Process for manufacturing full-bamboo embossed pattern plate

A technology of manufacturing process and pattern template, which is applied in the field of manufacturing process of all-bamboo embossed pattern plate, can solve the problems of damaging the natural ecological environment, wasting human resources, wasting energy consumption, etc., achieves the simplification of subsequent processing technology, and increases the field of use , The effect of saving processing time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

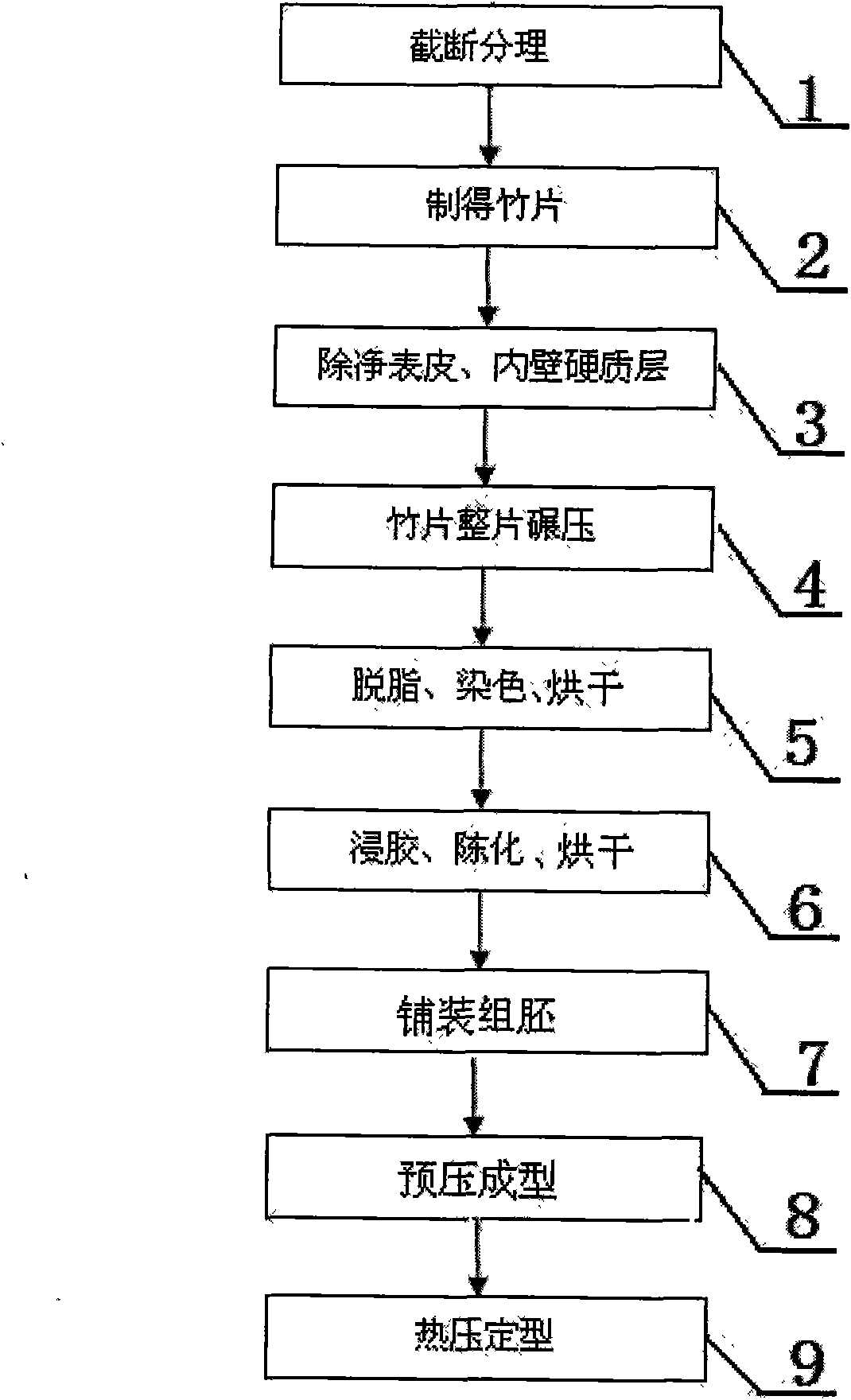

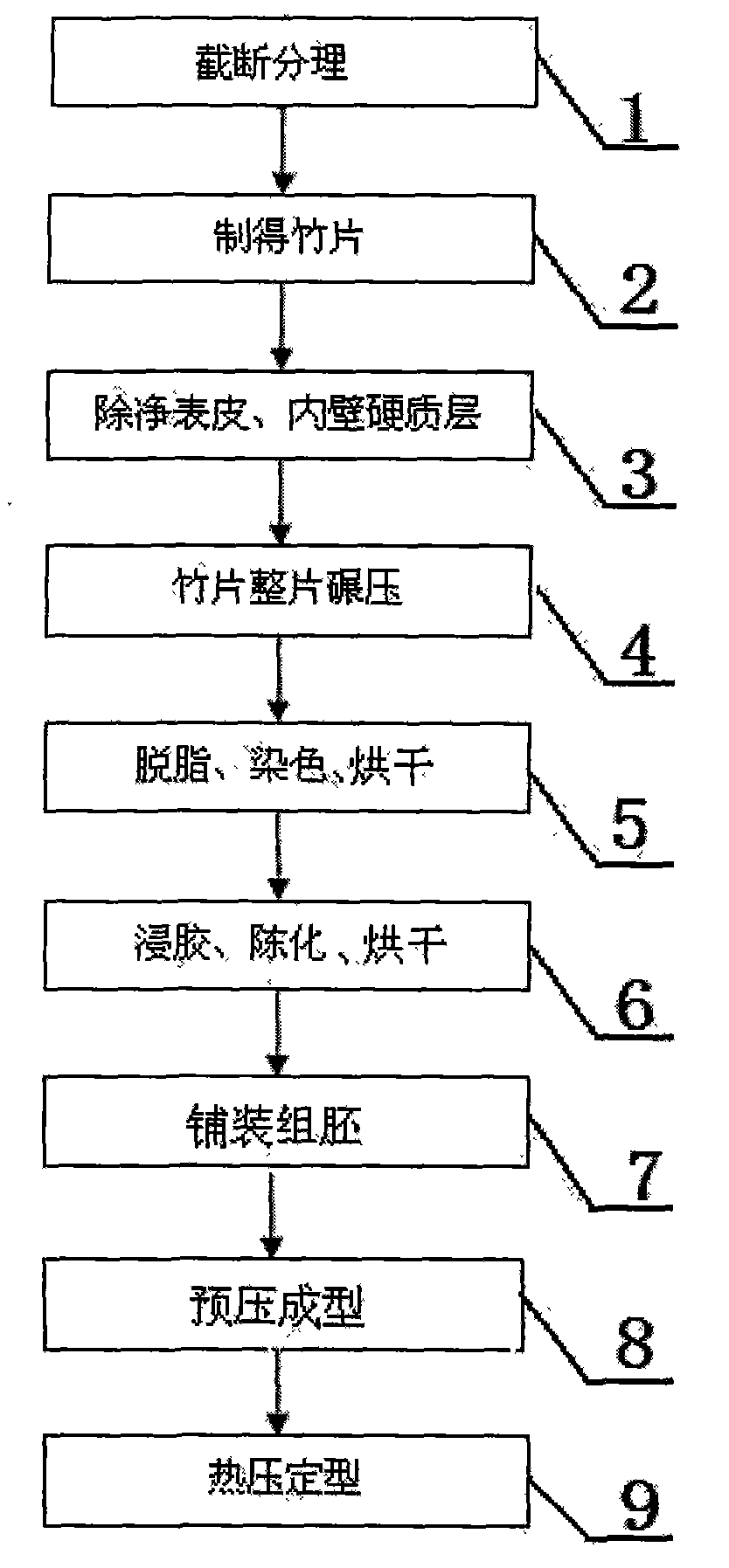

Method used

Image

Examples

Embodiment Construction

[0033] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific illustrations.

[0034] In order to solve the existing problems that most of the main furniture, decoration materials, construction, engineering and agricultural boards are made of solid wood materials, stone materials, chemical synthetic materials, metal materials or reinforced cement, the present invention provides a kind of manufacturing of all-bamboo boards. The method, the main application fields of the plate produced according to the method: furniture parts, stool and chair parts, sofa frame, door and door cover board, window and window cover board, rain (yang) awning, garage material, stick material, decoration material , Building materials, structural parts, handicrafts and engineering materials such as highway anti-collision guardrails, columns, agricult...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Diameter size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com