Aluminum hydroxide and preparation method thereof

A technology of aluminum hydroxide and preparation steps, applied in the field of material chemical industry, can solve the problems of difficulty in preparing aluminum hydroxide, and the morphology of aluminum hydroxide particles is not single, and achieve the effect of uniform morphology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

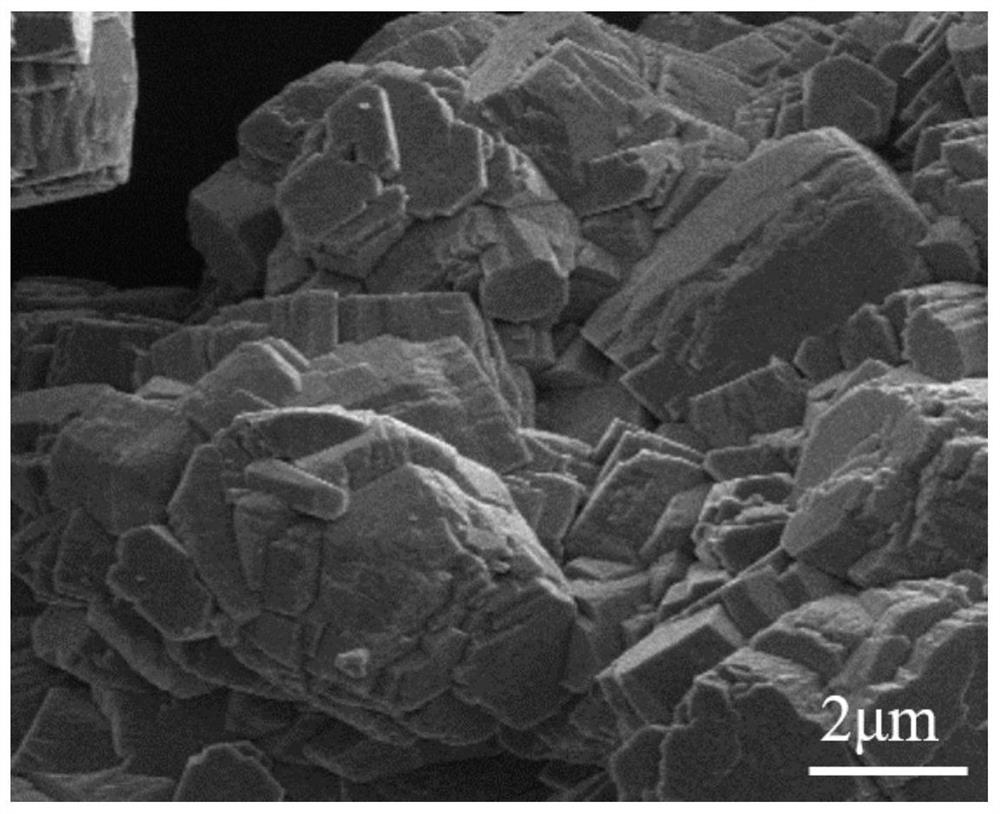

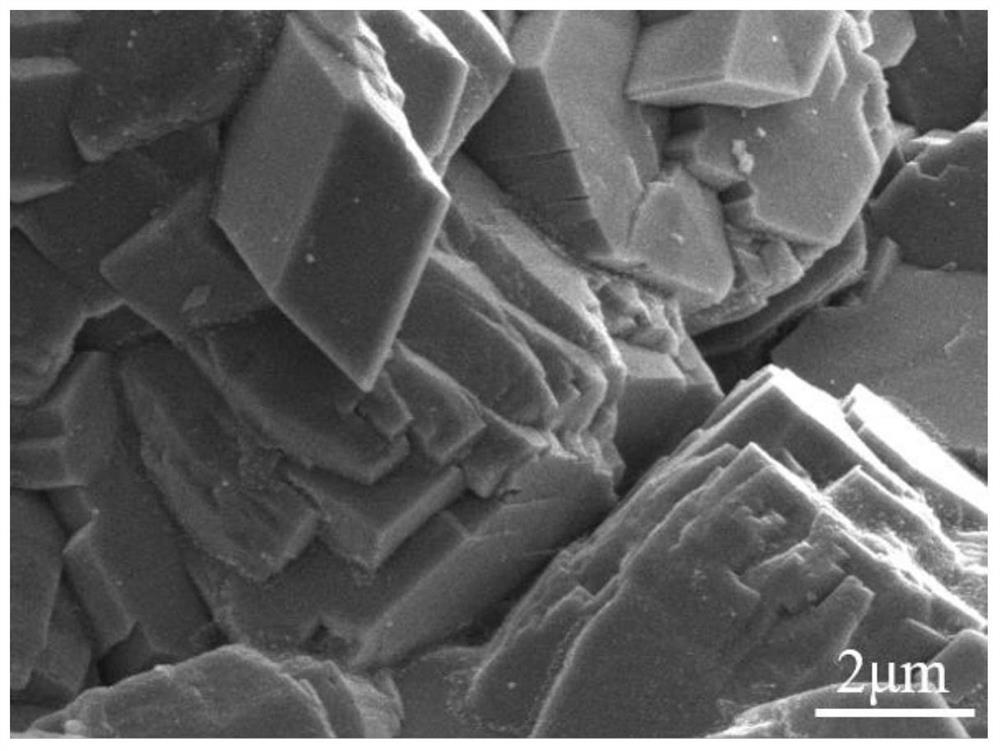

[0030] At present, there are many preparation methods for hydroxide, and the industrial is mainly based on Bayer, sintering, and hydrothermal. Among them, the amount of aluminum hydroxide prepared by Bayer is high, large particle size, and aluminum hydroxide particles are not single. For the process of adding a metal catalyst in some aluminum water reactions, the addition of a metal catalyst is inevitably brought into some metal impurities, thereby affecting the purity of the product, and has an effect on its morphology control.

[0031] The present application example provides aluminum hydroxide and preparation thereof, which can be prepared, and aluminum hydroxide of three hydrolyzine stone is prepared.

Embodiment 1

[0063] This embodiment provides a method of preparation of aluminum hydroxide, and its preparation steps include:

[0064] Methanol sodium was added to water to mix the first solution, and the purity of 99.99% was added to the first solution in the first solution to stir the second solution at a stirring rate of 800 r / min, and heated to 80 ° C for 4 hours to obtain a product Solution. Among them, the molar ratio of sodium methoxide with the aluminum foil is 1: 1, the liquid solid ratio of the first solution and the aluminum foil is 5: 1.

[0065] The product solution was filtered off, and the aluminum hydroxide was filtered over, and the filtered aluminum hydroxide was dried 10 times, then dried under temperature conditions at 80 ° C to give aluminum hydroxide.

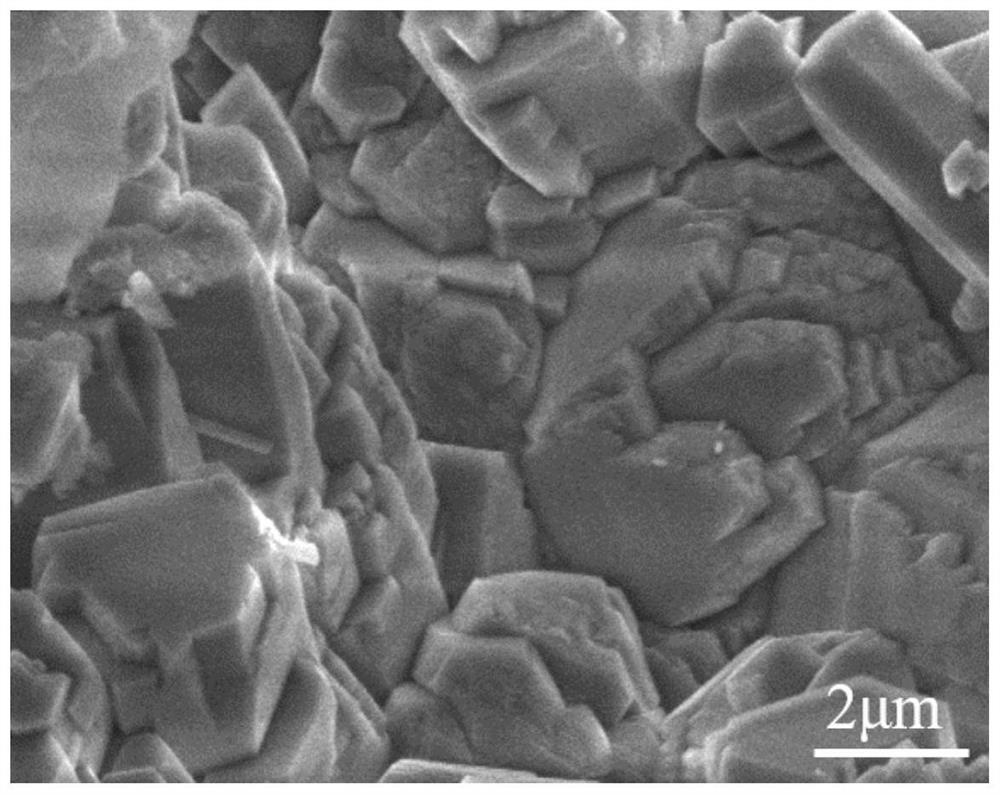

Embodiment 2

[0067] This embodiment provides a method of preparation of aluminum hydroxide, and its preparation steps include:

[0068] Methanol sodium was added to water to mix the first solution, and the purity of 99.99% was added to the first solution in the first solution to stir the second solution at a stirring rate of 800 r / min, and heated to 80 ° C for 4 hours to obtain a product Solution. Among them, the molar ratio of sodium methoxide and the aluminum foil is 20: 1, the liquid solid ratio of the first solution and the aluminum foil is 40: 1.

[0069] The product solution was filtered off, and the aluminum hydroxide was filtered over, and the filtered aluminum hydroxide was dried 10 times, then dried under temperature conditions at 80 ° C to give aluminum hydroxide.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com