Side column type laundry dryer

A dryer and side column technology, which is applied in the field of side column dryers, can solve the problems of different materials and colors, inconsistent shapes, and poor visual aesthetics, so as to achieve a beautiful appearance and a more beautiful appearance. Uniform, concise intensity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

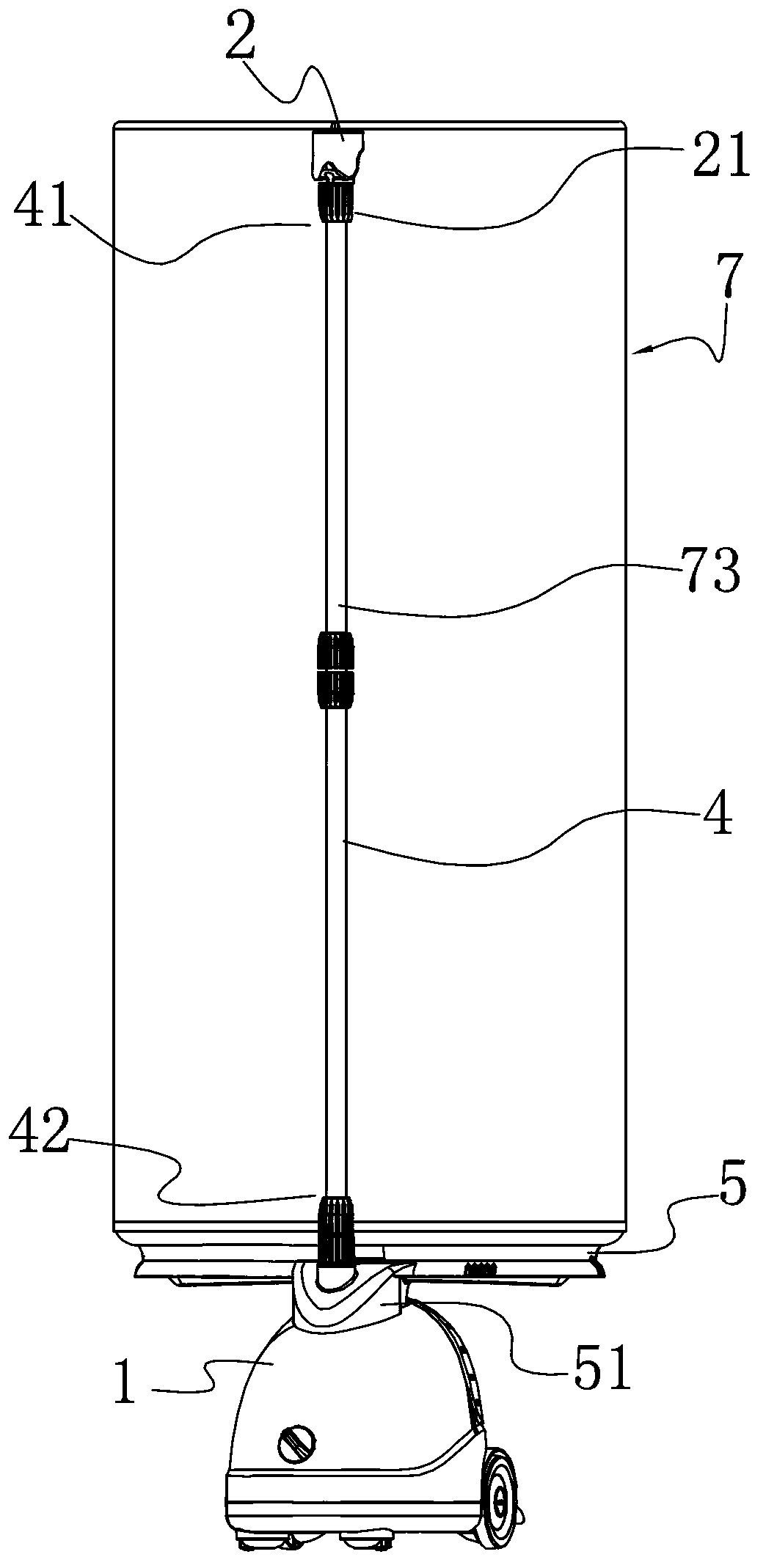

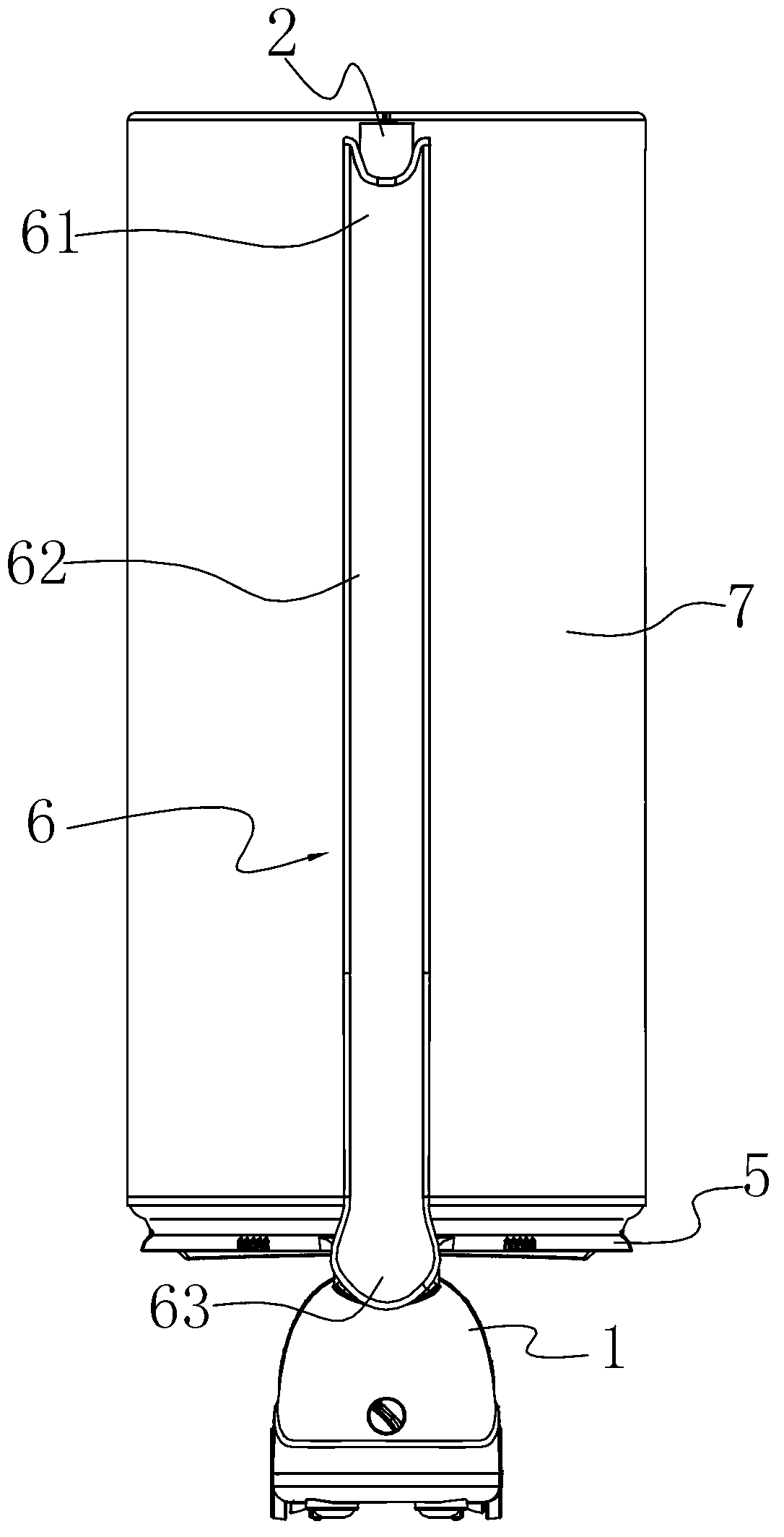

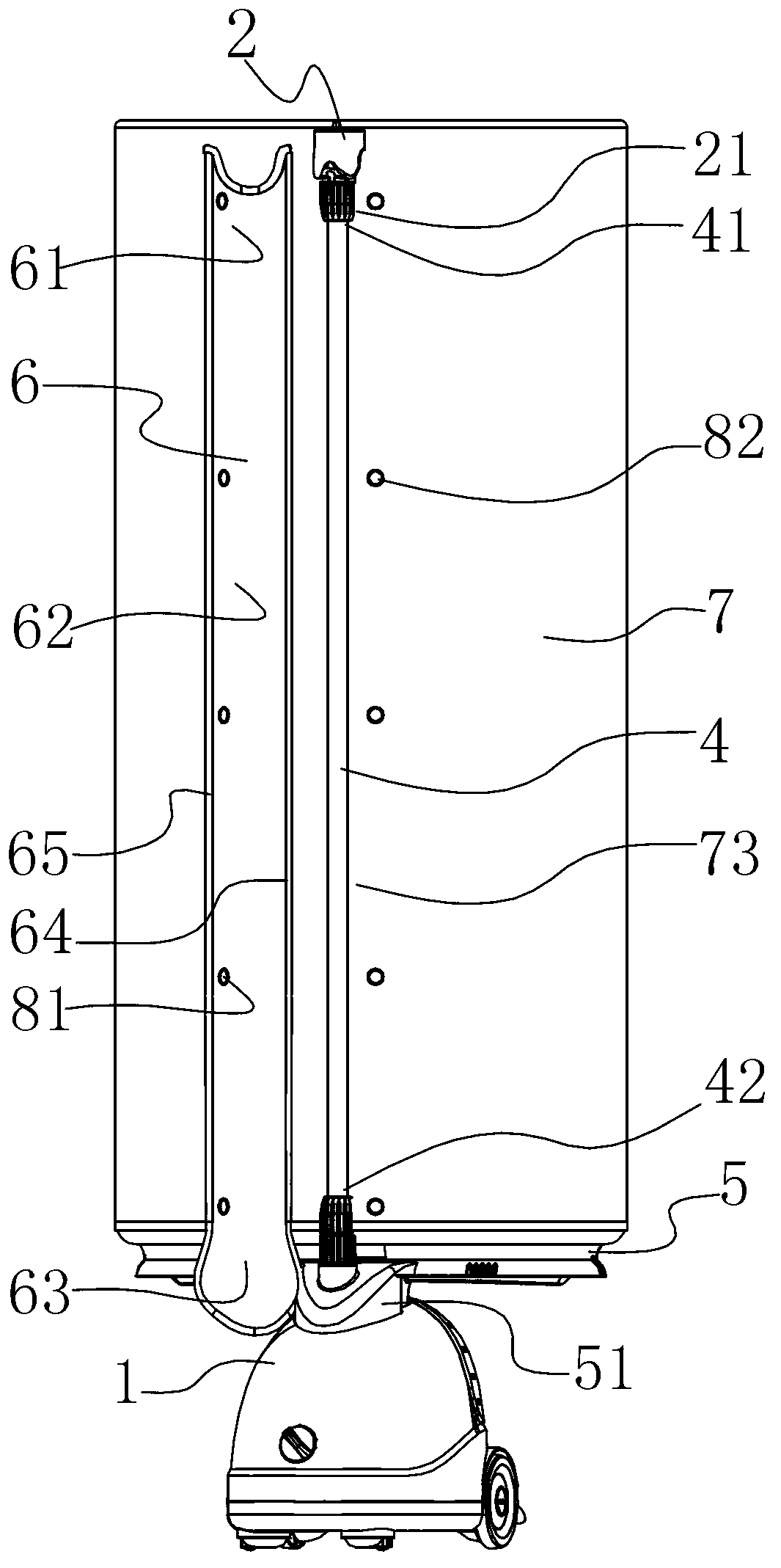

[0027] Such as Figure 1A , 1B As shown, this clothes dryer is assembled by frame part and cloth cover 7. The frame part includes a base 1, a column 4 whose lower end 42 is fixed on the base, a drying rack component 2 fixed on the upper end 41 of the column through the drying rack component fixing part 21, and an air outlet plate fixed on the lower end of the column through the air outlet disc fixing part 51 5; The upper end surface of the cloth cover 7 is supported on the drying frame part 2, and the lower end surface is closed on the air outlet tray 5. After packing together like this, the column 4 of section between the fixed part 21 of the drying rack part and the fixed part 51 of the air outlet tray 5 is exposed outside the cloth cover 7, and one side of the column 4 is close to the cloth cover 7 back side. The upper section 61 of a cover sheet 6 covers the fixing part 21 of the drying rack part, the middle section 62 covers the column 4 of the section between the fixing...

no. 2 example

[0033] Such as image 3 As shown, different from the above-mentioned first embodiment, the cover sheet 6 includes an outer ring portion 66 and an inner ring portion 67 extending longitudinally, the inner ring portion 67 is located in the middle, and the outer ring portion 66 is located in the inner ring part 67 on both sides. The longitudinal strip-shaped inner ring portion 66 extends from the upper section 61 to the lower section 63 through the middle section 62 , but does not extend to the bottom end of the cover sheet 6 . That is to say, the cover sheet 6 is divided into three strips in the longitudinal direction except the bottom end, the middle one is the inner ring portion 66 , and the other two on both sides are the outer ring portion 67 .

[0034] The advantage of such a structure is that the outer ring portion 67 can use a fabric that is more conducive to the fixing of the female button 81 than the inner ring portion 66. For example, the density of the fabric is rela...

no. 3 example

[0037] The difference from the second embodiment is that, optionally, all or part of the material of the cover sheet 6 is made of see-through material, so as to form a see-through window. Such as Figure 4A As shown, the inner ring portion 66 of the cover sheet 6 adopts a see-through material, and the inner ring portion 66 forms a see-through window 68, through which the operator can clearly know the specific positions of each component, which is beneficial to the oven through the cover sheet 6. The operation inside the clothes machine is of course also conducive to quickly and accurately opening the snap button at the position to be operated, so as to operate the inside. For example, when the column 4 is composed of multiple stretchable short pipes, the operator can clearly see the fixed connections between the short pipes at a glance, and can quickly and conveniently operate the corresponding fixed connections to adjust the height of the dryer. So the role of the perspectiv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com