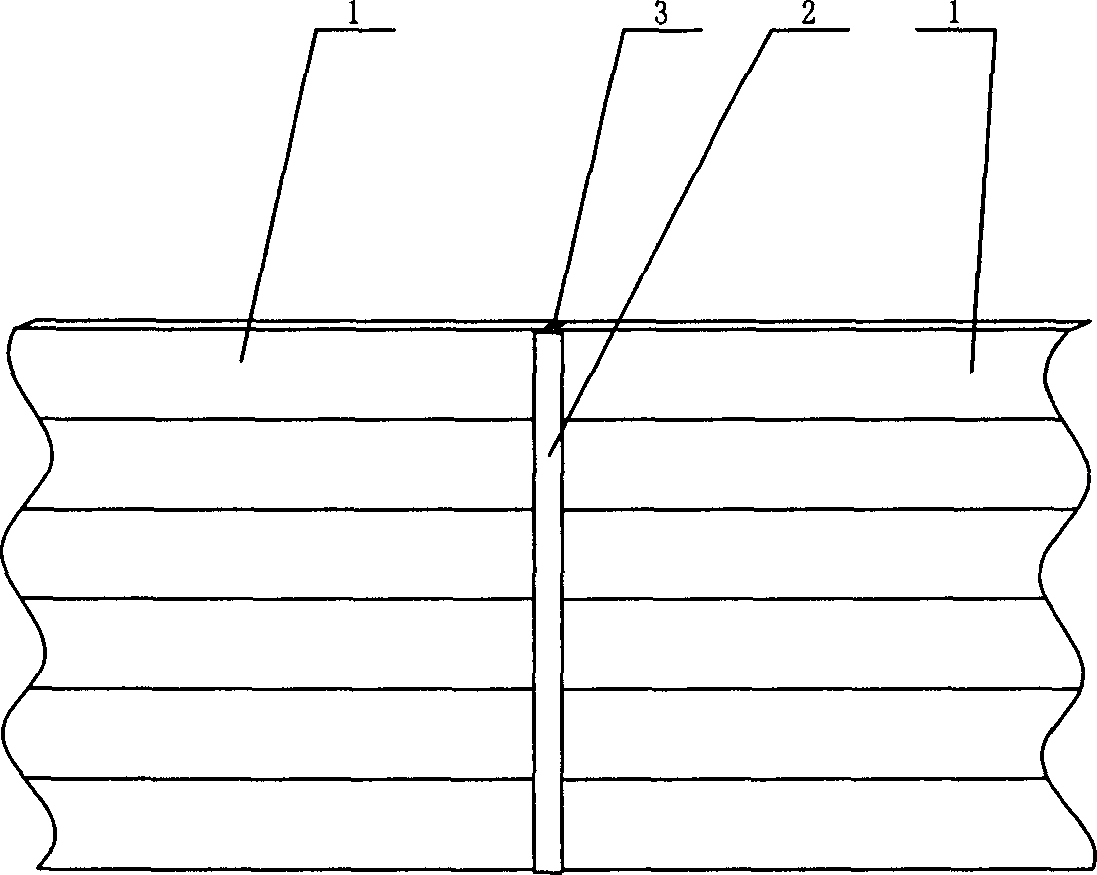

Three-dimensional reinforced fabric knitted with foam strips

InactiveCN101787602AImprove the sound insulation effectHigh strength and lightweight performanceWoven fabricsTransfer moldingEngineering

A three-dimensional reinforced fabric knitted with foam strips is composed of warp yarns (1), weft yarns (2), connecting yarns (3) and foam strips (4), and is characterized in that upper warp yarns (1) and upper weft yarns (2) are knitted to form an upper surface, lower warp yarns (1) and lower weft yarns (2) are knitted to form a lower surface, the upper and lower surfaces are connected with each other into a whole by connecting yarns (3), and foam strips (4) are knitted in the interlayer of the upper and lower surfaces. The foam strips (4) are knitted in the interlayer of the three-dimensional reinforced fabric to have a certain rigid support so that vacuum resin import composite process and resin transfer molding process can be adopted to improve the qualified rate, quality, accuracy and anti-fatigue and other properties of the reinforced composite material, and the foam strips are knitted to lead the fabric to have better sound and heat insulation performance.

Owner:常州同维佳业新材料科技有限公司

Lightweight concrete wall body having self-heat preservation effect

InactiveCN108484204ALight weightImprove the sound insulation effectFibre typesMonocomponent copolyesters artificial filamentWaste rubberPulverized fuel ash

The invention relates to the technical field of concrete, in particular to a lightweight concrete wall body having a self-heat preservation effect. The lightweight concrete wall body is prepared fromthe following raw materials: 15 to 35 parts of pulverized fuel ash, 10 to 18 parts of ash calcium powder, 8 to 15 parts of mountain flour 70 sand, 3 to 11 parts of glass beads, 20 to 35 parts of Portland cement, 5 to 10 parts of porous fiber, 5 to 12 parts of kieselguhr, 4 to 11 parts of attapulgite, 0.5 to 3.6 parts of first foaming agent, 20 to 48 parts of lightweight aggregate, 2 to 7 parts ofwaste rubber powder, 0.6 to 1.8 parts of water reducing agent and 1 to 5 parts of other assistants, wherein the porous fiber is prepared from the following substances: 15 to 36 parts of first polymeremulsion, 13 to 49 parts of second polymer emulsion, 0.3 to 6.4 parts of second foaming agent, 3 to 9 parts of soluble metal salt, 5 to 25 parts of chain extender and 6 to 23 parts of graphene oxide.According to the lightweight concrete wall body disclosed by the invention, by adding the glass beads, the porous fiber and the waste rubber powder in concrete, a rich composite porous structure not only is capable of effectively reducing self weight of the concrete and meeting the requirements on light weight, but also has higher sound insulation and heat preservation properties, so that the self-heat preservation effect of the lightweight concrete wall body is ensured.

Owner:合肥宸翊商贸有限公司

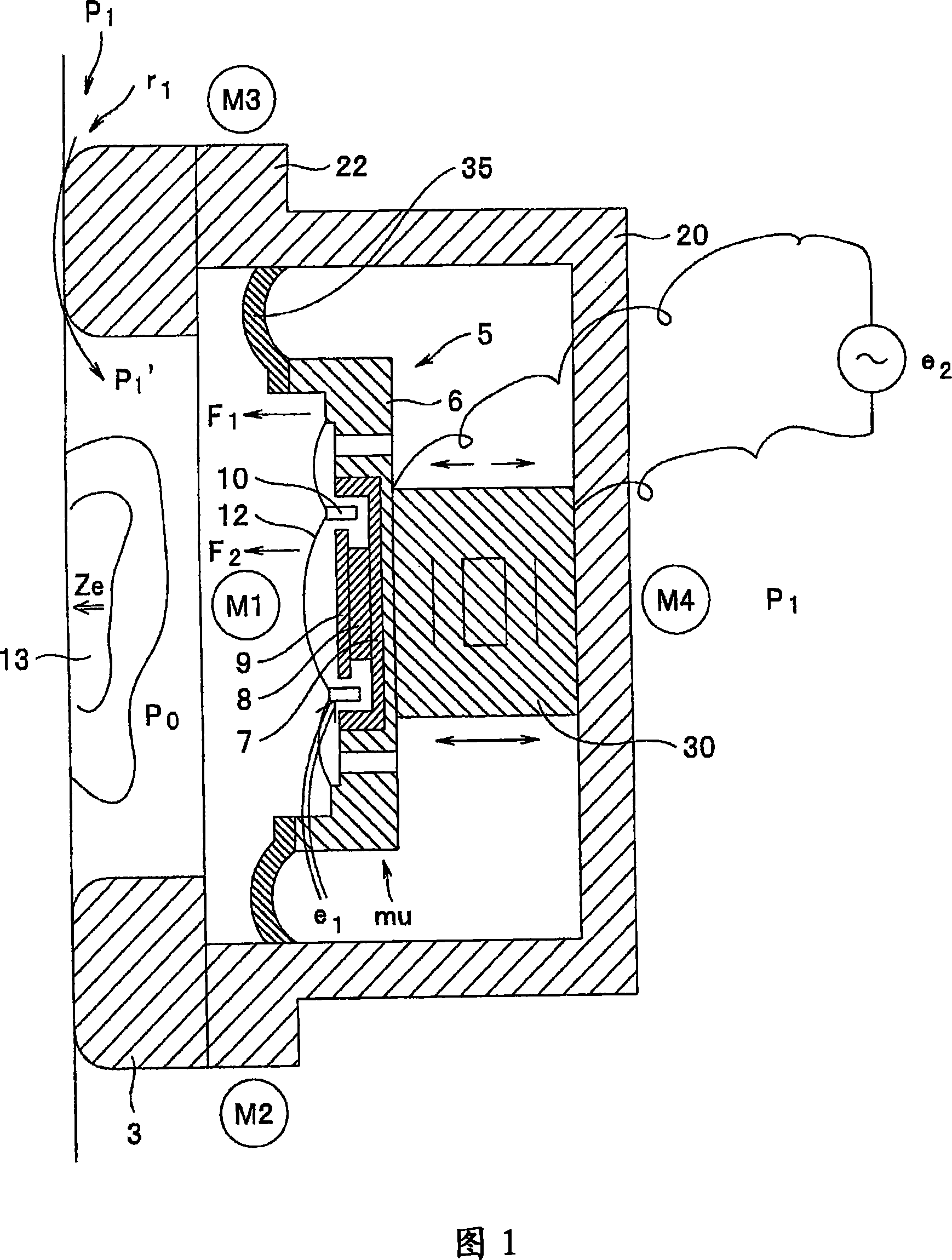

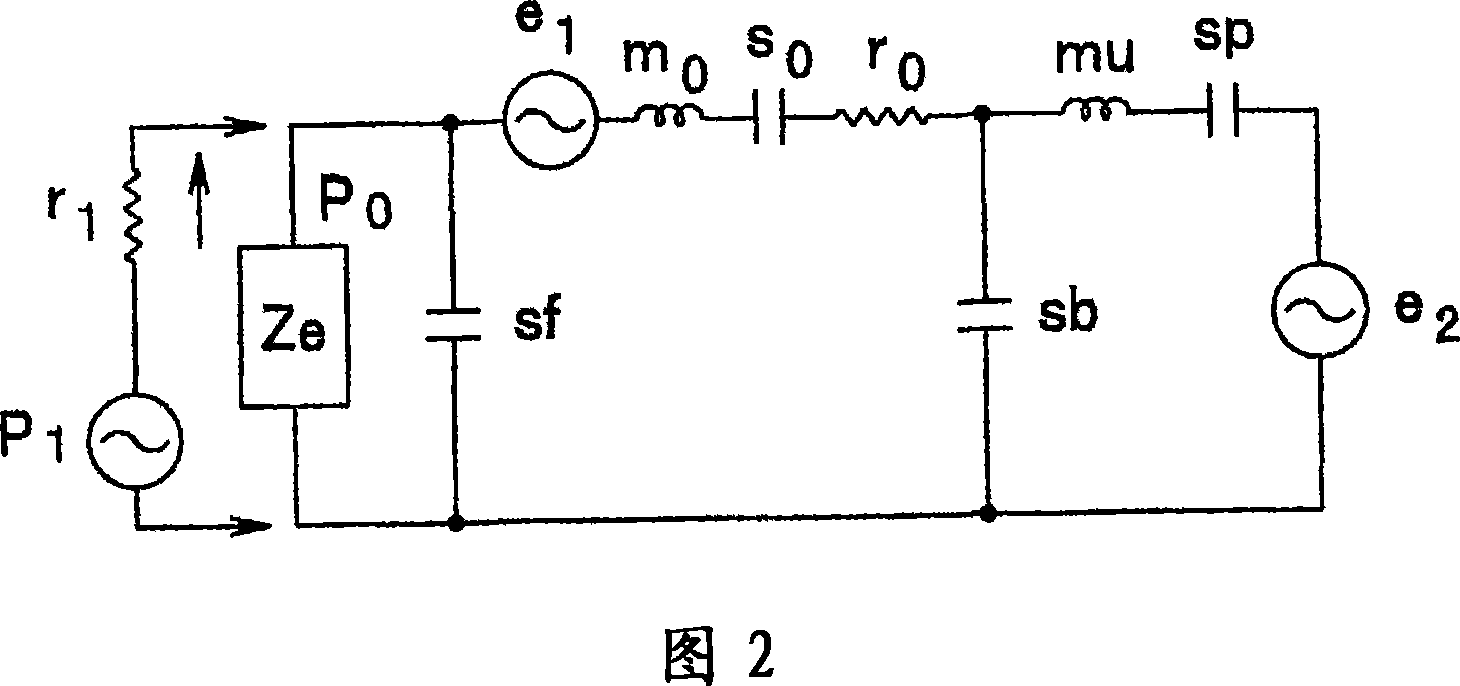

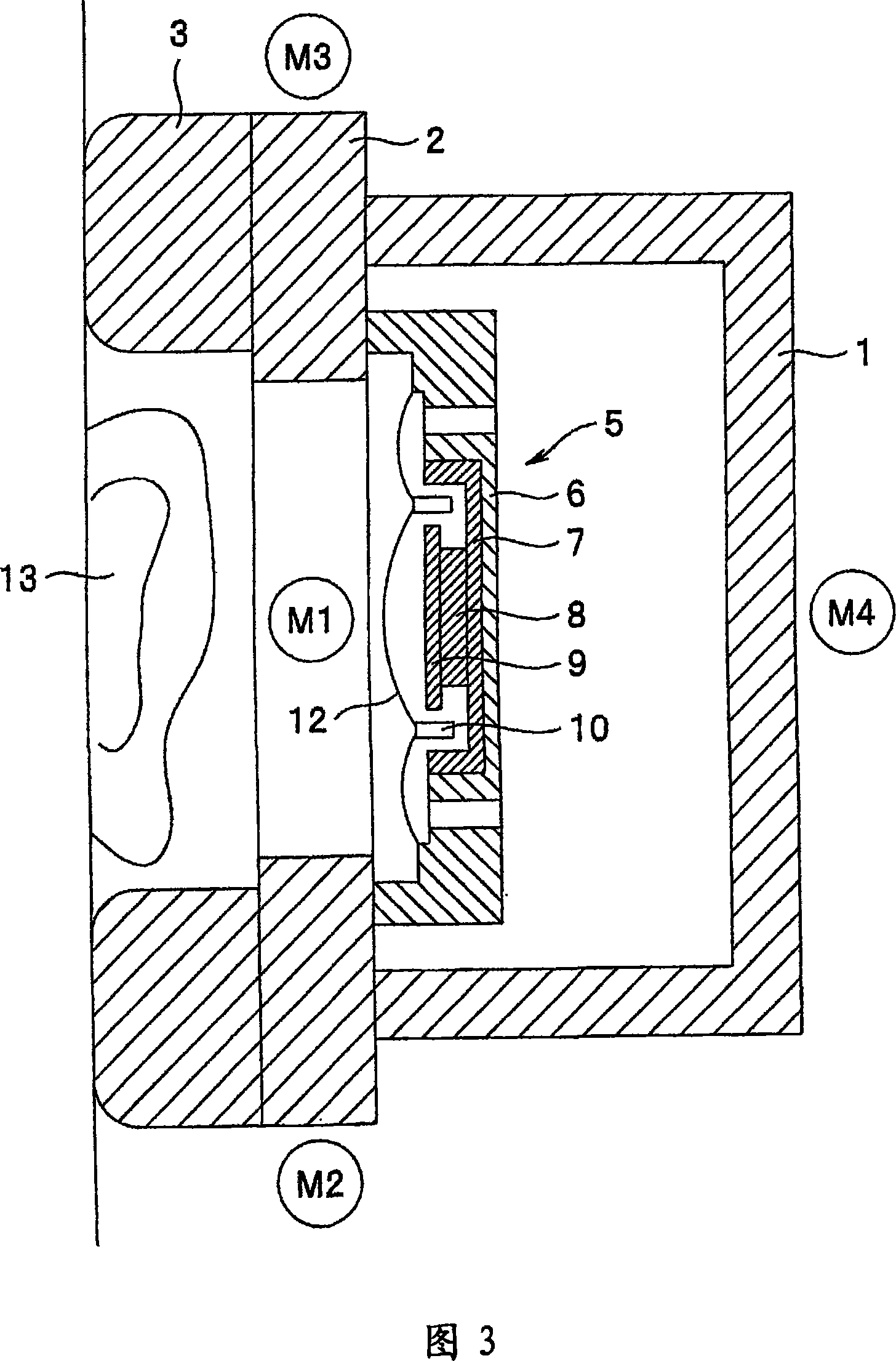

Earphone

InactiveCN101163351AImprove the sound insulation effectExtend your lifeEarpiece/earphone attachmentsTransducer circuitsEngineeringHeadphones

An earphone is equipped with a loudspeaker component driven by musical sound signal, a microphone for detecting ambient noise, a piezoelectric element for driving framework of loudspeaker component by noise elimination signal generated based on noise signal detected by microphone. The piezoelectric element is disposed between the framework of loudspeaker component and earphone housing, the two sides of which is combined with the framework and the earphone housing. Therefore, the earphone with weak electric coupling of noise elimination signal and musical sound signal, less influence of noise elimination signal to musical sound signal is obtained, both the power amplification circuit of noise elimination signal and musical sound signal can not be load for each other, which is capable of listening reproduction sound based on musical sound signal with excellent quality even if the embedded battery is expended and the noise elimination circuit is out of working.

Owner:AUDIO-TECHNICA

Lightweight partition board and making method thereof

InactiveCN107162632AHigh compressive strengthHigh tensile strengthConstruction materialCeramicwareFiberFoaming agent

The invention discloses a lightweight partition board and a making method thereof, and relates to the technical field of partition boards. The lightweight partition board comprises 55-65 parts of Portland cement, 45-50 parts of modified fiber particles, 42-43 parts of modified clay, 40-42 parts of paraffin-diatomite phase transition gel, 37-40 parts of latex, 35-37 parts of phosphate, 32-35 parts of hollow glass beads, 27-29 parts of a foaming agent, 23-25 parts of a plasticizer, 21-22 parts of a fire retardant and 65-68 parts of water. The lightweight partition board has the advantages of good comprehensive strength, good tensile strength, good cracking resistance, good suspending ability, good sound and heat insulation effect, low production cost and high economic promotion benefit.

Owner:合肥市旺友门窗有限公司

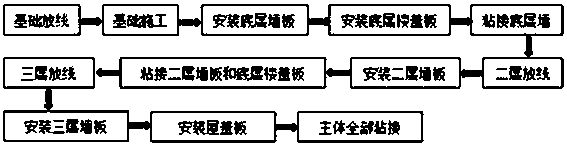

Mineral powder combined fiber composite board as well as production method and application

InactiveCN109053125AImprove bending resistanceImprove stress resistanceConstruction materialLaminationFiberChloride

The invention relates to a mineral powder combined fiber composite board as well as a production method and application, which belongs to the technical field of construction materials, and can solve the problems that the existing board is short in service life, poor in mechanical performance, non-fire-proof and high in construction cost. The mineral powder combined fiber composite board comprisesthe following components in parts by mass: 12 percent of magnesium chloride, 23 percent of magnesium oxide, 6 percent of plant fibers, 58 percent of wood board, and the balance of water. The mineral powder combined fiber composite board is assembled in steps of foundation wire layout, foundation construction, installation of bottom wallboards, installation of bottom floor cover plates, adhesion ofbottom walls, wire layout on the second floor, installation of second-floor wallboards, adhesion of second-floor wallboards and bottom floor cover plates, wire layout on the third floor, installationof third-floor wallboards, installation of roof cover plates, and adhesion of a main body. The mineral powder combined fiber composite board is low in cost and favorable for the environmental protection.

Owner:孙杰

Non-asbestos-fiber oil-resistant and high-temperature-resistant calcium silicate plate and preparation method thereof

The present invention relates to the field of building wall materials, particularly to a non-asbestos-fiber oil-resistant and high-temperature-resistant calcium silicate plate and a preparation method thereof, wherein the non-asbestos-fiber oil-resistant and high-temperature-resistant calcium silicate plate comprises, by weight, 30-45% of cement, 3-4% of fly ash, 3-3.5% of sodium silicate, 45-60% of polyisoprene rubber, and 3-3.5% of a water reducer. According to the present invention, the produced non-asbestos-fiber oil-resistant and high-temperature-resistant calcium silicate plate has characteristics of good sound insulation, good thermal insulation, good fire resistance and environmental protection during the production and use process; the added polyurethane elastomer has excellent wear resistance and excellent oil resistance, belongs to the polar polymer, and can be organically and integrally combined with polypropylene so as to efficiently improve the mechanical property of polypropylene; the added fluorine rubber has characteristics of high temperature resistance, oil resistance and the like; and the added other fillers have other physical properties and processability.

Owner:CHANGZHOU WUJIN GOLDEN SUNSHINE ELECTRONICS

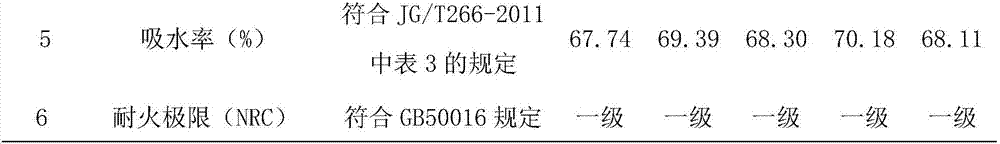

Process for manufacturing full-bamboo embossed pattern plate

InactiveCN101890748AImprove deep processingIncrease profitDecorative surface effectsWood treatment detailsHigh intensityManufacturing engineering

The invention discloses a process for manufacturing a full-bamboo embossed pattern plate. In the process, modified bamboo fibers, bamboo filaments and bamboo strips are paved and arranged in a bundle shape on a pattern template with a customized pattern and are made into a wide high-strength high-density embossed pattern-face embryonic plate through high temperature and high pressure. The process for manufacturing the full-bamboo embossed pattern plate can increase specifications and varieties of materials and save the materials and labor.

Owner:葛会龙 +1

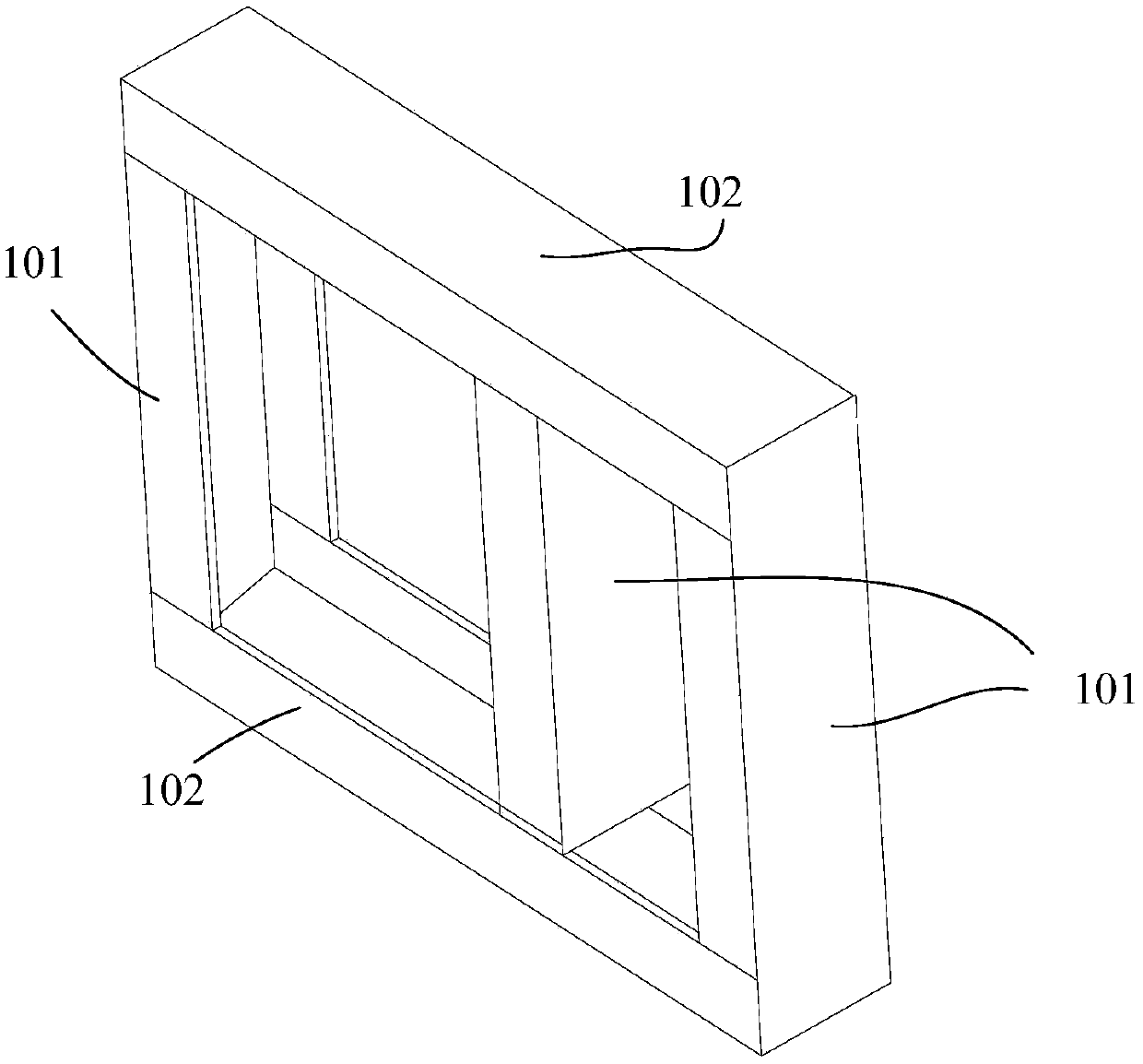

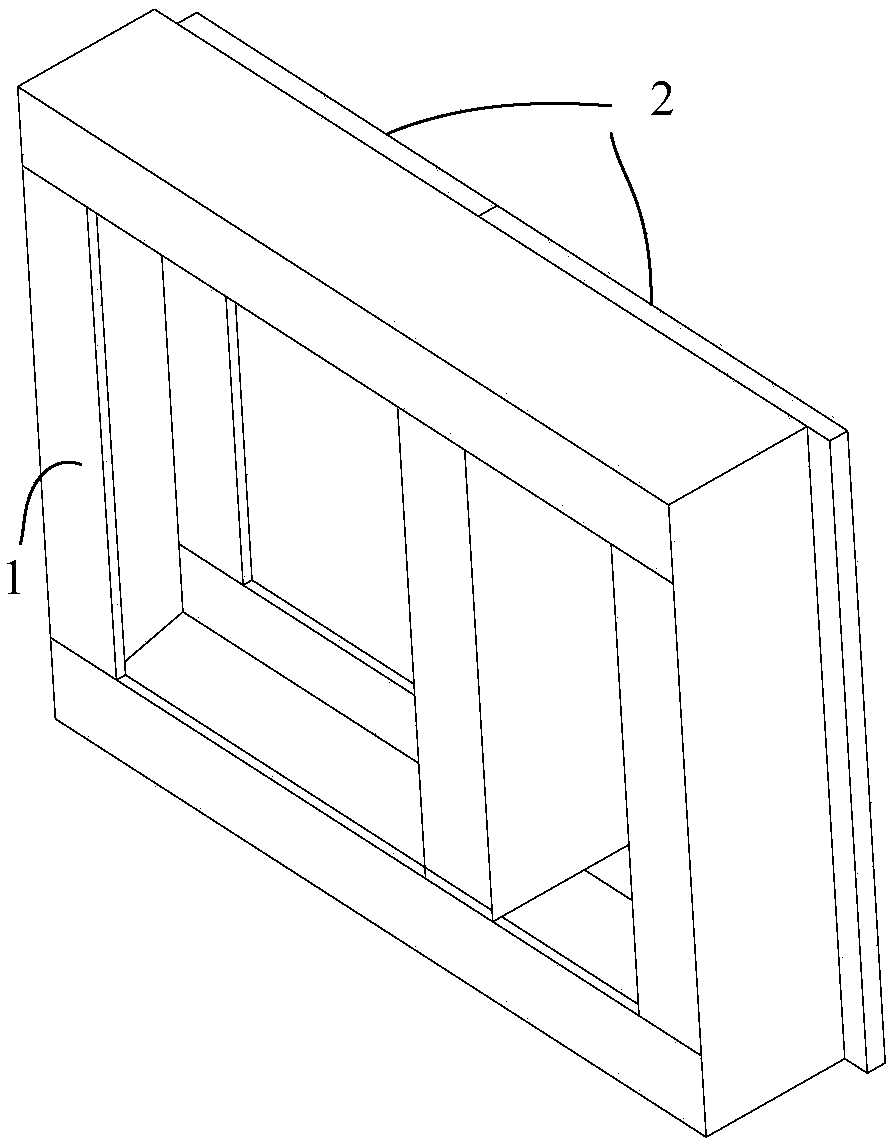

Wall manufacturing method and wall prepared by same

PendingCN110761565AImprove building efficiencyReduce waste pollutionWallsHeat proofingThermal insulationWall plate

The invention discloses a wall manufacturing method and a wall prepared by the same, and relates to the field of buildings. The wall manufacturing method mainly includes the following steps of splicing keel skeletons, splicing mortise ports and tenon ports, filling a thermal insulation material, arranging and inserting and fixing second wall panels. The wall includes a plurality of wall units spliced to each other and a plurality of second wall panels fixed to one sides of the wall units. The wall units each include a keel skeleton, a plurality of first wall panels closing one side of the corresponding keel skeleton and the thermal insulation material filled in the corresponding keel skeleton, and the thermal insulation material is bonded to the first wall panels. The mortise ports and thetenon ports for insertion are separately formed in two ends of the wall units in the length direction, and the adjacent wall units are inserted to each other. The second wall panels close the other sides of the keel skeletons, and are arranged asymmetrically with the first wall panels. The wall manufacturing method for convenient installation and the wall which is prepared by the wall manufacturing method and has good sound insulation and thermal insulation properties are provided.

Owner:BEIJING NEW BUILDING MATERIAL

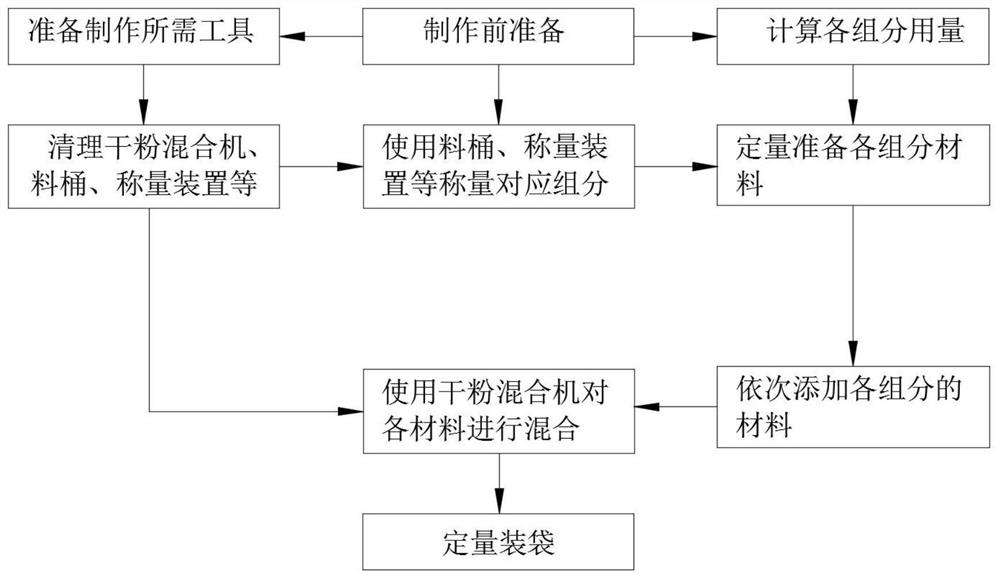

Gypsum-based self-leveling sound-insulation thermal-insulation mortar manufacturing process and operation flow

PendingCN113061009AImprove the sound insulation effectImprove practicalityCeramicwareCelluloseThermal insulation

The invention discloses a gypsum-based self-leveling sound-insulation thermal-insulation mortar manufacturing process and operation flow, gypsum-based self-leveling sound-insulation thermal-insulation mortar comprises the following components in parts by weight: 70 parts of desulfurized gypsum, 3 parts of glass beads, 2.5 parts of cellulose, 1.5 parts of aerogel, 20 parts of light sand, 1.5 parts of latex powder, 1 part of A retarder and 0.5 part of a water reducing agent. based on 100 parts of desulfurized gypsum with the same weight. According to the gypsum-based self-leveling sound-insulation thermal-insulation mortar , the glass beads and the aerogel are mixed in the gypsum-based self-leveling sound-insulation thermal-insulation mortar, so that the gypsum-based self-leveling sound-insulation thermal-insulation mortar has a better sound insulation and thermal insulation effect, the sound insulation and thermal insulation effect of a building is improved, the building has a better use effect, the practicability of the gypsum-based self-leveling sound insulation and thermal insulation mortar is improved, and the market competitiveness is higher.

Owner:浙江森林人新型材料有限公司

Exterior wall hanging plate jointed by slab seam connection pieces

ActiveCN1837542AImprove the sound insulation effectEfficient exclusionCovering/liningsBuilding insulationsThermal expansionWater tightness

The invention relates to an external wall suspending plate connected via seam connector, which is formed by parallel external wall suspending plates with through holes, waterproof sealing material, and the seam connector fixed on the construction. The seam connector is at the inner side of plates to be fixed on the connection of ends of plates, to form a longitudinal space with the external wall suspending plates, while the space is connected to the through hole. And the outer side of connection part of plates is filled with waterproof sealing material. the invention can effectively avoid the distortion of wall with better sound insulation property, etc.

Owner:BEIJING NEW BUILDING MATERIALS PLC

Integrative solar-energy building board

ActiveCN101761177AImprove protectionAvoid damageRoof covering using slabs/sheetsRoof covering using tiles/slatesElectricityArchitectural engineering

The invention relates to a solar-energy building board, comprising a building core board, a solar panel and a supporting board, wherein the solar panel is arranged at the upper surface of the building core board, and the bottom part of the building core board is provided with the supporting board playing a supporting role. The upper part of the building core board provided with the solar panel is provided with a groove for heat dissipation of the solar panel. The solar panel for generating solar energy and the building core board used as building materials are combined together to form the integrative solar-energy building board, so the solar panel can be utilized to generate electricity and can also be used as building materials, the manufacturing and installation process is simplified, and the building board and the solar panel are installed well once.

Owner:HUIZHOU HECHENG MECHANICAL EQUIP CO LTD

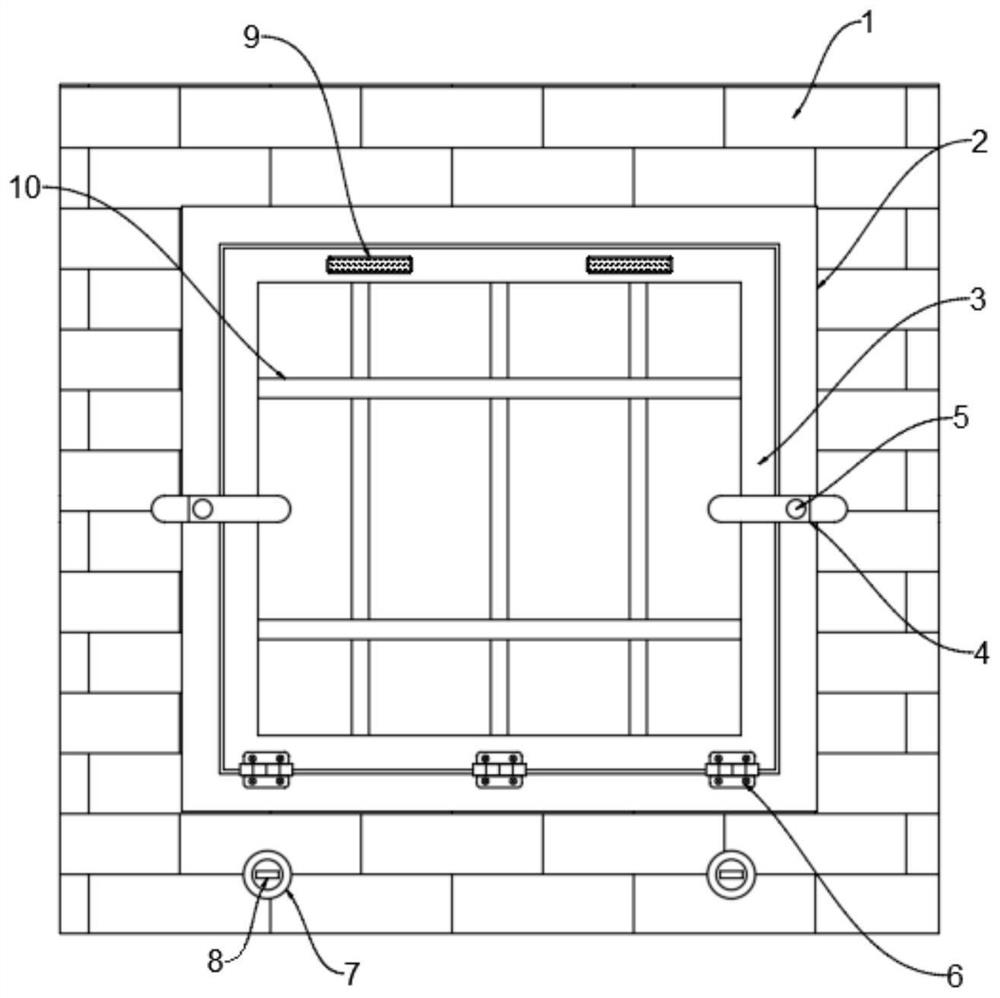

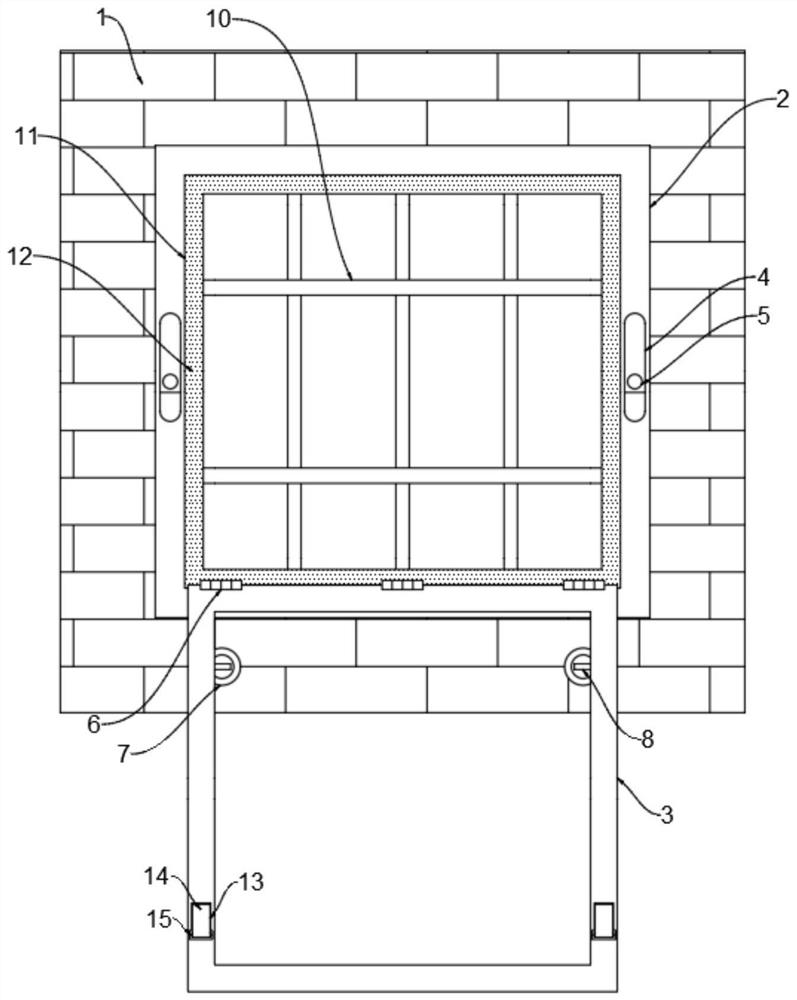

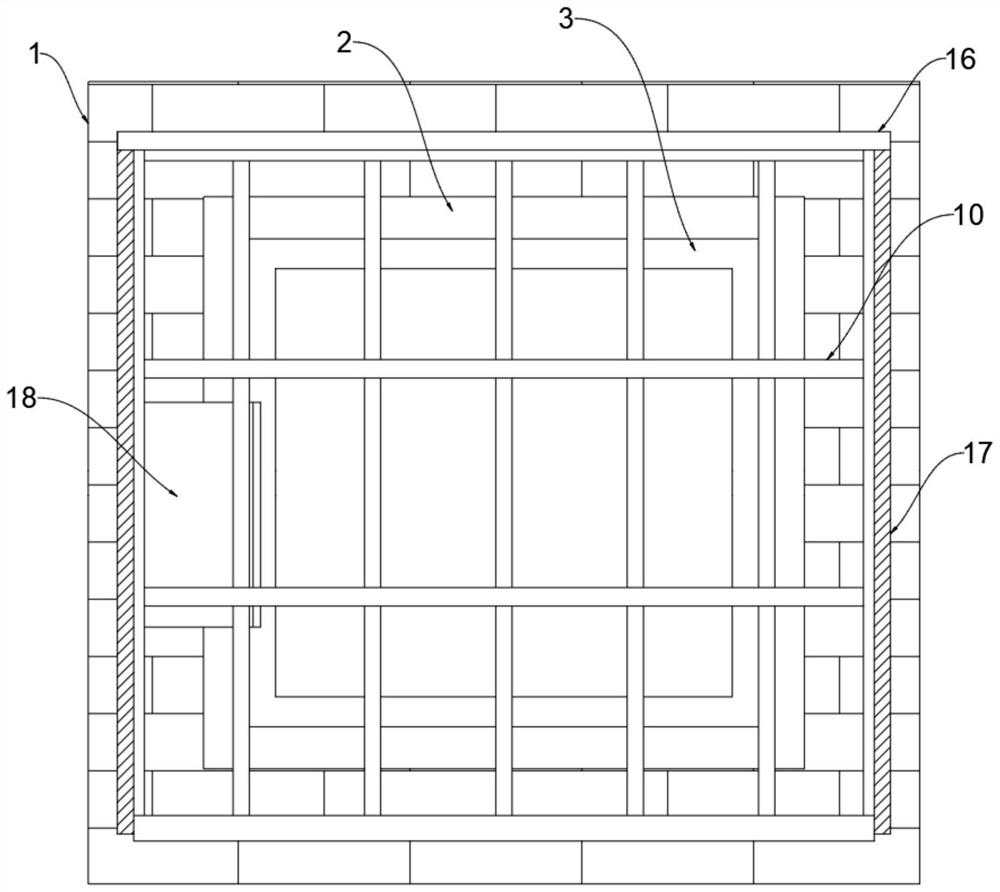

Sound insulation and heat preservation quick escape window

InactiveCN111997493APrevent looseningImprove survival rateShutters/ movable grillesBuilding rescueFixed frameHeat conservation

The invention discloses a sound insulation and heat preservation quick escape window, relates to the technical field of escape windows, and aims to solve existing problems. A fixed frame is arranged in a wall and fixedly connected with the wall, a window frame is arranged in the fixed frame, an anti-theft fixed window is fixedly installed outside the wall, two sides of the inner walls of the anti-theft fixed window are provided with guide rails, an anti-theft movable window is arranged in the anti-theft fixed window, and the two sides of the anti-theft movable window are slidingly connected with the guide rails at the two sides of the inner wall of the anti-theft fixed window, the lower ends of the guide rails are fixedly installed with limiting blocks, and an escape box is fixedly installed on one side in the anti-theft fixed window.

Owner:南京博洪环保科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com