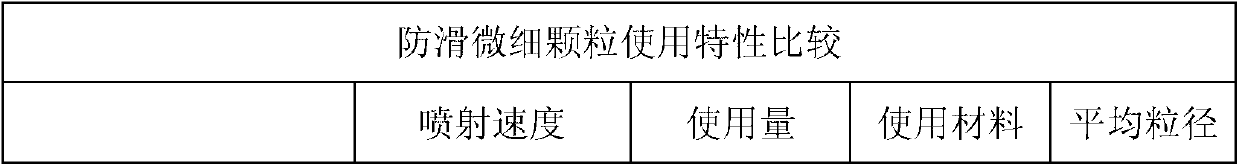

Preparation method of viscous anti-skid particles used in rail locomotives

A technology of anti-slip particles and rail locomotives, applied in chemical instruments and methods, and other chemical processes, can solve the problems of affecting the effect, difficulty, and loss of effect, and achieve the effects of increasing the friction coefficient, extending the replacement cycle, and improving safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0030] A kind of preparation method of sticky anti-slip granule for rail locomotive of the present invention, it comprises the following steps:

[0031] a. Select one or more inorganic material powders, first sieve, and require the particle size to reach 100 mesh or more, or the particle size is less than 150 μm; then fully mix the inorganic material powders;

[0032] b. Select water-based organic glue and add water to configure;

[0033] c. Put the mixed inorganic material powder and water-based organic glue in the fluidized bed granulation device through the blowing action of hot air entering from the bottom, so that the inorganic material powder is in a fluidized state, and the water-based spray of mist The organic glue is in uniform contact with the powder particles and adheres to the surface of the particles, so that the fine particles are bonded into larger particles, and the sticky non-slip between 20 mesh to 40 mesh or particle size between 400 μm and 800 μm is continu...

Embodiment 1

[0046] Select natural sand powder and stone powder as raw materials, and sieve them with a 100-mesh sieve to obtain powder raw materials with a particle size of less than 150 μm. Weigh 100 kg of natural sand powder and 100 kg of stone powder after sieving, and mix them evenly to obtain Mix 200kg of inorganic powder raw materials. Select polyvinyl alcohol as the raw material of organic glue, dissolve bubbles in hot water to obtain thick polyethanol glue, add water to adjust to 20 kg of polyethanol glue with a weight concentration of 2%. Add 50kg of inorganic powder raw materials into the fluidized bed granulation device, and use hot air for fluidization, so that the inorganic material powder is in a fluidized state. Keep the superficial air velocity of the hot air in the fluidized bed granulator at 0.5m / s. Then open the organic glue pipeline valve, spray polyvinyl alcohol glue into the fluidized bed in the form of mist, and keep the injection speed at 100g / min. After 10 minut...

Embodiment 2

[0048] Select clay powder and stone powder as raw materials, and sieve them with 100-mesh sieves to obtain powder raw materials with a particle size of less than 150 μm. Weigh 100 kg of sieved clay and 100 kg of stone powder, and mix them evenly to obtain mixed inorganic powder. Body raw material 200kg. Select ethylene-vinyl acetate emulsion as the organic rubber raw material, and add water to prepare 10 kg of ethylene-vinyl acetate dilute emulsion with a weight concentration of 5%. Add 50kg of inorganic powder raw materials into the pilot test device for fluidized bed granulation, and use hot air for fluidization, so that the inorganic material powder is in a fluidized state. Keep the superficial air velocity of the hot air in the fluidized bed granulator at 0.35m / s. Then open the organic glue pipeline valve, spray ethylene-vinyl acetate dilute emulsion into the fluidized bed granulation device in the form of mist, and keep the injection speed at 50g / min. After 10 minutes o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com