Forming method of self-aligned double pattern

A dual-pattern and self-alignment technology, which is applied in electrical components, semiconductor/solid-state device manufacturing, circuits, etc., can solve problems such as poor graphics and difficult size control, and achieve stable and good device performance, consistent feature size, The effect of reducing the size of semiconductor devices

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] As mentioned in the background art, in the prior art, after etching with a mask formed by a self-aligned double patterning process, the pattern formed by etching has poor morphology and is difficult to control in size.

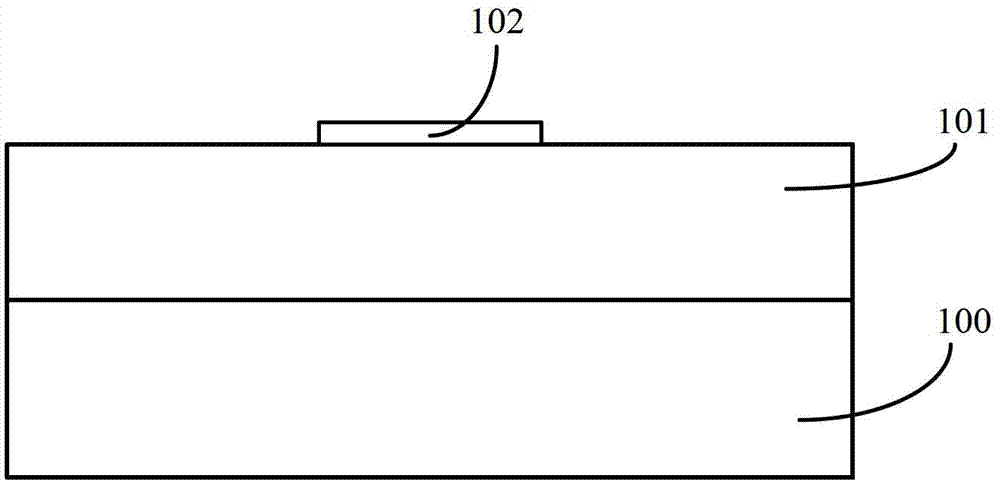

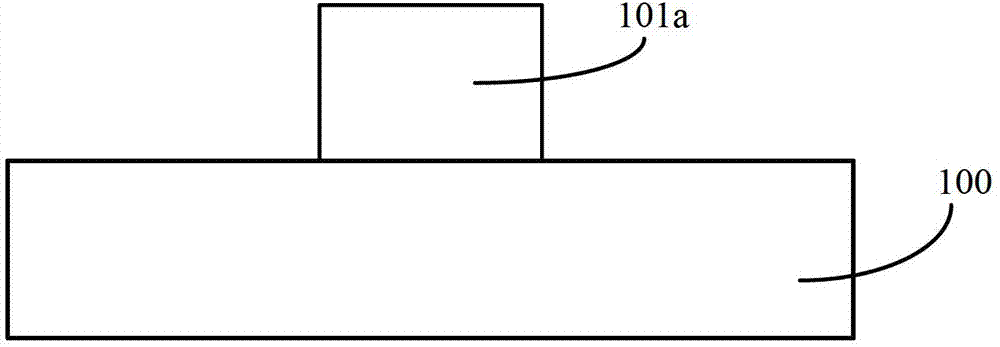

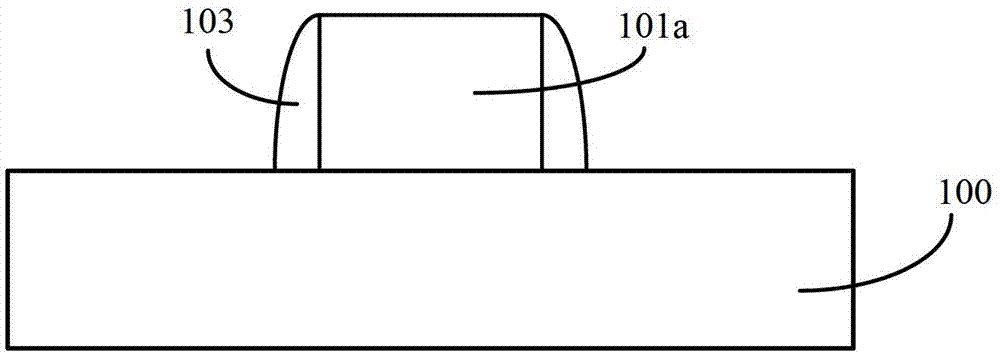

[0035] After research by the inventors of the present invention, it is found that due to the formation of the mask sidewall (such as image 3 As shown), the process is: deposit a mask layer on the surface of the semiconductor substrate 100 and the sacrificial layer 101a; etch back the mask layer until the surface of the semiconductor substrate 100 and the sacrificial layer 101a is exposed, forming a mask side wall 103; therefore, in the mask spacer 103 formed in the prior art, the sidewall of the mask spacer 103 in contact with the sacrificial layer 101a is perpendicular to the surface of the semiconductor substrate 100, and the etch-back process The other side of the formed mask spacer 103 is inclined relative to the surface of the semiconductor substr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com