Heat-insulating and sound-isolating light foamed concrete material and preparation method thereof

A foamed concrete, thermal insulation and sound insulation technology, applied in ceramic products, other household appliances, sustainable waste treatment, etc., can solve the problems of high cost and complex preparation process, achieve low cost, reduce production cost, and good impermeability performance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

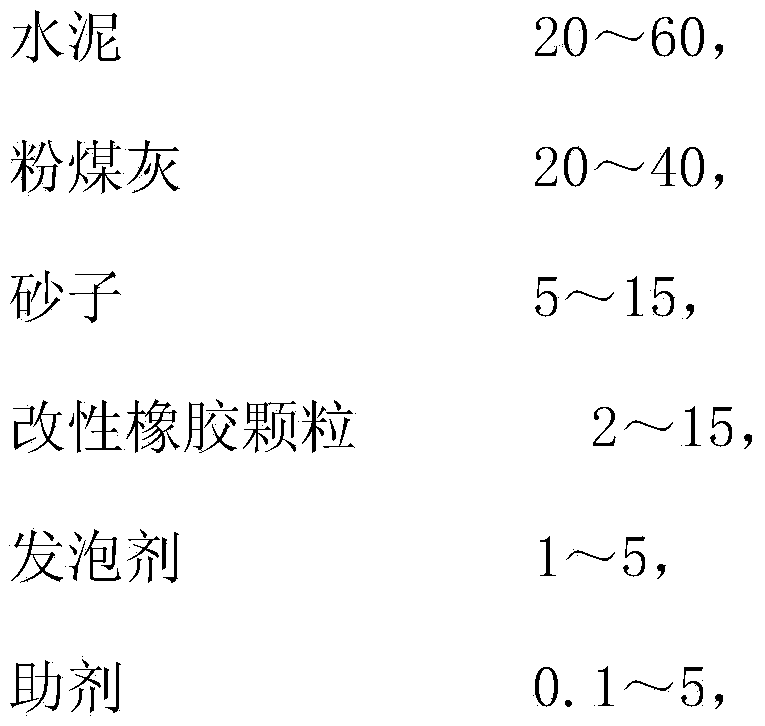

Method used

Image

Examples

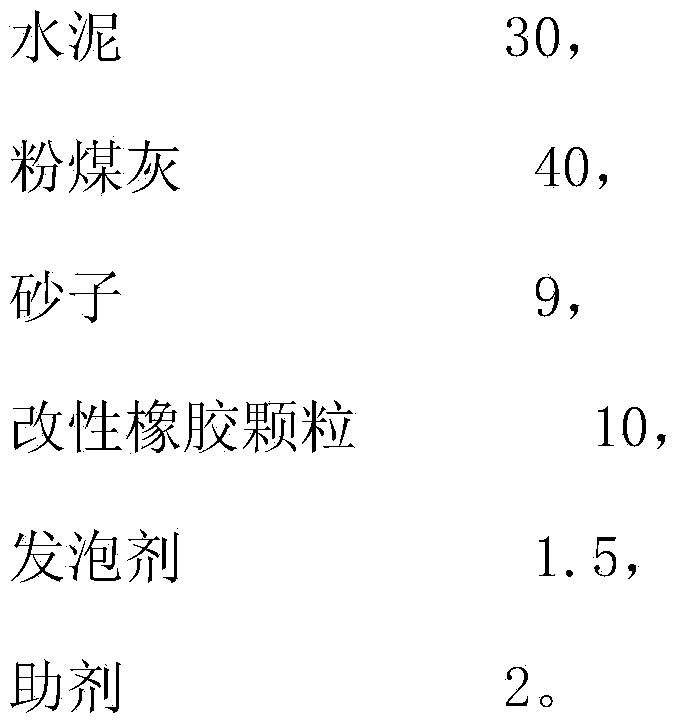

Embodiment 1

[0029] A method for preparing a heat-insulating and sound-insulating lightweight foamed concrete material, the preparation method has the following steps:

[0030] (1) Preparation of modified rubber particles

[0031] Prepare waste rubber granules 9.8, cement 0.2 and water in parts by mass; first, soak the waste rubber granules in water for 24 hours, then mix the soaked waste rubber granules and cement evenly under mechanical agitation, and leave it to stand for 24 hours to change permanent rubber particles;

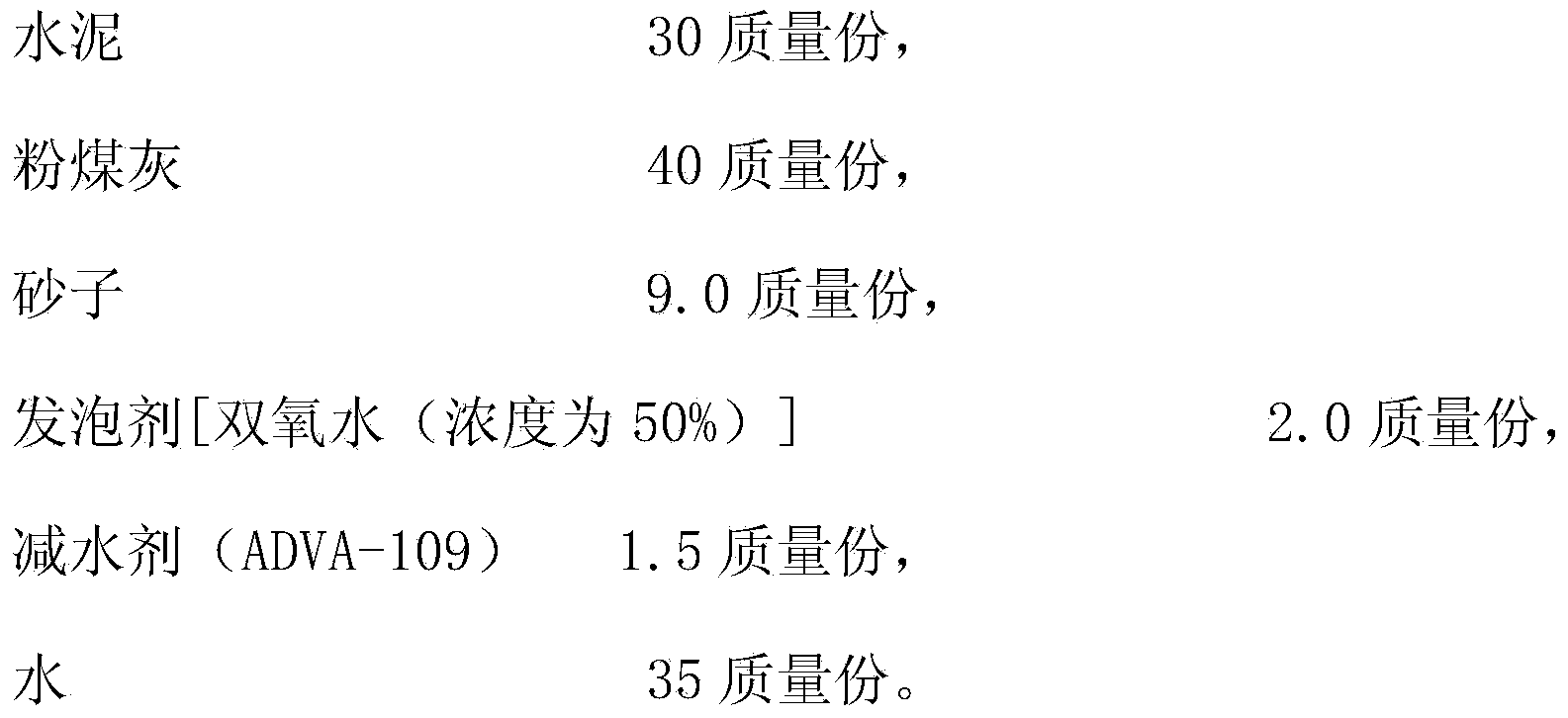

[0032] (2) Preparation of concrete material precursor

[0033] In terms of parts by mass, prepare 30 cement, 40 fly ash, 9.0 sand, 10 modified rubber particles, 1.5 hydrogen peroxide (50% concentration), 35 water reducing agent ADVA-1092; first, cement, modified rubber Granules and fly ash are uniformly mixed under mechanical stirring conditions to obtain a cement rubber fly ash mixture; then, the water reducer is uniformly dispersed in water to obtain a uniform soluti...

Embodiment 2

[0037] A method for preparing a heat-insulating and sound-insulating lightweight foamed concrete material, the preparation method has the following steps:

[0038] (1) Preparation of modified rubber particles

[0039] Prepare waste rubber granules 9.7, cement 0.3 and water in parts by mass; first, soak the waste rubber granules in water for 24 hours, then mix the soaked waste rubber granules and cement evenly under mechanical agitation, and leave to stand for 24 hours to change permanent rubber particles;

[0040] (2) Preparation of concrete material precursor

[0041] In parts by mass, prepare cement 40, fly ash 30, sand 9.0, modified rubber particles 10, hydrogen peroxide (50%) 2.0, water reducer ADVA-1091.0, water 42; first, cement, modified rubber Granules and fly ash are uniformly mixed under mechanical stirring conditions to obtain a cement rubber fly ash mixture; then, the water reducer is uniformly dispersed in water to obtain a uniform solution of the water reducer,...

Embodiment 3

[0045] A method for preparing a heat-insulating and sound-insulating lightweight foamed concrete material, the preparation method has the following steps:

[0046] (1) Preparation of modified rubber particles

[0047] Prepare waste rubber granules 7.7, cement 0.3 and water in parts by mass; first, soak the waste rubber granules in water for 24 hours, then mix the soaked waste rubber granules and cement evenly under mechanical agitation, and leave to stand for 24 hours to change permanent rubber particles;

[0048] (2) Preparation of concrete material precursor

[0049] In parts by mass, prepare cement 50, fly ash 30, sand 9.0, modified rubber particles 8.0, hydrogen peroxide (50% concentration) 2.5, water reducing agent ADVA-1091.5, water 35; first, cement, modified rubber Granules and fly ash are uniformly mixed under mechanical stirring conditions to obtain a cement rubber fly ash mixture; then, the water reducer is uniformly dispersed in water to obtain a uniform solution o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com