Assembled light wall plate and mounting process

A lightweight wall and wall panel technology, which is applied to walls, building components, thermal insulation, etc., can solve the problems of lack of sound insulation and fire prevention, thermal insulation and energy saving, heavy labor, complexity and tediousness, etc., so as to improve construction flexibility, Easy to carry and small in size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] specific implementation plan

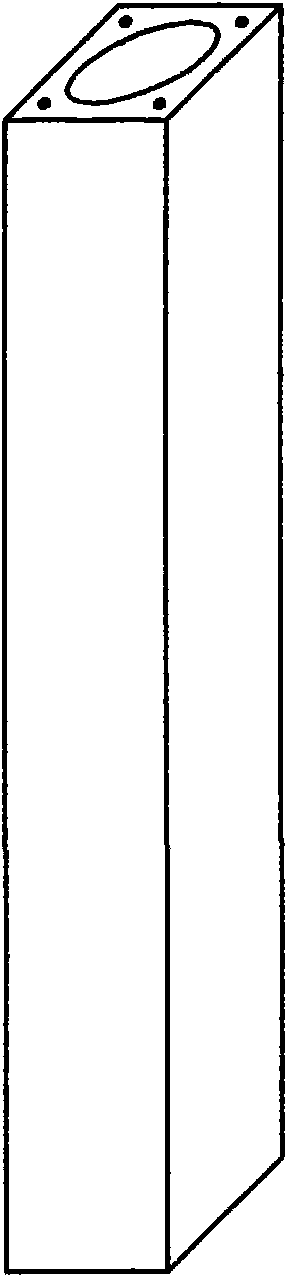

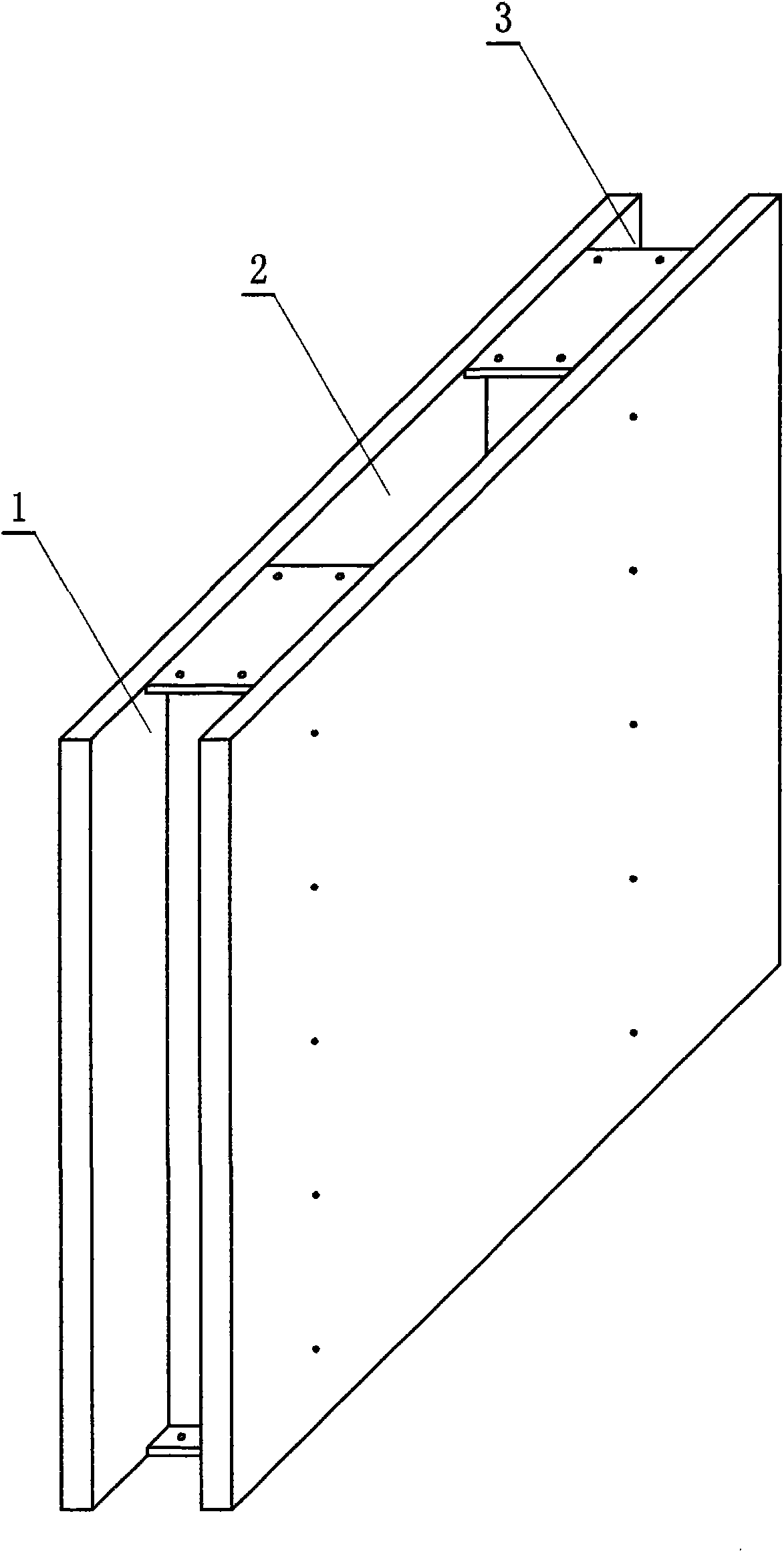

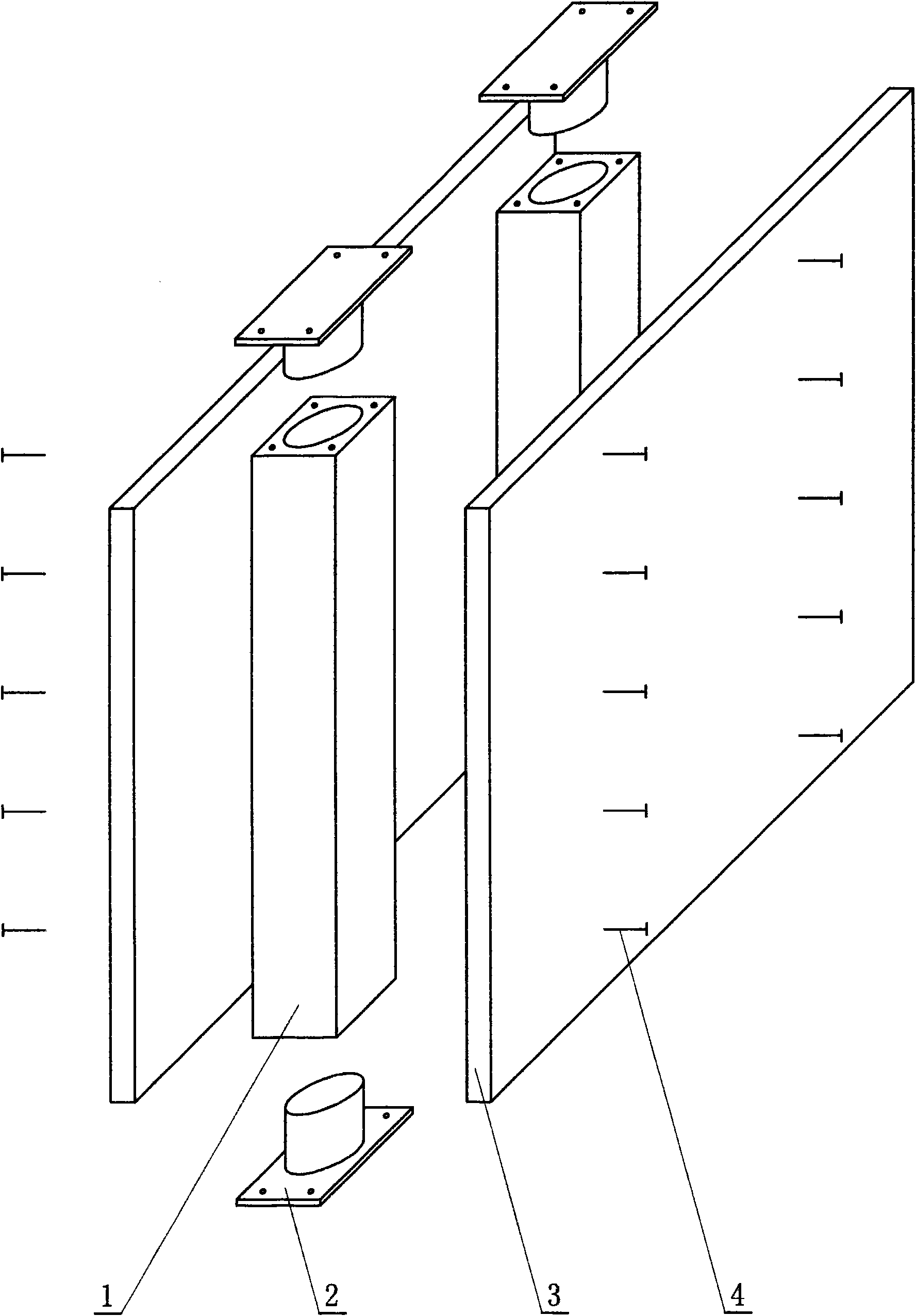

[0014] Such as figure 2 The shown wall panel of the present invention is mainly composed of keel, connecting card and gypsum slab, which can be used for partition walls, partition walls and low-rise exterior walls of buildings; as Figure 4 The multi-layer assembled light-weight wall panel shown can be used for the partition wall of the building and the sound insulation partition wall of places such as entertainment; Figure 5 The assembled light-weight wall panels formed after dislocation installation shown in the figure can prevent through-cracking and can be used for building partition walls.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com