Patents

Literature

43results about How to "Unified appearance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

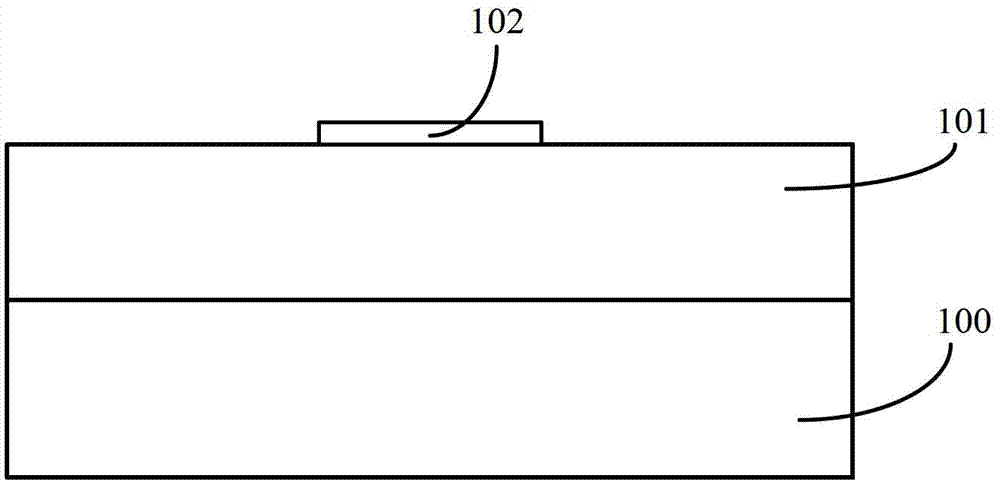

Forming method of self-aligned double pattern

ActiveCN103715080AConsistent sizeConsistent feature sizeSemiconductor/solid-state device manufacturingEngineeringElectrical and Electronics engineering

The invention relates to a forming method of a self-aligned double pattern. The provided forming method comprises the following steps that: a to-be-etched layer is provided, wherein first sacrificial layers are arranged at the surface of the to-be-etched layer and the width of one first sacrificial layer is identical with the distance between the two adjacent first sacrificial layers; first mask side walls are formed at the surface of the to-be-etched layer at the two sides of the first sacrificial layers; second sacrificial layers covering the surfaces of the first mask side walls are formed at the surface of the to-be-etched layer, wherein the surfaces of the second sacrificial layers are flush with the surfaces of the first sacrificial layer; after the forming of the second sacrificial layers, the first sacrificial layers are removed and the surface of the to-be-etched layer is exposed; after removing of the first sacrificial layers, second mask side walls are formed at the second sacrificial layers and the etched layer surface at the two sides of the first mask side walls, wherein the profile shapes of the second mask side walls are symmetrical with those of the first mask side walls; and after the forming of the second mask side walls, the second sacrificial layers are removed. According to the invention, the pattern that is formed by using the formed double pattern as the mask for etching has the unified dimension and morphology.

Owner:SEMICON MFG INT (SHANGHAI) CORP

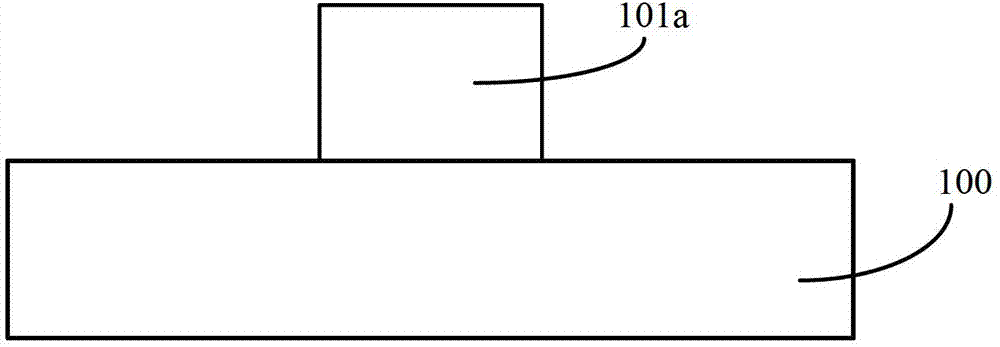

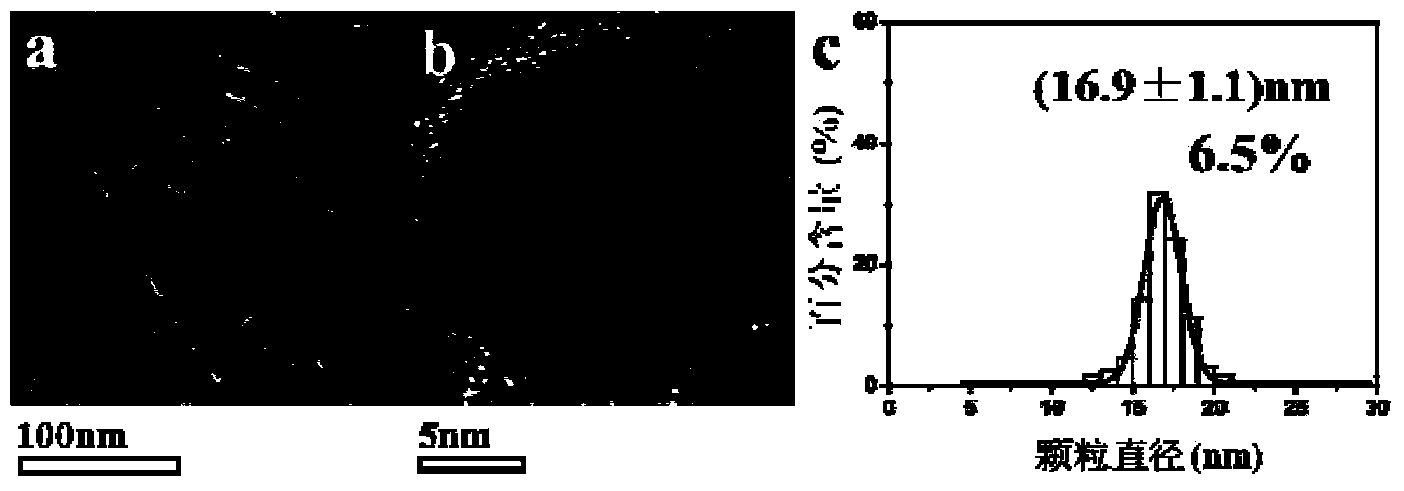

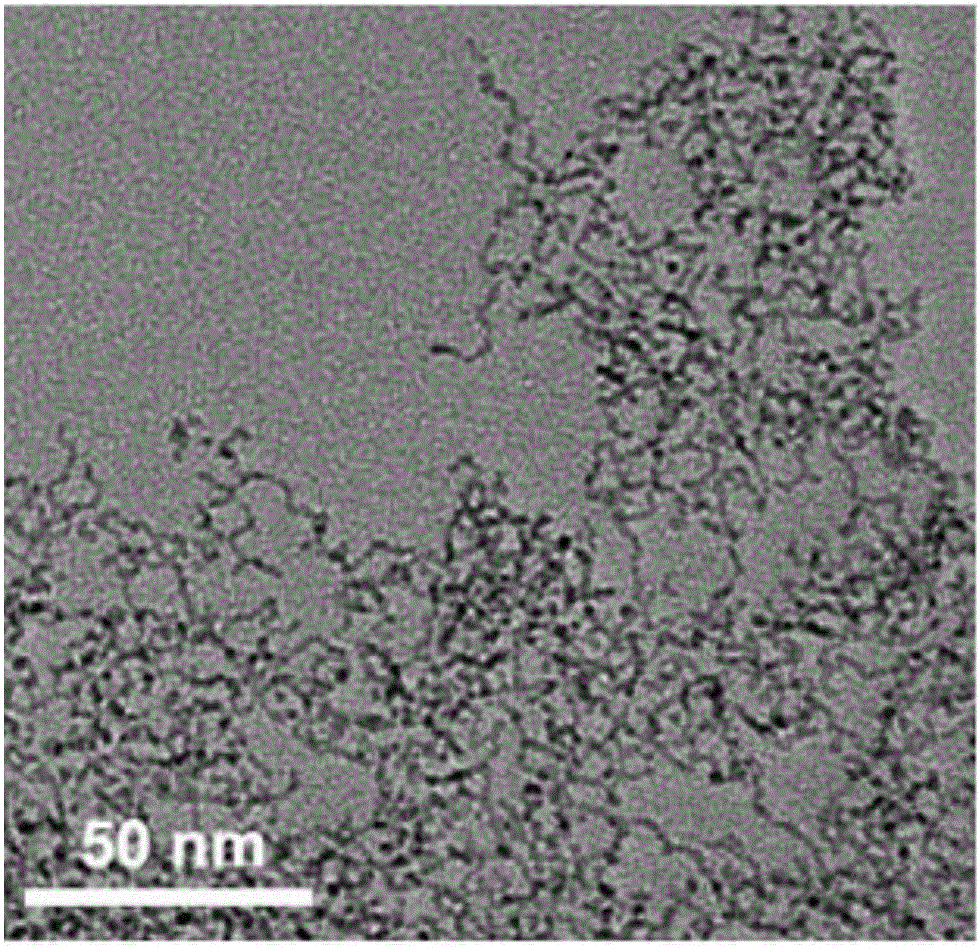

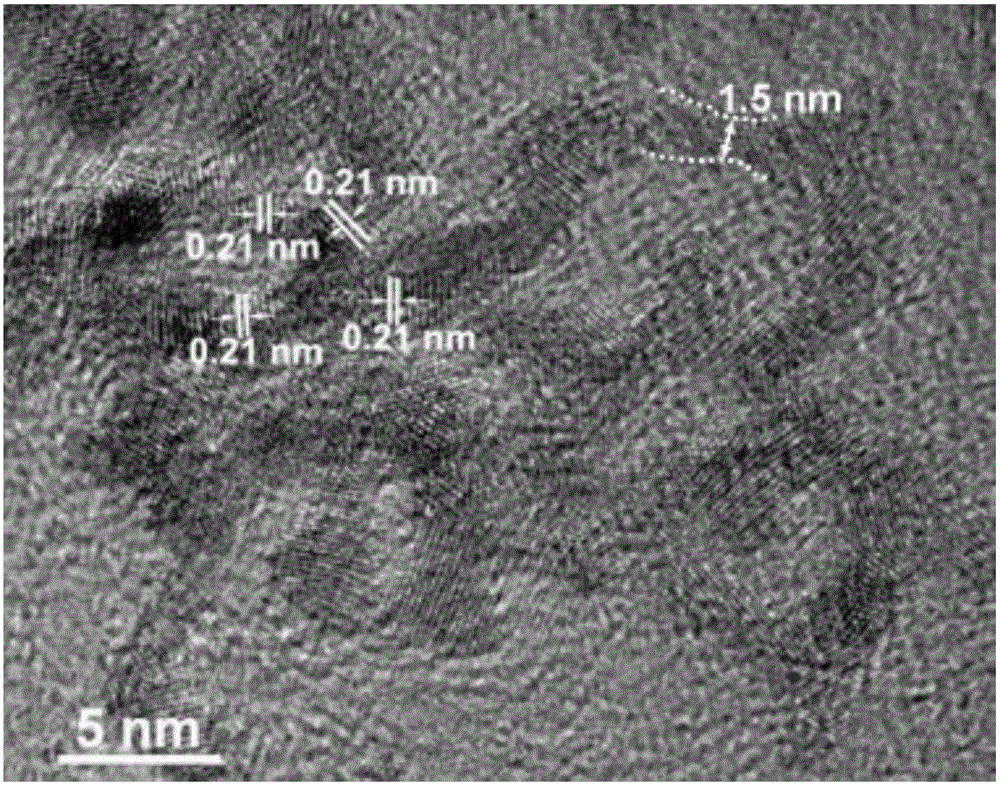

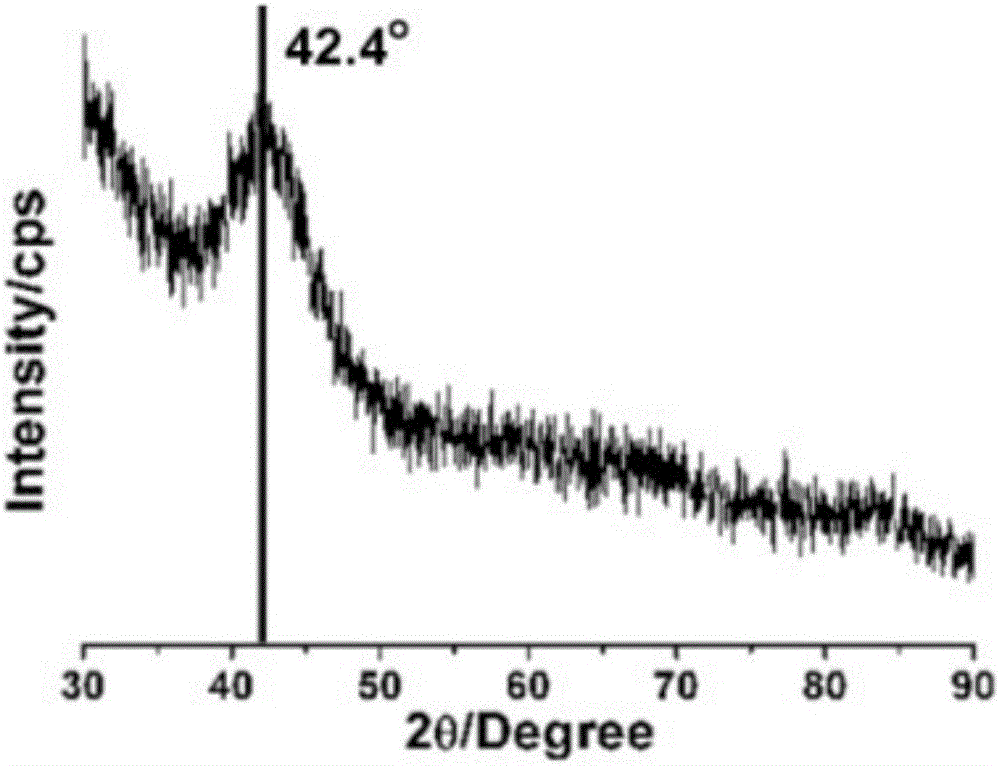

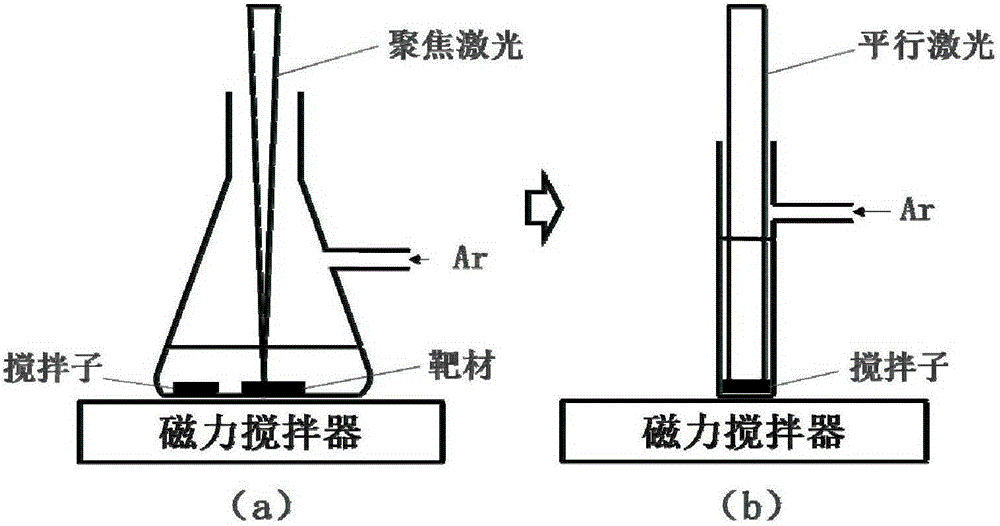

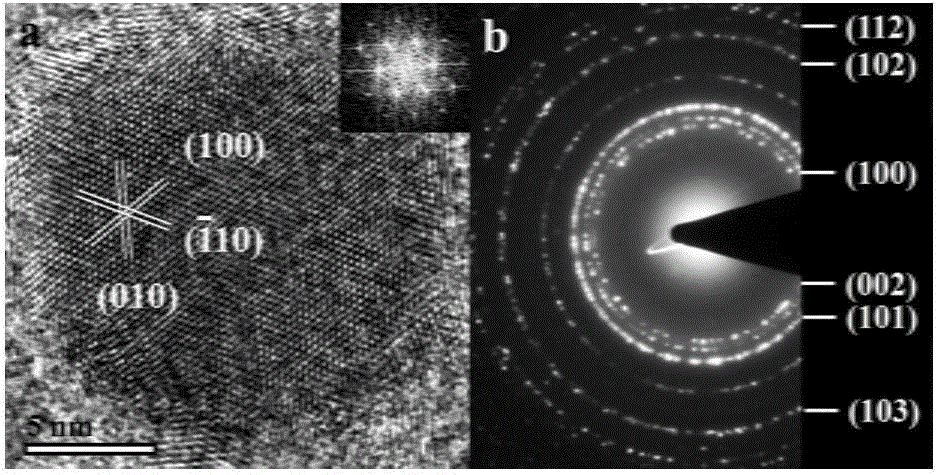

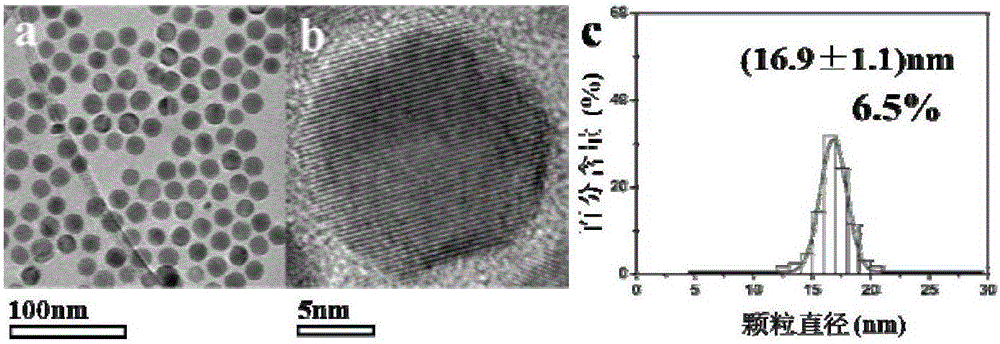

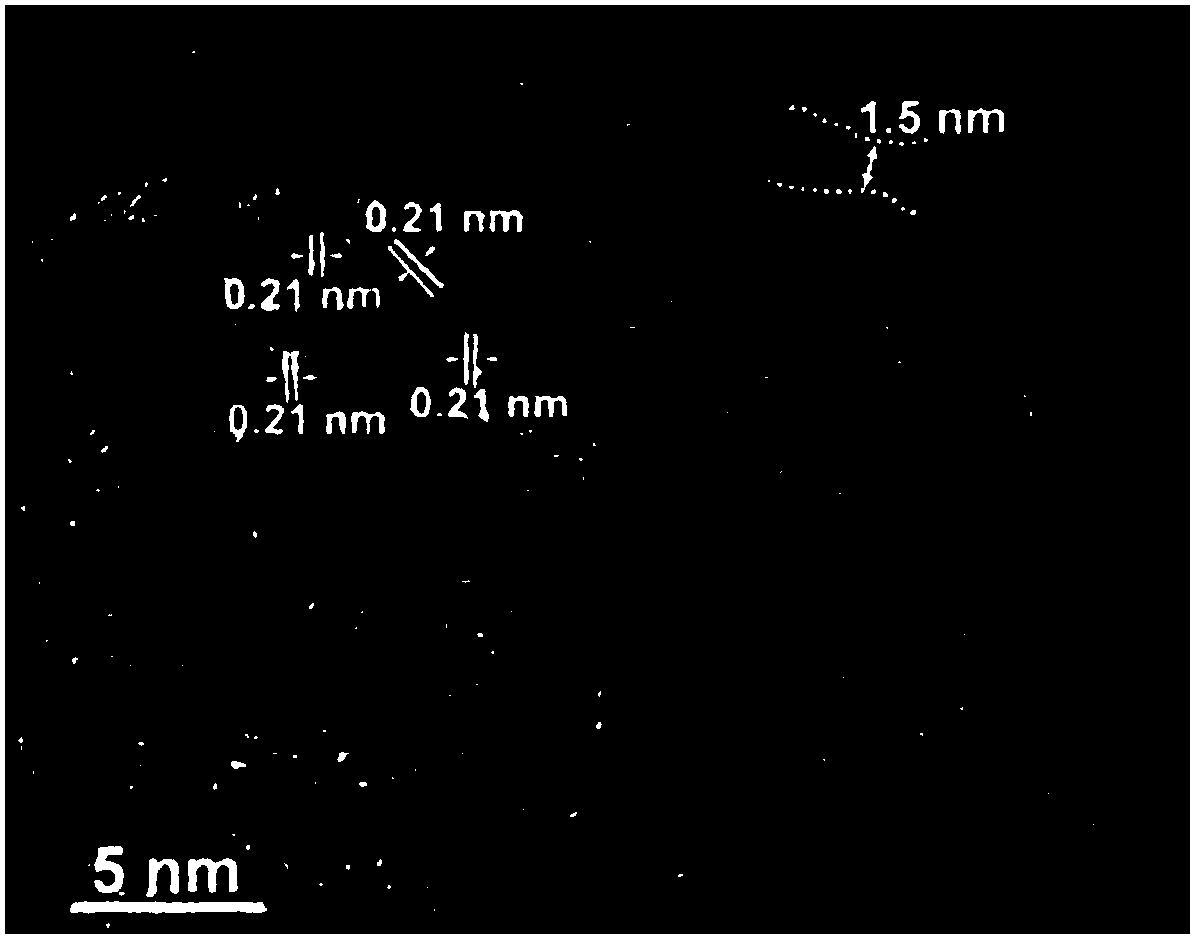

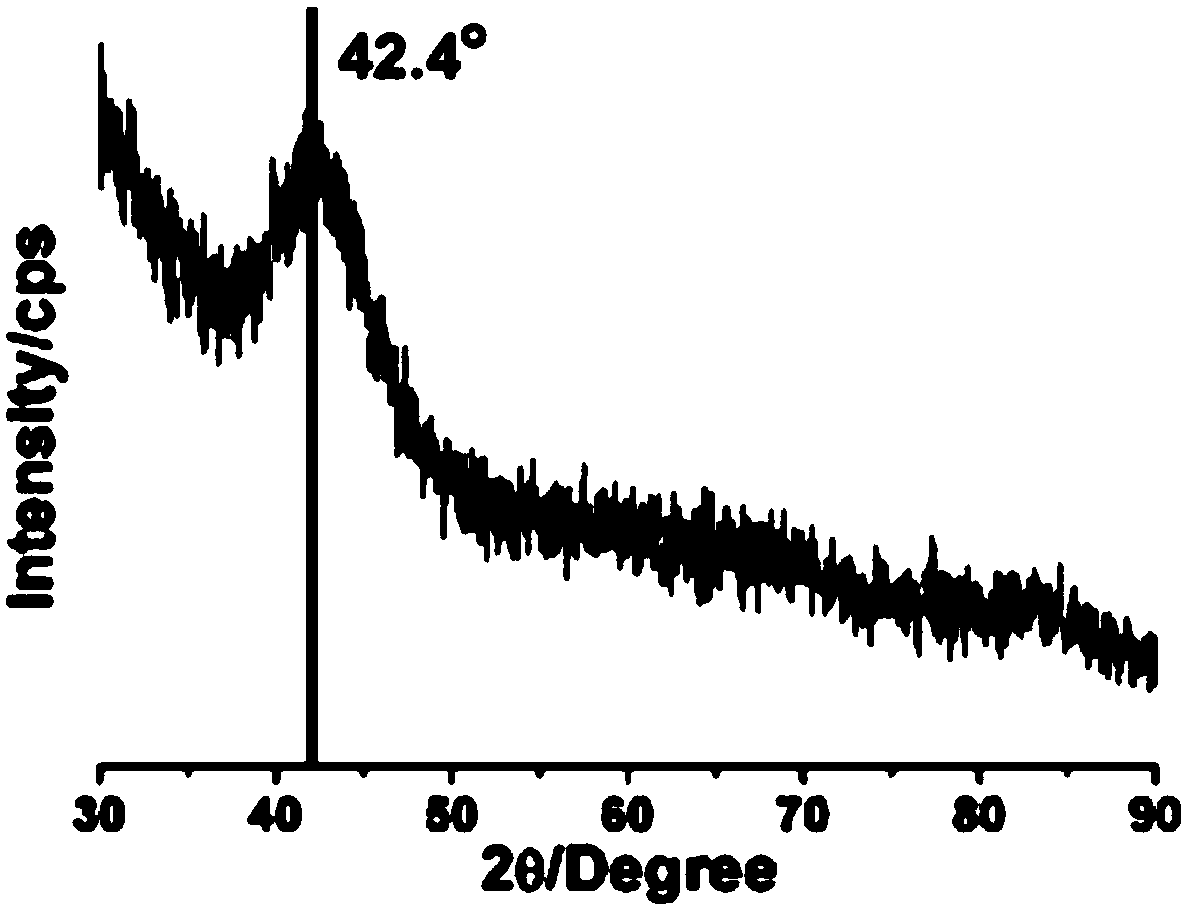

Preparing method for controllably synthesizing monodisperse active metal nanoparticles through lasers

The invention discloses a preparing method for controllably synthesizing monodisperse active metal nanoparticles through lasers. The method comprises the steps that pure-metal target materials serve as raw materials, the processed target materials are placed into a laser radiating device, the laser radiating device is inflated with argon, cyclohexane and oleic acid are added into the laser radiating device, and then the volume solubility of the oleic acid is larger than 0.05 percent but smaller than 0.12 percent; the target materials are ablated through a nanosecond focus pulse laser to prepare a pure-metal nanometer colloid solution; the colloid solution is transferred to the other laser radiating device, and the volume concentration of the oleic acid in the cyclohexane is adjusted to range from 0.14 percent to 0.17 percent; a nanosecond parallel pulse laser is utilized for irradiating the metal nanometer colloid solution to prepare the monodisperse active metal nanoparticles with the diameter ranging from 5 nm to 20 nm. According to the preparing method, the active metal nanoparticles uniformed in appearance under the normal-temperature and normal-pressure liquid phase condition are controllably synthesized, and the size distribution of the active nanometer particles is smaller than 10 percent. The method is simple in technology, convenient to operate, free of by-products and impurities and suitable for synthesizing most active metal nanometer particles, and is an environmental-friendly synthesizing technology.

Owner:TIANJIN UNIV

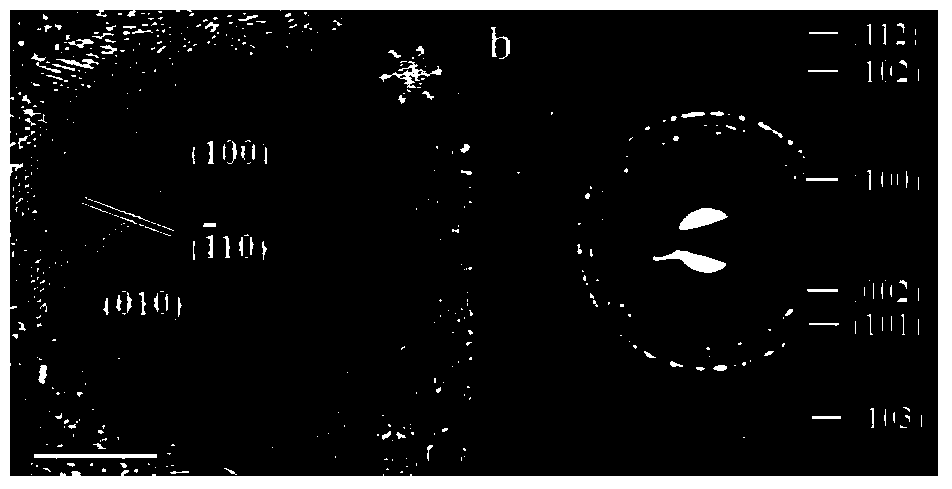

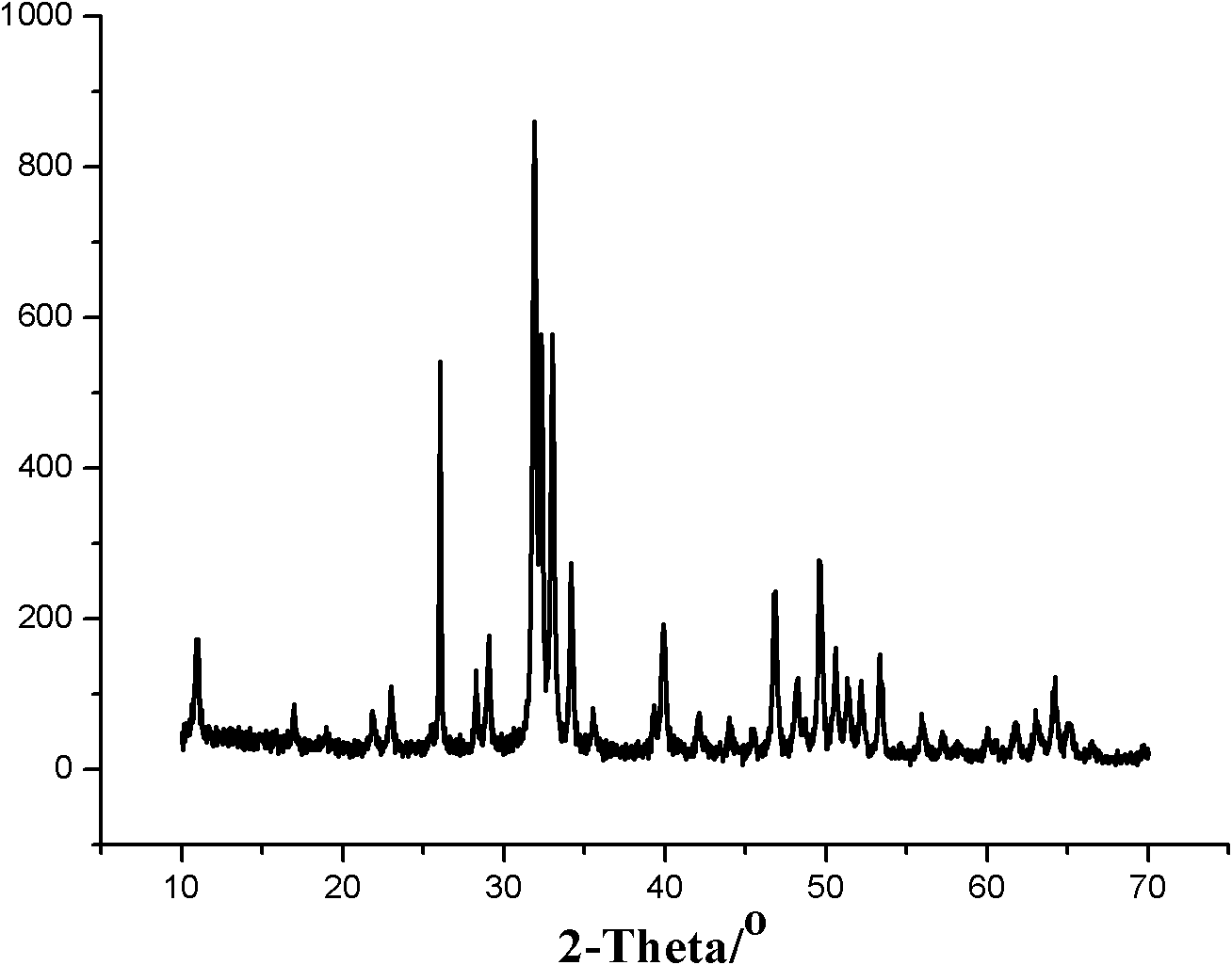

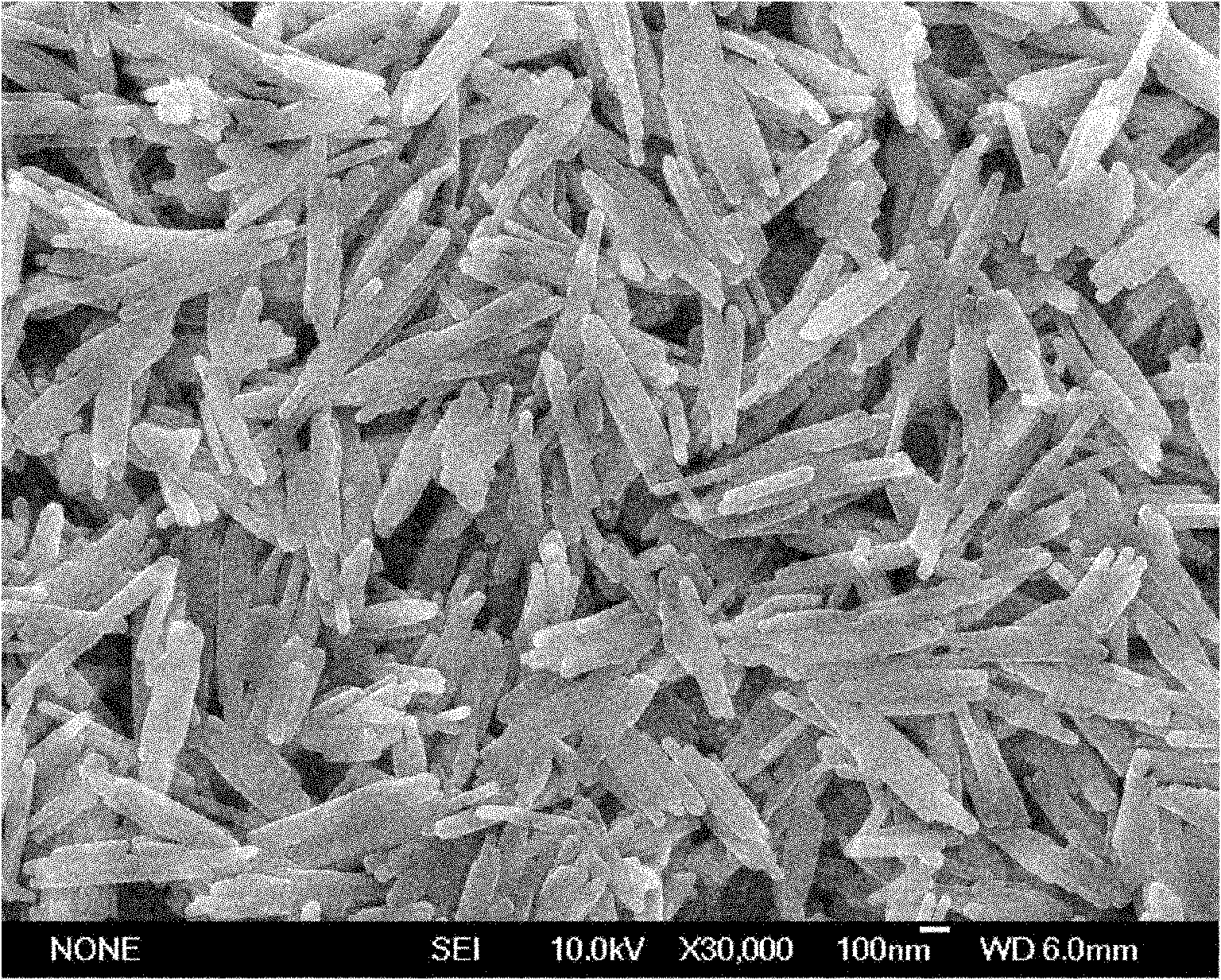

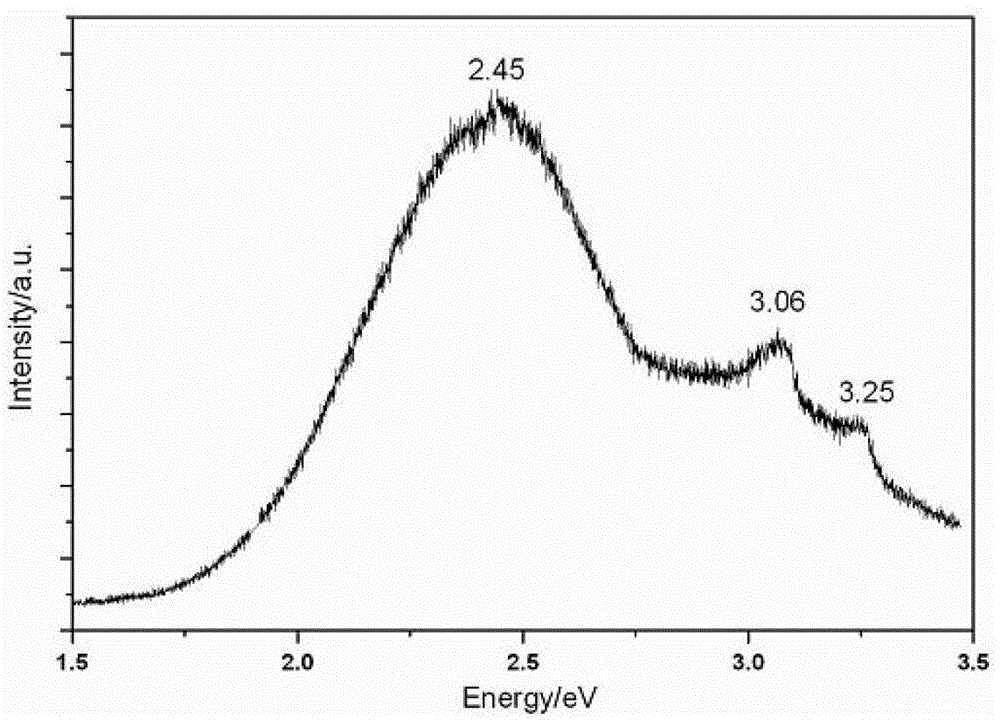

Preparation method of hydroxyapatite nano grain

InactiveCN102464307AUniform sizeUnified appearanceImpression capsDentistry preparationsSolventPolytetrafluoroethylene

The invention relates to a preparation method capable of regulating and controlling uniform size and ordered arrangement of a hydroxyapatite nano grain, belonging to the field of biological materials. The preparation method comprises the steps of: adding a calcium source, a phosphorus source and a fat-free protein colloid into a mixed solvent of an organic solvent and water, regulating pH of a solution to be 10-14 by using a pH regulating agent, carrying out water bath constant-temperature reaction to obtain a mixes solution; and then transferring to a sealed stainless steel agitated reactor internally lined with polytetrafluoroethylene to obtain an intermediate product through a hydro-thermal reaction, and finally, washing with water, freezing and drying to obtain a final product. The method can be used for preparing a hydroxyapatite nano rod structure with the characteristics of uniform size and appearance and a certain parallel arrangement. The hydroxyapatite nano grain can be widely applied to biological materials such as a dental material, a bone substitution material, a biological agent and the like.

Owner:SHANGHAI INST OF CERAMIC CHEM & TECH CHINESE ACAD OF SCI

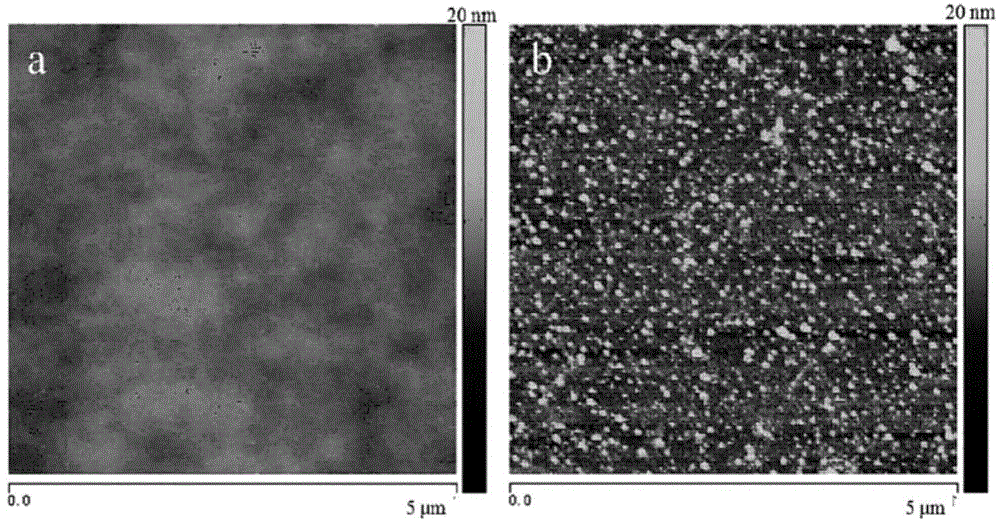

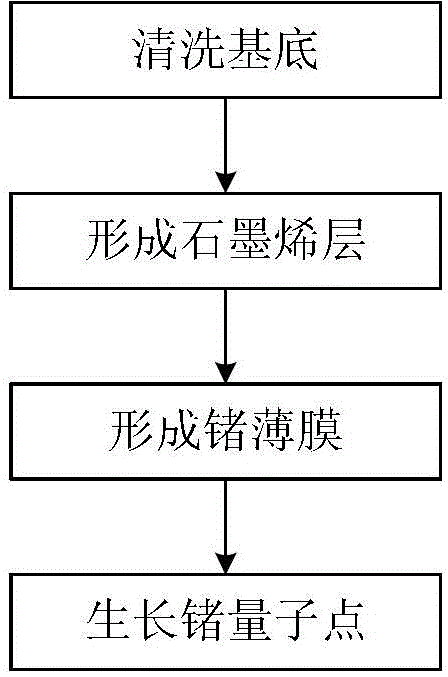

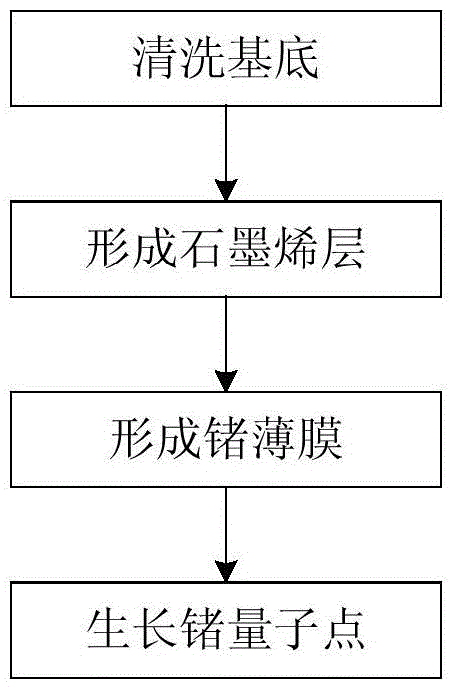

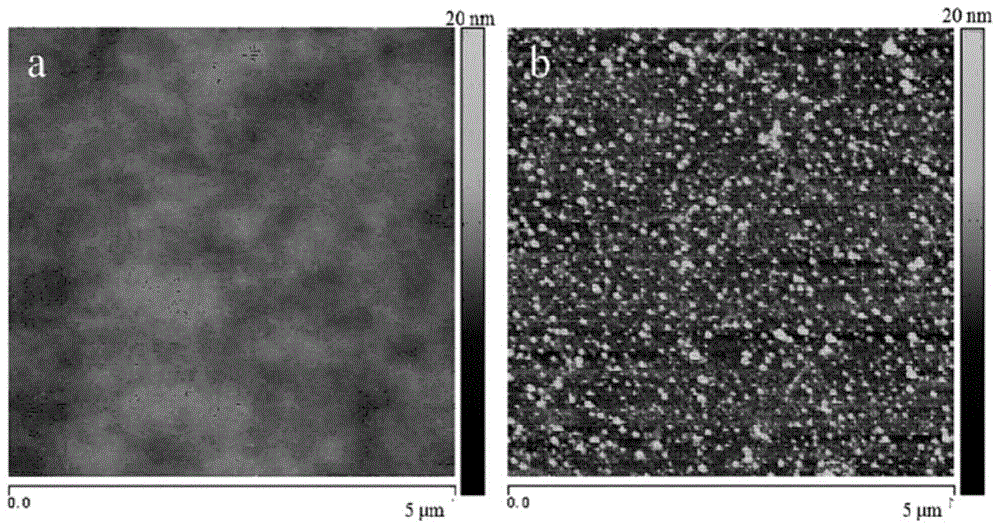

Germanium quantum dot growing method, germanium quantum dot composite material and application of germanium quantum dot composite material

ActiveCN104377114AAchieve growthAvoid complicated cleaning proceduresSemiconductor/solid-state device manufacturingPhotovoltaic energy generationQuantum dotCvd graphene

The present invention relates to a method for growth of germanium quantum dots. In the method, germanium quantum dots are grown on graphene interfaces with different quantities of layers. In the present invention, ultra-high uniformity graphene interfaces are introduced on a conventional substrate surface, Ge quantum dots are grown on the interfaces, and complicated cleaning processes for obtaining high-quality interfaces are avoided, and process flows are simplified; in addition, the low-matrix element content and the low defect rate of the germanium quantum dots are ensured, a self-organization growth process of the germanium quantum dots is ensured, and germanium quantum dots with good shape and uniformity are formed.

Owner:THE NAT CENT FOR NANOSCI & TECH NCNST OF CHINA

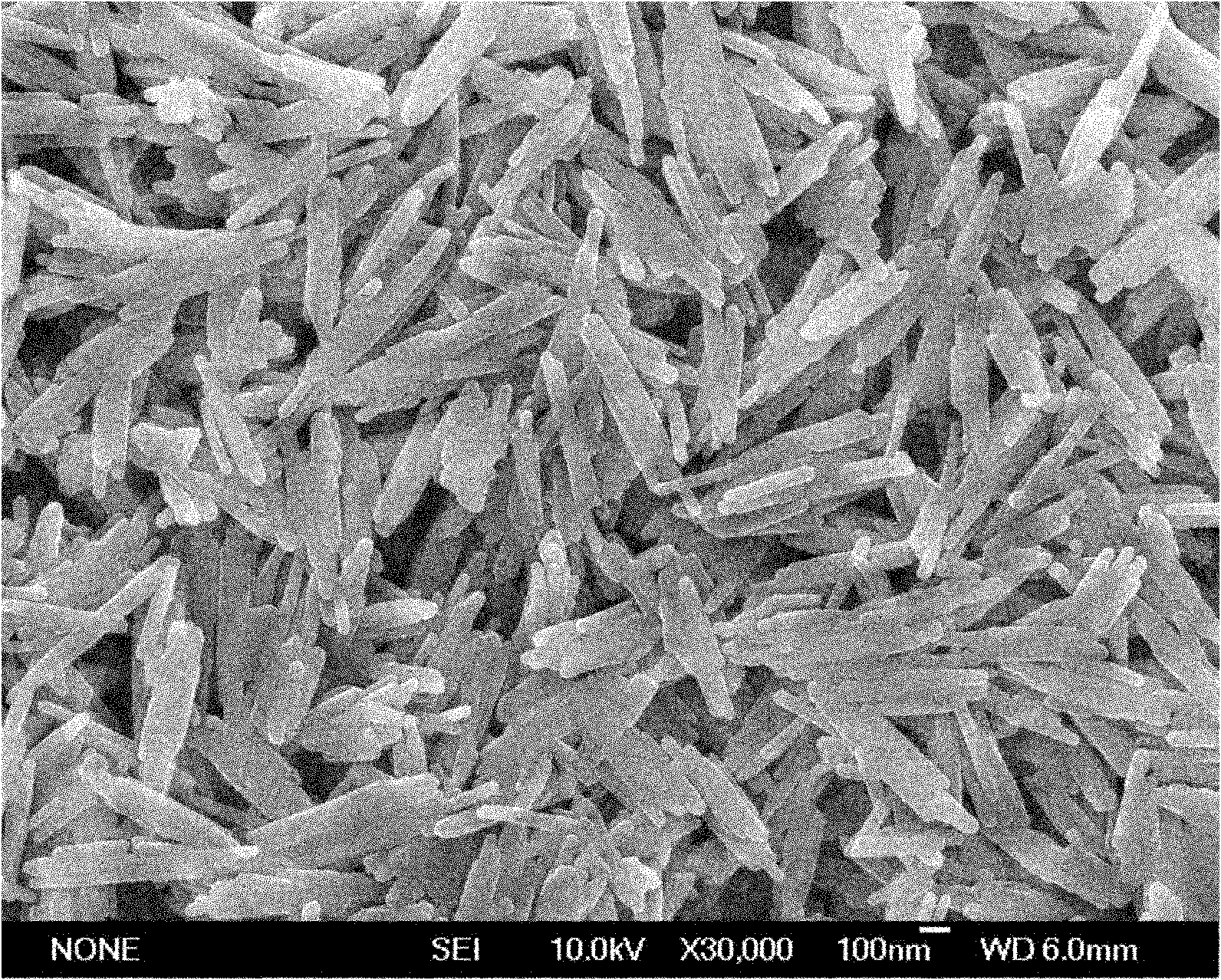

Preparation method of nanometer nickel sulfide

InactiveCN105449171AImprove securityUnified appearanceMaterial nanotechnologyCell electrodesAluminium-ion batteryNickel sulfide

The invention relates to a preparation method of nanometer nickel sulfide. The method comprises steps as follows: evenly mixing nickel acetate and sodium thiosulfate according to certain proportion, dissolving in deionized water, obtaining mixed solution; adding the mixed solution in an autoclave, reacting for certain period of time at certain temperature; cooling, carrying out centrifugal washing, drying, obtaining black solid matter, namely nanometer banding NiS with hexagonal phase, wherein the particle diameter is 10-500 nanometers. The invention has advantages that the preparation material is low in cost and price and is green and environment protective, the preparation method is simple and easy in operation, the prepared product is nanometer material, is even in appearance and particle and has good electrochemical activity, when being taken as the cathode material of the aluminium ion battery, the battery specific capacity of the product reaches 100 mAh / g, and the product can circulate stably.

Owner:BEIJING ALUMINUM ENERGY S&T +2

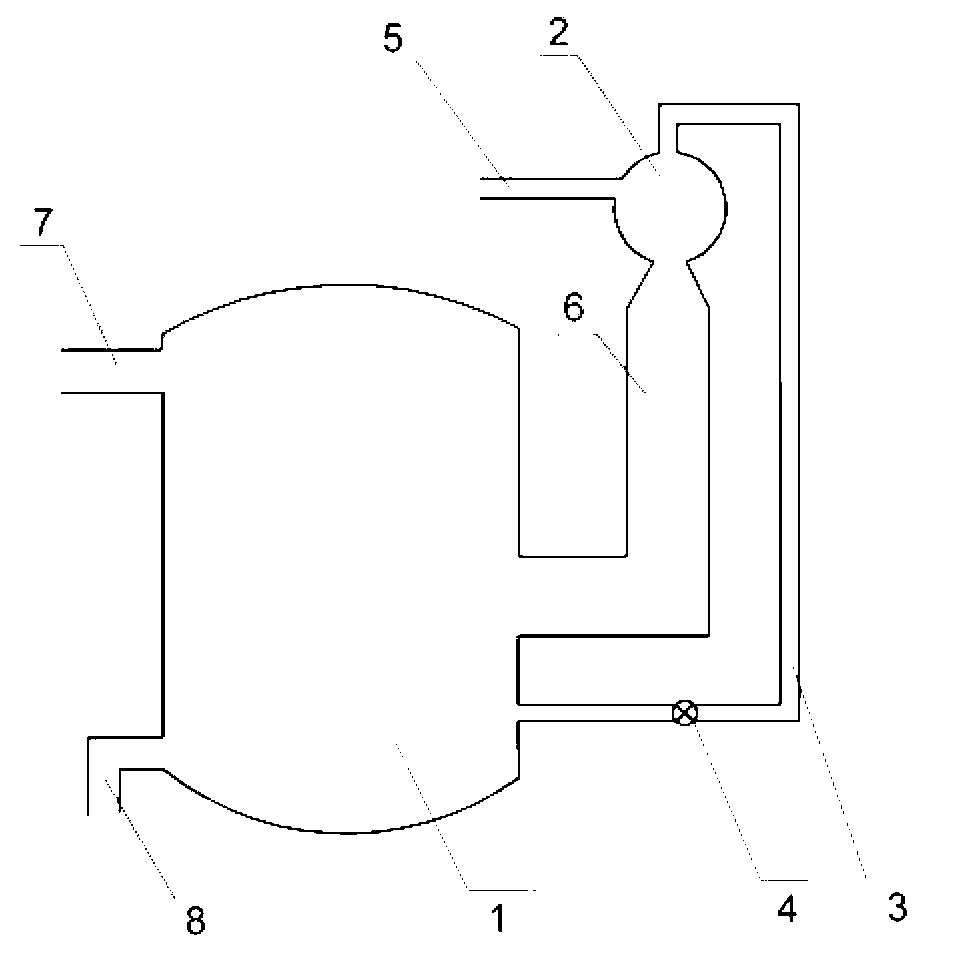

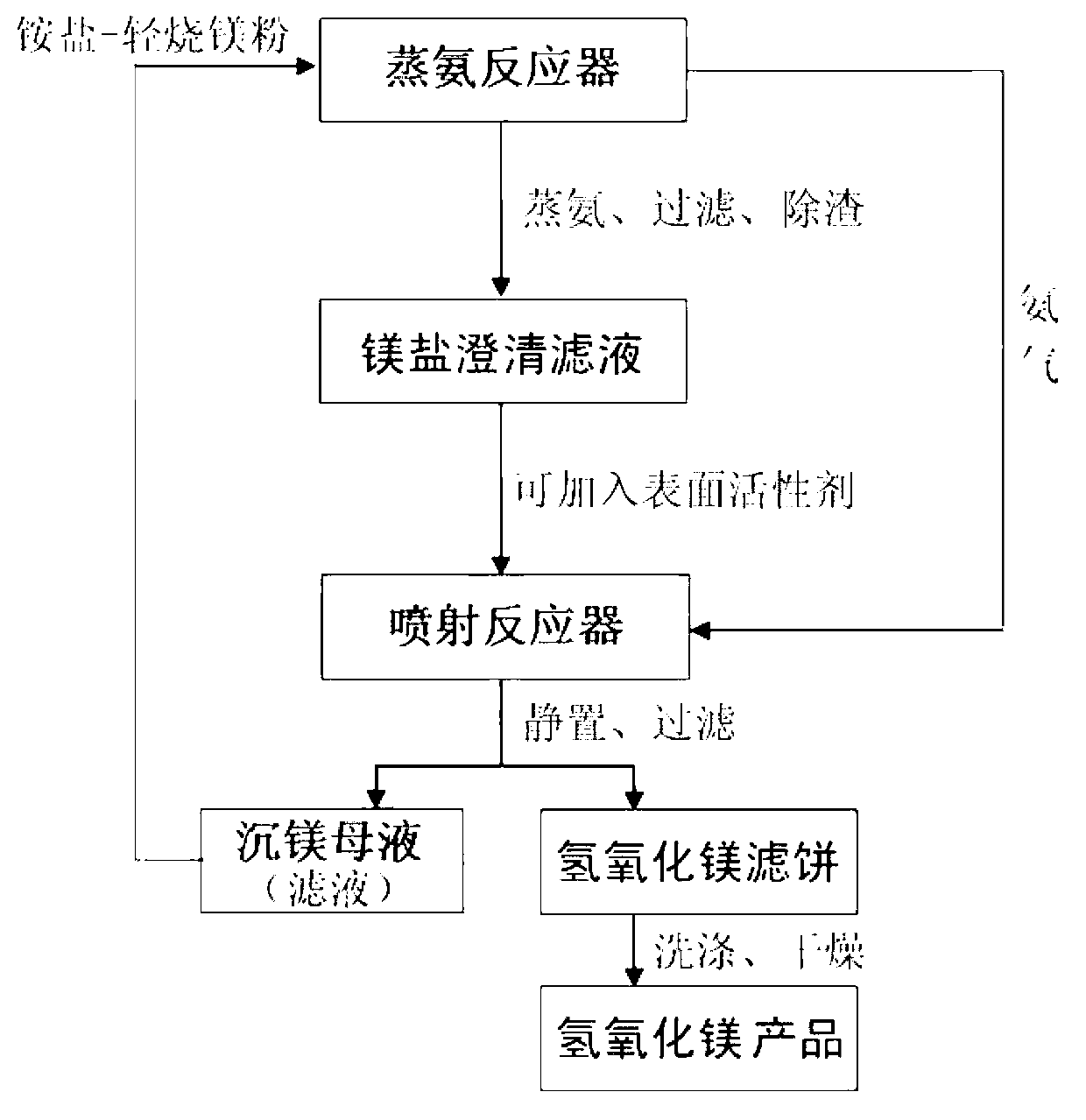

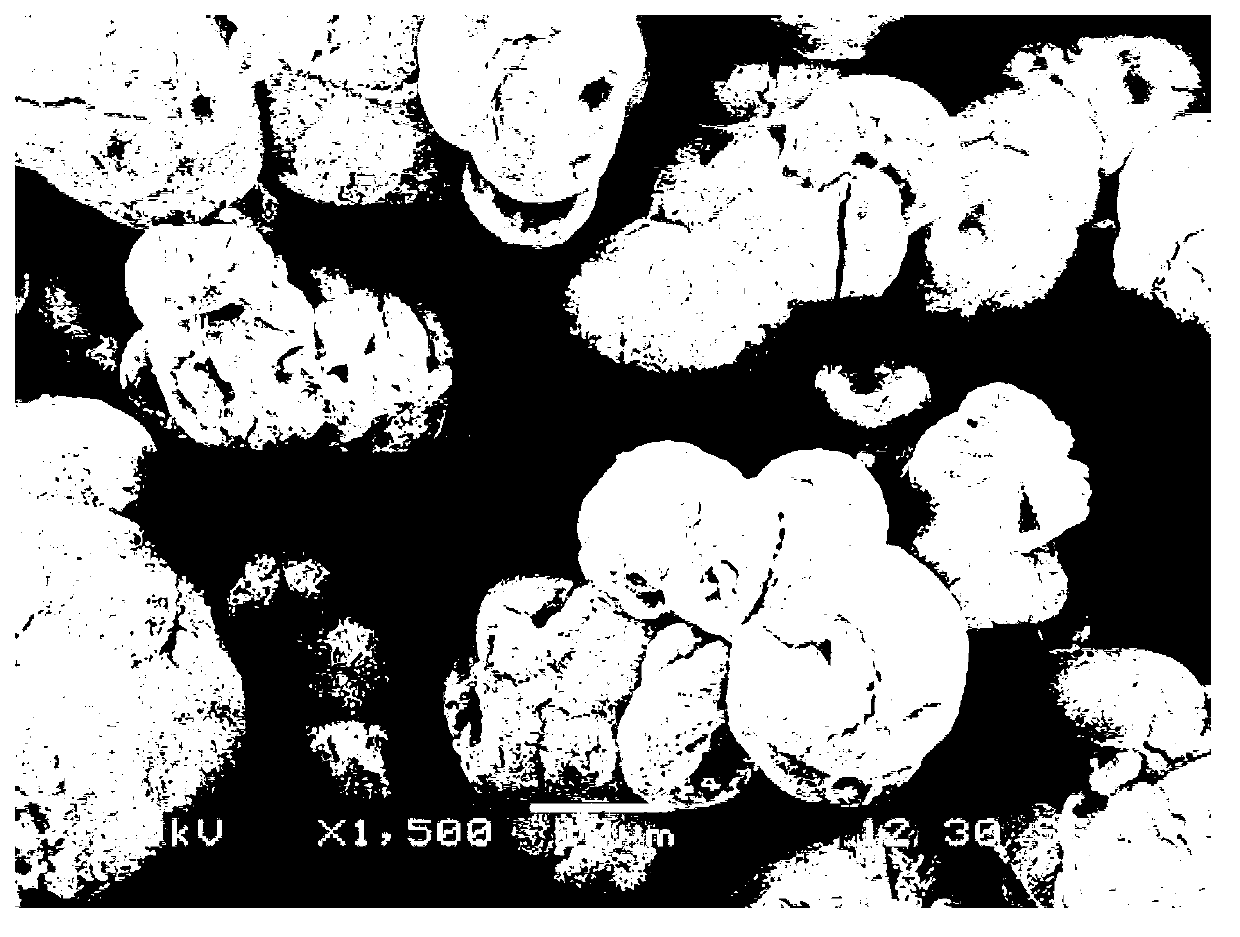

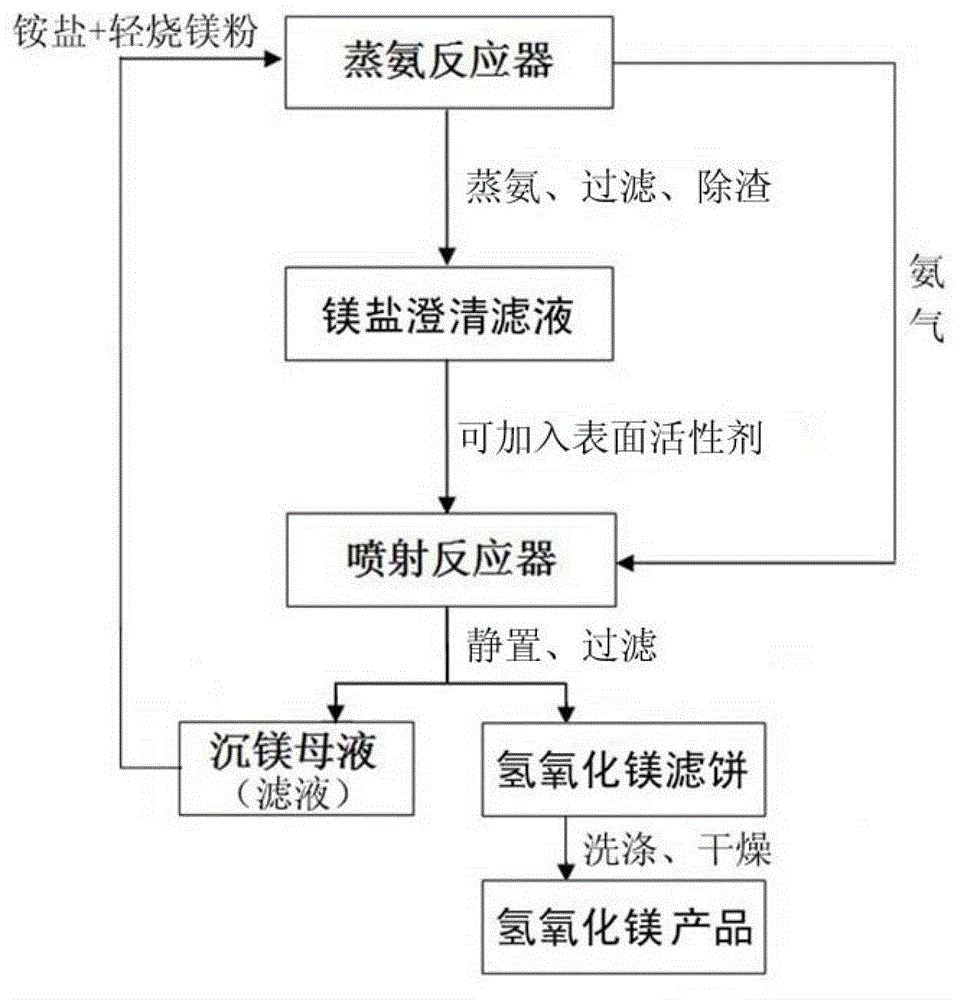

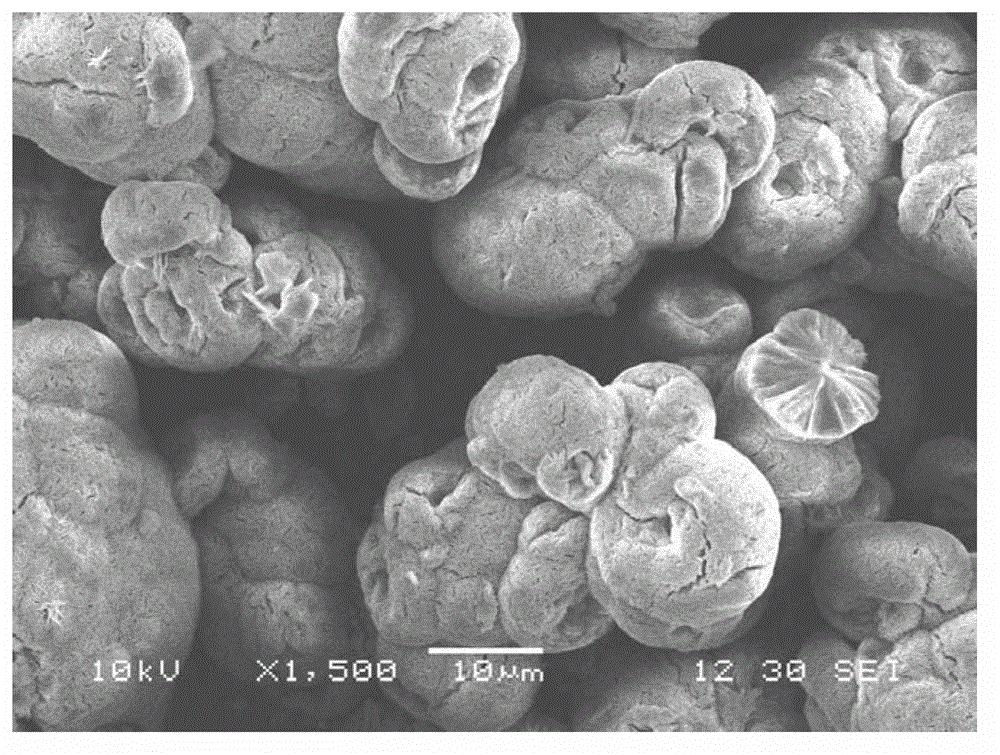

Method for preparing magnesium hydrate through ammonia spray method

ActiveCN103101936AReduce manufacturing costReduce shipping costsMagnesium hydroxideMagnesium saltMagnesite

The invention discloses a method for preparing magnesium hydrate through ammonia spray method. The method comprises the following steps: by using caustic calcined magnesite and ammonium salt as raw materials, carrying out ammonia stilling reaction to obtain an ammonium and magnesium salt solution, wherein the ammonium and magnesium salt are contacted in a spray type reactor and magnesium hydrate precipitation reaction is performed, aging product mother liquor for a proper time, filtering, returning filtrate containing ammonium salt to an ammonia stilling system, washing and drying filter cake to obtain magnesium hydrate product with uniform particle shape and good dispersion state. The process disclosed by the invention is used for preparing magnesium hydrate through one-step reaction, is simple in operation step, mild in reaction condition, uniform in product particle shape, and the particle shape can be regulated by changing the reaction condition. The ammonium slat is circulated with the ammonia in the reaction process, the production cost is low, the pollution is less, and the scale production is realized, the product can be used as production raw material of high-pure magnesium oxide and inflaming retarding additive of polymer material.

Owner:YINGKOU YINGXIN CHEM TECH CO LTD

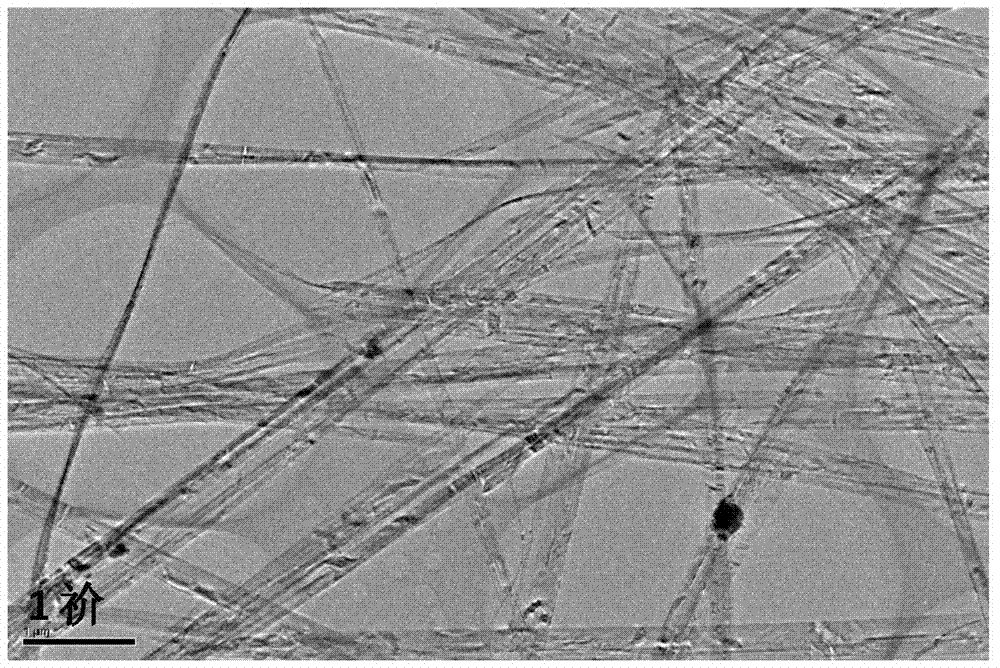

Sub-2nm ruthenium (Ru) nanowire network and preparation method thereof

InactiveCN105798325AControl shapeUnified appearanceMaterial nanotechnologyTransportation and packagingNanowireSynthesis methods

The invention discloses a sub-2nm ruthenium (Ru) nanowire network and a synthesis method thereof. The method is characterized by comprising the following steps: (1) a surface active agent and a reducing agent are added in water for stirring for 3-5 minutes at room temperature; the mass ratio of the surface active agent to the reducing agent is 1: 2-2: 1; and the quantity of the added water needs to meet the condition that the added water can totally dissolve the surface active agent and the reducing agent; (2) metal ruthenium salt precursor solution is added in the obtained mixed solution in the step (1) for stirring for 1-3 minutes at room temperature; the ratio of the added water to the ruthenium precursor solution is 5: 1-10: 1; and the concentration of the ruthenium metal precursor is 0.05-0.5 mol / L; (3) the mixed solution obtained in the step (2) is transferred into a high-pressure reaction kettle for reacting for 12-30 hours; and the temperature is controlled within 150-200 DEG C; and (4) the product obtained in the step (3) is cooled for washing, and is centrifugally separated to obtain the sub-2nm Ru nanowire network.

Owner:GUIZHOU UNIV

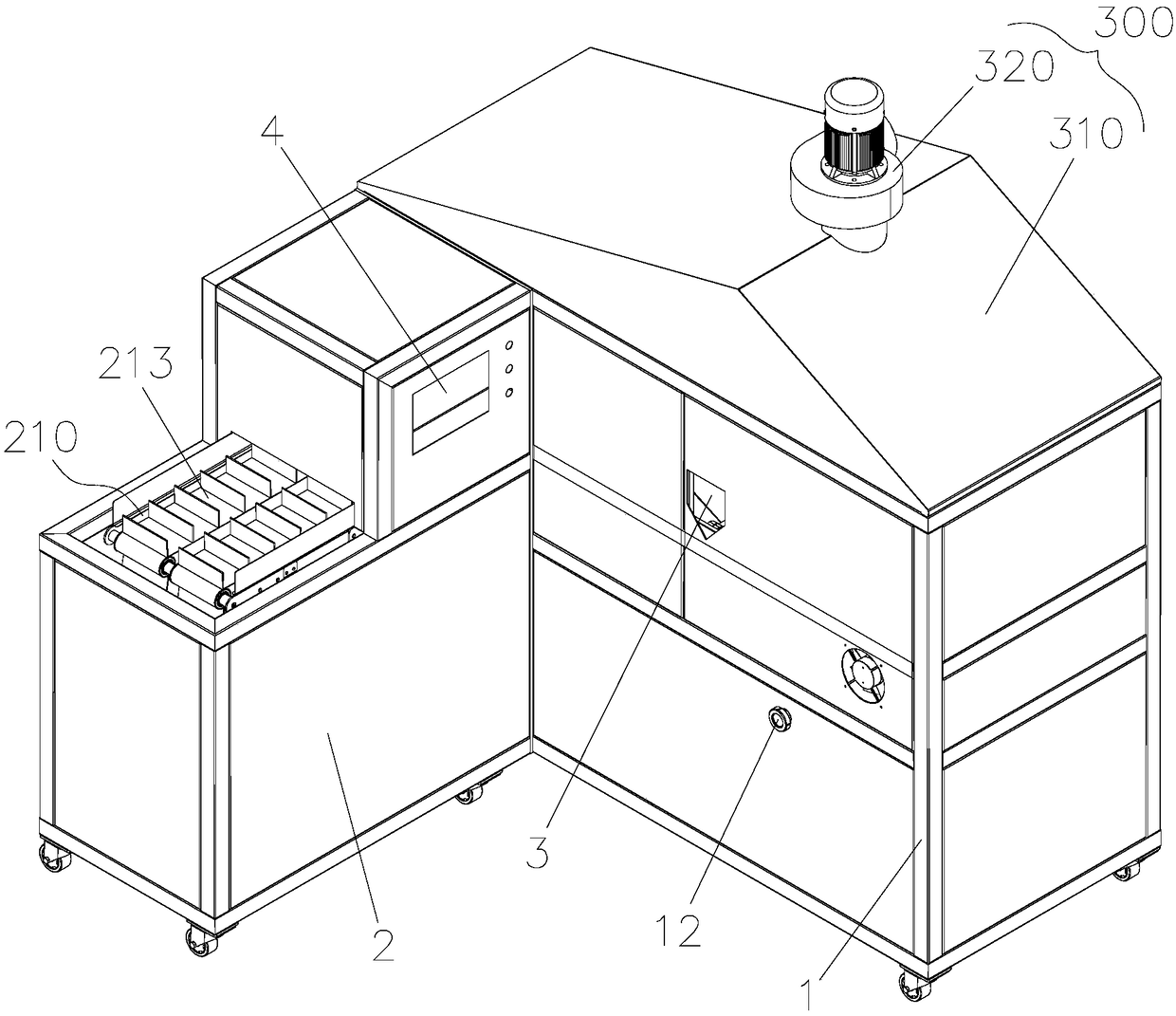

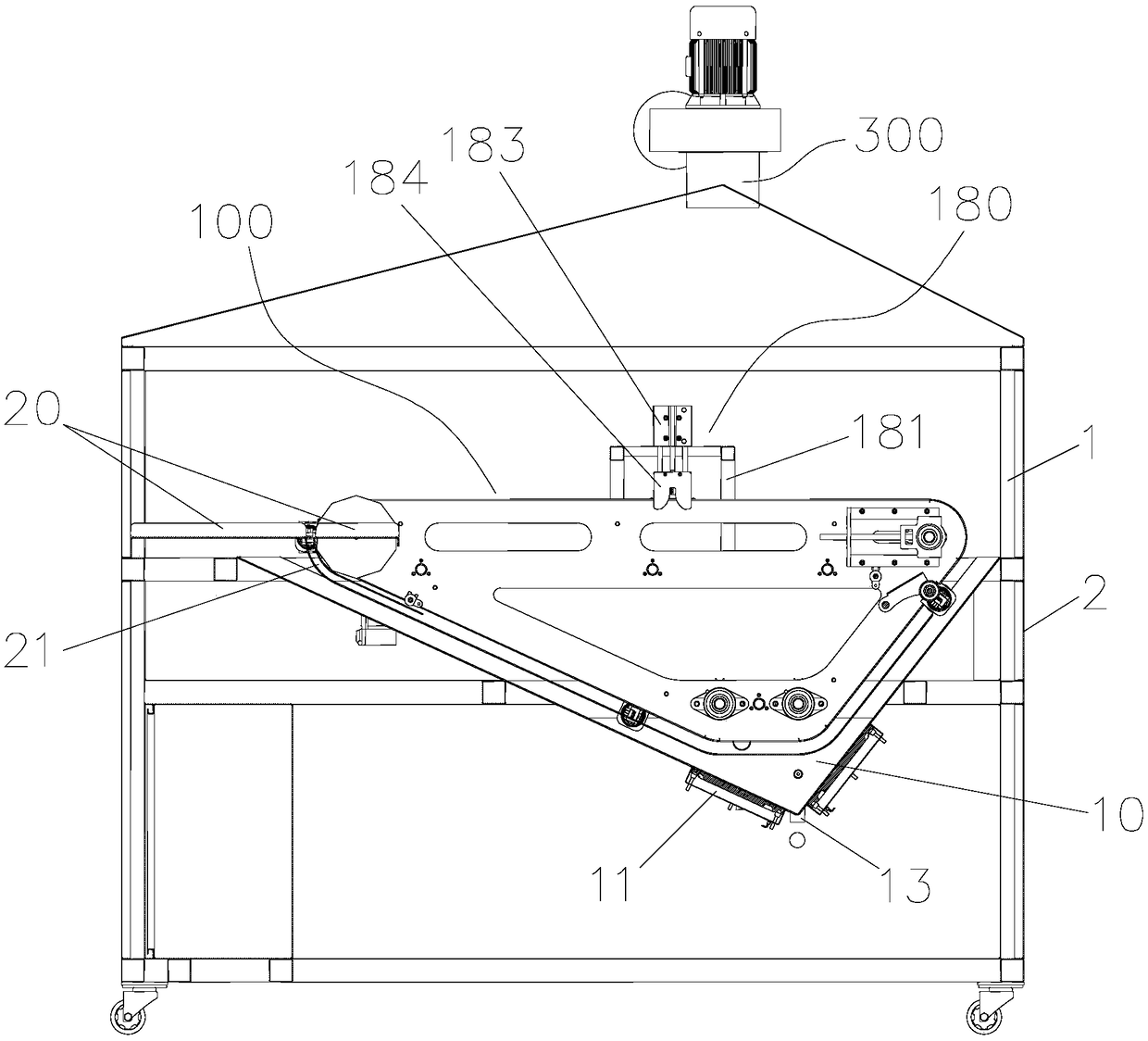

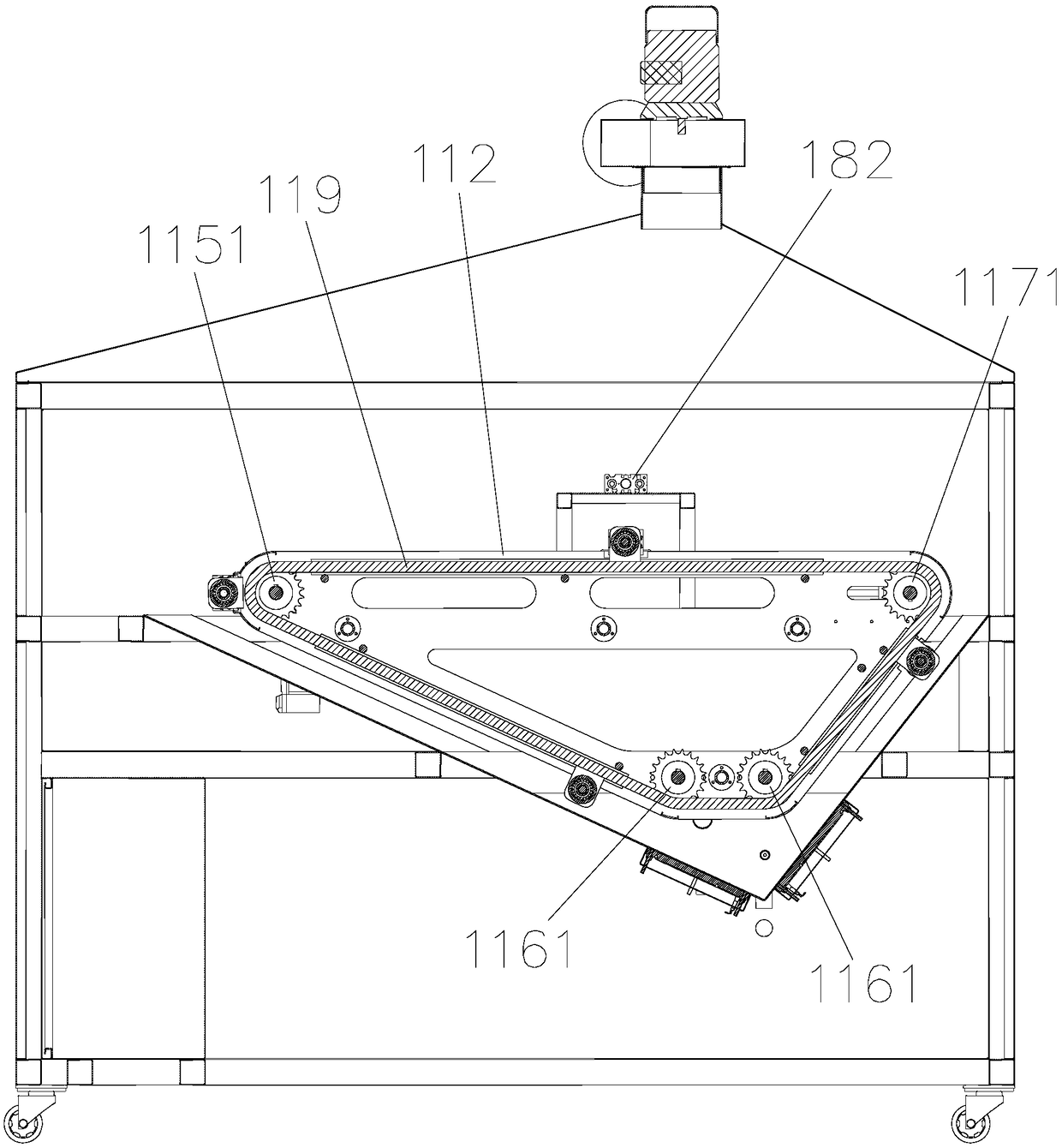

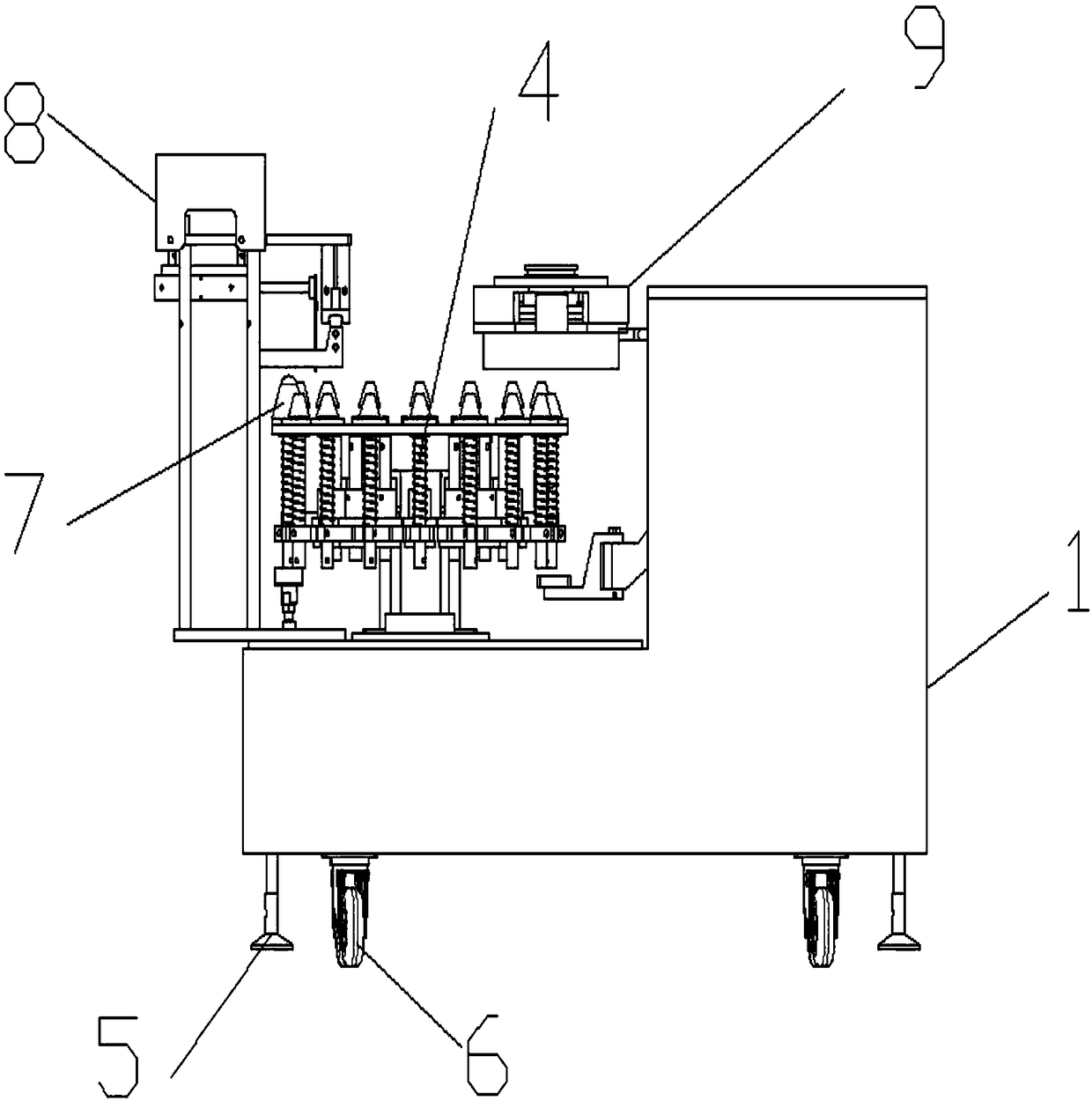

Full-automatic frying and tofu skin coiling all-in-one machine

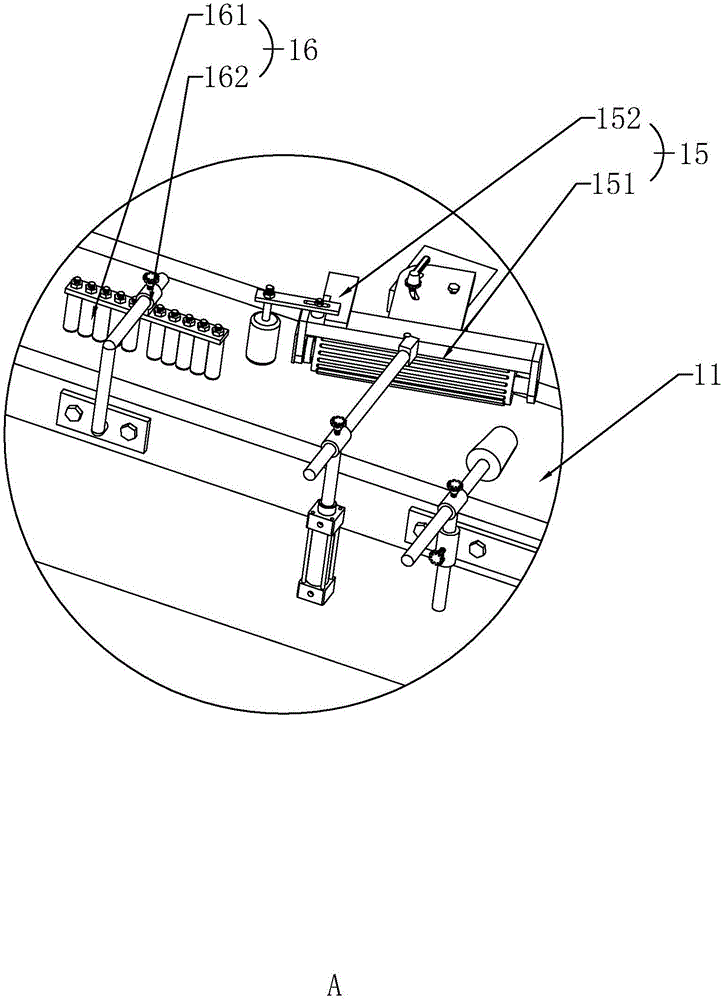

ActiveCN109275672ARealize automatic windingEasy to take offOil/fat bakingBaking plantsPulp and paper industryManipulator

The invention discloses a full-automatic frying and tofu skin coiling all-in-one machine. The full-automatic frying and tofu skin coiling all-in-one machine comprises a rack, wherein the rack is provided with a frying groove body and a frying device located in the frying groove body, the frying device comprises a first belt type conveying mechanism, a tofu skin clamping air cylinder, a tofu skin coiling motor, a tofu skin coiling pressing wheel and a demoulding air cylinder, the first belt type conveying mechanism comprises a first conveying bracket and a first conveying belt, the outer surface of the first conveying belt is provided with multiple manipulators distributed at intervals, a feeding platform is arranged above a feeding end of the frying groove body, the feeding platform is provided with a channel allowing execution ends of the manipulators to penetrate through, the tofu skin clamping air cylinder is arranged at a feeding end of the first conveying bracket, the tofu skin coiling motor and the tofu skin coiling pressing wheel are arranged at a discharging end of the first conveying bracket respectively, the demoulding air cylinder is arranged in the middle of the top ofthe first conveying bracket, and execution ends of the tofu skin clamping air cylinder, tofu skin coiling motor and demoulding air cylinder cooperate with driving ends of the corresponding manipulators respectively. The full-automatic frying and tofu skin coiling all-in-one machine can conduct automated and standardized frying and coiling on tofu skin, so that the production efficiency is high.

Owner:QUANZHOU TIANFA FOOD MACHINERY

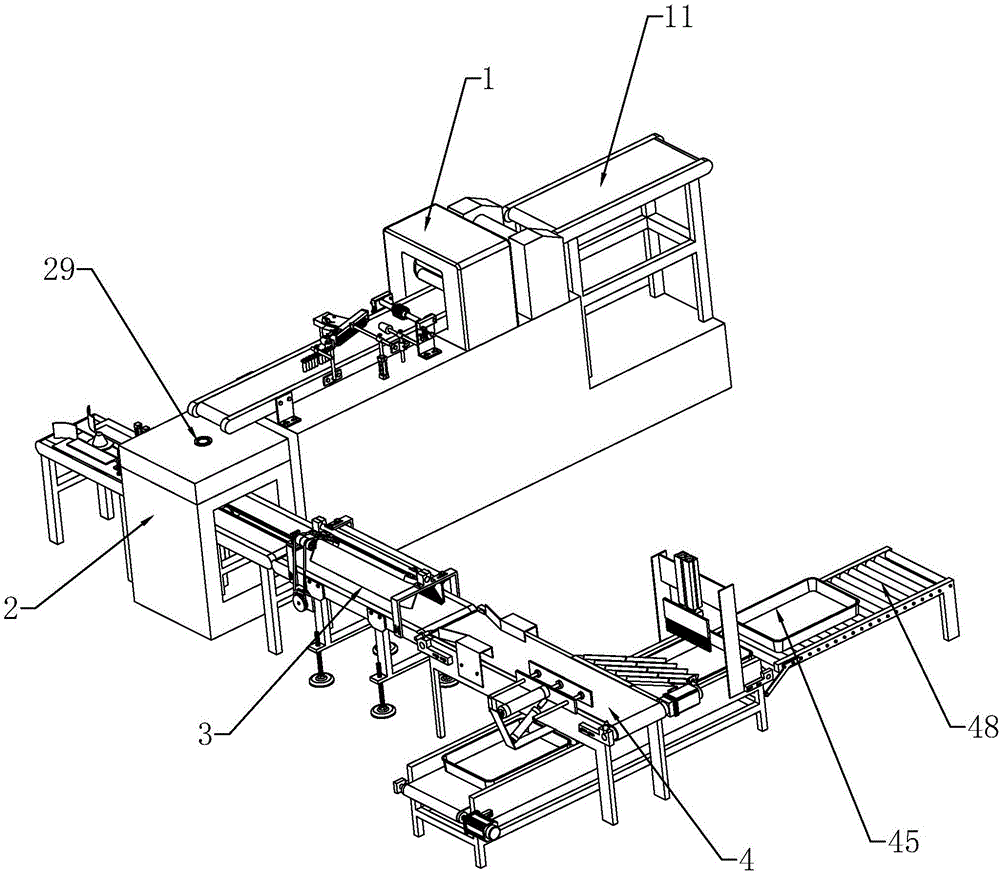

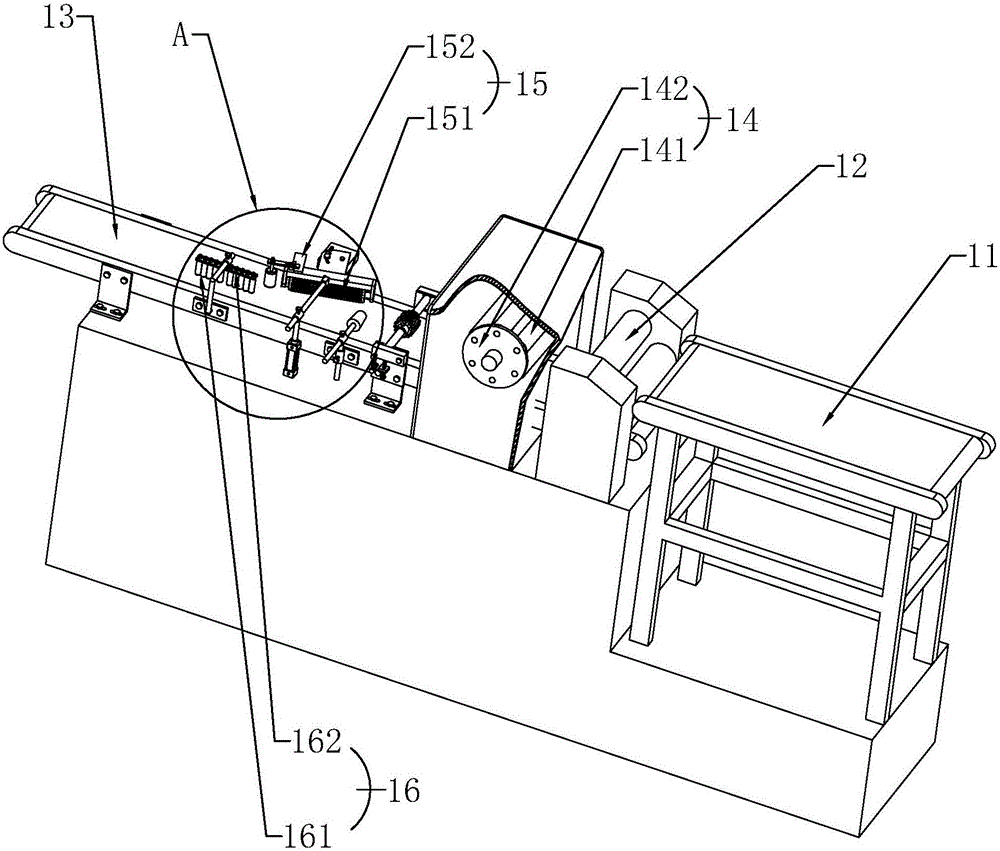

Steamed hard-breadroll forming machine

ActiveCN105831190AUnified appearanceSmall size differenceDough-sheeters/rolling-machines/rolling-pinsDough shaping and cutting apparatusEngineeringMechanical engineering

The invention discloses a steamed hard-breadroll forming machine and a steamed hard-breadroll forming process. The steamed hard-breadroll forming machine is characterized by comprising a dough feeding conveying device for processing dough materials into strips in sequential connection, wherein the dough feeding conveying device is sequentially connected with a pre-pressing forming device, a shaping device and a disc ranging device; the pre-pressing forming device is used for cutting dough materials and pre-pressing the dough materials into a cap shape with the hemispherical recessed bottom; the shaping device is used for performing shaping processing on the shaped steamed hard-breadroll; the disc ranging device is used for collecting the shaped steamed hard-breadroll; the dough is kneaded and pressed to be made into plane-shaped strips; the strips are flatly pressed by the dough feeding conveying device; strip-shaped dough materials capable of being conveniently cut are formed; through the pre-pressing forming device, the dough materials are sheathed and connected onto a mold to obtain a steamed hard-breadroll mold primarily in a cap shape; then, the shaping device is used for performing shaping smoothening processing to obtain the final steamed hard-breadroll appearance; collection is performed through the disc ranging device; the goal of automatically making the dough materials into the formed steamed hard-breadroll is achieved; the production efficiency is improved; the labor and the materials are effectively saved; the automatic mass production effect is realized.

Owner:杭州贝加尔食品有限公司

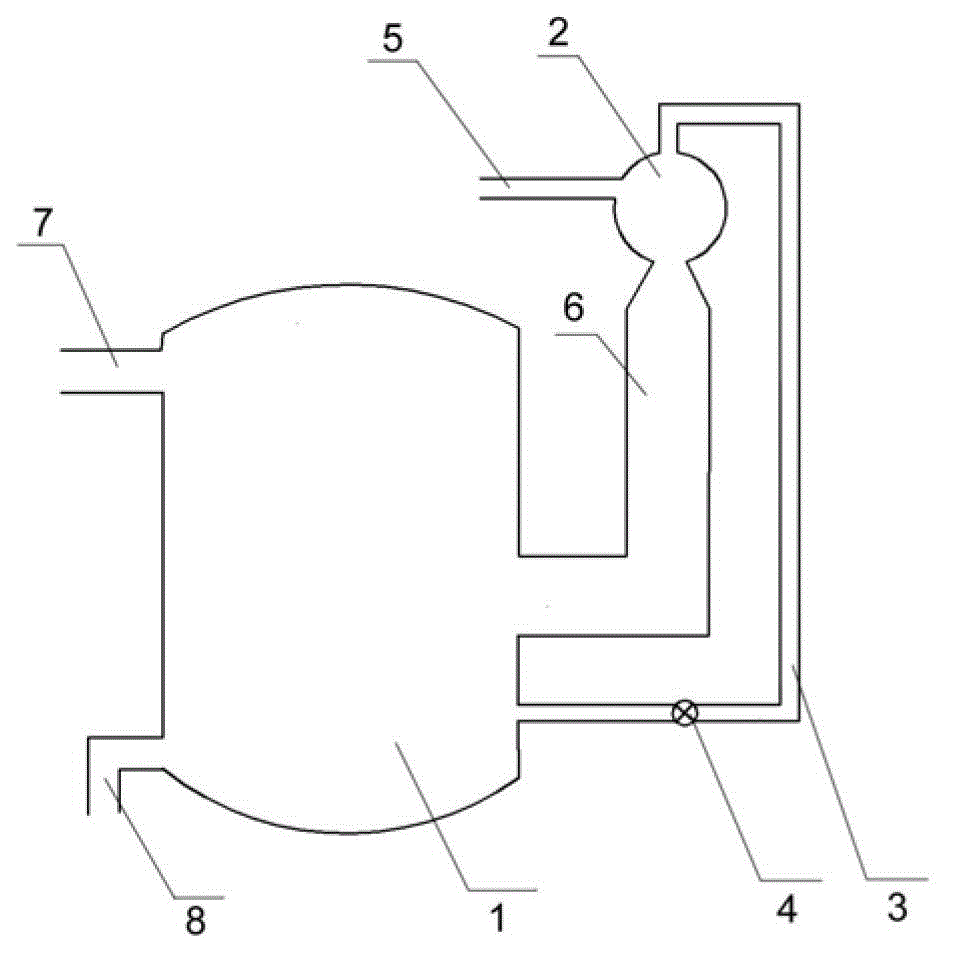

Articulated type dump truck fuel tank

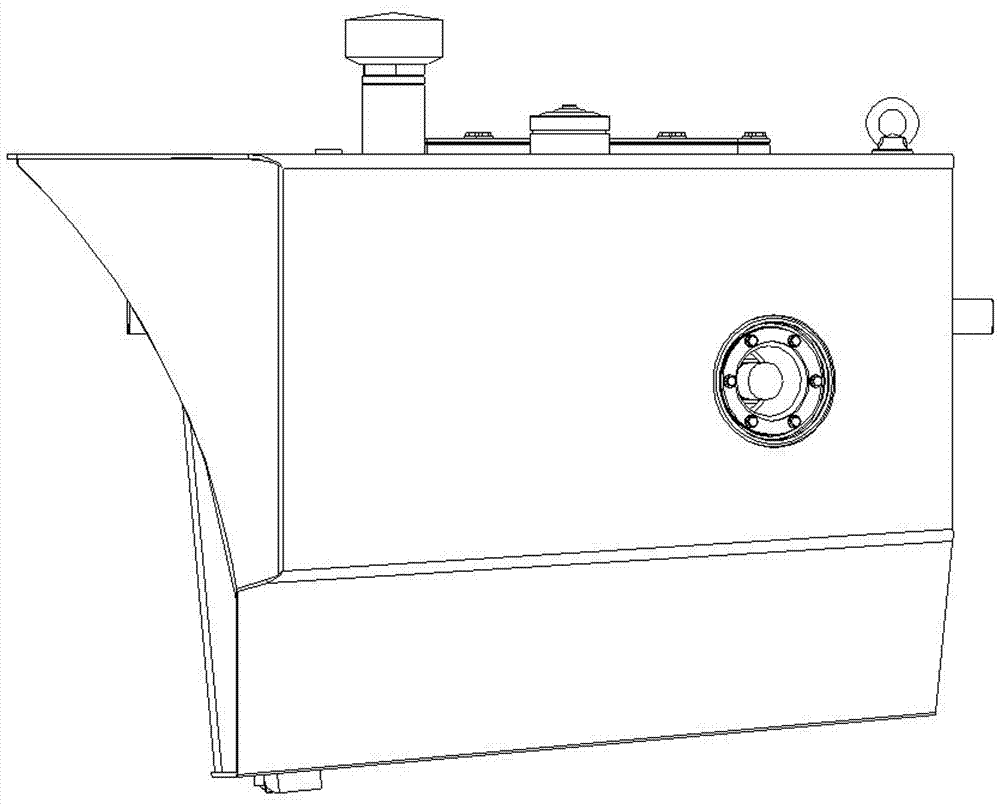

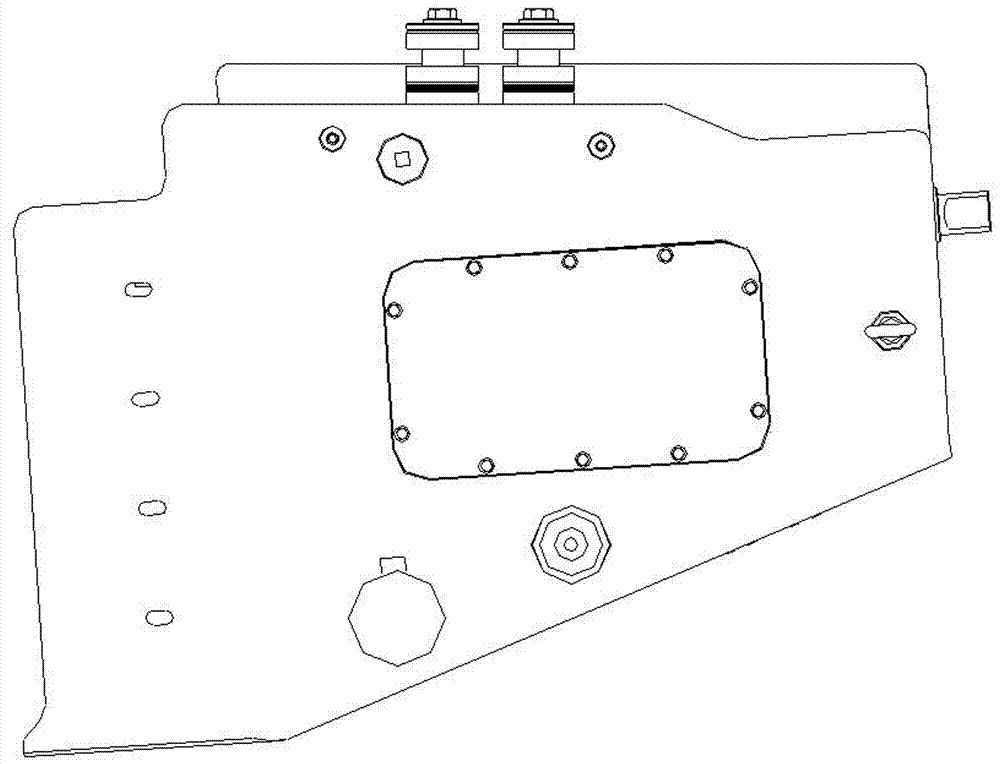

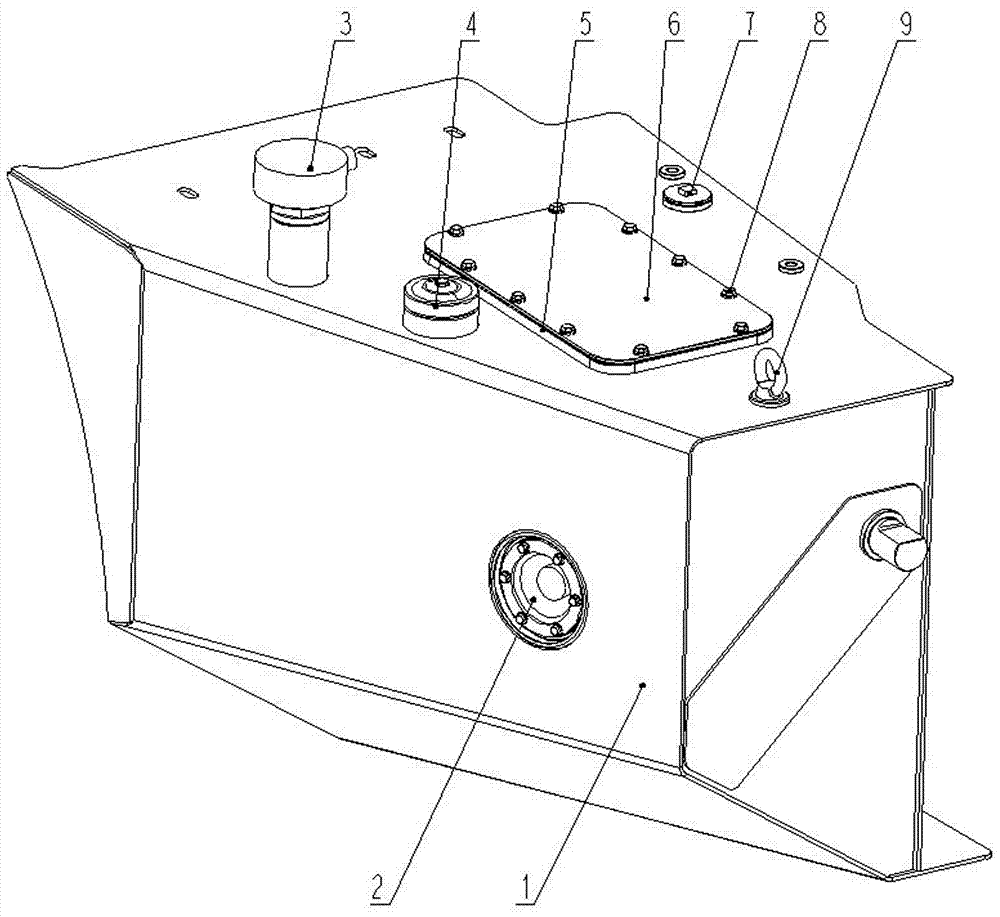

PendingCN107351677AReduce cross motionReduce vibration in the front and rear directionsUnderstructuresFuel supplyMarine engineeringFuel tank

The invention discloses an articulated type dump truck fuel tank. The articulated type dump truck fuel tank comprises a fuel tank body. The fuel tank body is composed of a front plate, a left side plate, a right side plate and a rear plate, a rapid refueling assembly is arranged on the front side surface of the front plate, a breather, a lock cover, a cleaning opening cover and a liquid level sensor are installed on the top surface of the front plate, and a magnetic fuel dumping screw plug is installed on the bottom surface of the front plate; and a plurality of dampers are installed on the rear plate, the whole tank body of the inner portion of the fuel tank body is divided into four cavities through a transverse baffle and a longitudinal baffle, and through-flow holes are formed in the transverse baffle and the longitudinal baffle correspondingly. According to the articulated type dump truck fuel tank, the problems that the occupied installation space of a traditional fuel tank is large, and the extroversion tendency in the steering process is caused are solved, and the articulated type dump truck fuel tank can effectively reduce the displacement of the fuel tank in the left-right direction and the vibration of the fuel tank in the front-back direction.

Owner:XUZHOU XCMG MINING MACHINERY CO LTD

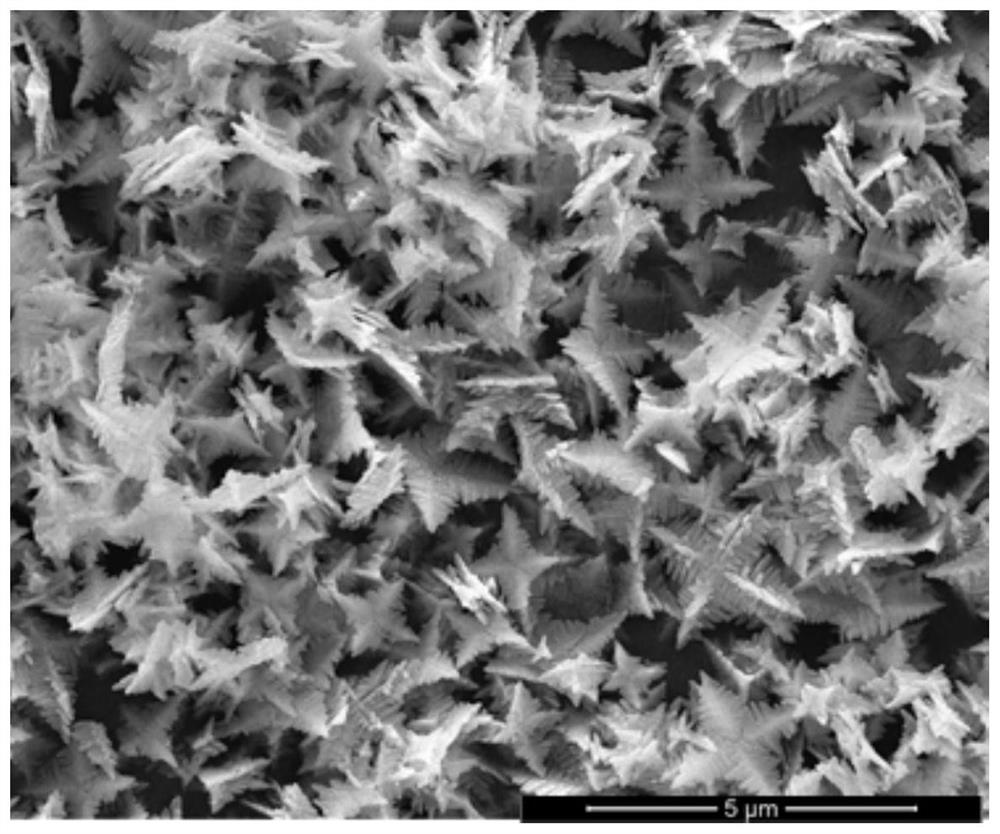

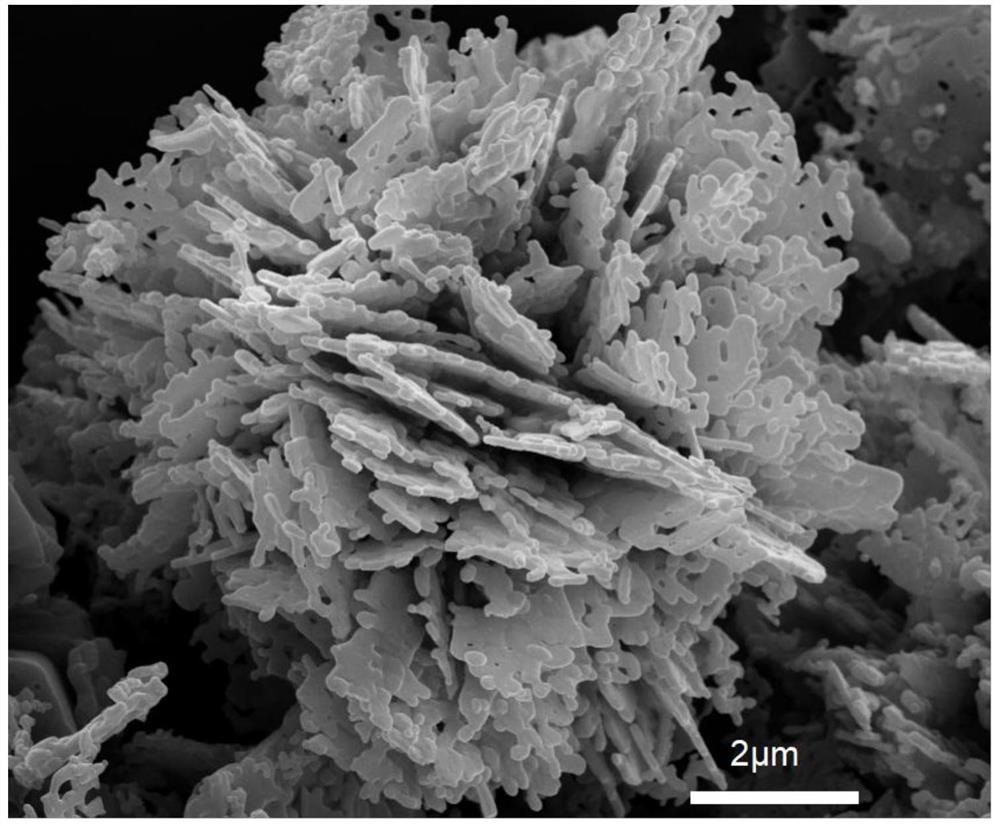

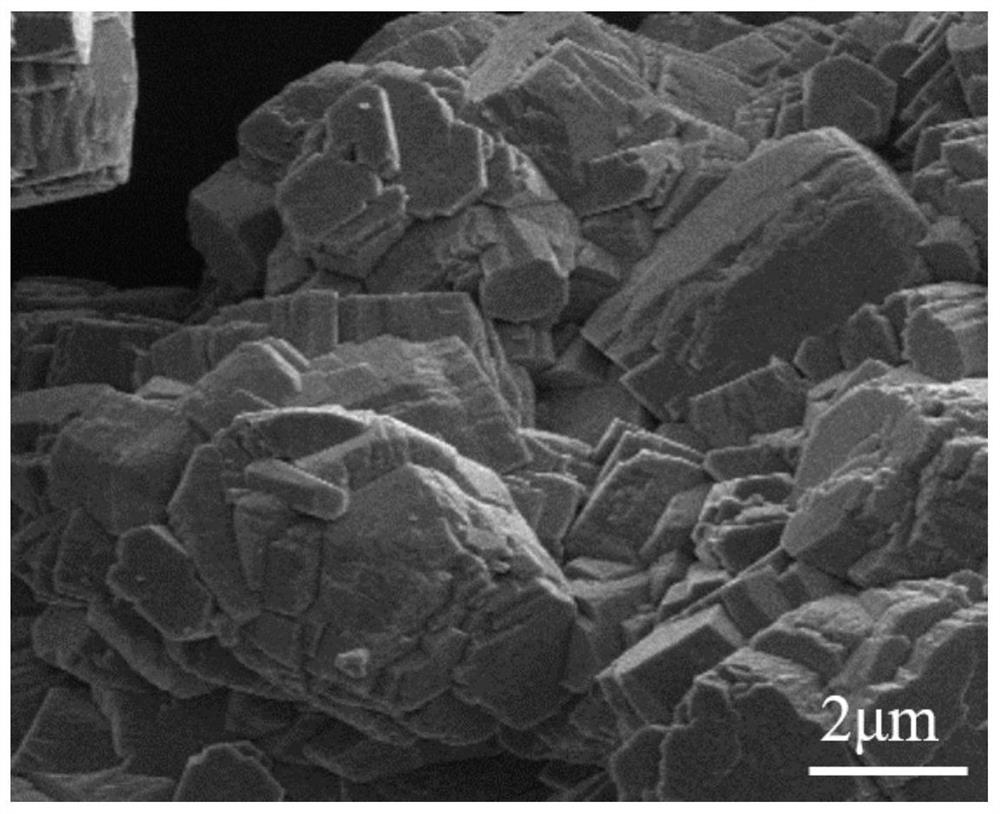

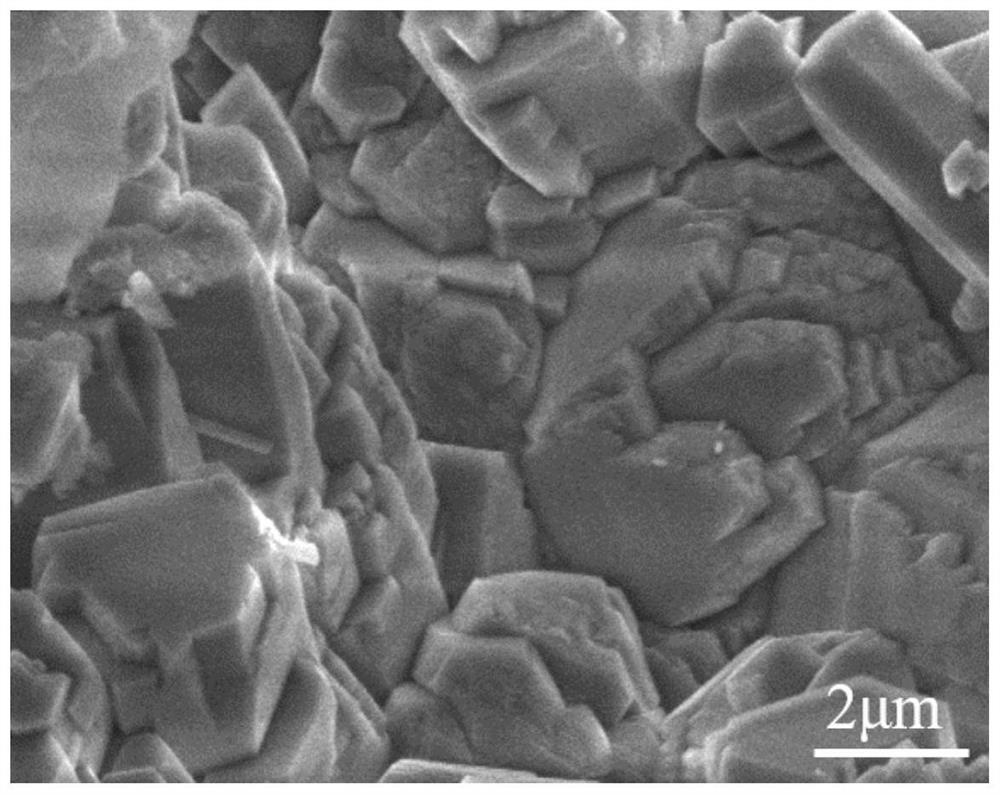

Preparation method of star-shaped bismuth vanadate/boron alkene composite material

ActiveCN112569924AChanging the problem of insufficient compounding of the structureImprove photocatalytic performanceMetal/metal-oxides/metal-hydroxide catalystsMicron scaleBismuth vanadate

The invention discloses a preparation method of a star-shaped bismuth vanadate / boron alkene composite material, which comprises the following steps: synthesizing a star-shaped bismuth vanadate three-dimensional structure by using a hydrothermal method, and synthesizing the bismuth vanadate / boron alkene composite material by using star-shaped bismuth vanadate and boron alkene as raw materials and using the hydrothermal method. According to the preparation method disclosed by the invention, the star-shaped bismuth vanadate with uniform micron-sized morphology is obtained, and compared with an existing bismuth vanadate material with a common structure, the star-shaped bismuth vanadate prepared by the preparation method disclosed by the invention has a micron-sized size, so that a two-dimensional boron-alkene nano material can be effectively loaded, excessive stacking of boron-alkene sheets is effectively avoided, and the star-shaped bismuth vanadate / boron-alkene composite material with ordered morphology is obtained; the photocatalytic performance of the material is effectively improved.

Owner:JIANGSU XFNANO MATERIALS TECH CO LTD

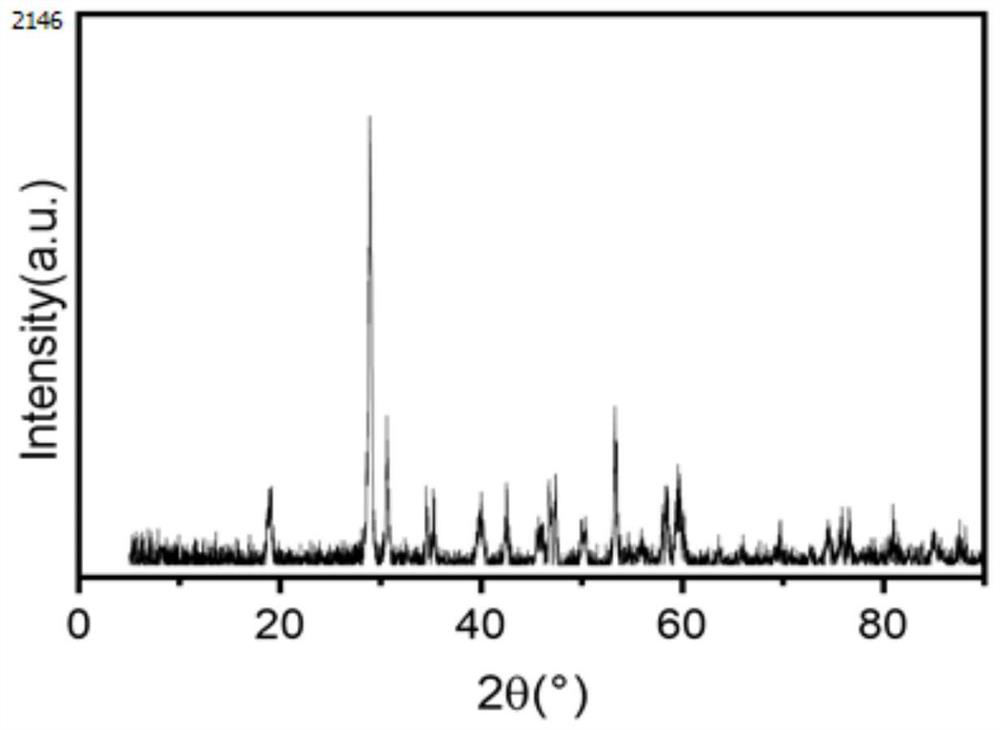

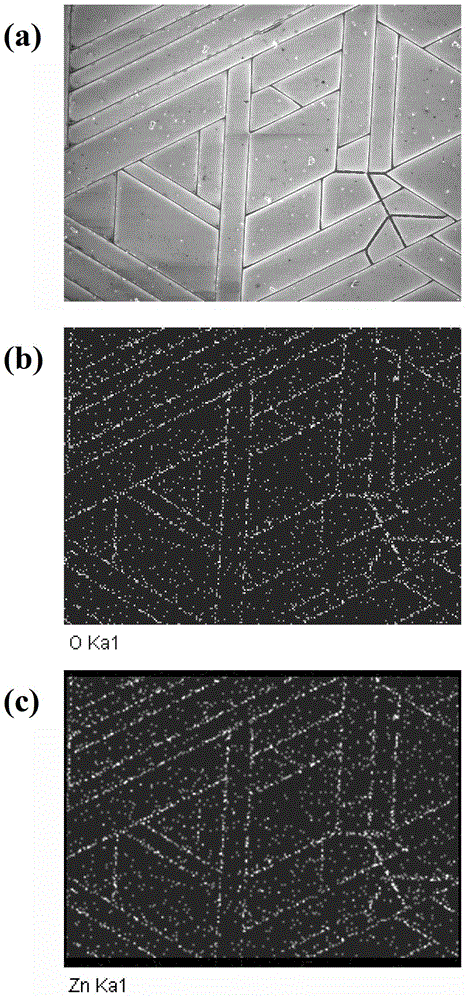

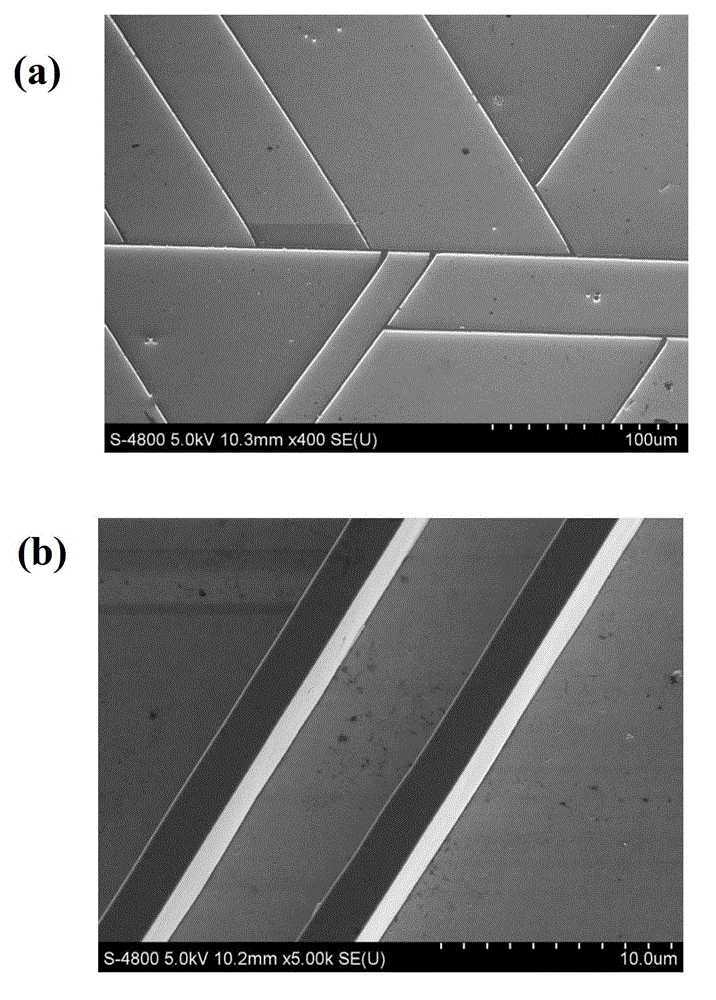

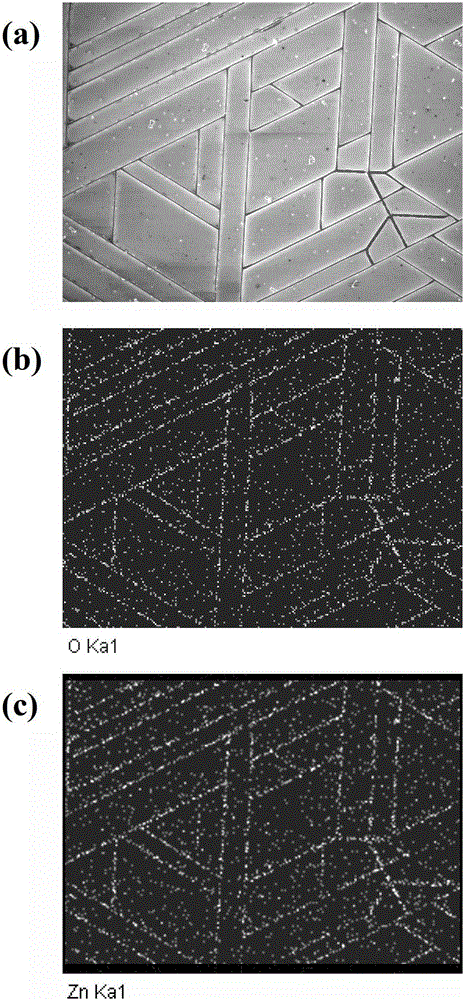

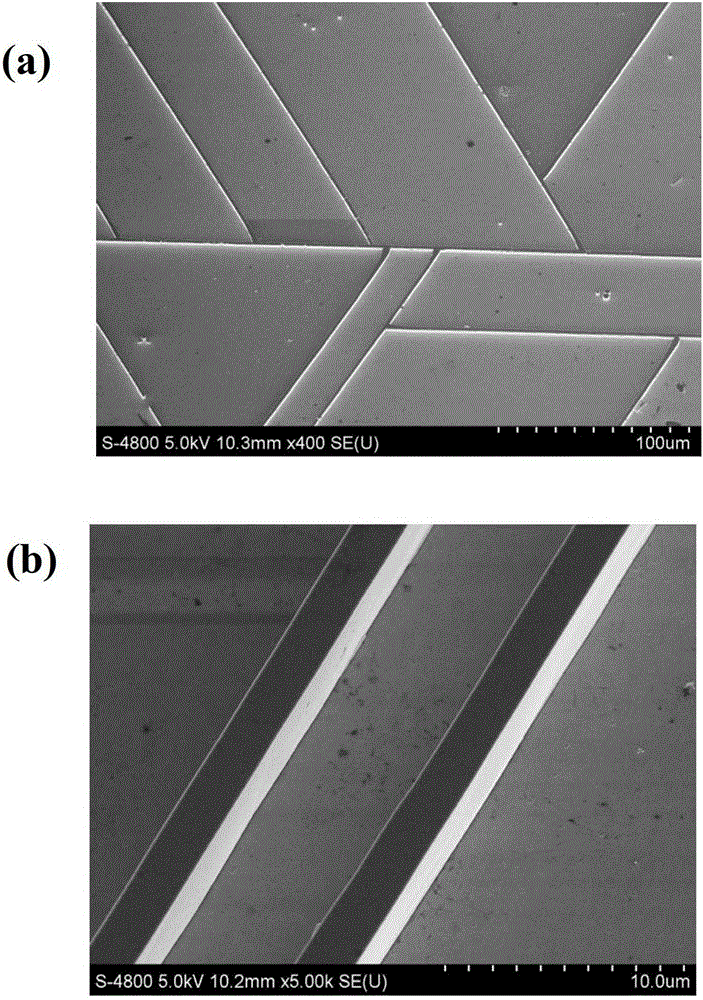

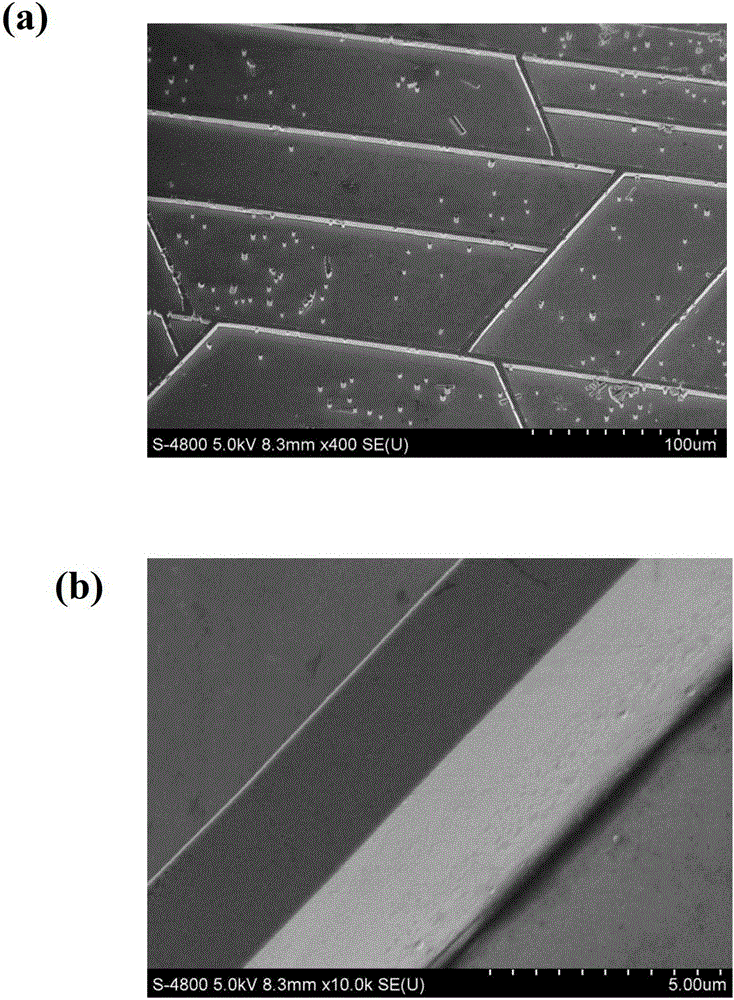

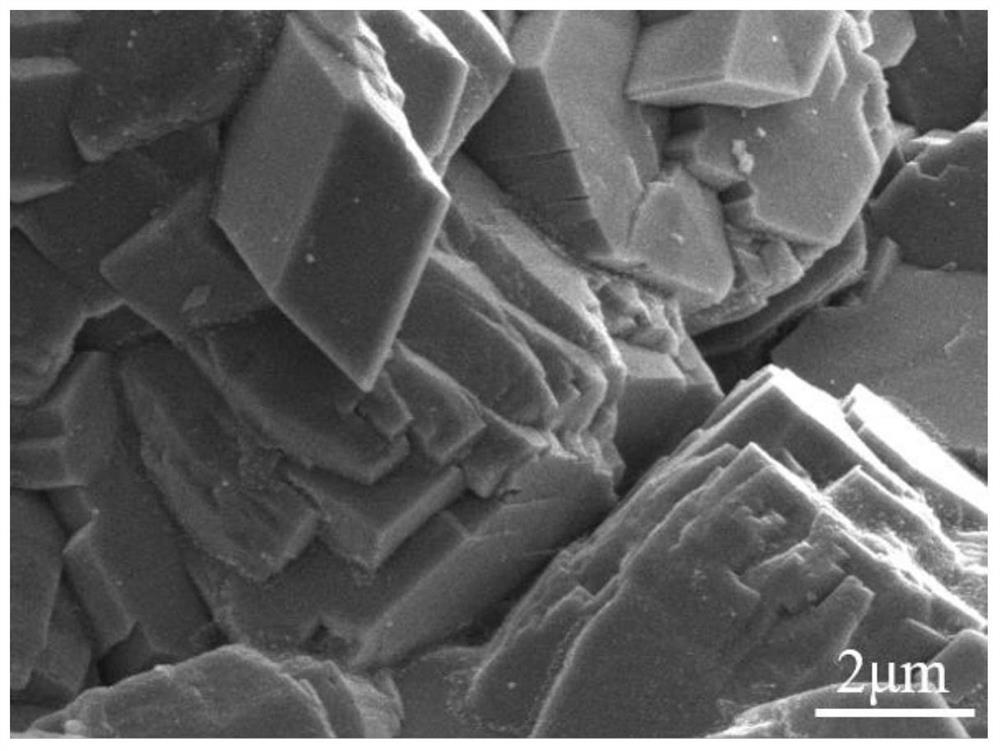

Method for growing large-area zinc oxide micron wall

InactiveCN102719886AUnified appearanceFlat surfacePolycrystalline material growthLiquid-phase epitaxial-layer growthAcetic acidDiameter ratio

The invention discloses a zinc oxide micron wall material and a preparation method thereof. A method for obtaining a zinc oxide micron wall on a silica-based gallium nitride substrate with cracks by the low-temperature water bathing method includes utilizing zinc acetate, hexamine and deionized water as raw materials and silica-based gallium nitride with cracks as a substrate, inducing the zinc oxide to preferentially form a core via the cracks and forming the zinc oxide micron wall in self-assembly manner. The method is simple in reaction conditions, and the zinc oxide micron wall grown is large in specific surface area, high in length diameter ratio and purity and controllable in height. The low-temperature preparation of the large-area zinc oxide micron wall controllable in growth is realized. The large-area zinc oxide micron wall can be hopefully and importantly applied in the fields of microelectronics, microelectronic photoelectric devices and sensors. The preparation method has no special requirements for heating environment, is simple and easily controllable to operate, high in repeatability and suitable for industrialized production, and raw materials are easy to obtain and low in cost.

Owner:DALIAN NATIONALITIES UNIVERSITY

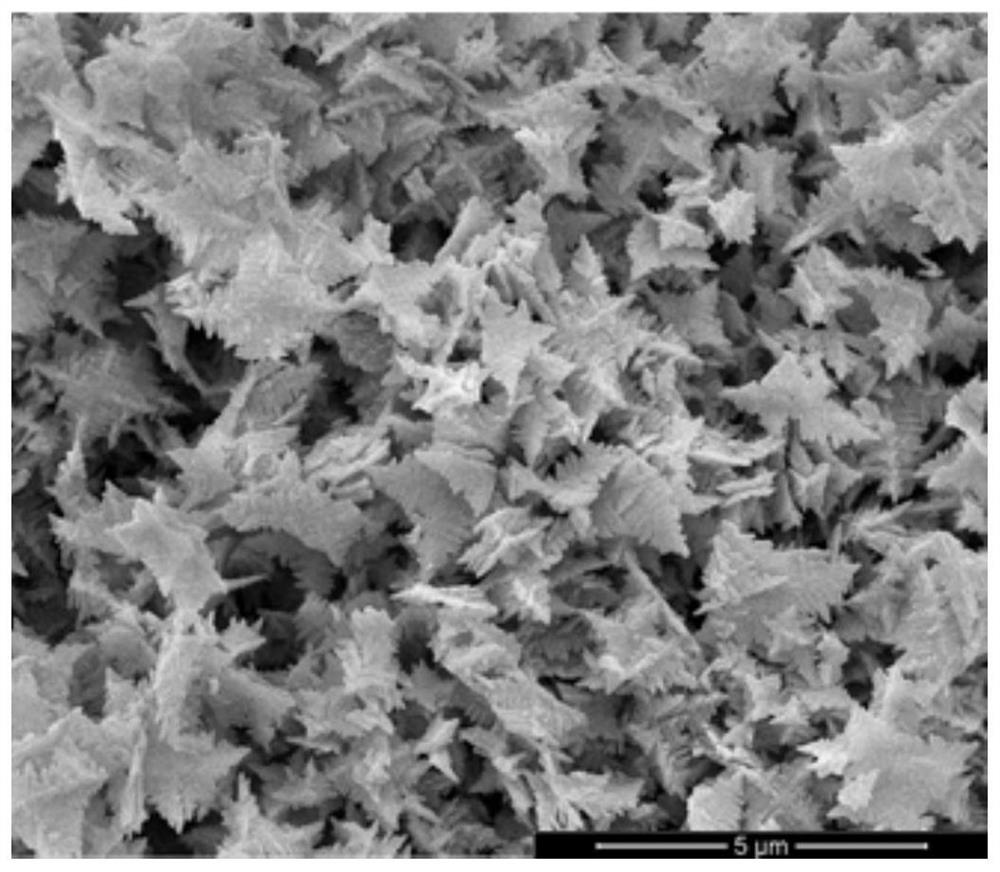

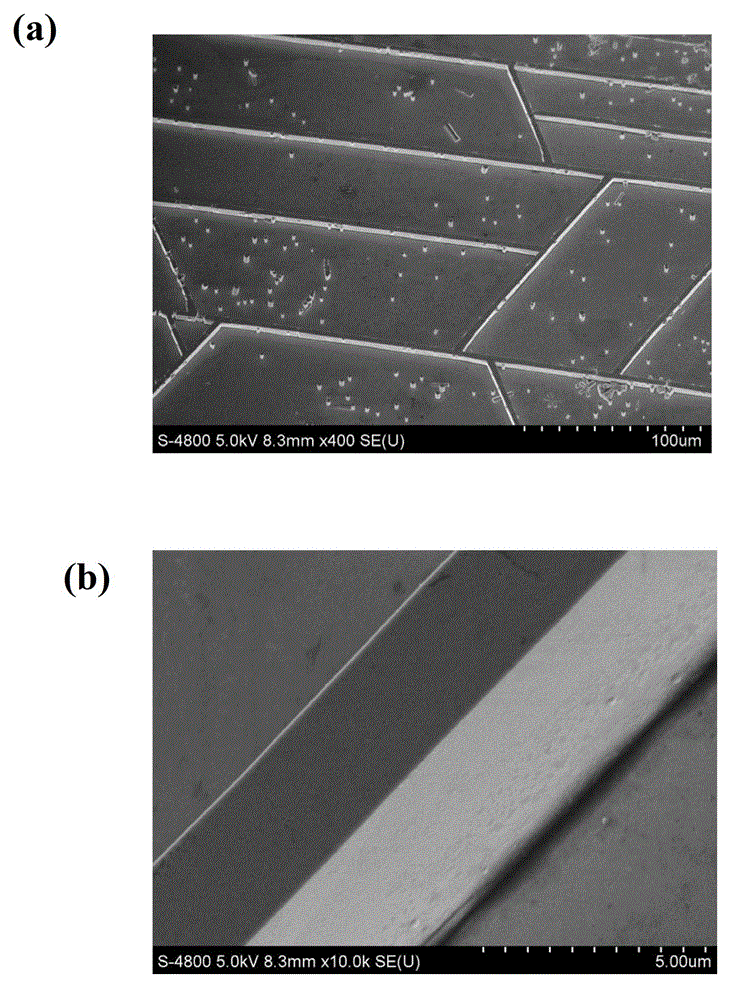

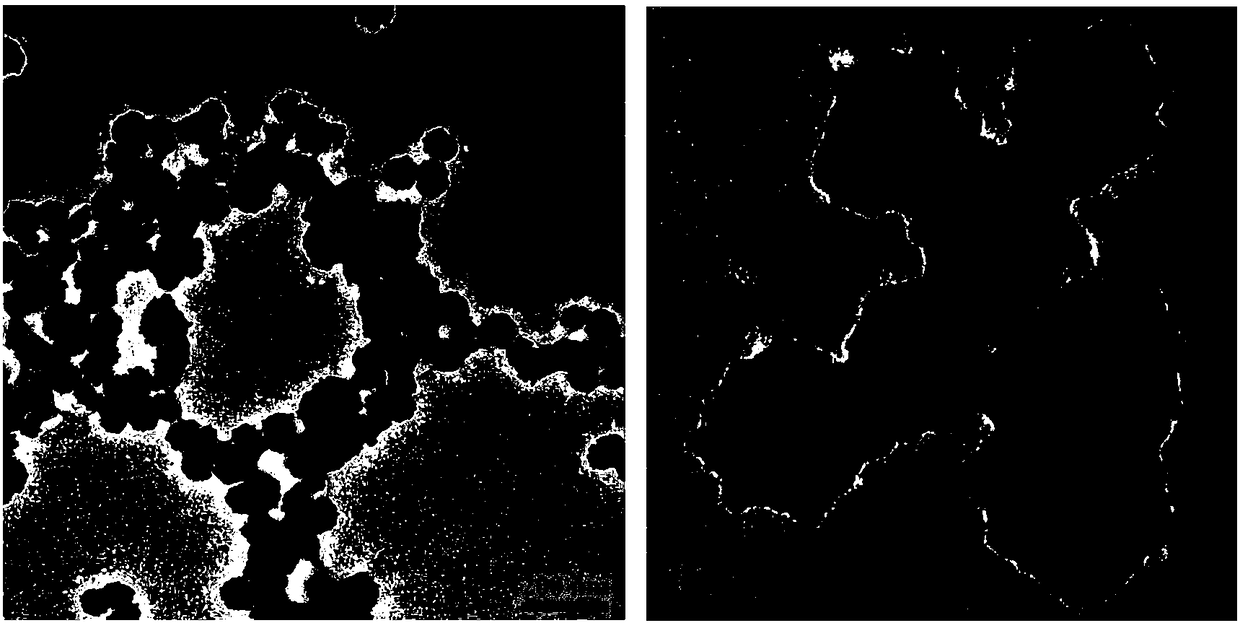

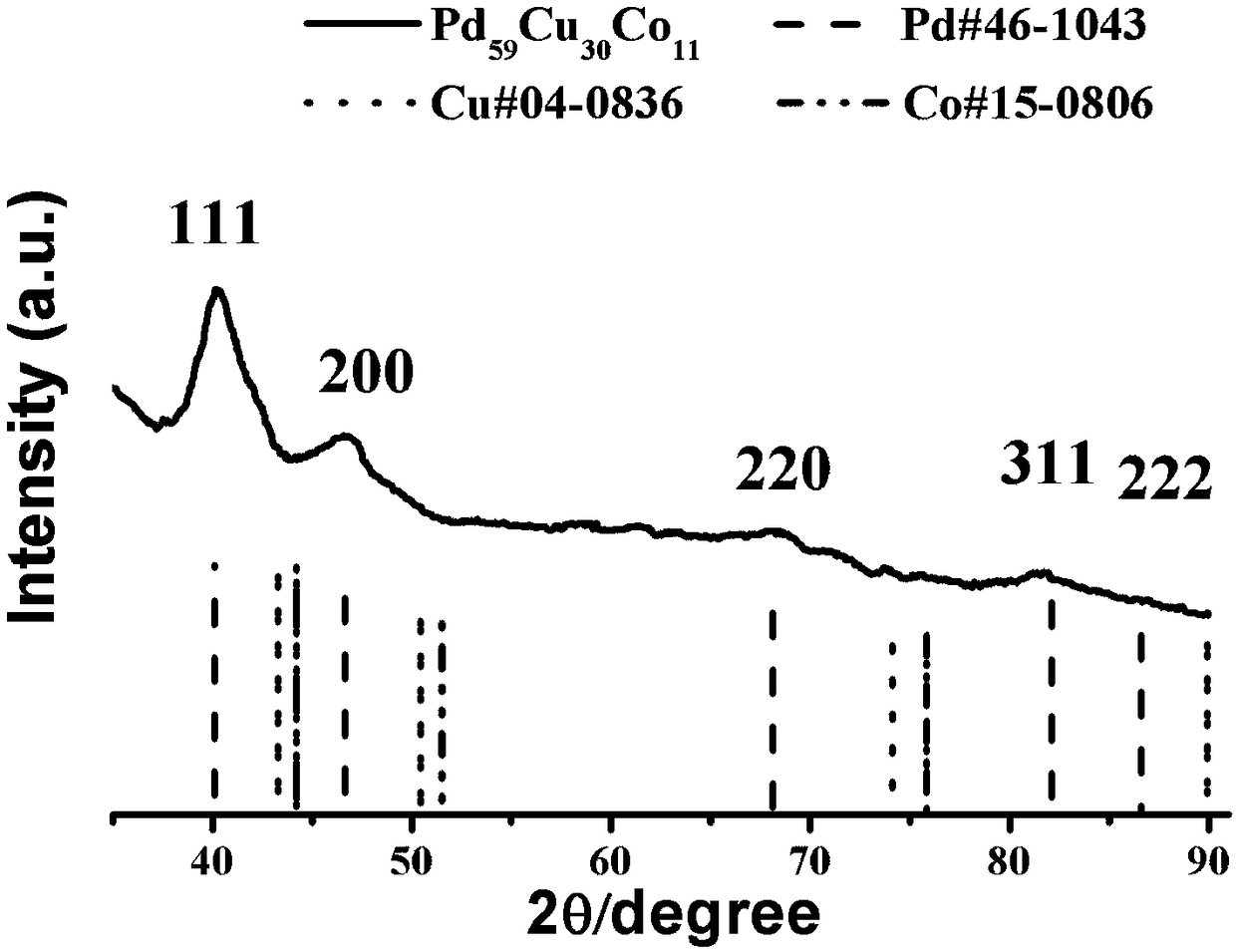

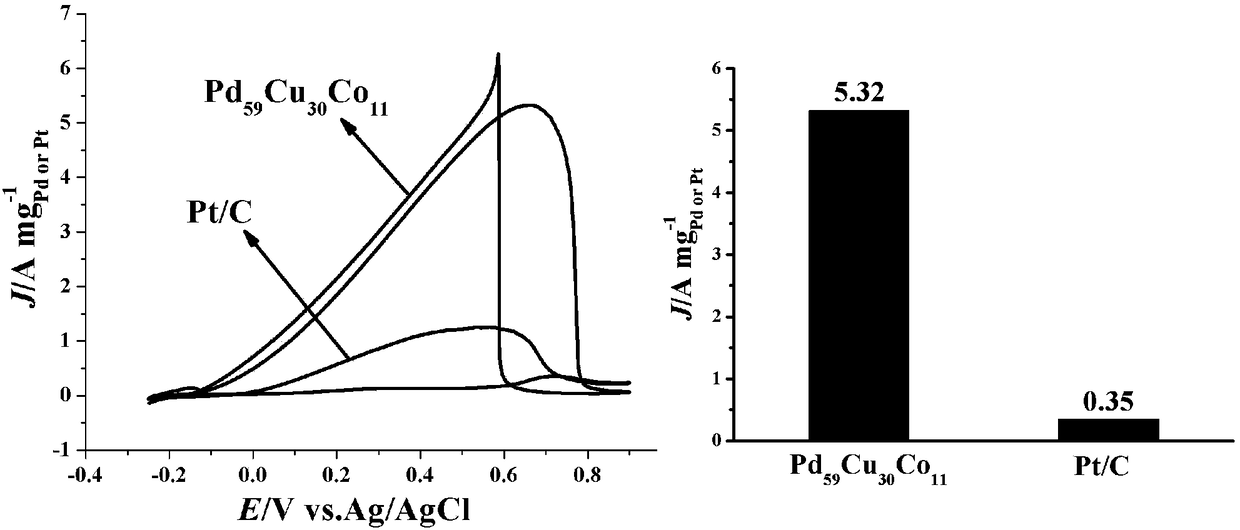

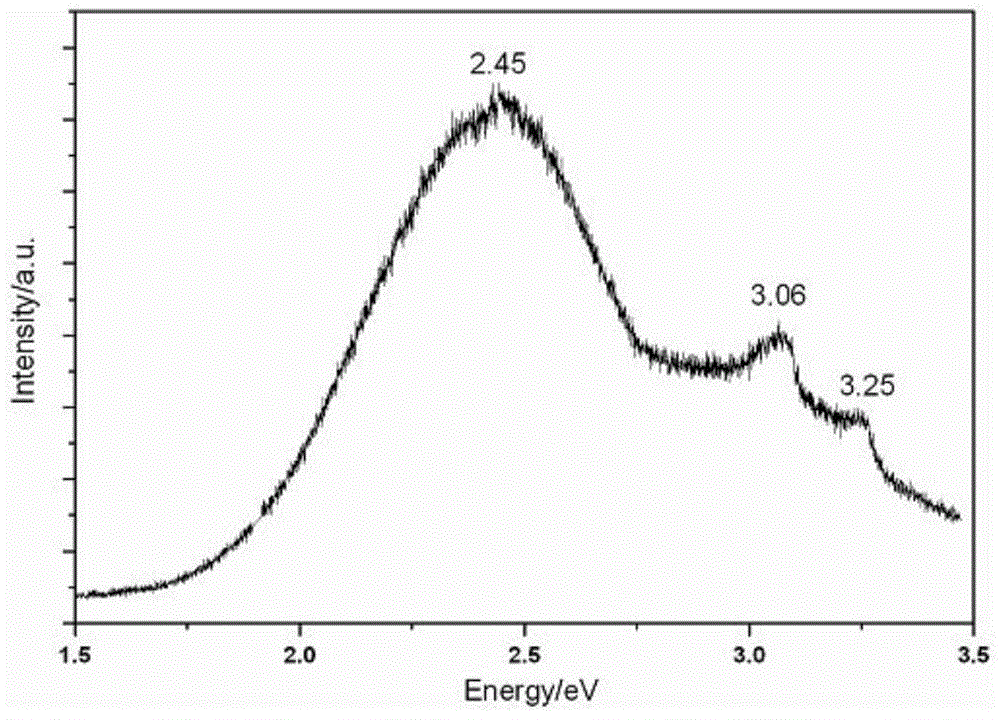

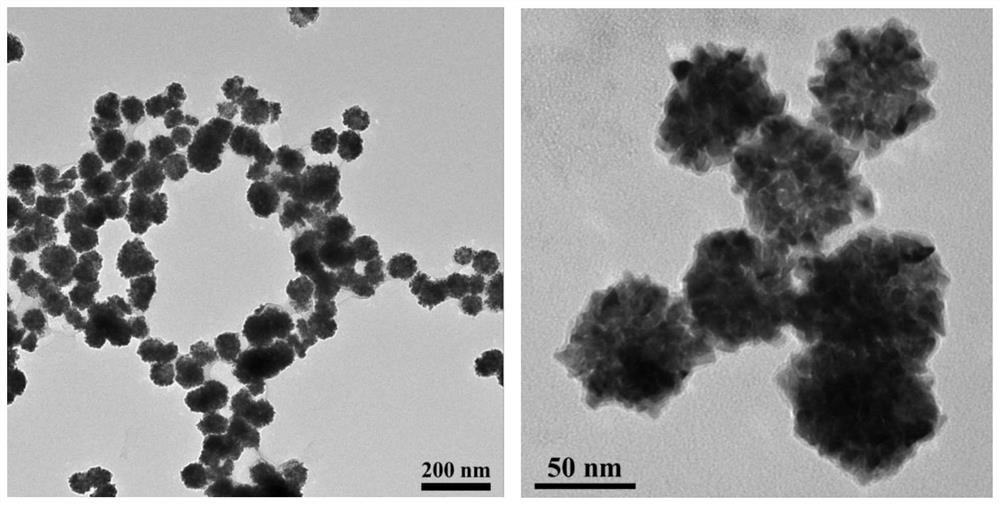

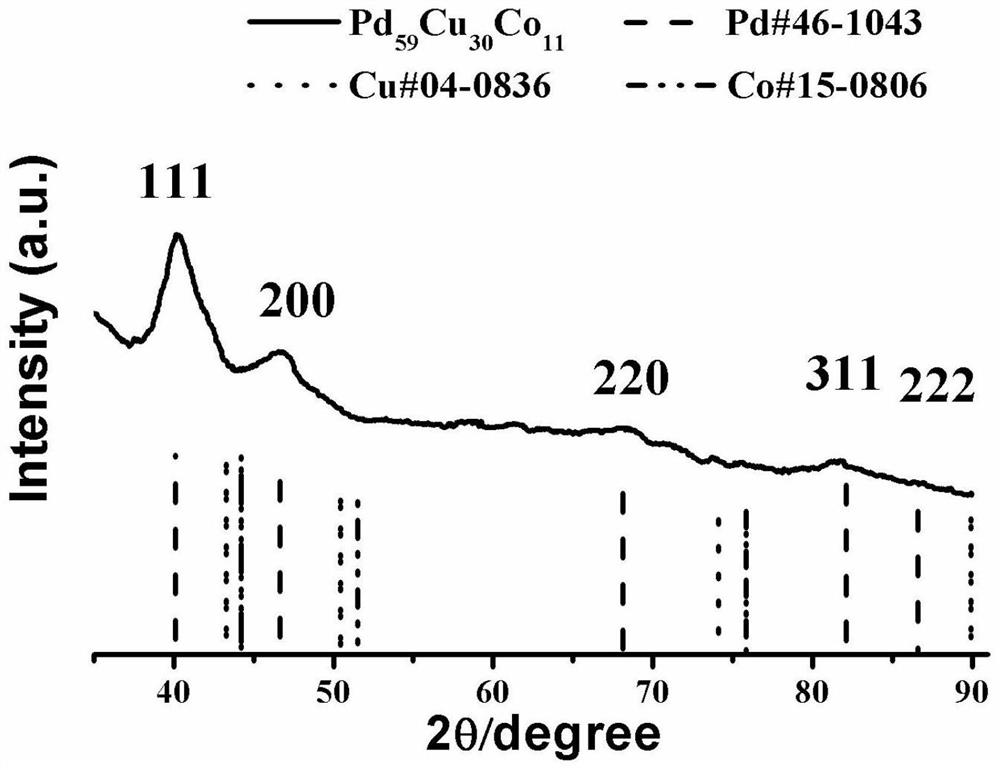

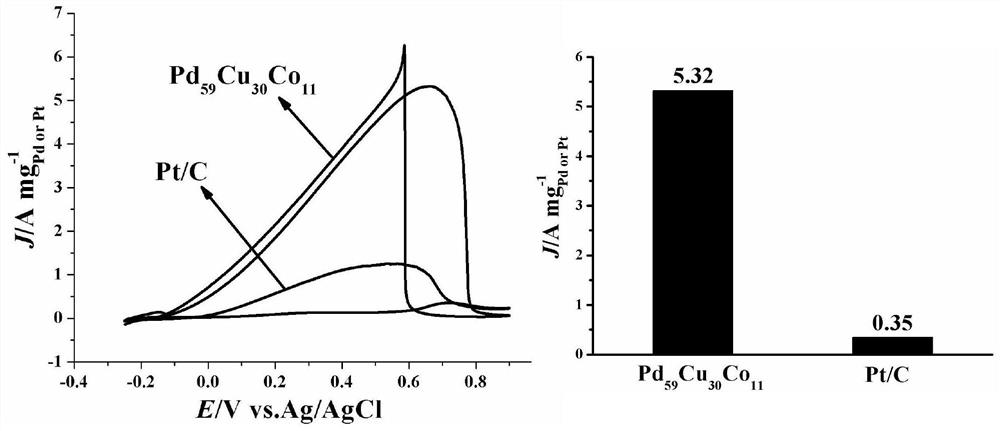

Non-platinum dendritic crystal-shaped ternary PdCuCo alloy nanometer catalyst used for fuel cell

ActiveCN108365233AExcellent alcohol toleranceUnified appearanceMaterial nanotechnologyCell electrodesNano catalystSynthesis methods

The invention discloses a synthesis method of a non-platinum dendritic crystal-shaped ternary PdCuCo alloy nanometer catalyst used for a fuel cell. The synthesis method comprises the following steps of (1) adding PVP with the mass of 10-200mg into an ethylene glycol solution, and performing stirring at the room temperature for about 10min until the solution is uniformly mixed; (2) adding metal precursor palladium salt, copper salt and cobalt salt into the solution obtained in the step (1), wherein the amount of the metal precursor is 0.01-0.04mol; and performing stirring for about 10min untilthe solution is uniformly mixed; (3) adding ammonium hydroxide into the solution obtained in the step (2), wherein the volume of ammonium hydroxide is 0.05-1mL; and performing stirring for about 10minuntil the solution is uniformly mixed; (4) transferring the solution obtained in the step (3) into a high-pressure reaction kettle to be reacted for 4-16h at the temperature of 120-180 DEG C; and (5)performing cooling on the product obtained in the step (4), and then carrying out washing, centrifuging and separating to obtain the non-platinum dendritic crystal-shaped ternary PdCuCo nanometer alloy.

Owner:GUIZHOU UNIV

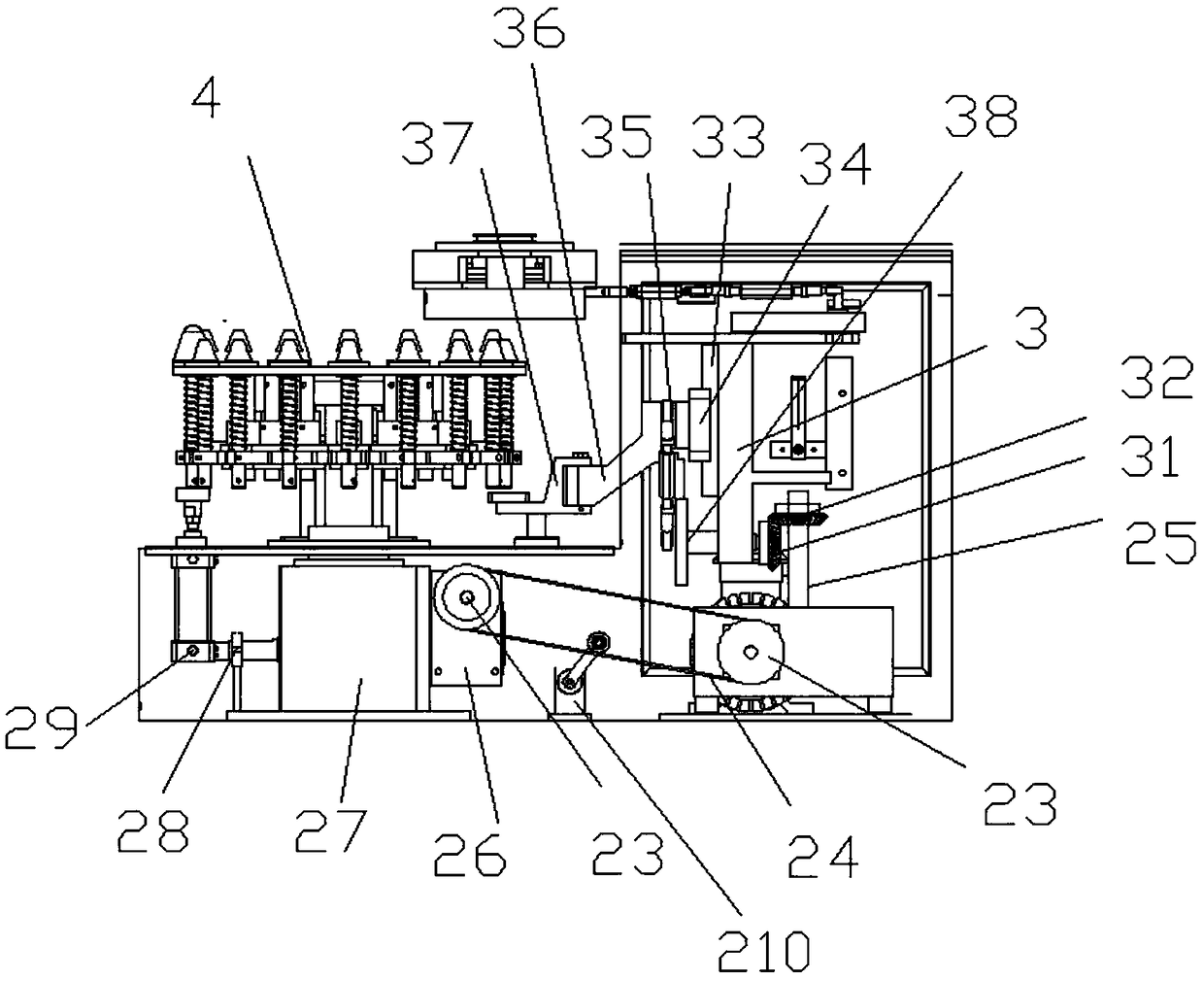

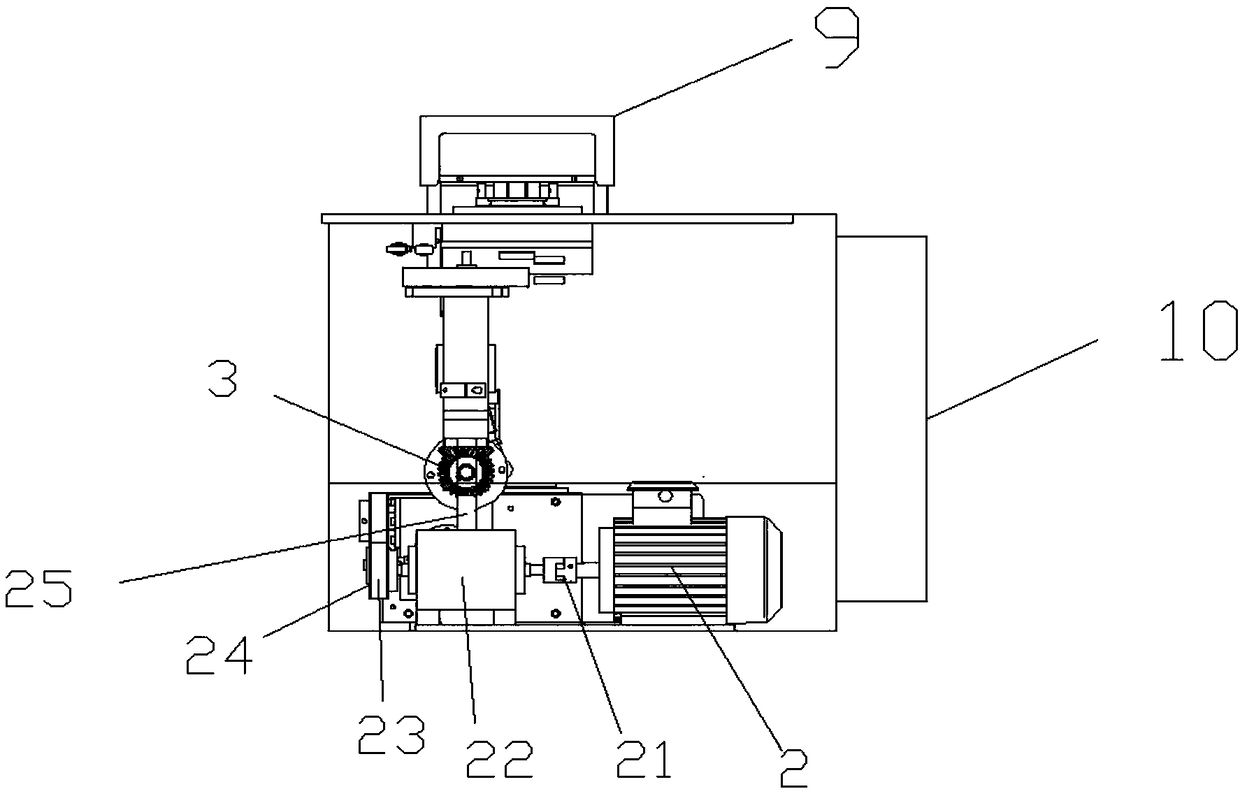

Rotary steamed corn bread processing and molding apparatus

ActiveCN108402119AUnified appearanceSmall size differenceDough shapingGlass productionMaterial resourcesCam

The invention discloses a rotary steamed corn bread processing and molding apparatus. The rotary steamed corn bread processing and molding apparatus comprises a shell, foot cups, big foot wheels, steamed corn bread moulds, a mould unloading assembly, a mould loading assembly, and a work box; a transmission device and the mould loading assembly are arranged in the shell, wherein the transmission device is composed of a motor, a coupling, a first reducer, a drive wheel, a conveyor belt, a first rotating shaft, a second reducer, a third reducer, a joint bearing, a cylinder, a tensioning device, atransmission frame, a first bevel gear, a second bevel gear, a slide rail, a slider, a connecting rod, a first connecting block, a cam assembly and a second rotating shaft; and a rotating device andthe mould unloading assembly are arranged on a surface of the shell. By adopting combined usage of the transmission device and the tensioning device, the rotary steamed corn bread processing and molding apparatus has improved production efficiency , so that, manpower and material resources can be effectively saved. The prepared steamed corn bread is uniform in appearance, and small in size difference; moreover, manual operation is avoided, so that, the steamed corn bread is green and pollution-free. And thus, safe and sanitary production of foods is further ensured, and the effect of automaticmass production is realized.

Owner:东莞市格特机械有限公司

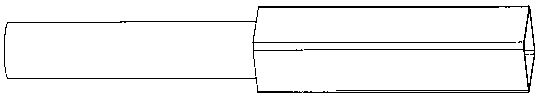

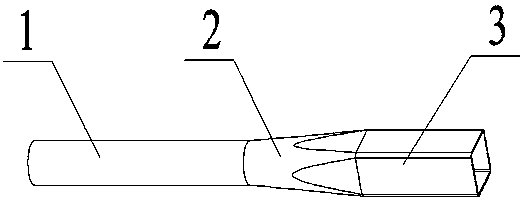

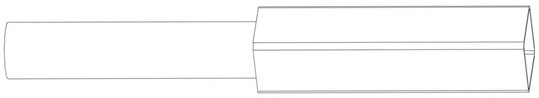

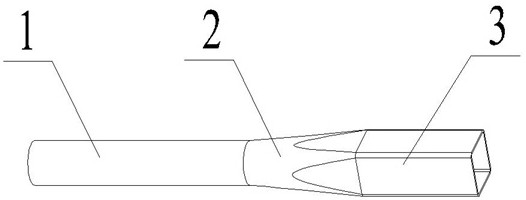

Circle-to-square gradual-change tube of turbulence generator and equipment

ActiveCN109706775AReduce eddy currentImprove uniformityMachine wet endHigh volume manufacturingEngineering

The invention provides a circle-to-square gradual-change tube of a turbulence generator. The circle-to-square gradual-change tube comprises a circular tube section, a transitional tube section and a polygonal tube section; the transitional tube section is connected with the circular tube section and polygonal tube sections which are respectively located at two sides; the section of the circular tube section is a circle, the section of the polygonal tube section is a polygon, and the section of the transitional tube section gradually varies from a polygon to a circle in a direction from the polygonal tube section to the circular tube section; the circular tube section, the transitional tube section and the polygonal tube section are of an integrally connected structure, wherein the polygonal tube section comprises, but is not limited to, a quadrangle, a pentagon and a hexagon. The circle-to-square gradual-change tube is prepared by using a hydraulic pipe contracting machine and at leasttwo sets of rolling pressing wheels. The size and the appearance of the circular-variable square tube are controlled by equipment, the size is uniform, simplicity and groups of rollers, and the sizeand appearance of the circular-variable square tube is controlled by equipment. The size is uniform, convenience and high efficiency are achieved, and the appearance is attractive. The diameter changing place is connected through the transitional section in a gradual-change mode, so that generation of vortex of a slurry flow is reduced, the uniformity degree of the slurry flow is improved, and theservice life is prolonged. The equipment has a simple structure, manufacturing is convenient, mass production can be realized, and cost is saved.

Owner:HENAN JIANGHE PAPER +1

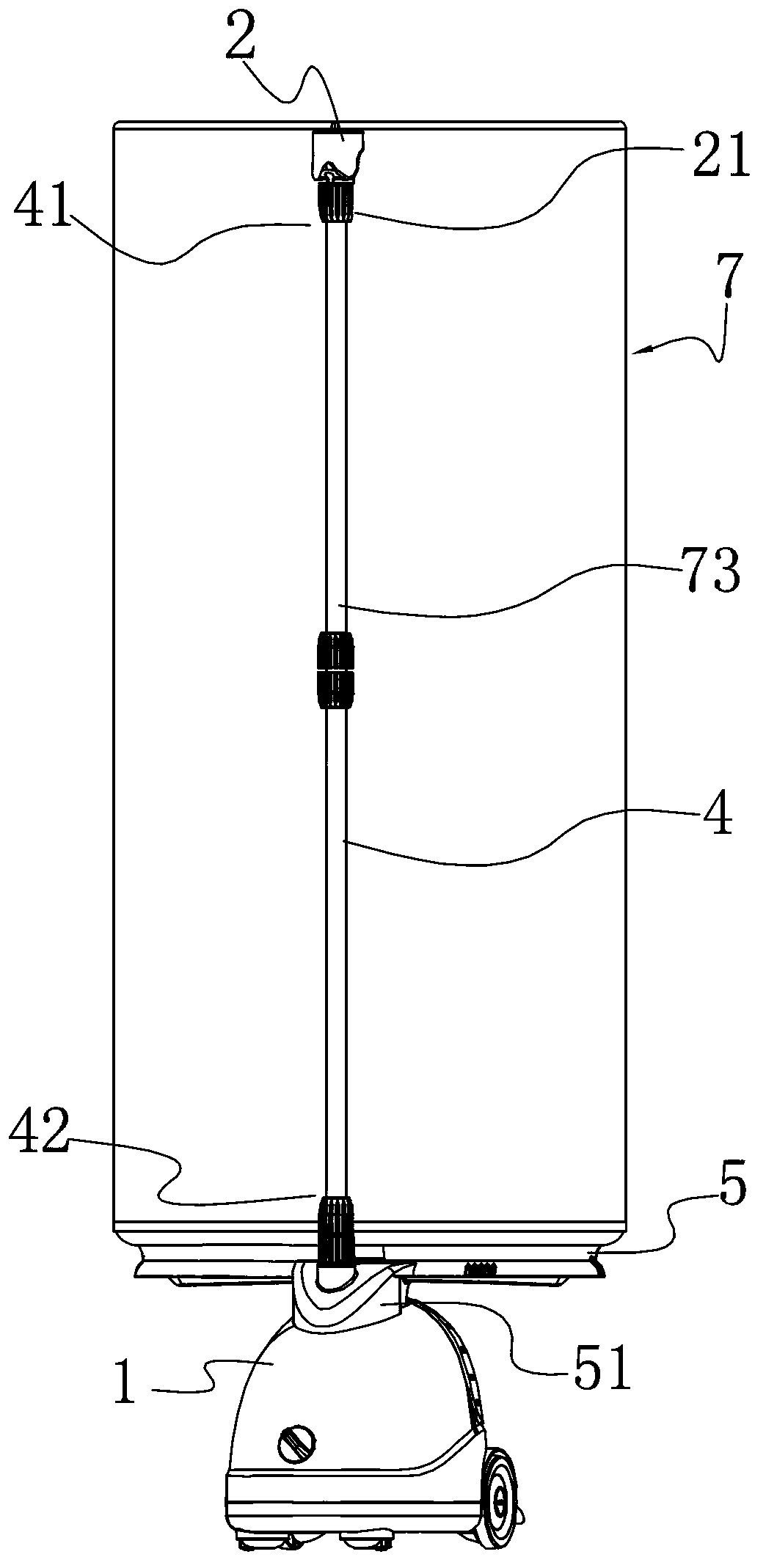

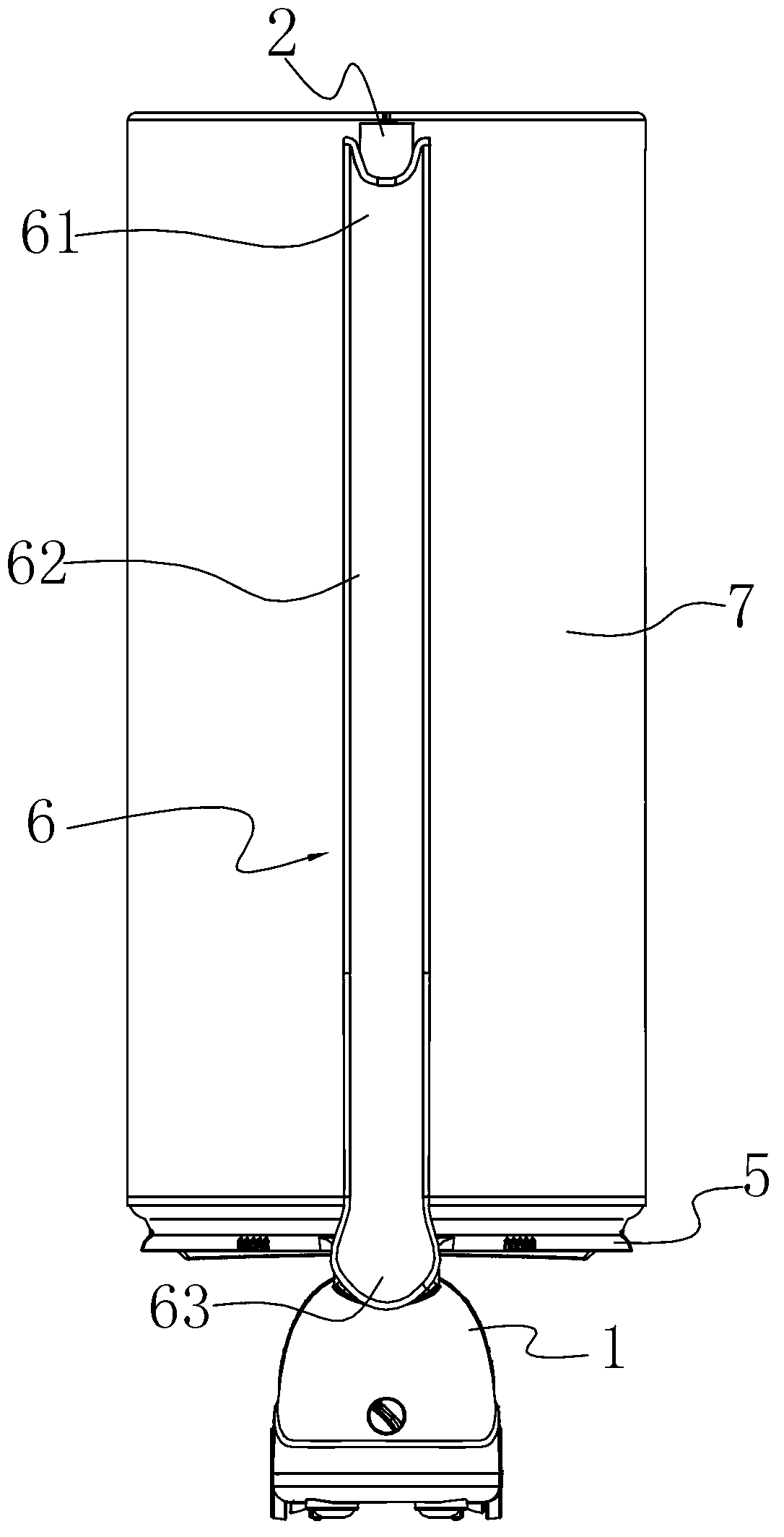

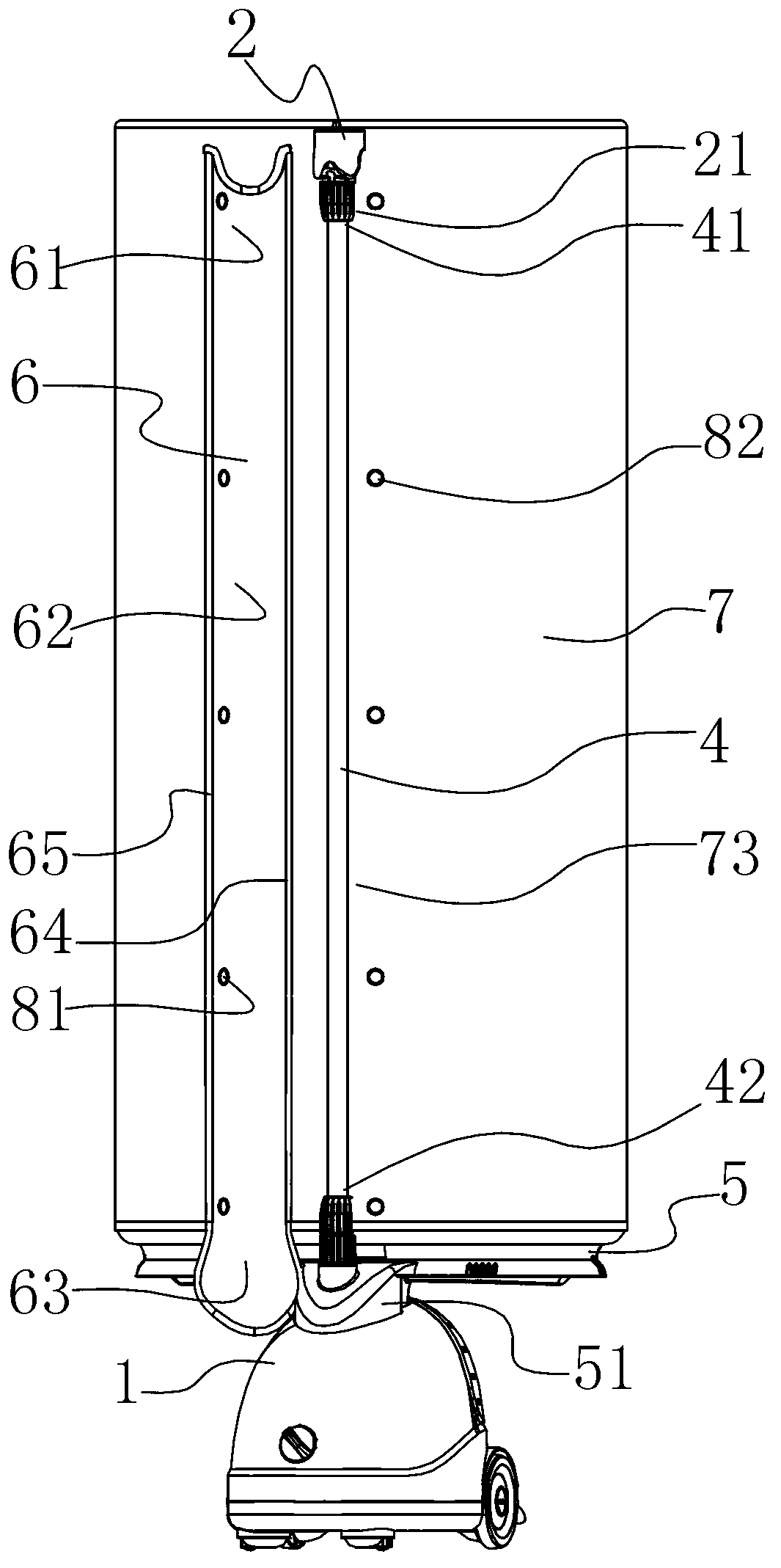

Side column type laundry dryer

ActiveCN103194878AUniform appearanceUnified appearanceTextiles and paperLaundry driersPulp and paper industryLaundry

A side column type laundry dryer comprises a base, an upright, a cloth cover positioned on one side of the upright, a drying frame part fixing portion positioned at the upper end of the upright, and an air outgoing disc fixing portion positioned at the lower end of the upright. The side column type laundry dryer is characterized in that an elongated cover piece longitudinally extending, the upper section of the cover piece covers the drying frame part fixing portion, the middle section of the cover piece covers the part of the upright, between the drying frame part fixing portion and the air outgoing disc fixing portion, the lower section of the cover piece covers the air outgoing disc fixing portion, and two lateral edges in the longitudinal direction of part of the cover piece are connected on the bonding sides of the cloth cover and the upright respectively. The cover piece is arranged on the outer side of the upright, so that the side column type laundry dryer is uniform in overall appearance posture, good in visual effect and higher in strength while attractiveness and compactness in appearance is guaranteed.

Owner:NINGBO JIMU ELECTRICAL APPLIANCE

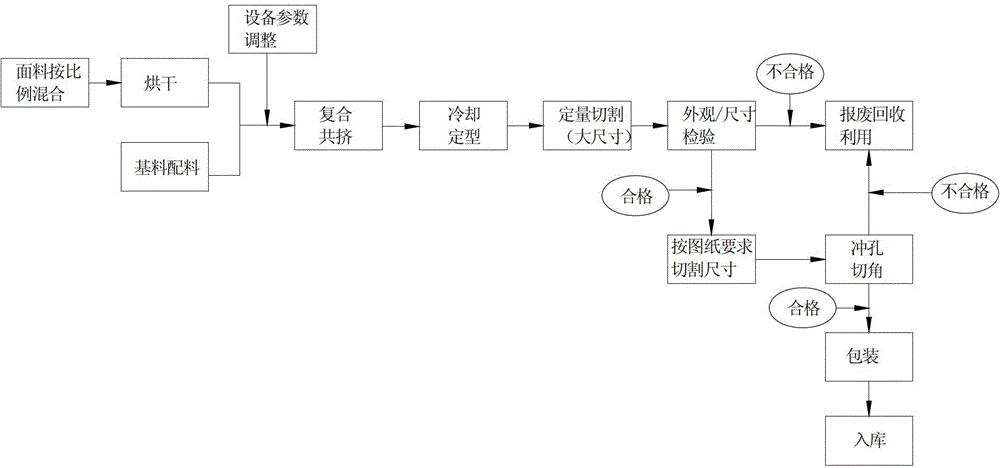

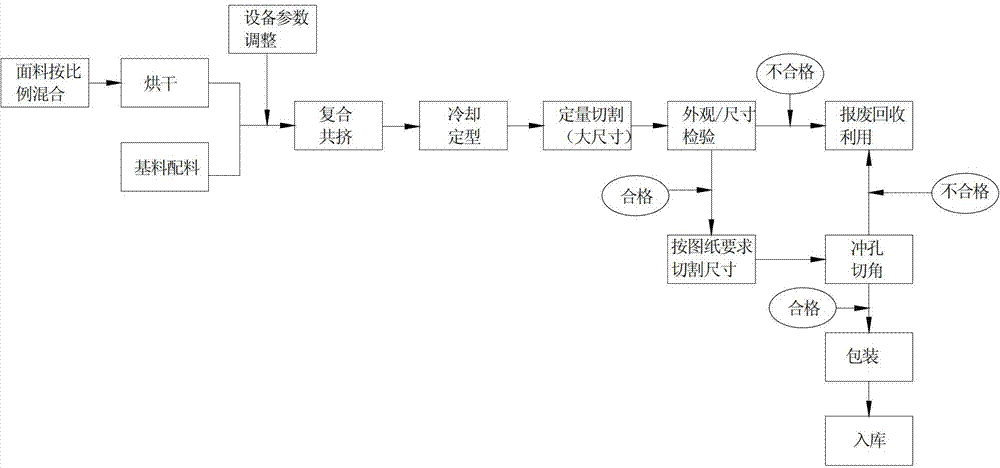

Plastic product as well as preparation method and refrigeration equipment thereof

ActiveCN103148664AConsistent appearanceUniform colorDomestic cooling apparatusLighting and heating apparatusSurface layerCo extrusion

The invention discloses a plastic product as well as a preparation method and a piece of refrigeration equipment thereof. The preparation method for the plastic product comprises the following steps that a plastic base stock and a surface layer base stock are molded in a co-extrusion way, so that the plastic base stock forms a body, and the surface layer base stock forms a surface layer, wherein the surfer layer is formed in at least a part of surface of the body. The plastic product is prepared by the method for preparing the plastic product, common formation of the body and the surface layer can be effectively realized, so that the technical problems of inconsistent product appearance, large color difference, low product percent of pass, low surface strength and easiness in scratches in the current preparation technology are solved successfully; and in addition, the preparation process is simple, the production cycle is short and the environment cannot be polluted.

Owner:HEFEI MIDEA REFRIGERATOR CO LTD

A method for preparing magnesium hydroxide by ammonia injection method

ActiveCN103101936BReduce manufacturing costReduce shipping costsMagnesium hydroxideMagnesium saltMagnesite

The invention discloses a method for preparing magnesium hydrate through ammonia spray method. The method comprises the following steps: by using caustic calcined magnesite and ammonium salt as raw materials, carrying out ammonia stilling reaction to obtain an ammonium and magnesium salt solution, wherein the ammonium and magnesium salt are contacted in a spray type reactor and magnesium hydrate precipitation reaction is performed, aging product mother liquor for a proper time, filtering, returning filtrate containing ammonium salt to an ammonia stilling system, washing and drying filter cake to obtain magnesium hydrate product with uniform particle shape and good dispersion state. The process disclosed by the invention is used for preparing magnesium hydrate through one-step reaction, is simple in operation step, mild in reaction condition, uniform in product particle shape, and the particle shape can be regulated by changing the reaction condition. The ammonium slat is circulated with the ammonia in the reaction process, the production cost is low, the pollution is less, and the scale production is realized, the product can be used as production raw material of high-pure magnesium oxide and inflaming retarding additive of polymer material.

Owner:YINGKOU YINGXIN CHEM TECH CO LTD

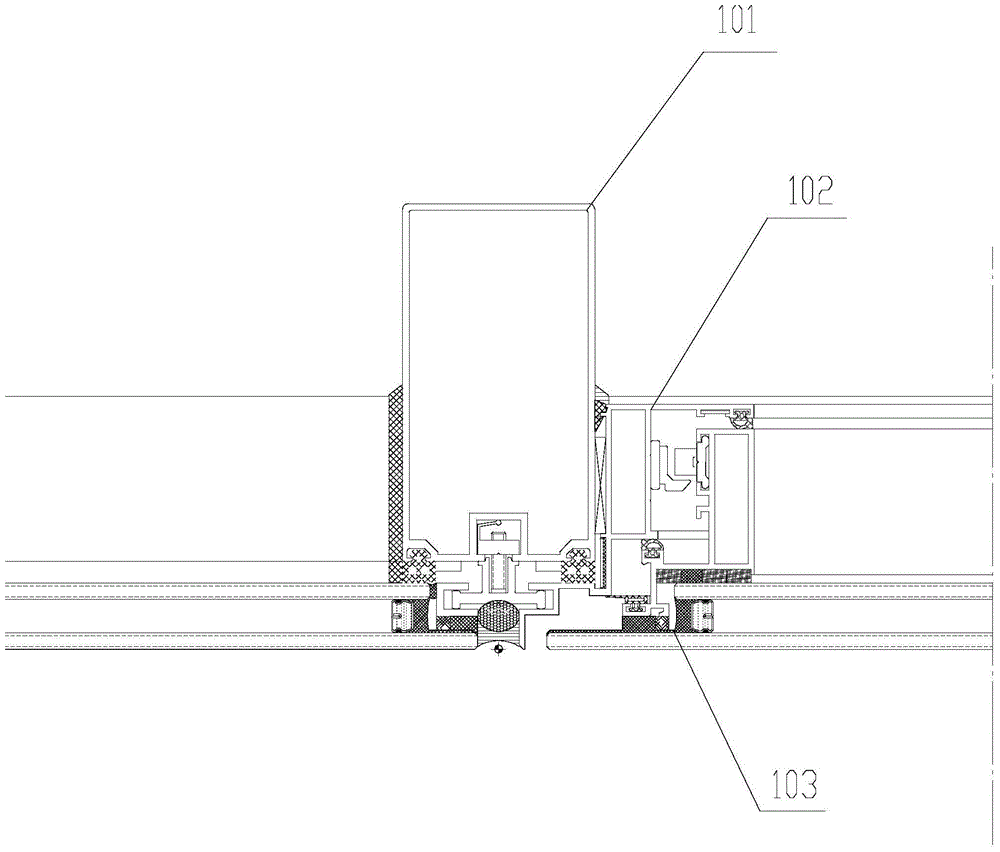

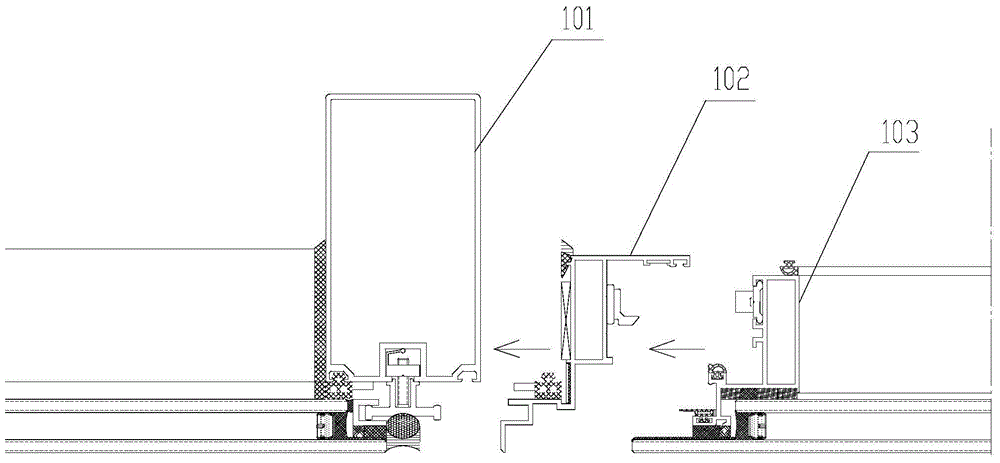

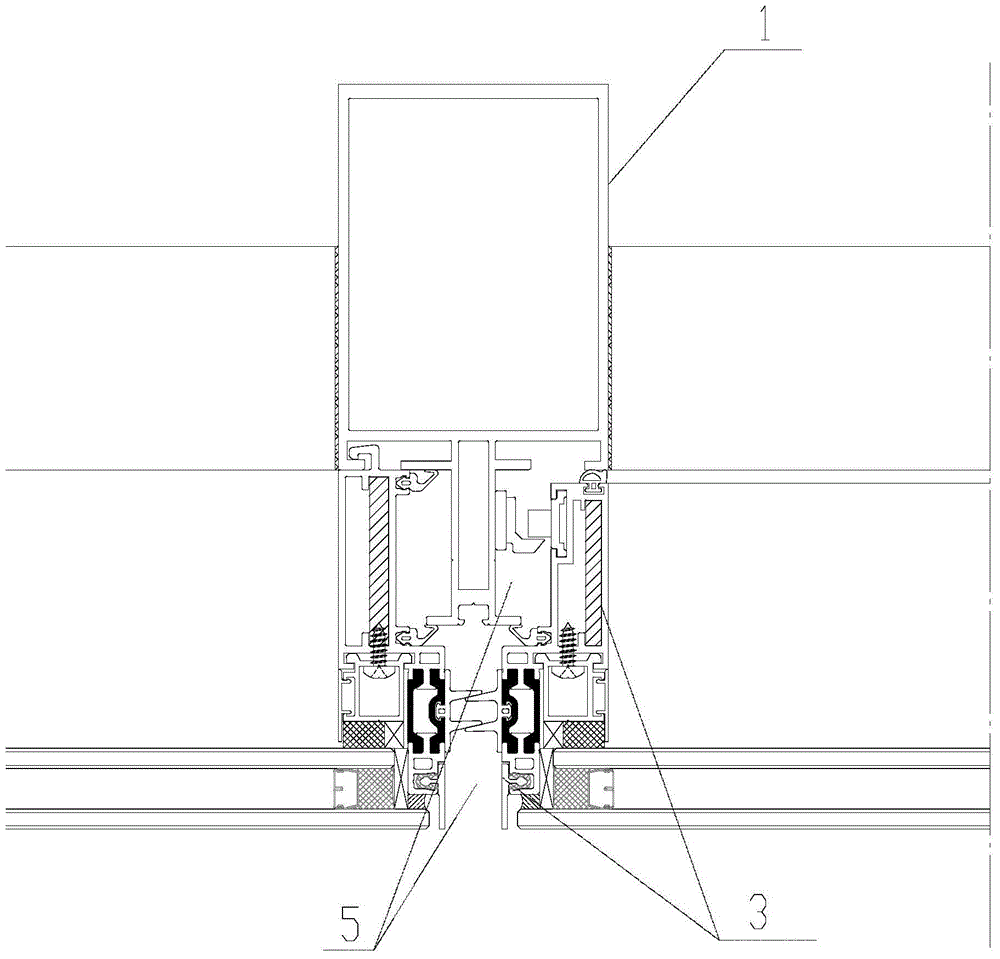

Opening window without window frame

InactiveCN105113921AUnified appearanceShorten the construction periodGlass wingsSealing arrangementsStructural engineering

The invention discloses an opening window without a window frame and relates to technical field of architectural engineering. The opening window without the window frame comprises vertical columns, a cross beam and a glass auxiliary frame, wherein bosses are arranged on the front surfaces of the vertical columns and the cross beam; lock seats are arranged on the side surfaces of the bosses; lock catches corresponding to the lock seats are arranged on the side surfaces of the glass auxiliary frame; the edge part of the glass auxiliary frame is positioned in front the vertical columns or the cross beam justly; and the width of the edge part of the glass auxiliary frame is smaller than the width of the vertical columns and the cross beam. For the opening window without the window frame, a window frame structure is eliminated, the opening window is directly connected with the glass auxiliary frame through bosses on the front surfaces of the cross beam and the vertical columns, and the orthographic projection of the edge of the glass auxiliary frame is overlapped with the vertical columns and the cross beam, so that an appearance effect of a curtain wall is uniform; in addition, since the window frame structure is eliminated, the construction period of the curtain wall is shortened and the cost is reduced.

Owner:SUZHOU GOLD MANTIS CURTAIN WALL CO LTD

Preparation method of laser controllable synthesis of monodisperse active metal nanoparticles

ActiveCN104014800BOvercoming size regulation problemsUnified appearanceSolubilityOleic Acid Triglyceride

Owner:TIANJIN UNIV

Plastic product as well as preparation method and refrigeration equipment thereof

ActiveCN103148664BConsistent appearanceUniform colorDomestic cooling apparatusLighting and heating apparatusSurface layerCo extrusion

The invention discloses a plastic product as well as a preparation method and a piece of refrigeration equipment thereof. The preparation method for the plastic product comprises the following steps that a plastic base stock and a surface layer base stock are molded in a co-extrusion way, so that the plastic base stock forms a body, and the surface layer base stock forms a surface layer, wherein the surfer layer is formed in at least a part of surface of the body. The plastic product is prepared by the method for preparing the plastic product, common formation of the body and the surface layer can be effectively realized, so that the technical problems of inconsistent product appearance, large color difference, low product percent of pass, low surface strength and easiness in scratches in the current preparation technology are solved successfully; and in addition, the preparation process is simple, the production cycle is short and the environment cannot be polluted.

Owner:HEFEI MIDEA REFRIGERATOR CO LTD

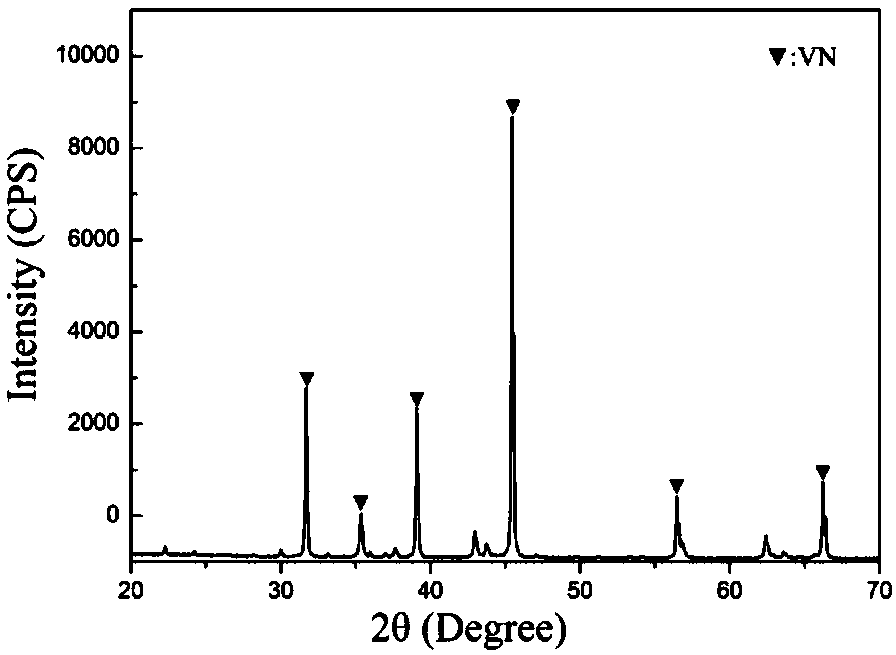

Low-temperature nitriding-based vanadium nitride powder and preparation method thereof

InactiveCN108569680ALow costSynthesis temperature is lowNitrogen-metal/silicon/boron binary compoundsNitrogen gasMechanical property

The invention relates to low-temperature nitriding-based vanadium nitride powder and a preparation method thereof. The preparation method is characerized in that the low-temperature nitriding-based vanadium nitride powder is prepared from aluminum powder, vanadium pentoxide powder and inorganic salt in a mass ratio of 1:(0.2-0.4):(0.7-0.9). The preparation method comprises the following steps: mixing the aluminum powder, the vanadium pentoxide powder and the inorganic salt to obtain a mixed powder; carrying out heat preservation on the mixed powder at a temperature of 700-900 DEG C for 1 to 3hours in a nitrogen atmosphere, and naturally cooling, so as to obtain a calcined product; and adding the calcined product to a hydrochloric acid solution, soaking for 1 to 2 hours, washing with distilled water for 3 to 5 times, and drying at 90-110 DEG C for 8 to 12 hours, so as to obtain the low-temperature nitriding-based vanadium nitride powder. The preparation method has the characteristics of simple process, short production cycle, low cost and low synthesis temperature. The low-temperature nitriding-based vanadium nitride powder has the advantages of high purity, high strength, good electrical conductivity and good corrosion resistance and mechanical properties.

Owner:WUHAN UNIV OF SCI & TECH

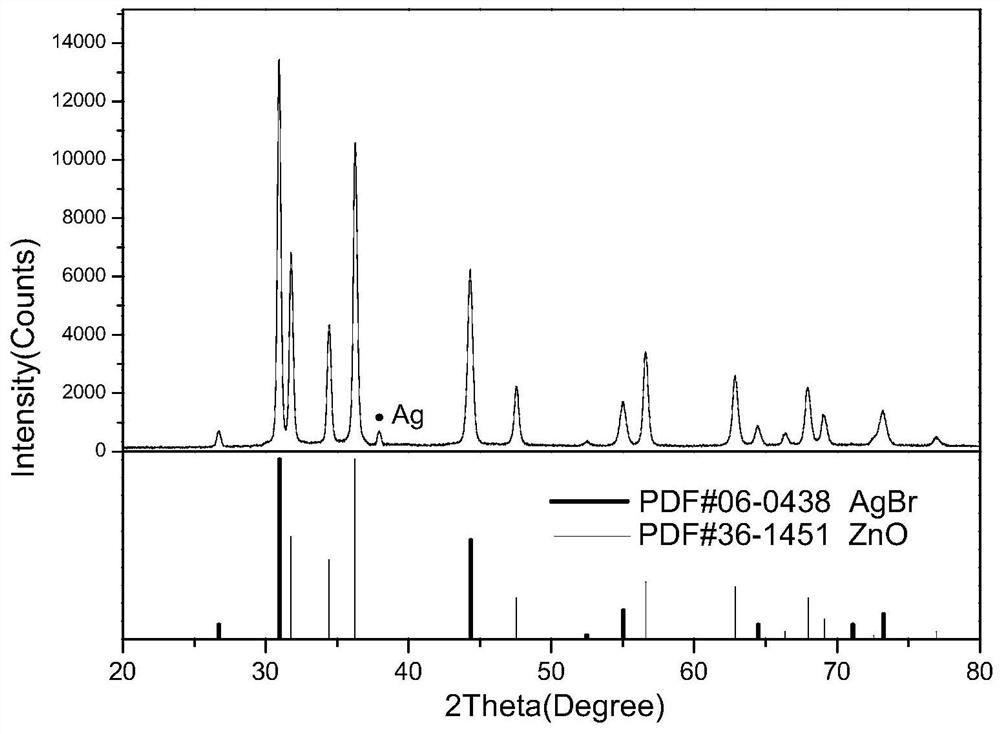

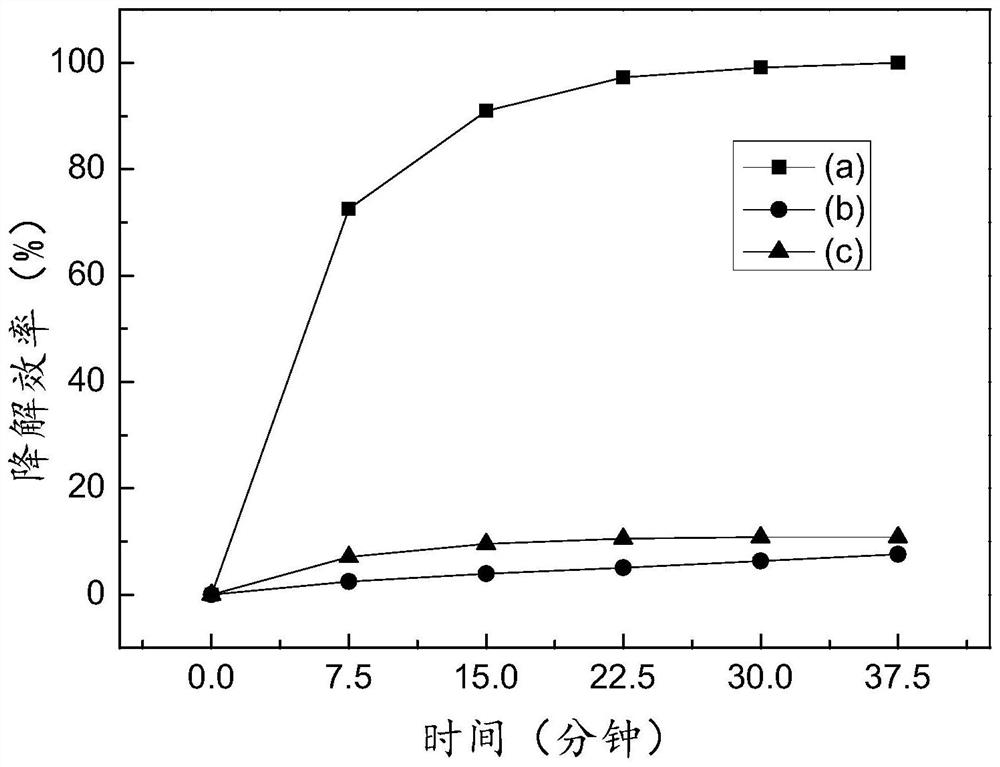

Preparation method of flower-like ag@agbr/zno photocatalytic material

ActiveCN110102322BUniform chemical compositionReduce manufacturing difficultyPhysical/chemical process catalystsHexamethylenetetramineActive agent

The invention discloses a preparation method of flower-like Ag@AgBr / ZnO photocatalytic material, and belongs to the field of nanomaterial preparation. The method adopts the following steps: 1) Configuring a certain concentration of surfactant and Zn source as a Zn source solution; Configuring a certain concentration of hexamethylenetetramine and Ag source as an Ag source solution; 2) Adding to the Ag source solution Add the oxidizing agent and add it dropwise to the Zn source solution at a certain rate; 3) Transfer the mixed solution to a high-pressure reactor, and perform a hydrothermal reaction at a certain temperature and for a certain time; 4) Wash the product with water, alcohol, and dry it Afterwards, it is calcined in air and cooled to room temperature to obtain a flower-like Ag@AgBr / ZnO photocatalytic material. The synthesis method adopted by the present invention has a simple process, easy operation and no secondary pollution. The synthesized photocatalytic material has the characteristics of uniform morphology and excellent performance. The work of the present invention belongs to the field of photocatalytic materials.

Owner:HARBIN UNIV OF COMMERCE

A kind of growth method of germanium quantum dot, germanium quantum dot composite material and application thereof

ActiveCN104377114BAchieve growthAvoid complicated cleaning proceduresSemiconductor/solid-state device manufacturingPhotovoltaic energy generationQuantum dotCvd graphene

The present invention relates to a method for growth of germanium quantum dots. In the method, germanium quantum dots are grown on graphene interfaces with different quantities of layers. In the present invention, ultra-high uniformity graphene interfaces are introduced on a conventional substrate surface, Ge quantum dots are grown on the interfaces, and complicated cleaning processes for obtaining high-quality interfaces are avoided, and process flows are simplified; in addition, the low-matrix element content and the low defect rate of the germanium quantum dots are ensured, a self-organization growth process of the germanium quantum dots is ensured, and germanium quantum dots with good shape and uniformity are formed.

Owner:THE NAT CENT FOR NANOSCI & TECH NCNST OF CHINA

A non-platinum, dendritic ternary PDCUCO alloy nanocatalyst for fuel cells

ActiveCN108365233BExcellent alcohol toleranceUnified appearanceMaterial nanotechnologyCell electrodesPtru catalystMetallurgy

The invention discloses a synthesis method of a non-platinum dendritic crystal-shaped ternary PdCuCo alloy nanometer catalyst used for a fuel cell. The synthesis method comprises the following steps of (1) adding PVP with the mass of 10-200mg into an ethylene glycol solution, and performing stirring at the room temperature for about 10min until the solution is uniformly mixed; (2) adding metal precursor palladium salt, copper salt and cobalt salt into the solution obtained in the step (1), wherein the amount of the metal precursor is 0.01-0.04mol; and performing stirring for about 10min untilthe solution is uniformly mixed; (3) adding ammonium hydroxide into the solution obtained in the step (2), wherein the volume of ammonium hydroxide is 0.05-1mL; and performing stirring for about 10minuntil the solution is uniformly mixed; (4) transferring the solution obtained in the step (3) into a high-pressure reaction kettle to be reacted for 4-16h at the temperature of 120-180 DEG C; and (5)performing cooling on the product obtained in the step (4), and then carrying out washing, centrifuging and separating to obtain the non-platinum dendritic crystal-shaped ternary PdCuCo nanometer alloy.

Owner:GUIZHOU UNIV

A turbulent flow generator circular to square gradient tube and its preparation method and equipment

ActiveCN109706775BReduce eddy currentImprove uniformityMachine wet endHigh volume manufacturingTriacontagon

The invention provides a circle-to-square gradual-change tube of a turbulence generator. The circle-to-square gradual-change tube comprises a circular tube section, a transitional tube section and a polygonal tube section; the transitional tube section is connected with the circular tube section and polygonal tube sections which are respectively located at two sides; the section of the circular tube section is a circle, the section of the polygonal tube section is a polygon, and the section of the transitional tube section gradually varies from a polygon to a circle in a direction from the polygonal tube section to the circular tube section; the circular tube section, the transitional tube section and the polygonal tube section are of an integrally connected structure, wherein the polygonal tube section comprises, but is not limited to, a quadrangle, a pentagon and a hexagon. The circle-to-square gradual-change tube is prepared by using a hydraulic pipe contracting machine and at leasttwo sets of rolling pressing wheels. The size and the appearance of the circular-variable square tube are controlled by equipment, the size is uniform, simplicity and groups of rollers, and the sizeand appearance of the circular-variable square tube is controlled by equipment. The size is uniform, convenience and high efficiency are achieved, and the appearance is attractive. The diameter changing place is connected through the transitional section in a gradual-change mode, so that generation of vortex of a slurry flow is reduced, the uniformity degree of the slurry flow is improved, and theservice life is prolonged. The equipment has a simple structure, manufacturing is convenient, mass production can be realized, and cost is saved.

Owner:HENAN JIANGHE PAPER +1

A kind of sub-2nm ruthenium (ru) nanowire network and preparation method thereof

InactiveCN105798325BControl shapeUnified appearanceMaterial nanotechnologyTransportation and packagingNanowireMass ratio

The invention discloses a sub-2nm ruthenium (Ru) nanowire network and a synthesis method thereof. The mass ratio to the reducing agent is 1:2 to 2:1; the amount of water added needs to completely dissolve the surfactant and the reducing agent; (2) Add the metal ruthenium salt precursor solution to the mixed solution obtained in step (1) , the ratio of the added water to the ruthenium precursor solution is 5:1~10:1; the concentration of the ruthenium metal precursor is 0.05~0.5mol / L; stir at room temperature for 1~3 minutes; (3) the step (2) obtained Transfer the mixed solution to an autoclave to react for 12-30 hours, the temperature is controlled at 150-200°C; (4) Wash the product obtained in step (3) after cooling, and obtain a sub-2nm Ru nanowire after centrifugation network.

Owner:GUIZHOU UNIV

A method for large-area growth of zinc oxide micron walls

InactiveCN102719886BUnified appearanceFlat surfacePolycrystalline material growthLiquid-phase epitaxial-layer growthCrazingPhysical chemistry

Owner:DALIAN NATIONALITIES UNIVERSITY

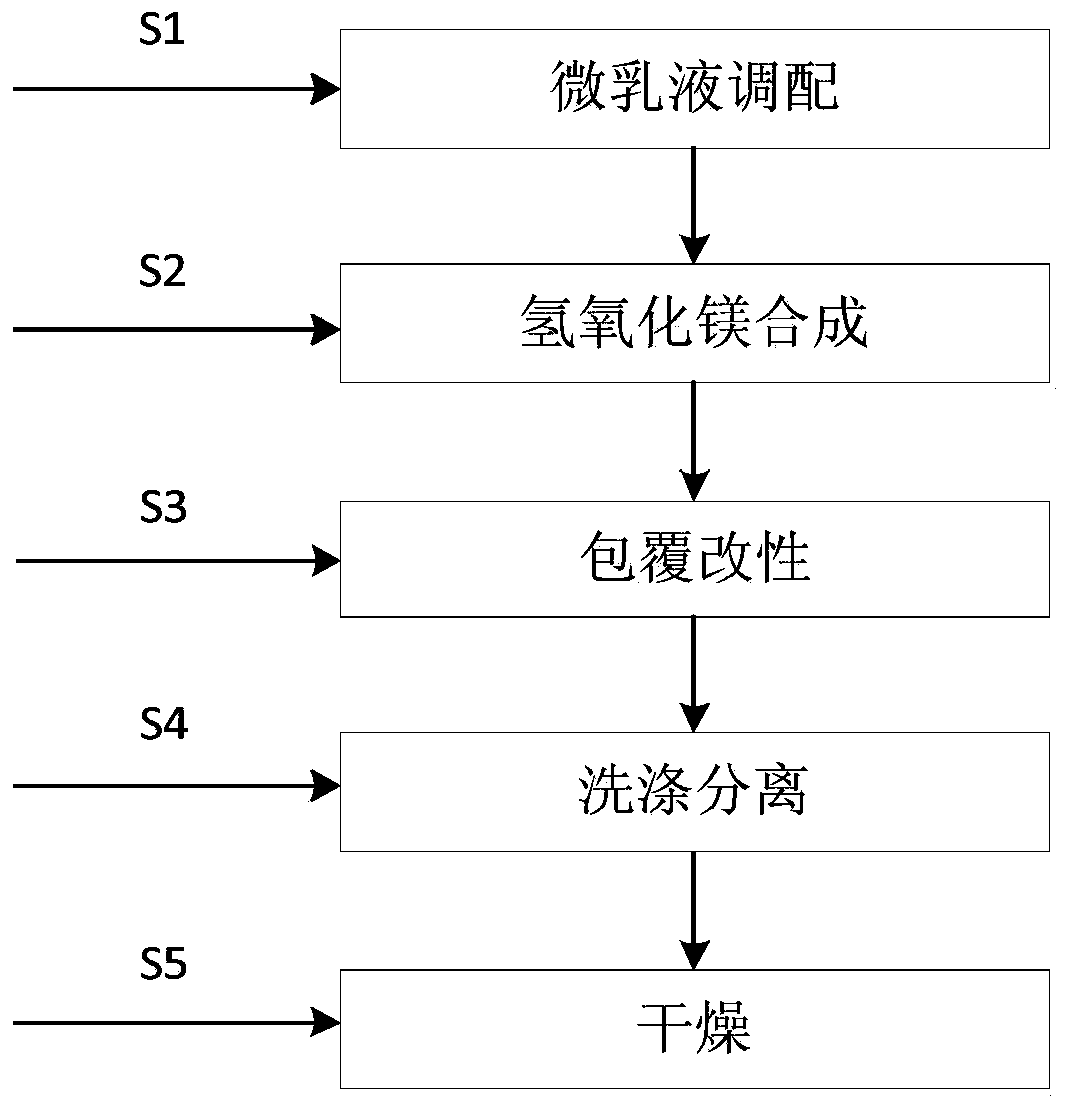

A kind of preparation and modification method of magnesium hydroxide flame retardant

ActiveCN107722355BGood application effectUnified appearanceMagnesium hydroxideMagnesium saltDistilled water

The invention discloses a preparation and modification method of a magnesium hydroxide flame retardant. The technical steps comprise micro-emulsion blending, magnesium hydroxide synthesis, coating modification, washing separation and drying. The preparation method comprises the following steps: preparing an W / O type microemulsion by using an oil phase containing a polymer monomer, a surfactant, asoluble magnesium salt and a cosurfactant, adding an alkaline precipitant under stirring for a precipitation reaction, performing aging after the reaction, performing centrifugal separation on the obtained mixed solution, separately washing the obtained precipitate after the centrifugal separation with ethanol and distilled water, and finally performing drying to obtain the magnesium hydroxide. According to the method, the ''water core'' of the microemulsion is used as a magnesium hydroxide reactor, the polymer monomer in the microemulsion oil phase is used as a coating modifying matrix, and the preparation and the modification of magnesium hydroxide are synchronously realized. The operation is simple; the obtained magnesium hydroxide has a nano partical size, and is uniformly dispersed; the surface is oleophylic; and the magnesium hydroxide flame retardant has good application potential.

Owner:自然资源部天津海水淡化与综合利用研究所

Aluminum hydroxide and preparation method thereof

ActiveCN113233487ASingle crystal formUnified appearanceAluminium oxide/hydroxide preparationAluminium oxides/hydroxidesChemical industryChemistry

The invention provides an aluminum hydroxide and a preparation method thereof, belong to the field of material chemical industry. The preparation method of the aluminum hydroxide comprises the following steps: mixing sodium alkoxide, water and an aluminum material to obtain a second solution, and carrying out aluminum-water reaction at the temperature of 40-100 DEG C to obtain the aluminum hydroxide. The preparation method can be used for preparing the aluminum hydroxide which is relatively uniform in morphology and has a crystal form of gibbsite.

Owner:上海交通大学包头材料研究院 +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com