Heat-insulated sound-insulated building block and building method

A technology of thermal insulation and sound insulation and building blocks, which is applied in the direction of construction, building materials, building components, etc., can solve problems such as stress cracks and deformation cracks that cannot be overcome, and achieve good sound insulation and thermal insulation effects and high bonding strength.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

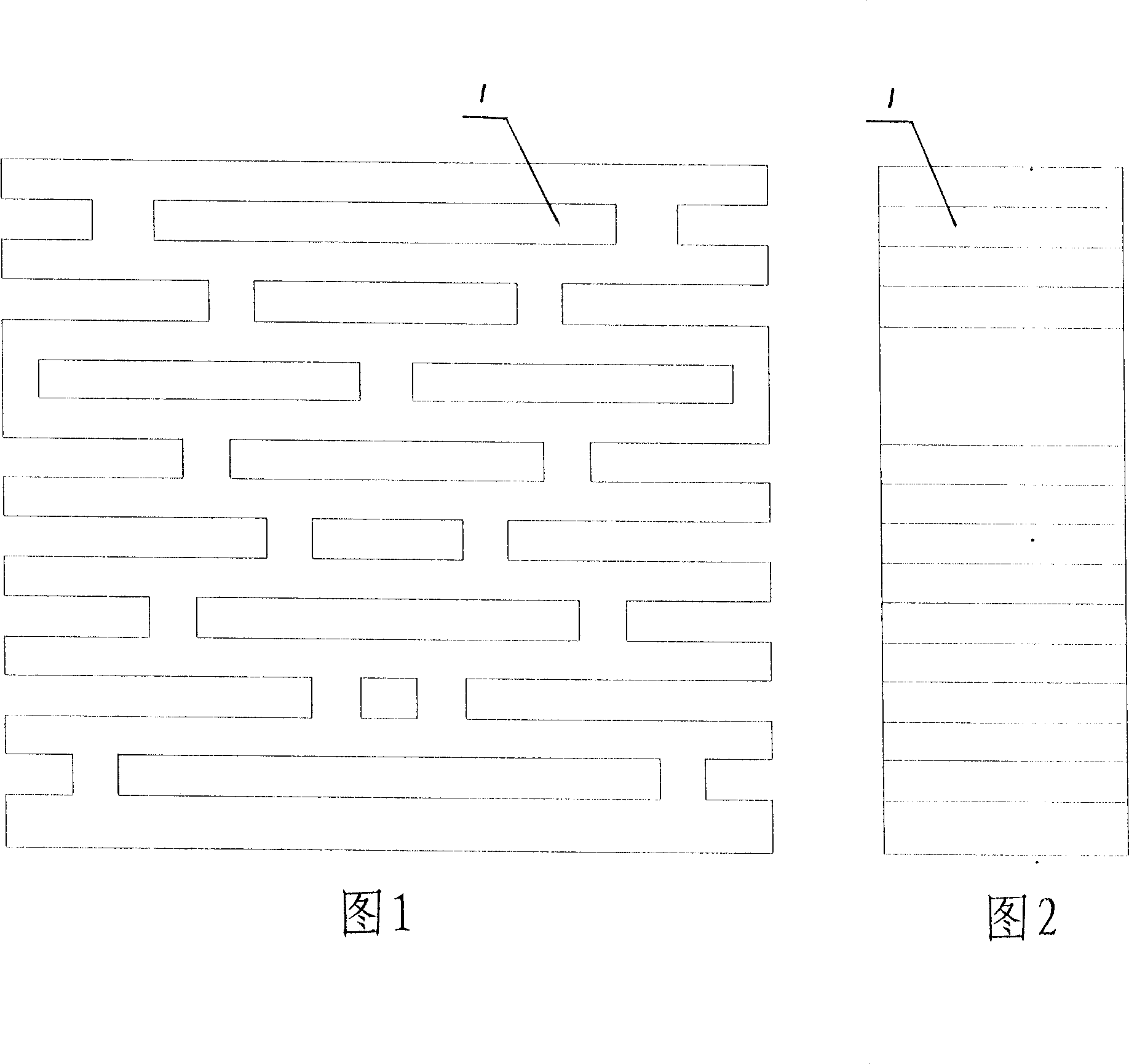

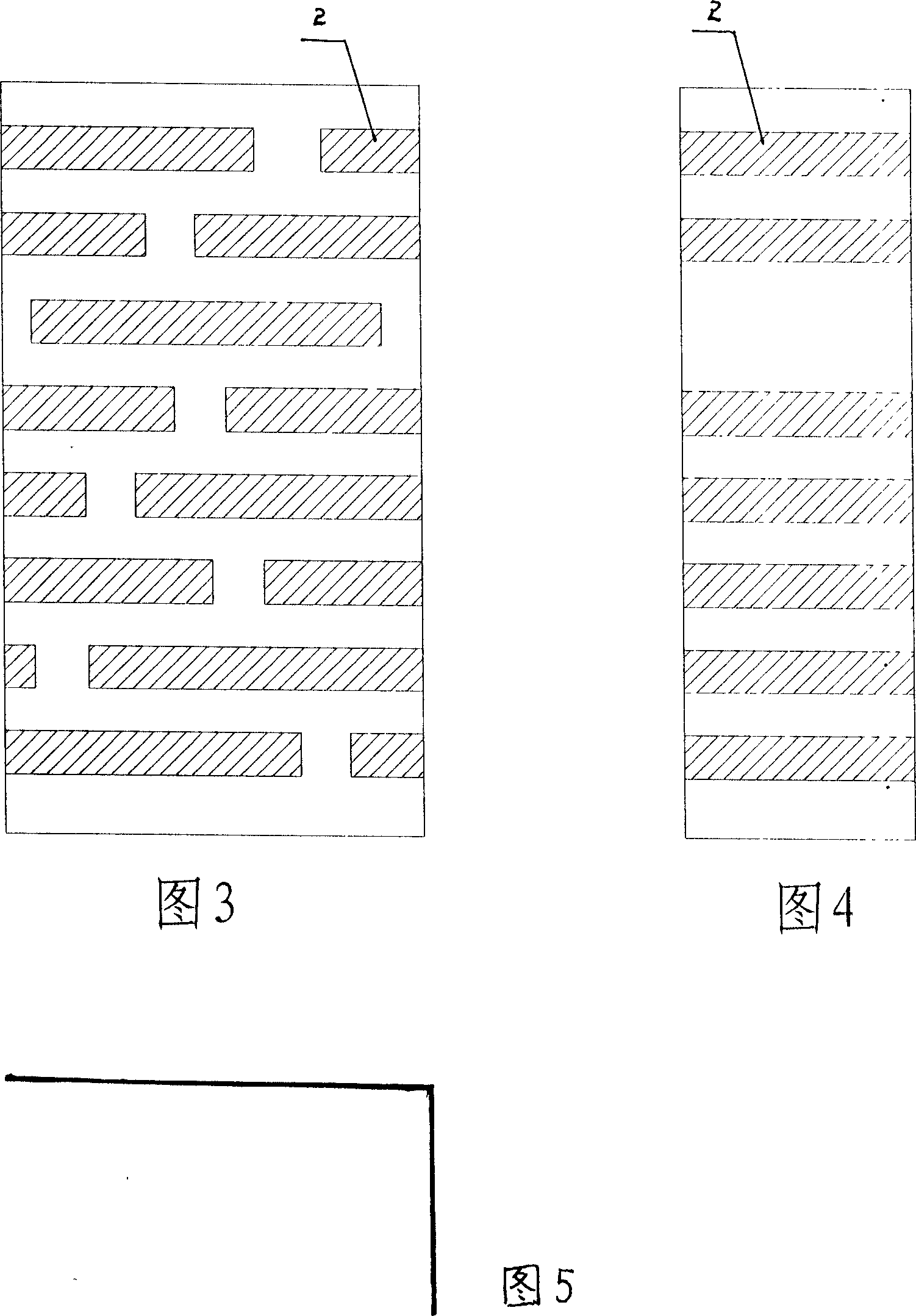

[0033] Thermal insulation and sound insulation blocks (load-bearing), with partition grooves, block width, composition, and the number of partition grooves are determined according to the building structure and energy-saving requirements of each region; see Figures 1 and 2 (the number 1 is the partition groove), the partition The grooves are arranged through the block from top to bottom, separated and staggered, and have a longitudinal symmetrical structure on the flat seam surface; there is at least one partition groove section on the edge of the tooth seam surface of the block (this embodiment is a plurality of rectangular blocks, starting from the flat seam Seen from the seam, there are 7 partition grooves on the liquid flow channel, with a width of 15mm); the gap of the partition groove accounts for 30-45% of the total surface of the flat seam of the block; by weight percentage, the block composition is 15% bonding agent, 85% slag (mineral powder, particle size 10mm); where...

Embodiment 2

[0038] The difference from Example 1 is that the block is a non-load-bearing block for a frame structure, and by weight percentage, the aggregate in the composition is 79% fly ash and 21% binding agent (7% Gypsum (CaSO 4 2H2O), 7% lime and 7% alkaline cement), the tolerance in size is 0.10mm, and its compressive strength is 5Mpa; the width of the partition groove is 20mm; the dry powder composition of mortar (by weight percentage) is 70 % fly ash and 30% cement, so that the compressive strength is 15Mpa, mix with water according to the amount of 100cm slump (add 3 tons of water for every 1 ton of mortar dry powder).

[0039] The block of the present invention is under the premise of the same price per M 2 The construction area can reduce the cost by 80 yuan / M 2 , The effective area is increased by about 5%, the construction period is advanced by 30%, and the labor intensity is reduced.

[0040] Insulation principle:

[0041] The thermal insulation and sound insulation bloc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com