Novel sound insulation and heat preservation board for light steel houses

A technology for sound insulation and steel houses, applied in the direction of heat preservation, sound insulation, building components, etc., can solve the problems of waste of raw materials, high energy consumption, and a lot of construction waste, and achieve reasonable overall structure settings, good heat insulation and sound insulation effects, and high use intensity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

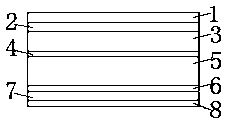

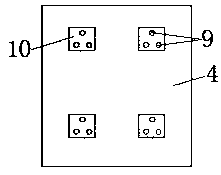

[0011] Such as figure 1 and figure 2 As shown in the present invention, a new type of sound insulation and heat insulation board for light steel houses according to the present invention includes a carbon fiber panel 1, a heat radiation reflection layer 2 is provided on the inside of the carbon fiber panel 1, and a heat radiation reflection layer 2 is provided on the inside of the heat radiation reflection layer 2. There is a sound insulation layer 3, a detection layer I4 is provided inside the sound insulation layer 3, an insulation layer 5 is provided inside the detection layer I4, a detection layer II6 is provided inside the insulation layer 5, and a detection layer II6 is provided inside the detection layer II6. A fireproof layer 7 is arranged on the inside, a decorative layer 8 is arranged inside the fireproof layer 7, and sensors 9 are arranged ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com