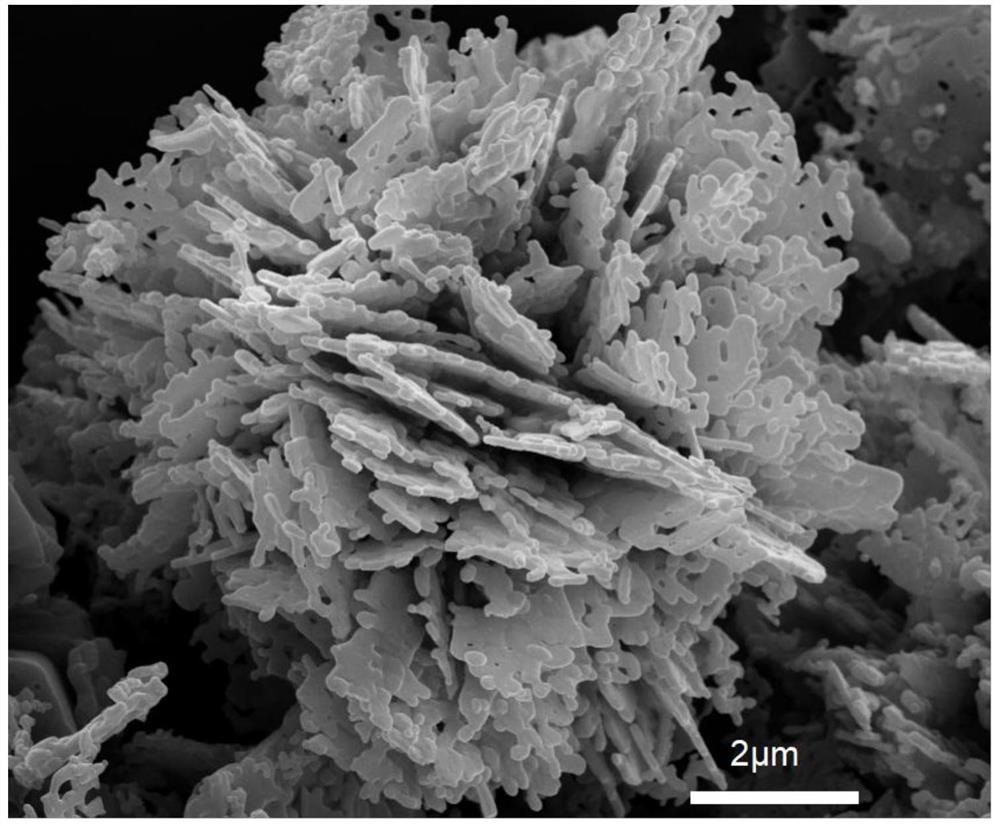

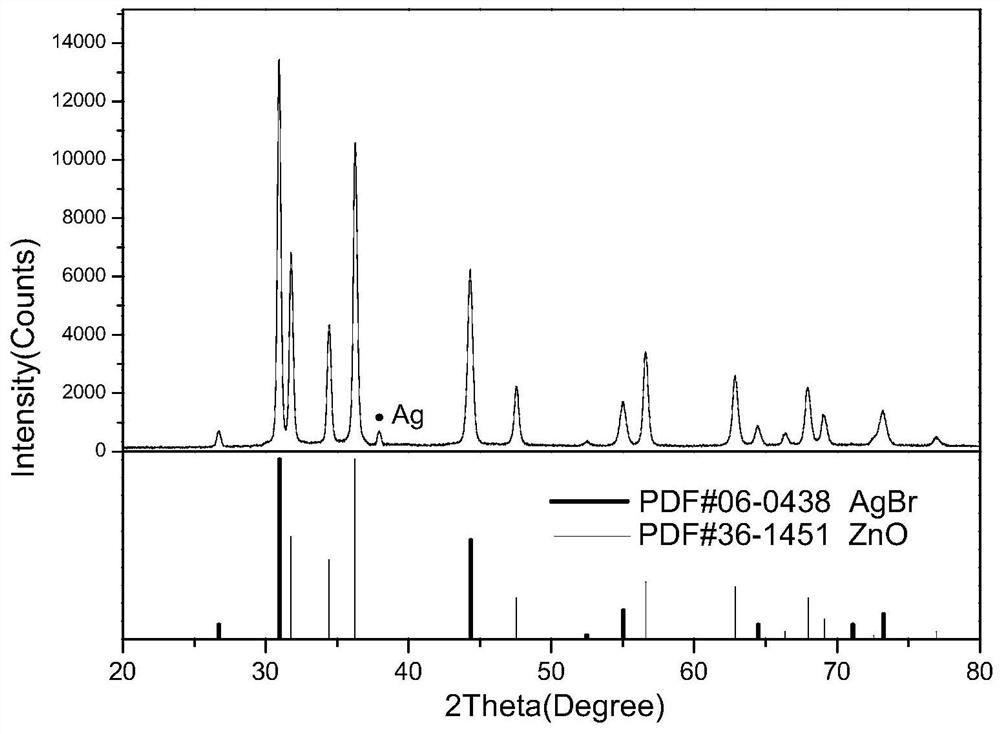

Preparation method of flower-like ag@agbr/zno photocatalytic material

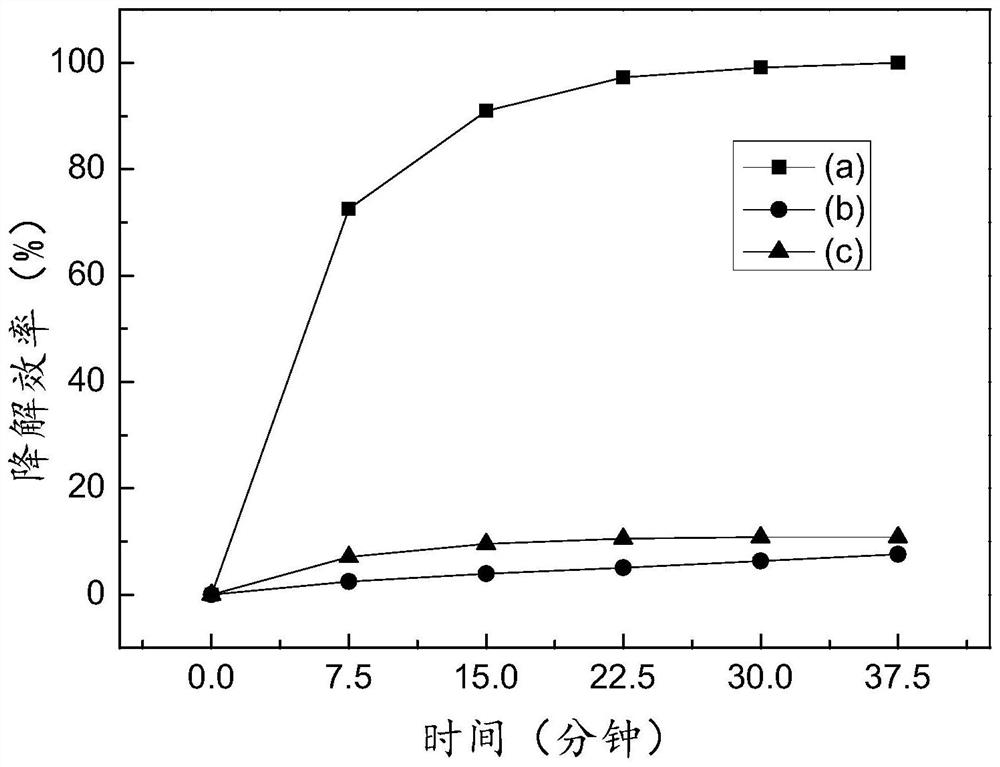

A photocatalytic material and flower-like technology, applied in chemical instruments and methods, physical/chemical process catalysts, chemical/physical processes, etc., can solve problems such as unsuitable production efficiency, long preparation time, complex and cumbersome process, etc., to achieve The effect of reducing the difficulty of preparation, saving costs, and strong photocatalytic activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

[0035] Specific implementation mode 1: In this implementation mode, the preparation method of the flower-shaped Ag@AgBr / ZnO material photocatalytic material is carried out according to the following steps:

[0036] 1. Weigh zinc acetate dihydrate, silver nitrate, and hexamethylenetetramine according to the ratio of Zn element, Ag element, hexamethylenetetramine and surfactant in the ratio of 1:0.2:1:0.55. Amine and CTAB, configure 0.3333mol / L and 0.1833mol / L of Zn source and surfactant in 30mL distilled water to obtain Zn source solution; configure 0.1mol / L and 0.5mol / L of Ag source and hexamethylene tetra Amine in 20mL distilled water, and add oxidant, Ag source solution;

[0037] 2. Add the Ag source solution drop by drop to the Zn source solution at a rate of 1 second / drop, transfer the mixed solution to a high-pressure reactor for hydrothermal reaction, the mixed solution accounts for about 50% of the reactor volume, set The water heating temperature is 140°C, and the wat...

specific Embodiment approach 2

[0044] 1. Weigh zinc acetate dihydrate, silver nitrate, and hexamethylenetetramine according to the ratio of Zn element, Ag element, hexamethylenetetramine and surfactant in the ratio of 1:0.2:1:0.55. Amine and CTAB, configure 0.3333mol / L and 0.1833mol / L of Zn source and surfactant in 30mL distilled water to obtain Zn source solution; configure 0.1mol / L and 0.5mol / L of Ag source and hexamethylene tetra Amine in 20mL distilled water, and add oxidant, Ag source solution;

[0045] 2. Add the Ag source solution drop by drop to the Zn source solution at a rate of 3 seconds / drop, transfer the mixed solution to a high-pressure reactor for hydrothermal reaction, the mixed solution accounts for about 50% of the reactor volume, set The water heating temperature is 160°C, and the water heating time is maintained at this temperature for 2.5 hours;

[0046] 3. After the resultant was washed with water, washed with alcohol and dried, it was transferred into a muffle furnace, calcined at 50...

specific Embodiment approach 3

[0048] 1. Weigh zinc acetate dihydrate, silver nitrate, and hexamethylenetetramine according to the ratio of Zn element, Ag element, hexamethylenetetramine and surfactant in the ratio of 1:0.2:1:0.55. Amine and CTAB, configure 0.3333mol / L and 0.1833mol / L of Zn source and surfactant in 30mL distilled water to obtain Zn source solution; configure 0.1mol / L and 0.5mol / L of Ag source and hexamethylene tetra Amine in 20mL distilled water, and add oxidant, Ag source solution;

[0049] 2. Add the Ag source solution drop by drop to the Zn source solution at a rate of 2 seconds / drop, transfer the mixed solution to the high-pressure reactor for hydrothermal reaction, the mixed solution accounts for about 50% of the reactor volume, set The water heating temperature is 130°C, and the water heating time is maintained at this temperature for 4 hours;

[0050] 3. After the product was washed with water, washed with alcohol and dried, it was transferred into a muffle furnace, calcined at 700°...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com