A kind of separation and purification method of pyrroloquinoline quinone in methylotrophic bacteria fermentation broth and its application

A technology for separation and purification of pyrroloquinoline quinone is applied in the field of separation and purification of pyrroloquinoline quinone, which can solve the problems of environmental pollution and high application cost, and achieve the effects of simple process operation, high degree of connection and single crystal form

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

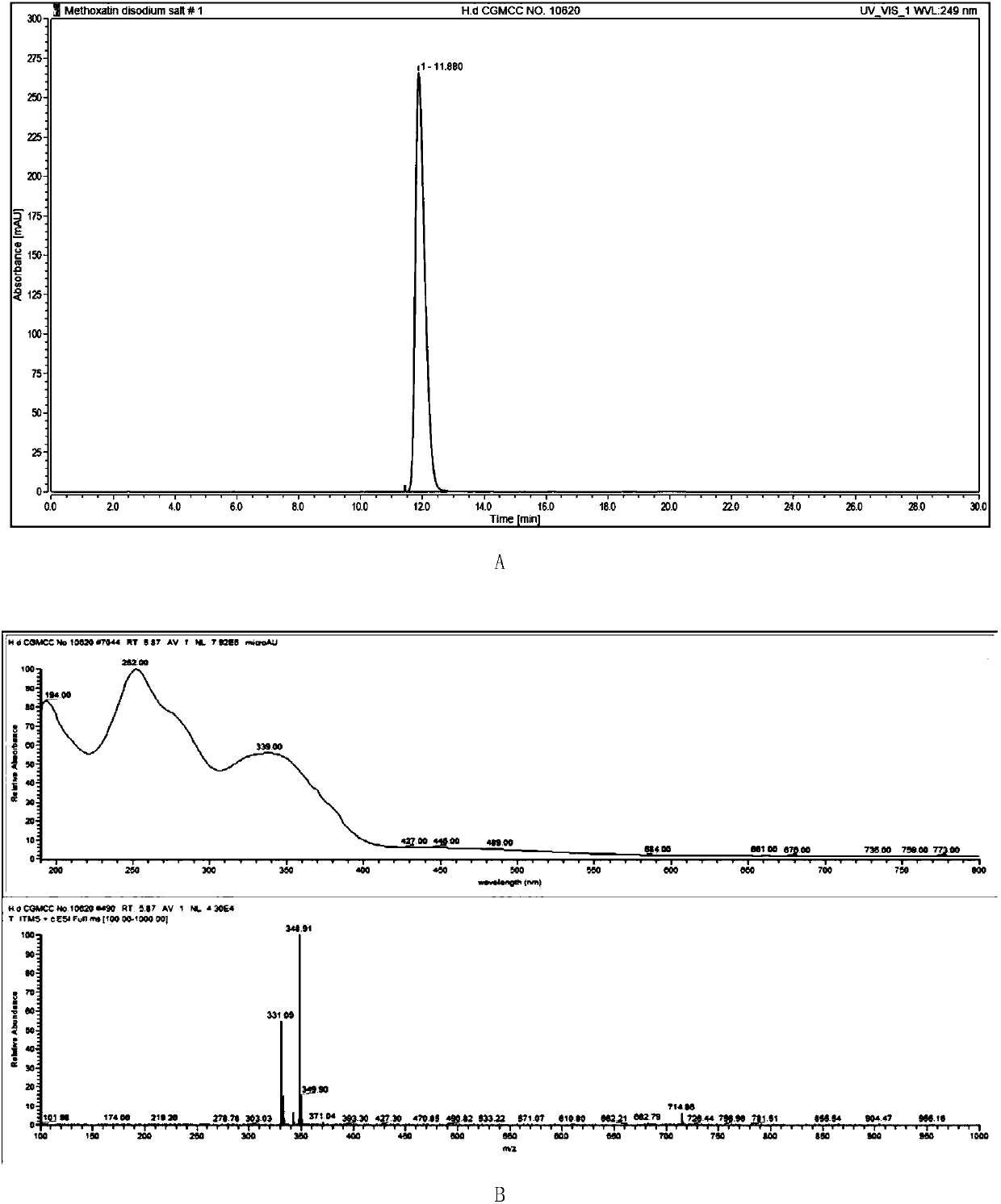

[0039] Embodiment 1, pyrroloquinoline quinone produced by denitrification hyphae microbacteria FJNU-R8

[0040] 1. Fermentation and supernatant preparation of denitrifying hyphaetic bacteria FJNU-R8

[0041] (1) Pick a single colony of FJNU-R8 into a Erlenmeyer flask filled with medium, and culture it at 32°C and 220rpm for 24-36 hours (OD 650 Between 2.5-3.0, adjust to zero with the seed medium) to obtain the seed solution.

[0042] The seed liquid is transferred to the fermentation medium with an inoculum amount of 10% (volume fraction), and fermented and cultivated at 30°C for 5-6 days to obtain a fermentation liquid; fermentation conditions: liquid loading (volume ratio of the fermentation medium to the fermenter) During the fermentation process, by feeding methanol and ammonia water, the concentration of methanol in the fermentation broth is controlled at 1-2g / L, and the pH is controlled at 6.8-7.0; stirring is associated with dissolved oxygen, and the dissolved oxygen (...

Embodiment 2

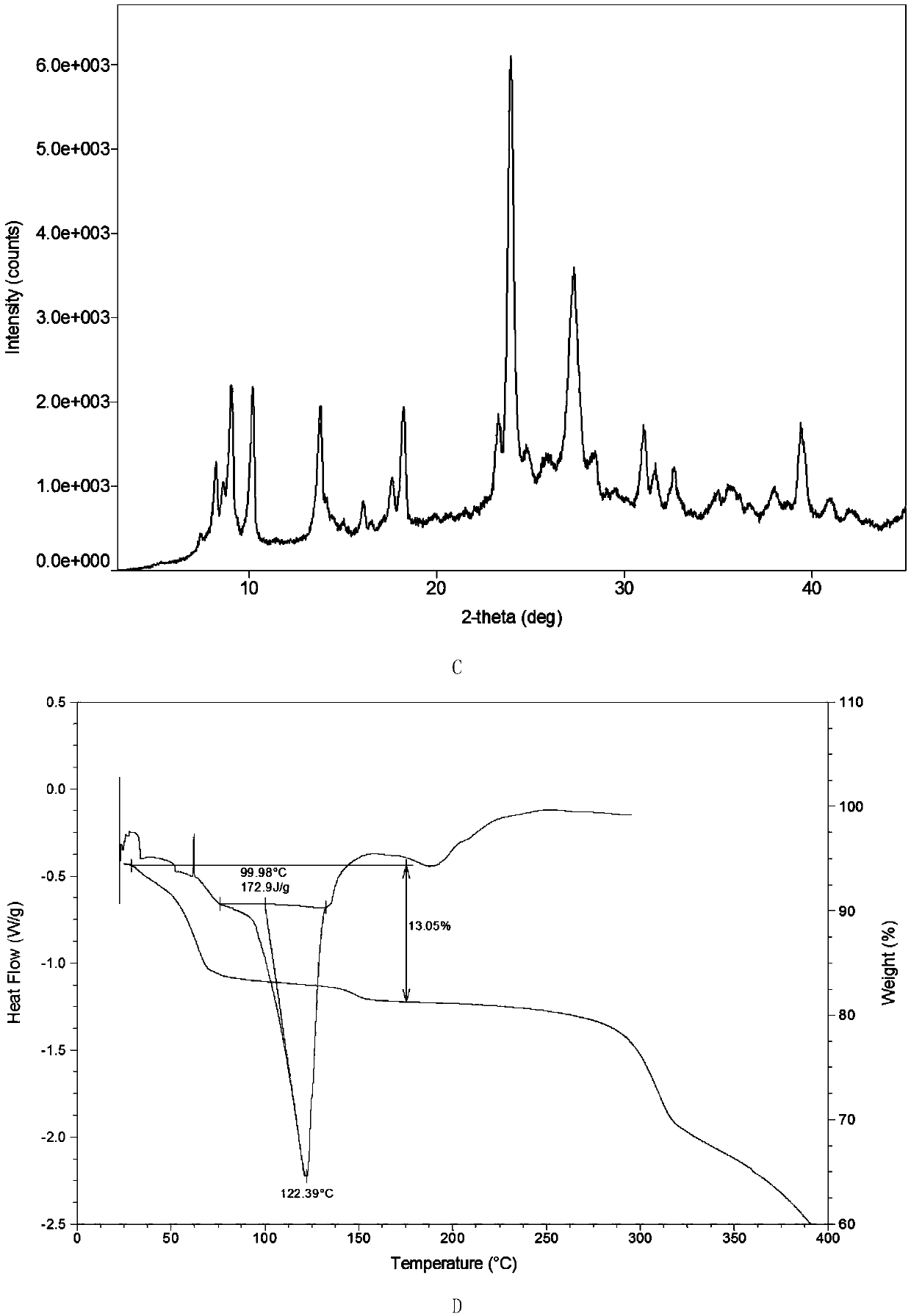

[0067] Embodiment 2, pyrroloquinoline quinone produced by denitrifying hyphaetic bacteria DSM 1869

[0068] 1. Fermentation and supernatant preparation of denitrifying hyphaetic bacteria DSM 1869

[0069] (1) Pick a single colony of DSM 1869 into a Erlenmeyer flask equipped with seed medium, and cultivate it for 24-36 hours at 32°C and 220rpm (OD 650 Between 2.5-3.0, adjust to zero with the seed medium) to obtain the seed liquid.

[0070] Transfer the seed liquid into the fermentation medium with an inoculation amount of 10% (volume fraction), and ferment and cultivate at 30°C for 7-8 days to obtain a fermented liquid; fermentation and culture conditions: the liquid loading is 70%, and methanol is added during the fermentation process and ammonia water, so that the concentration of methanol in the fermentation broth is controlled at 1-2g / L, and the pH is controlled at 6.8-7.0; stirring is associated with dissolved oxygen, and the dissolved oxygen amount (DO) is controlled at ...

Embodiment 3

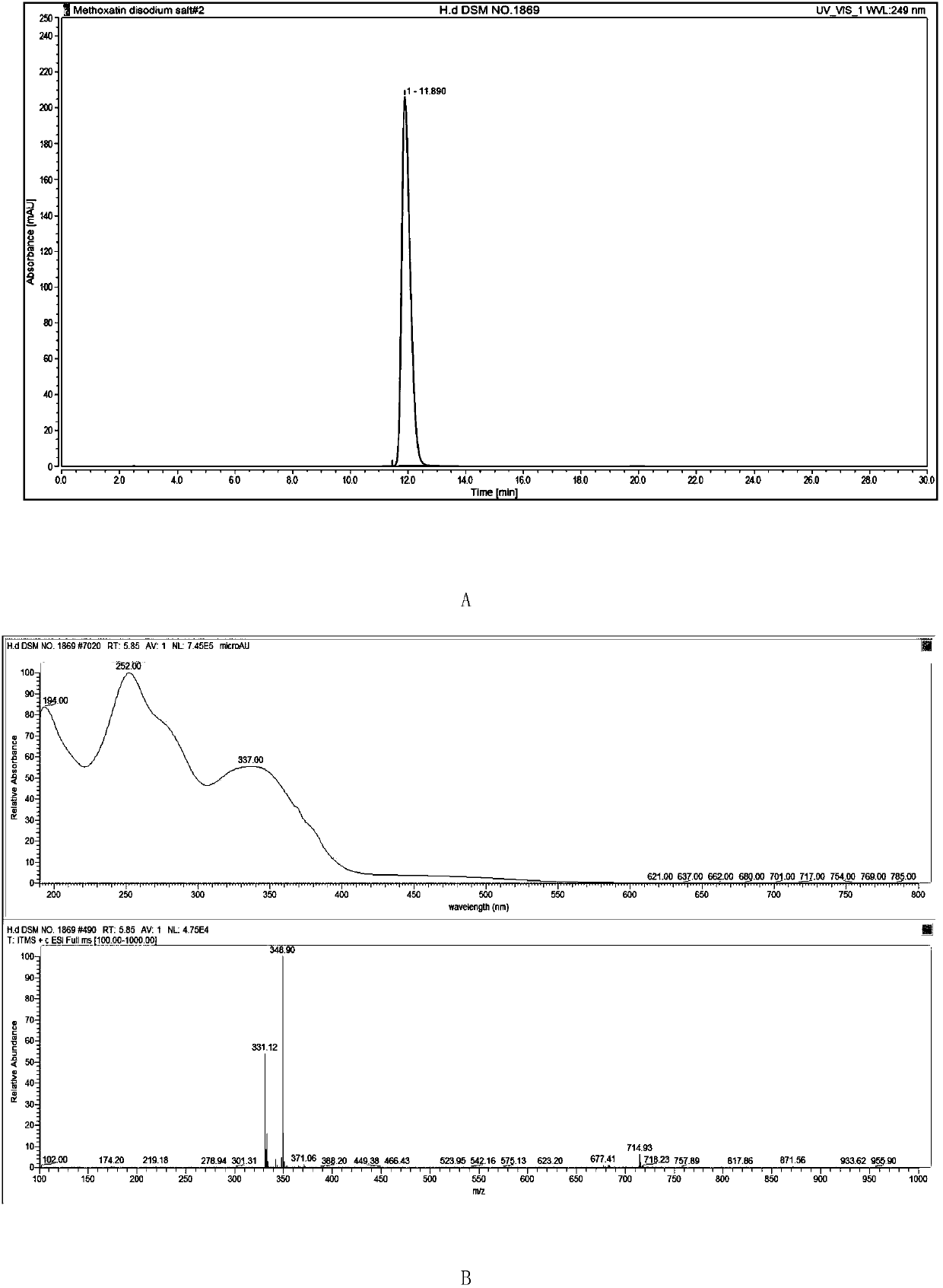

[0095] Embodiment 3, the production of pyrroloquinoline quinone by Methylobacter spirochete CGMCC 1.6987

[0096] 1. Fermentation and supernatant preparation of Methylobacter spirochete CGMCC 1.6987

[0097] (1) Pick a single colony of CGMCC 1.6987 into a Erlenmeyer flask equipped with seed medium, and cultivate it for 24-36 hours at 32°C and 220rpm (OD 650 Between 2.5-3.0, adjust to zero with the seed medium) to obtain the seed liquid.

[0098] The seed liquid is transferred to the fermentation medium with an inoculum amount of 10% (volume fraction), and fermented and cultivated at 30°C for 4-5 days to obtain a fermented liquid; fermented culture conditions: the liquid load is 70%, and methanol is added during the fermentation process and ammonia water, so that the concentration of methanol in the fermentation broth is controlled at 1-2g / L, and the pH is controlled at 6.8-7.0; stirring is associated with dissolved oxygen, and the dissolved oxygen amount (DO) is controlled at...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com