Variable sheet resistance film resistor network

A thin-film resistor and resistor network technology, applied in other resistor networks and other directions, can solve the problems of large parasitic effect, layout size jump, deterioration of the functional parameters and performance of the resistor network, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The implementation of the present invention will be described in detail below in conjunction with the drawings and examples.

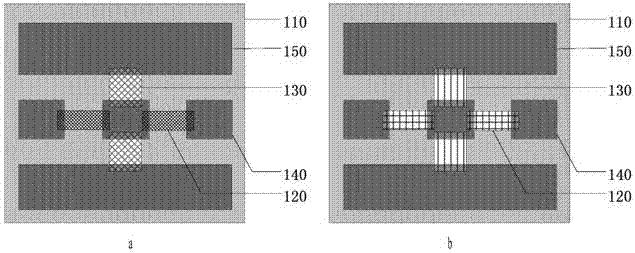

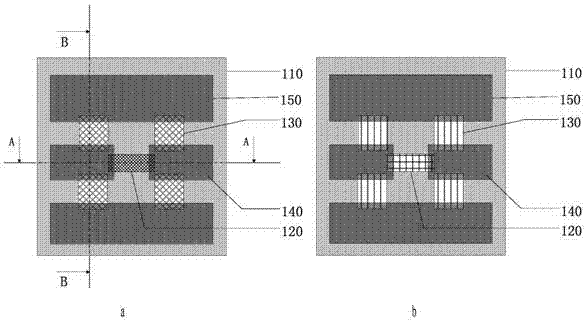

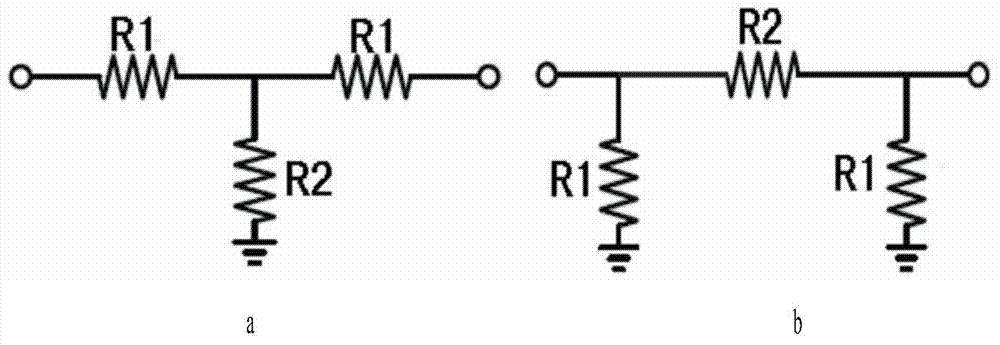

[0030] see figure 2 , 3 , 4, 5, a kind of variable square resistance film resistance network, comprises a substrate 100, is provided with buffer isolation layer 110 on the substrate, is provided with center film resistance 120, bypass film resistance 130, signal transmission line on the buffer isolation layer 110 140 and the ground wire 150, they together form a T-type / π-type resistor network. The signal transmission line 140 and the ground line 150 together form a coplanar waveguide transmission line. The central thin film resistor 120 and the bypass thin film resistors contain different concentrations of impurity elements.

[0031] see figure 2 , the T-shaped resistor network includes two central film resistors 120 , two bypass film resistors 130 , three sections of signal transmission lines 140 and two ground lines 150 . Three sections...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com