Low-power laser-induced TIG electric arc-based additive manufacturing method of stainless steel structural member and manufacturing system

A technology of additive manufacturing and laser induction, which is applied in the direction of manufacturing tools, laser welding equipment, welding equipment, etc., can solve the problems of low mechanical properties, achieve the effects of smaller active area, stable arc shape, and less energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

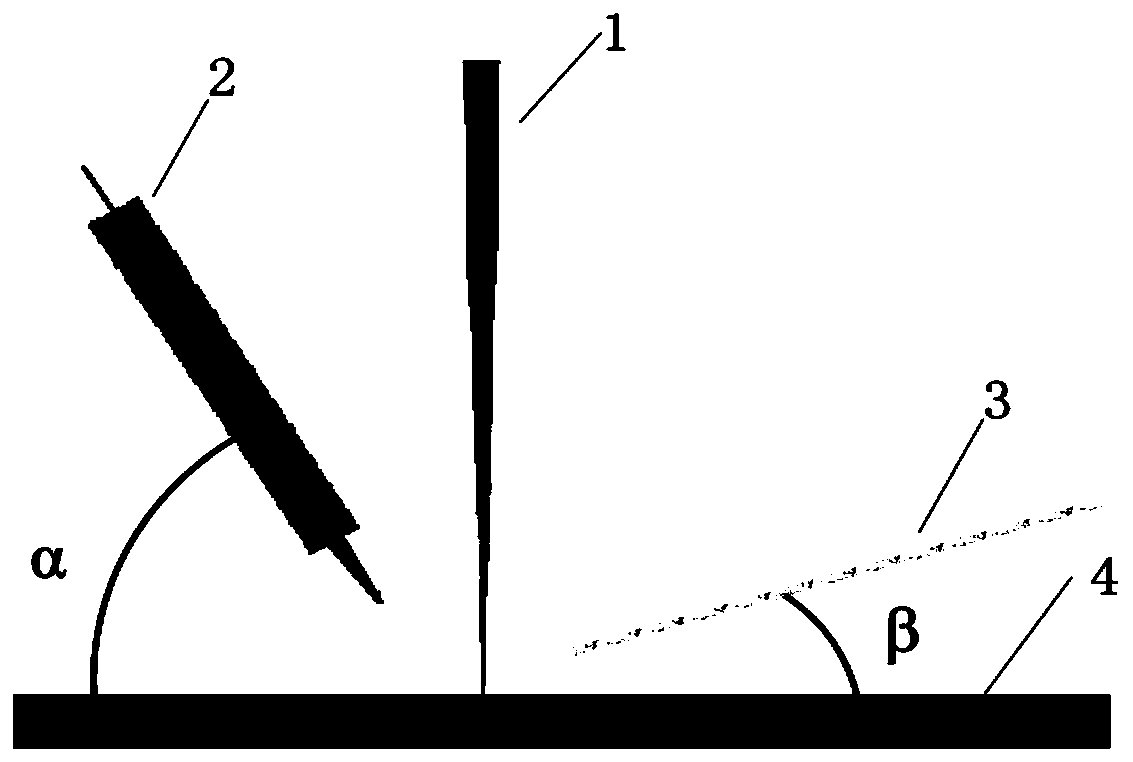

[0064] The following is an example of using 316 stainless steel to add material to the wall. The specific method is as follows:

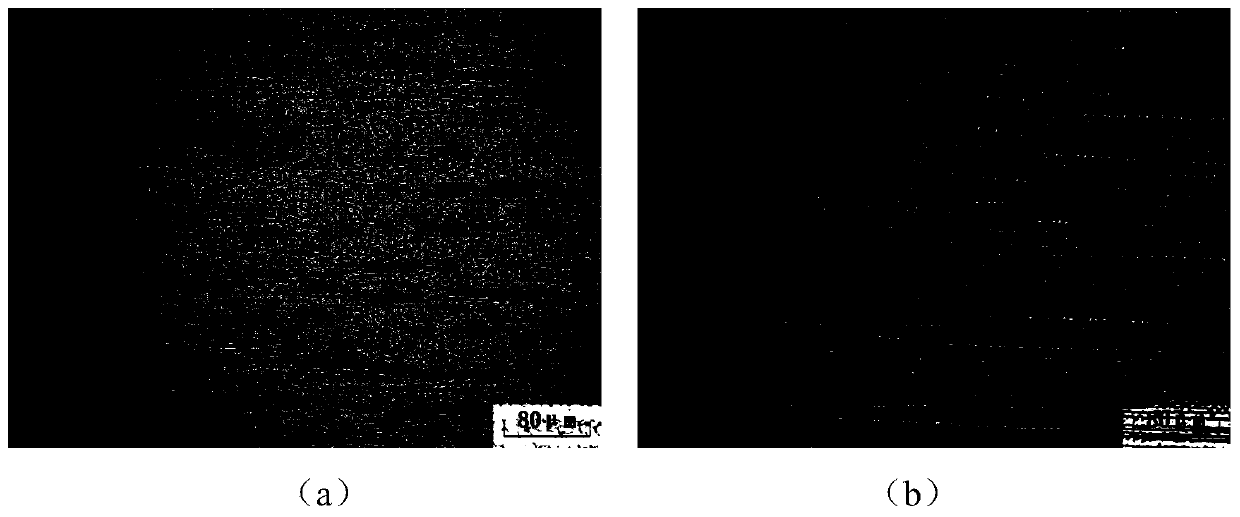

[0065] For stainless steel additive manufacturing, because of its strong fluidity and poor metal thermal conductivity, the surfacing welding is unstable, and it is easy to cause problems such as laying down and irregular side forming. At this time, it is necessary to increase the amount of cutting, which will increase the material The amount of processing, there is unnecessary waste. Therefore, the introduction of low-power laser-induced arc is considered for the manufacture of stainless steel walls.

[0066] The manufacturing system selects Riton LWS-1000 with the maximum output power of 1000W as the low-power laser emission device, OTC ACCUTIG-500P welding machine and WF-007 multi-functional automatic argon arc wire filling machine (wire feeding device). The linkage gantry type welding fixture holds and fixes the laser output head, TIG welding to...

Embodiment 2

[0075] Taking the accumulation of 304 stainless steel low-power laser-induced TIG arc composite additive manufacturing wall as an example, the low-power laser and TIG arc composite additive manufacturing system consists of welding gantry tooling, a laser with a maximum power of 1000W, a TIG welding machine and a wire feeding device. constitute.

[0076] Specific implementation method:

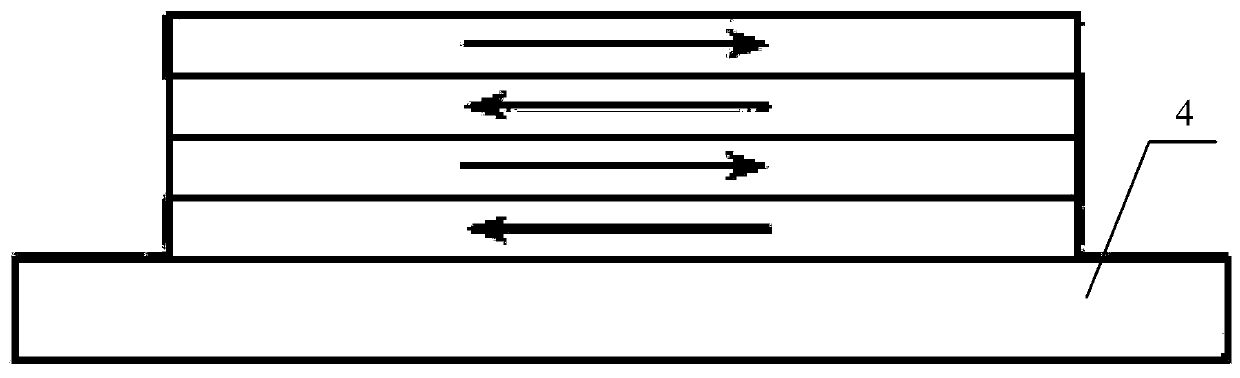

[0077] Use SolidWorks software to make a 3D model, and then import it into EasyPrint 3D software for path planning, slice the model, and generate a processing path.

[0078] The substrate is made of 300mm×300mm×25mm Q235 plate, the surface of the substrate is ground and milled, cleaned with absolute ethanol and fixed on a horizontal workbench, and the substrate is preheated at a temperature of 160 °C.

[0079] The welding wire type is ASTM304 stainless steel, the diameter is 1.2mm, the shielding gas is ordinary argon gas, and the shielding gas flow rate is 30L / min.

[0080] Adjust the welding...

Embodiment 3

[0085] Taking the accumulation of 308 stainless steel low-power laser-induced TIG arc composite additive manufacturing wall as an example, the low-power laser and TIG arc composite additive manufacturing system consists of Riton LWS-1000 laser, OTC-TIG welding machine and wire feeding device and OTC Welding robot pose.

[0086] Specific implementation method:

[0087] Use 3dsmax software to make a 3D model, and then import it into RepetierHost software for path planning, slice the model, and generate a processing path.

[0088] The substrate is made of 200mm×200mm×10mm Q235 plate, the surface of the substrate is ground and milled, cleaned with absolute ethanol and fixed on a horizontal workbench, and the substrate is preheated at 80°C.

[0089] The welding wire is ER308L stainless steel with a diameter of 0.8mm.

[0090] The welding current is 100A, the welding speed is 200mm / min, the wire feeding speed is 800mm / min, the laser power is 100W, and the shielding gas flow rate i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Size | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Average tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com