Rotary steamed corn bread processing and molding apparatus

A technology of rotary processing and forming devices, which is applied in the fields of dough forming machinery or equipment, baking, food science, etc., can solve the problems of increased labor intensity and low work efficiency, and achieve safe and hygienic production, improve production efficiency, and shape Unified effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

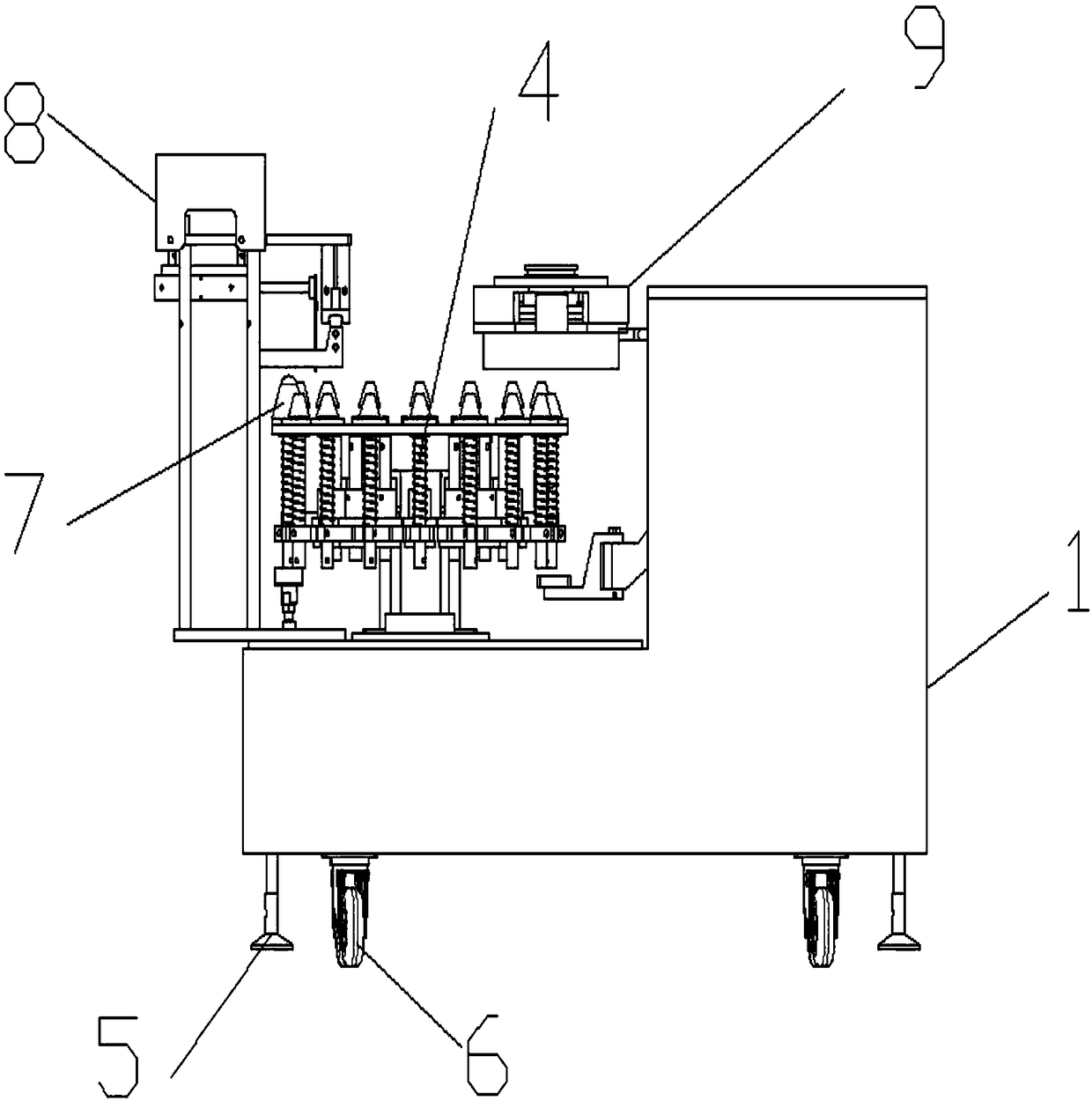

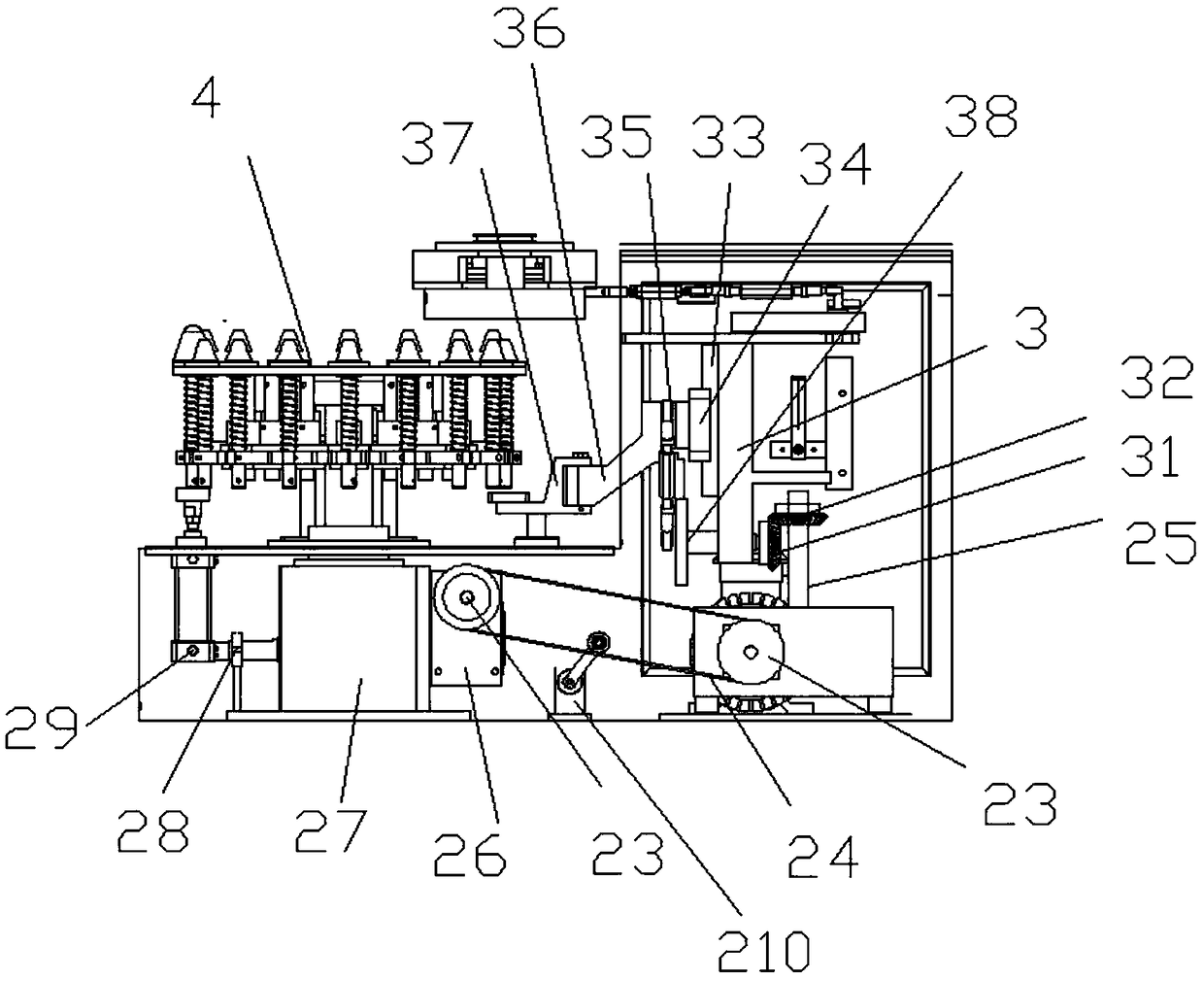

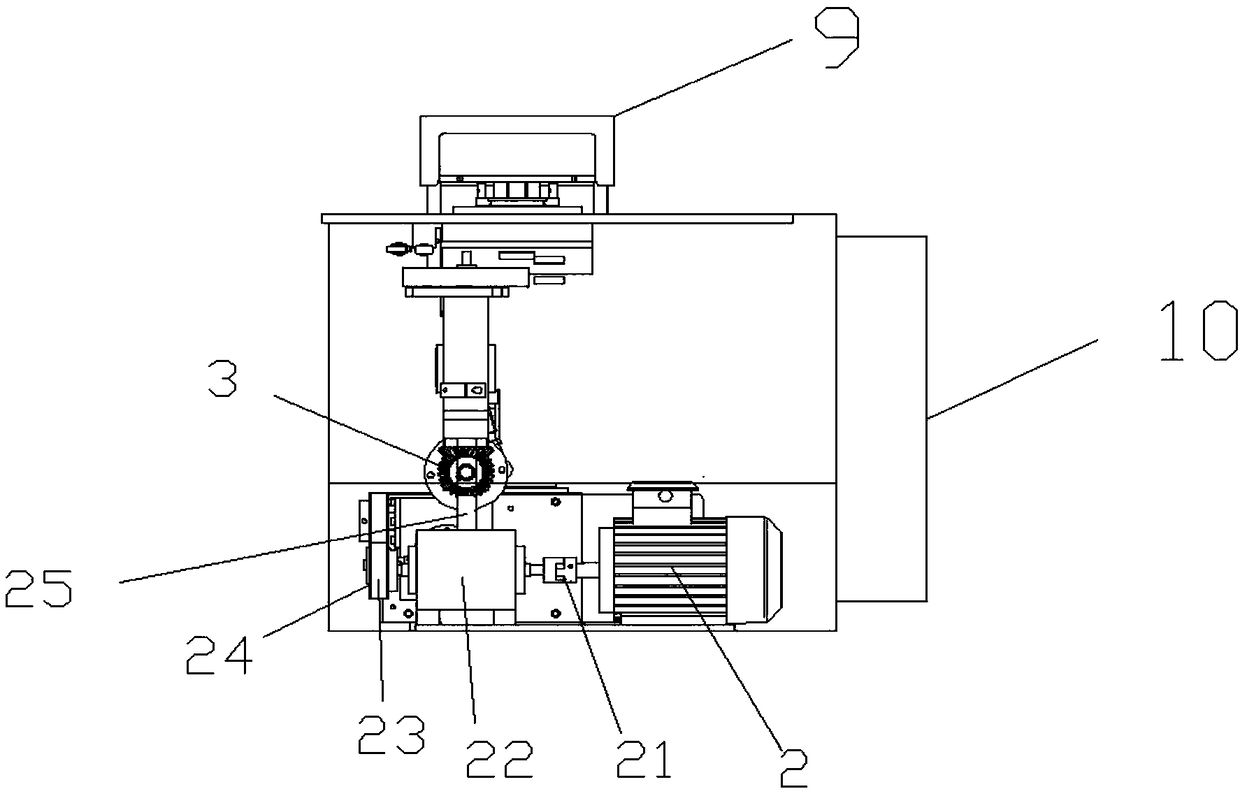

[0024] see Figure 1-6 , in an embodiment of the present invention, a steamed cornbread rotary processing and forming device includes a housing 1, a foot cup 5, a large caster 6, a steamed cornbread 7, a mold ejection assembly 8, an upper mold assembly 9, and a working box 10; The casing 1 is provided with a transmission device inside, and the transmission device includes a motor 2, a shaft coupling 21, a first reducer 22, a transmission wheel 23, a conveyor belt 24, a first rotating shaft 25, a second reducer 26, and a third reducer 27. Joint bearing 28, cylinder 29, tensioning device 210, transmission frame 3, first bevel gear 31, second bevel gear 32, slide rail 33, slider 34, connecting rod 35, first connecting block 36, cam assembly 37. The second rotating shaft 38; the left end of the motor 2 is connected to the first reducer 22 through the coupling 21, the left end of the first reducer 22 is connected to the transmission wheel 23, and the transmission wheel 23 is connec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com