Color film substrate, and manufacturing method and display device thereof

The technology of a color filter substrate and a manufacturing method, which is applied in the field of liquid crystal displays, can solve the problems of rough surface, high cost, uneven unevenness, and achieve the effects of good display effect, small size difference and stable liquid crystal cell.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

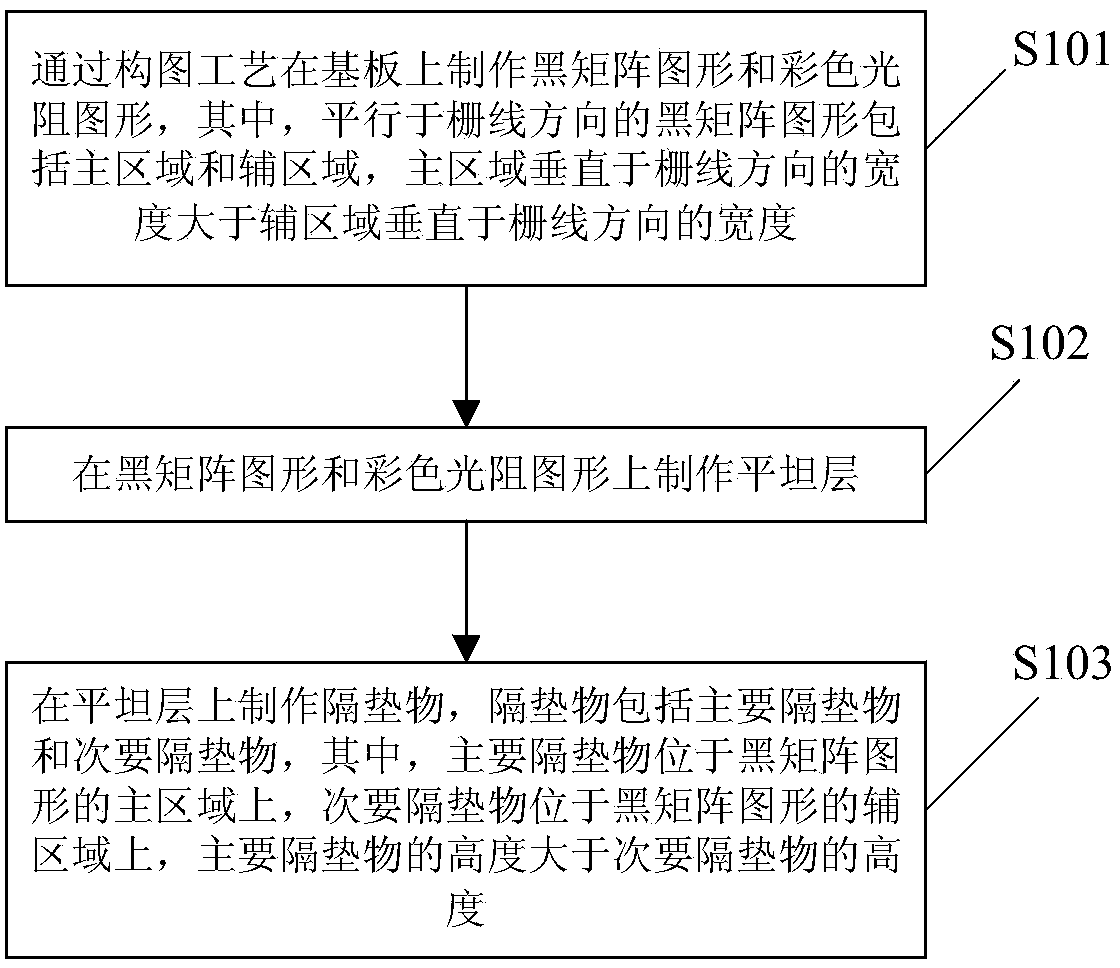

[0047] An embodiment of the present invention provides a method for manufacturing a color filter substrate, such as figure 1 As shown, the method includes:

[0048] Step S101, fabricate a black matrix pattern and a color photoresist pattern on the substrate through a patterning process, wherein the black matrix pattern parallel to the gate line direction includes a main area and an auxiliary area, and the width of the main area perpendicular to the gate line direction is greater than that of the auxiliary area Width in the grid line direction.

[0049] Step S102, making a flat layer on the black matrix pattern and the color photoresist pattern.

[0050]Step S103, making a spacer on the flat layer, the spacer includes a main spacer and a secondary spacer, wherein the main spacer is located on the main area of the black matrix pattern, and the secondary spacer is located on the black matrix The height of the primary spacer is greater than the height of the secondary spacer o...

Embodiment 2

[0084] based on figure 1 The provided color filter substrate manufacturing method, the embodiment of the present invention also provides a color filter substrate, the color filter substrate includes a substrate 1, the substrate 1 is usually a glass substrate or a quartz substrate with good light transmission, and the color filter substrate Membrane substrates also include:

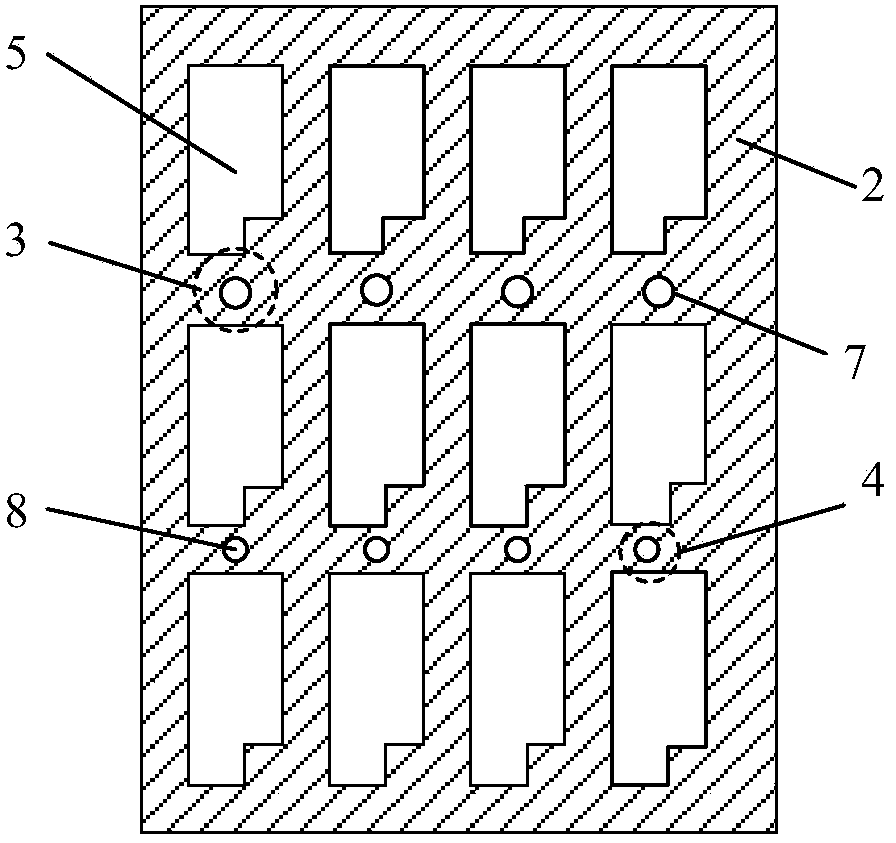

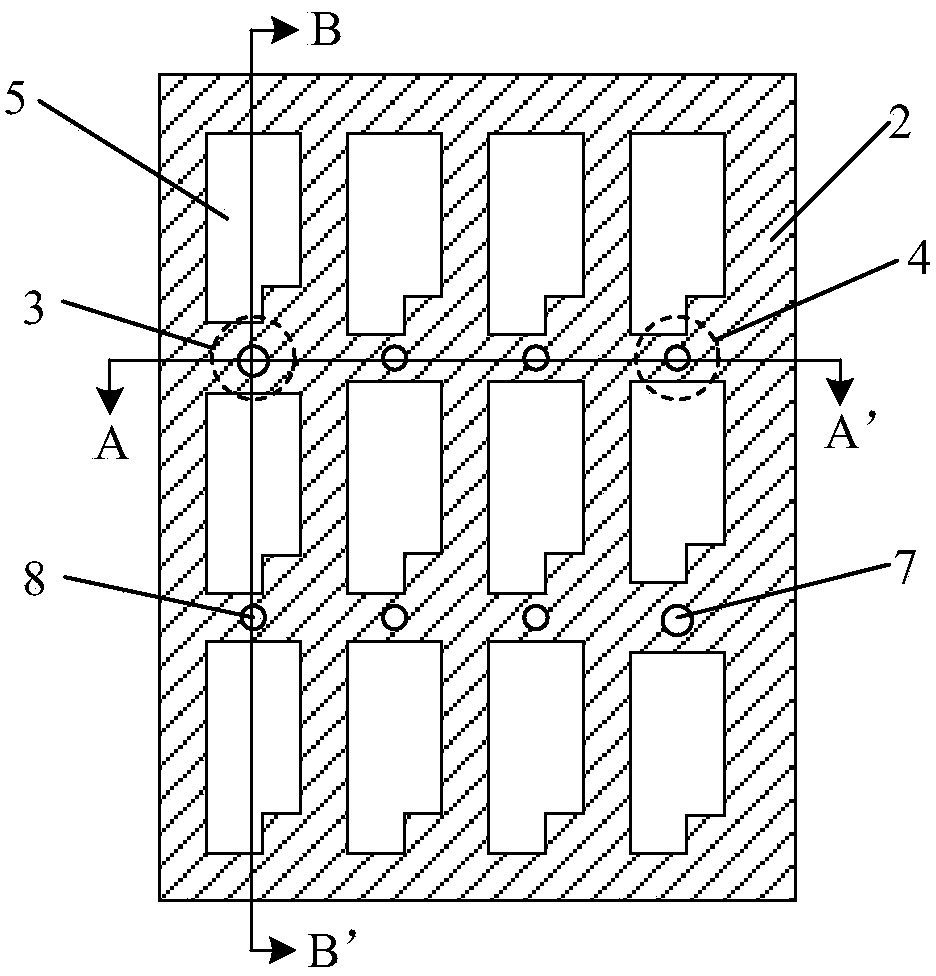

[0085] Black matrix pattern 2, wherein the black matrix pattern parallel to the gate line direction includes a main area and an auxiliary area, and the width of the main area perpendicular to the gate line direction is greater than the width of the auxiliary area perpendicular to the gate line direction. The material of the black matrix pattern 2 is usually carbon black and black resin.

[0086] It should be noted that the black matrix patterns parallel to the direction of the gate lines include main areas and auxiliary areas, including: any row of black matrix patterns 2 parallel to the direction of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com