Novel environment-friendly stone paper and preparation method thereof

An environmentally friendly stone paper, a new type of technology, applied in the field of papermaking, can solve the problems of increased proportion of stone paper, decreased functional effect, and lower quality of stone paper, achieving the effect of lower specific gravity, lower specific gravity, and improved physical and mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

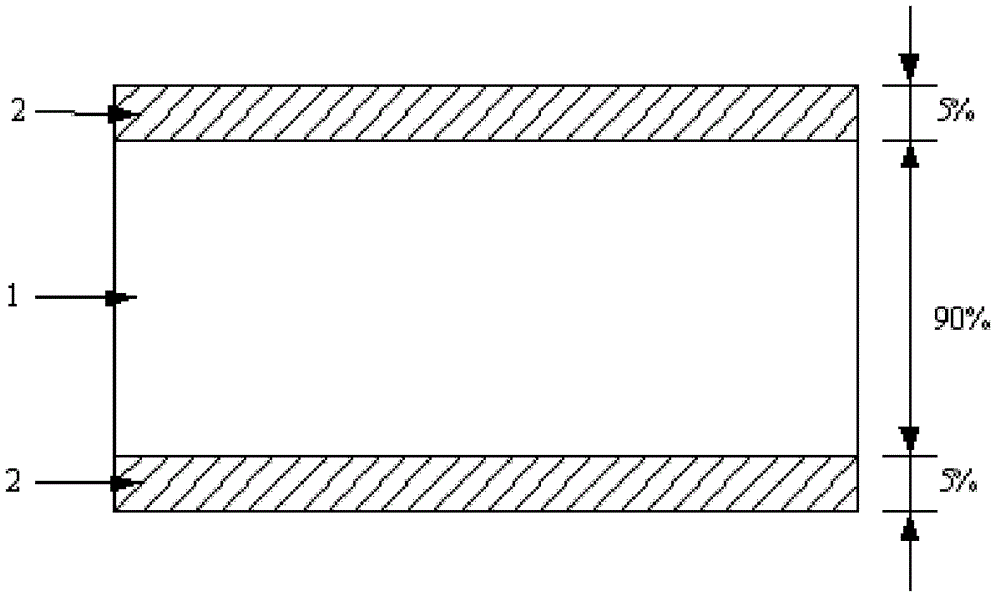

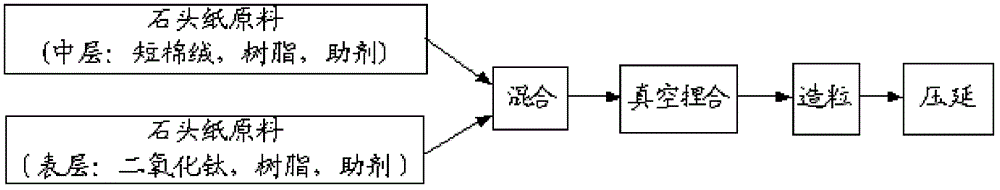

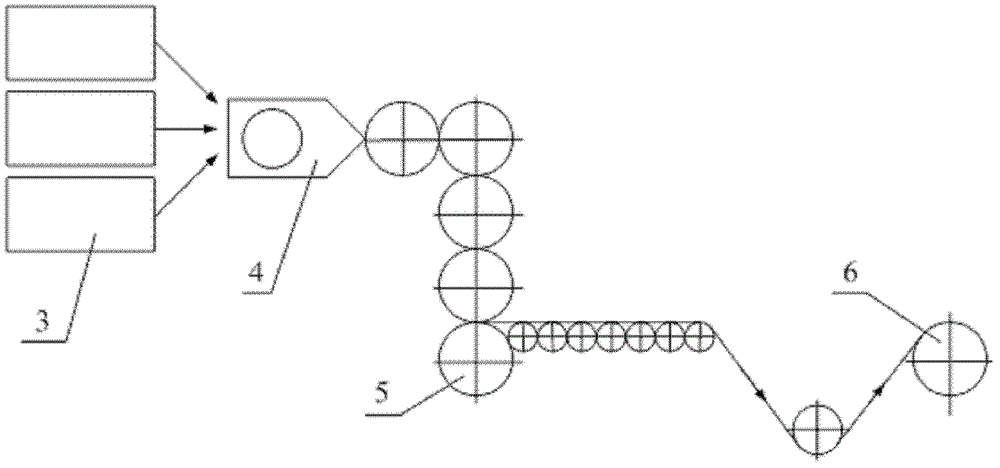

[0044] The preparation method of the three-layer co-extrusion environment-friendly stone paper provided by the invention, such as figure 2 As shown, including: A. Dry all component materials until the water content is less than 2%, so as to ensure the smooth progress of the entire process. B. Add the middle layer material and the surface layer material respectively into the high-speed mixer and mix and stir at 100-110°C. The mixing order is as follows: the middle layer material: first stir the short fibers for 3-5 minutes, then add the additives and stir for 3-5 minutes, mix After uniformity, add resin and stir for 3-5 minutes; surface material: first stir titanium dioxide for 3-5 minutes, then add additives and stir for 3-5 minutes, mix well, add resin and stir for 3-5 minutes. C. Vacuum knead the mixed middle layer material and surface layer material respectively and then granulate to obtain surface layer particles and middle layer particles respectively; D send the surface...

Embodiment 1

[0050] Prepare the eco-friendly stone paper according to the following recipe.

[0051] Surface layer components (each component is based on the mass of the surface layer): 57.5% polyethylene, 40% titanium dioxide, 0.5% composite coupling agent, 0.5% dispersant, 0.5% flame retardant, 0.5% compatibilizer, and 0.5% smooth agent %.

[0052] Middle layer components (each component is based on the mass of the middle layer): 55% polyethylene, 42.5% short cotton linters, 0.5% composite coupling agent, 0.5% dispersant, 0.5% flame retardant, 0.5% compatibilizer, smooth agent 0.5%.

[0053] Among them, the composite coupling agent is OL-AT series aluminum-titanium composite coupling agent, the dispersant is polyethylene wax dispersant, the flame retardant is FZY series composite flame retardant and smoke suppressant, and the compatibilizer is POE8100 compatibilizer or POE8210 One of the type compatibilizers, the slip agent is RH type lubricant.

[0054] Concrete preparation process i...

Embodiment 2

[0061] Prepare the eco-friendly stone paper according to the following recipe.

[0062] Surface layer components (each component is based on the mass of the surface layer): 57.5% polyethylene, 40% titanium dioxide, 0.5% composite coupling agent, 0.5% dispersant, 0.5% flame retardant, 0.5% compatibilizer, and 0.5% smooth agent %.

[0063] Middle layer components (each component is based on the mass of the middle layer): 67% polyethylene, 30.8% short cotton linters, 0.2% composite coupling agent, 0.5% dispersant, 0.5% flame retardant, 0.5% compatibilizer, smooth agent 0.5%.

[0064] Its preparation steps are the same as in Example 1 to obtain product 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| water content | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com