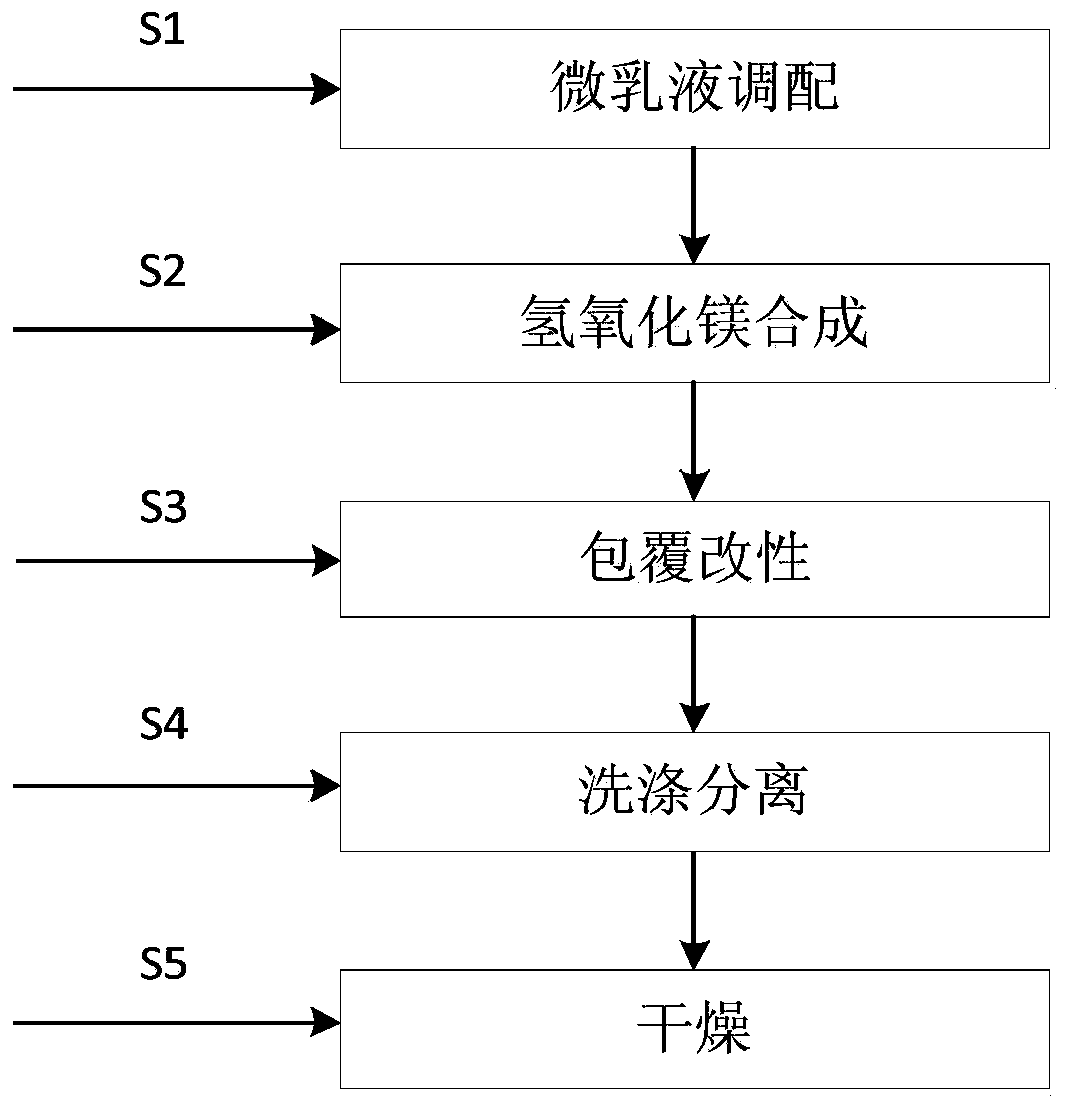

A kind of preparation and modification method of magnesium hydroxide flame retardant

A magnesium hydroxide and flame retardant technology, applied in magnesium hydroxide and other directions, can solve the problems of easy product agglomeration, large reaction rate, large particle size range, etc., to reduce particle agglomeration, enhance application ability, and uniform appearance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] First mix 5mL styrene (PS) and 5mL cyclohexane in a 150mL Erlenmeyer flask, then add 4g cetyltrimethylammonium bromide (CTAB) and 10mL of 1mol / L magnesium chloride solution successively, and then 10 mL of isopropanol was added dropwise under stirring, and stirred for 30 min to obtain a clear and transparent inverse microemulsion. Under magnetic stirring, add 20mL of 1mol / L sodium hydroxide solution dropwise to the above microemulsion, continue to stir for 2h after the dropwise addition, and leave the resulting mixed solution to stand and age at room temperature for 2h to fully react to obtain a white precipitate . Centrifuge, wash once with ethanol and distilled water respectively, centrifuge again, and finally dry the obtained precipitate in an electric blast drying oven at 80°C to obtain the magnesium hydroxide flame retardant product.

Embodiment 2

[0026] First mix 8mL methyl methacrylate (MMA) and 4mL toluene in a 150mL Erlenmeyer flask, then add 4g dioctyl sodium sulfosuccinate (AOT) and 10mL of 1mol / L magnesium chloride solution in turn, and then in With stirring, 10 mL of n-amyl alcohol was added dropwise, and stirred for 30 min to obtain a clear and transparent inverse microemulsion. Under magnetic stirring, 30 mL of 1 mol / L sodium hydroxide solution was added dropwise to the above microemulsion, and then 0.15 g of azobisisobutyronitrile (AIBN) was added, stirred for 30 min, and the resulting mixture was aged at room temperature 2h to fully react, a white precipitate was obtained. Centrifuge, wash with ethanol and distilled water three times, then centrifuge again, and finally dry the obtained precipitate in an electric blast drying oven at 60°C to obtain the magnesium hydroxide flame retardant product.

Embodiment 3

[0028] First mix 10mL of isoprene and 10mL of n-hexane in a 150mL Erlenmeyer flask, then add 5g of dodecyltrimethylammonium chloride (DTAC) and 10mL of 1mol / L magnesium sulfate solution in sequence, and then With stirring, 5 mL of n-butanol and 5 mL of n-octanol were added dropwise, and stirred for 30 min to obtain a clear and transparent inverse microemulsion. Under magnetic stirring, 30 mL of 1 mol / L ammonia water was added dropwise to the above-mentioned microemulsion, and the stirring was continued for 2 h after the dropwise addition, and the obtained mixture was aged at room temperature for 4 h to fully react, and a white precipitate was obtained. Centrifuge, wash twice with ethanol and distilled water, then centrifuge again, and finally dry the resulting precipitate in an electric blast drying oven at 100°C to obtain a magnesium hydroxide flame retardant product.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com