Patents

Literature

79results about How to "Small size difference" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Polymerizable compound, polymer, positive resist composition, and patterning process using the same

ActiveUS20090297979A1High sensitivity and resolutionPattern configurationOrganic chemistryOrganic compound preparationResistSize difference

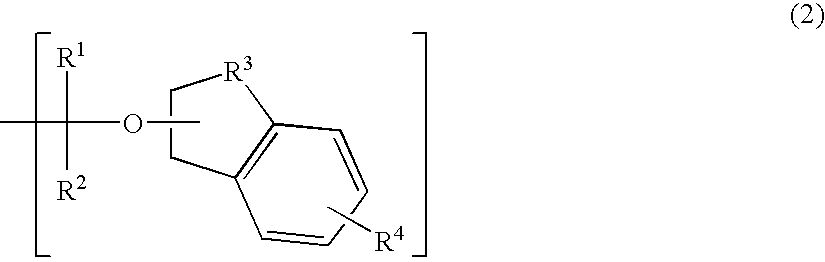

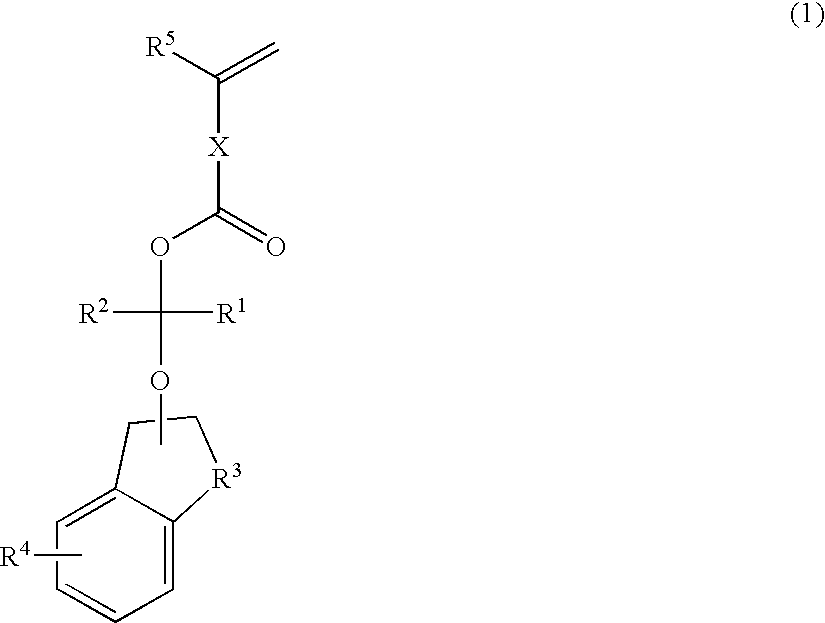

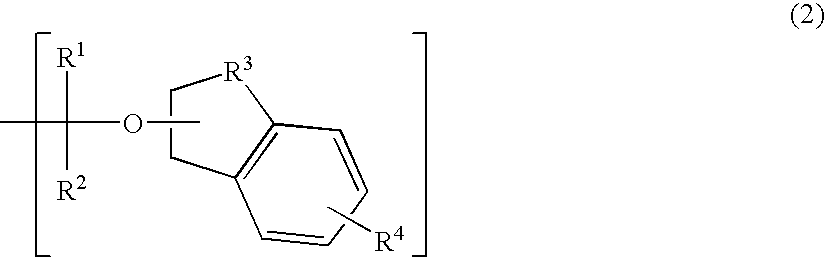

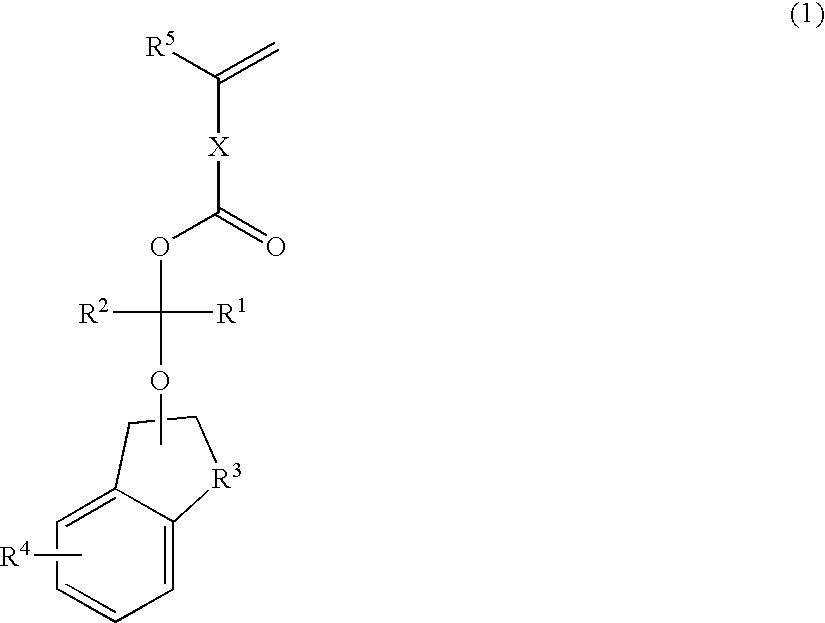

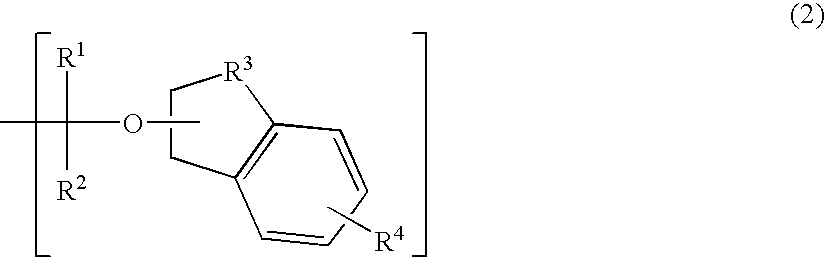

The present invention provides; a polymer suitable as a base resin for a positive resist composition, in particular a chemically amplified positive resist composition, having a higher resolution, a larger exposure allowance, a smaller sparse-dense size difference, a better process applicability, a better pattern configuration after exposure, and in addition, a further excellent etching resistance, than a conventional positive resist; a positive resist composition using the same; a patterning process; and a novel polymerizable compound to obtain a polymer like this.The present invention was accomplished by a polymer whose hydrogen atom of at least a carboxyl group is substituted by an acid labile group represented by the following general formula (2), a positive resist composition using the same, a patterning process, and a novel polymerizable compound to obtain a polymer like this.

Owner:SHIN ETSU CHEM IND CO LTD

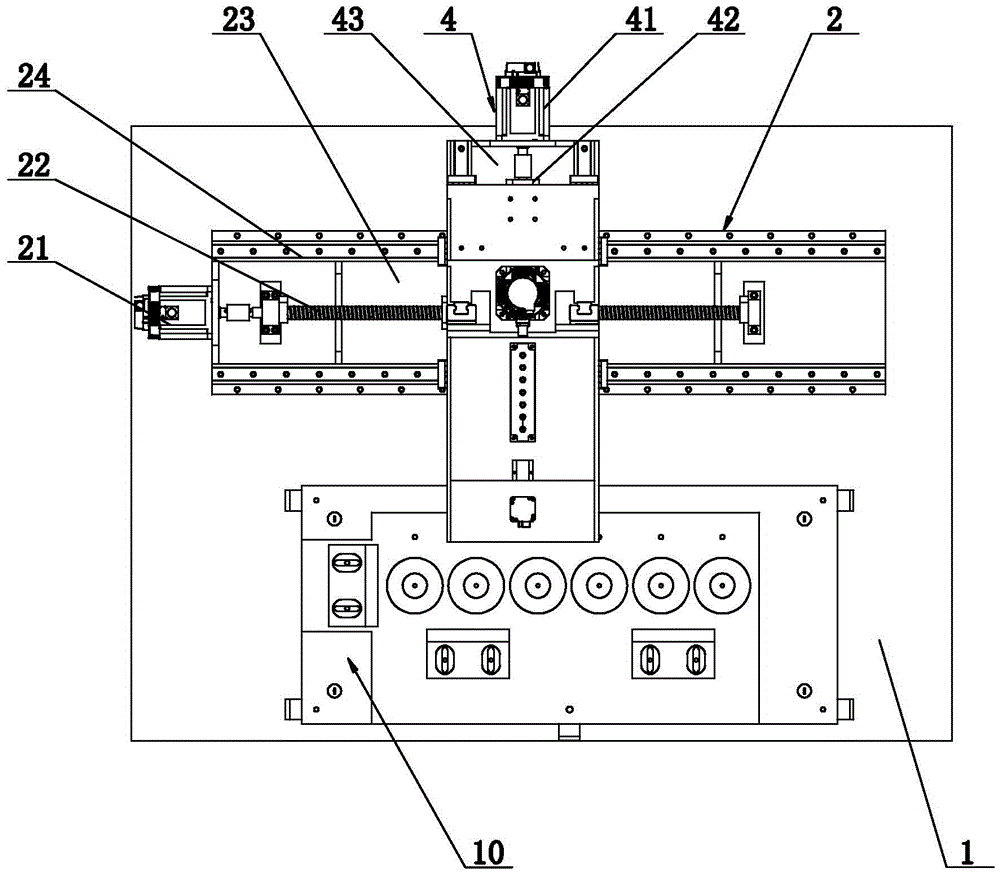

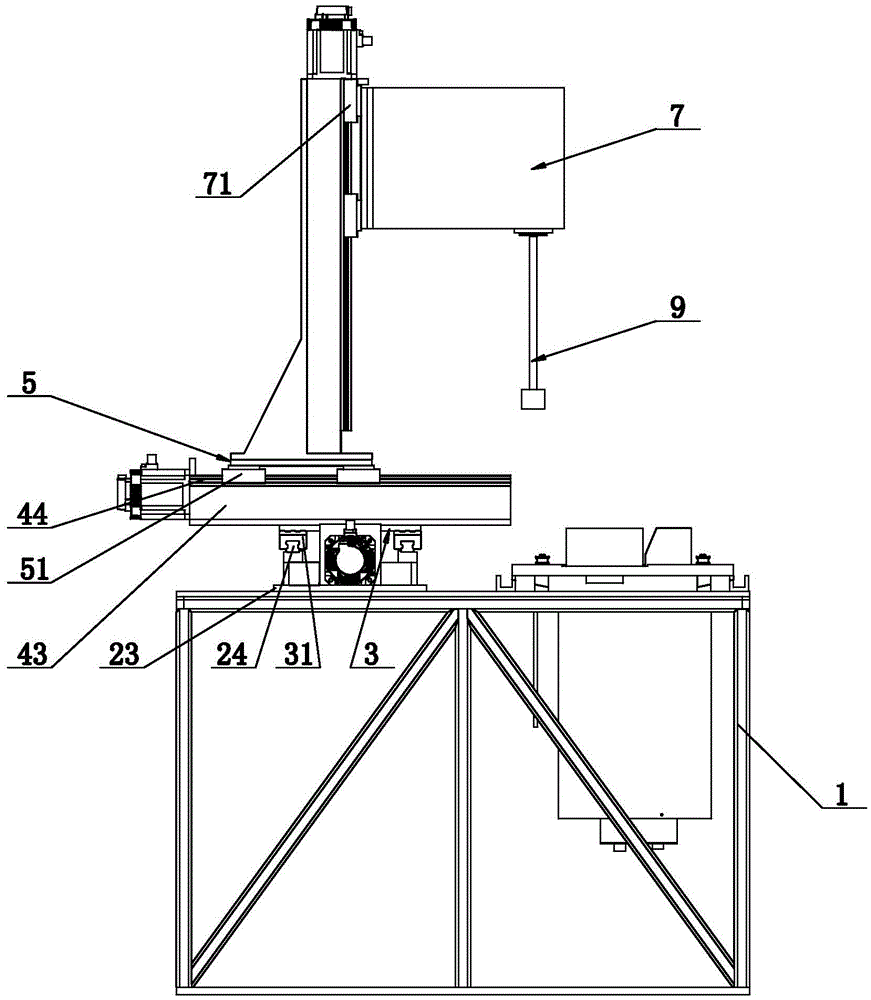

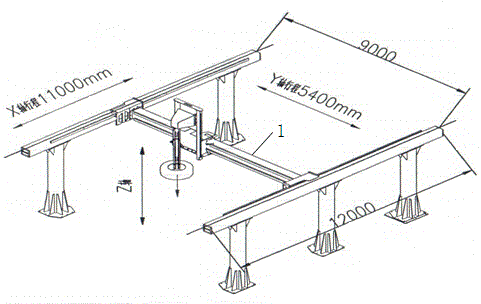

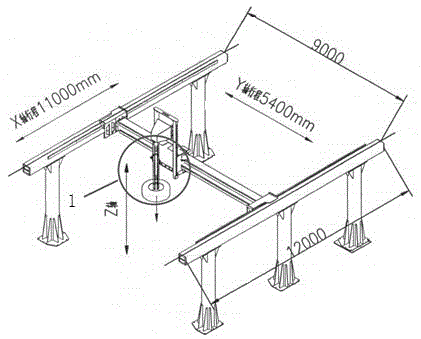

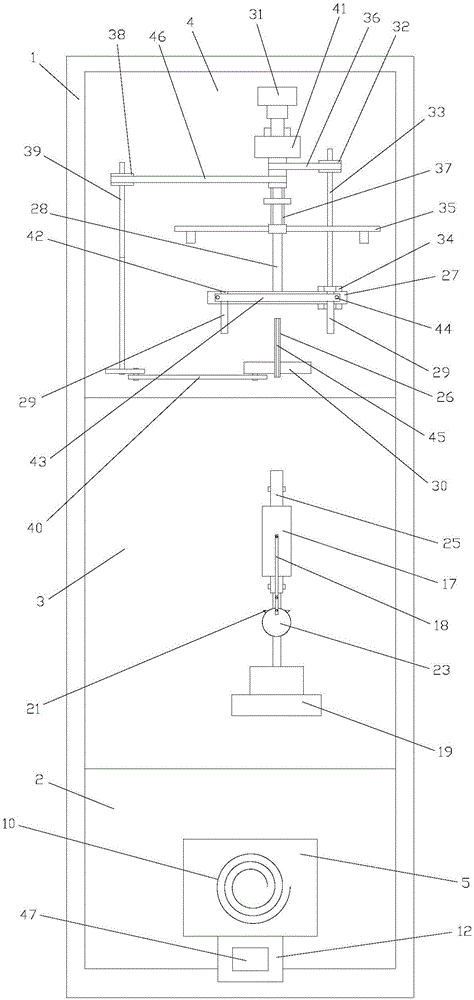

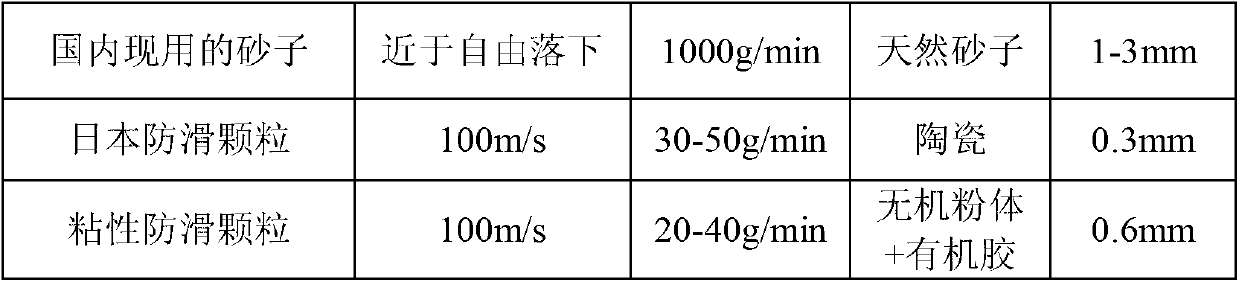

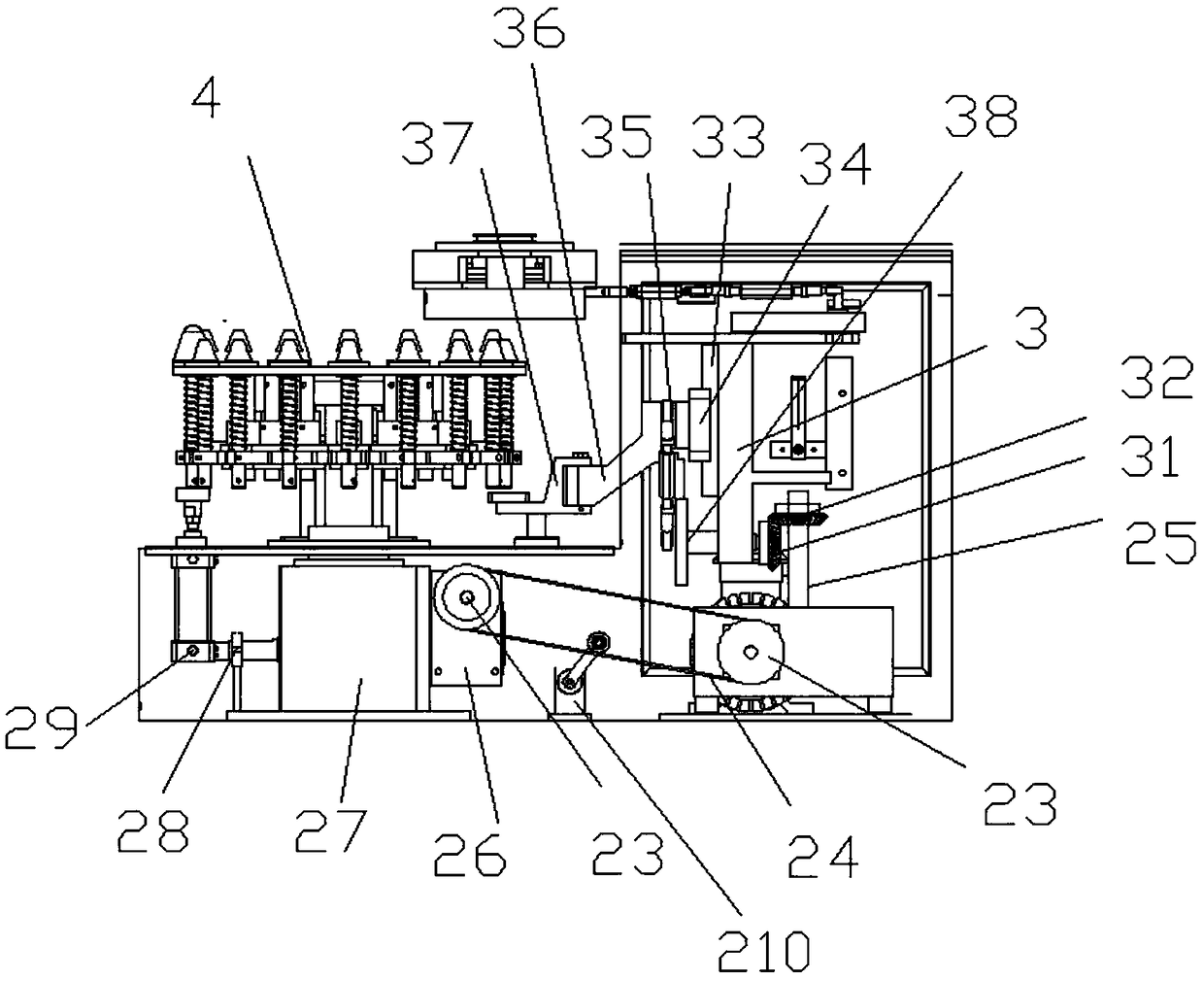

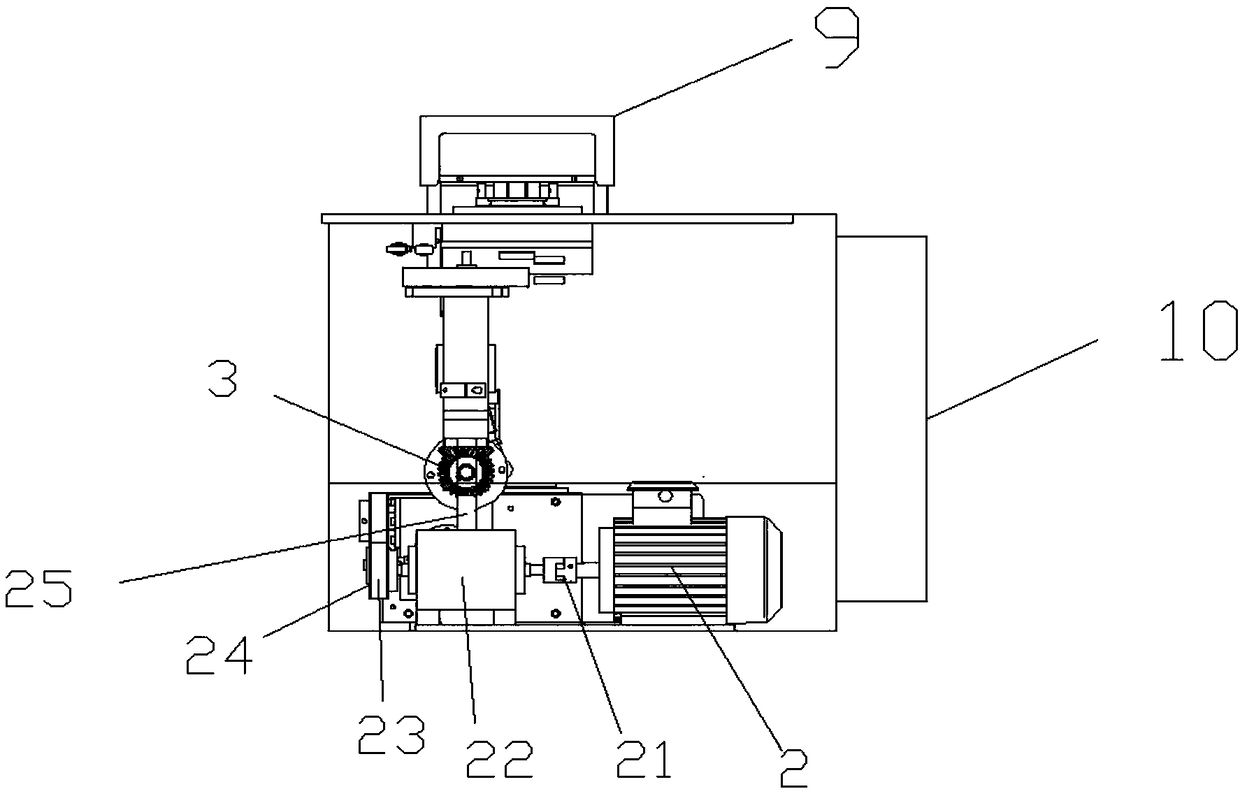

Automatic brush electroplating equipment

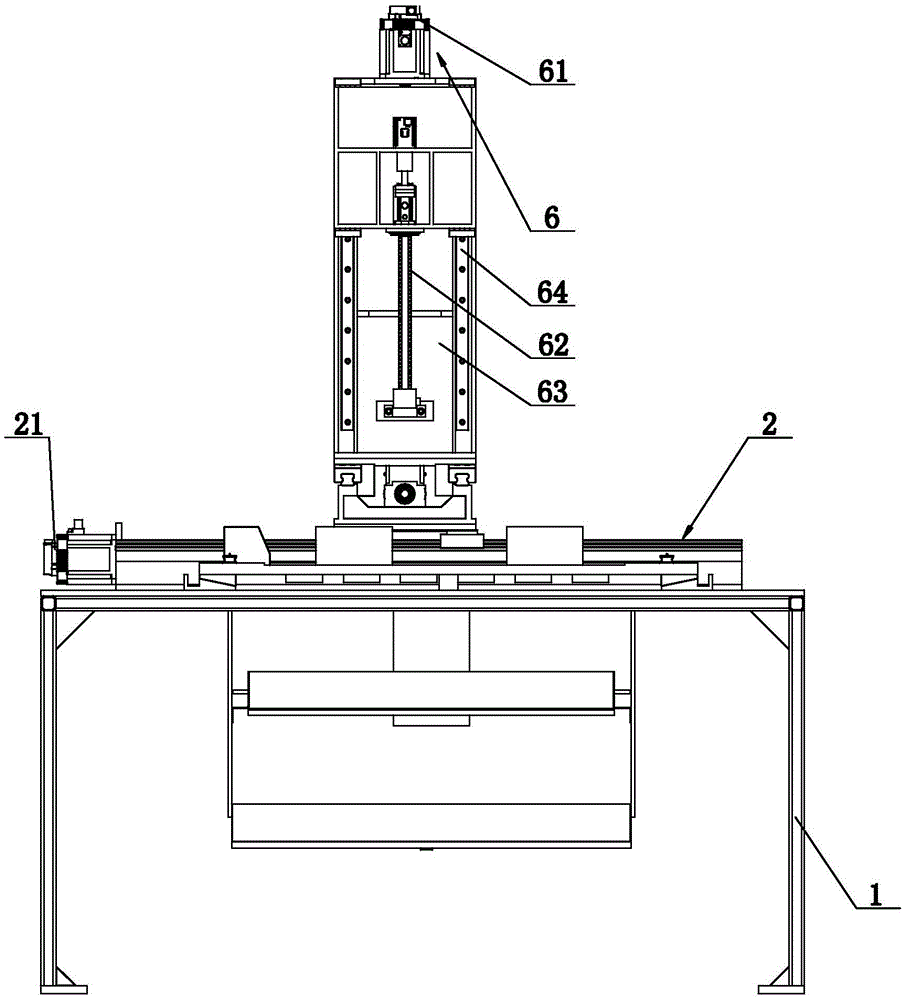

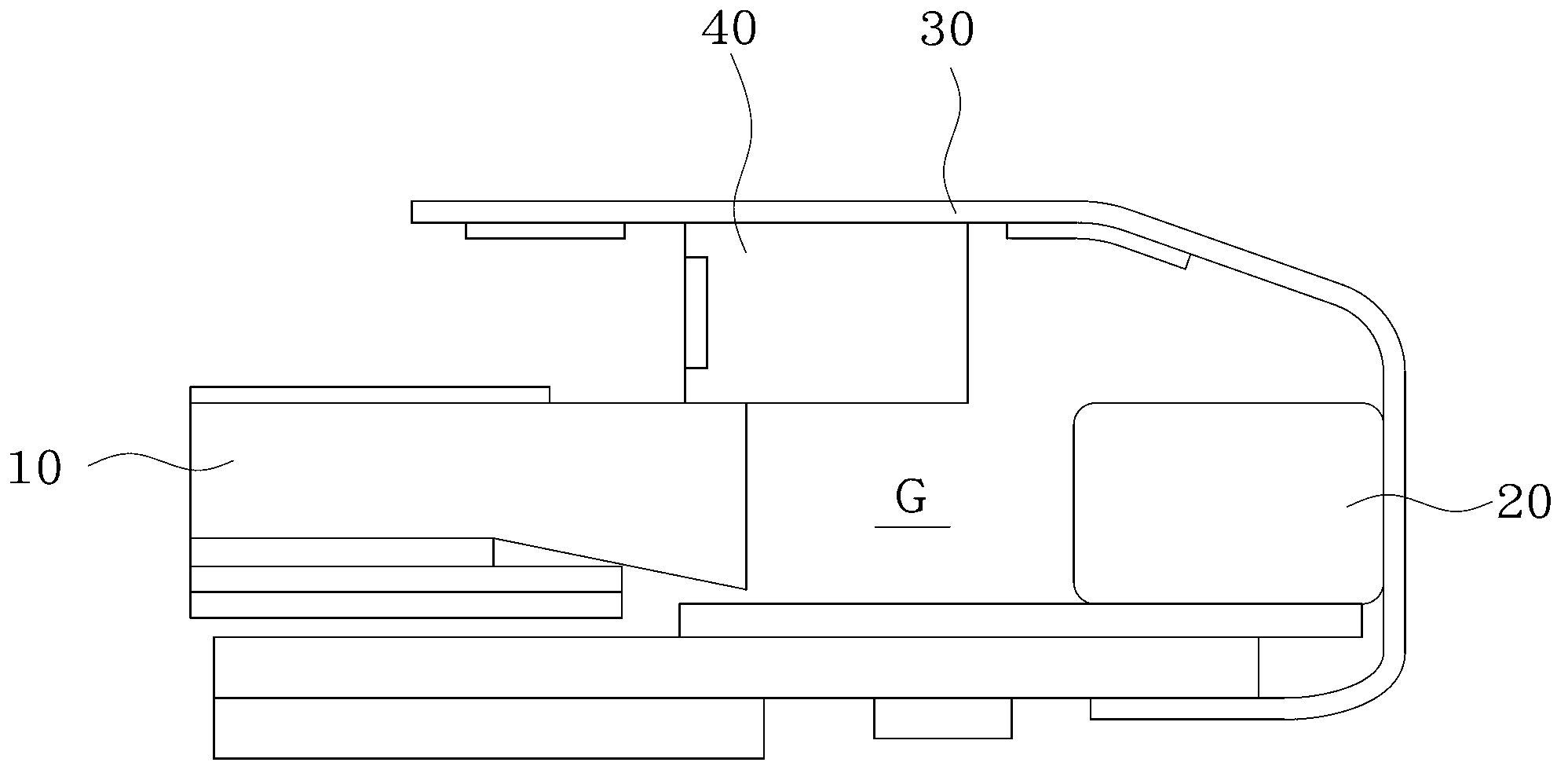

The invention discloses automatic brush electroplating equipment belonging to the technical field of engine reproduction equipment. The automatic brush electroplating equipment comprises a rack, wherein the rack is slidably provided with a first slide box driven by a first power device along the X direction; the first slide box is slidably provided with a second slide box driven by a second power device along the Y direction; the second slide box is slidably provided with a third slide box driven by a third power device along the Z direction; the third slide box is rotationally provided with a plating pen driven by a fourth power device and arranged along the Z direction; the side, located on the first slide box, on the rack is fixedly provided with a clamp for clamping a workpiece; and the rack is also provided with a plating solution supply and recovery system. By using the automatic brush electroplating equipment provided by the invention, automatic operation is realized, the motion control is precise, the uniformity of a plating layer is ensured, the labor efficiency is increased, and the repaired workpiece is small in size difference; and the automatic brush electroplating equipment is suitable for mass remanufacture.

Owner:WEICHAI POWER CO LTD

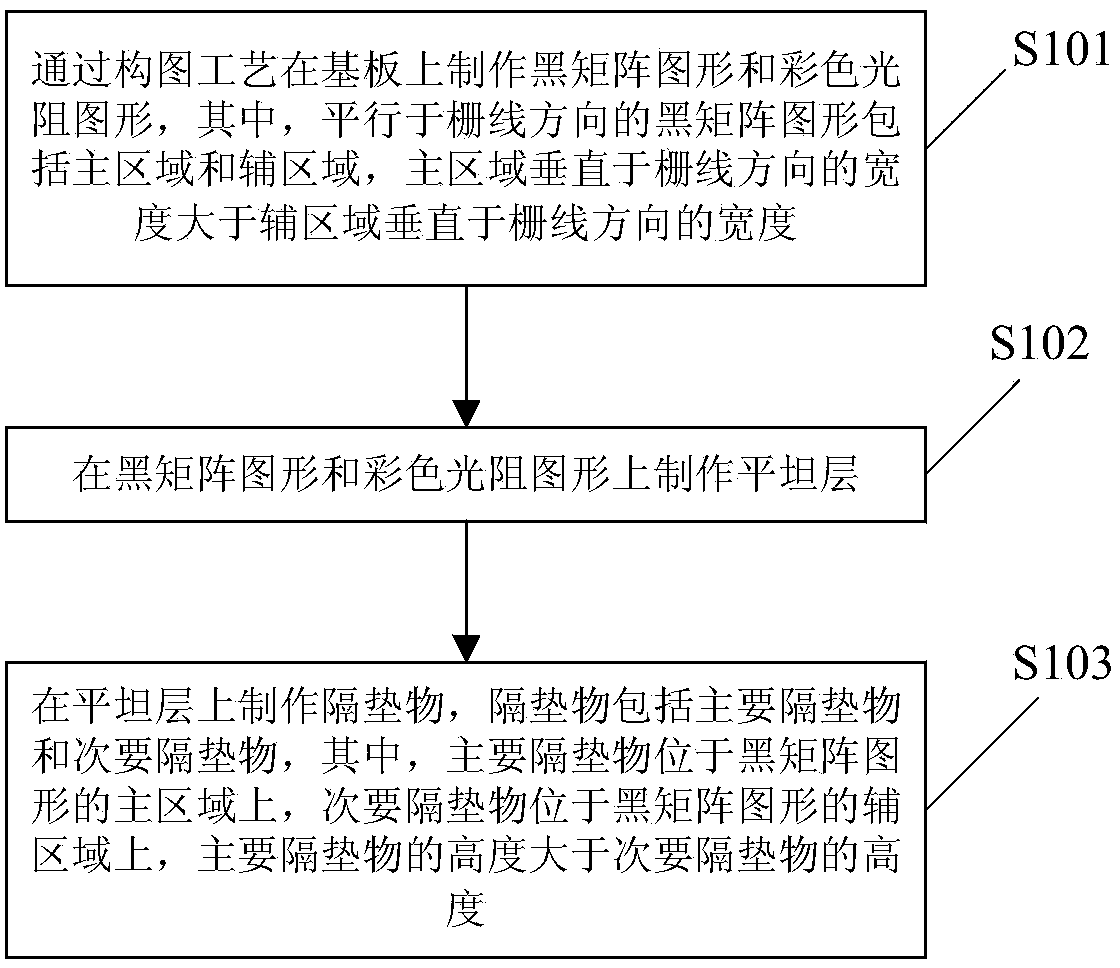

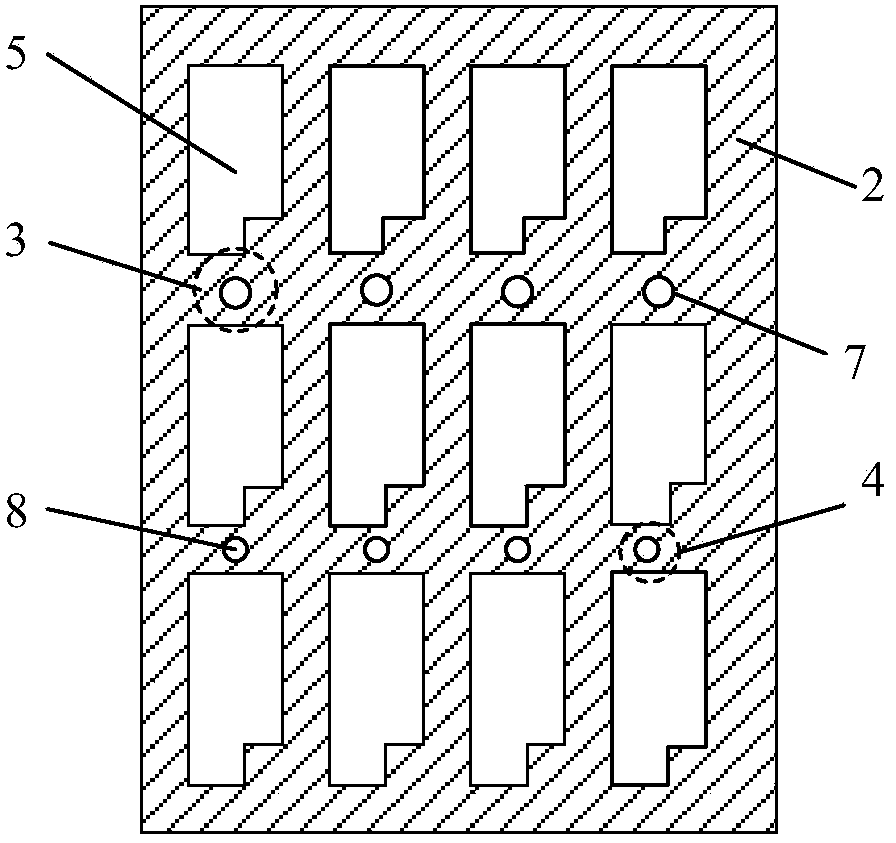

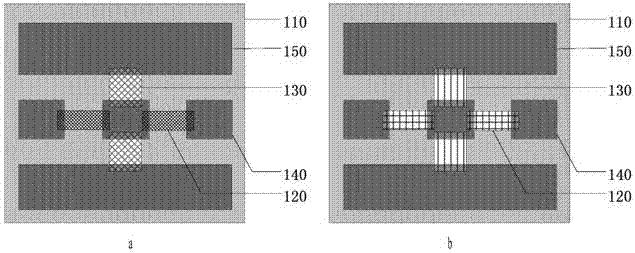

Color film substrate, and manufacturing method and display device thereof

ActiveCN103676293AImprove the display effectSmall size differenceNon-linear opticsOptical elementsDisplay deviceColor film

An embodiment of the invention discloses a color film substrate, and a manufacturing method and a display device thereof, relates to the technical field of display, and aims at lowering manufacturing cost of the color film substrate, easily forming a main insulator and an auxiliary insulator which are different in height, approximate in size, uniform in appearance, better in supporting effect and higher in display quality. The manufacturing method of the color film substrate includes: manufacturing a black matrix pattern and a color photoresist pattern on the substrate, wherein the black matrix pattern parallel to the grid line direction comprises a main zone and an auxiliary zone, and the width of the main zone, perpendicular to the grid line direction is greater than the width of the auxiliary zone, perpendicular to the grid line direction; manufacturing a flat layer and an insulator layer, wherein the insulator layer comprises the main insulator and the auxiliary insulator, the main insulator is located on the main zone of the black matrix pattern, the auxiliary insulator is located on the auxiliary zone of the black matrix pattern, and the main insulator is higher than the auxiliary insulator.

Owner:BOE TECH GRP CO LTD +1

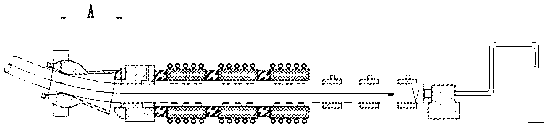

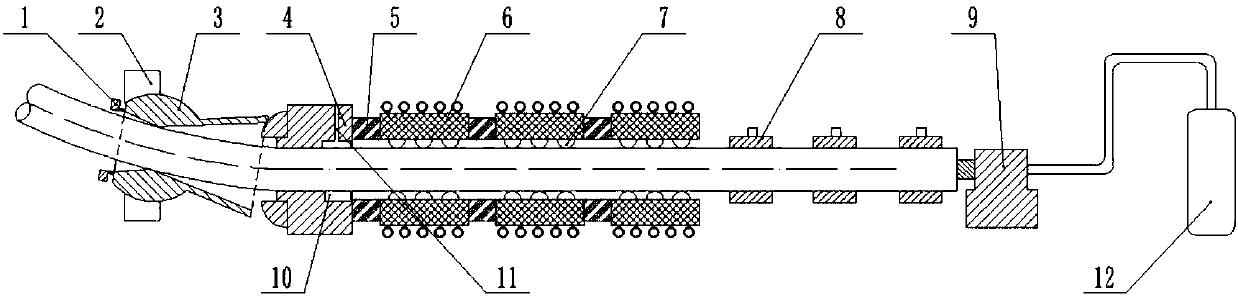

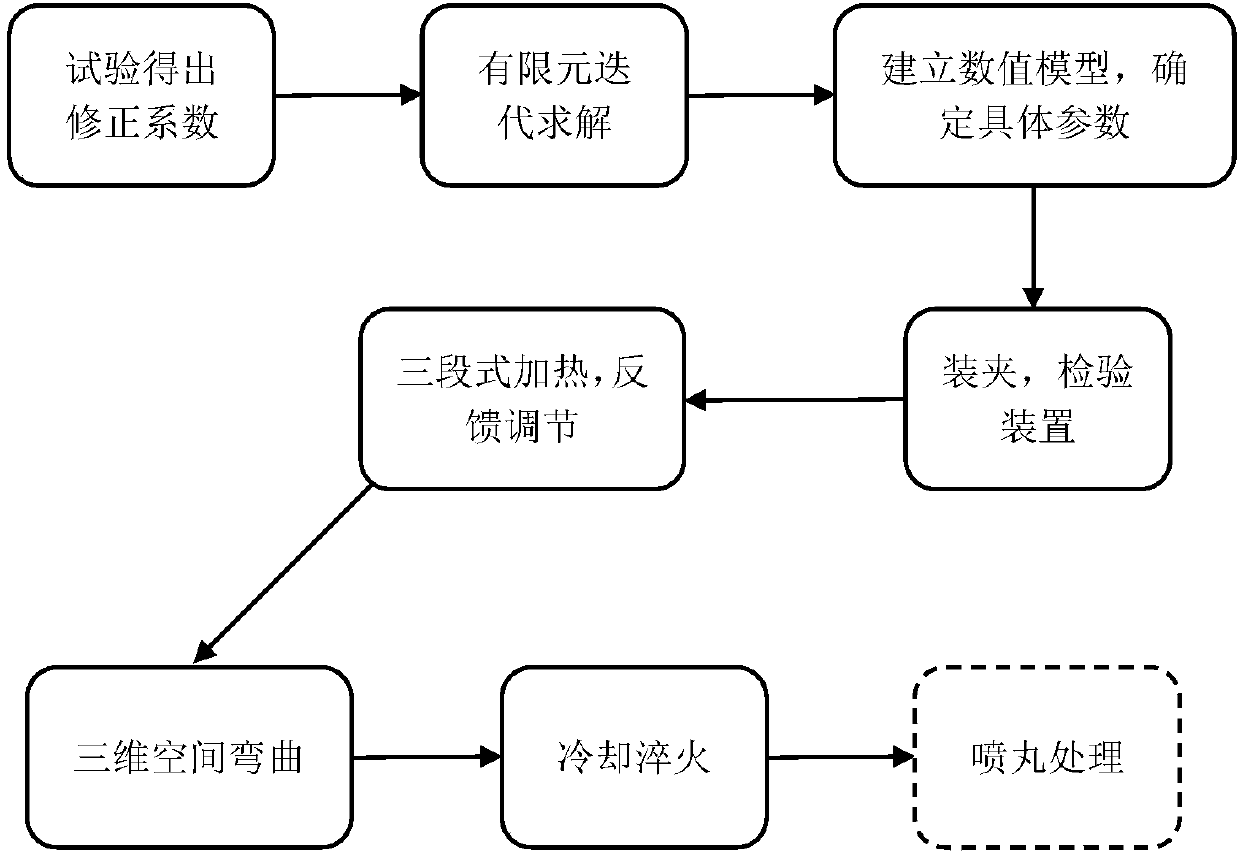

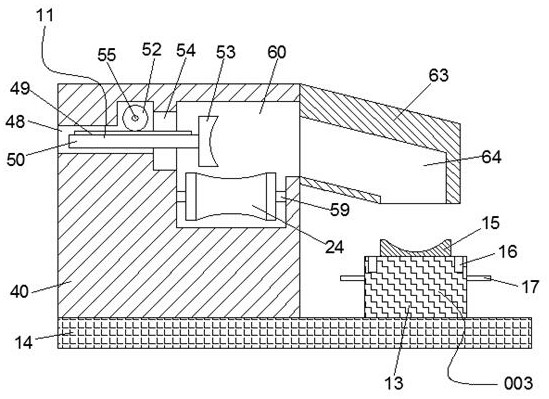

Martensite steel 3D free-bending forming device and method

ActiveCN107755490AIncrease productivityRealization of free bending pipeShaping toolsMetal-working feeding devicesNuclear powerMartensite

The invention discloses a martensite steel 3D free-bending forming device and method and belongs to the technical field of advanced manufacturing and plastic forming. Firstly, based on relative parameters of the forming performance of a pipe material, a corresponding correction factor of the material is obtained through repeated iterative calculation, and an initial model is corrected; after the using situations of parts are tested and calibrated, a three-stage type induction heating device and sensors are matched to achieve precise temperature-control heating; the three-dimensional space of abending mould rotates to extrude the front end of the pipe material to enable the front end of the pipe material to be in a bent shape with the complicated space; and the quenching process is conducted through an annular water-cooling spraying head and accordingly is rapid and uniform. The martensite steel 3D free-bending forming technical problem is solved, and high-temperature free-bending forming under the three-dimensional space is achieved; by means of a rapid quenching system, the strength of 1400 MPa or above is obtained, formation coordinated control of an ultrahigh-strength steel 3Dfree-bending member is achieved; and thus the martensite steel 3D free-bending forming device and method have important engineering application value in the fields of aerospace, rail transportation, automobiles and nuclear power.

Owner:NANJING INST OF TECH +1

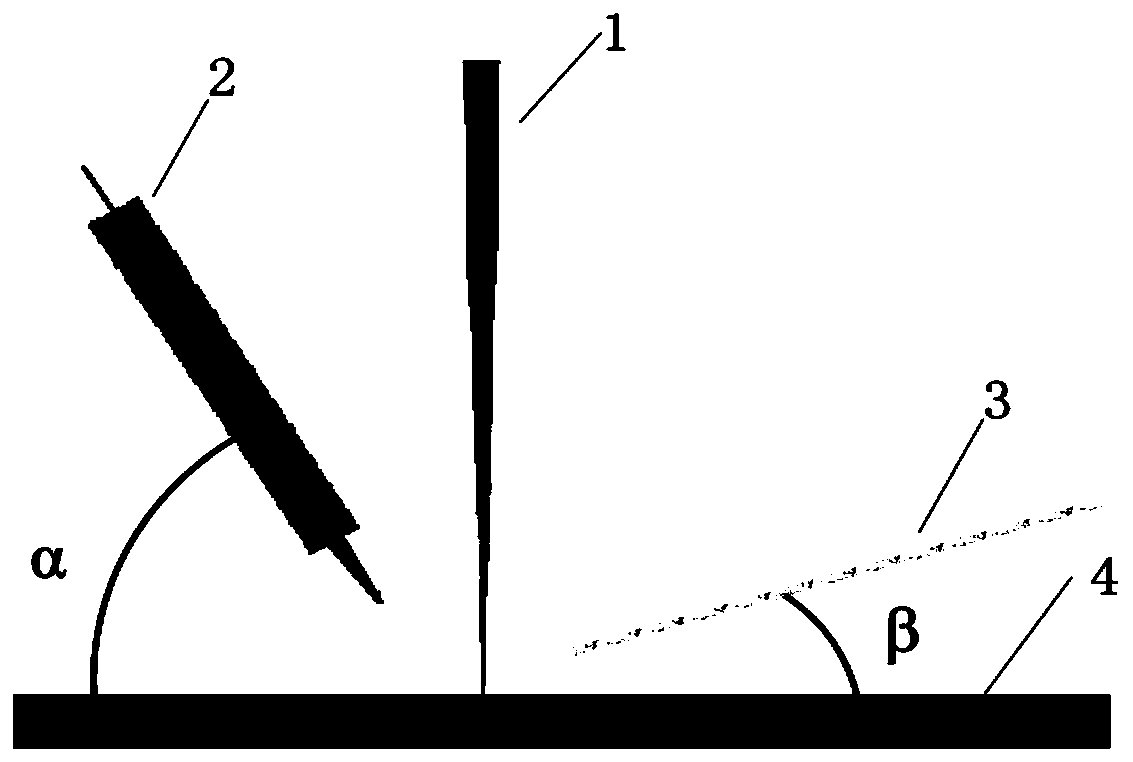

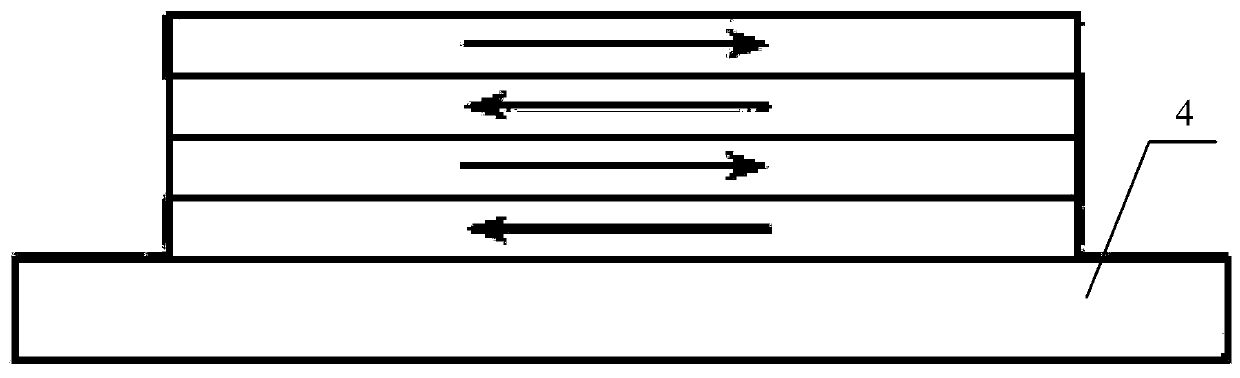

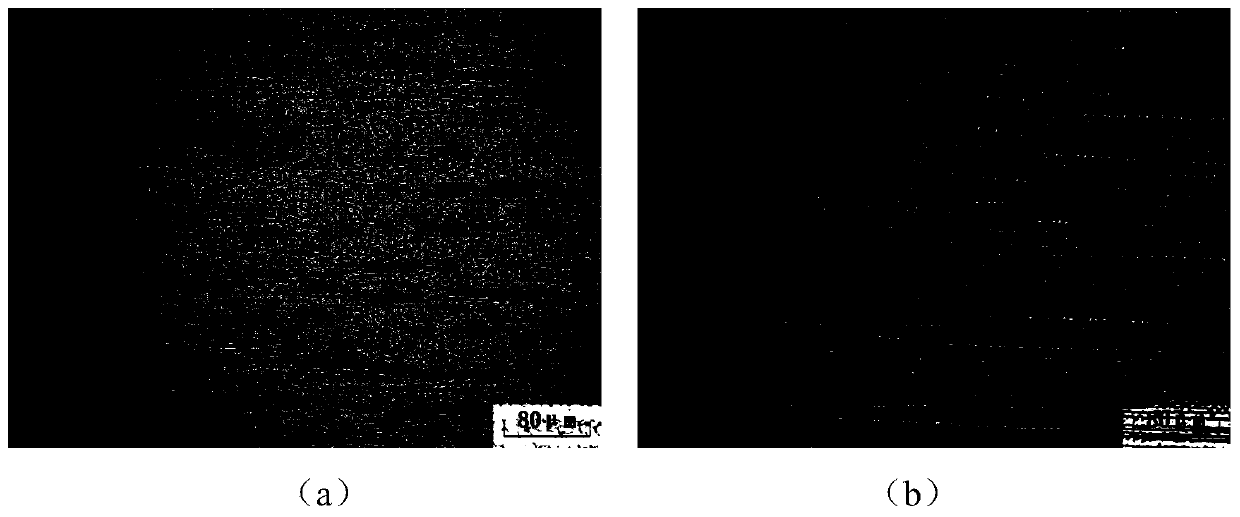

Low-power laser-induced TIG electric arc-based additive manufacturing method of stainless steel structural member and manufacturing system

ActiveCN109909616ACases to prevent spot depositsHigh precisionLaser beam welding apparatusArc stabilitySidewall roughness

The invention provides a low-power laser-induced TIG electric arc-based additive manufacturing method of a stainless steel structural member and a manufacturing system. According to the method, a low-power laser and a TIG electric arc are taken as a composite heat source, an included angle relationship among a welding gun, the laser and a substrate is arranged according to a welding environment, astainless steel welding wire is fed into a molten pool through an additional wire feeding device, is stably melted and spread on the treated substrate, surfacing is carried out according to a plannedroute, and a stainless steel workpiece with a required structure is formed by accumulating layer-by-layer. According to the method and the system, the process of electric arc additive manufacturing is effectively improved through the addition of the low-power laser, the electric arc stability is increased, the irregular flowing of the molten pool is reduced, the roughness of a side wall of an additive wall body is effectively improved, the forming quality is improved, the processing allowance is reduced, and the utilization rate of a material is increased; and the method and the system have the characteristics of high efficiency and energy saving, and speediness, high precision, short period, low cost and the like are achieved when the complicated large-scale member is manufactured by themethod and the system.

Owner:DALIAN UNIV OF TECH

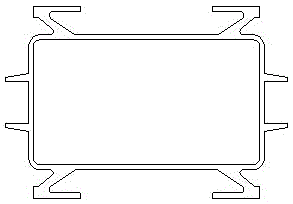

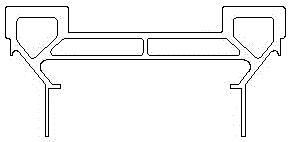

Manufacturing method of aluminum alloy mechanical arm track girder hollow profile

ActiveCN105039805AReduced risk of weakeningMeet the use requirementsUltimate tensile strengthAluminium alloy

The invention belongs to the technical field of aluminum alloy profiles and particularly relates to a manufacturing method for producing an aluminum alloy mechanical arm track girder hollow profile through an aluminum alloy replacing rolled steel. The manufacturing method comprises the steps that firstly, the intensity and the capacity of resistance to deformation of a steel cross beam are evaluated; secondly, the aluminum alloy is selected; thirdly, the structure of the aluminum alloy mechanical arm track girder hollow profile is designed; fourthly, the movement track and deformation of the aluminum alloy mechanical arm track girder hollow profile in a stressed state are simulated through a computer; fifthly, a mould of the aluminum alloy mechanical arm track girder hollow profile is manufactured; sixthly, the aluminum alloy mechanical arm track girder hollow profile is extruded and quenched online; seventhly, the aluminum alloy mechanical arm track girder hollow profile is aged; eighthly, the aluminum alloy mechanical arm track girder hollow profile is sampled; ninthly, the aluminum alloy mechanical arm track girder hollow profile is riveted; and tenthly, the aluminum alloy mechanical arm track girder hollow profile is packaged and delivered, and the aluminum replaces the steel to produce the aluminum alloy mechanical arm track girder hollow profile.

Owner:SHANDONG YUHANG SPECIAL ALLOY EQUIP

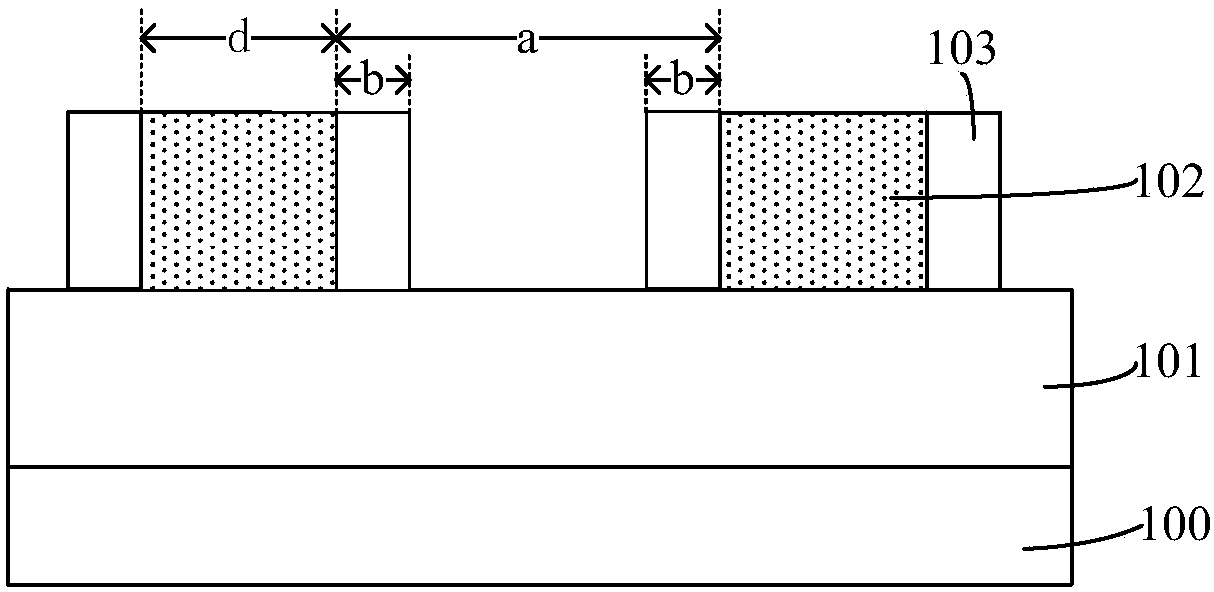

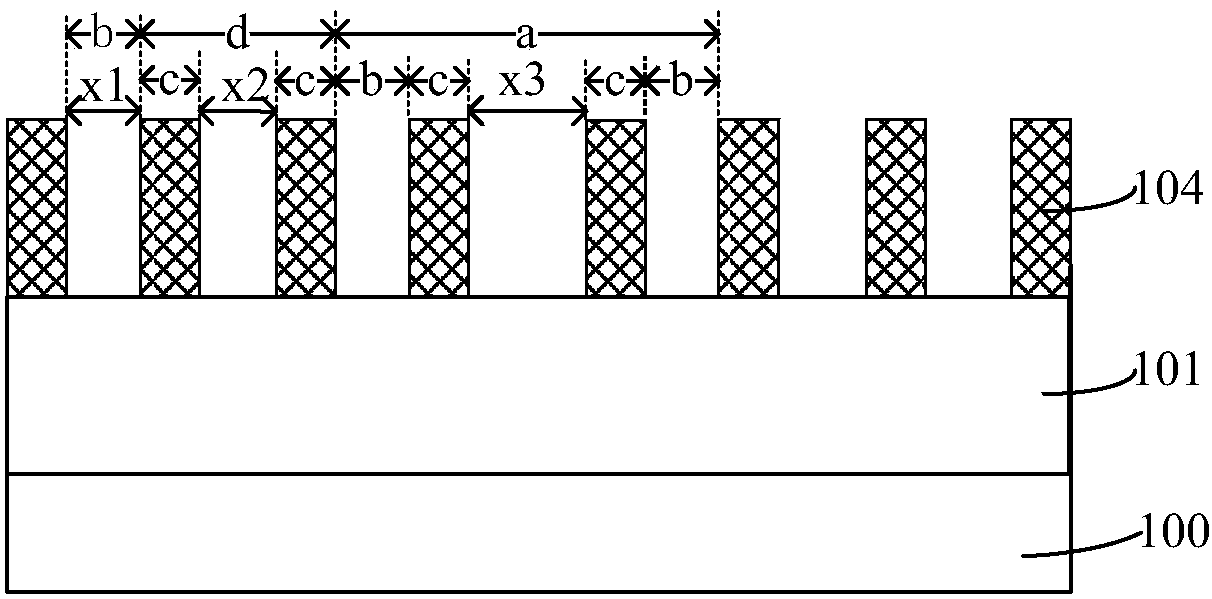

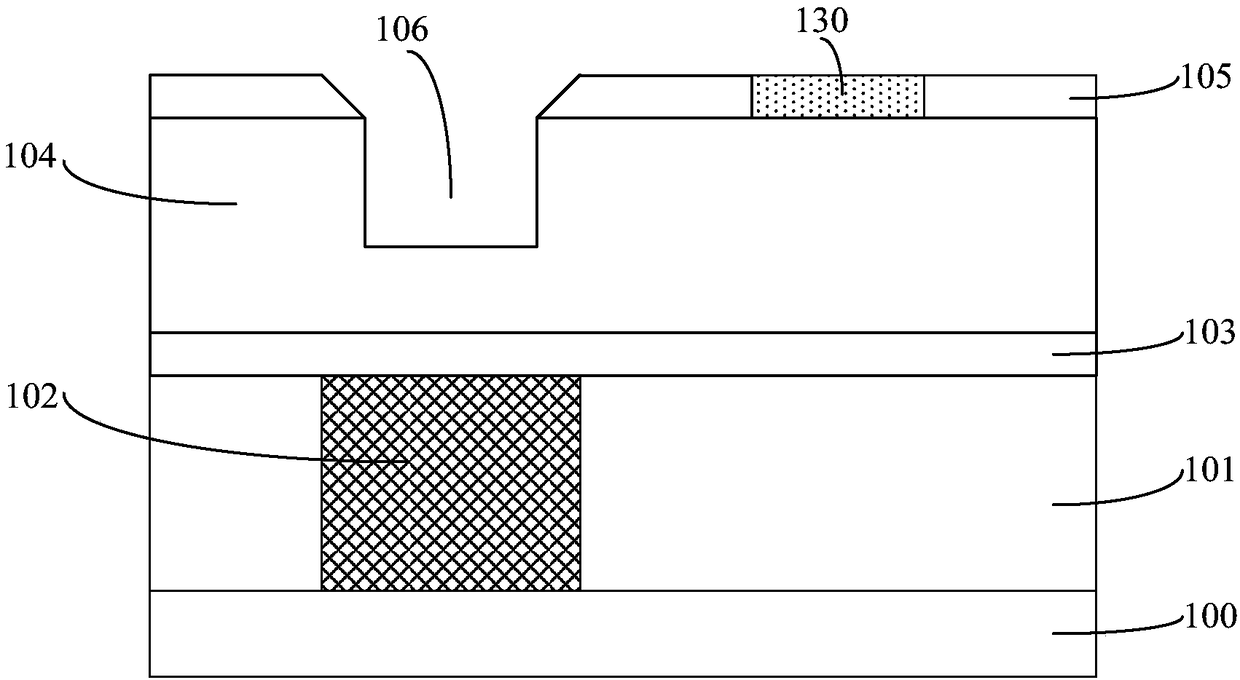

Semiconductor structure and forming method thereof

InactiveCN109427578AImprove performanceReduce varianceSemiconductor/solid-state device detailsSolid-state devicesSemiconductor structureEngineering

The present invention discloses a semiconductor structure and forming method of the semiconductor structure, the method comprises: providing a substrate; forming a first mask layer on a portion of thesubstrate; forming a first side wall on sidewall of the first mask layer; forming a second mask layer on the substrate, wherein the second mask layer covers the sidewall of the first side wall and exposes top surface of the first side wall; after forming the second mask layer, removing the first side wall; after removing the first side wall, using the first mask layer and the second mask layer asmasks, etching a portion of the substrate to form a groove in the substrate. The method subsequently form an interconnect structures within the groove, therefore provide better performance with the interconnect structure formed by the method.

Owner:SEMICON MFG INT (SHANGHAI) CORP +1

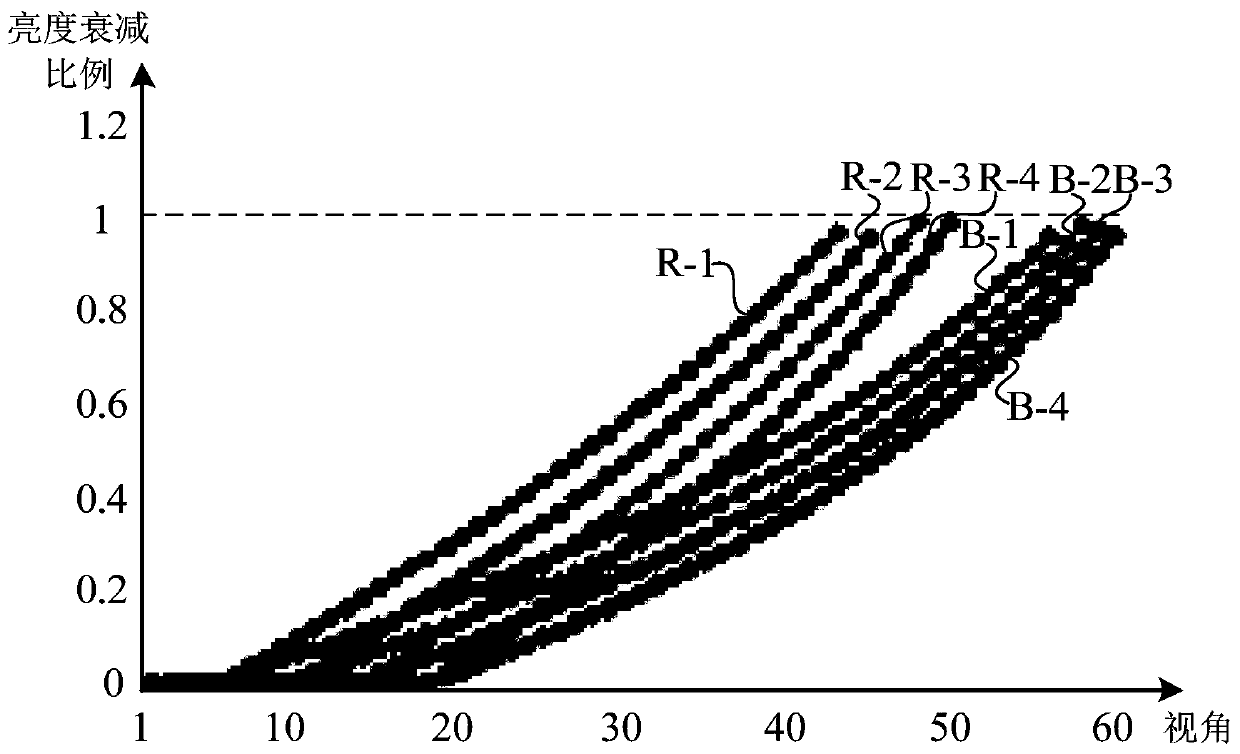

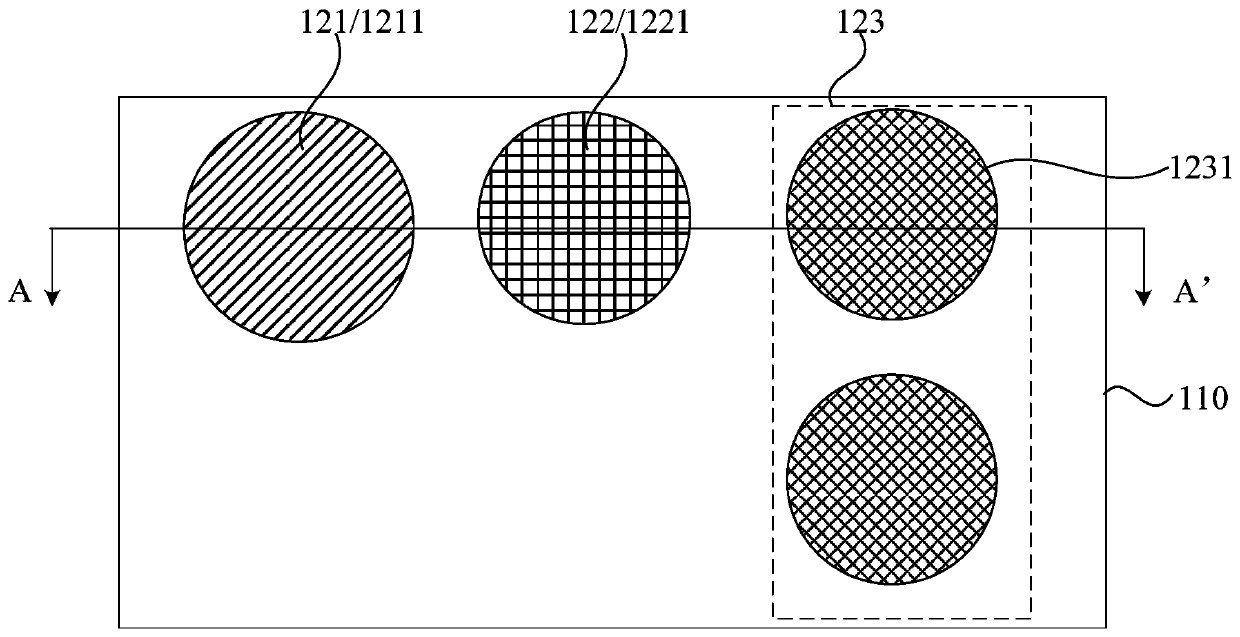

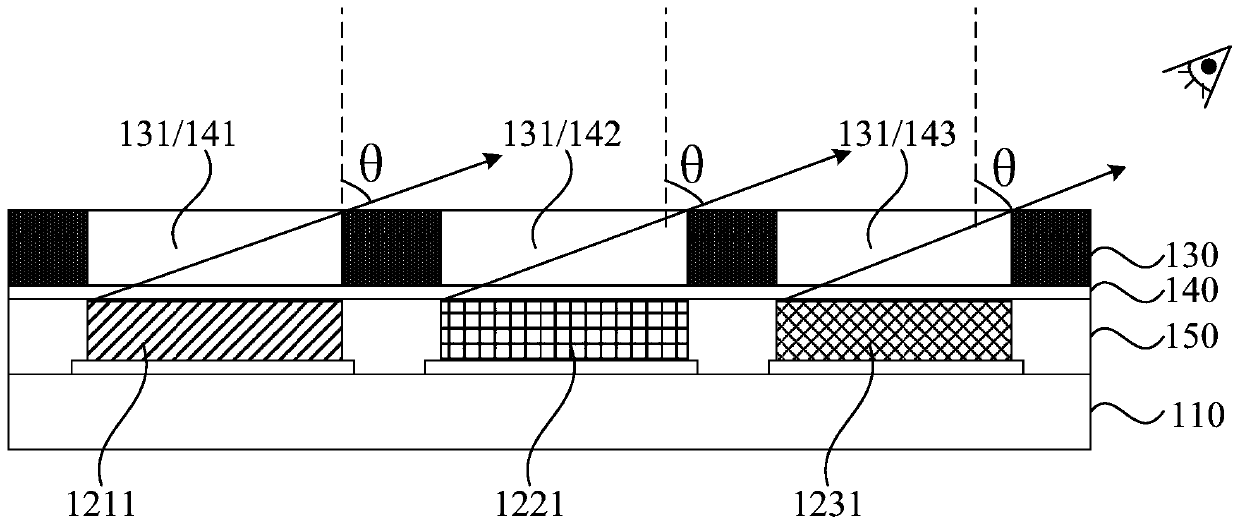

Display panel and display device

ActiveCN111599938ASmall brightness attenuation ratioConsistent brightness attenuation ratioSolid-state devicesSemiconductor/solid-state device manufacturingDisplay deviceLightness

The embodiment of the invention discloses a display panel and a display device. According to the arrangement, the sub-pixels of at least one light-emitting color comprise two or more light-emitting units of the corresponding color, the sub-pixels of other light-emitting colors comprise at least one light-emitting unit of the corresponding color, and the size difference between the light-emitting unit of any color and the light-emitting units of other colors in the set direction is less than or equal to the set size, so that the size difference of different light emitting colors enabled to be small in any direction, the change difference of the area proportions of the light-emitting units with different light-emitting colors shielded by a black matrix is small along with the change in screen viewing angle of a user, so that the brightness attenuation proportions of the light-emitting units with different colors along with the change of the visual angle are consistent, the brightness attenuation proportions of the sub-pixels with different colors along with the change of the visual angle are enabled to be consistent, and the color cast of a large visual angle is improved.

Owner:HEFEI VISIONOX TECH CO LTD

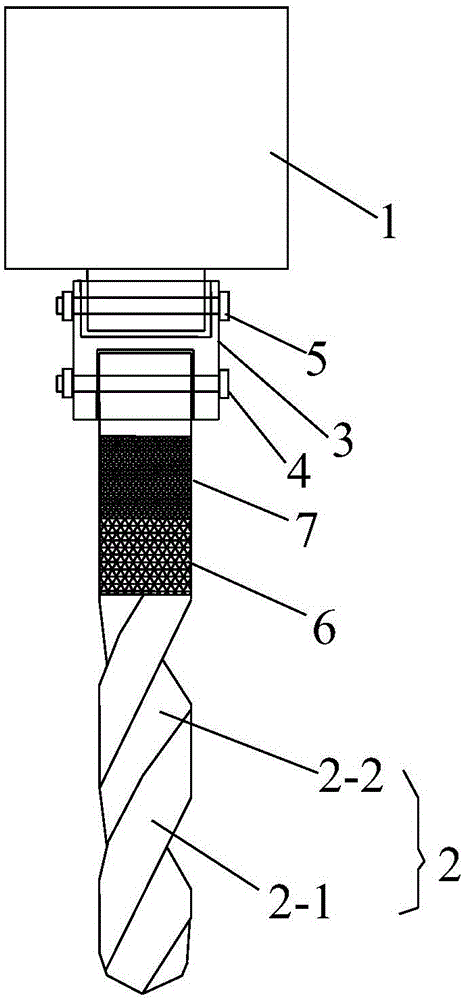

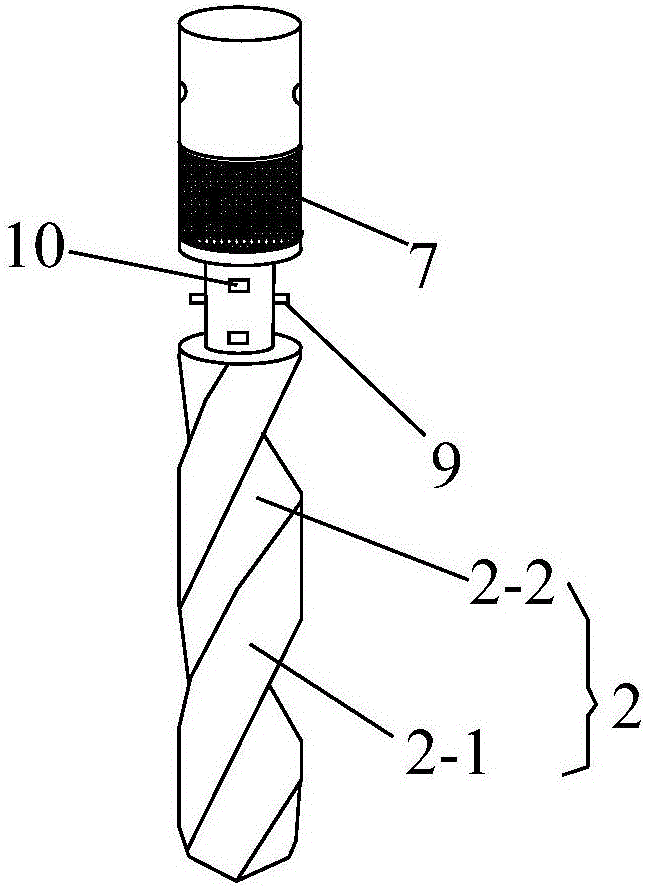

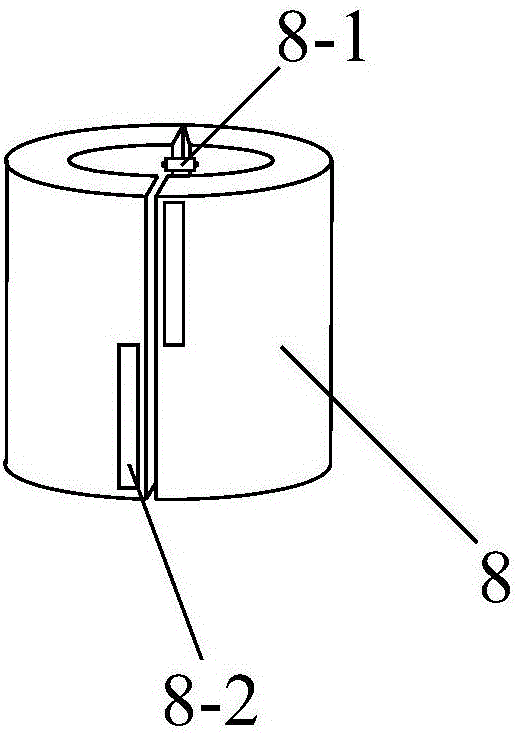

Drill-mill dual-purpose device for precise machine manufacturing

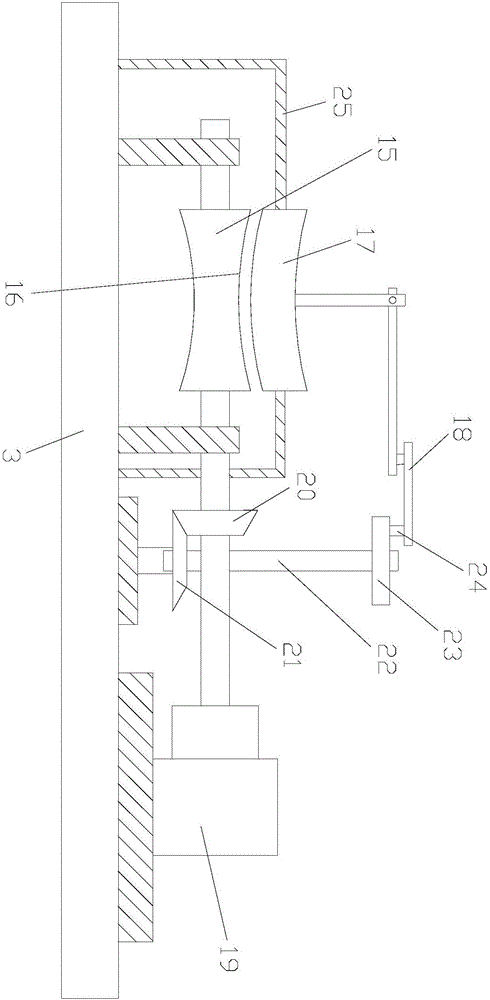

InactiveCN106736574ASmall size differenceImprove quality and efficiencyOther manufacturing equipments/toolsSize differenceEngineering

The invention relates to the technical field of machining equipment and discloses a drill-mill dual-purpose device for precise machine manufacturing. The drill-mill dual-purpose device comprises a bracket, wherein a motor is arranged on the bracket, and an output shaft of the motor is connected with a drill bit; and the drill bit comprises a hole drilling section and a hole milling section which are integrated, the hole drilling section is located below the hole milling section, the hole milling section comprises a coarse milling section and a fine milling section, and the coarse milling section is located below the fine milling section. According to the drill-mill dual-purpose device for precise machine manufacturing, the hole drilling section and the hole milling section are arranged on the same drill bit, a hole drilling procedure and a hole milling procedure are combined into one procedure, and meanwhile, the size difference between the drill bit and a dull polish block is reduced, so that the machining quality and the working efficiency are improved.

Owner:LIAONING INST OF SCI & TECH

Manufacturing method for aluminum alloy-made robot arm hollow profile

The invention belong to the technical field of aluminum alloy profile and concretely relates to a manufacturing method for slide rail hollow profile for robot arm movements with aluminum alloy replacing steel. The manufacturing method comprises first, analyzing steel connection member motion and stress conditions, second, selecting aluminum-alloy material, third, designing hollow profile, fourth, simulating aluminum profile connection member motion and stress conditions by a computer to determine whether the hollow profile meets demands, fifth, selecting an extruding machine and designing an aluminum alloy hollow profile connection member via a die, sixth, casting aluminum alloy ingot, seventh, extruding aluminum alloy hollow profile connection member and conducting online quenching, eighth, conducting aluminum alloy hollow profile connection member tension extension and aging treatment, ninth, sampling and checking the aluminum alloy hollow profile connection member, and tenth, hardening and packing the aluminum alloy hollow profile. Motion and stress conditions of the aluminum alloy hollow profile connection member can be simulated by the computer; strength and plasticity meet use requirements; and hollow profile can be manufactured in batches by the use of the method.

Owner:SHANDONG YUHANG SPECIAL ALLOY EQUIP

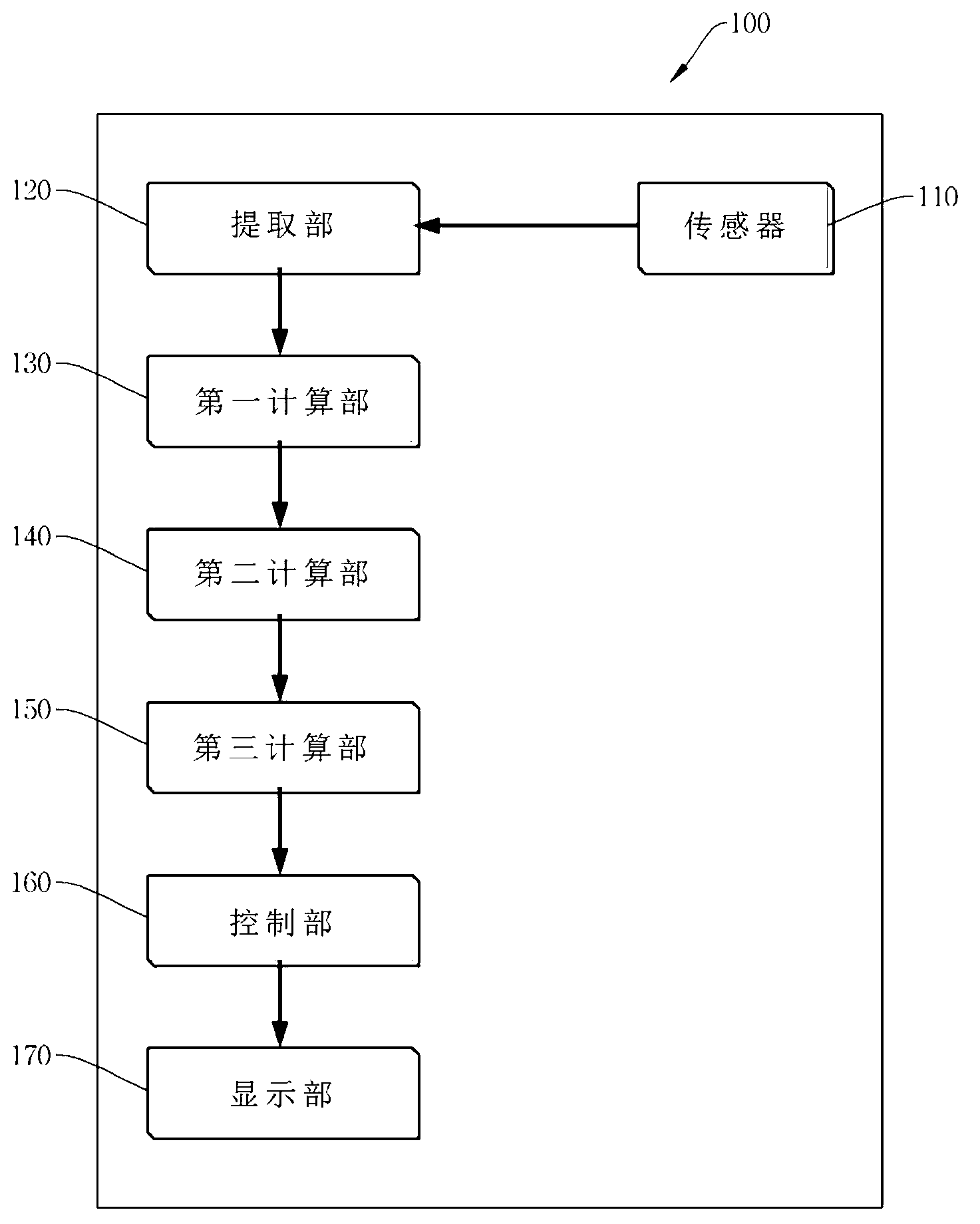

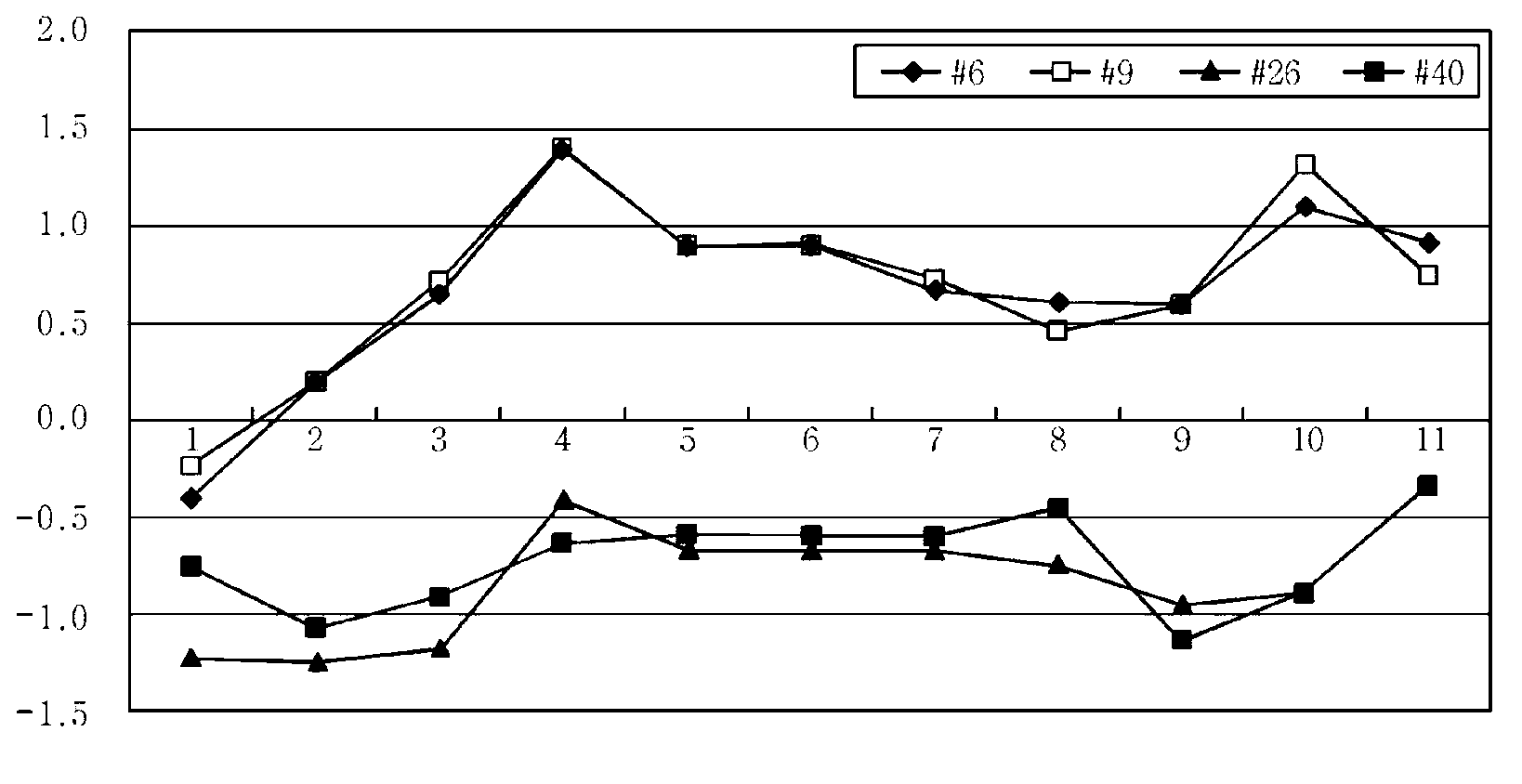

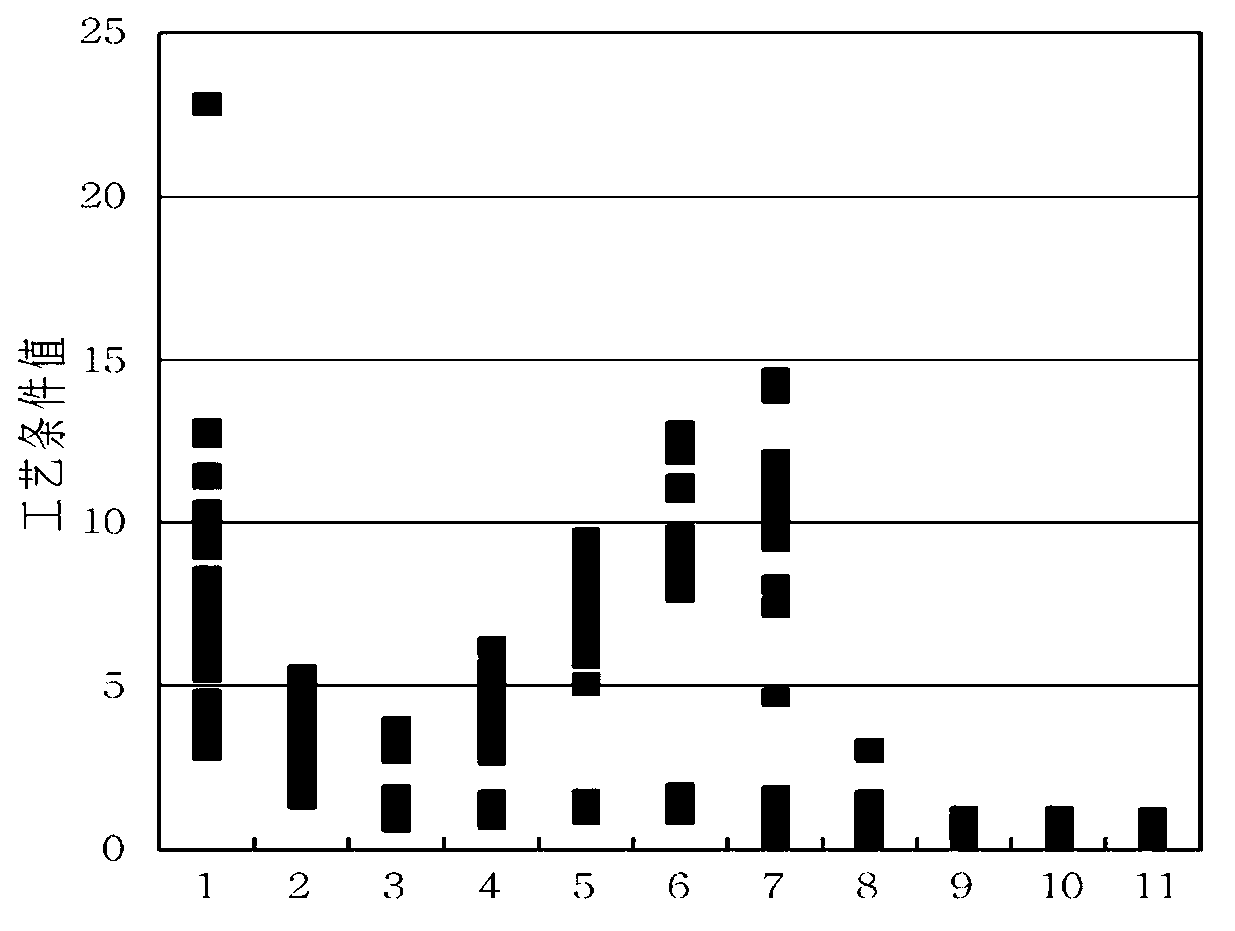

Representative-value calculating device and method

ActiveCN103329136AImprove accuracySmall size differenceComplex mathematical operationsProcess systemsEngineering

Provided is a representative-value calculating device for calculating a representative value of process condition values by using values of process conditions measured in a process system. The representative-value calculating device according to an embodiment of the present invention calculates a median and a median absolute deviation (MAD) of process condition values at each sampling point by using the process condition values measured for each sample at each sampling point through a sensor; calculates a standardized value by using the process condition values, the median, and the MAD; and calculates a representative value of the process condition values for each sample on the basis of the calculated standardized values.

Owner:缇拉优特科技有限公司

Polymerizable compound, polymer, positive resist composition, and patterning process using the same

ActiveUS8129086B2High sensitivity and resolutionPattern configurationOrganic chemistryOrganic compound preparationSize differenceResist

A polymer suitable as a base resin for a positive resist composition, in particular a chemically amplified positive resist composition, having a higher resolution, a larger exposure allowance, a smaller sparse-dense size difference, a better process applicability, a better pattern configuration after exposure, and in addition, a further excellent etching resistance, than a conventional positive resist. A positive resist composition using the same, a patterning process, and a novel polymerizable compound to obtain the polymer. A polymer has a hydrogen atom of at least a carboxyl group is substituted by an acid labile group represented by the following general formula (2), a positive resist composition using the same, a patterning process, and a novel polymerizable compound to obtain a polymer like this.

Owner:SHIN ETSU CHEM IND CO LTD

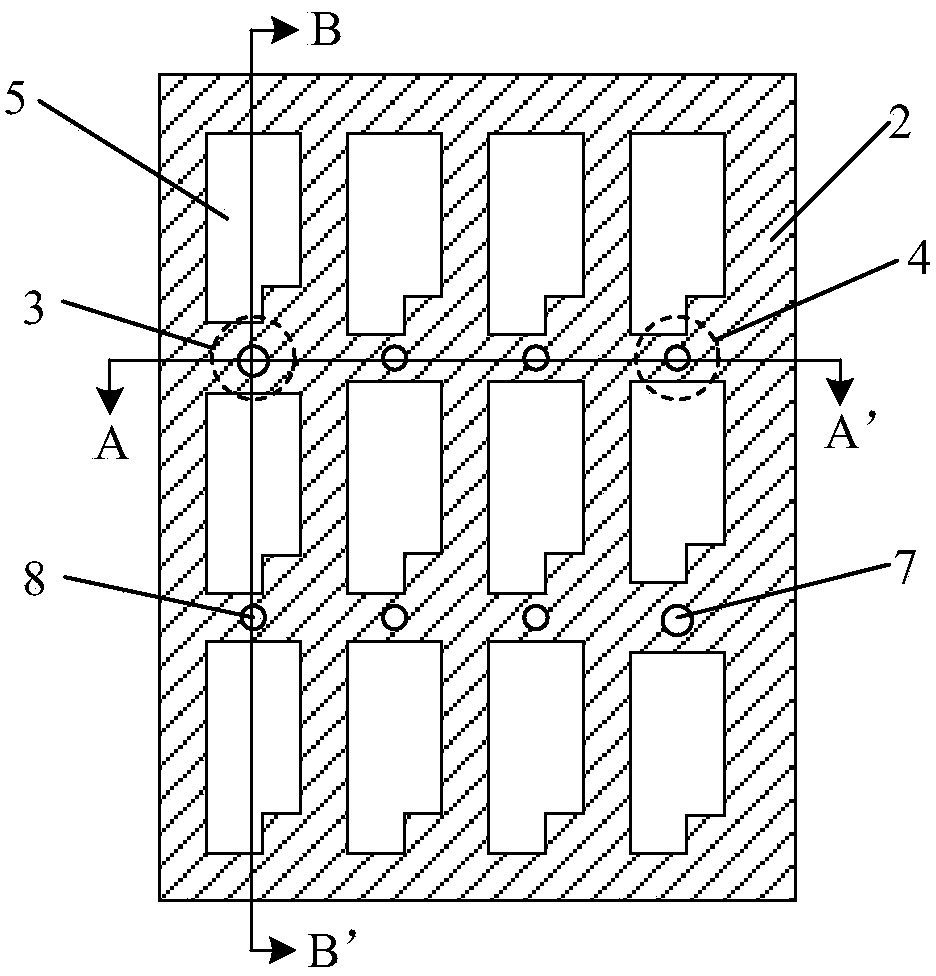

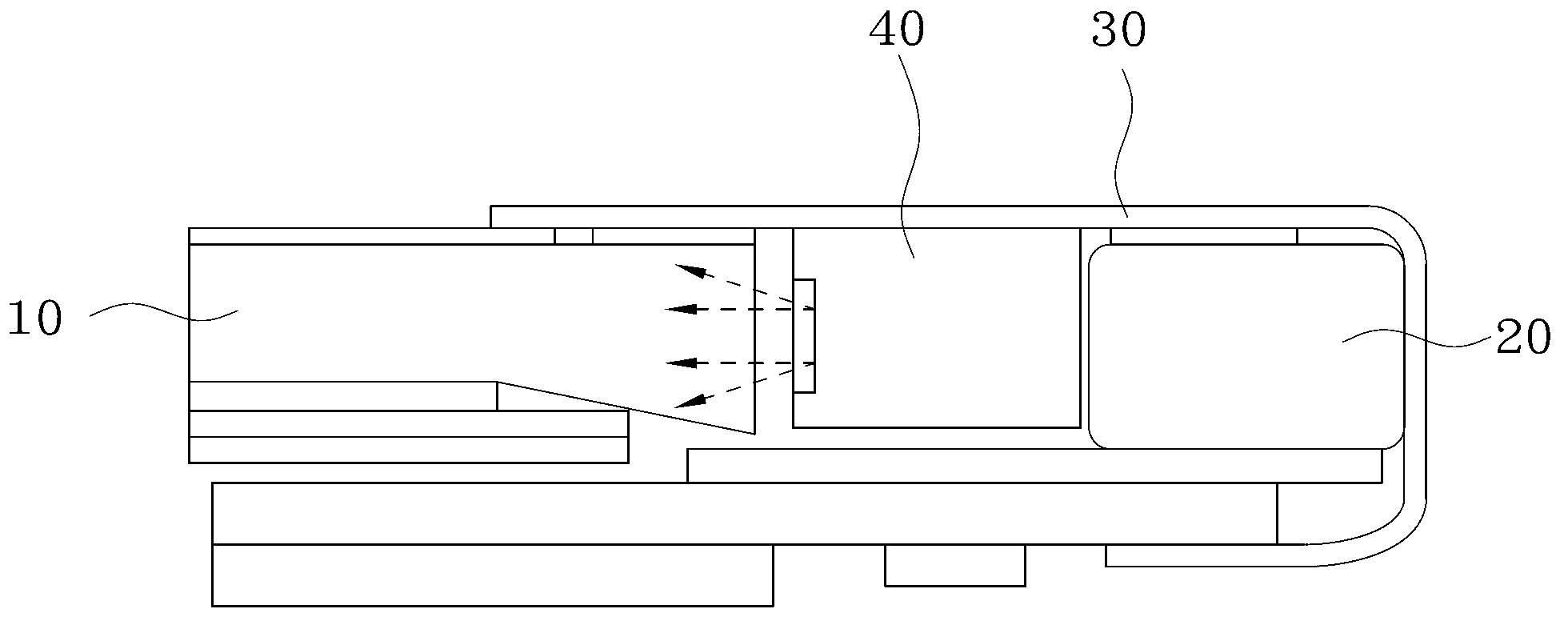

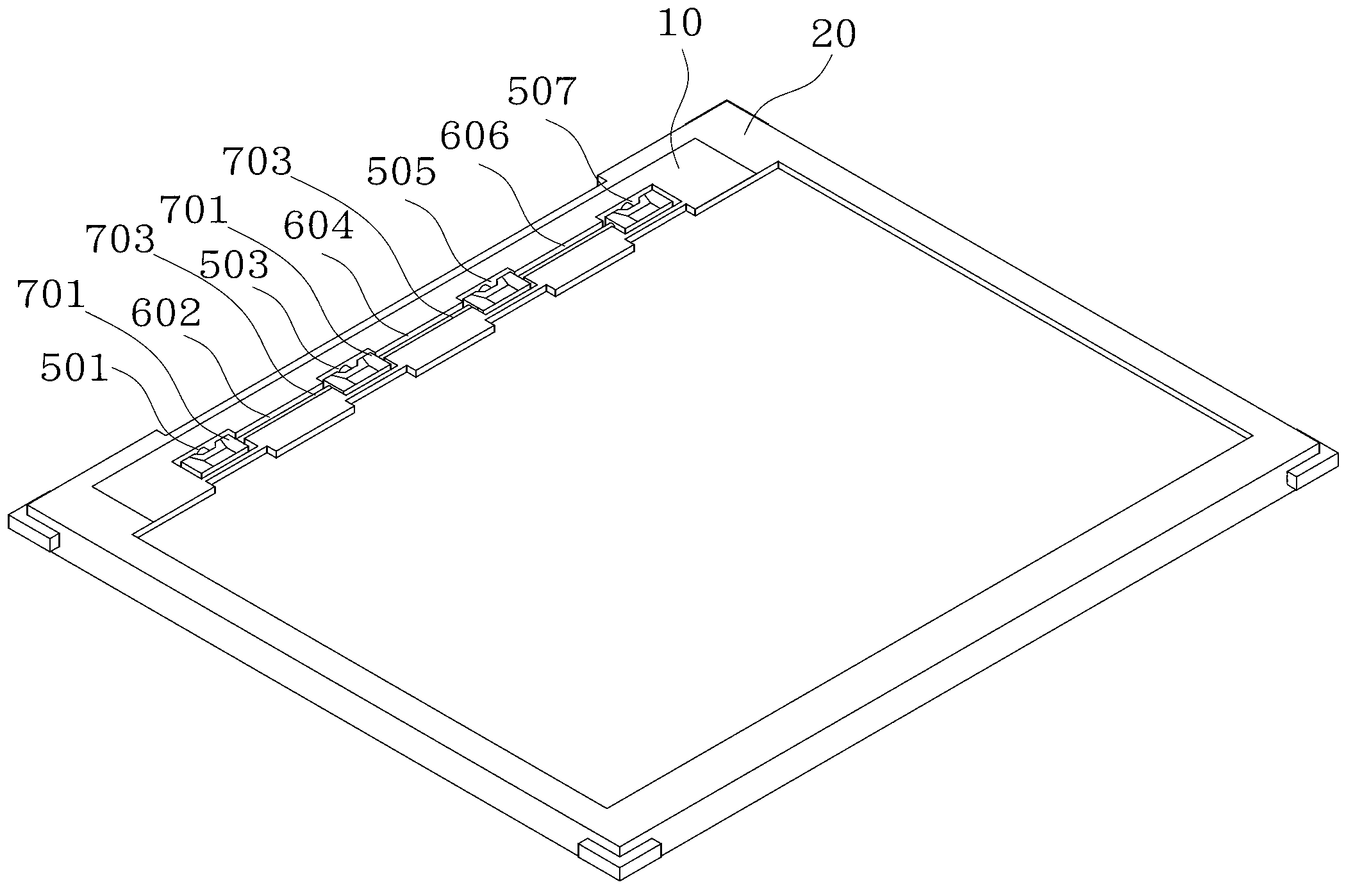

Method for assembling LED (Light-Emitting Diode) and light guide plate and backlight module

InactiveCN102937262AGuaranteed parallelismSmall size differencePoint-like light sourceLight fasteningsEngineeringLight guide

The invention provides a method for assembling an LED (Light-Emitting Diode) and a light guide plate and a backlight module. The backlight module comprises a plurality of LEDs, a light guide plate and a flexible circuit, wherein the light guide plate comprises a plurality of first grooves and a plurality of second grooves which are arranged in a staggered manner; the flexible circuit comprises a plurality of containing parts and a plurality of connecting parts; each containing part is arranged in the corresponding first groove; and each connecting part is located in the corresponding second groove. The connecting parts of the flexible circuit are located between the adjacent two containing parts; and the adjacent LEDs are electrically connected in series by the connecting parts. With the adoption of the method disclosed by the invention, the plurality of first grooves and the plurality of second grooves are formed on the light guide plate by adopting a mould direct molding manner; the containing parts are placed into the first grooves and the connecting parts are placed into the second grooves; and the adjacent two LEDs are electrically connected in series by the connecting parts so that the parallelism degree of an LED lamp can be guaranteed, the size difference of different LED grooves is reduced and the assembling precision is improved.

Owner:AU OPTRONICS (XIAMEN) CORP +1

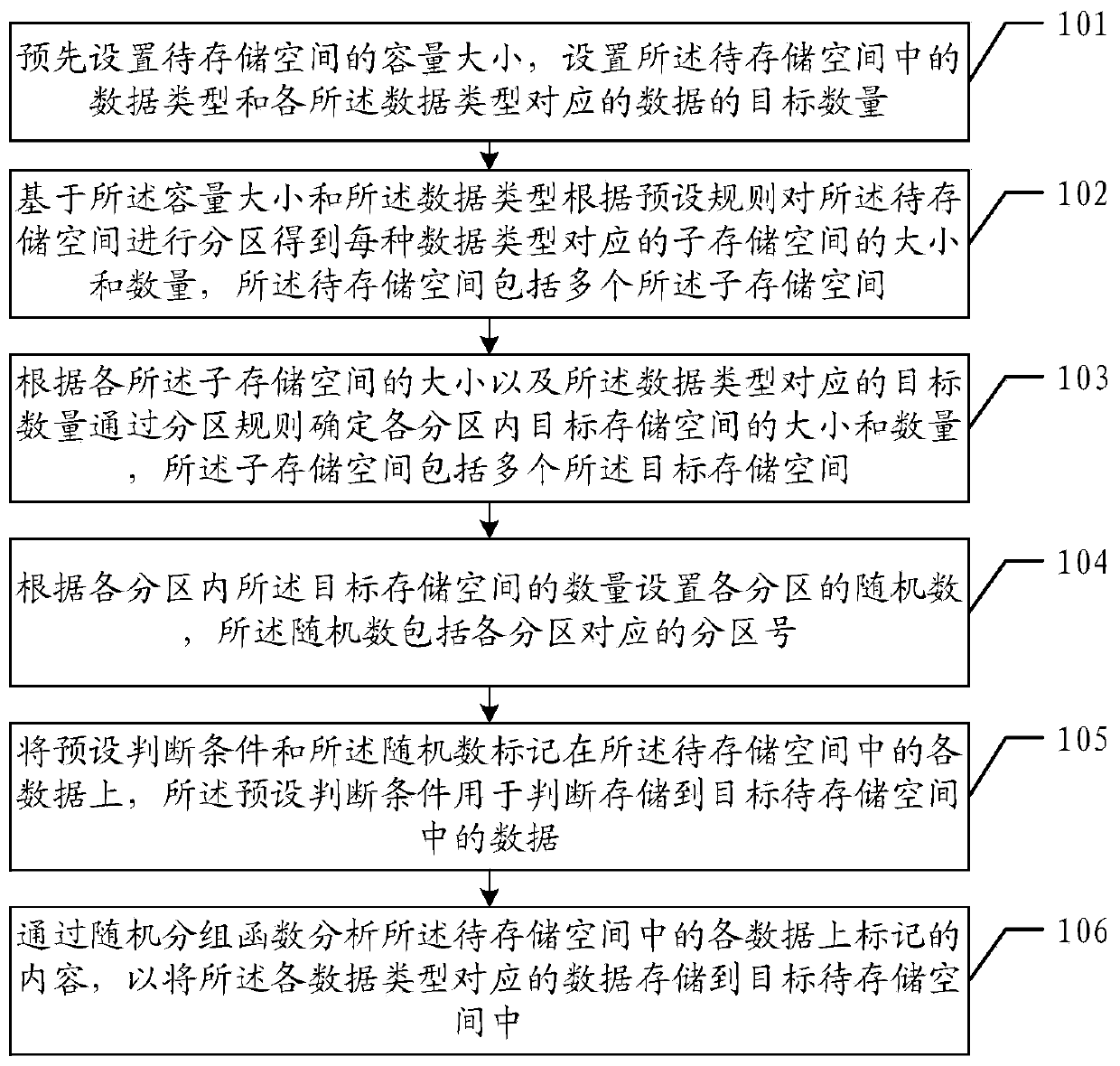

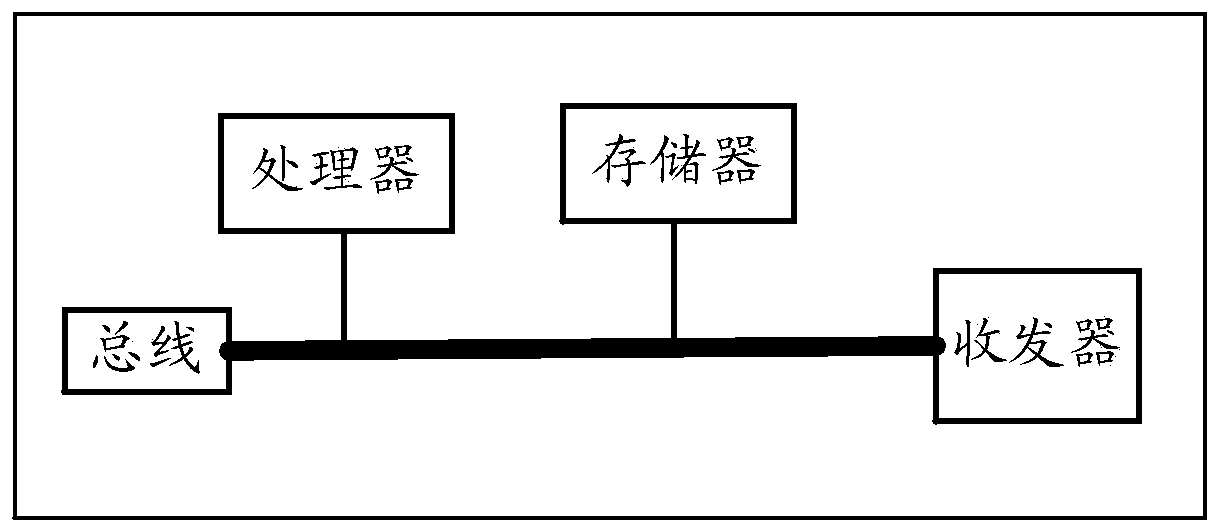

Method, device and equipment for processing data skew and storage medium

PendingCN111046045ATroubleshoot tilt handling issuesSmall size differenceDatabase distribution/replicationMulti-dimensional databasesData classAlgorithm

The invention relates to the field of big data, and provides a method, device and equipment for processing data skew and a storage medium. The method comprises the steps: presetting the capacity of ato-be-stored space, and setting the data type and target number in the to-be-stored space; partitioning the to-be-stored space according to a preset rule based on the capacity and the data types to obtain the size and the number of sub-storage spaces corresponding to each data type; according to the size of each sub-storage space and the target number corresponding to the data type, determining the size and the number of target storage spaces in each partition through a partition rule; setting a random number of each partition according to the number of the target storage spaces in each partition; marking the random number and a preset judgment condition on each part of data in the to-be-stored space; and analyzing the content marked on each part of data in the to-be-stored space through the random grouping function so as to store the data corresponding to each data type into the target to-be-stored space. By adopting the scheme, the problem of data skew processing can be effectively solved.

Owner:CHINA PING AN PROPERTY INSURANCE CO LTD

Method for preparing integral small-diameter aquatic hard-particle feed

InactiveCN101103778ASmall size differenceRegular shapeAnimal feeding stuffWorking-up animal fodderNutrientWater quality

The invention discloses a production method for a complete minor diameter hard particle aquatic feed, which comprises the following steps: 1. the raw materials is mixed and crushed into 0.02 to 0.30mm in proportion; 2. the flour with a weight content of 18% to 30 percent is added into the mixed powder lot; 3. a steam softening materials is added into the mixed powder lot so as to make the weight content of moisture reach 12 percent to 18 percent, thereby the moist heat materials is formed; 4. a die mold with the ratio between the depth and the diameter of die hole of 20:1-28:1 is adopted; 5.the moist heat materials is delivered into a forming machine to produce the particles with a diameter of 0.8 to 1.2 mm; 6. after the heat preservation for 20 to 50 min, the particles are cooled to 28 DEG C to 40 DEG C by cold wind; 7. the crushed grain and powder of cooling particle feed are filtered by a grading screen; 8. the complete minor diameter hard particle aquatic feed is packed and stored. The minor diameter hard particle aquatic feed which is made by the method of the invention has the advantages that: the utilization rate is high; the need of feed of the fish and shrimp larvae can be met, and the waste of feed can be reduced; furthermore, the pollution of the quality of the cultivation is reduced, and the balance of nutriment for the fish and shrimp larvae is improved.

Owner:何金林 +1

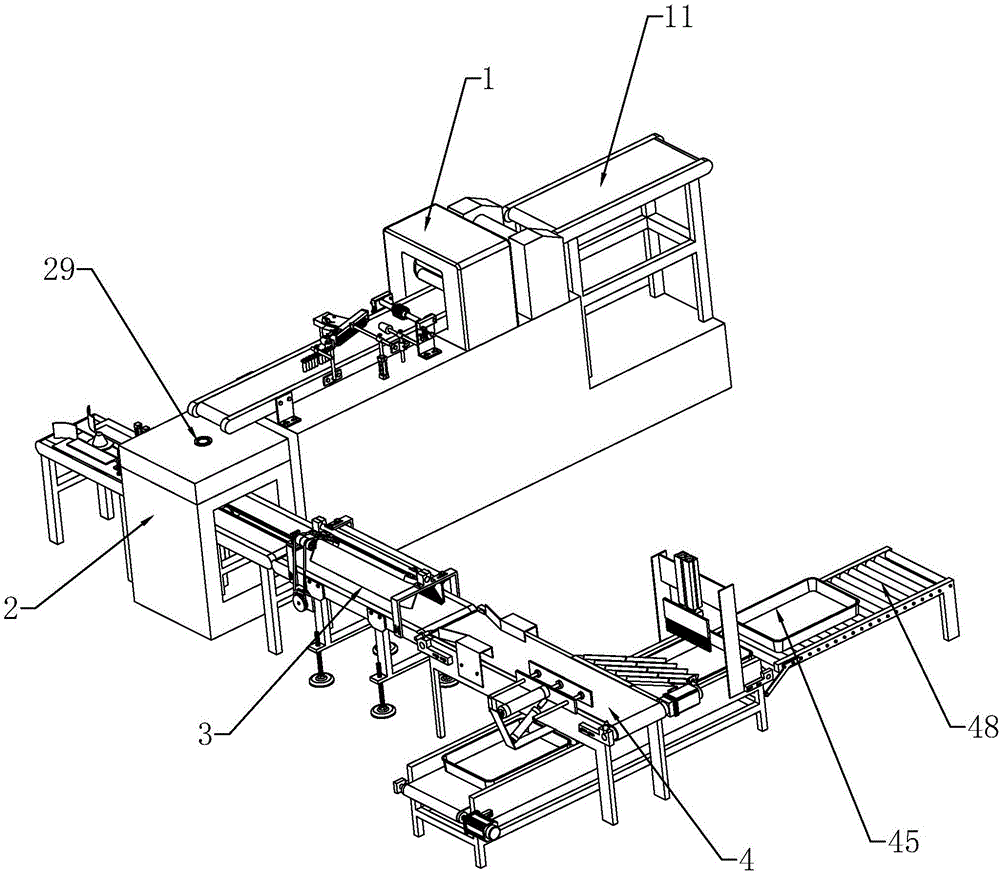

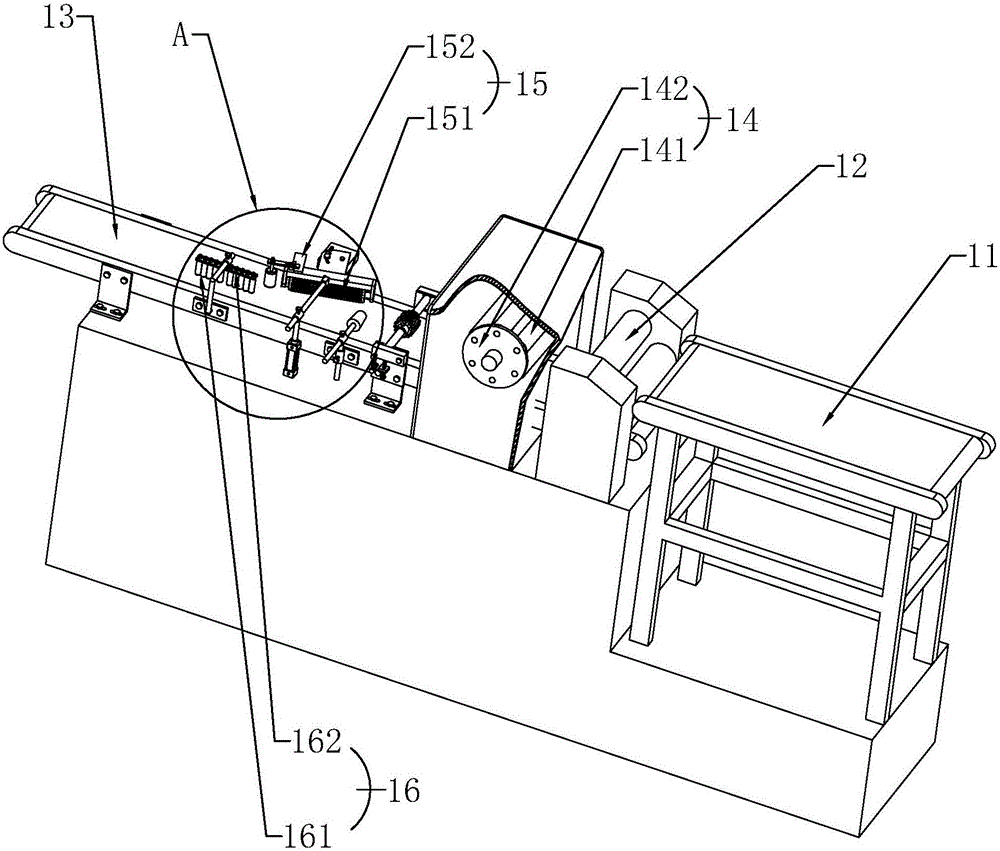

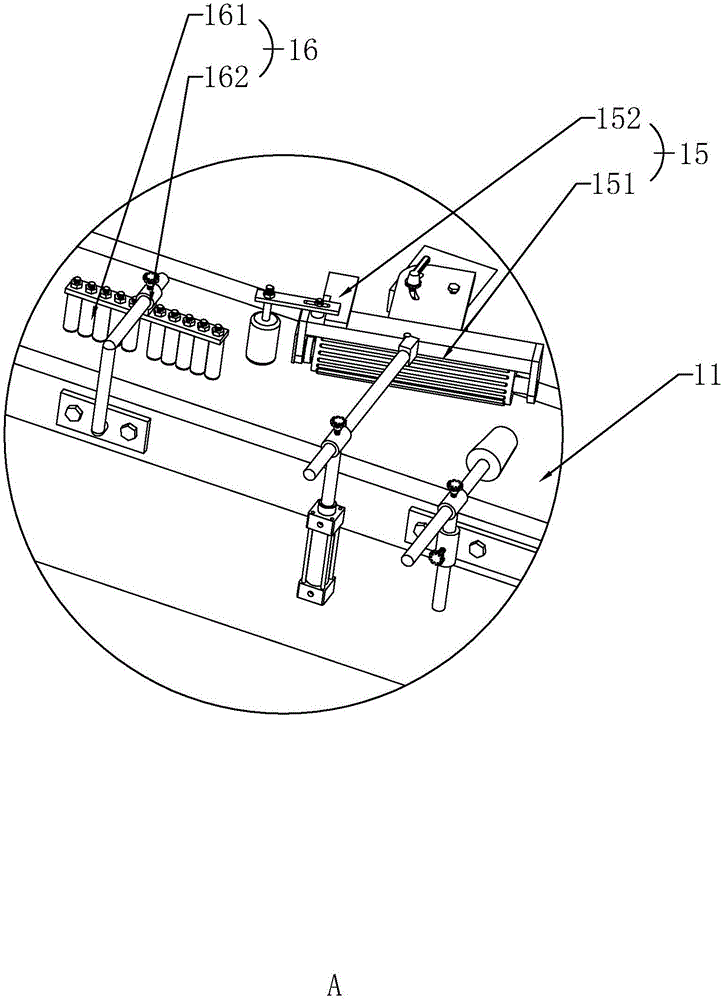

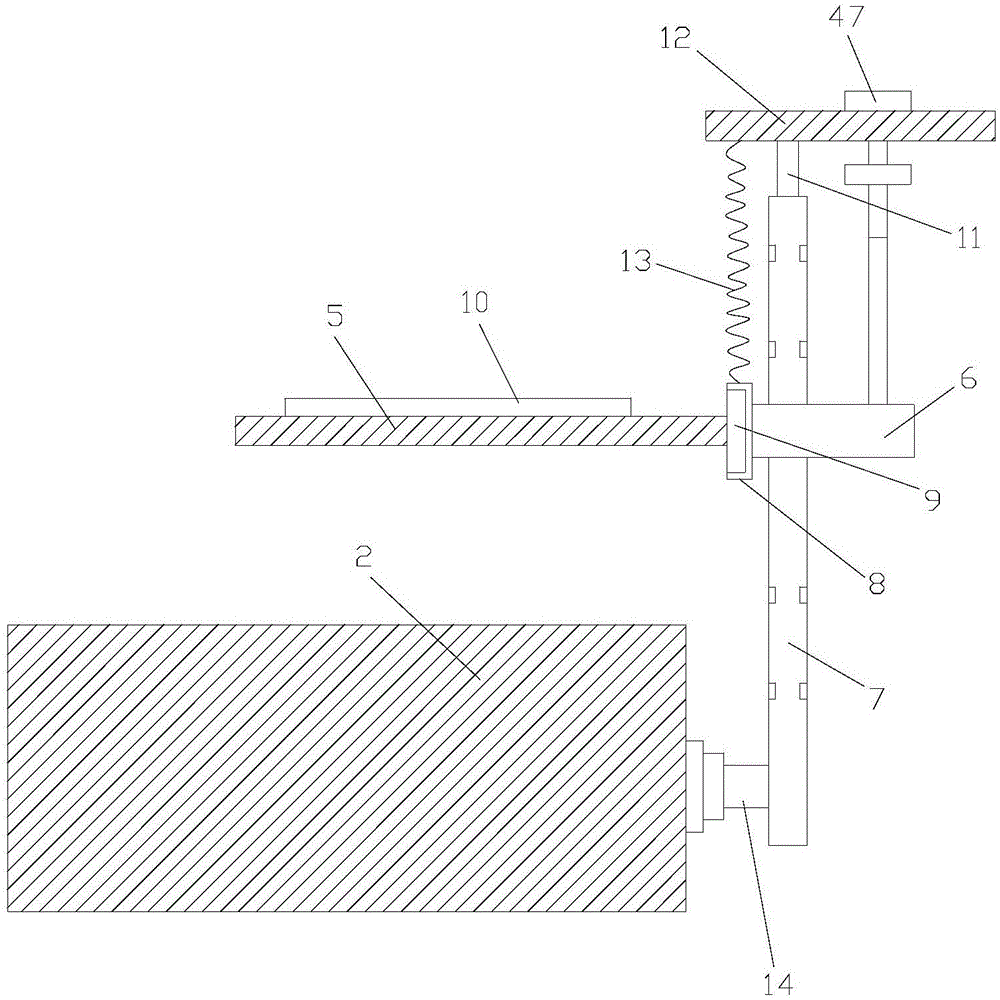

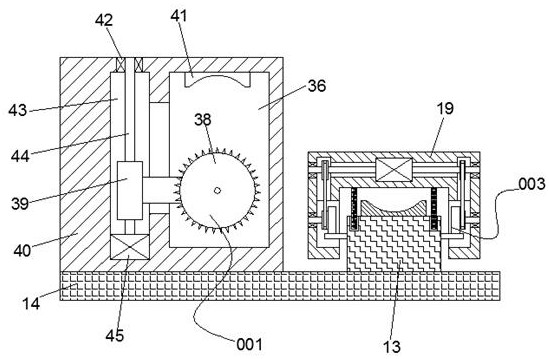

Steamed hard-breadroll forming machine

ActiveCN105831190AUnified appearanceSmall size differenceDough-sheeters/rolling-machines/rolling-pinsDough shaping and cutting apparatusEngineeringMechanical engineering

The invention discloses a steamed hard-breadroll forming machine and a steamed hard-breadroll forming process. The steamed hard-breadroll forming machine is characterized by comprising a dough feeding conveying device for processing dough materials into strips in sequential connection, wherein the dough feeding conveying device is sequentially connected with a pre-pressing forming device, a shaping device and a disc ranging device; the pre-pressing forming device is used for cutting dough materials and pre-pressing the dough materials into a cap shape with the hemispherical recessed bottom; the shaping device is used for performing shaping processing on the shaped steamed hard-breadroll; the disc ranging device is used for collecting the shaped steamed hard-breadroll; the dough is kneaded and pressed to be made into plane-shaped strips; the strips are flatly pressed by the dough feeding conveying device; strip-shaped dough materials capable of being conveniently cut are formed; through the pre-pressing forming device, the dough materials are sheathed and connected onto a mold to obtain a steamed hard-breadroll mold primarily in a cap shape; then, the shaping device is used for performing shaping smoothening processing to obtain the final steamed hard-breadroll appearance; collection is performed through the disc ranging device; the goal of automatically making the dough materials into the formed steamed hard-breadroll is achieved; the production efficiency is improved; the labor and the materials are effectively saved; the automatic mass production effect is realized.

Owner:杭州贝加尔食品有限公司

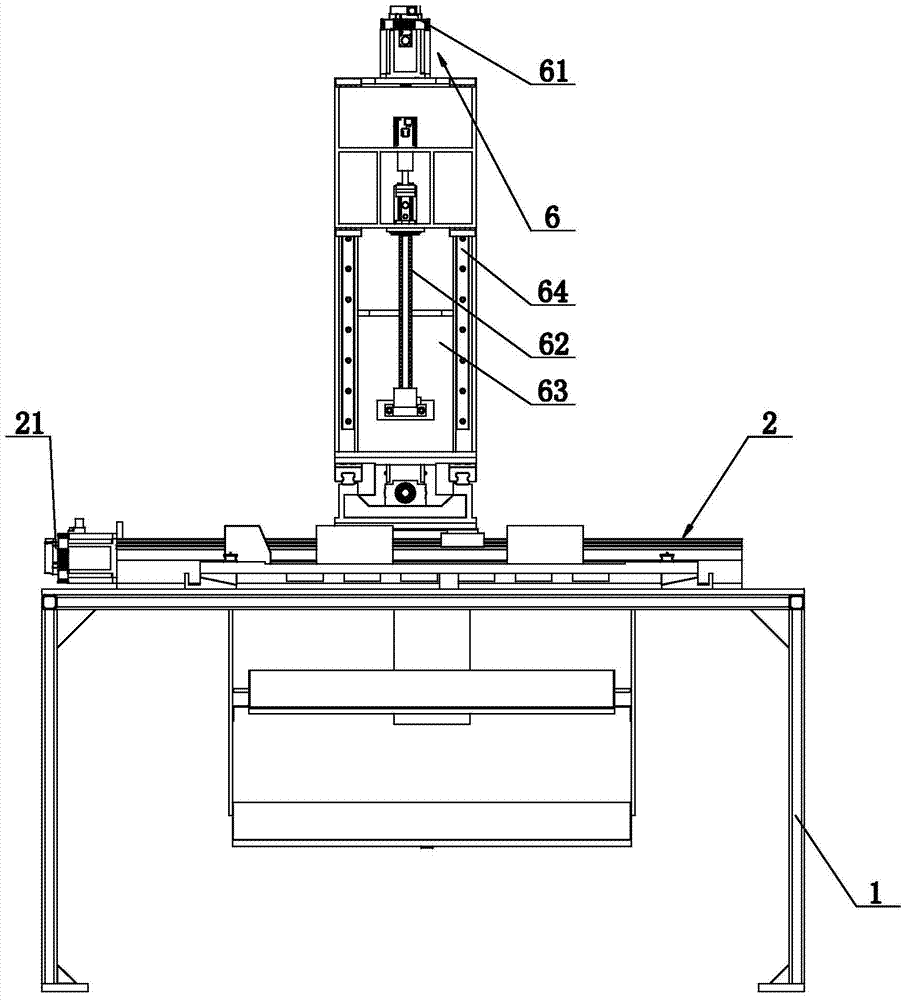

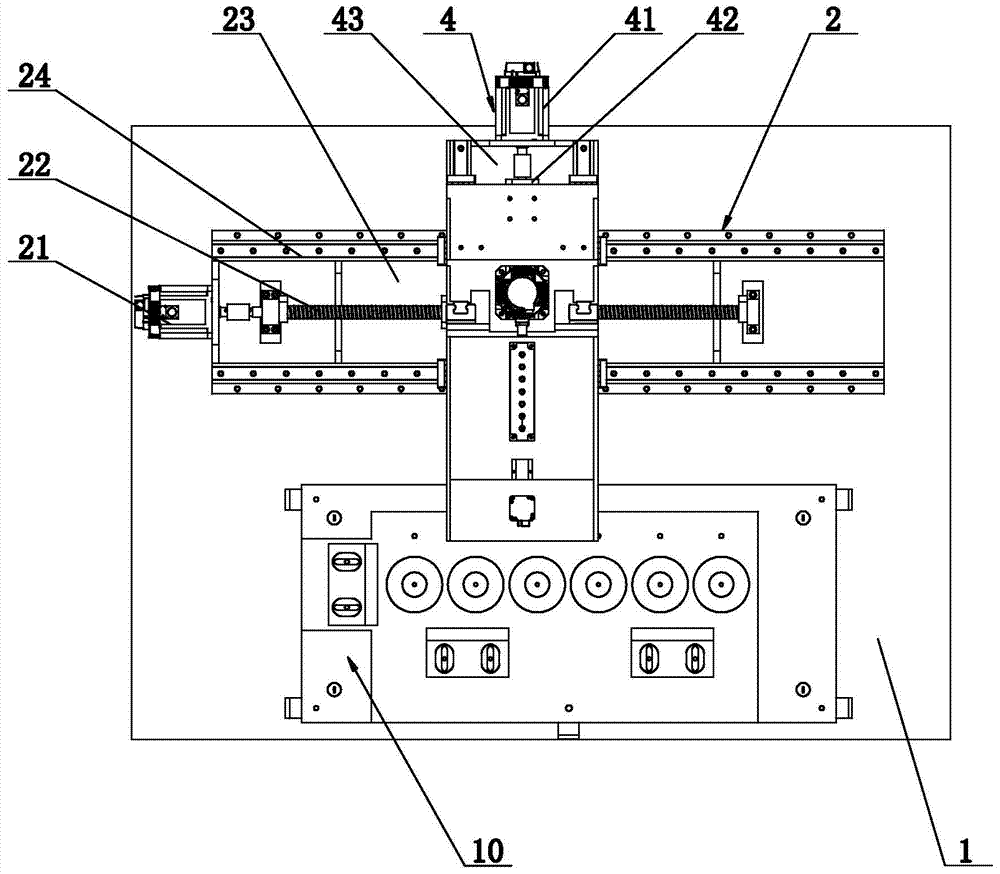

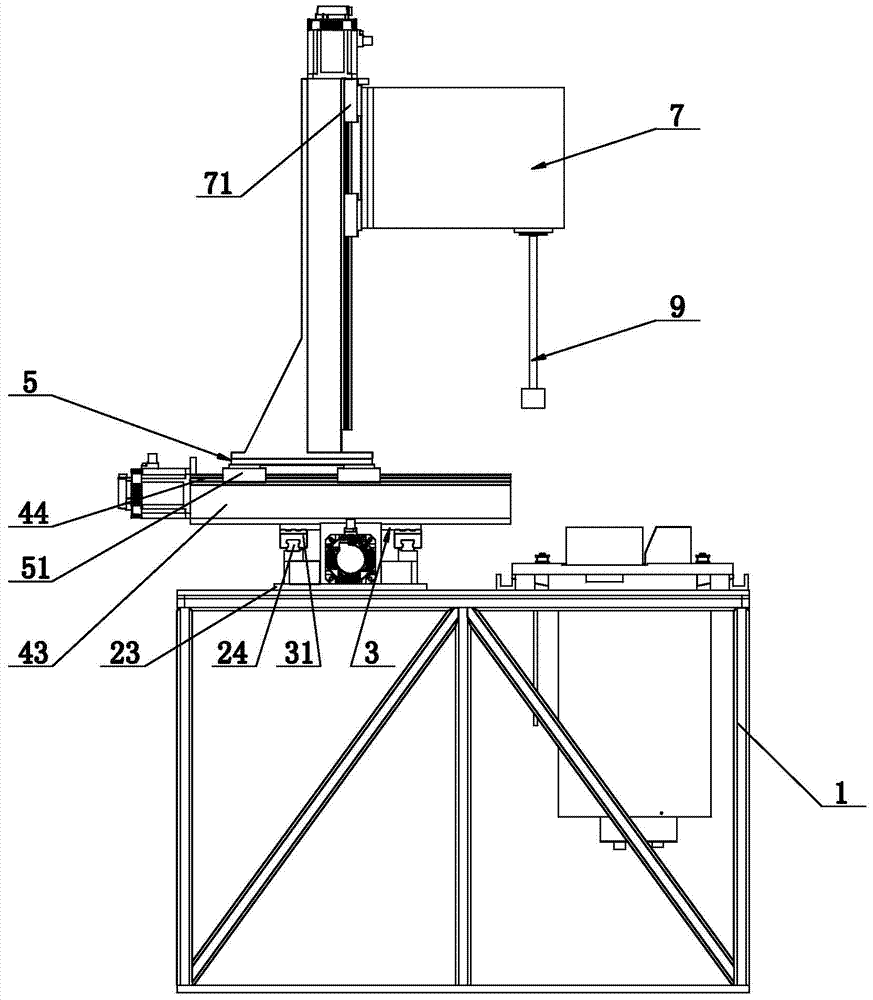

Automatic brush plating equipment

The invention discloses automatic brush electroplating equipment belonging to the technical field of engine reproduction equipment. The automatic brush electroplating equipment comprises a rack, wherein the rack is slidably provided with a first slide box driven by a first power device along the X direction; the first slide box is slidably provided with a second slide box driven by a second power device along the Y direction; the second slide box is slidably provided with a third slide box driven by a third power device along the Z direction; the third slide box is rotationally provided with a plating pen driven by a fourth power device and arranged along the Z direction; the side, located on the first slide box, on the rack is fixedly provided with a clamp for clamping a workpiece; and the rack is also provided with a plating solution supply and recovery system. By using the automatic brush electroplating equipment provided by the invention, automatic operation is realized, the motion control is precise, the uniformity of a plating layer is ensured, the labor efficiency is increased, and the repaired workpiece is small in size difference; and the automatic brush electroplating equipment is suitable for mass remanufacture.

Owner:WEICHAI POWER CO LTD

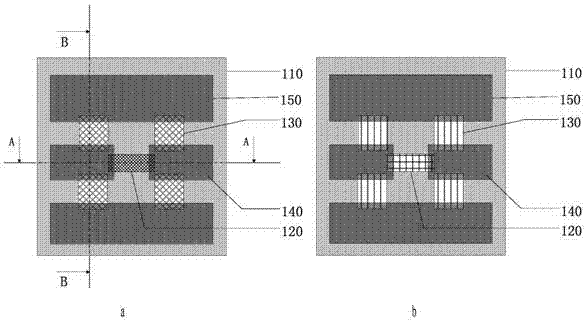

Variable sheet resistance film resistor network

ActiveCN103811138ASmall size differenceSolve the size jump problemOther resistor networksEngineeringImpurity

The invention discloses a variable sheet resistance film resistor network relating to the field of device and signal measurement. The variable sheet resistance film resistor network is prepared by a polycrystalline silicon film resistor technique and a surface micro processing technique, and comprises a complete signal channel which is formed by a central film resistor, a bypass film resistor, a signal transmission line as well as a ground wire together, such as a T-type / pi-type network. In order to obtain great decrement, the central resistor and the bypass resistor are great in difference value, and the size jump problem can be brought by adopting the same sheet resistance. According to the variable sheet resistance film resistor network, the central film resistor and the bypass film resistor have different impurity element concentrations by controlling the ion implantation technology condition, so that different sheet resistances are obtained; the length and the width of the resistor network are regulated effectively when the signal is regulated substantially; meanwhile, the resistor network of the same size has different regulation functions by adopting the principle; compared with the existing resistor network, the variable sheet resistance film resistor network provided by the invention has the advantages that the structural area can be saved and the induced parasitic effect is reduced.

Owner:TSINGHUA UNIV

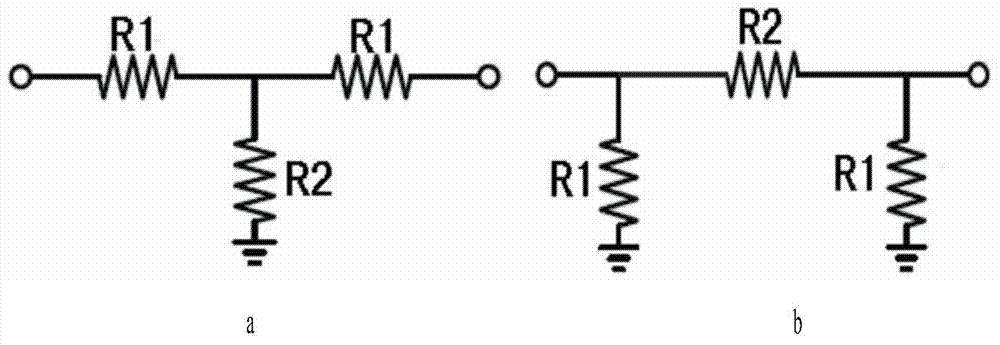

Organic light-emitting diode and method for making the same, and display device

ActiveCN108305952AHigh light transmittanceImprove pass rateSolid-state devicesSemiconductor/solid-state device manufacturingDisplay deviceReflective layer

The application discloses an organic light-emitting diode and a method for making the same, and a display device. The organic light-emitting diode comprises a first electrode, a light emitting layer and a second electrode that are laminated. The first electrode consists of a lower electrode layer, a reflective layer and an upper electrode layer that are laminated; and the upper electrode layer isadjacent to the light emitting layer. The upper electrode is a transparent electrode; and a difference value between a maximum size and a minimum size of the crystal grain included by the upper electrode is less than or equal to 0.05 microns and the crystal grain are distributed uniformly. Therefore, the luminous efficiency of the organic light emitting diode is enhanced and the brightness of theorganic light-emitting diode is improved.

Owner:WUHAN CHINA STAR OPTOELECTRONICS SEMICON DISPLAY TECH CO LTD

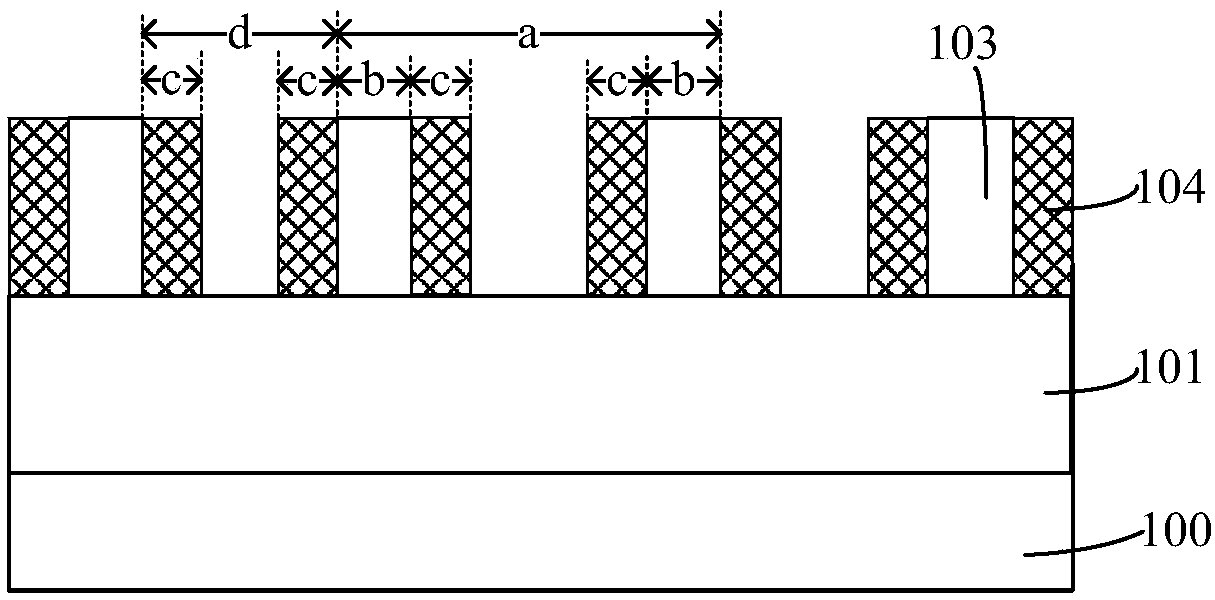

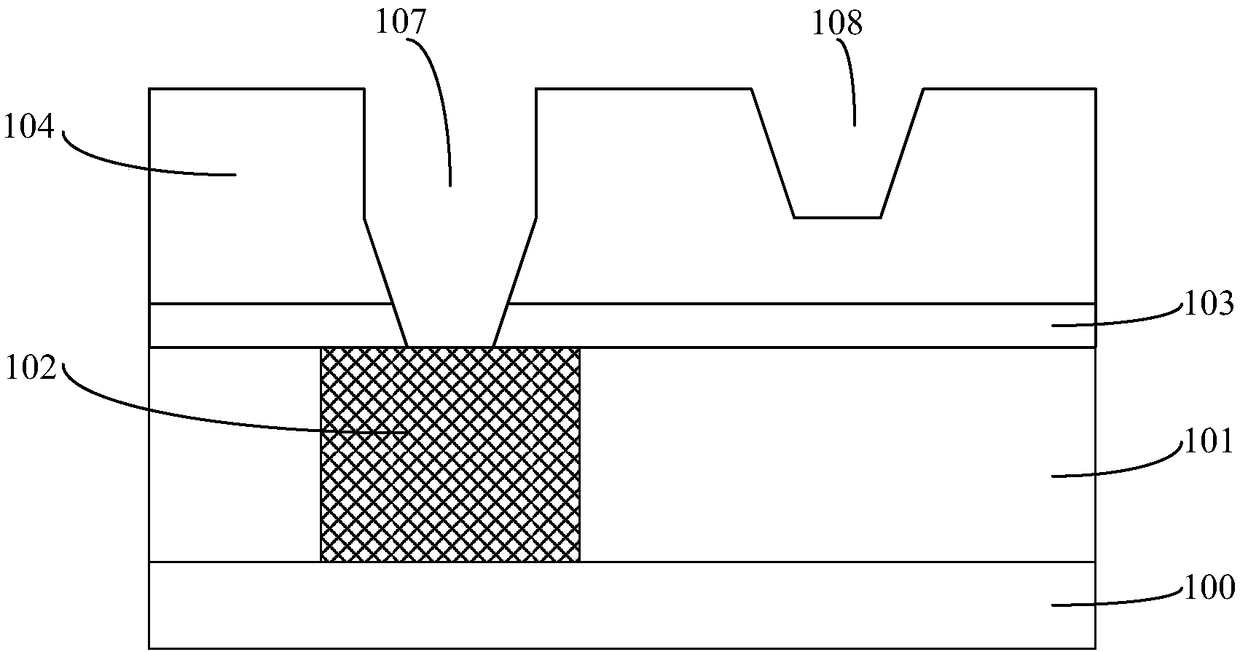

Semiconductor structure and forming method thereof

ActiveCN109427650AImprove performanceSmall size differenceSemiconductor/solid-state device detailsSolid-state devicesSemiconductor structureEngineering

The present invention discloses a semiconductor structure and forming method of the semiconductor structure, the method comprises: providing a substrate, wherein the substrate has a first interconnectstructure; forming a first stop layer on the first interconnect structure; forming a first dielectric layer on the substrate and the first stop layer; using a first etching process to etch the firstdielectric layer on the first interconnect line until the first stop layer is exposed, and forming a first opening inside the first dielectric layer; and using a second etching process to etch the first dielectric layer, forming a groove in the first dielectric layer, etching the first stop layer at bottom of the first opening until the first interconnect structure is exposed, and forming a through hole in the first stop layer and the first dielectric layer, wherein the through hole is in communication with the groove. Components formed by the method have better performance.

Owner:SEMICON MFG INT (SHANGHAI) CORP +1

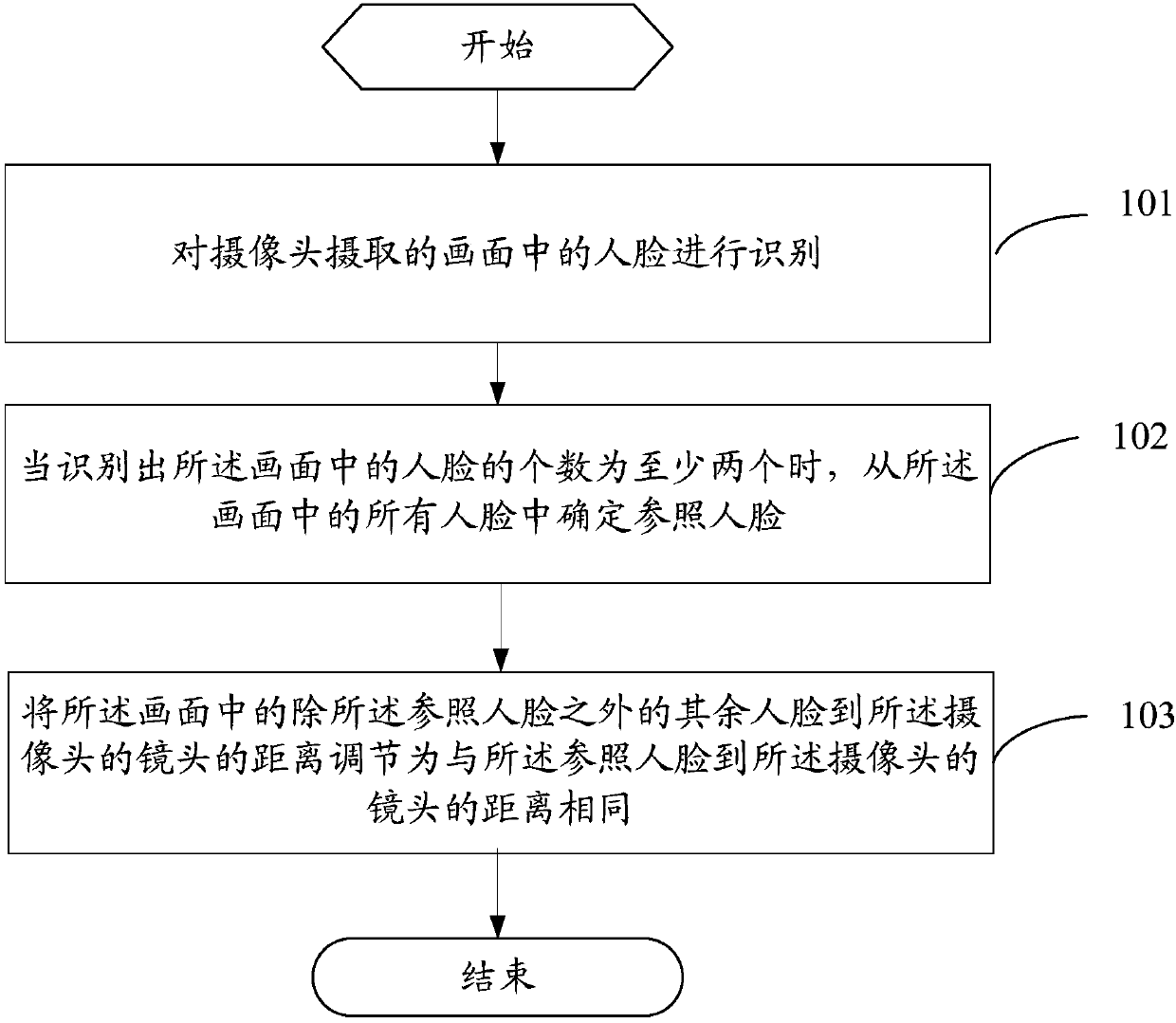

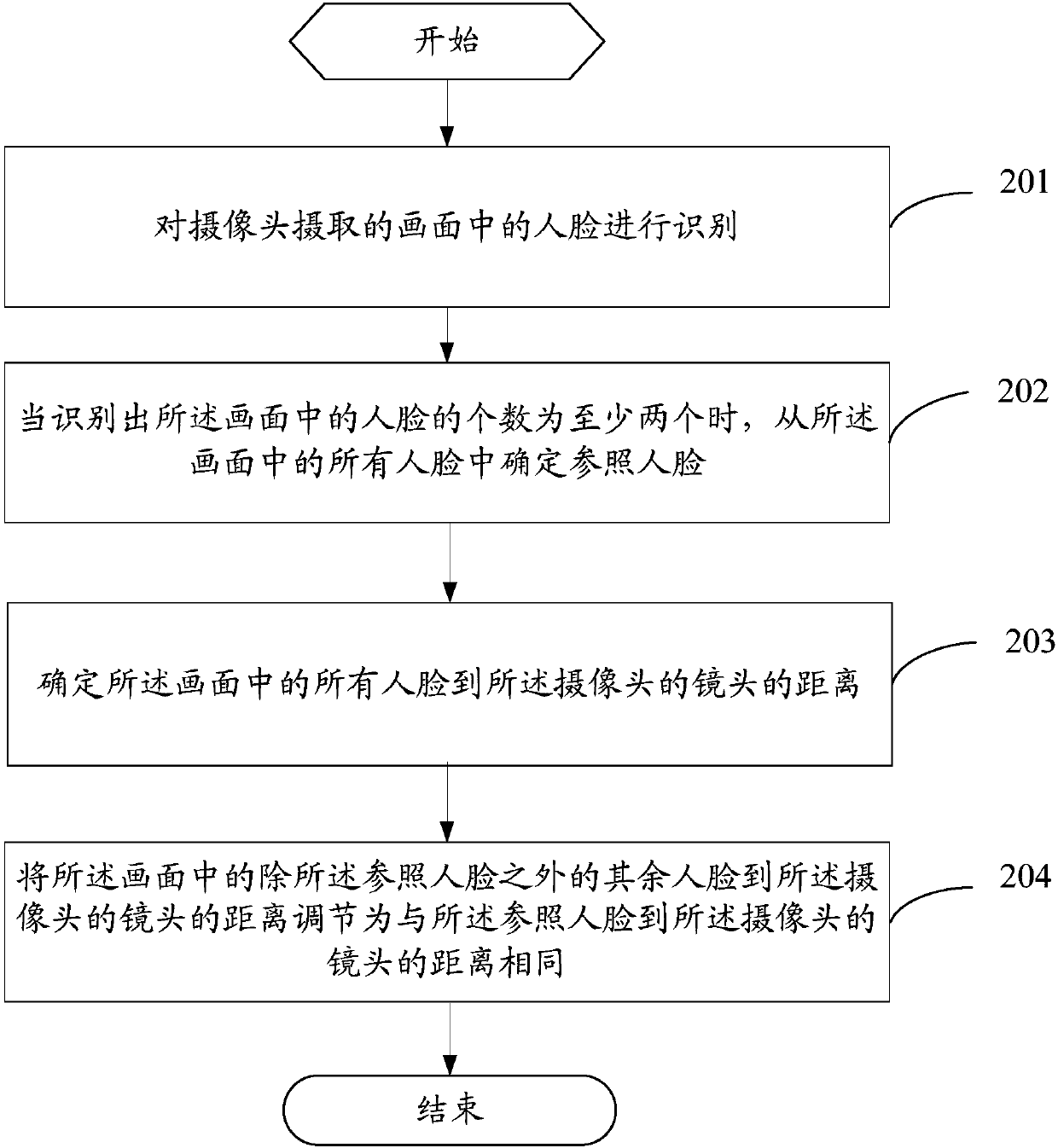

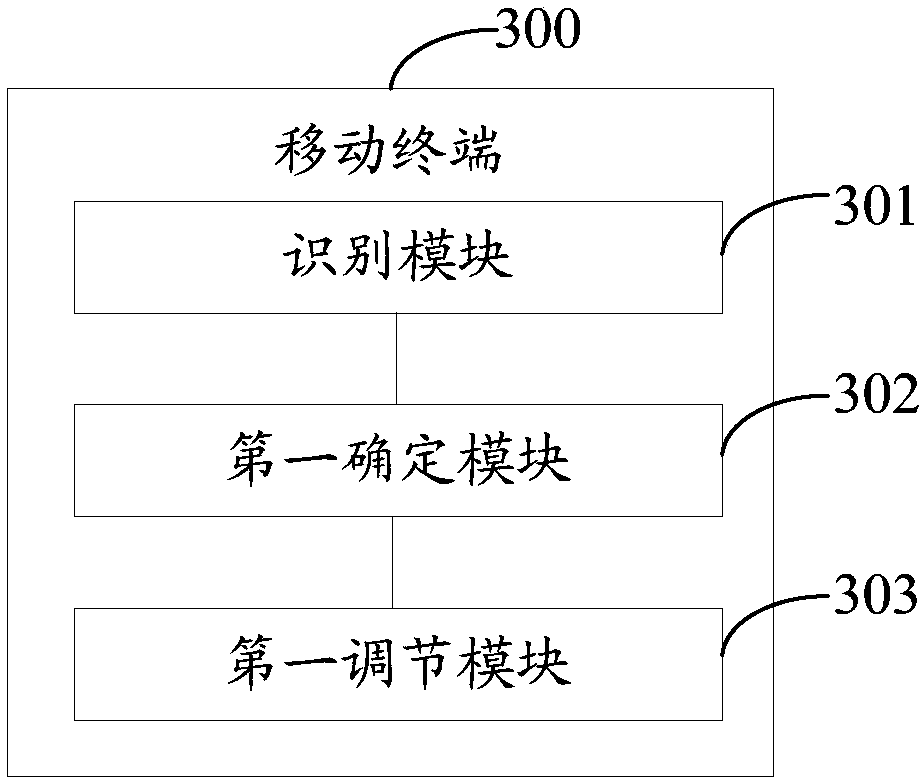

Image processing method for camera and mobile terminal

InactiveCN107820007ASmall size differenceSize difference is fairTelevision system detailsCharacter and pattern recognitionCamera lensImaging processing

The invention provides an image processing method for a camera and a mobile terminal. The method is applied to the mobile terminal, and comprises the steps of: carrying out identification on faces inan image shot by the camera; when the number of the identified faces in the image is at least two, determining a reference face from all the faces in the image; and regulating distances from other faces in the image except for the reference face to a lens of the camera into a distance from the reference face to the lens of the camera. The faces in the image shot by the camera, which are at different distances, are regulated to the same horizontal line, so that in a case of not having the aid of other matched equipment, dimensional variations of a face of each user in a group photo can be reduced, and the dimensional variations among each face in the image are closer to the real condition and are fairer, and thus, use convenience of the mobile terminal can be improved.

Owner:VIVO MOBILE COMM CO LTD

Automatic S-shape-winding winding machine for Suo noodles (a kind of hanging noodles in South Zhejiang)

PendingCN106719993AImprove work efficiencyQuality improvementMixing/kneading structural elementsDough shaping and dividing combinationWinding machineEngineering

The invention discloses an automatic S-shape-winding winding machine for Suo noodles (a kind of hanging noodles in South Zhejiang). The automatic S-shape-winding winding machine for the Suo noodles comprises a machine frame; a Workbench One, a Workbench Two and a Workbench Three are orderly arranged on the machine frame; a press plate is arranged on the Workbench One; a conveyor wheel and a rubbing plate are arranged on the Workbench Two; a material loading rod and a swing rod are arranged on the Workbench Three; and an insert rod is arranged on the swing rod. The invention has the following beneficial effects: the automatic S-shape-winding winding machine for the Suo noodles is capable of realizing the effects of automatic pressing and cutting of dough so as to improve work efficiency of Suo noodle preparation; moreover, the cut noodles are even and uniform, so that subsequent rubbing and winding processes are facilitated so as to improve overall qualities of the Suo noodles. The automatic S-shape-winding winding machine for the Suo noodles is capable of automatically rubbing thick noodles into long and thin noodles so as to realize the effect of automatic noodle-rubbing, so that the automatic S-shape-winding winding machine for the Suo noodles is economical of time and labor, and realizes automation; moreover, the rubbing process is soft and uniform, so that the output qualities of the Suo noodles can be improved, and the qualities of the Suo noodles are improved. In addition, the automatic S-shape-winding winding machine for the Suo noodles is capable of realizing automatic winding of the noodle bases so as to reduce manual winding time, so that the work efficiency of winding of the noodle bases are improved.

Owner:王武法

Segmented slicing and slitting machine for thick bamboo poles

InactiveCN111716474ASave human effortImprove work efficiencyCane mechanical workingWood working apparatusStructural engineeringKnife blades

The invention discloses a segmented slicing and slitting machine for thick bamboo poles. The segmented slicing and slitting machine comprises a device base of a segmented cutting machine body. The device base is fixedly arranged at the front position of the upper end face. A cutting cavity is formed in the right end face of the segmented cutting machine body, and a segmented cutting device capableof cutting the whole thick bamboo poles apart in a segmented manner is arranged in the cutting cavity. The thick bamboo poles can be conveyed into a conveying cavity through a conveying belt, throughthe cooperation of a trigger sensor on the left side wall of the conveying cavity and the segmented cutting device, the whole thick bamboo poles are cut into fixed lengths in the segmented manner, the thick bamboo poles cut in the segmented manner are pushed to a slitting bearing table through a pushing device, and through the cooperation of a pushing disc reciprocating left and right and a slitting blade shaped like a Chinese character 'mi', the thick bamboo poles on the slitting bearing table are cut into fine strips.

Owner:台州辛安科技有限公司

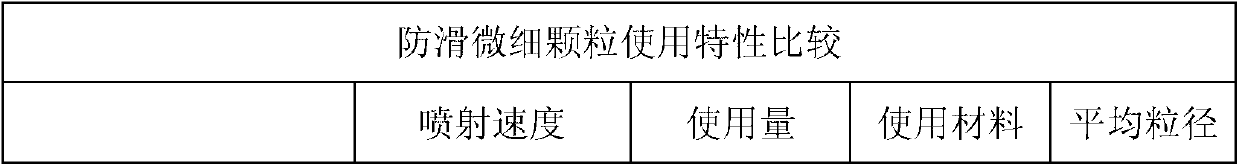

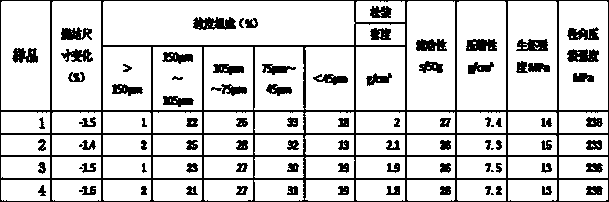

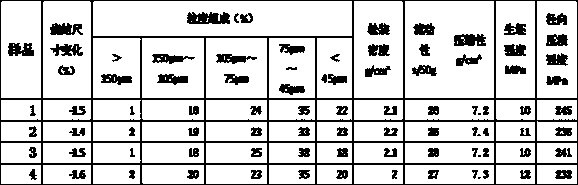

Preparation method of viscous anti-skid particles used in rail locomotives

ActiveCN103131387AReduce dosageIncrease coefficient of frictionOther chemical processesEngineeringInorganic materials

The invention discloses a preparation method of viscous anti-skid particles used in rail locomotives. According to the invention, a fluidized bed granulation device is adopted. Fine inorganic material powder is bound by using aqueous organic glue, such that anti-skid particles with a particle size of 400-800mum and have certain viscosity to rail and locomotive wheels are prepared. The viscous anti-skid particles are especially suitable to be used in train traveling in rainy and snowy weathers. During train high-speed travelling, wheel slippage can be reduced, and travelling speed can be ensured. During braking, braking time and braking distance can be reduced.

Owner:连云港倍特超微粉有限公司

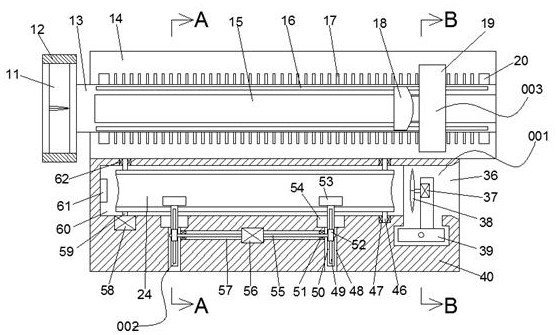

Rotary steamed corn bread processing and molding apparatus

ActiveCN108402119AUnified appearanceSmall size differenceDough shapingGlass productionMaterial resourcesCam

The invention discloses a rotary steamed corn bread processing and molding apparatus. The rotary steamed corn bread processing and molding apparatus comprises a shell, foot cups, big foot wheels, steamed corn bread moulds, a mould unloading assembly, a mould loading assembly, and a work box; a transmission device and the mould loading assembly are arranged in the shell, wherein the transmission device is composed of a motor, a coupling, a first reducer, a drive wheel, a conveyor belt, a first rotating shaft, a second reducer, a third reducer, a joint bearing, a cylinder, a tensioning device, atransmission frame, a first bevel gear, a second bevel gear, a slide rail, a slider, a connecting rod, a first connecting block, a cam assembly and a second rotating shaft; and a rotating device andthe mould unloading assembly are arranged on a surface of the shell. By adopting combined usage of the transmission device and the tensioning device, the rotary steamed corn bread processing and molding apparatus has improved production efficiency , so that, manpower and material resources can be effectively saved. The prepared steamed corn bread is uniform in appearance, and small in size difference; moreover, manual operation is avoided, so that, the steamed corn bread is green and pollution-free. And thus, safe and sanitary production of foods is further ensured, and the effect of automaticmass production is realized.

Owner:东莞市格特机械有限公司

Preparation method of degradable bamboo fiber straw

ActiveCN112961394ALow hygroscopicitySmall size differenceTablewaresSodium bicarbonatePolymer science

The invention provides a preparation method of a degradable bamboo fiber straw, and the method comprises the following steps: primarily screening crushed bamboo, selecting bamboo fibers, mixing with water, performing steam explosion treatment, washing with water, and performing drying to obtain pretreated bamboo fibers; preheating and cooling degradable plastic, adding the pretreated bamboo fiber, polyvinyl alcohol, azodicarbonamide, filler, nano-silver and sodium bicarbonate, performing mixing, and performing granulating to obtain bamboo fiber reinforced degradable modified plastic particles; the bamboo fiber reinforced degradable modified plastic particles are continuously injected into an annular mold for directional heating in a microcellular foaming extrusion molding mode, and the degradable bamboo fiber suction pipe is obtained. According to the invention, hemicelluloses and part of lignin in bamboo fibers can be effectively degraded, the moisture absorption performance of the bamboo fibers is reduced, large pores exist among the fibers in the foaming process of the bamboo fiber reinforced degradable modified plastic particles, so that water escapes to the outer layer, a compact layer is formed on the inner wall of the bamboo fiber straw, and the stability of the internal structure of the straw is ensured.

Owner:ZHEJIANG FORESTRY ACAD +1

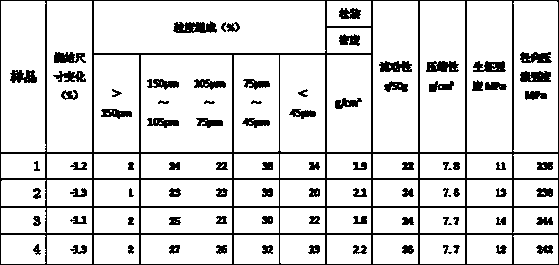

Preparation method of high-performance CuSn10 powder for oil-containing bearing

PendingCN110394456AGood strength and wear resistanceUniform distribution of poresTransportation and packagingMetal-working apparatusHigh pressureParticle-size distribution

The invention discloses a preparation method of high-performance CuSn10 powder for an oil-containing bearing. The method specifically comprises the following steps: preparing CuSn5 alloy powder by adopting a high-pressure atomization method of 100 Mpa or above; drying the atomized CuSn5 alloy powder in a belt drying furnace, weighing 95% by weight of CuSn5 alloy powder after drying, and weighing 5% by weight of tin powder with particle size smaller than or equal to 45 microns; introducing oxygen for calcining the CuSn5 alloy powder with the weight ratio of 95%; uniformly mixing the oxidized CuSn5 alloy powder with 5% by weight of the tin powder with the particle size smaller than or equal to 45 microns in the step (2), and adding the mixture into a reduction furnace for reduction treatment; crushing the reduced CuSn10 alloy powder; sieving the crushed reduced CuSn10 alloy powder through a screen of 150 microns; and adding the screened CuSn10 alloy powder into a mixer, and adding 0.5-0.7% by weight of zinc stearate to be uniformly mixed with the CuSn10 alloy powder. By adopting the technical scheme, the prepared CuSn10 alloy powder is excellent in performance, uniform in particle size distribution and difficult to segregate.

Owner:铜陵鑫佳粉体新材料科技有限公司

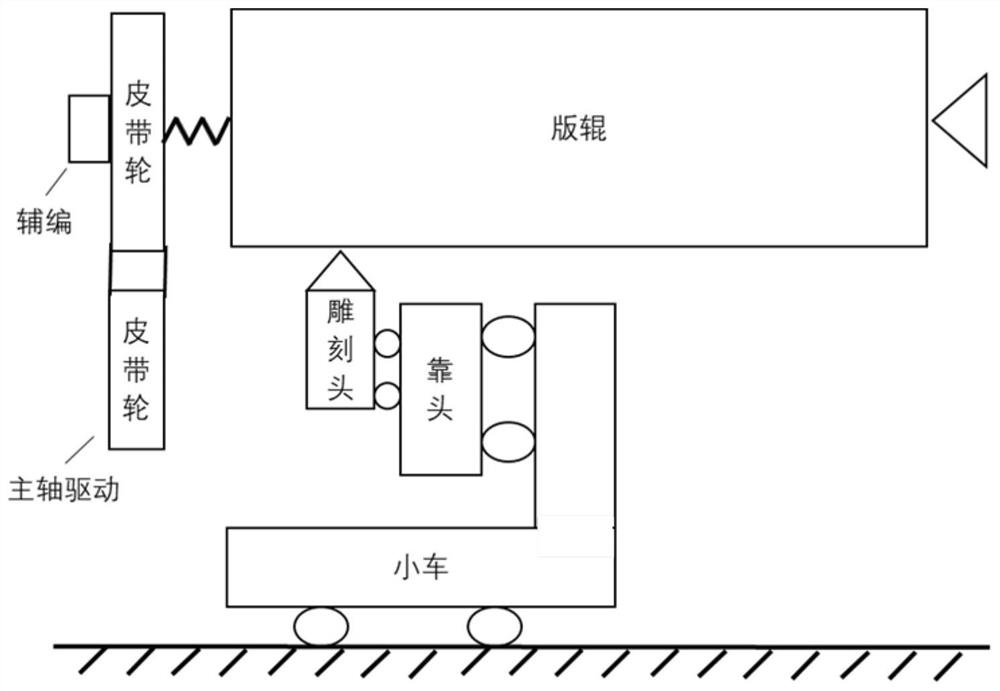

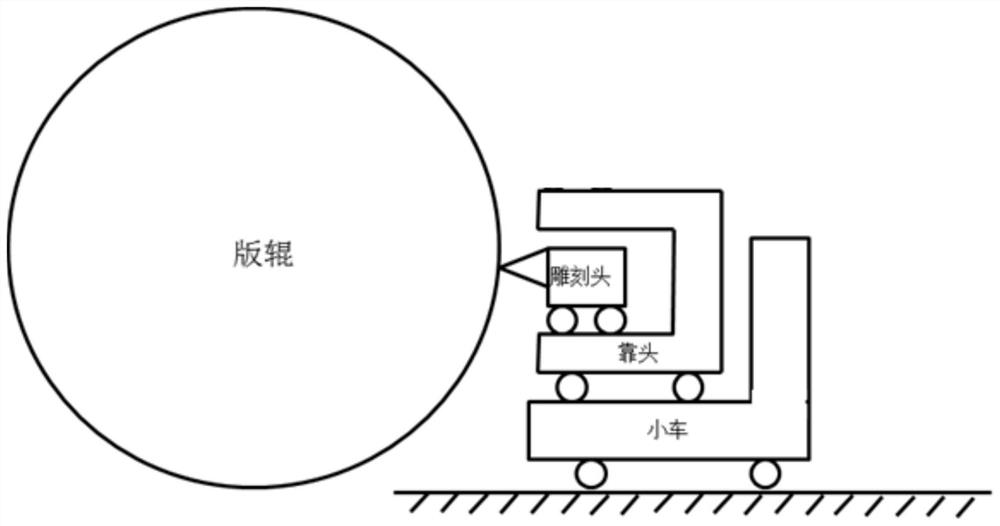

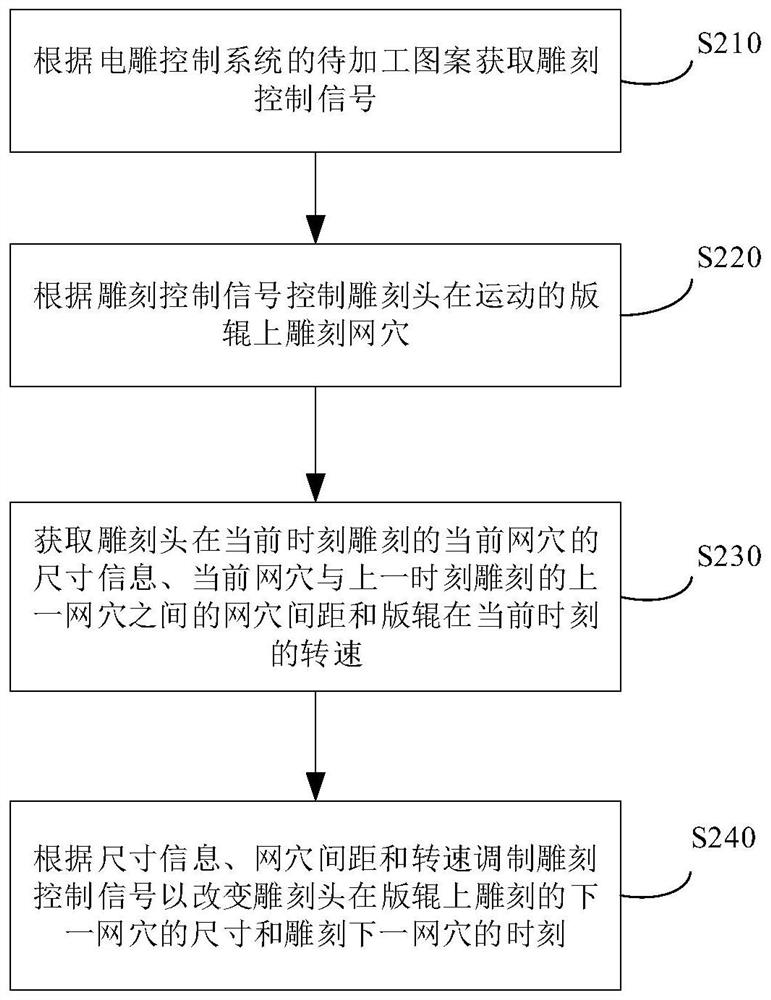

Electric carving control method and device, electric carving control system and storage medium

ActiveCN112355368AImprove size differenceSmall size differenceAutomatic control devicesMeasurement/indication equipmentsControl signalControl system

The invention relates to electric carving control method and device, an electric carving control system and a storage medium. The electric carving control method comprises the steps of, obtaining a carving control signal according to a to-be-processed pattern of the electric carving control system, and then controlling a carving head to carve an ink cell in a moving plate roller; obtaining the size information of the current ink cell carved by the carving head at the current moment, the ink cell spacing between the current ink cell and the previous ink cell carved at the previous moment, and the rotating speed of the plate roller at the current moment; and modulating the carving control signal according to the size information, the ink cell spacing and the rotating speed so as to change the size of the next ink cell carved on the plate roller by the carving head and the time of carving the next ink cell. The carving control signal acting on the next ink cell can be fed back and adjusted, so that the purposes of improving the size difference of the ink cells and reducing the spacing difference of the ink cells are achieved.

Owner:GOOGOL TECH SHENZHEN LTD GUANGDONG

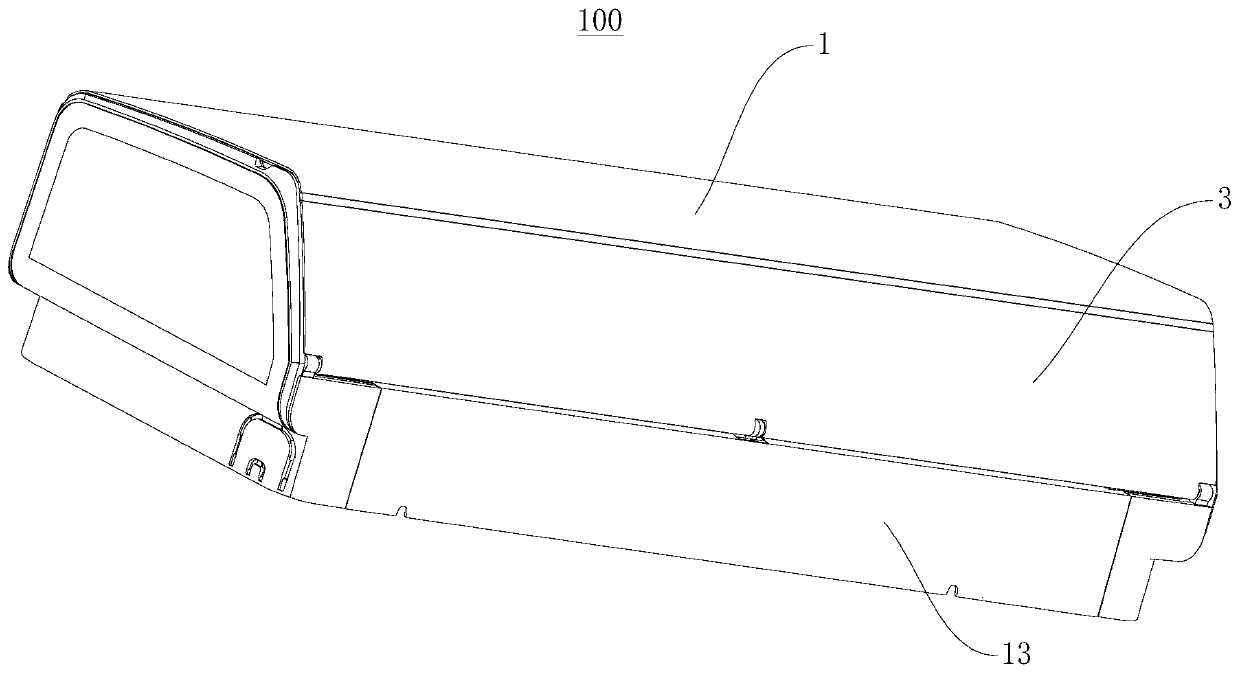

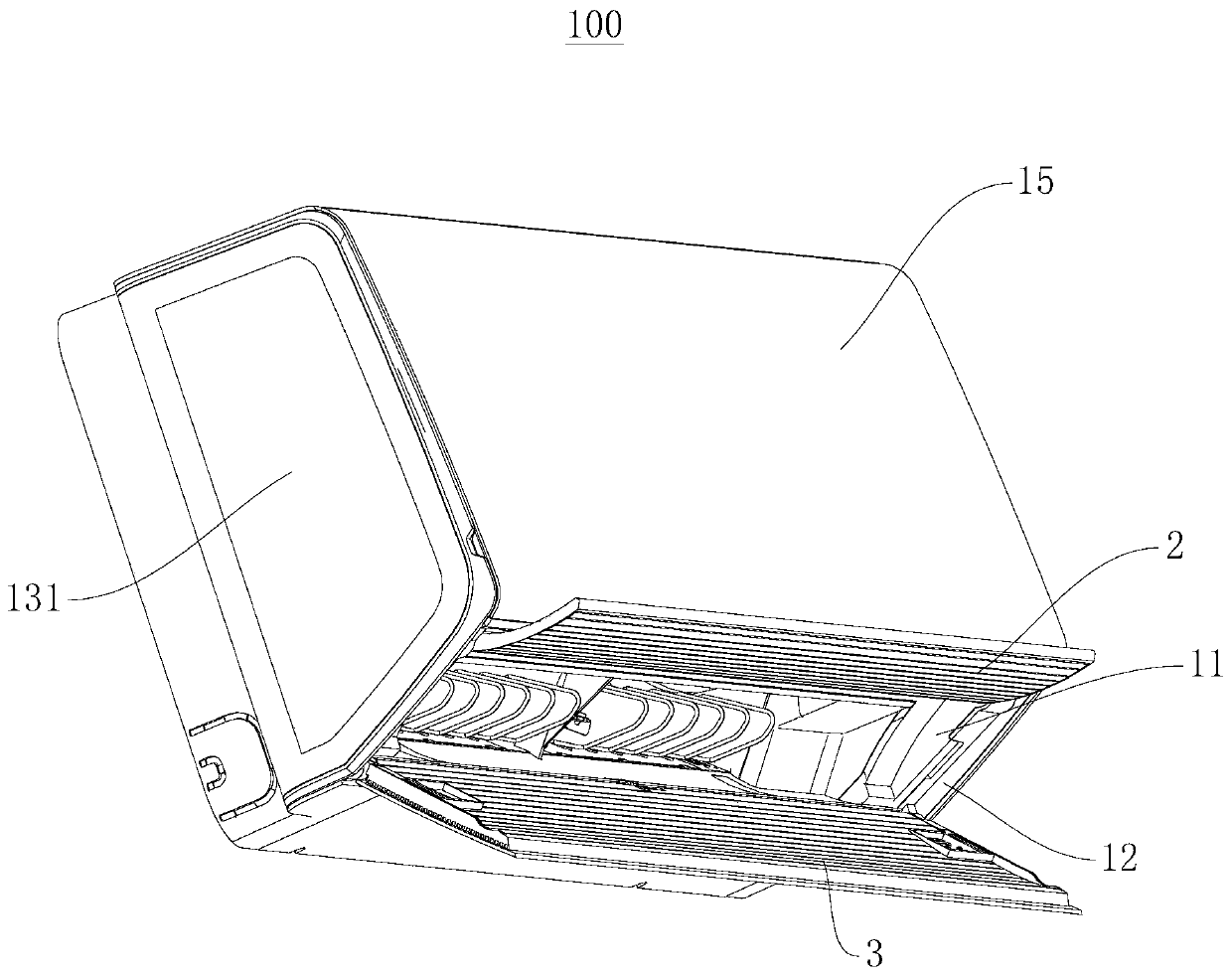

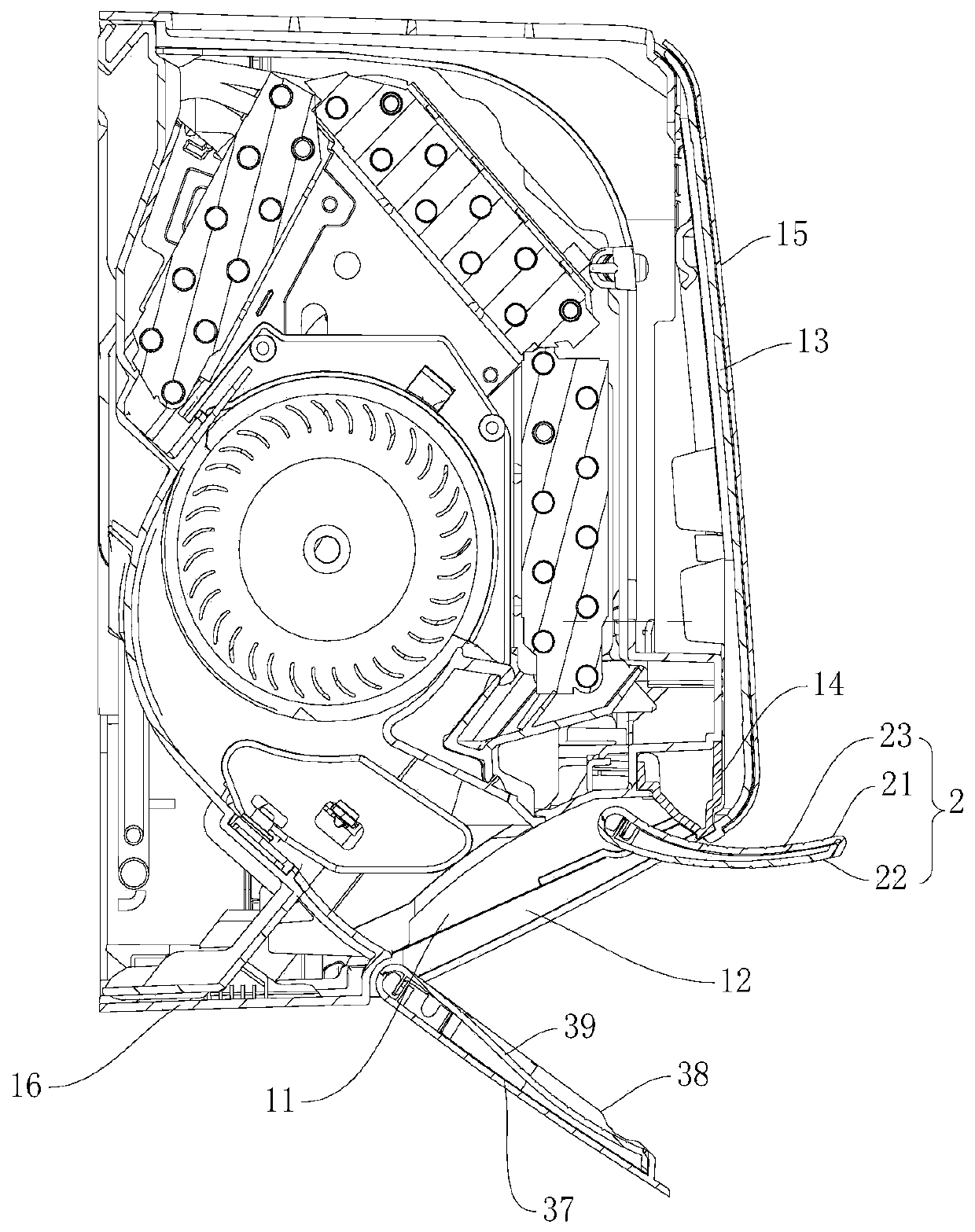

Air conditioner indoor unit

PendingCN110966659AGuaranteed aestheticsSmall size differenceLighting and heating apparatusAir conditioning systemsEngineeringMechanical engineering

The invention discloses an air conditioner indoor unit, comprising: a housing including a first accommodating portion having a first accommodating space and a second accommodating portion having a second accommodating space, the first accommodating portion having an air outlet; an inner air deflector rotatable between a first closed position accommodated in the first accommodating space and a first open position that opens the air outlet; and an outer air deflector rotatable between a second closed position accommodated in the second accommodating space and a second open position that opens the second accommodating space. When the inner air deflector is at the first closed position and the outer air deflector is at the second closed position, the inner air deflector is located behind the outer air deflector and is shielded by the outer air deflector. According to the air conditioner indoor unit of the present invention, the size difference between the outer air air deflector and the inner air deflector is reduced, and the attractive appearance of the housing of the air conditioner indoor unit is ensured.

Owner:HISENSE (GUANGDONG) AIR CONDITIONER

A method of manufacturing 6082t6 aluminum alloy large-scale rods for power equipment

The invention belongs to the technical field of aluminum alloy materials for electric power equipment and particularly relates to a method for manufacturing large-sized aluminum alloy bars with high strength and high electrical conductivity. The large-sized 6082 bars with high strength and high electrical conductivity, especially 6082T6 aluminum alloy bars with diameter from 150mm above to 300mm, are utilized for processing large-sized electrical elements with high strength and high electrical conductivity in the electric power equipment. An aluminum alloy ingot used in the method contains the following elements in percentage by mass: 1.0%-1.05% of Si, no more than 0.12% of Fe, no more than 0.10% of Cu, 0.55%-0.65% of Mn, 0.9%-0.95% of Mg, no more than 0.10% of Cr, no more than 0.10% of Zn, no more than 0.05% of Ti, no more than 0.05% of isolated impurity, no more than 0.15% of total impurities, and the balance being Al. According to the method, mass production and delivery can be achieved, the strength and the electrical conductivity of the large-sized aluminum alloy bars are enhanced, and processing and use are facilitated; the mechanical property and the electrical conductivity of the large-sized aluminum alloy bars obtained by the method are stable; in repeated operation, the bars can satisfy the Chinese standard of bars with diameter smaller than 150mm, the Chinese standard of bars with diameter from 150mm above to 300 mm can be supplemented or perfected and each performance index can be introduced into the Chinese standard.

Owner:SHANDONG YUHANG SPECIAL ALLOY EQUIP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com