Fabricated composite light heat preservation and sound insulation wallboard and manufacturing method thereof

A thermal insulation and sound insulation, prefabricated technology, applied in the field of wall panel manufacturing, can solve the problems of poor sound insulation effect, heavy quality, and high cost of wall panel production, and achieve superior thermal insulation, low cost, and light weight effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

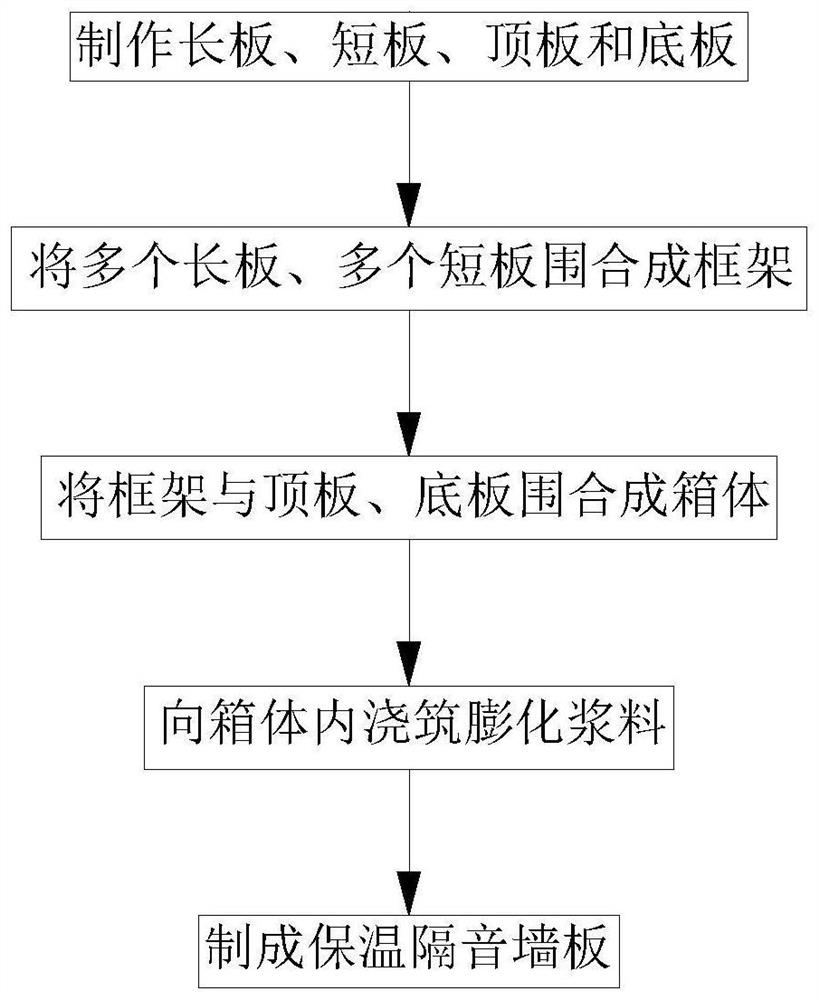

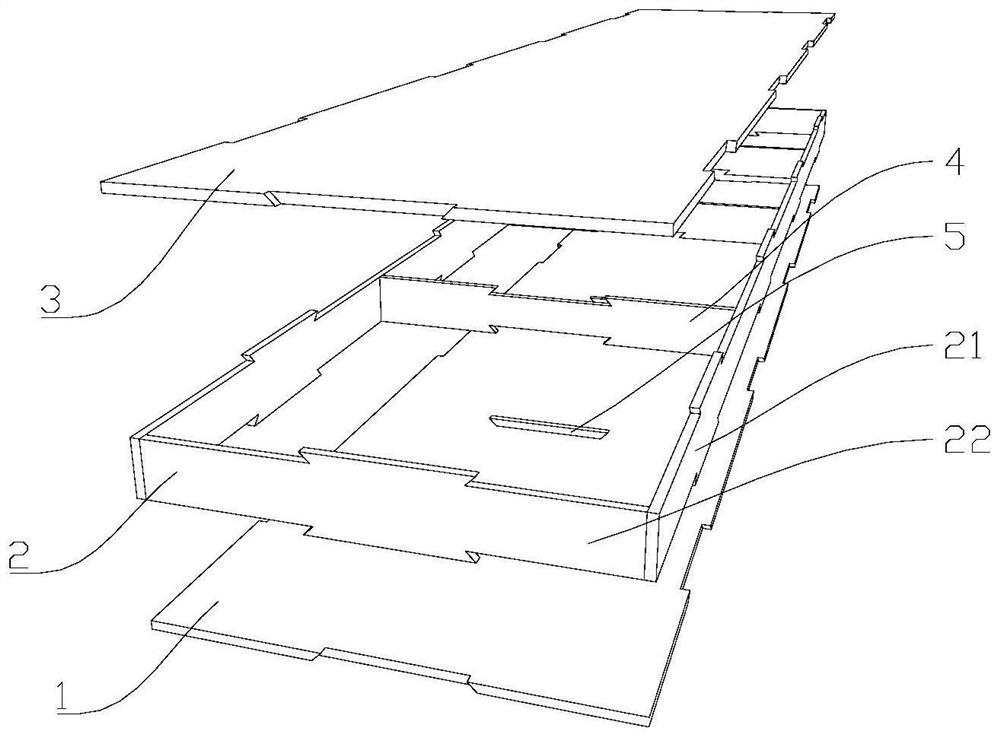

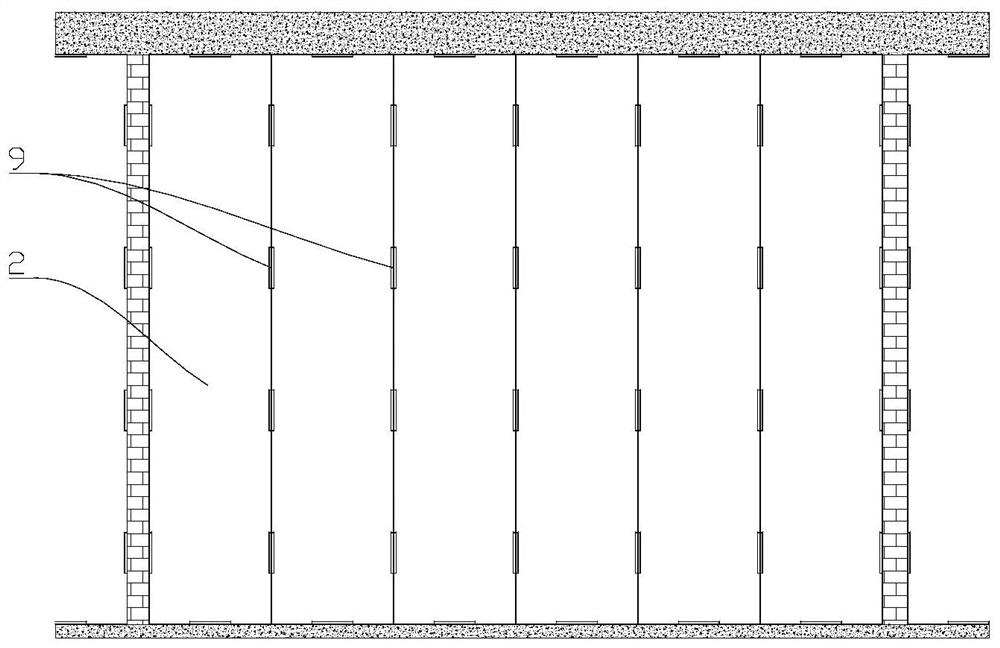

[0044] Such as figure 1As shown, this embodiment provides a method for manufacturing an assembled composite lightweight thermal insulation and sound insulation wallboard, including the following steps: making a plurality of long boards 21, a plurality of short boards 22, a top board 3 and a bottom board 1, long boards 21, The short board 22, the top board 3 and the bottom board 1 can be made of cement fiber pressure board or other boards of the same strength, and the multiple long boards 21 and the multiple short boards 22 are enclosed into a frame 2, and the multiple long boards 21 and the multiple short boards 22 The room can be fixed by mortise and tenon structure and adhesive nail riveting. The top plate 3 and the frame 2, and the bottom plate 1 and the frame 2 are respectively connected by the mortise and tenon structure to form a box body, and a pouring port is left on the box body. The mortise and tenon structure The size of the mortise can be 200 mm, and the spacing ca...

Embodiment 2

[0056] Such as figure 1 As shown, the present embodiment provides a manufacturing method of an assembled composite lightweight thermal insulation and sound insulation wallboard, including the following steps: making a plurality of long boards 21, short boards 22, top boards 3 and bottom boards 1, long boards 21, short boards 22. The top board 3 and the bottom board 1 can be made of cement fiber pressure board or other boards of the same strength, and multiple long boards 21 and multiple short boards 22 are surrounded to form a frame 2, and multiple long boards 21 and multiple short boards 22 can be The mortise and tenon structure and adhesive nail riveting are used for fixing. The top plate 3 and the frame 2, and the bottom plate 1 and the frame 2 are respectively connected to form a box by the mortise and tenon structure, and there is a pouring opening on the box. The mortise and tenon structure The tenon size can be 200 mm, and the spacing can be 600 mm. The bonding process ...

Embodiment 3

[0068] Such as figure 1 As shown, the present embodiment provides a manufacturing method of an assembled composite lightweight thermal insulation and sound insulation wallboard, including the following steps: making a plurality of long boards 21, short boards 22, top boards 3 and bottom boards 1, long boards 21, short boards 22. The top board 3 and the bottom board 1 can be made of cement fiber pressure board or other boards of the same strength, and multiple long boards 21 and multiple short boards 22 are surrounded to form a frame 2, and multiple long boards 21 and multiple short boards 22 can be The mortise and tenon structure and adhesive nail riveting are used for fixing. The top plate 3 and the frame 2, and the bottom plate 1 and the frame 2 are respectively connected to form a box by the mortise and tenon structure, and there is a pouring opening on the box. The mortise and tenon structure The tenon size can be 200 mm, and the spacing can be 600 mm. The bonding process ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com