Method for preparing nickel hydroxide electrode material of supercapacitor

A supercapacitor, nickel hydroxide technology, applied in capacitor electrodes, capacitors, electrolytic capacitors and other directions, can solve the problems of complex process, harmful substances in waste liquid, difficult to treat waste liquid, etc., and achieve simple preparation method, long cycle life, high The effect of specific capacitance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

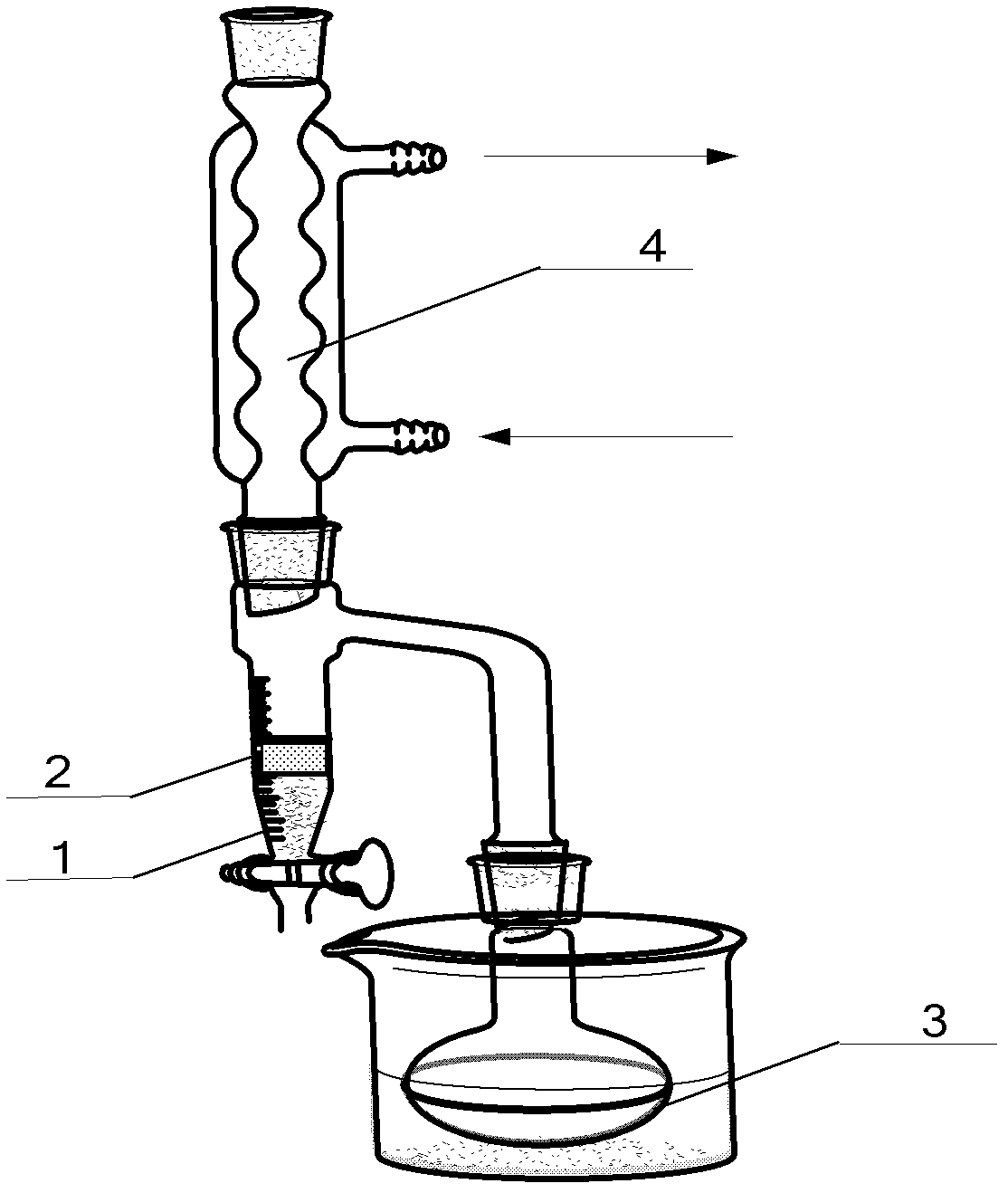

[0020] Sodium hydroxide was used as precipitant and nickel sulfate hexahydrate was used as precursor. The thickness of the quartz sand in the isolation dilution area is 2cm. A temperature of 115° C. was selected by controlling the heating temperature of the main reaction chamber.

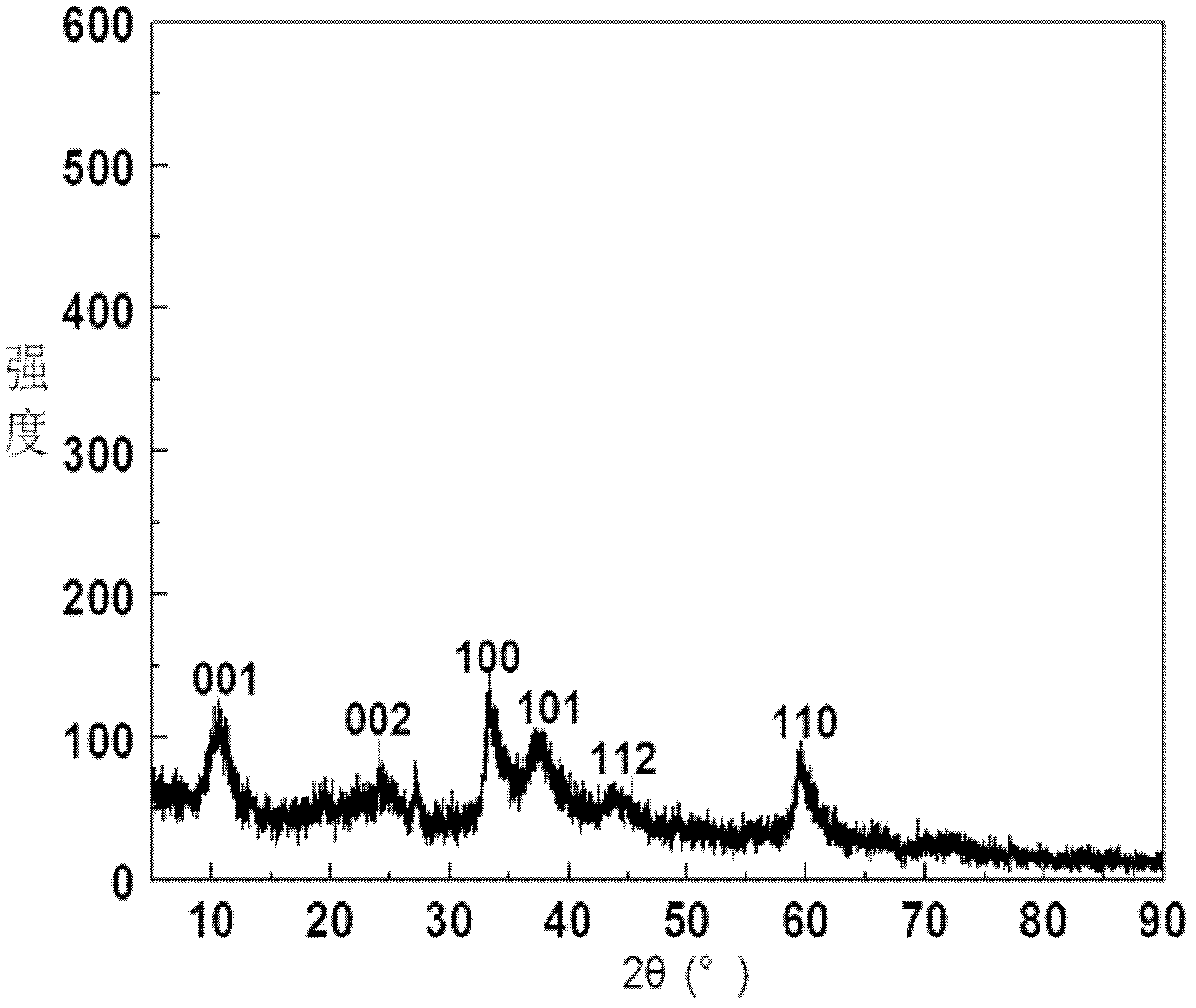

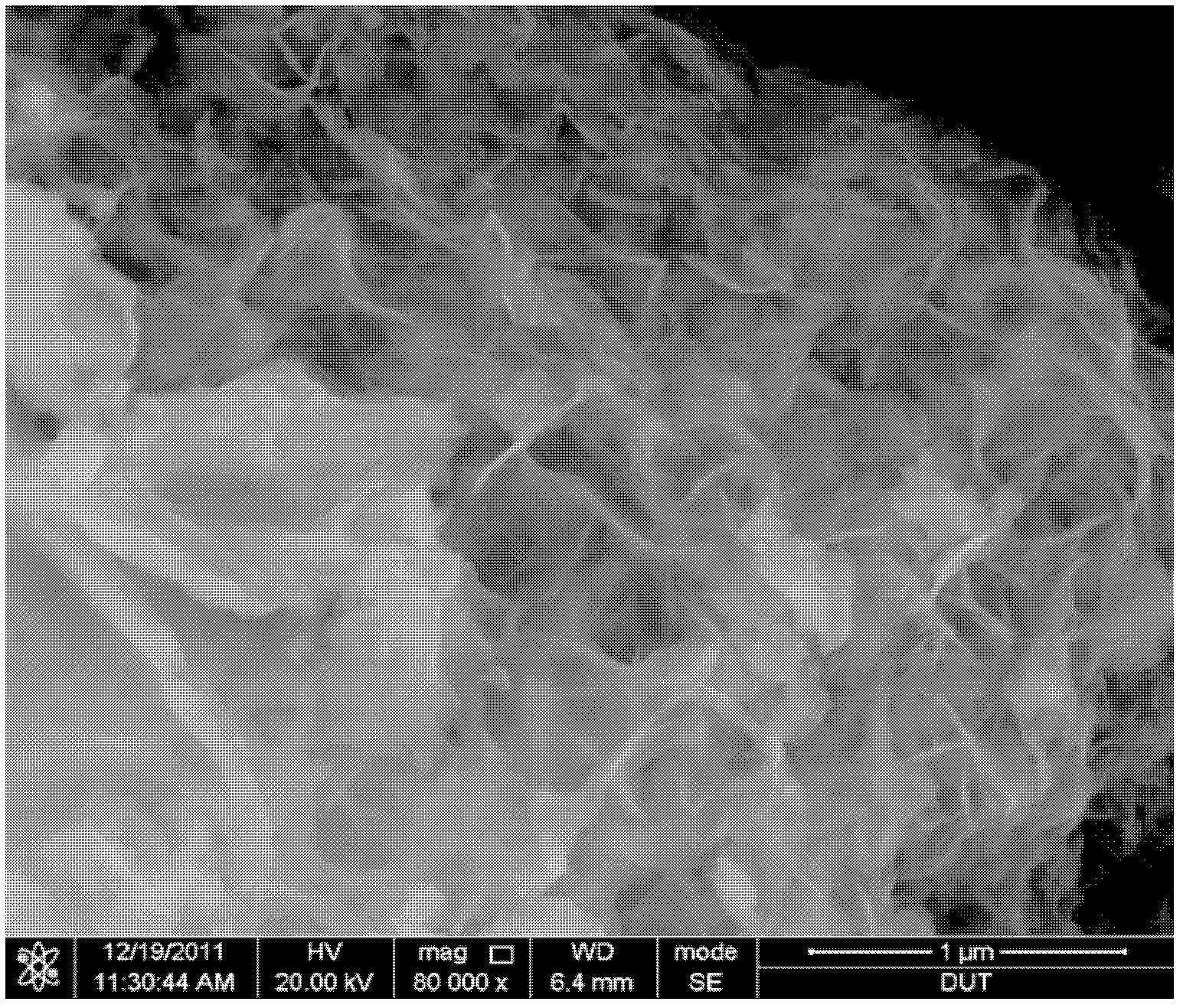

[0021] Here, the thickness of quartz sand is controlled at 2cm and the heating temperature of the main reaction chamber is controlled at 115°C as an example, and 7.8g of nickel sulfate hexahydrate (NiSO 4 ·6H 2 O, AR) into 30mL of deionized water, stirred evenly and added to the main reaction chamber; 2.4g of sodium hydroxide (NaOH, AR) was added to the precipitant chamber, and a layer of 2cm in thickness was covered in the upper isolation dilution area. Quartz sand; stop heating the main reaction chamber at 115°C for 8 hours, filter after cooling to room temperature, wash repeatedly with deionized water for 3 times and centrifugally filter, dry at 80°C for 2 hours to obtain a single green scale-l...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com