Three-dimensional reinforced fabric knitted with foam strips

A technology for strengthening fabrics and foam strips, applied in the directions of fabrics, textiles, textiles and papermaking, can solve problems such as poor molding, and achieve the effects of improving the yield of finished products, improving sound insulation and thermal insulation performance, and improving sound insulation and thermal insulation performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments.

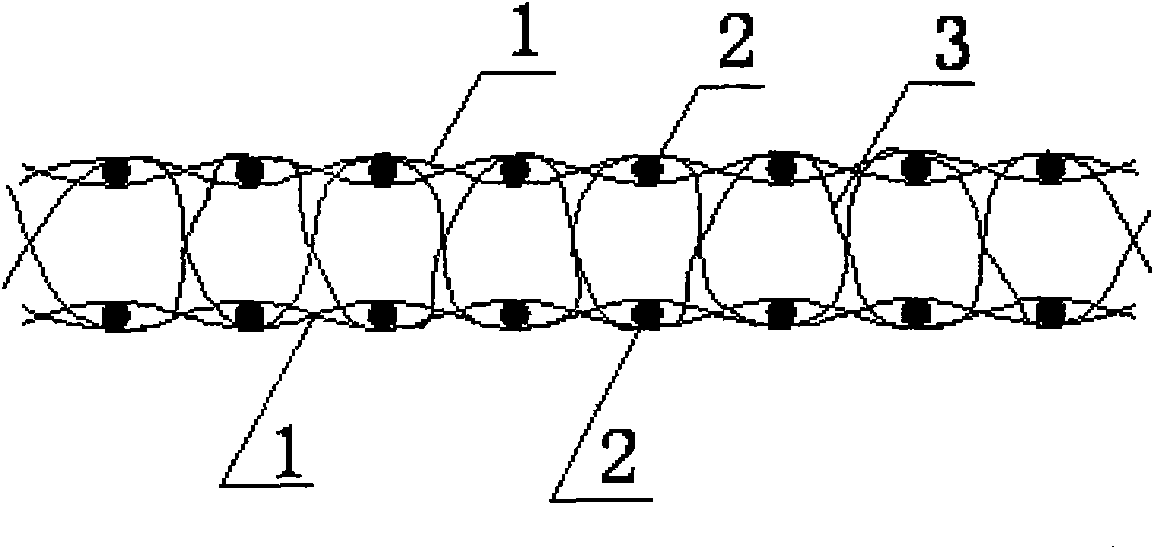

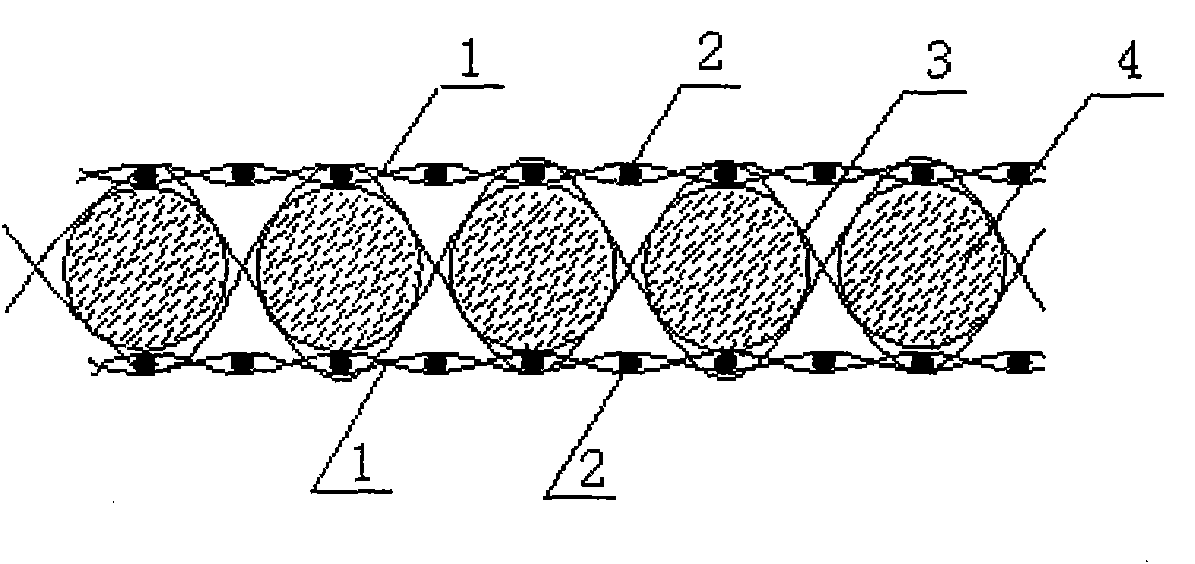

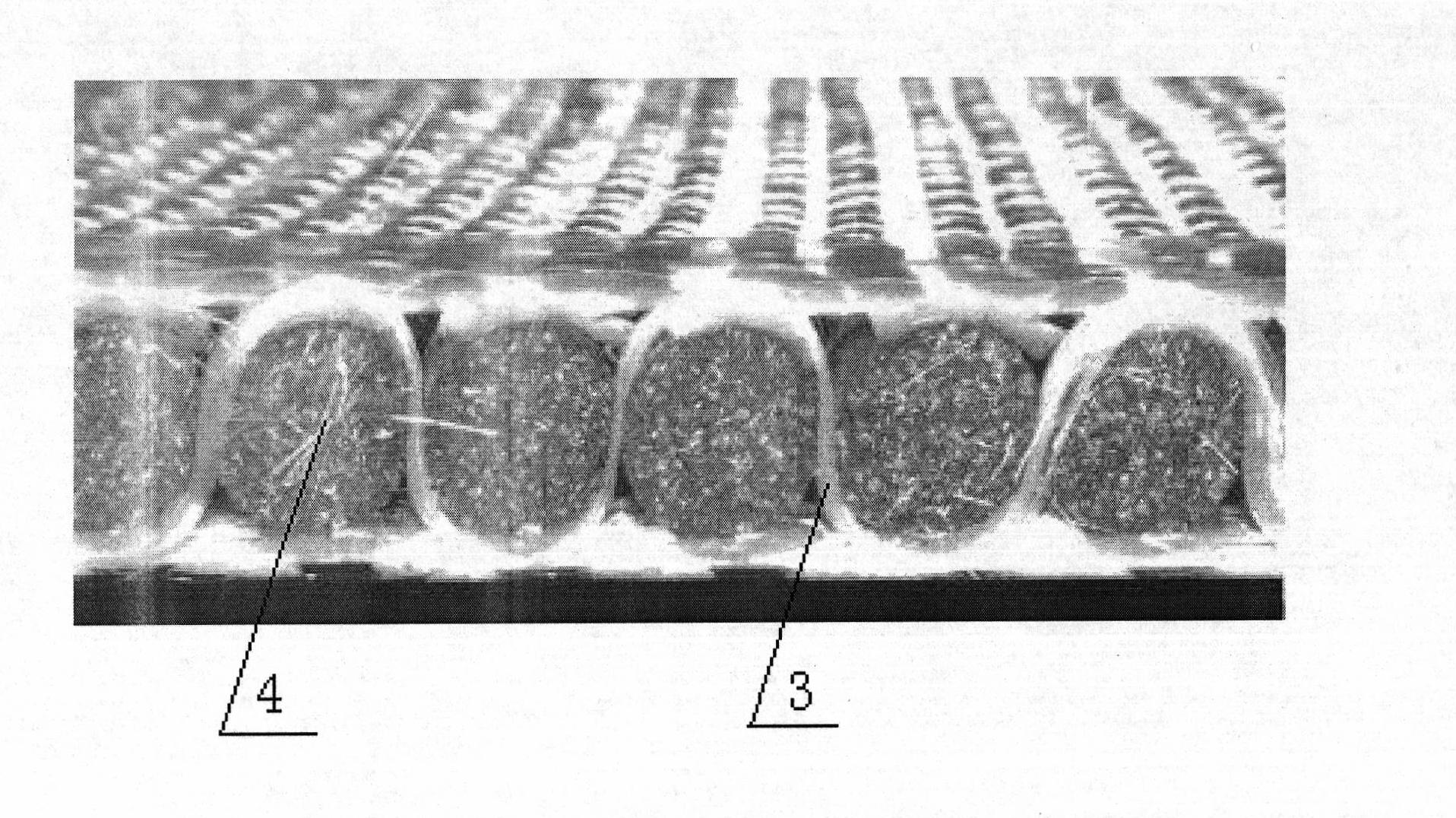

[0018] Such as figure 1 As shown, the upper warp yarn 1 and the upper weft yarn 2 are knitted to form the upper surface, the lower warp yarn 1 and the lower weft yarn 2 are knitted to form the lower surface, and the connecting yarn 3 is interspersed on the upper and lower surfaces to connect the upper and lower surfaces as a whole and form The middle layer, this is the three-dimensional hollow layer connected fabric, in which the middle layer only has the connecting yarn 3, which will be deformed under a little pressure, so the vacuum resin introduction composite process and the resin transfer molding process cannot be used, and such as figure 2 As shown, the foam strip 4 is just woven into the middle layer. The three-dimensional reinforced fabric has a certain rigid skeleton, so that the vacuum resin introduction composite process and the r...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com