Additive manufacturing method and additive manufacturing device for aluminum alloy based on laser-double-MIG composite heat source

A composite heat source and additive manufacturing technology, used in manufacturing tools, metal processing equipment, welding equipment, etc., can solve the problems of insufficient high-speed stability, low laser energy absorption rate, etc., and achieve excellent comprehensive performance and uniform chemical composition of weldments. , the effect of high welding speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

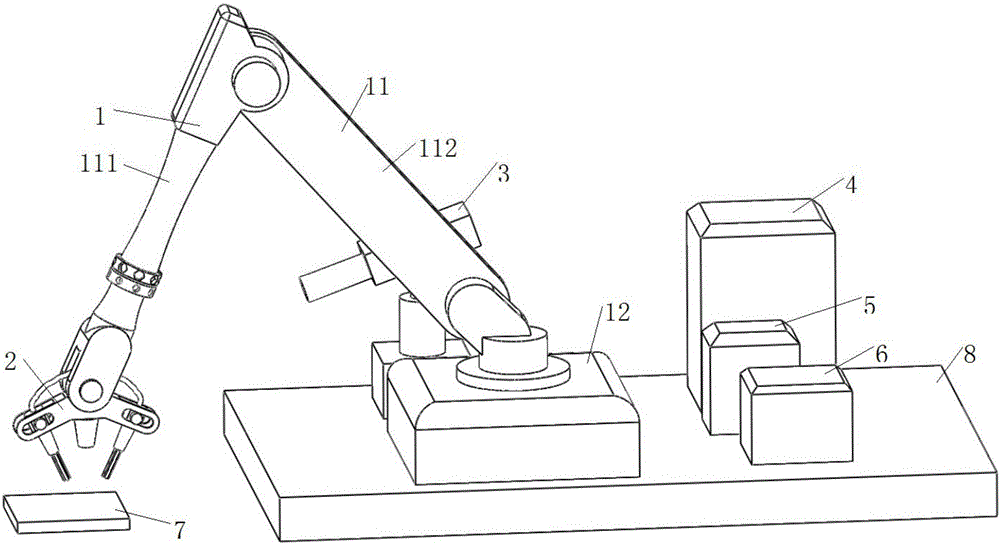

[0031] figure 1 It is an aluminum alloy additive manufacturing device based on a laser-double MIG composite heat source of the present invention, which includes an automatic welding robot 1, a composite heat source system 2, a video monitoring system 3, a digital control system 4, a wire feeding system 5, and a shielding gas system 6. The substrate 7 and the base 8; the compound heat source system 2 is connected with the automatic welding robot 1; the video monitoring system 3, the digital control system 4, the wire feeding system 5, the shielding gas system 6 and the automatic welding robot 1 are all set on the base 8 ; The video monitoring system 3 , the wire feeding system 5 , the shielding gas system 6 and the automatic welding robot 1 are all connected with the digital control system 4 .

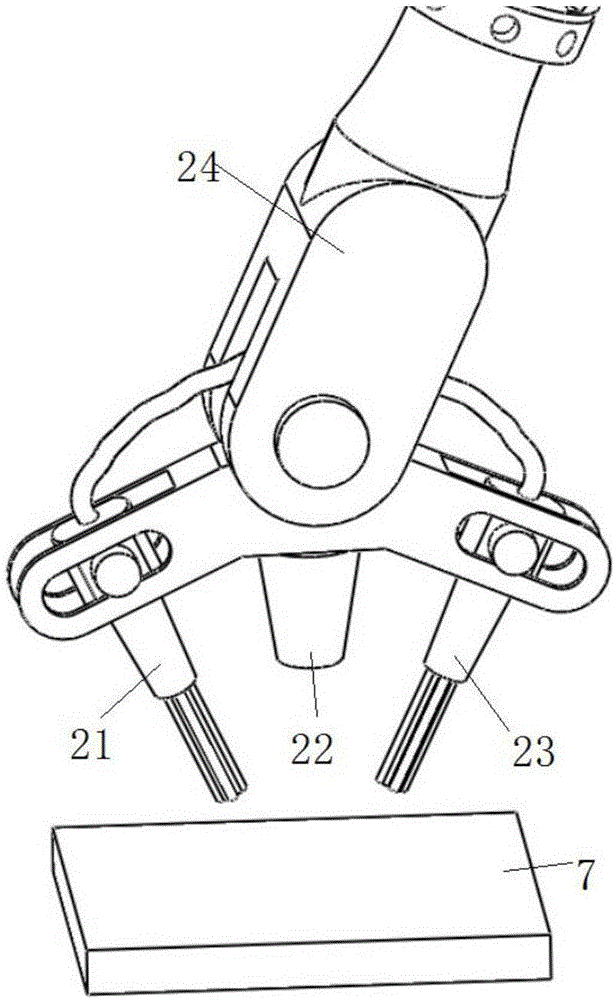

[0032] The automated robot 1 includes an arm 11 and a base 12. The arm 11 includes a first arm 111 and a second arm 112. The composite heat source system 2 is installed on the first arm...

Embodiment 2

[0038] The present invention utilizes the surfacing welding aluminum alloy weldment of the aluminum alloy additive manufacturing device based on the laser-double MIG composite heat source as described above, and the steps of the aluminum alloy additive manufacturing method based on the laser-double MIG composite heat source are as follows:

[0039] Step 1: After double MIG welding DC reverse connection, equip the composite heat source system on the first arm of the automatic welding robot 1; at the same time, electrically connect the digital control system 4 to the automatic welding robot 1, and place the digital control system 4 on the At the appropriate position of the base 8; for the parts that need to be manufactured by surfacing, the programming is to formulate the running route of the automatic welding robot arm, and the automatic welding robot arm is moved to the initial position (arc starting point); the video control system and the digital control system connection;

...

Embodiment 3

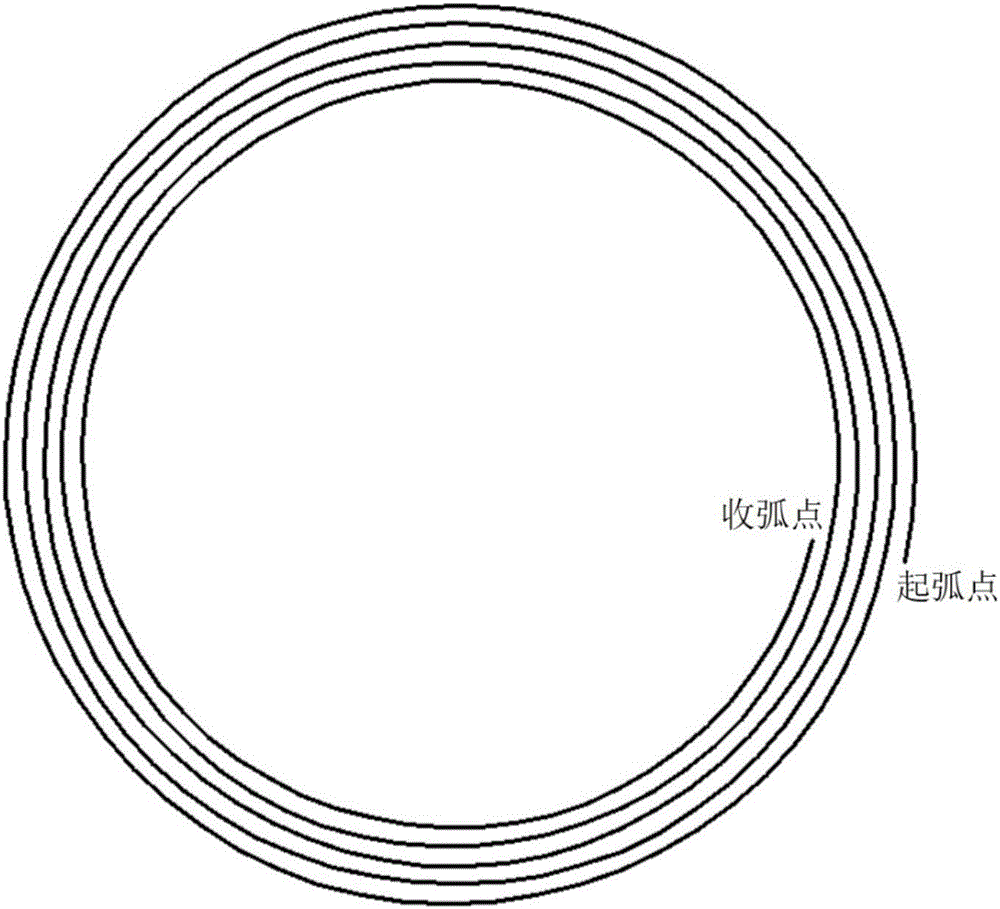

[0048] In this embodiment, a circular shell with a height of 300 mm, a diameter of 200 mm, and a wall thickness of 20 mm is used for surfacing welding of the second embodiment. It is formed by surfacing welding of 200 layers of girth welds, and the height of each layer of surfacing welding is 1.5 mm. Such as image 3 and Figure 4 as shown, Figure 4 1 is the surfacing workpiece, and 2 is the substrate. In the surfacing process, except for the surfacing workpiece, other parameters are the same as in Embodiment 2, and the specific steps are as follows:

[0049] Step 1: Pre-ventilate for 5 seconds before surfacing on the carbon steel substrate. Before and after starting the MIG welding torch and the middle welding head, surfacing from the outer radial direction of the bottoming circumferential surface to the center of the circle to complete the first layer of bottoming surfacing, surfacing A layer of circular surface with a diameter of 300mm is produced.

[0050] Step 2: Aft...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| Defocus amount | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com