A kind of growth method of germanium quantum dot, germanium quantum dot composite material and application thereof

A composite material and growth method technology, which is applied in the field of semiconductor quantum dot preparation, can solve problems such as difficult control, difficult control, and complicated preparation process of germanium quantum dots, and achieve excellent performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

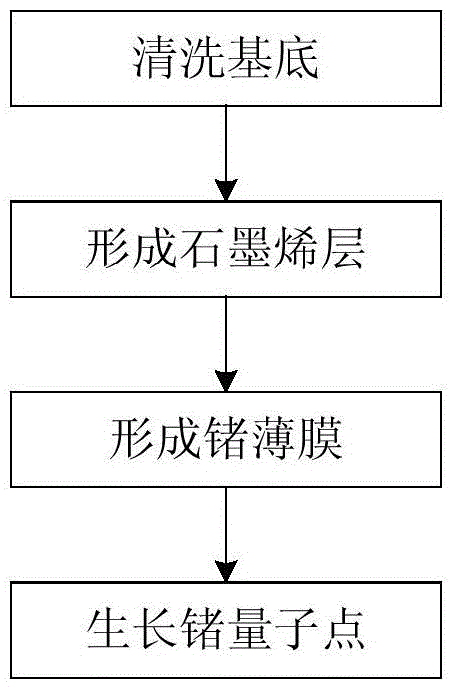

[0083] A kind of growth method of germanium quantum dot comprises the steps:

[0084] (1) Provide a silicon substrate, ultrasonically clean it with tap water for 3 minutes, deionized water for 5 minutes, and acetone for 5 minutes, and repeat the ultrasonic cleaning step twice to remove pollutants on the substrate;

[0085] (2) Place the silicon substrate cleaned in step (1) in the reaction chamber of the tube furnace, seal the reaction chamber, and feed argon to ensure that the tube furnace is in an argon atmosphere, and feed methane gas as the carbon source gas , heating the reaction chamber to 1000° C., and keeping it warm for 20 minutes. After the reaction is completed, cool the reaction chamber under an argon atmosphere to obtain a graphene layer grown on the substrate, and the thickness of the graphene layer is 1 to 15 nm;

[0086] (3) Using the high-purity germanium target as the target material, under the sputtering radio frequency power of 300W and the Ar gas flow rate...

Embodiment 2

[0090] A kind of growth method of germanium quantum dot comprises the steps:

[0091] (1) Provide a silicon substrate, ultrasonically clean it with tap water for 4 minutes, deionized water for 4 minutes, and acetone for 10 minutes, and repeat the ultrasonic cleaning step 4 times to remove pollutants on the substrate;

[0092] (2) Place the silicon substrate cleaned in step (1) in the reaction chamber of the tube furnace, seal the reaction chamber, and feed argon to ensure that the tube furnace is in an argon atmosphere, and feed methane gas as the carbon source gas , heating the reaction chamber to 1200° C., and keeping it warm for 15 minutes. After the reaction is completed, cool the reaction chamber under an argon atmosphere to obtain a graphene layer grown on the substrate, and the thickness of the graphene layer is 1 to 8 nm;

[0093] (3) Using the radio frequency magnetron sputtering method, using the high-purity germanium target as the target material, under the radio fr...

Embodiment 3

[0097] A kind of growth method of germanium quantum dot comprises the steps:

[0098] (1) Provide a silicon substrate, ultrasonically clean it with tap water for 5 minutes, deionized water for 5 minutes, and acetone for 10 minutes, and repeat the ultrasonic cleaning step once to remove pollutants on the substrate;

[0099] (2) Place the silicon substrate cleaned in step (1) in the reaction chamber of the tube furnace, seal the reaction chamber, and inject helium gas to ensure that the tube furnace is in the helium atmosphere, and turn on the precision flow pump to make 99.9% Pure ethanol is injected into the reaction chamber through the capillary at a rate of 18 μL / min, the reaction chamber is heated to 900°C, and kept for 30 minutes. After the reaction is completed, the reaction chamber is cooled under a helium atmosphere to obtain a graphene layer grown on the substrate. The thickness of the graphene layer is 20~30nm;

[0100] (3) Using the high-purity germanium target as t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com