Manufacturing method for aluminum alloy-made robot arm hollow profile

A robot arm and hollow profile technology, applied in the field of aluminum alloy profiles, to achieve the effect of light weight, satisfactory plasticity and uniform structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be further described below in conjunction with specific embodiments, so that those skilled in the art can better understand the present invention, but the present invention is not limited thereby.

[0035] Example process

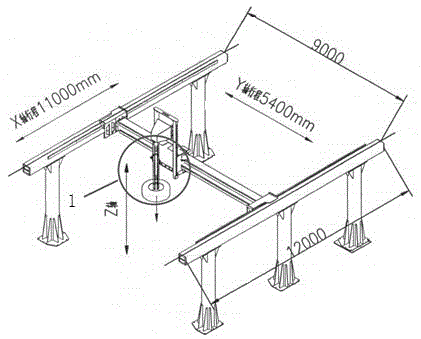

[0036] 1. According to the current working state of the steel structure, the steel beam will not deform under the condition of bearing 120 kg of moving gravity, and it will work stably and normally. For the working state of the steel beam, see figure 1 ;

[0037] 2. Select 6005A aluminum alloy as the aluminum alloy instead of steel, and cast the aluminum alloy round ingot. The mass percentage of elements in the aluminum alloy ingot is 0.75% Si, 0.12% Fe, 0.20% Cu, 0.33% Mn, Mg 0.65%, Cr 0.15%, Zn 0.10%, Mn+Cr 0.48, Ti 0.10%, single impurity ≤ 0.05%, total impurity ≤ 0.15%, the rest is Al, casting specification: Ф375×7000mm, ingot Wagon to Ф366±2mm, cut-off size is 1000mm, homogeneously process Ф366±2mm×1000mm ingot, hea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com