Lightweight concrete wall body having self-heat preservation effect

A lightweight concrete, self-insulation technology, applied in the field of concrete, can solve problems such as poor strength, and achieve the effect of ensuring the tightness of filling, good sound insulation and thermal insulation performance, and meeting the requirements of light weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

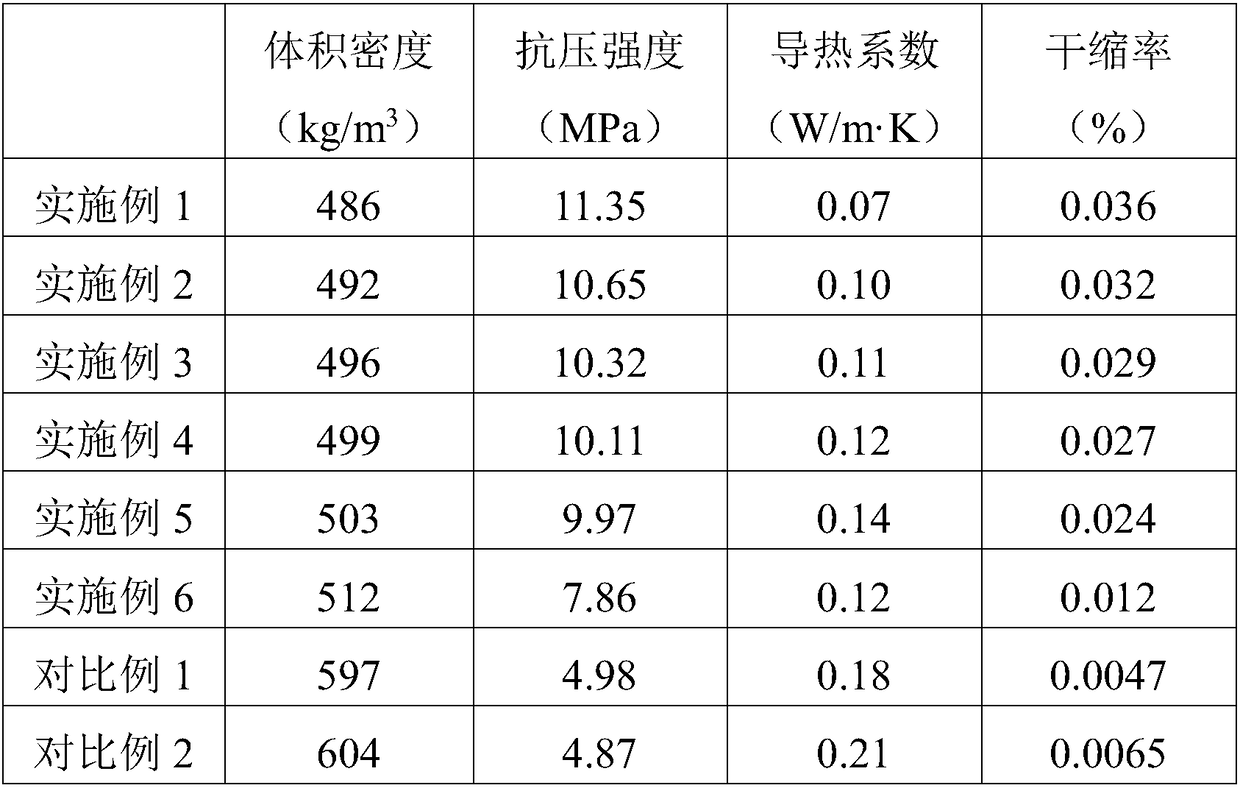

Examples

Embodiment 1

[0049] A method for preparing a lightweight concrete wall, comprising the following steps:

[0050] (1) Electrospinning is carried out after 25kg of the first polymer emulsion polyethylene terephthalate emulsion and 2.3kg of the second blowing agent azodicarbonamide are mixed uniformly, and the described electrospinning process is: power supply Voltage 30KV, spinning environment condition is temperature 25 ℃, relative humidity 60%; Multi-needle spinneret unit pitch 15cm, the number of spinneret unit pinheads is 45, obtain polymer fiber, then the polymer fiber obtained, 16kg 1 , 3-butanediol, 16kg of graphene oxide and 6kg of ferric chloride were added to 28kg of the second polymer emulsion polyvinylidene fluoride emulsion, heated to 85 ° C for 35 minutes, and then soaked in hydrochloric acid solution to obtain porous fibers;

[0051] (2) porous fiber 8kg obtained in step (1) and 20kg fly ash, 14kg ash calcium powder, 12kg stone powder 70 sand, 8kg vitrified microspheres (bulk ...

Embodiment 2

[0056] A method for preparing a lightweight concrete wall, comprising the following steps:

[0057] (1) Electrospinning is carried out after 20kg of the first polymer emulsion polyethylene terephthalate emulsion and 1.5kg of the second foaming agent azodicarbonamide are mixed evenly, and the described electrospinning process is: power supply Voltage 30KV, spinning environment condition is temperature 25 ℃, relative humidity 60%; Multi-needle spinneret unit pitch 15cm, the number of spinneret unit pinheads is 45, obtains polymer fiber, then will obtain polymer fiber, 12kg 1 , 3-butanediol, 12kg of graphene oxide and 5kg of ferric chloride were added to 25kg of the second polymer emulsion polyvinylidene fluoride emulsion, heated to 80 ° C for 30 minutes, and then soaked in hydrochloric acid solution to obtain porous fibers;

[0058] (2) porous fiber 5kg obtained in step (1) and 15kg fly ash, 10kg ash calcium powder, 8kg stone powder 70 sand, 3kg vitrified microspheres (bulk dens...

Embodiment 3

[0063] A method for preparing a lightweight concrete wall, comprising the following steps:

[0064] (1) Electrospinning is carried out after mixing 28kg of the first polymer emulsion polyethylene terephthalate emulsion and 3.5kg of the second blowing agent azodicarbonamide evenly, and the described electrospinning process is: power supply Voltage 30KV, spinning environment condition is temperature 25 ℃, relative humidity 60%; Multi-needle spinneret unit needlehead spacing 15cm, spinneret unit needlehead number is 45, obtain polymer fiber, then the polymer fiber obtained, 20kg1, 3-Butanediol, 18kg of graphene oxide and 8kg of ferric chloride were added to 30kg of the second polymer emulsion polyvinylidene fluoride emulsion, heated to 95°C for 40 minutes, and then soaked in hydrochloric acid solution to obtain porous fibers;

[0065] (2) porous fibers 10kg and 35kg fly ash, 18kg lime calcium powder, 15kg stone powder 70 sand, 11kg vitrified microspheres obtained in step (1) (bul...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com