Full-automatic frying and tofu skin coiling all-in-one machine

A fully automatic, all-in-one technology, used in oil/fat roasting, roasting, roasting workshops, etc., can solve the problems of many defective products, low production efficiency, large difference in taste, etc., to achieve uniform appearance and quality, save labor Cost, better molding effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] In order to make the above-mentioned features and advantages of the present invention more comprehensible, the following specific embodiments will be described in detail with reference to the accompanying drawings.

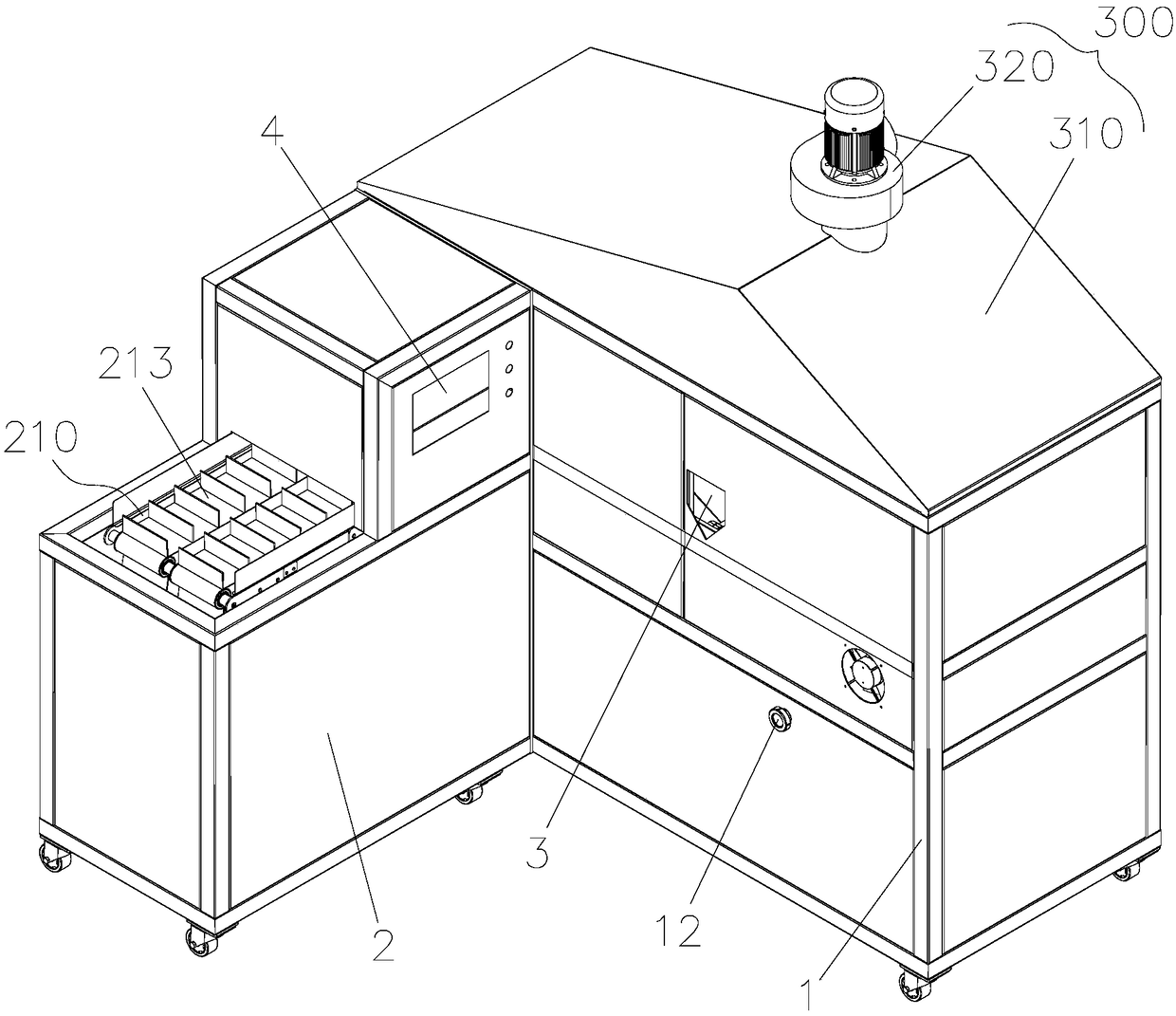

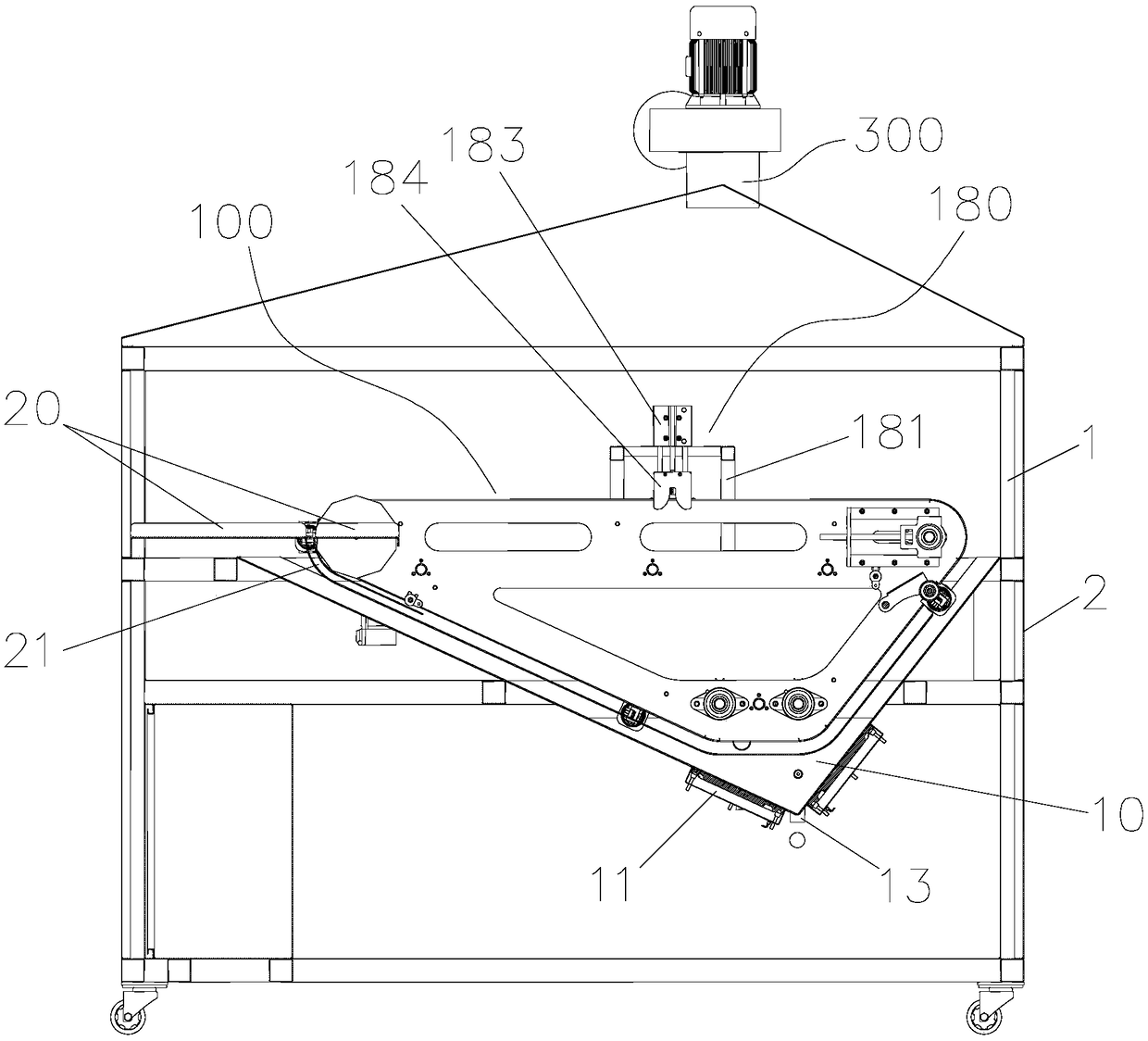

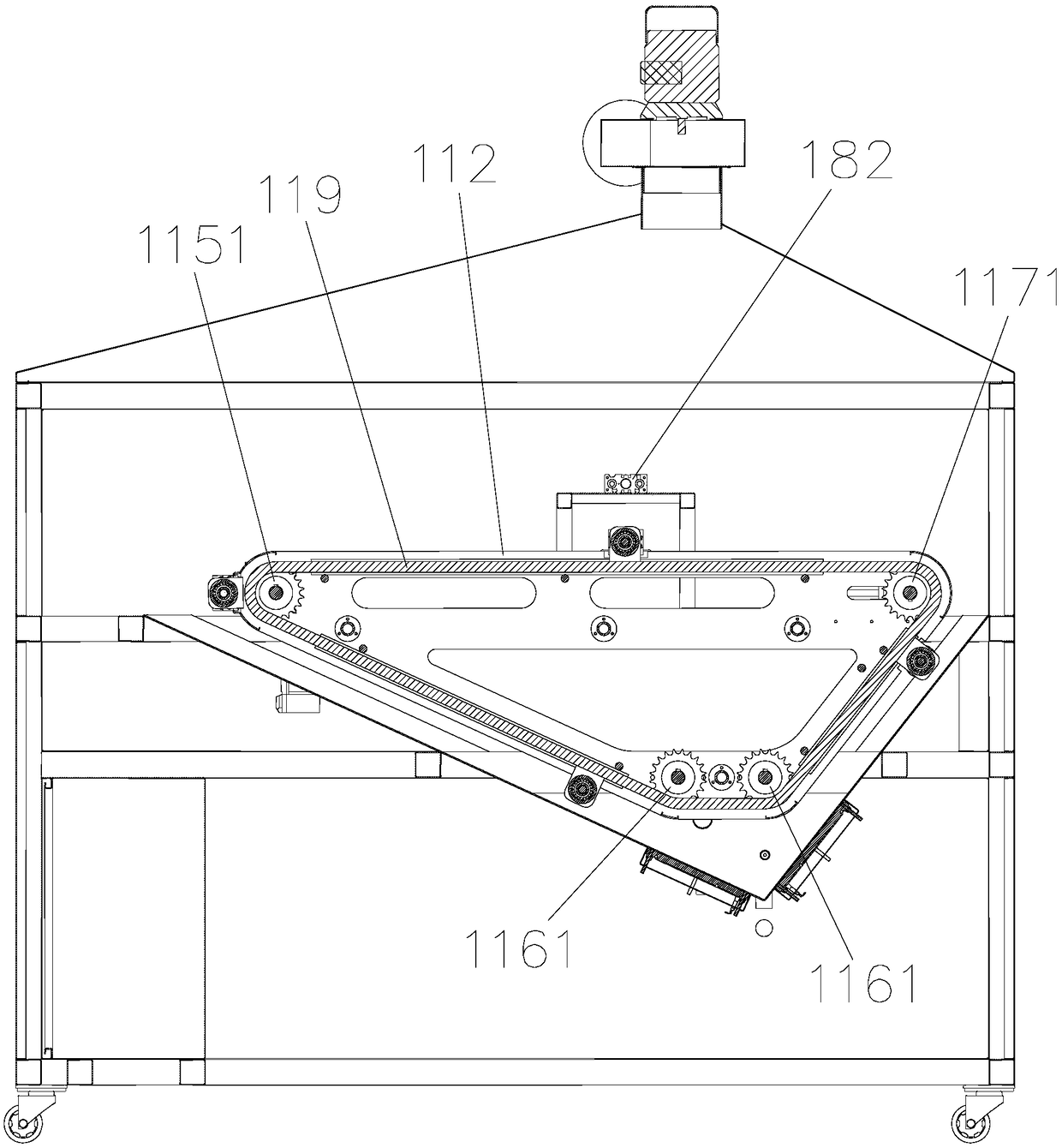

[0030] Such as Figure 1~13 Shown, a kind of fully automatic deep-frying wrapper all-in-one machine comprises frame 1, and described frame 1 is installed with frying tank body 10 and is positioned at frying device 100 in frying tank body 10, and described frying tank body 100 The device 100 includes a first belt conveying mechanism 110, a skin clamping mobile driving mechanism 120, a roll skin rotating drive mechanism 130, a roll skin pressing wheel 140 and a demoulding mobile driving mechanism 150, and the first belt conveying mechanism 110 includes a first Conveying support 111 and first conveyer belt 112, described first conveying support 111 is fixed on the frame 1, and the outer surface of described first conveyer belt 112 is provided with the manipula...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com