Method for growing large-area zinc oxide micron wall

A zinc oxide micron, growth solution technology, applied in chemical instruments and methods, zinc oxide/zinc hydroxide, single crystal growth, etc., can solve the problems of high production cost, complex preparation process, low product purity, etc., and achieves easy operation. , the preparation process is simple, the effect of high purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] 1. The preparation method of ultra-long zinc oxide micron wall:

[0030] 1. First, clean the GaN-on-Si substrate with cracks and dry it for later use.

[0031] 2. Accurately weigh 50mM hexamethylenetetramine (0.7009g) and zinc acetate (1.0975g) with an electronic balance, and put them into a beaker. Then add 100ml of deionized water, stir quickly and evenly.

[0032] 3. Put the gallium nitride substrate in step 1 into the beaker in step 2, wrap the mouth of the beaker with tinfoil, put it in a water bath, and start heating. Set the final heating temperature to 90°C and heat at a constant temperature for 30min.

[0033] 4. After the reaction, the substrate was repeatedly rinsed with deionized water to remove excess ammonium salts and ions, and dried for characterization.

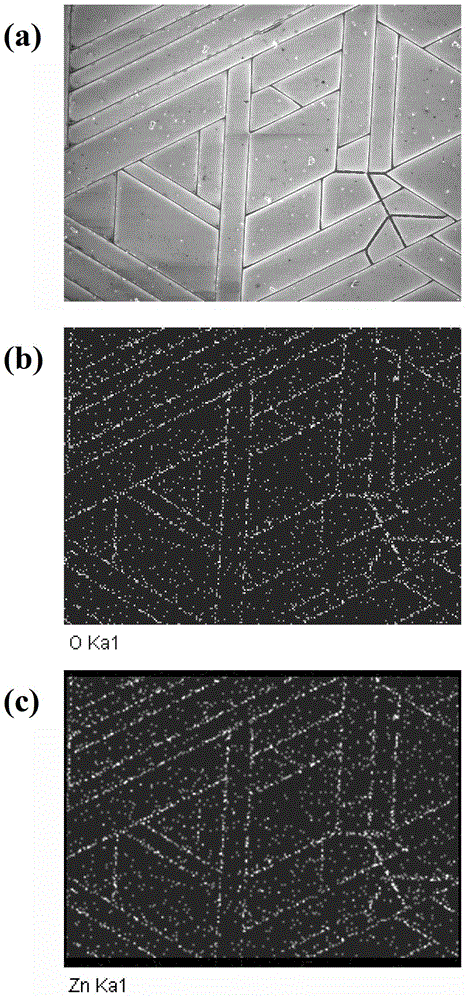

[0034] For the materials grown in the above embodiments, the scanning electron microscope (SEM) and energy spectrum element surface distribution are used for analysis, and the present invention will...

Embodiment 2

[0039] The steps of this example are the same as those of Example 1, except that the reaction time in Example 1 is changed.

[0040] In this example, hexamethylenetetramine and zinc acetate were 50 mM, namely 0.7009 g and 1.0975 g, respectively, and were dissolved in 100 ml of deionized water. In the present embodiment, the reaction time of constant temperature heating in a water bath is 90min.

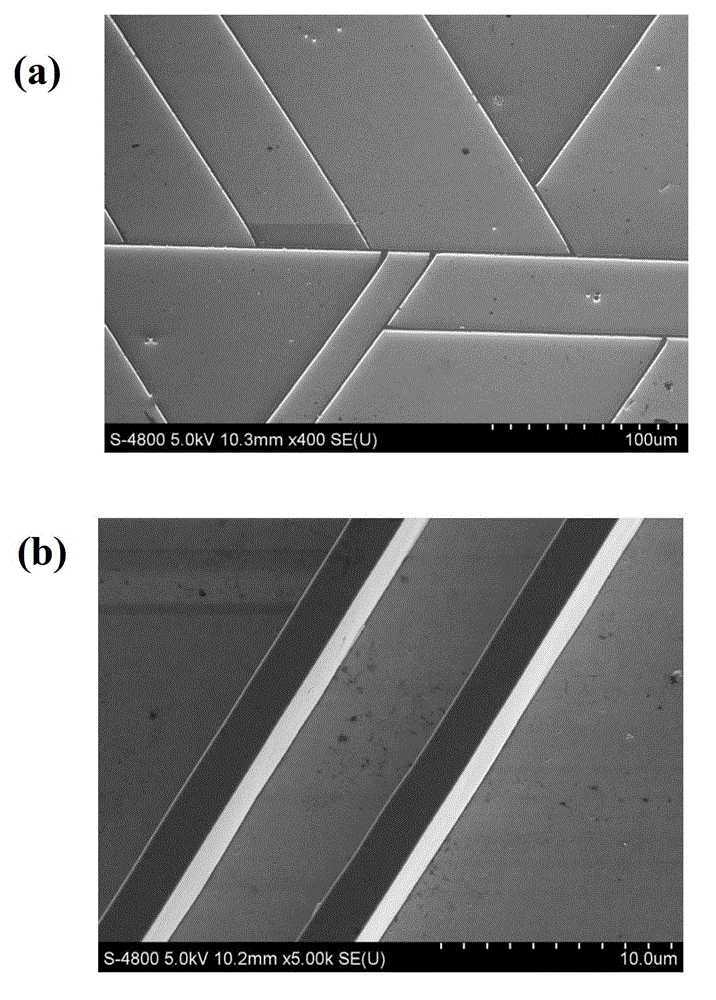

[0041] See attached image 3 , Prepare the surface topography figure of sample by the method described in example 2. image 3 (a) is a scanning electron microscope low-magnification image of the ultra-long zinc oxide micro-wall prepared in Example 2 of the present invention, and the sample is at a certain inclination angle. It can be seen from the figure that the product morphology is uniform and orderly, all along the direction of the crack grows to hundreds of microns in length. image 3 (b) is a high-magnification image of the scanning electron microscope of the zinc oxide micro...

Embodiment 3

[0043] The steps of this embodiment are the same as those of Examples 1 and 2, except that the amounts and reaction times of the two reactants in Examples 1 and 2 have been changed. The hexamethylenetetramine and zinc acetate in this example were 30 mM, namely 0.4205 g and 0.6585 g, respectively, and were dissolved in 100 ml of deionized water. The medium water bath of the present embodiment was heated at a constant temperature for 90min.

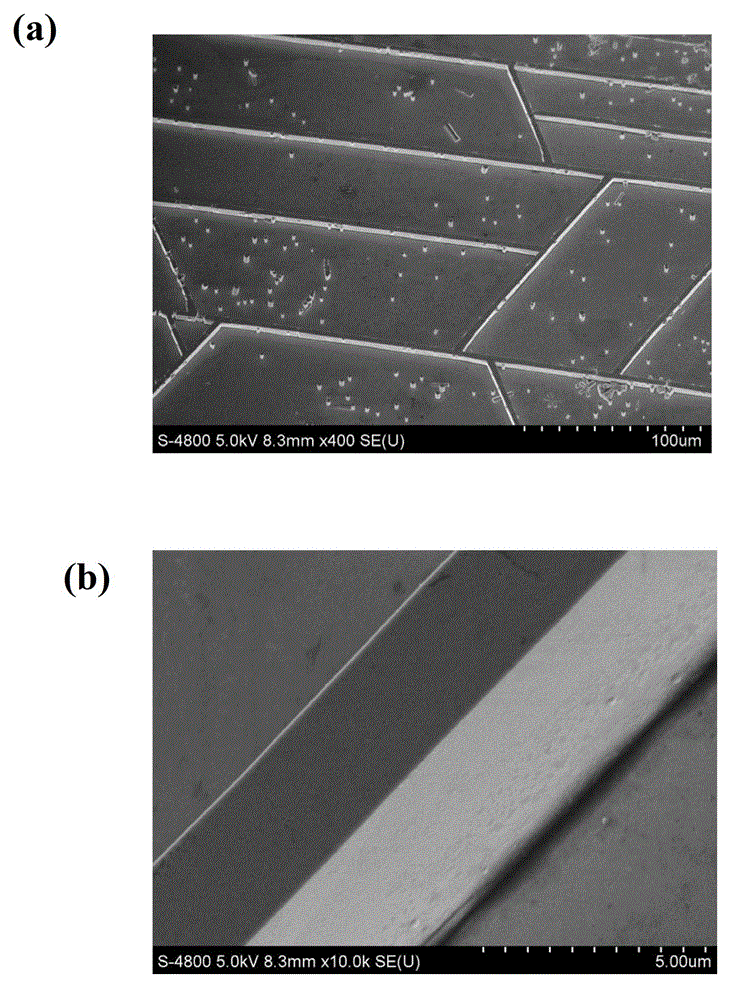

[0044] See attached Figure 4 , Prepare the surface topography figure of the sample according to the method described in example 3. Figure 4 (a) is a low-magnification image of the scanning electron microscope of the zinc oxide micro-wall prepared in Example 1 of the present invention. It can be seen from the figure that the product has a uniform appearance, a longer length, and a higher aspect ratio. Figure 4 (b) is a scanning electron microscope high-magnification image of the ultra-long zinc oxide micro-wall prepared in Example 1 of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com