Patents

Literature

84results about How to "Small area of action" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

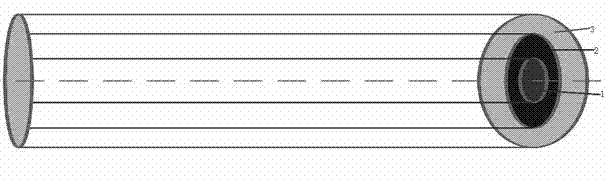

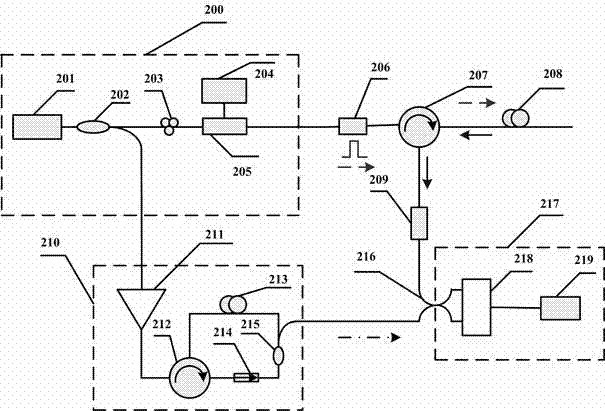

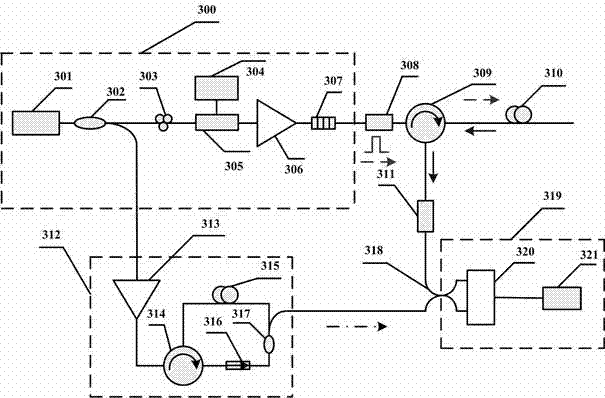

Narrow-bandwidth Brillouin optical timedomain reflectometer (OTDR) based on sensing optical fiber of three-layer structure

InactiveCN102393182AIncrease sensing lengthSave bandwidthThermometers using physical/chemical changesUsing optical meansFrequency shiftClock control

The invention discloses a narrow-bandwidth Brillouin optical timedomain reflectometer (OTDR) based on a sensing optical fiber of a three-layer structure. The OTDR comprises a light pulse generating unit (200), wherein light pulses generated by the light pulse generating unit (200) enter into a first port of a circulator (207) after passing through a polarization scrambler (206), and enter into the sensing optical fiber (208) through a second port of the circulator; and backward scattered light of pulsed light in the sensing optical fiber (208) enter into a filter unit (209) through a third port of the circulator; light output by the filter unit and light output by a local oscillation light unit (210) are coupled into a detection and signal processing unit (217) through a coupler (216); and a pulse generator is used for driving a modulator to generate pulse and clock control. The sensing optical fiber in the OTDR can not only increase Brillouin threshold, but also reduce Brillouin frequency shift and bandwidth of a detector; and as a Brillouin ring-shaped cavity laser is designed to serve as local oscillation light concerned with detection, the bandwidth of the detector is greatly reduced, and the measuring accuracy of the Brillouin OTDR is improved.

Owner:NANJING UNIV

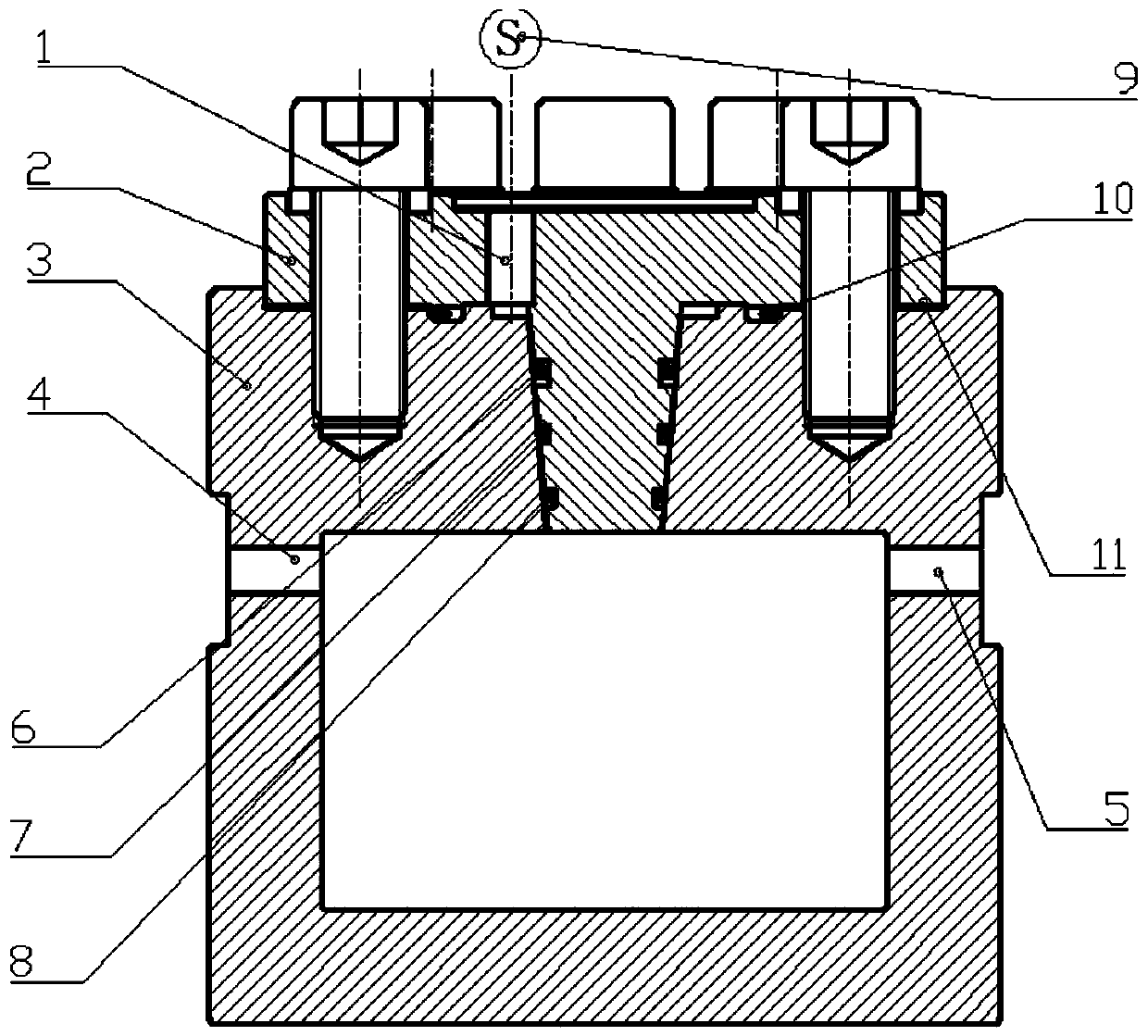

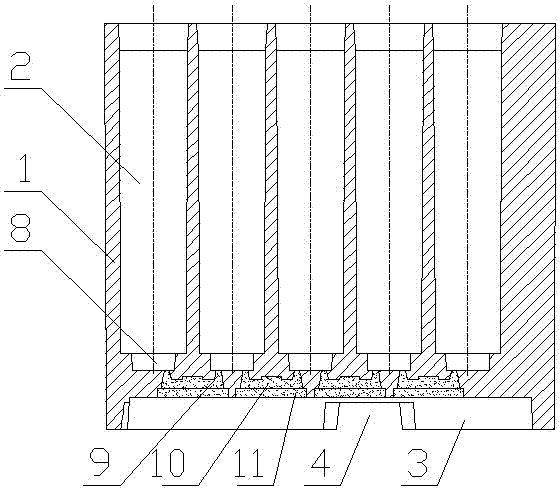

Multi-stage compression rate adjustable static sealing test experiment device

ActiveCN110274735AComprehensive test functionEasy to detectDetection of fluid at leakage pointMachine sealing rings testingPre compressionEngineering

The invention discloses a multi-stage compression rate adjustable static sealing test experiment device. The device comprises a leak detection port, a sealing end cover, an experimental box body, a medium inlet, a medium outlet, a test sealing ring 1, a test sealing ring 2, a test sealing ring 3, a gas sensor, and external seal. The experimental box body is fixed on a workbench, and the sealing end cover is fixedly connected with the experimental box body. A plurality of sealing grooves are arranged at a conical surface of the sealing end cover to achieve a sealing performance test of single channel sealing rings with different outer ring diameters and cross-sectional dimensions, and multi-stage sealing of two-channel and multi-channel O-shaped rings. A gasket between the sealing end cover and the box body is replaced to adjust a distance between the two so as to realize sealing performance detection under different pre-compression ratios.

Owner:TSINGHUA UNIV

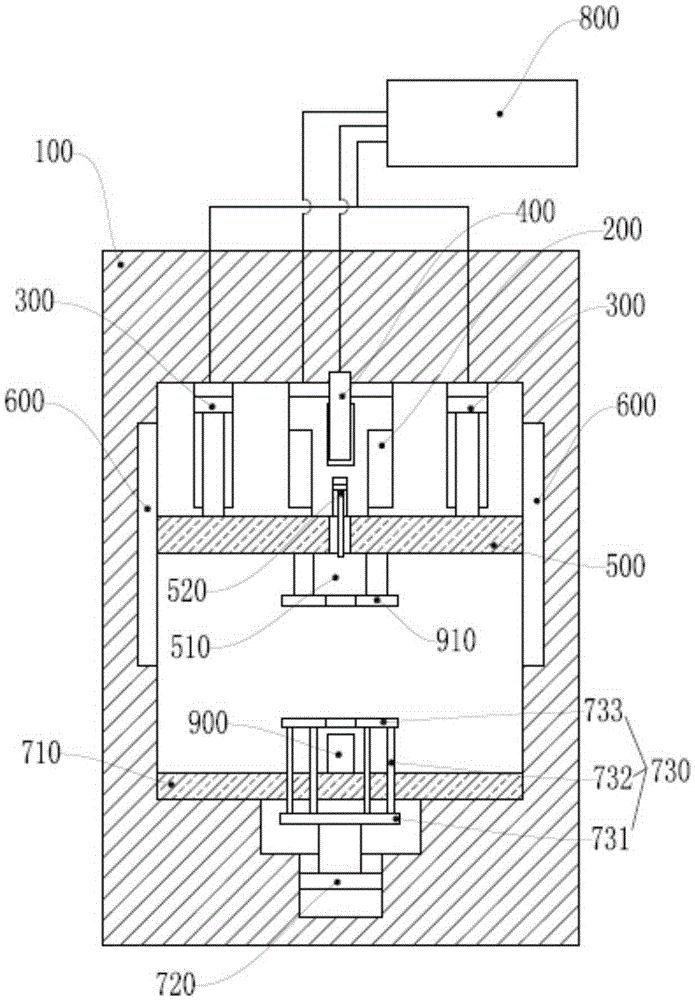

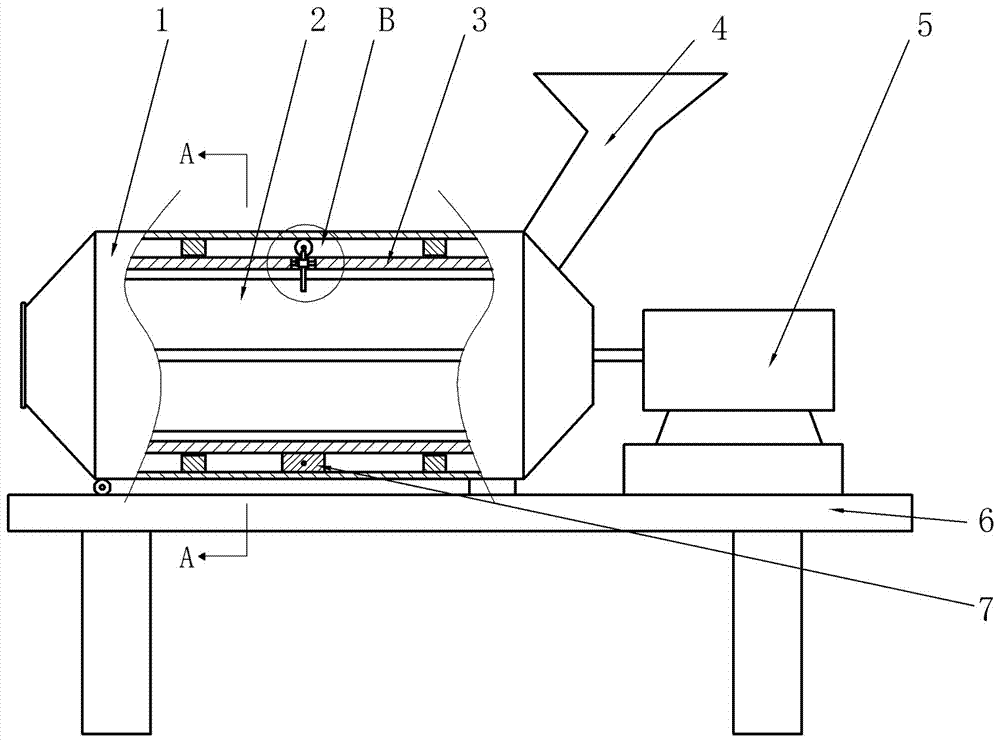

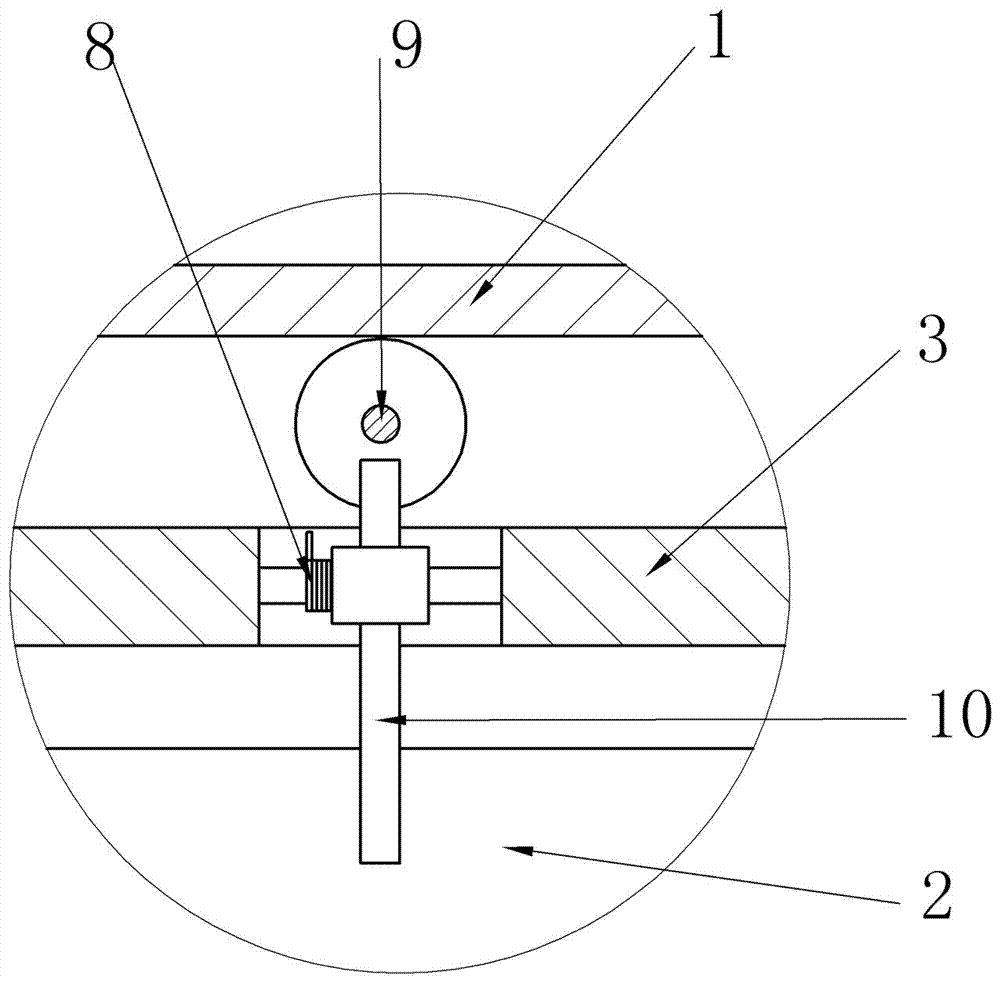

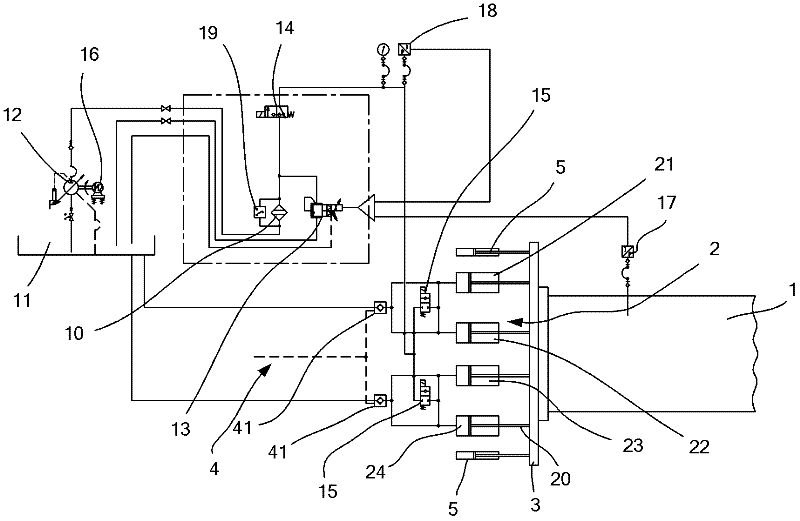

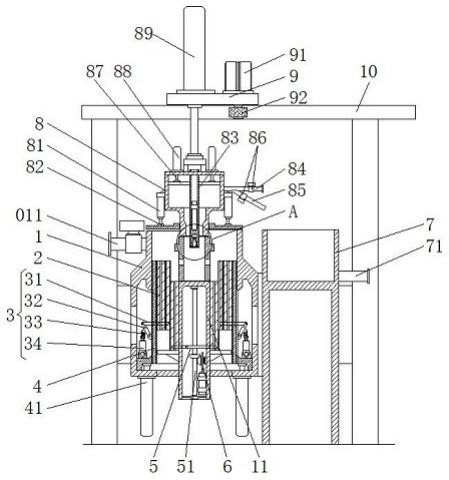

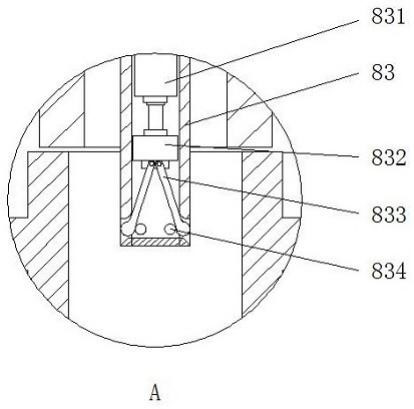

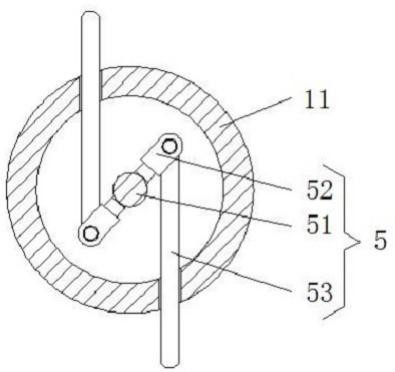

Multifunctional combined hydraulic machine

InactiveCN105312384AIncrease the area of actionSmall area of actionPress ramEngineeringMultiple function

The invention relates to the field of metallurgy pressing machines, in particular to a multifunctional combined hydraulic machine. The multifunctional combined hydraulic machine comprises a rack, a main driving cylinder, a built-in rapid driving cylinder, an auxiliary driving cylinder, a movable cross beam, a guide mechanism, a workbench, a control system, a male die and a female die, wherein the workbench is arranged at the lower end of the rack in a sliding way; the movable cross beam is arranged on the upper end of the rack and located right above the workbench; and the main driving cylinder and the auxiliary driving cylinder are connected with the movable cross beam. The action areas of piston rods of the main driving cylinder, the auxiliary driving cylinder and the built-in rapid driving cylinder are unequal, the action area of the piston rod of the main driving cylinder is maximum, and the action area of the piston rod of the built-in driving cylinder is minimum, so that when hydraulic liquid flow amounts are equal, the extension extent of the piston rod of the built-in rapid driving cylinder is maximum, and the extension extent of the piston rod of the main driving cylinder is minimum. According to the multifunctional combined hydraulic machine, under the control of a control system, the hydraulic machine is provided with different feeding speeds and can adapt to the production technology of different materials.

Owner:FOSHAN CONSTANT HYDRAULIC MACHINERY

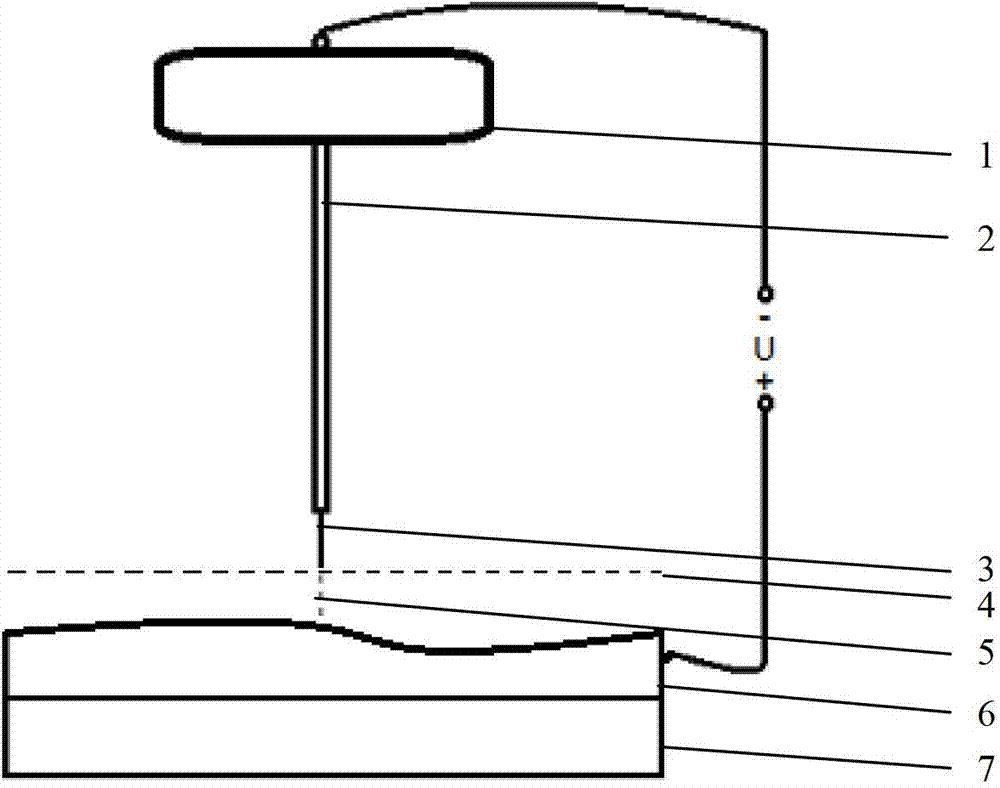

Ultrahigh vacuum fast scanning microscopy method based on carbon nanotube probe

InactiveCN102768292AImprove reliabilityReliable scanningScanning probe microscopyIn planeScanning electron microscope

The invention belongs to the field of scanning probe microscopy and relates to an ultrahigh vacuum fast scanning microscopy method based on a carbon nanotube probe, comprising the following steps of: fixing a nanotube probe at the end of a probe of a scanning tunneling microscope; calibrating the field emission current sensitivity curve family of the carbon nanotube probe in the Z direction; fixing the carbon nanotube probe in a probe clamp and adjusting the carbon nanotube probe in a vacuum state required by scanning; enabling the carbon nanotube probe to enter a tunneling state under a constant current mode; keeping a piezoelectric ceramic scanner stationary in the Z direction; setting a scanning range, scanning velocity and sampling point parameters, recording the field emission current i of the carbon nanotube probe one point after another, and carrying out quick imaging scanning of a sample to be detected under a constant height mode. The ultrahigh vacuum fast scanning microscopy method based on the carbon nanotube probe is high in reliability and speed and capable of improving the in-plane resolution of scanning imaging.

Owner:TIANJIN UNIV

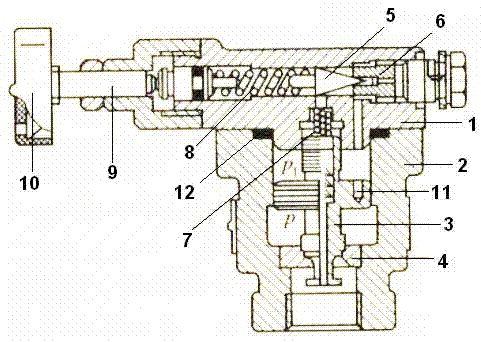

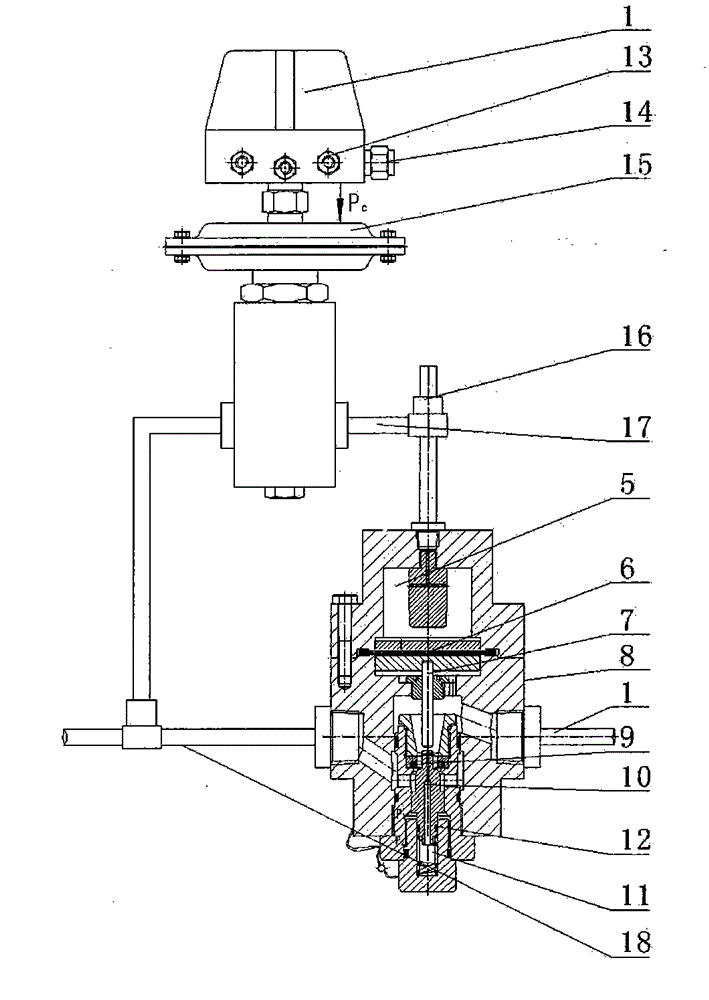

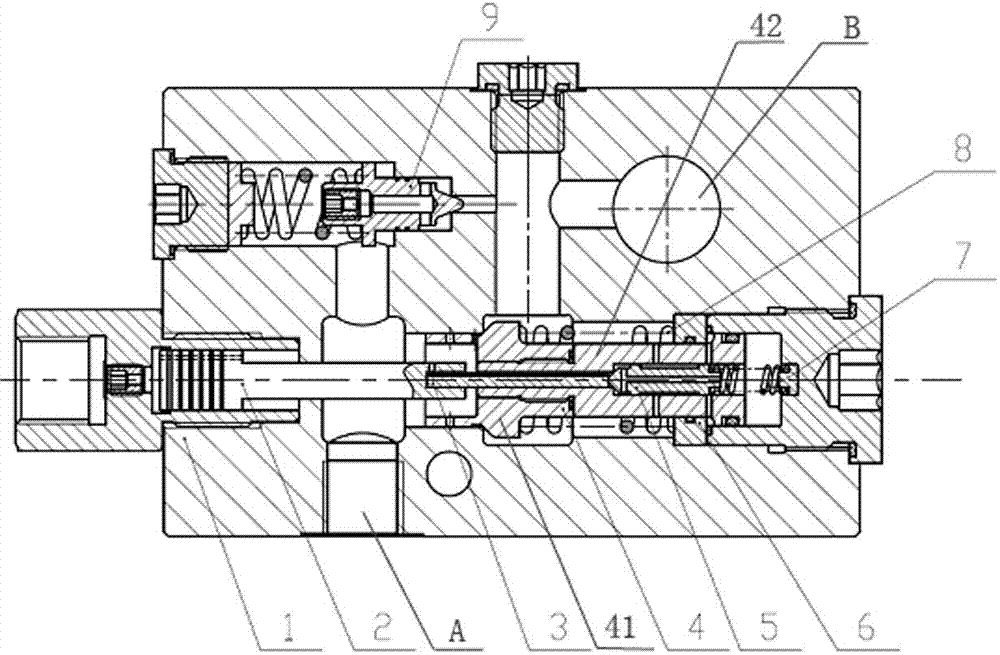

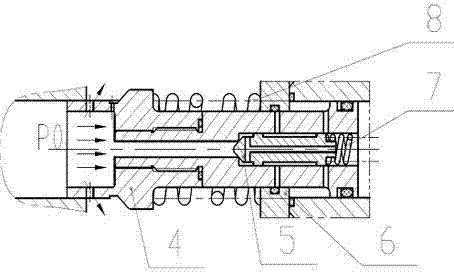

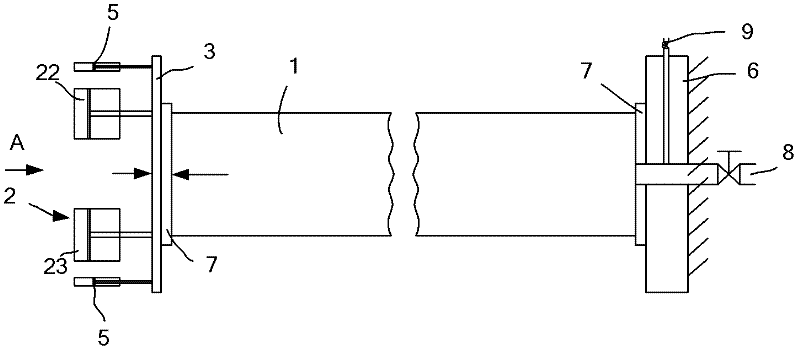

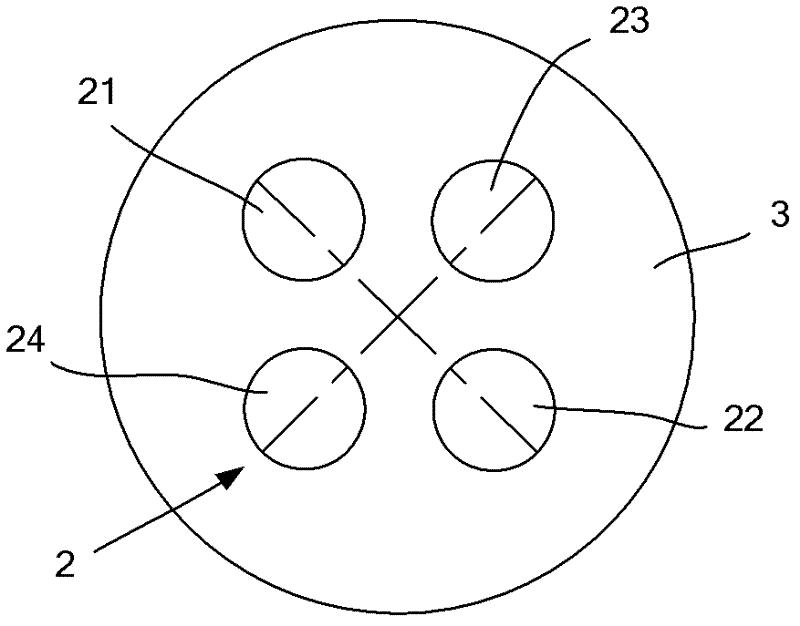

Overflow valve

InactiveCN105443483ASmall area of actionPortable pressure regulationFluid-pressure actuator safetyServomotor componentsEngineeringValve seat

The invention discloses an overflow valve. The overflow valve comprises a valve cover, a valve body, a main valve core, a main valve seat, a pilot cone valve and a pilot valve seat, wherein the valve cover is arranged at the top of the valve body, the main valve seat is arranged inside the valve body, and the main valve core is arranged on the main valve seat; the pilot valve seat is arranged inside the valve cover, and the pilot cone valve is arranged on the pilot valve seat; the top end of the main valve core is in contact with the pilot cone valve through a main valve spring. The overflow valve further comprises a pressure adjusting spring, an adjusting screw and an adjusting hand wheel; the adjusting spring is arranged at the tail end of the pilot cone valve, the adjusting screw is arranged at the tail end of the adjusting spring, and the tail end of the adjusting screw is connected with the adjusting hand wheel. The overflow valve further comprises a damping hole, and the damping hole is formed in the main valve core. The overflow valve provided by the invention has a small cone valve acting area, and can achieve pressure adjusting conveniently; the main valve spring is flexible, the pressure fluctuation is small, and the static characteristic is excellent; the main valve core adopts a conical surface valve seat type structure for sealing, overlapping is avoided, and actions are sensitive.

Owner:SUZHOU YUANSHUO PRECISION MOLD

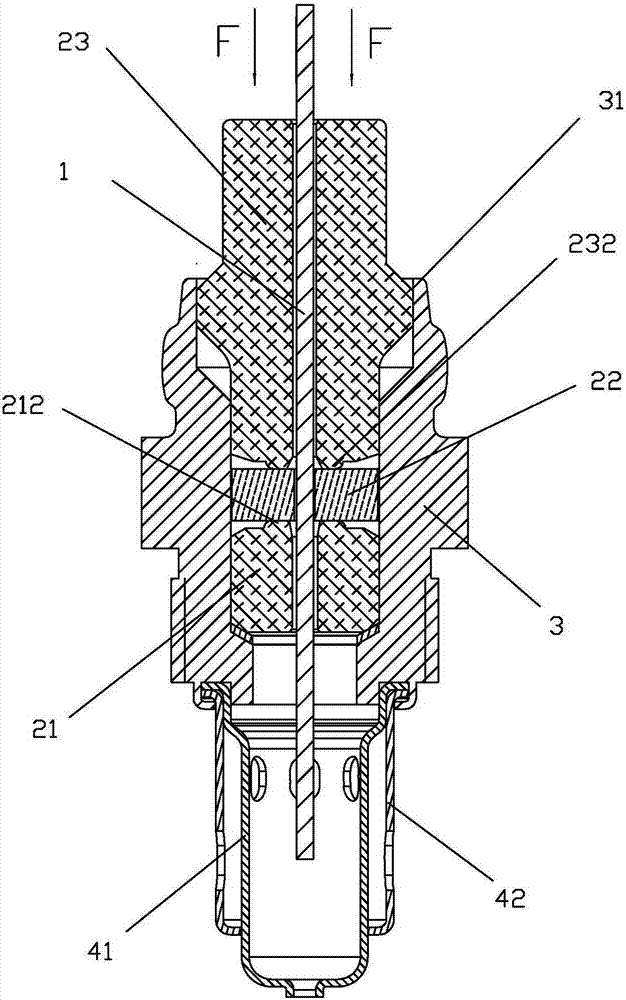

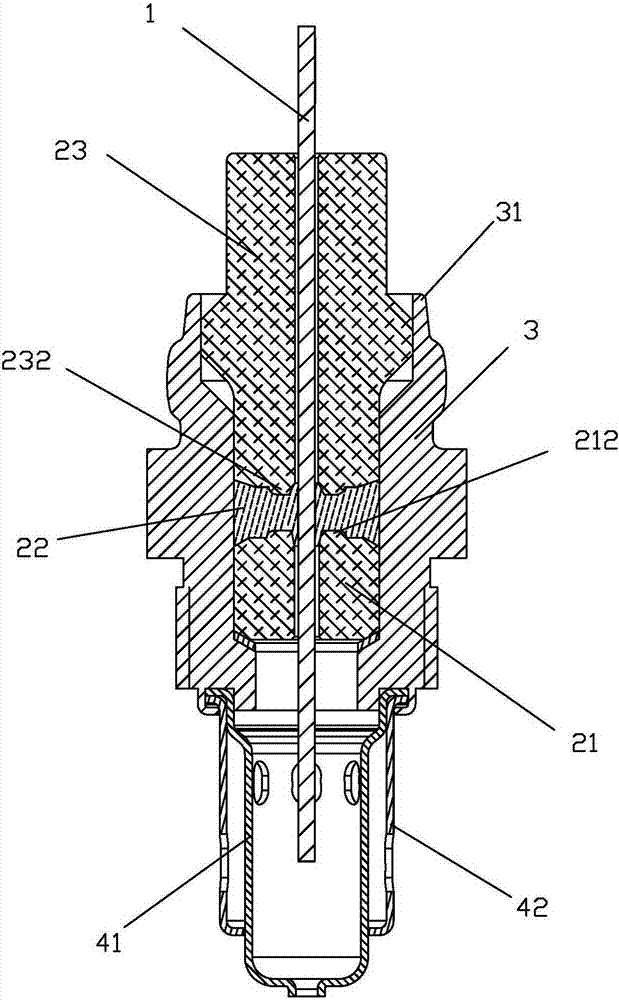

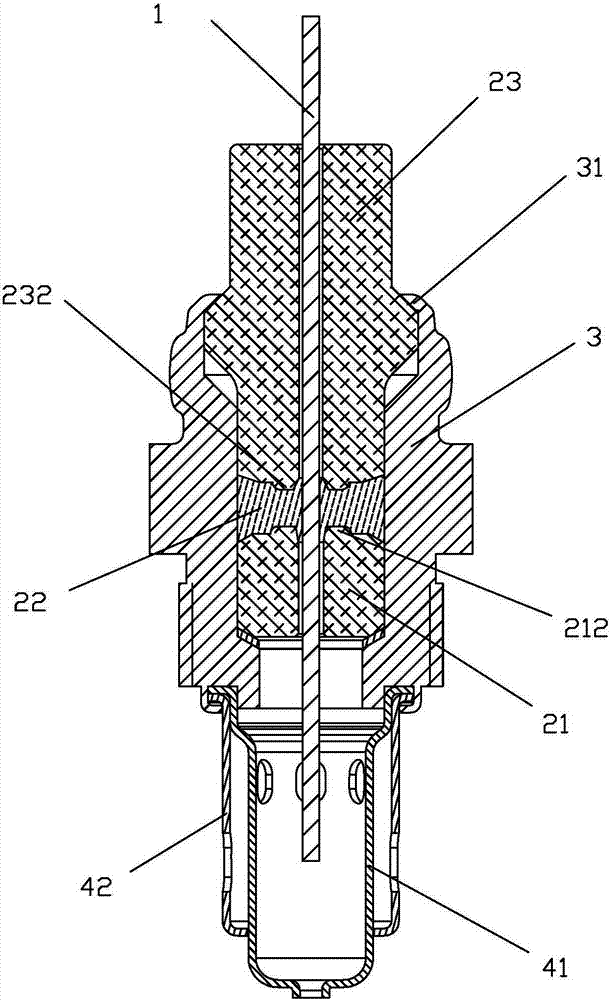

Chip type oxygen sensor structure and manufacturing method thereof

InactiveCN105445352APrevent rotationEasy to crushMaterial analysis by electric/magnetic meansOxygen sensorWhole body

The invention discloses a chip type oxygen sensor structure and a manufacturing method thereof. The chip type oxygen sensor structure comprises a sensitive element, a sealing device and a mounting shell, wherein the sensitive element is fixedly mounted in the shell through the sealing device; the sealing device comprises a front-end ceramic piece, a sealing ring and a rear-end ceramic piece; the sealing ring is filled into a space formed by the ceramic pieces, the mounting shell and the sensitive element; in the front-end ceramic piece and the rear-end ceramic piece, at least one convex object is arranged on the corresponding end face which is in contact with the sealing ring; and the convex object is embedded into the end face, which is in contact with the corresponding ceramic piece, of the sealing ring so that a whole body, which rotates simultaneously is formed by the ceramic pieces and the sealing ring in a rotary direction. The chip type oxygen sensor structure can be used for preventing phenomena that relative rotation of the sealing ring and the ceramic pieces is caused by the fact that the rear end of the shell presses a rivet ring to rivet in an assembling process and a product vibrates in a utilization process, and the sealing ring is easy to break in the assembling process, so that the sealing reliability of the sealing ring is improved, and furthermore, the production cost is reduced and the yield of the product is improved.

Owner:XIAMEN HONGFA ELECTRIC POWER CONTROLS

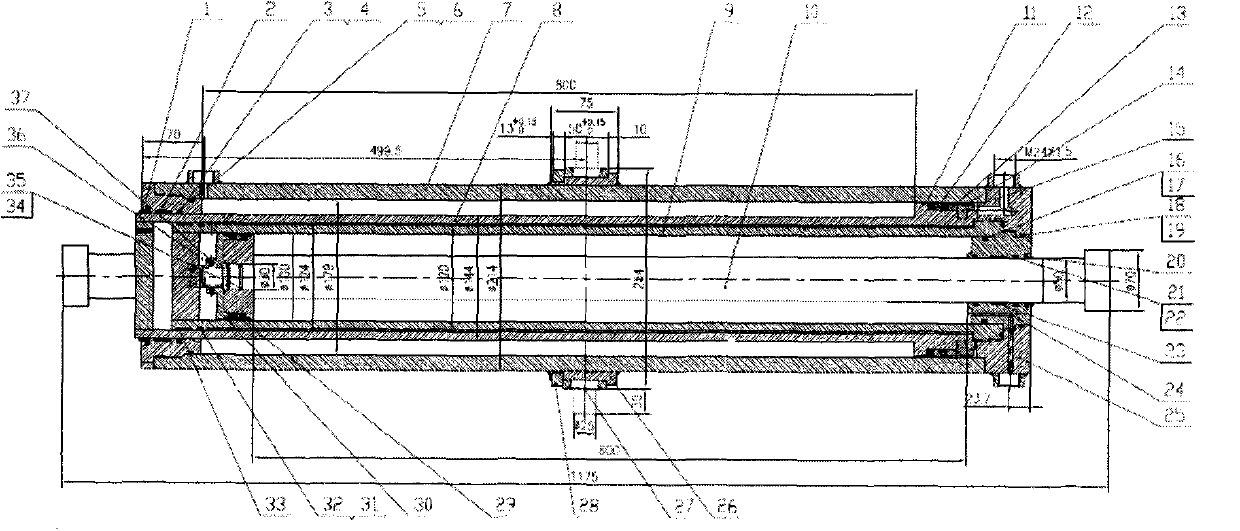

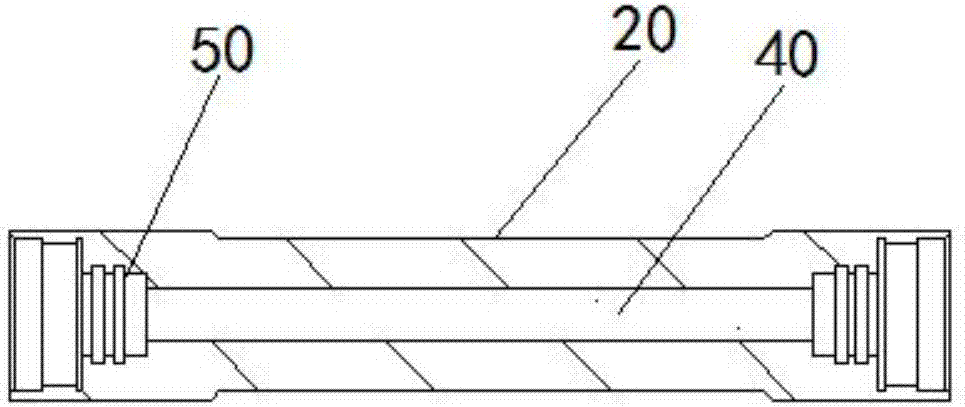

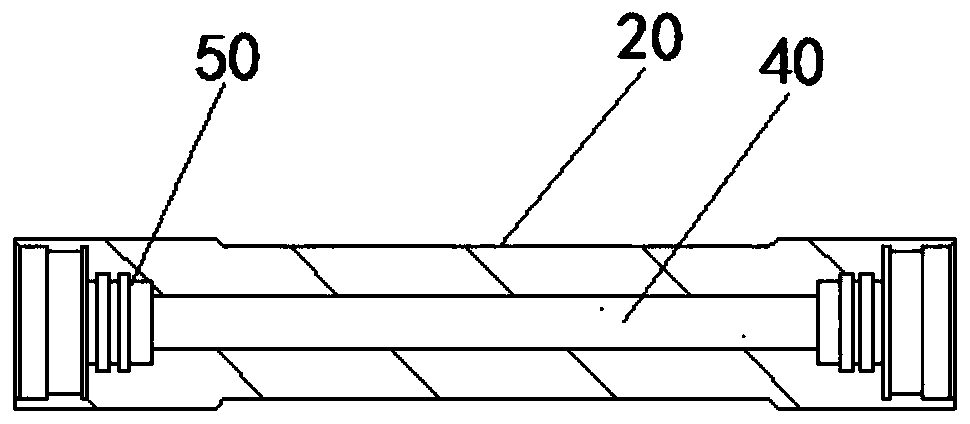

Bidirectional single-flexible hydraulic cylinder

ActiveCN103343763ASmall area of actionAvoid the vicious pressurization effectFluid-pressure actuatorsEngineeringCylinder block

The invention discloses a bidirectional single-flexible hydraulic cylinder which is characterized in that a guide cylinder body and a set of piston rods with opposite directions are additionally arranged inside the single-flexible hydraulic cylinder through an overlapping method, and the piston rods extend out from holes in the rear side of an external cylinder body. Meanwhile, a lower cavity is shared through a method of providing a communicating hole in the guide cylinder body, thus the single flexing capable of being bidirectionally independently controlled is realized. Meanwhile, through regulating the acting area of one piston rod, the bad pressurizing effect is avoided.

Owner:CCTEG CHINA COAL RES INST

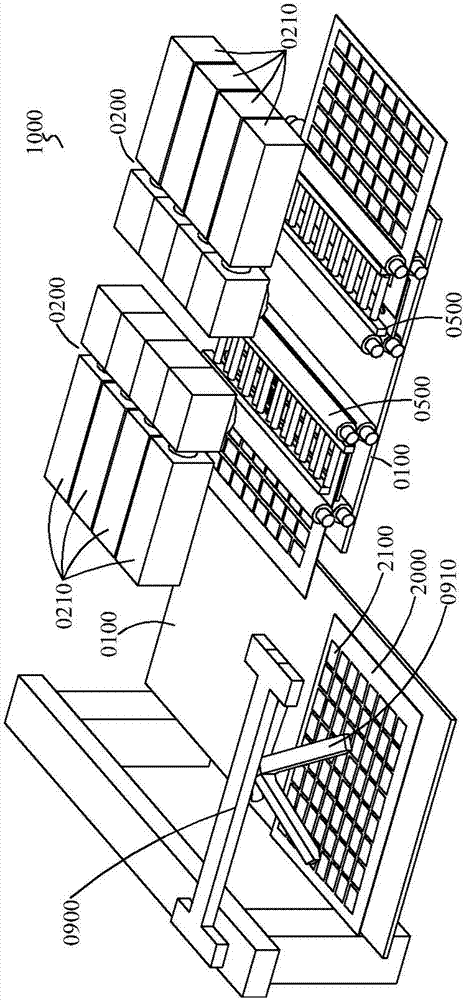

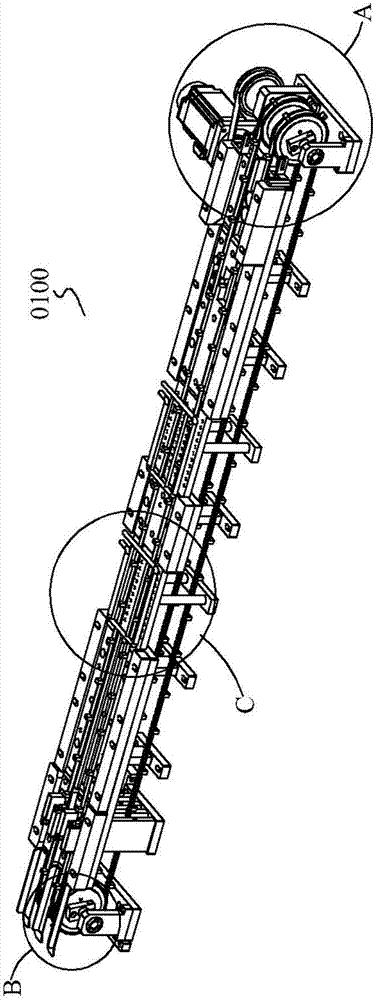

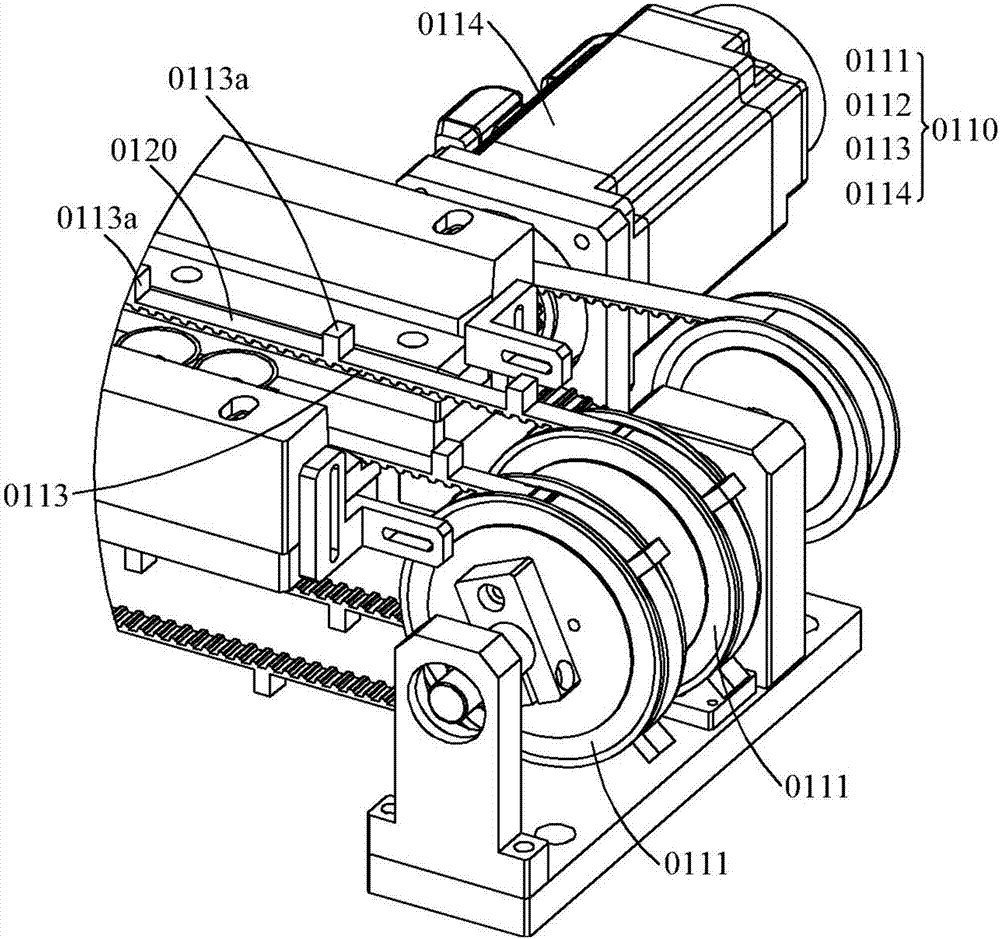

Multi-axis laser slot milling machine

PendingCN107511589ASmall area of actionImprove processing efficiencyWelding/cutting auxillary devicesAuxillary welding devicesEngineeringMulti axis

A multi-axis laser slot milling machine comprises a conveying mechanism and at least one milling mechanism. The conveying mechanism comprises a moving portion and multiple base plate clamps arranged on the moving portion. The base plate clamps are used for clamping base plates in a one-to-one correspondence manner. The base plate clamps move along with the moving portions and pass through the milling station. Each base plate is provided with multiple card bases at least arranged in array in a first direction. The first direction and the movement direction of the base plate are not parallel. When multiple milling mechanisms are arranged, the milling mechanisms are distributed in the movement direction of the base plates. The milling mechanisms comprise multiple laser devices. The multiple laser devices are arranged on the milling station and distributed in array in the first direction. The laser devices are used for emitting laser beams and milling burying slots on the surface of the corresponding card bases. The multi-axis laser slot milling machine is high in machining efficiency and good in precision and has the multi-axis machining capacity.

Owner:深圳华创兆业科技股份有限公司

Electronic control pilot-operated type high-precision large-flow regulating valve

InactiveCN105889589AIncrease outlet pressureRealize long-distance precise controlEqualizing valvesSafety valvesClosed loop feedbackThe Internet

The invention discloses an electronic control pilot-operated type high-precision large-flow regulating valve. The electronic control pilot-operated type high-precision large-flow regulating valve comprises a first connection pipe which is connected with a high-voltage large-flow valve. The high-voltage large-flow valve comprises a shell, wherein the first connection pipe is connected with one side of the shell, a valve seat is arranged on the lower portion inside the shell, and a valve rod is installed in the valve seat. An electronic pressure controller can select and regulate a fixed point signal source, wherein the current of an external analog signal ranges from 4 mA to 20 mA or the voltage of the external analog signal ranges from 1 VDC to 5 VDC, and feedback and error signals are limited in a programmable mode. The electronic control pilot-operated type high-precision large-flow regulating valve provides closed-loop feedback control for a system, has the supernormal accuracy and response time, and can be connected with a computer to conduct internet control.

Owner:HENAN AEROSPACE HYDRAULIC & PNEUMATIC TECH

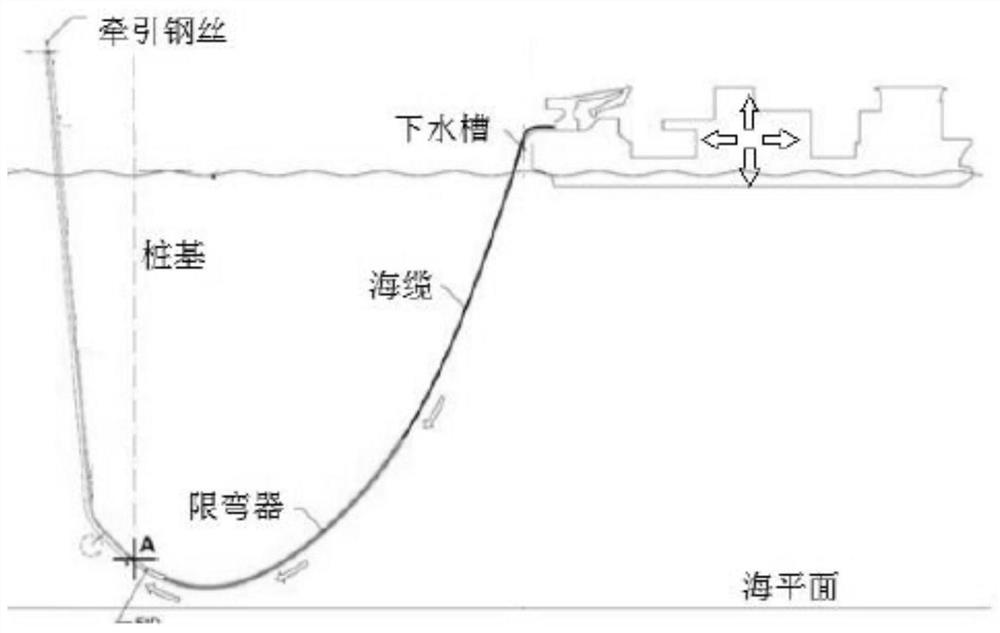

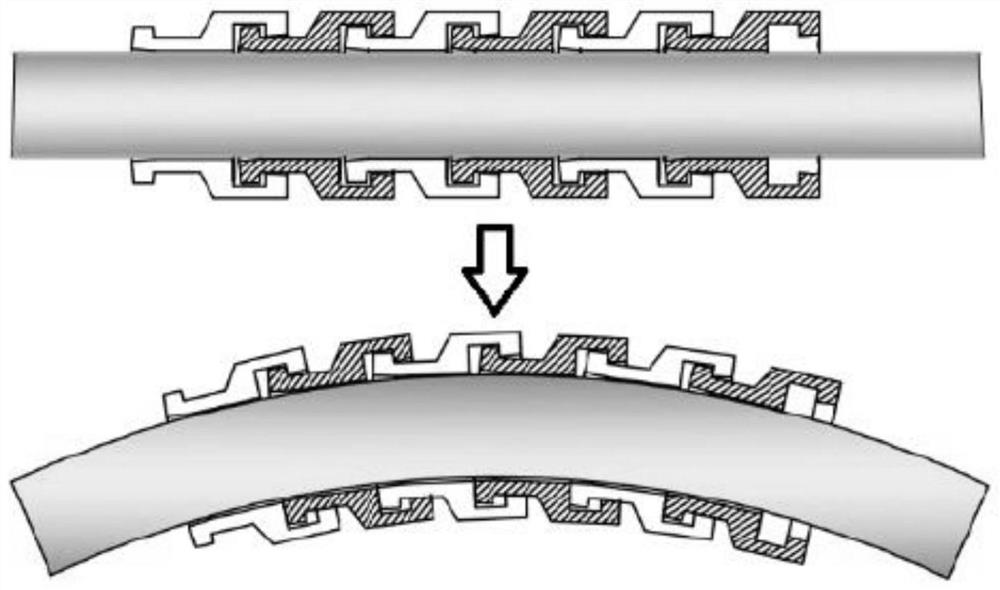

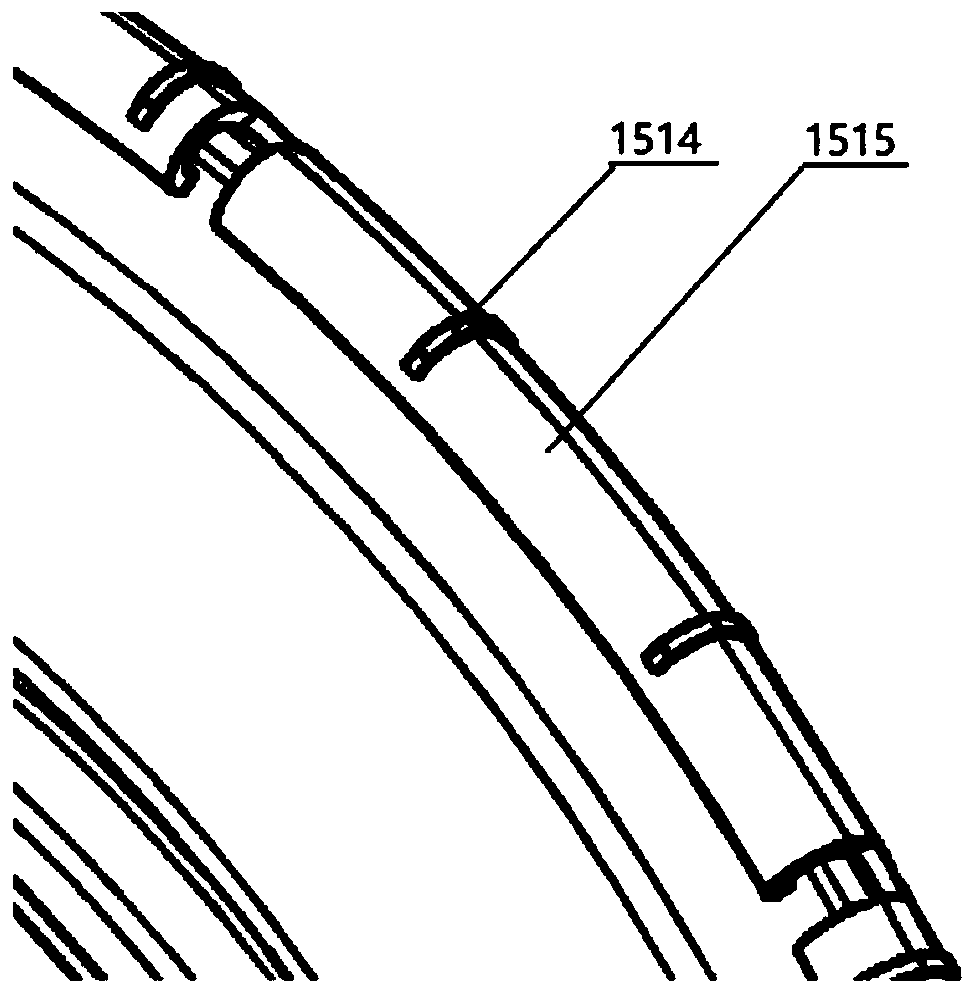

Topological optimization design method of submarine cable bending protector

PendingCN111814285AReduce weightReduce manufacturing costGeometric CADConstraint-based CADMarine engineeringStructural engineering

The invention discloses a topological optimization design method of a submarine cable bending protector. The topological optimization design method comprises the following steps: establishing an initial three-dimensional model of the submarine cable bending protector; importing the initial three-dimensional model into an OptiStrut module of the HyperMesh software; meshing the initial three-dimensional model and defining material attributes of the initial three-dimensional model; performing topological optimization design on the three-dimensional model of the submarine cable bending protector;determining three load sets and two working conditions are created, loads and constraints of the load sets, and defining topological optimization design variables; selecting a topological optimizationmodel component to contain all design attributes in the initial three-dimensional model, defining a mass fraction lower limit value and an objective function of the initial three-dimensional model asminimum strain energy, and performing iterative optimization and calculation solution on the density of the submarine cable bending protector; and comparing the two-dimensional topological optimization design result with the three-dimensional topological optimization design result to verify the accuracy of the three-dimensional topological optimization design result.

Owner:HARBIN ENG UNIV

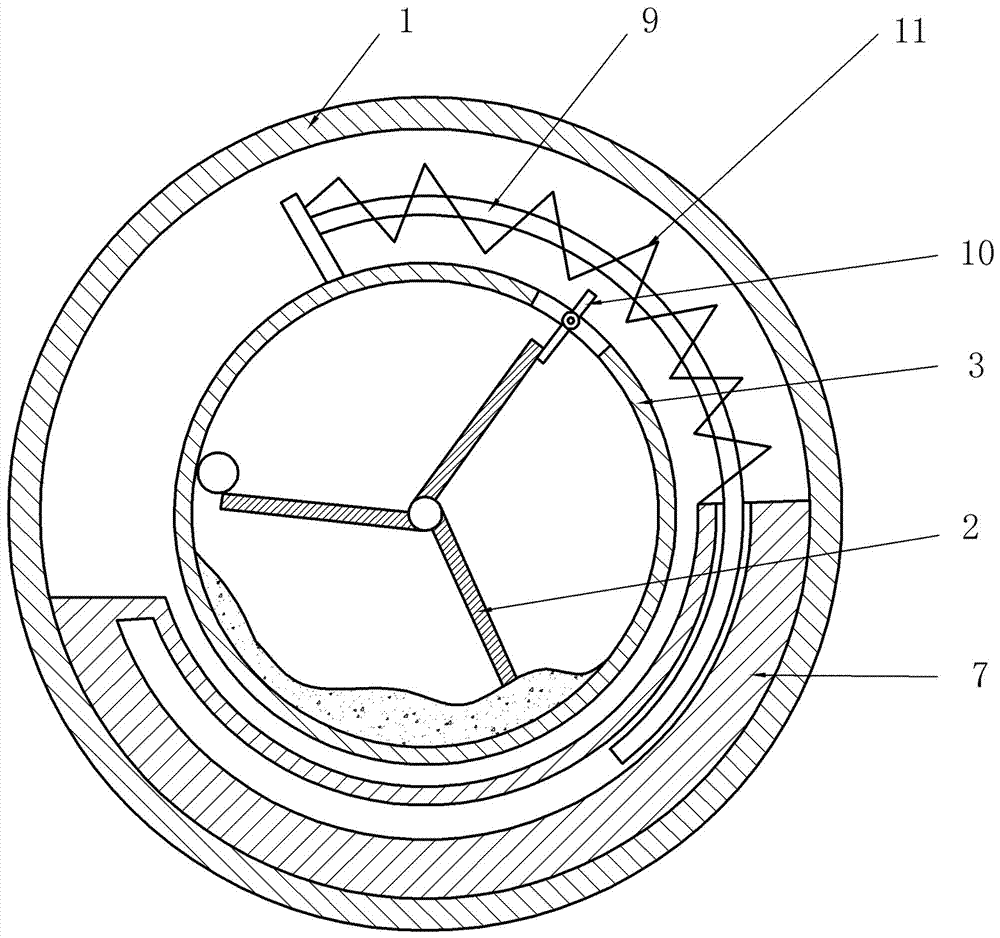

Stirring device for building operation

ActiveCN107972181AReduce noiseLower the altitudeCement mixing apparatusArchitectural engineeringDrive motor

The invention belongs to the field of stirring device, and specially discloses a stirring device for building operation. The major scheme is that a driving motor is fixed on a fixed station, the output end of the driving motor stretches into a mixing drum, the mixing drum is sleeved with an outer cylinder, the outer cylinder is fixed on the fixed station, mixing blades are fixed on the circumferential direction of the output end of the driving motor, and sieving clearances for sieving out larger stones is reserved between the mixing blades and the inner wall of the mixing drum; a guide block is located between the outer cylinder and the mixing drum and is fixed on the inner wall of the outer cylinder, one end of a guide arc rod is fixed on the outer wall of the mixing cylinder, and the other end of the guide arc rod is connected into the guide block in a sliding mode; and one end of a reset spring is fixed on the guide arc rod, the other end of the reset spring is fixed on the guide block, the middle portion of a deflector rod is hinged to the outer wall of the mixing drum, and the hinge joint of the deflector rod and mixing drum is provided with a strong torsional spring. The stirring device of for the building operation reduces noise generated by mixing drums in the prior art.

Owner:CHONGQING VOCATIONAL INST OF ENG

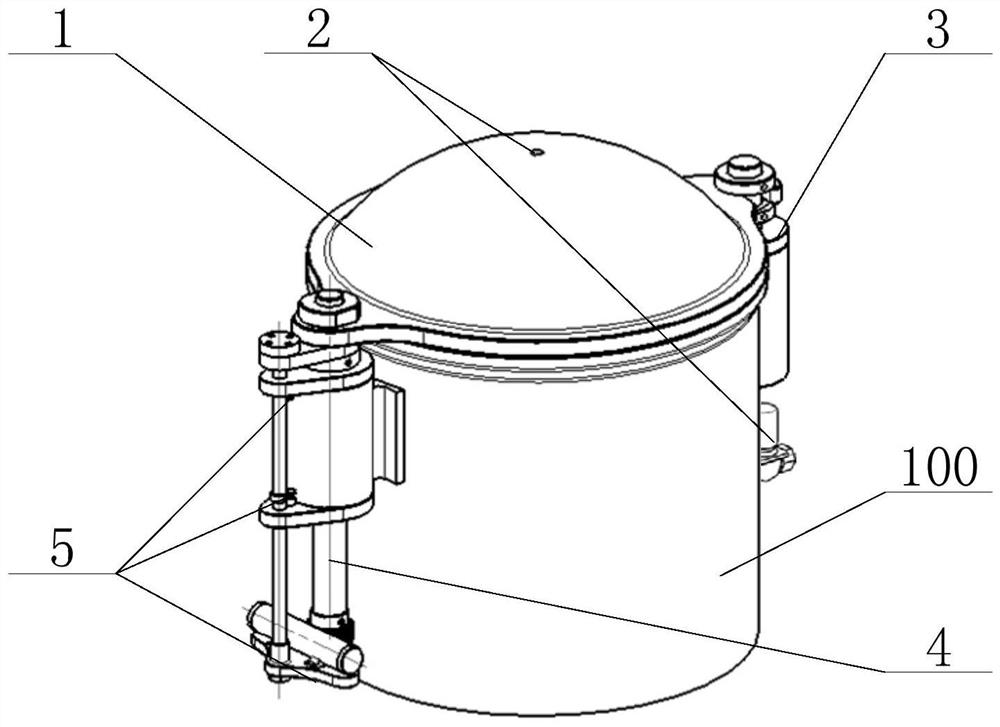

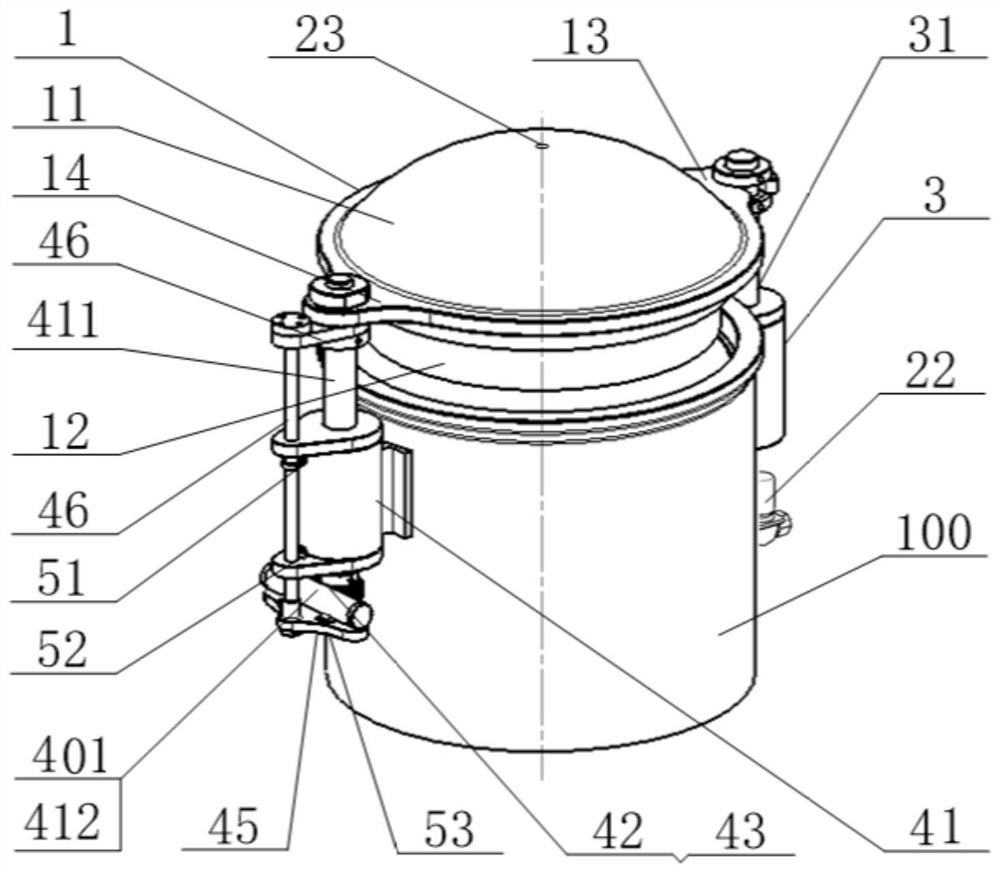

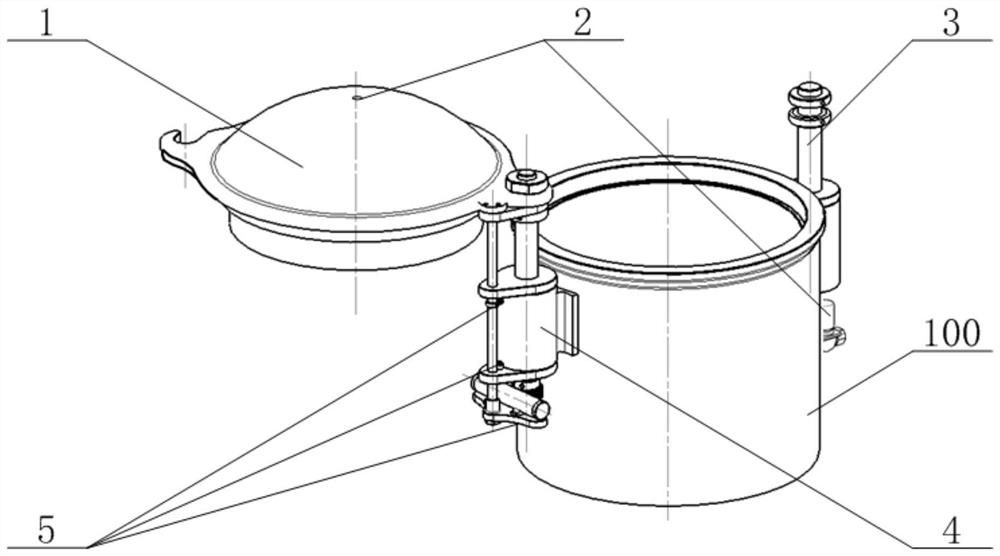

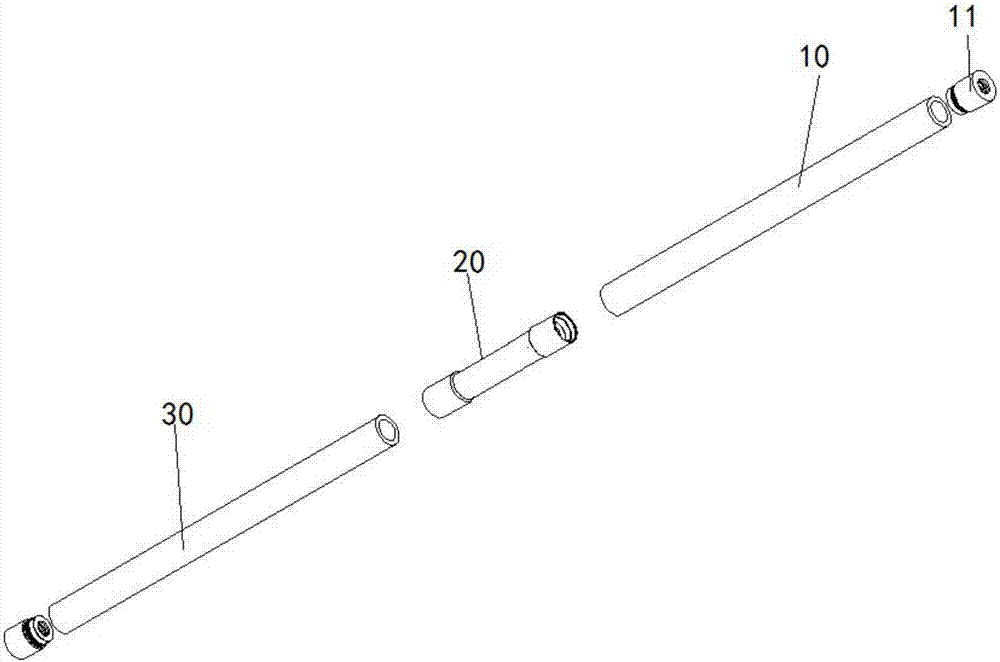

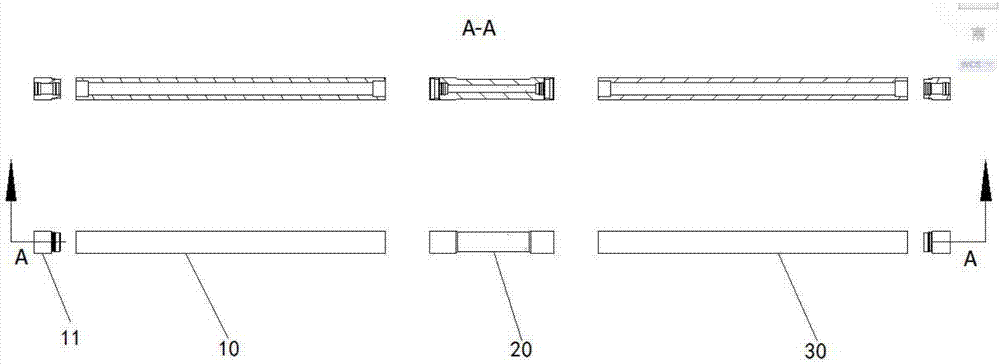

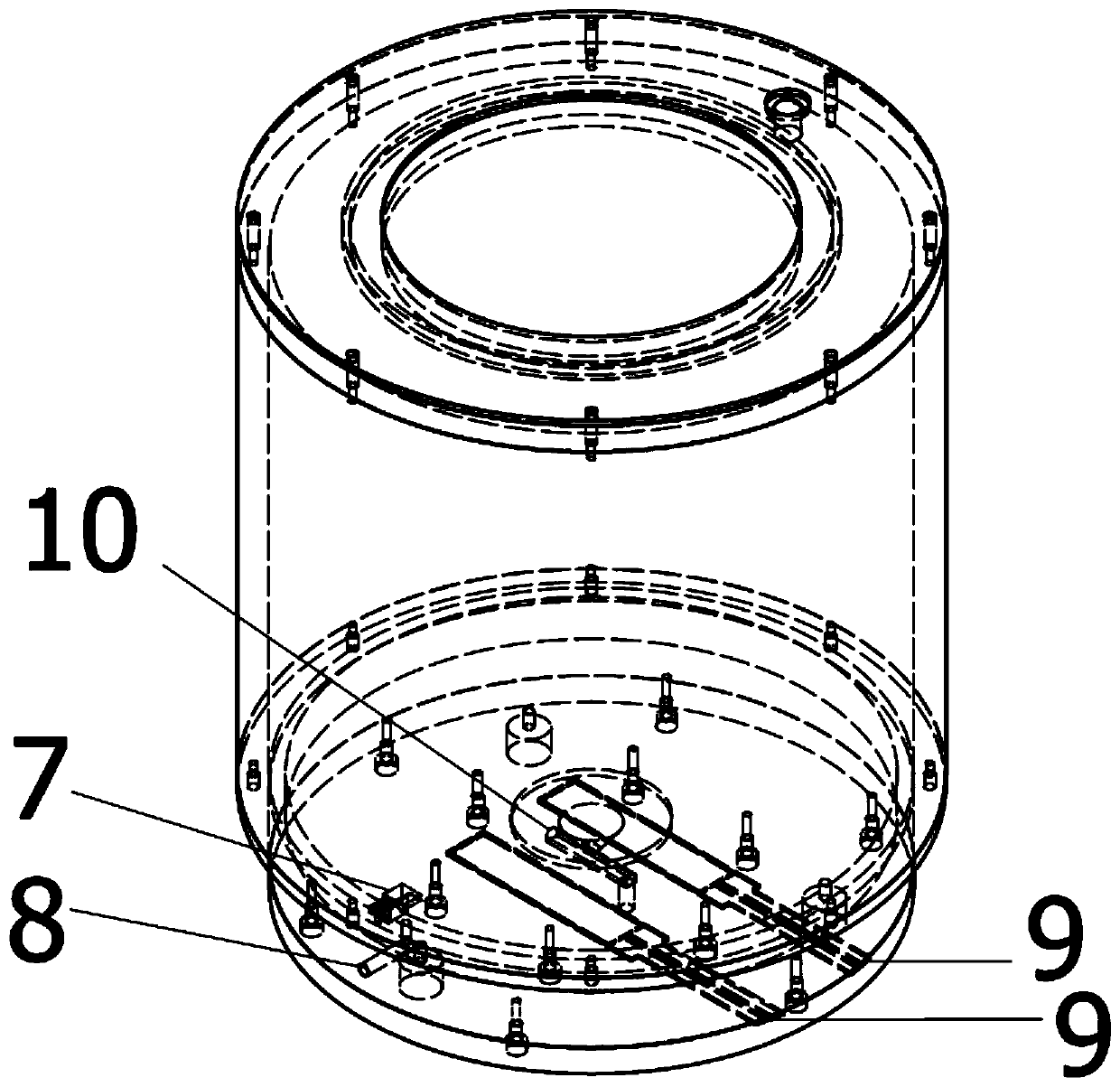

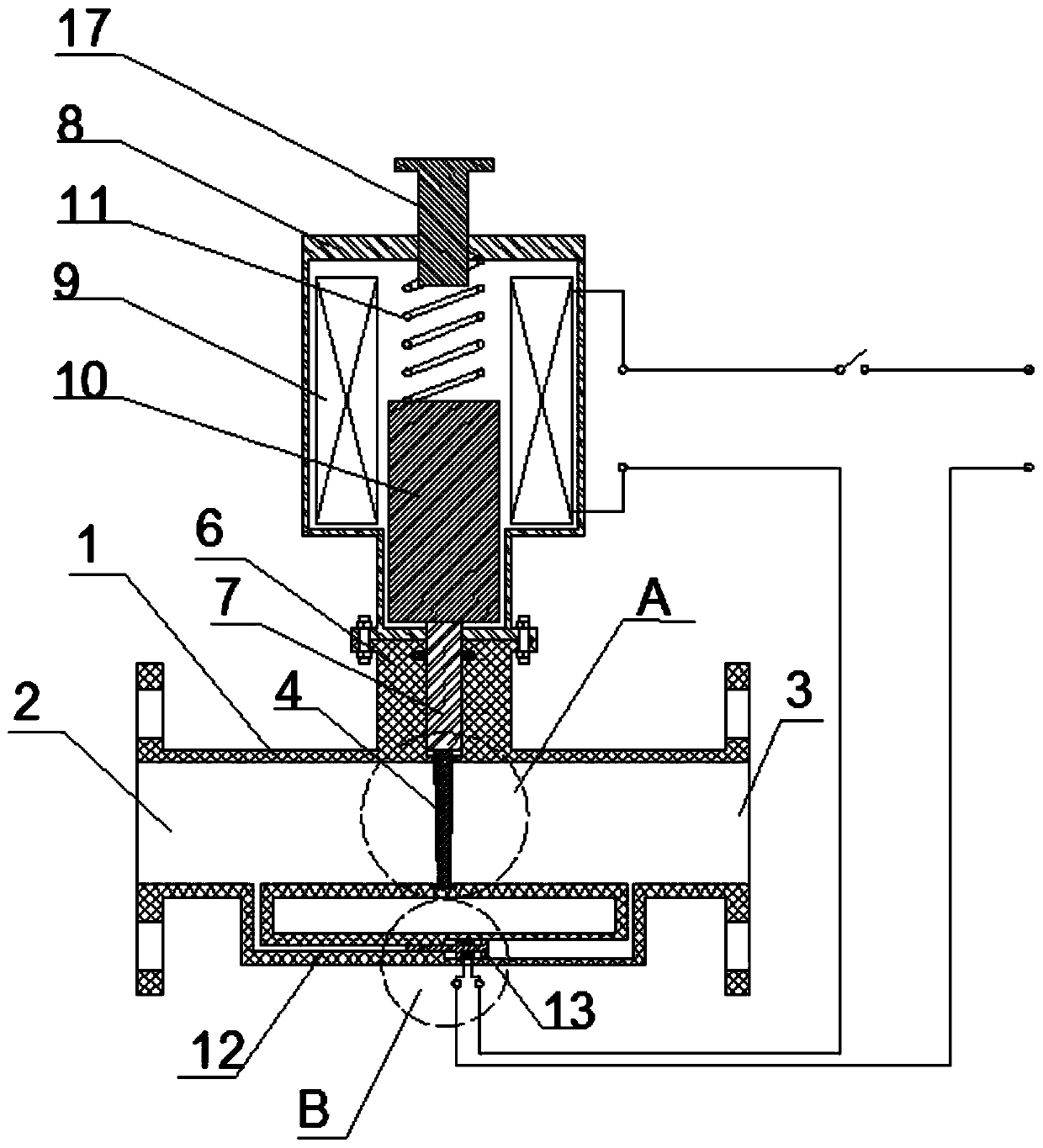

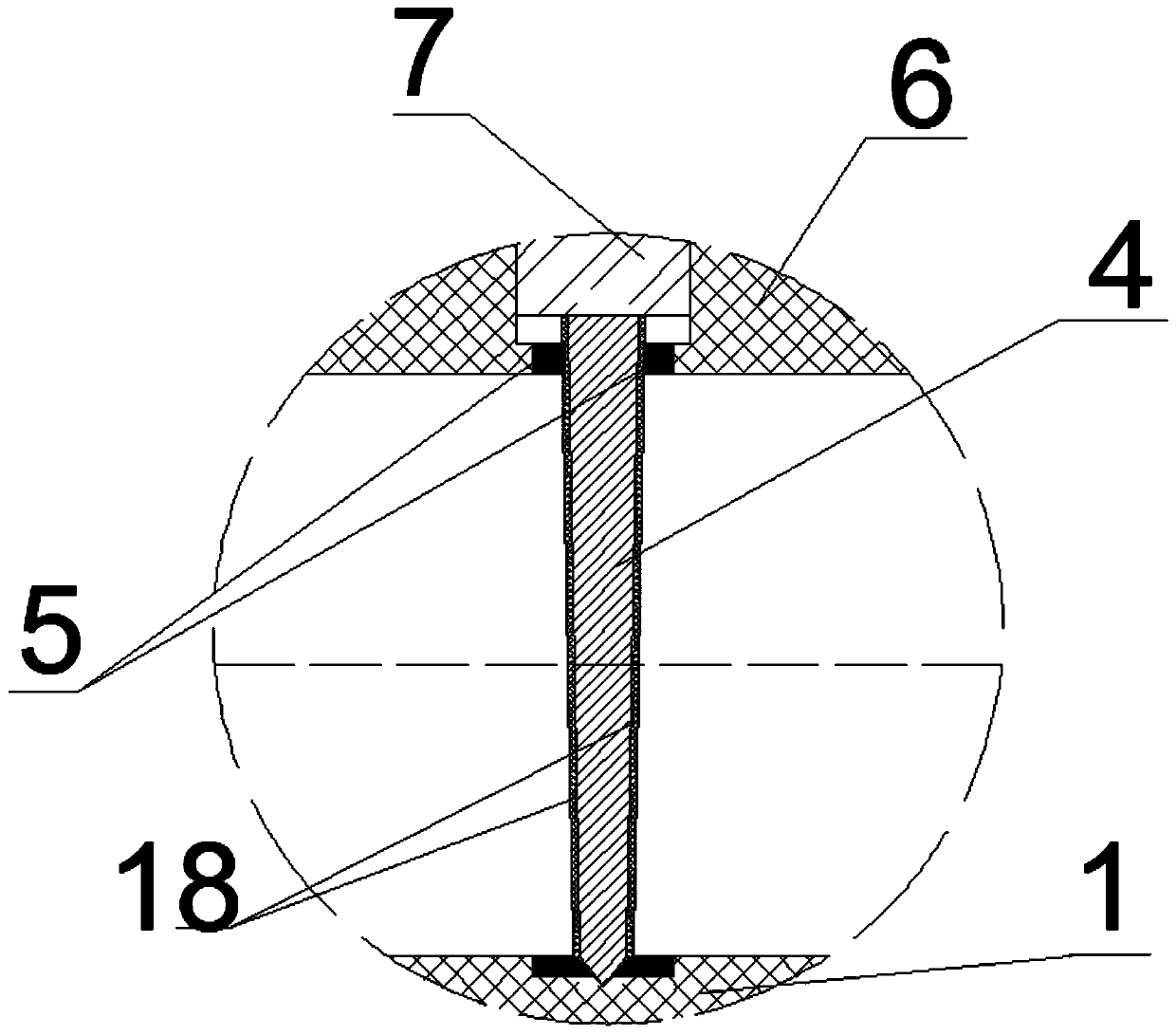

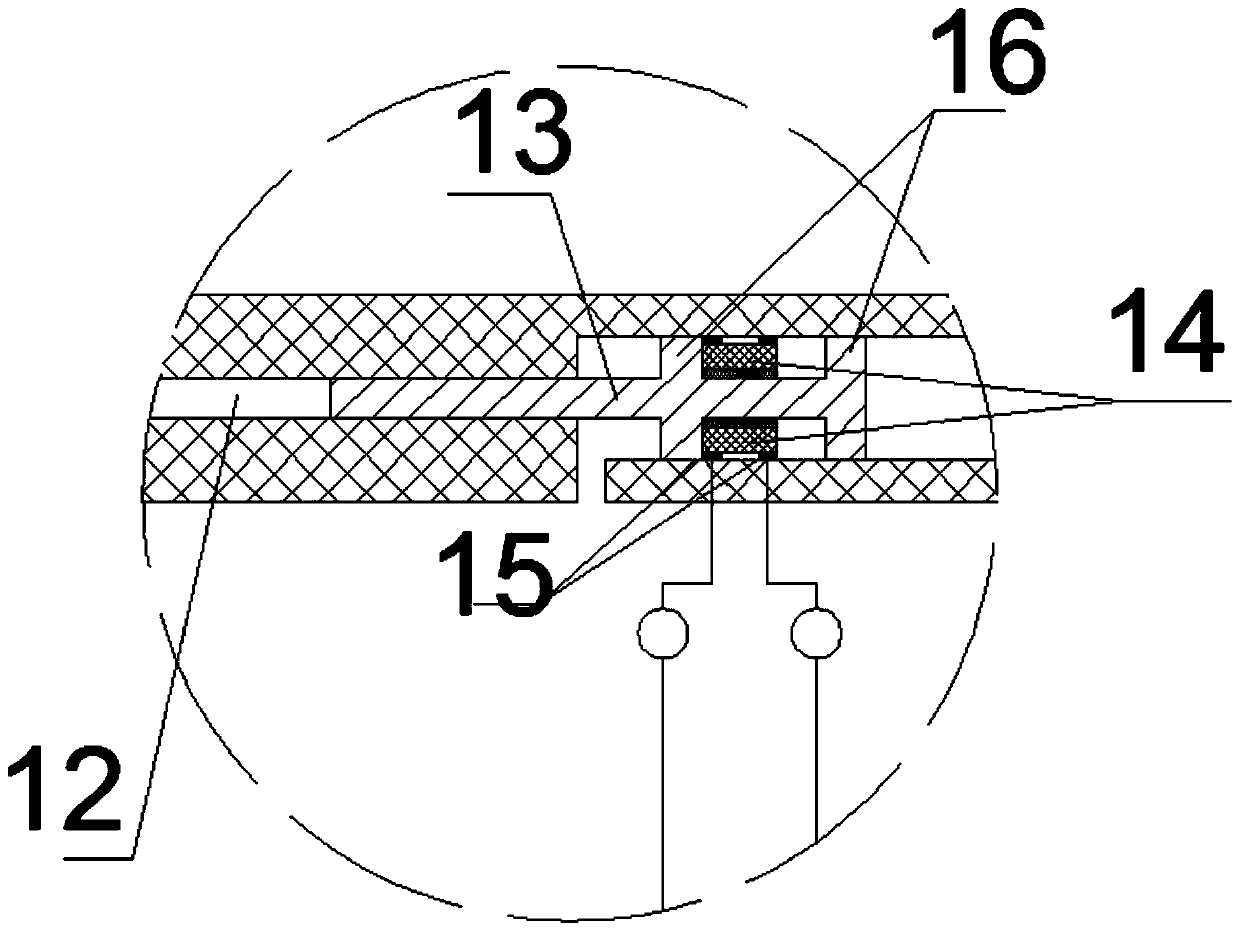

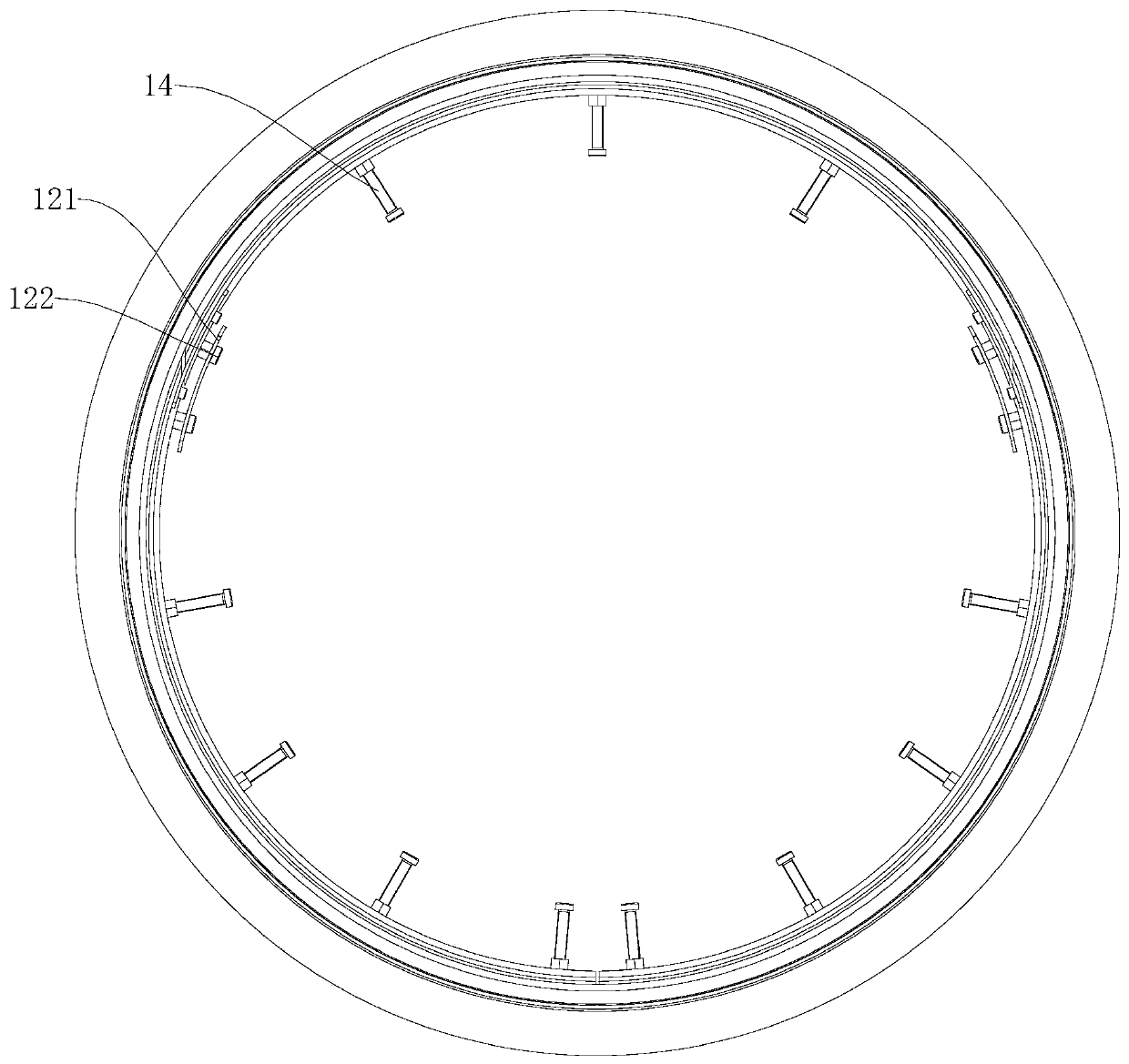

Underwater balance type barrel cover opening system and using method thereof

ActiveCN114056791AStable postureReduce buoyancy lossMeasurement devicesNuclear energy generationMarine engineeringHydraulic ram

The invention provides an underwater balance type barrel cover opening system and a using method thereof. The problems of gravity and buoyancy balance, buoyancy loss and the like of a barrel cover before and after cover opening can be effectively solved. In the barrel cover opening system, a barrel cover assembly in a zero-buoyancy state covers a top opening of a barrel body opening part and is used for sealing the top opening of the barrel body opening part; a pressure equalizing subsystem is used for realizing pressure equalizing inside and outside the barrel body opening part before the barrel cover assembly is opened; an auxiliary cover jacking subsystem and a cover jacking and screwing subsystem are fixed to the two opposite sides of the outer circumference of the barrel body opening part correspondingly; the cover jacking and screwing subsystem comprises a hydraulic cover jacking assembly and a hydraulic cover screwing assembly; the hydraulic cover jacking assembly and the auxiliary cover jacking system respectively eject or pull down the barrel cover assembly from two sides through a hydraulic oil cylinder; the hydraulic cover screwing assembly is used for driving the barrel cover assembly to horizontally rotate for opening or closing; a detection subsystem is used for detecting in-place of cover jacking, in-place of cover closing and a rotation angle; and a hydraulic subsystem controls the auxiliary cover jacking system and the cover jacking and screwing system to act according to an instruction of a barrel cover controller.

Owner:NO 719 RES INST CHINA SHIPBUILDING IND

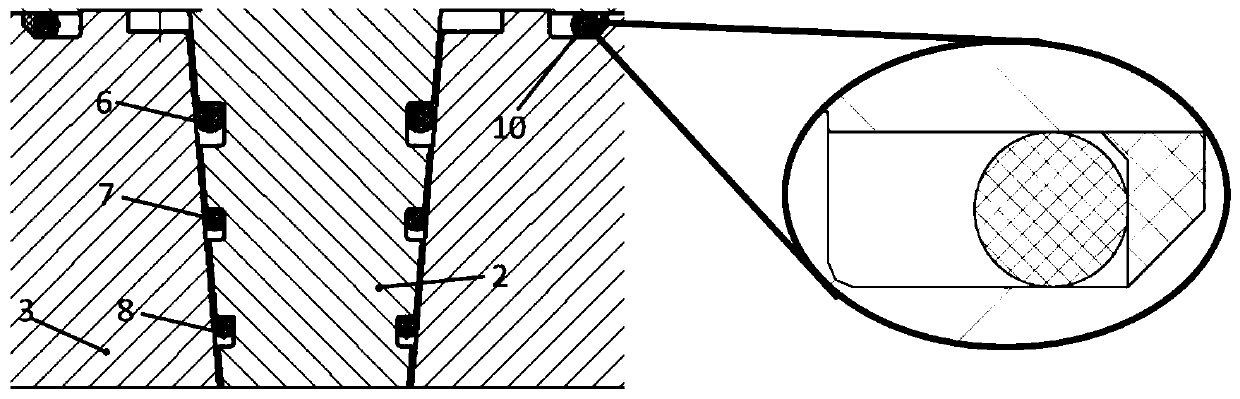

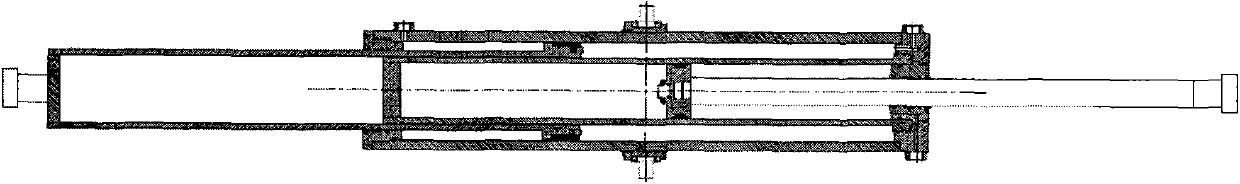

Down-hole packer system

ActiveCN107060680AHigh compressive strengthImprove pressure resistanceSealing/packingSystem pressureHigh pressure

The invention provides a down-hole packer system used for stress testing of a drilling in-situ water pressure fracturing position. The down-hole packer system comprises an upper packer body, a middle fracturing section and a lower packer body. The upper end of the upper packer body and the lower end of the lower packer body are arranged to be sliding ends correspondingly, the middle fracturing section is fixedly connected with the upper packer body and the lower packer body correspondingly, and high-pressure water routes are arranged in the upper packer body, the middle fracturing section and the lower packer body. By adoption of design of the down-hole packer system, the pressure-resisting capacity of a packer is increased, the high-pressure water routes are arranged in the upper packer body, the middle fracturing section and the lower packer body, the external diameter of the middle fracturing section is increased, and the middle fracturing section, the upper packer and the lower packer are connected into a whole; and after expansion of the upper packer and the lower packer is reduced, high-pressure water acts on areas of the lower end of the upper packer and the upper end of the lower packer, pulling stress acted on the middle fracturing section is reduced during fracturing operation, and system pressure-resisting strength is improved.

Owner:孙东生

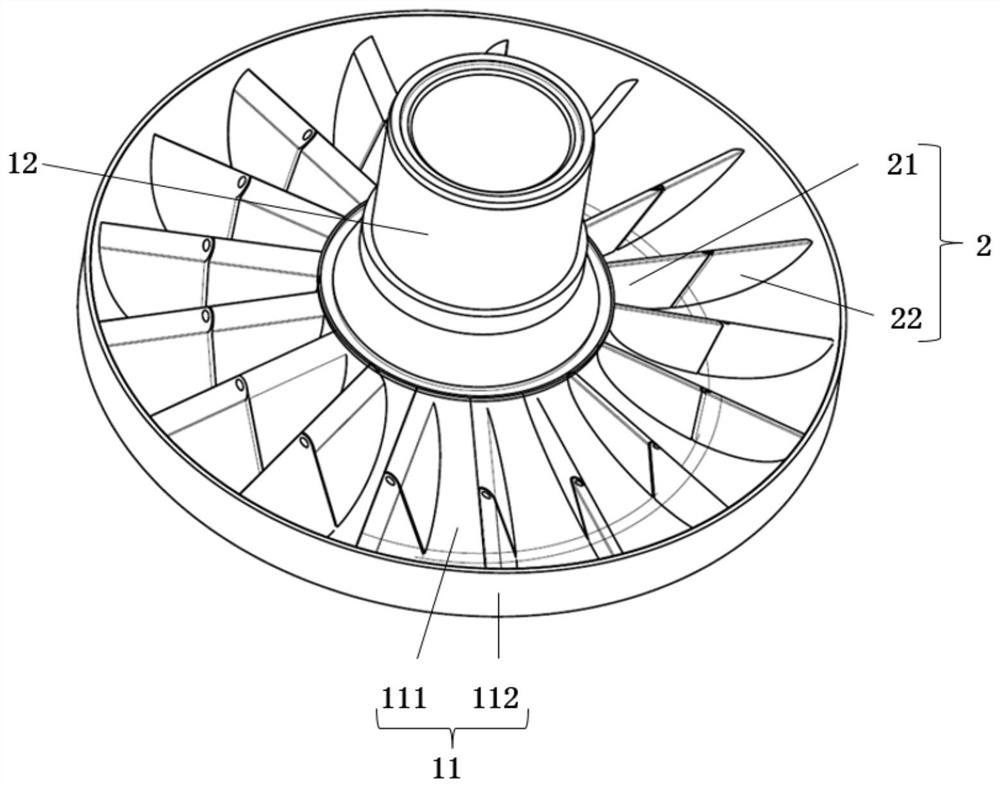

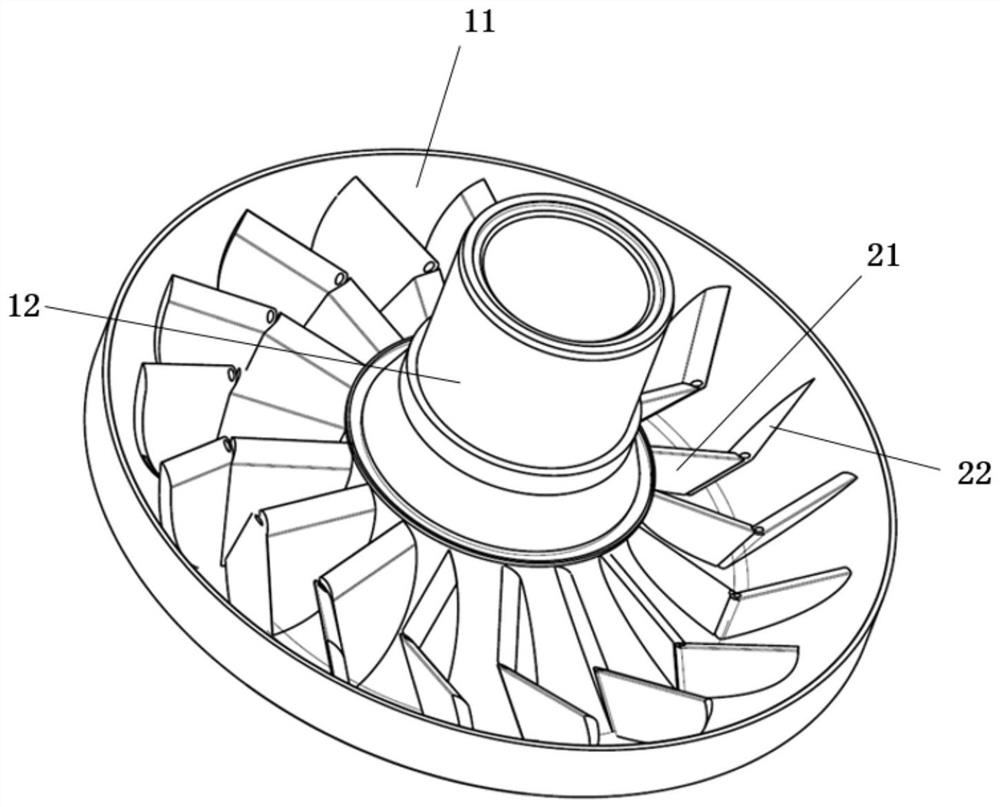

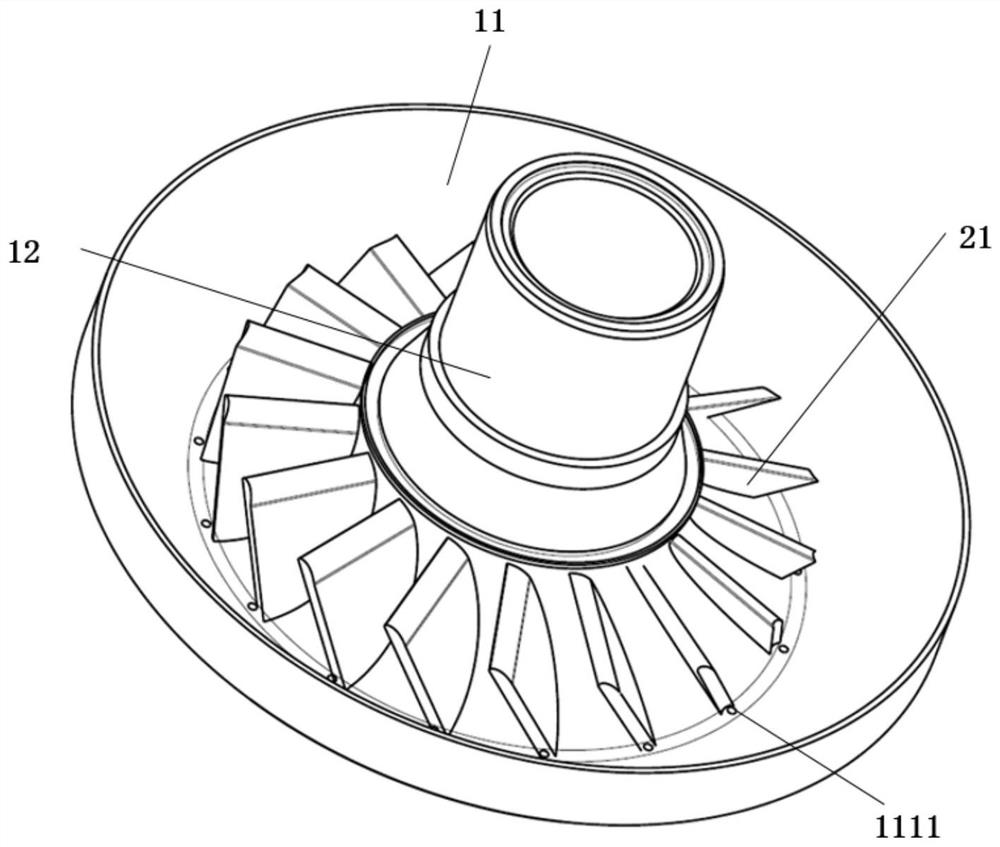

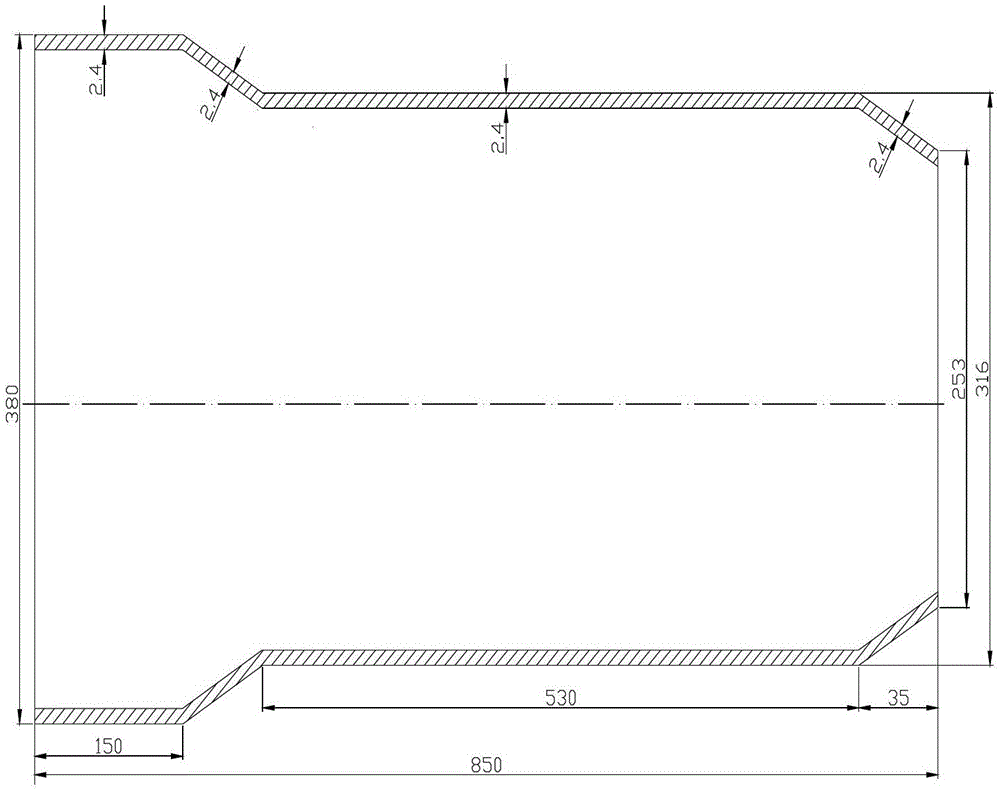

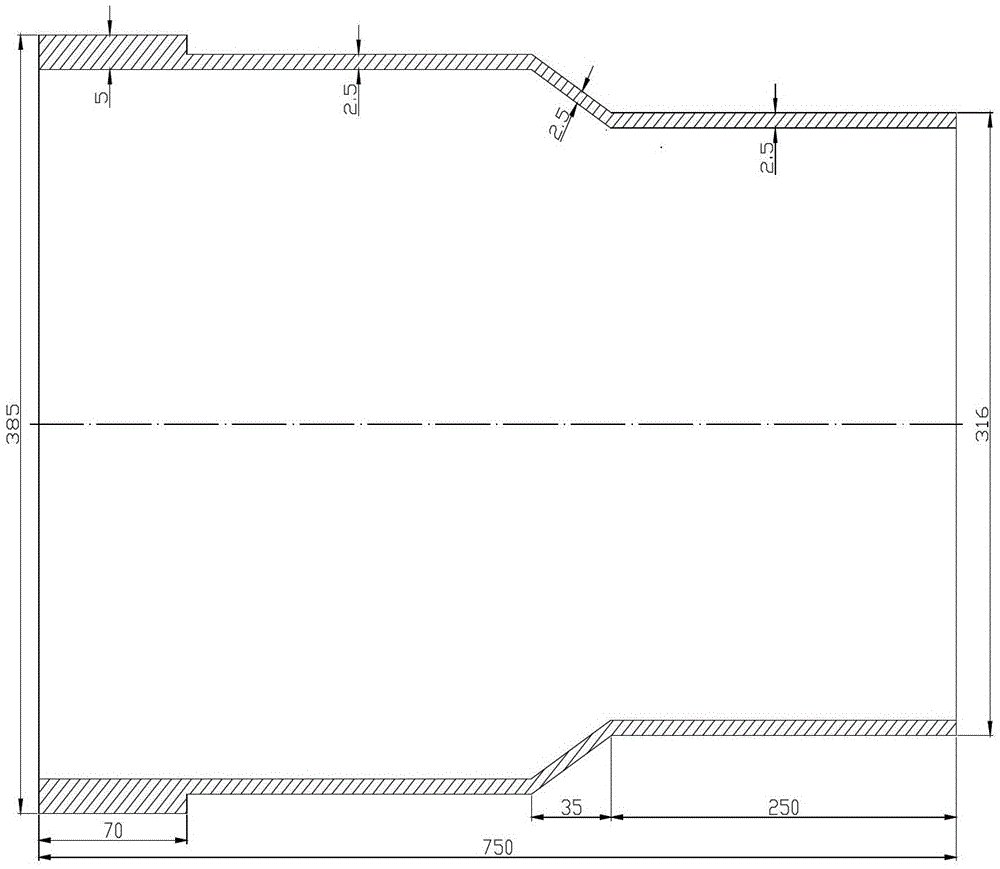

Hydrodynamic retarder rotor

ActiveCN112727955ASimple structureIncrease the area of actionLiquid resistance brakesElectric machinesEngineeringMechanical engineering

The invention belongs to the technical field of retarders, and discloses a hydrodynamic retarder rotor. The hydrodynamic retarder rotor comprises a rotor disc and a plurality of blades, and the rotor disc comprises a disc body and a middle shaft connected to the disc body; the blades are evenly distributed around the circumference of the middle shaft, each blade comprises a fixed piece part and a rotating piece part, the fixed piece parts are fixedly connected to the disc body and extend in the radial direction of the disc body, the rotating piece parts are rotationally arranged on the disc body, the blades have a working state and a loss reduction state, in the working state, the rotating piece parts and the fixed piece parts abut against each other and are coplanar, and in the loss reduction state, an included angle is formed between each rotating piece part and the corresponding fixed piece part. In the working state, the fixed piece parts and the rotating piece parts form the unfolded blades, at the moment, the acting area of pressure oil on the blades reaches the maximum, and large braking torque is generated on the blades; and when no-load occurs, the blades are adjusted to be in the loss reduction state, the included angle is formed between each rotating piece part and the corresponding fixed piece part, the bent blades are formed, the acting area of pressure oil on the blades is reduced, and therefore the effect of reducing no-load losses is achieved.

Owner:FAW JIEFANG AUTOMOTIVE CO

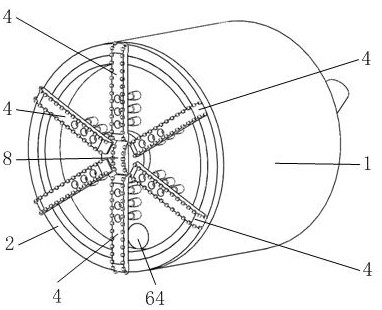

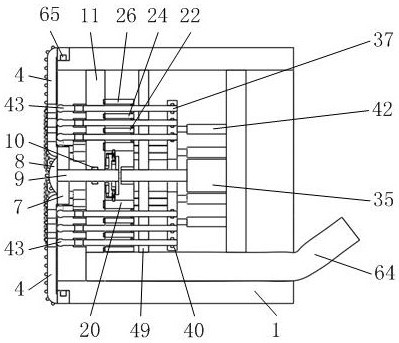

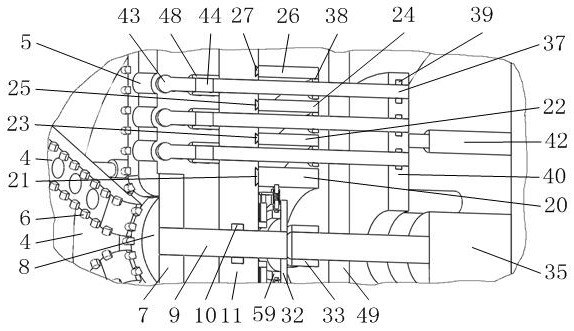

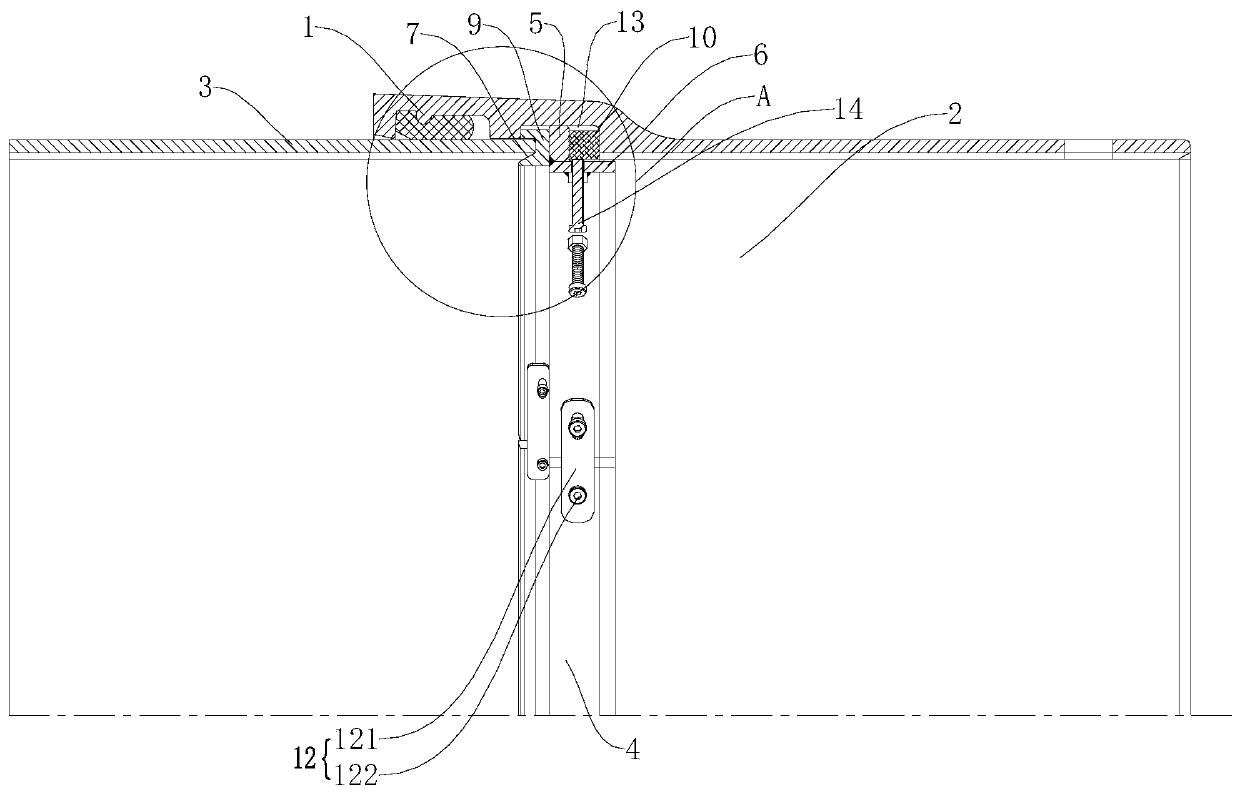

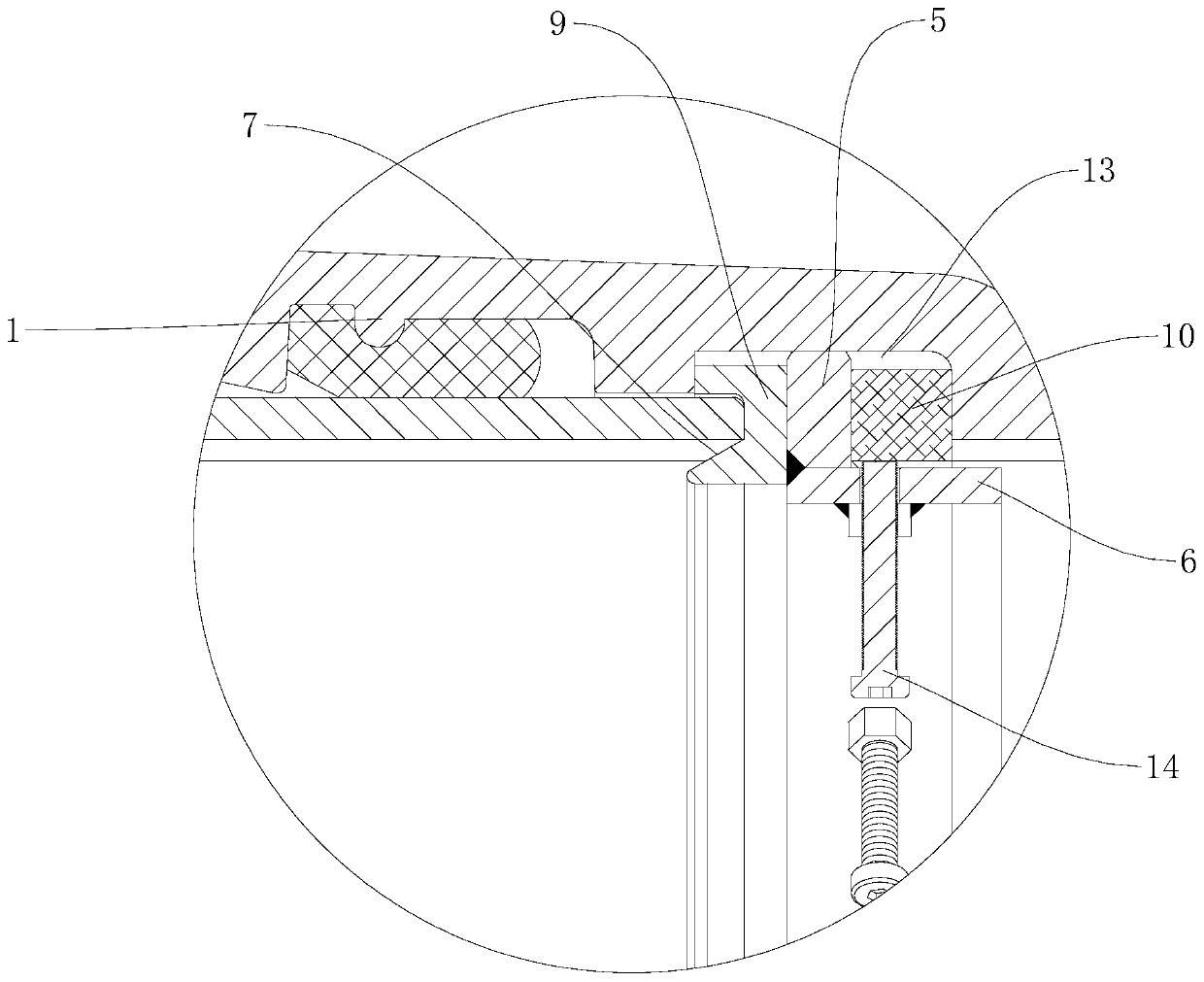

Municipal pipe jacking structure and construction method thereof

The invention belongs to the field of pipe jacking, and particularly relates to a municipal pipe jacking structure and a construction method thereof. The municipal pipe jacking structure comprises a barrel, tool aprons A, a tool bit, tool aprons B, a power device and the like, wherein the barrel is internally provided with a round fixing plate A, a shaft A is rotationally arranged in a shaft groove A at the center of the fixing plate A in a matched mode, and the shaft A is driven to rotate by the power device installed in the barrel; a drill bit drills a working surface of a hard rock stratumand conducts further broadening, knocking and breaking on drilled holes, thus, the tool bit on the tool aprons A and the tool aprons B is driven to conduct excavation pipe jacking construction on thehard rock stratum by the existing low-duty power device, the required standard for the duty of the power device is reduced, thus, the municipal pipe jacking structure can be driven by the low-duty power device to conduct efficient excavation pipe jacking construction, the whole cost of the pipe jacking device during pipe jacking construction is reduced, and the pipe jacking construction efficiencyis improved.

Owner:汇绿园林建设发展有限公司

Mechanical balance valve with foldable cantilever crane

InactiveCN104500475AAvoid attenuationAdd self-locking functionServomotor componentsEngineeringControl valves

The invention discloses a mechanical balance valve with a foldable cantilever crane. The mechanical balance valve comprises a first oil port, a second oil port, a valve body, a control valve core, a balance valve core, a high-pressure cavity and low-pressure cavity isolating block and an overflow valve core, wherein the valve body is provided with a pilot control oil cavity, a load cavity and a pilot valve spring cavity; the first oil port is communicated with the pilot control oil cavity; the second oil port is communicated with the load cavity; the control valve core is arranged in the pilot control oil cavity; the balance valve core is arranged in the load cavity; the pilot control oil cavity is isolated from the load cavity; the balance valve core comprises a valve head and a valve rod; the valve head is arranged at one end, which faces the control valve core, of the valve rod; the valve rod passes through a center hole of the high-pressure cavity and low-pressure cavity isolating block; a spring is arranged between the valve head and the high-pressure cavity and low-pressure cavity isolating block; a through hole is formed in the center of the valve rod; a small pilot valve core is arranged in the hole; the small pilot valve core is provided with a groove which is communicated with the load cavity and a high-pressure unloading cavity. The mechanical balance valve has the advantages of high dynamic stability, low control pressure and high locking property.

Owner:XIANGTAN UNIV

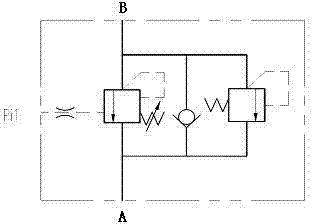

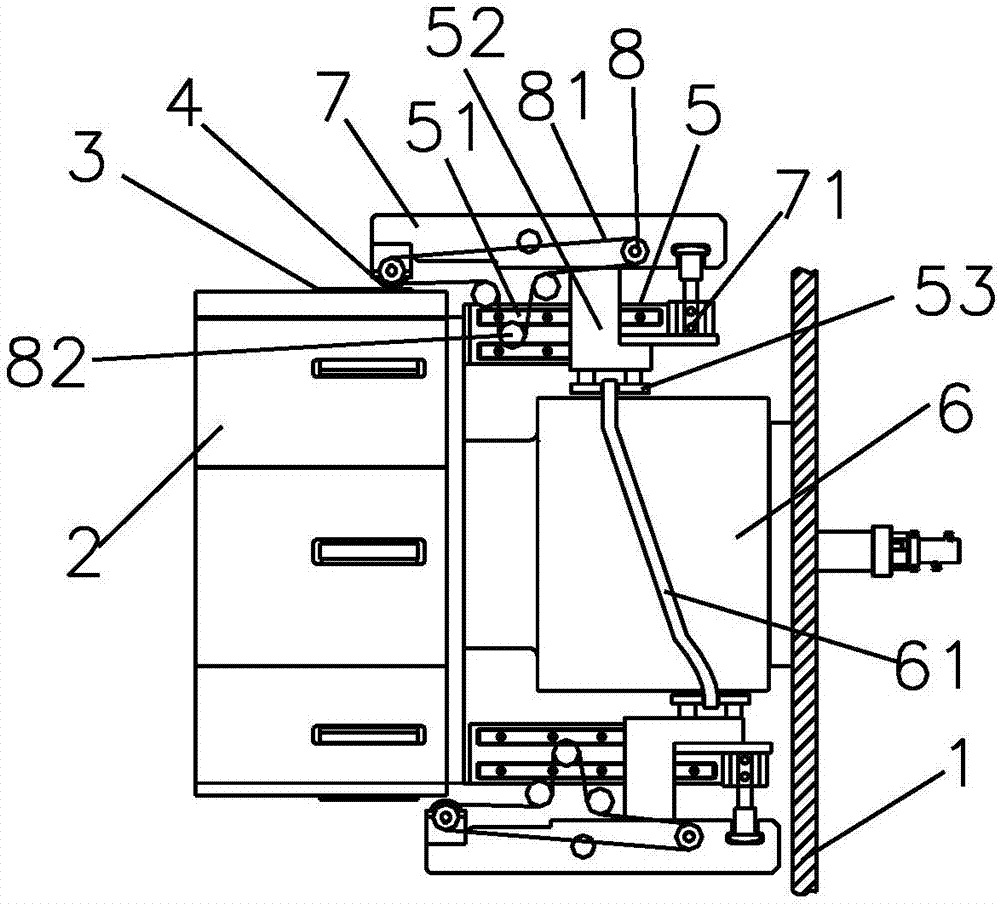

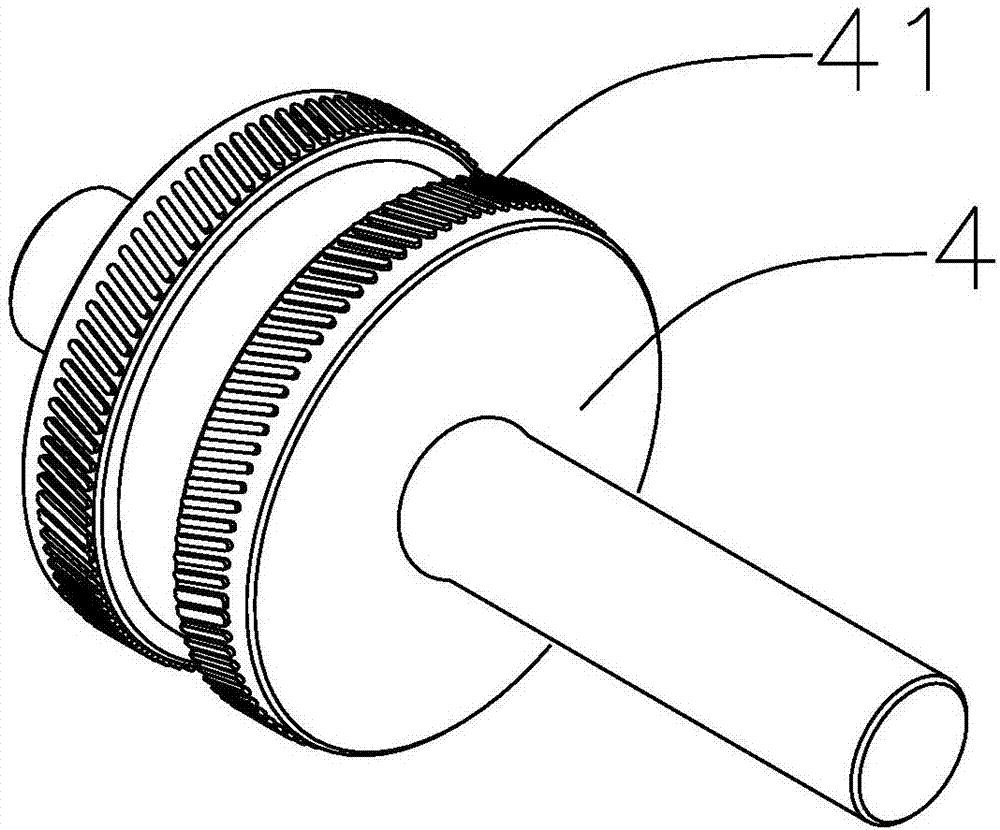

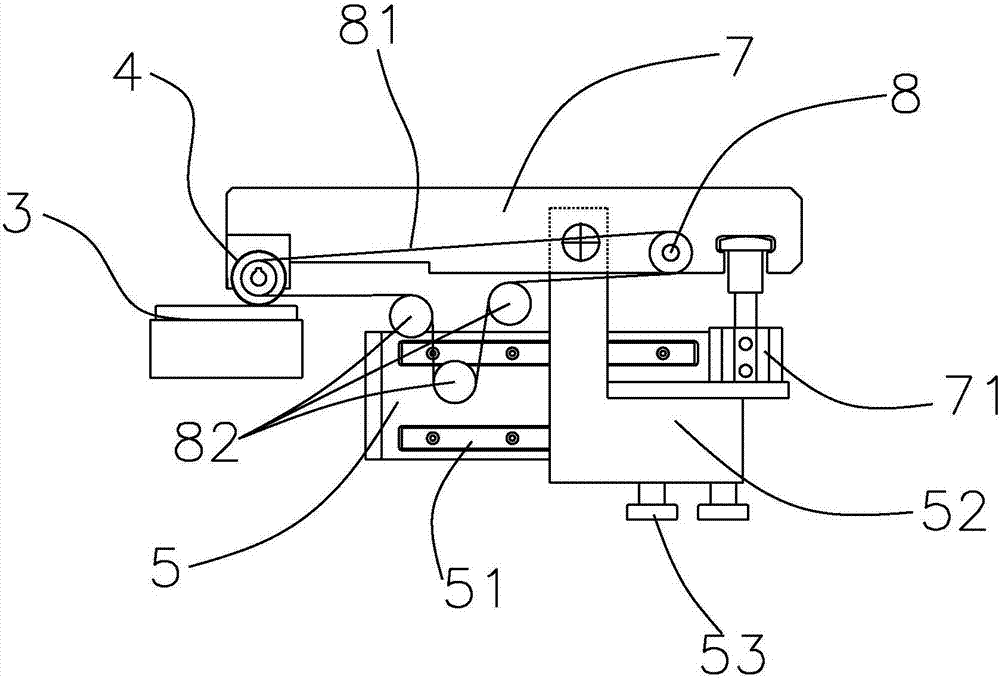

Hydraulic control system of balance cylinders in hydrostatic test

ActiveCN102393332ASmall area of actionReduced pre-sealing forceServomotorsMaterial strength using tensile/compressive forcesControl systemFuel tank

The invention discloses a hydraulic control system of balance cylinders in a hydrostatic test. The hydraulic control system comprises an oil tank, an oil pump, a proportional overflow valve, a main switch, a branch switch and the balance cylinders, wherein an inlet and an outlet of the oil pump are respectively communicated with the oil tank and an inlet of the main switch; the inlet of the main switch is also communicated with the oil tank through the proportional overflow valve; the balance cylinders are communicated with an outlet of the branch switch in parallel; an inlet of the branch switch is communicated with an outlet of the main switch; the balance cylinders are also communicated with a one-way channel which can be used for pumping oil from the oil tank; the proportional overflow valve is in communication connection with two pressure sensors; a test end of one pressure sensor is communicated with the inside of a welded tube to be tested; and a test end of the other pressure sensor is communicated with the outlet of the main switch. According to the hydraulic control system disclosed by the invention, a plurality of balance cylinders are grouped; and any one or several groups are selected and used according to actual requirement, and thereby the action areas of the balance cylinders can be effectively reduced and pre-sealing forces of the balance cylinders are reduced. In the hydraulic control system, the proportional overflow valve is not needed to be replaced and the ascending speed of the pressure of the balance cylinders cannot be reduced; and the operation process is simpler, quicker, safer and more reliable.

Owner:TAIYUAN HEAVY IND

Pressing treatment device for material machining and method

The invention belongs to the technical field of pressing, in particular to a pressing treatment device for material machining. The device comprises a rotating disc and multiple pressing modules; a walking path is formed in the outer peripheral surface of the rotating disc; the pressing modules include pressing welding heads arranged on the inner side of the walking path, and pressing mold rollers arranged on the outer side of the walking path; and when the pressing modules rotate with the rotating disc at the same time, the pressing mold rollers perform the reciprocating rolling on the pressing welding heads to press materials on the walking path. Pressing molds are designed as roller forms, so that the acting area is largely reduced during pressing, the pressure in unit area is increased, and the thermal compounding effect is better; the pressing mold rollers roll during pressing to reduce damage of the materials; and the pressing effect position can be preset, so that the accuracy of the hot pressing position is guaranteed, and the product precision and the material operating speed are greatly improved.

Owner:ANQING HENG CHANG MACHINERY

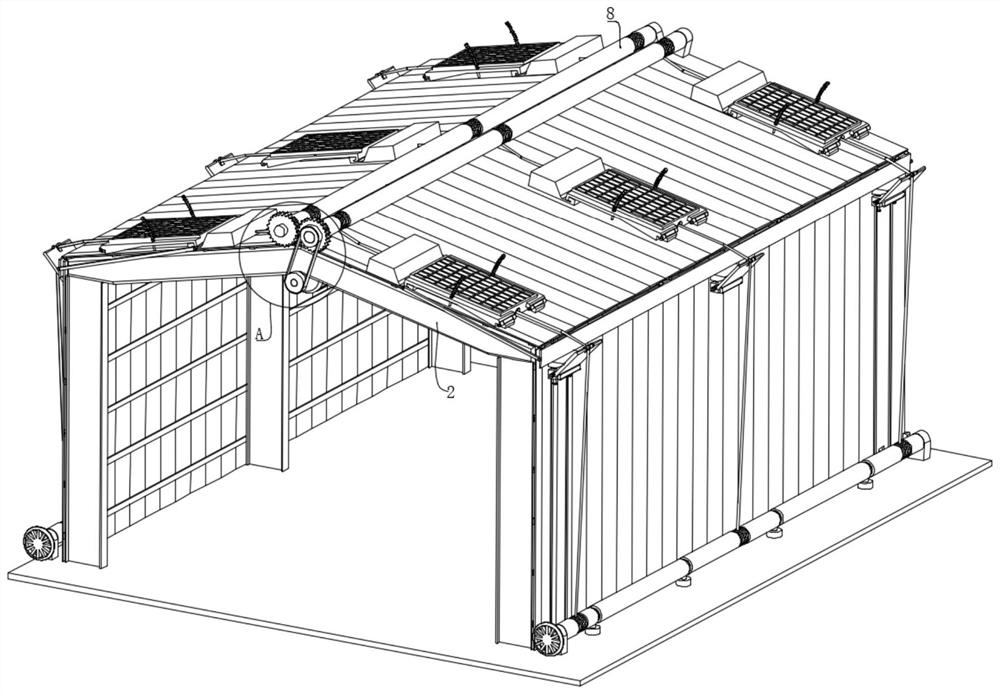

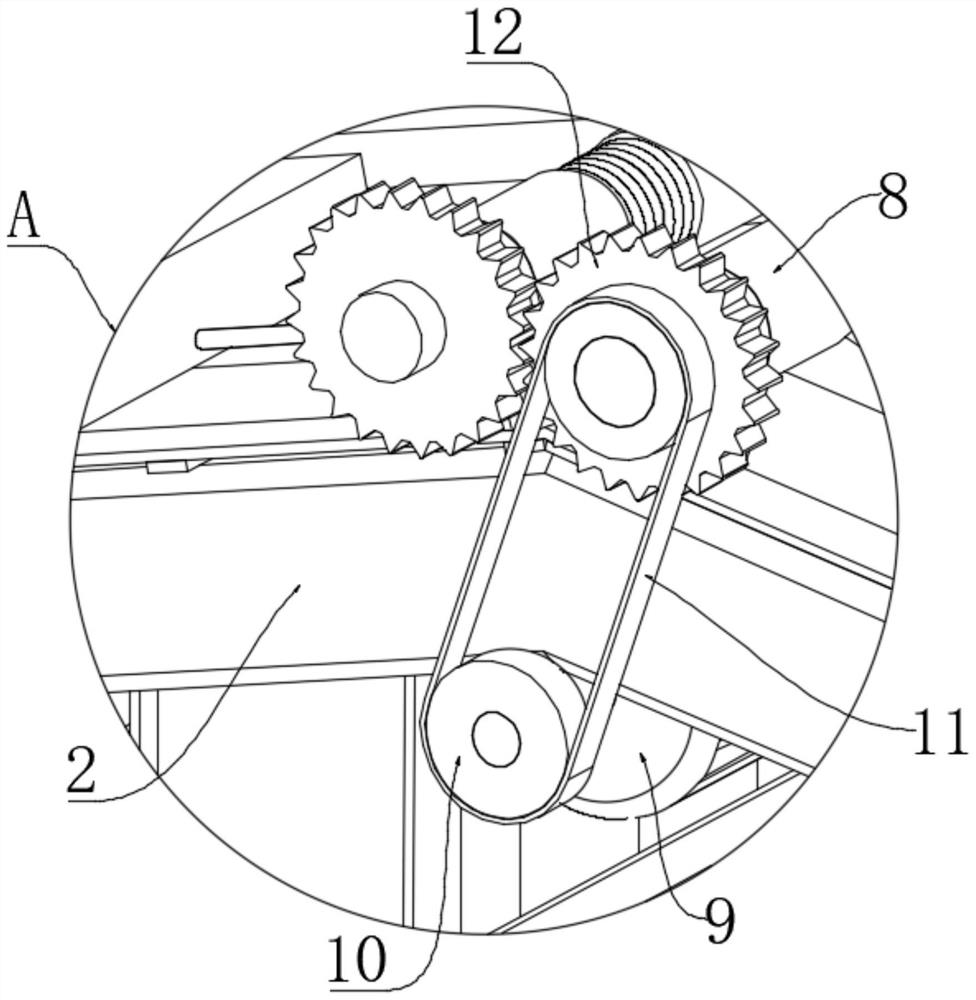

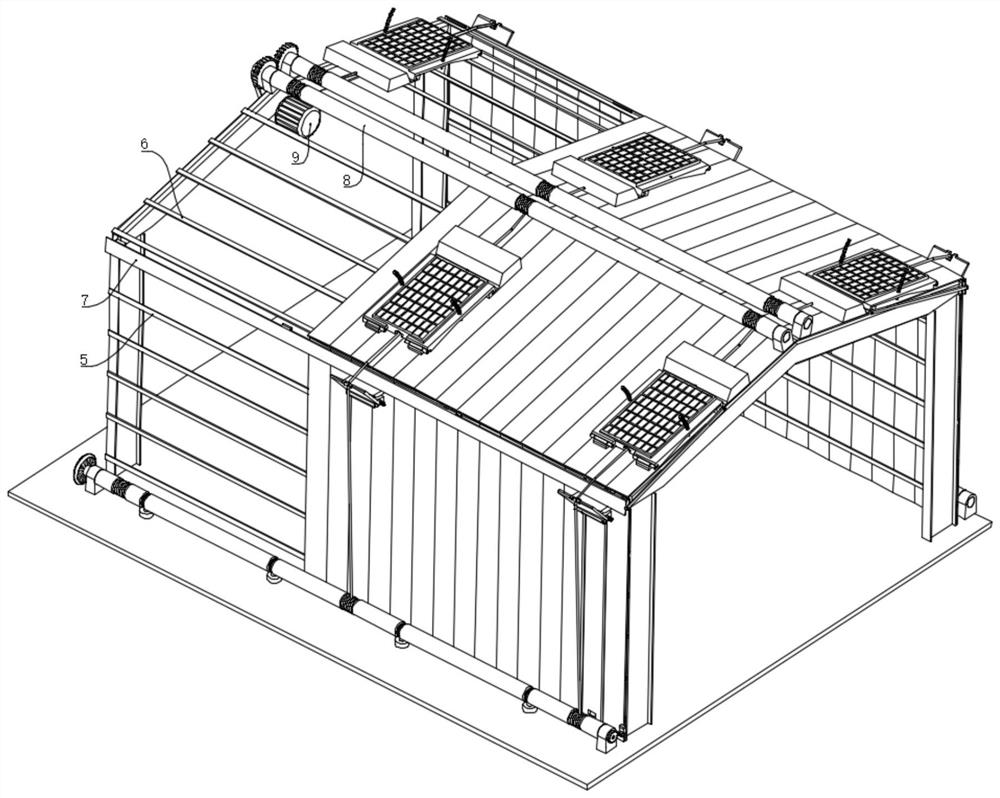

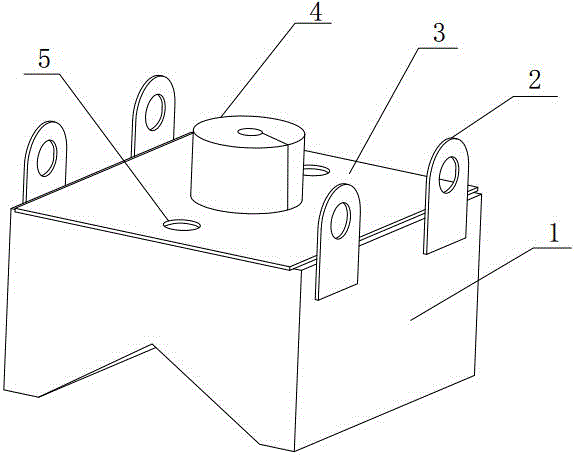

Green energy-saving fireproof building steel structure

PendingCN113266179AAvoid damageAdjustable anglePhotovoltaic supportsRoof covering using slabs/sheetsMechanical engineeringCivil engineering

The invention relates to the technical field of building steel structures, and particularly relates to a green energy-saving fireproof building steel structure. The green energy-saving fireproof building steel structure comprises a plurality of roof beams, wherein side columns are fixedly connected to the bottoms of the two sides of each roof beam, a plurality of roof purlines are fixedly connected between the tops of the multiple roof beams, a plurality of wall purlines are fixedly connected between the sides, deviating from each other, of the side columns, roof panels are fixedly connected to the tops of the roof purlines, and wall panels are fixedly connected to one sides of the wall purlines. According to the technical scheme, when a traction rope pulls a wedge-shaped block to be away from a connecting plate, a clamping block on the wedge-shaped block enters a clamping groove in one side of the connecting plate in the moving process, and therefore the connecting plate is fixed; and when tornado invades a solar panel, the side, away from the hinged position, of the connecting plate below the solar panel is fixed by the clamping block, and therefore the solar panel cannot turn over around the hinged position due to the action of the tornado, and the situation that the solar panel is damaged due to the fact that the solar panel turns over up and down violently under the action of the tornado is effectively prevented.

Owner:王娅

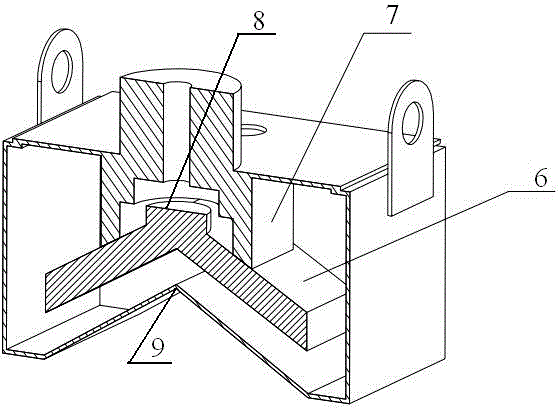

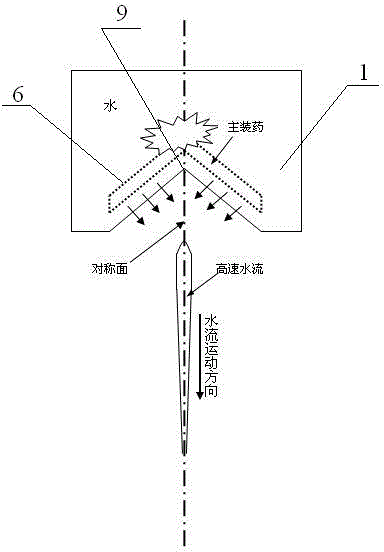

Underwater explosion technology based novel explosion clearing device

An underwater explosion technology based novel explosion clearing device comprises a water tank and a rear cover. The water tank is a square water trough with bottom sealed and top open, the bottom of the water trough is square and recessed to form a cylindrical wedge angle along the center line of two opposite sides of the square, the rear cover is same with the top opening of the water tank in shape and seals the top opening, a hollow cylindrical joint is adhered to the side, facing the water tank, of the rear cover, main charge is adhered to the bottom and is composed of a left wing, a right wing and a platform, and both the left wing and the right wing are plates in certain thickness and are connected to form an included angle. The left wing and the right wing are respectively parallel to two surface of the cylindrical wedge angle recessed at the bottom of the water tank, and the included angle is equal to the wedge angle. The platform is arranged at the joint of the left wing and the right wing and in the hollow cylindrical joint. The underwater explosion technology based novel explosion clearing device is simple and light in structure, good in cutting effect and wide in application range.

Owner:中国船舶重工集团公司第七〇二研究所

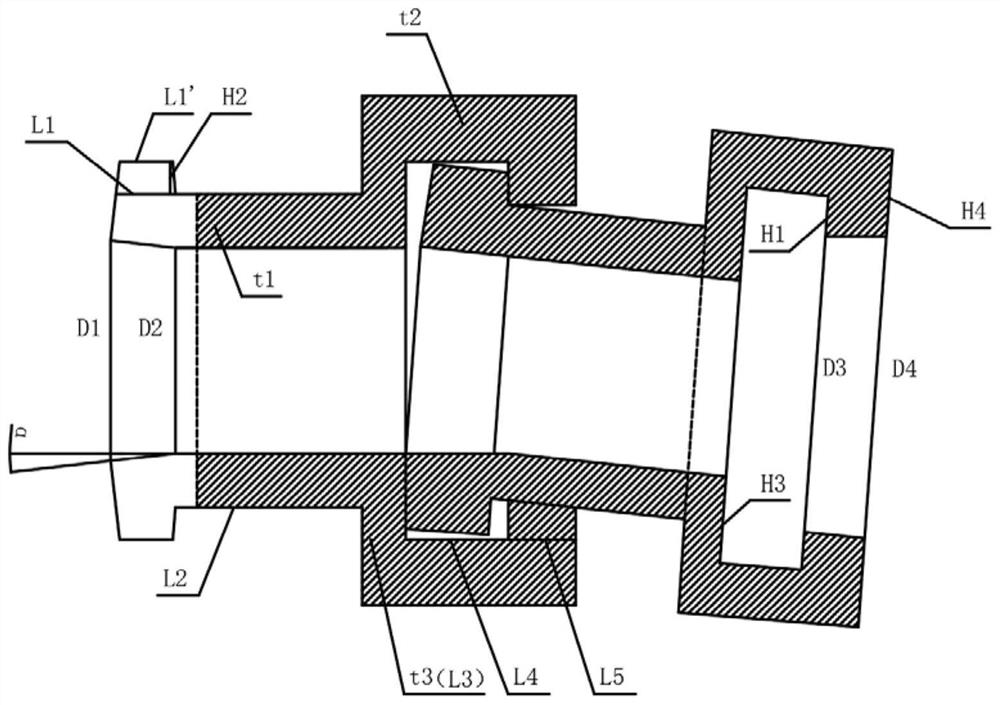

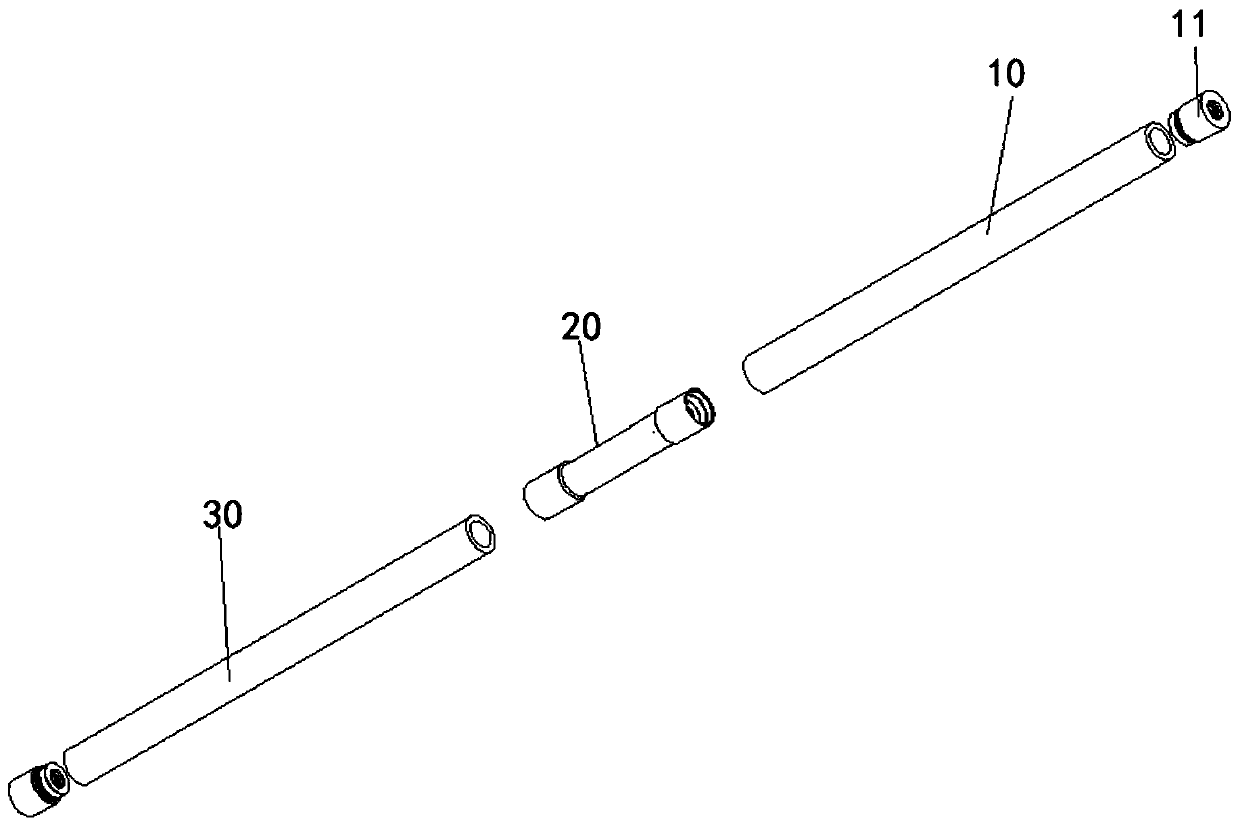

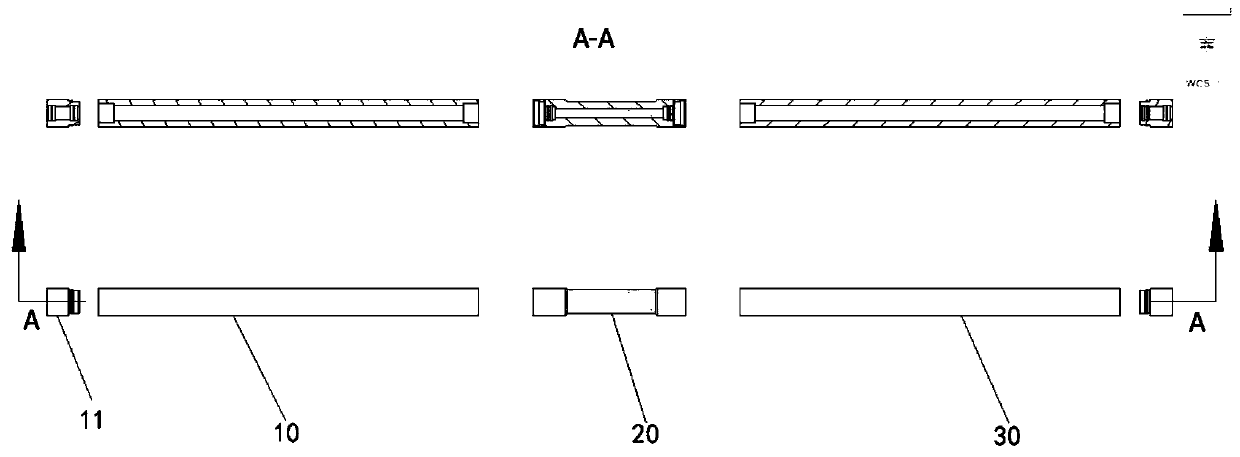

Downhole Packer System

ActiveCN107060680BImprove pressure resistanceSmall area of actionSealing/packingSystem pressureHigh pressure water

The invention provides a down-hole packer system used for stress testing of a drilling in-situ water pressure fracturing position. The down-hole packer system comprises an upper packer body, a middle fracturing section and a lower packer body. The upper end of the upper packer body and the lower end of the lower packer body are arranged to be sliding ends correspondingly, the middle fracturing section is fixedly connected with the upper packer body and the lower packer body correspondingly, and high-pressure water routes are arranged in the upper packer body, the middle fracturing section and the lower packer body. By adoption of design of the down-hole packer system, the pressure-resisting capacity of a packer is increased, the high-pressure water routes are arranged in the upper packer body, the middle fracturing section and the lower packer body, the external diameter of the middle fracturing section is increased, and the middle fracturing section, the upper packer and the lower packer are connected into a whole; and after expansion of the upper packer and the lower packer is reduced, high-pressure water acts on areas of the lower end of the upper packer and the upper end of the lower packer, pulling stress acted on the middle fracturing section is reduced during fracturing operation, and system pressure-resisting strength is improved.

Owner:孙东生

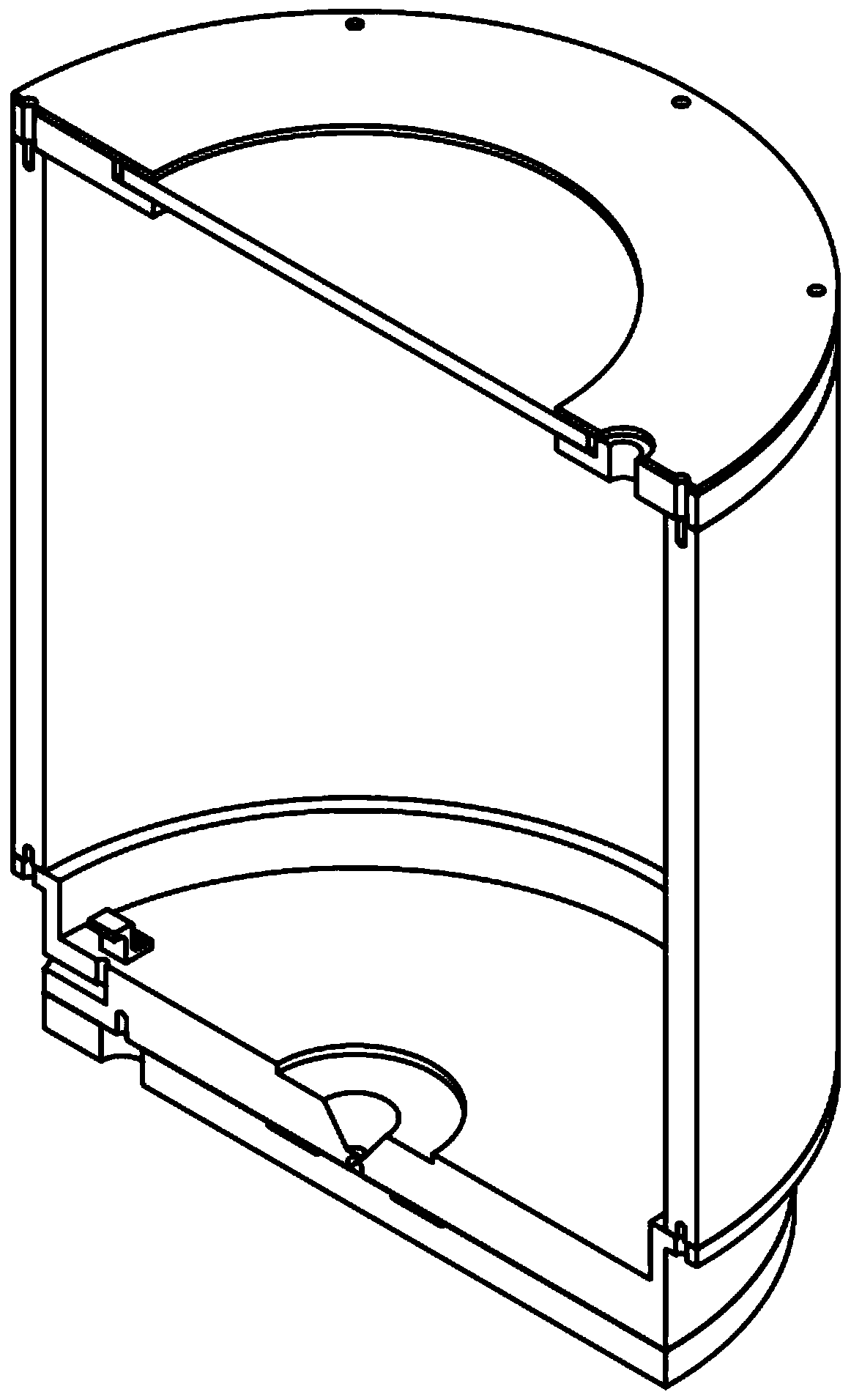

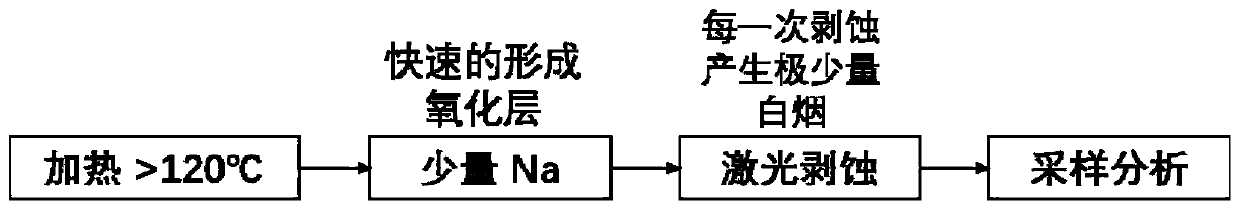

Sodium combustion experimental device and method for obtaining sodium aerosol with extreme low concentration

PendingCN110715846ASmall area of actionUse less sodiumPreparing sample for investigationNuclear energy generationPhysicsChemistry

The invention belongs to the technical field of reactors, and particularly relates to a sodium combustion experimental device and a method for obtaining a sodium aerosol with extreme low concentration. The device includes a sodium combustion reactor and an igniter; the igniter is sodium combustion reactor ignition; the sodium combustion reactor is of a cylinder-shaped structure, a cylindrical groove is formed in the bottom of the cylinder, and a conical groove is formed in the bottom of the cylindrical groove; a heating device and a thermocouple are arranged at the bottom of the cylinder outside of the sodium combustion reactor; and a quartz window is formed above a cylinder body of the sodium combustion reactor. The method performs obtaining by using the device and comprises the steps that a, the experimental device is prepared according to the device; b, the heating device is turned on, and the experimental device in the step a is heated to 115 DEG C to 125 DEG C; c, the melting of metal sodium into liquid is observed through the quartz window, and the high-energy pulsed laser igniter is turned on; d, a sodium aerosol detector is used for sampling; and e, the sodium aerosol withthe predetermined concentration is collected. The sodium combustion experimental device and the method for obtaining the sodium aerosol with the extreme low concentration are provided.

Owner:CHINA INSTITUTE OF ATOMIC ENERGY

Abrasive polishing equipment

InactiveCN114248191AAchieve polishImprove polishing efficiencyEdge grinding machinesPolishing machinesPolishingPhysics

The invention relates to the technical field of polishing equipment, in particular to abrasive polishing equipment which comprises a bottom cylinder barrel, a lower supporting table is arranged in the center of the bottom cylinder barrel, the height of a top opening of the bottom cylinder barrel is larger than that of the top of the lower supporting table, and an active push-pull barrel is slidably connected to the inner wall of the bottom cylinder barrel. A plurality of passive adjusting barrels which are connected in a sleeving mode are arranged between the inner wall of the active push-pull barrel and the outer wall of the lower supporting table, and the active push-pull barrel and the lower supporting table are connected with the passive adjusting barrels in a matched mode through a joint adjusting mechanism and a limiting adjusting assembly. The abrasive can be directly extruded again to flow back into the workpiece after being extruded out of the workpiece, polishing is achieved by enabling the abrasive to continuously flow inside and outside the workpiece, the abrasive does not need to be recycled after passing through complex transverse and longitudinal moving paths in the process, and the polishing efficiency is higher by directly utilizing the mode that the abrasive flows inside and outside the workpiece in a reciprocating mode.

Owner:杭州奔涌机械有限公司

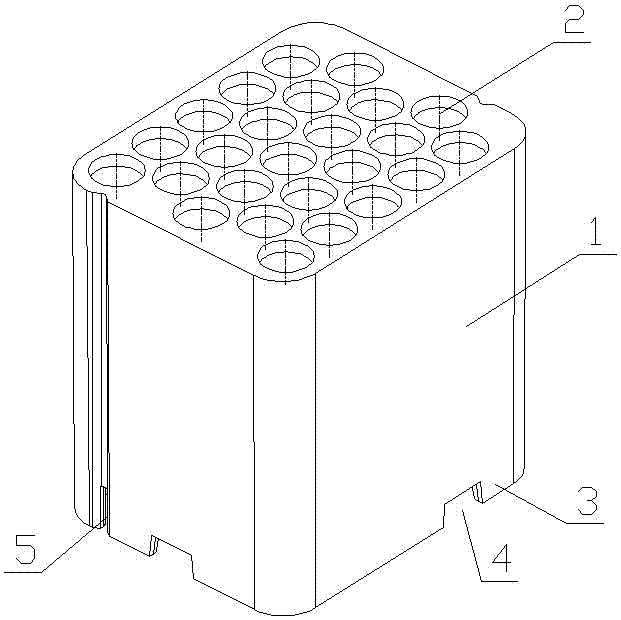

Lead-free combined firework concentrated in emission and filled with gunpowder

InactiveCN107328313AHigh bonding strengthSavingsFireworksStructural engineeringMechanical engineering

The invention relates to a lead-free combined firework concentrated in emission and filled with gunpowder. The bottom of each tubular body is provided with an explosive groove used for improving the concentration strength of gunpowder emission; the bottom face of each gunpowder groove is provided with a fire leading hole which is a through hole; the bottom face of a firework body is provided with a fire leading groove; the fire leading holes are communicated with the fire leading groove in the bottom face of the firework body; and the fire leading holes and the fire leading groove are filled with slip casting gunpowder. The lead-free combined firework concentrated in emission and filled with the gunpowder solves the problem that a lead, a glue lead, a cutting lead and an inserting lead need to be made for a combined firework, the work procedures are reduced, cost is reduced, safety is improved, and the problems that in the firework set-off process, rolling movement happens, the emission force is not concentrated, and direction is not stable are also solved.

Owner:浏阳世纪红烟花制造销售有限公司

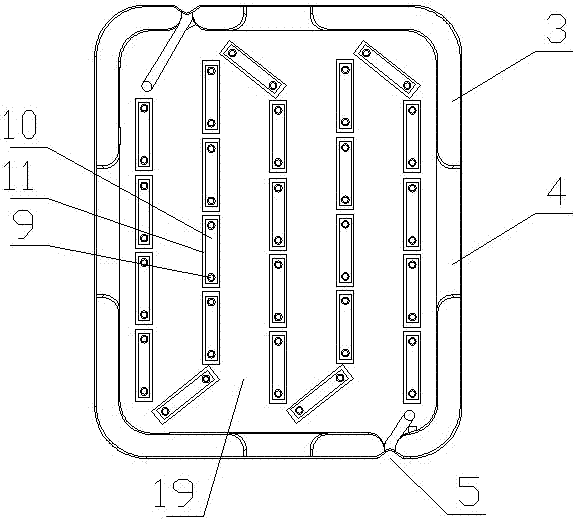

Magnetic force strengthening and steering component

PendingCN108597723AIncrease magnetic inductionSmall area of actionPermanent magnetsMagnetic tension forceForce lines

The invention mainly utilizes a principle that the magnetic induction intensity represents the number of magnetic force lines passing through a unit area vertically, and enhances the magnetic induction intensity on the basis of reducing a magnetic flux area without changing the number of the magnetic force lines. According to the scheme of the invention, the same magnetic poles of two magnets arerelatively squeezed to a small distance, so that the original magnetic flux area is reduced, and the magnetic induction intensity is enhanced; and then a special magnetizer is sandwiched between the two magnets, so that the magnetic force lines are deflected along with the magnetizer and diverged from a protruding part of the magnetizer, at this time, not only the magnetic induction intensity is enhanced, but also the magnetic force acting direction is changed by 90 degrees, and the size and shape of the protruding part of the magnetizer can be designed as required; and finally, a stainless steel housing is arranged to perform protection and fixation. The product of the invention can be used as a magnetic component unit for designing other magnetic products.

Owner:NANJING MAGNESTER ENVIRONMENTAL PROTECTION SCI & TECH LTD

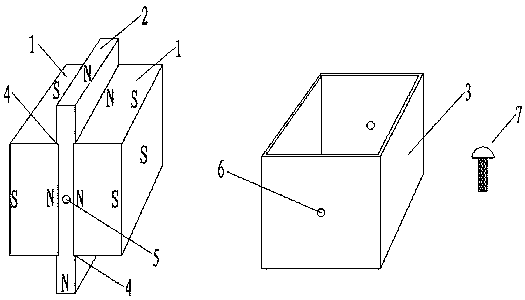

A method for preparing and processing a large thin-walled shell made of aluminum matrix composite material

The invention belongs to the field of preparation and processing of difficultly-deformed material thin-wall complex components and particularly relates to a preparing and processing method of an aluminum base composite material large thin-wall shell. The method comprises preparing ingot blanks through a stirring mixing and powder metallurgy process and forging the blanks; after feeding forged rods, punching and prefabricating the forged rods into hollow blanks, performing isothermal combined extrusion on the prefabricated hollow blanks to obtain tube blanks which are uniform in particle distribution and fine and even in matrix structure; performing multiple hot strengthened thinning spinning on the extruded tube blanks to obtain composite extruded tube blanks; performing multiple hot-warm combined spin forming to obtain composite material thin-wall shells; pickling and cleaning the obtained shells, and then performing finish product thermal treatment. The aluminum base composite material large thin-wall shell prepared through the method can effectively improve the distribution uniformity of composite material particles and enhance the plasticity and the forming capacities of the composite material particles and meanwhile is high in comprehensive performance, labor-saving in forming and high in additional value.

Owner:有研金属复材技术有限公司

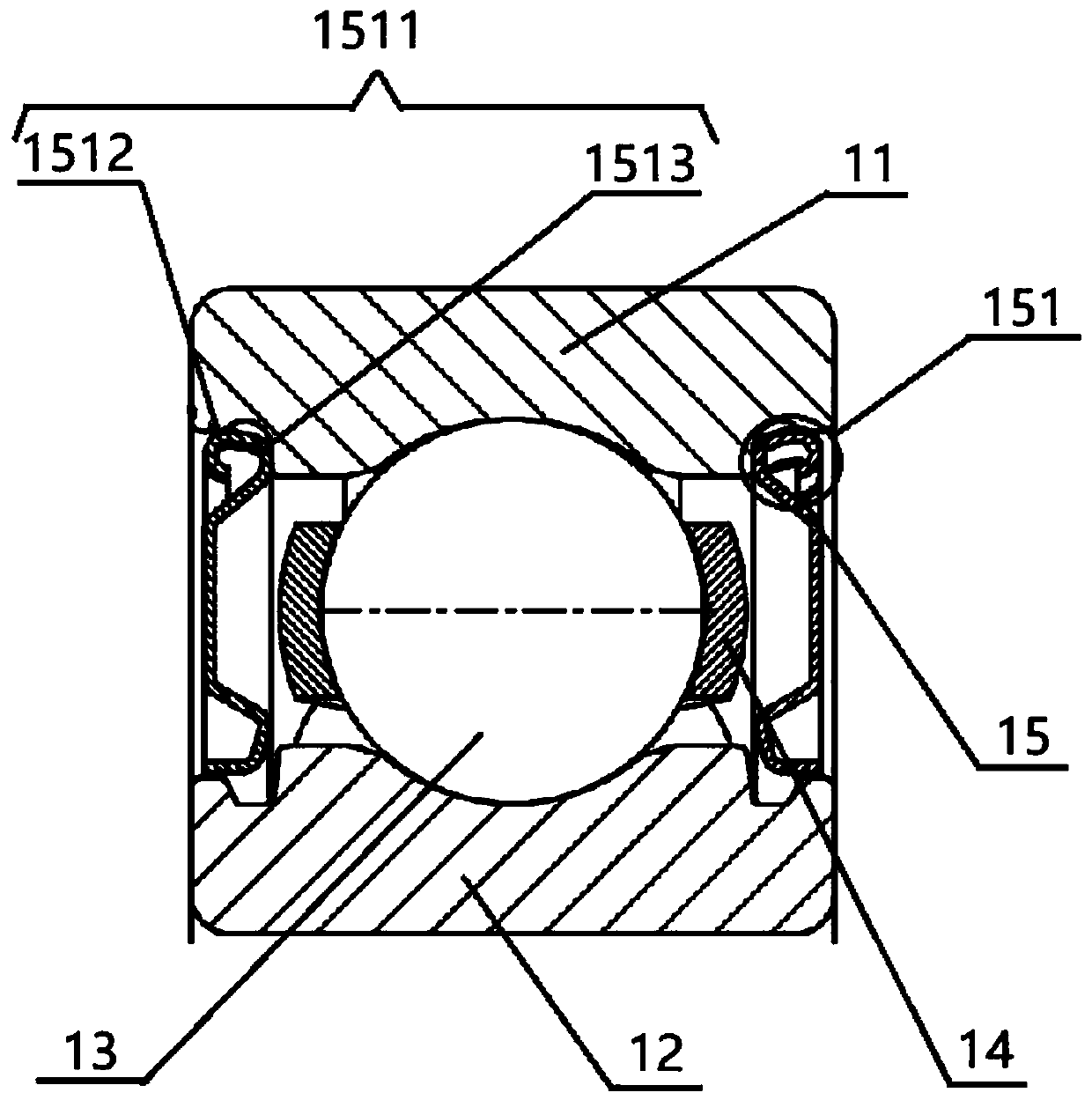

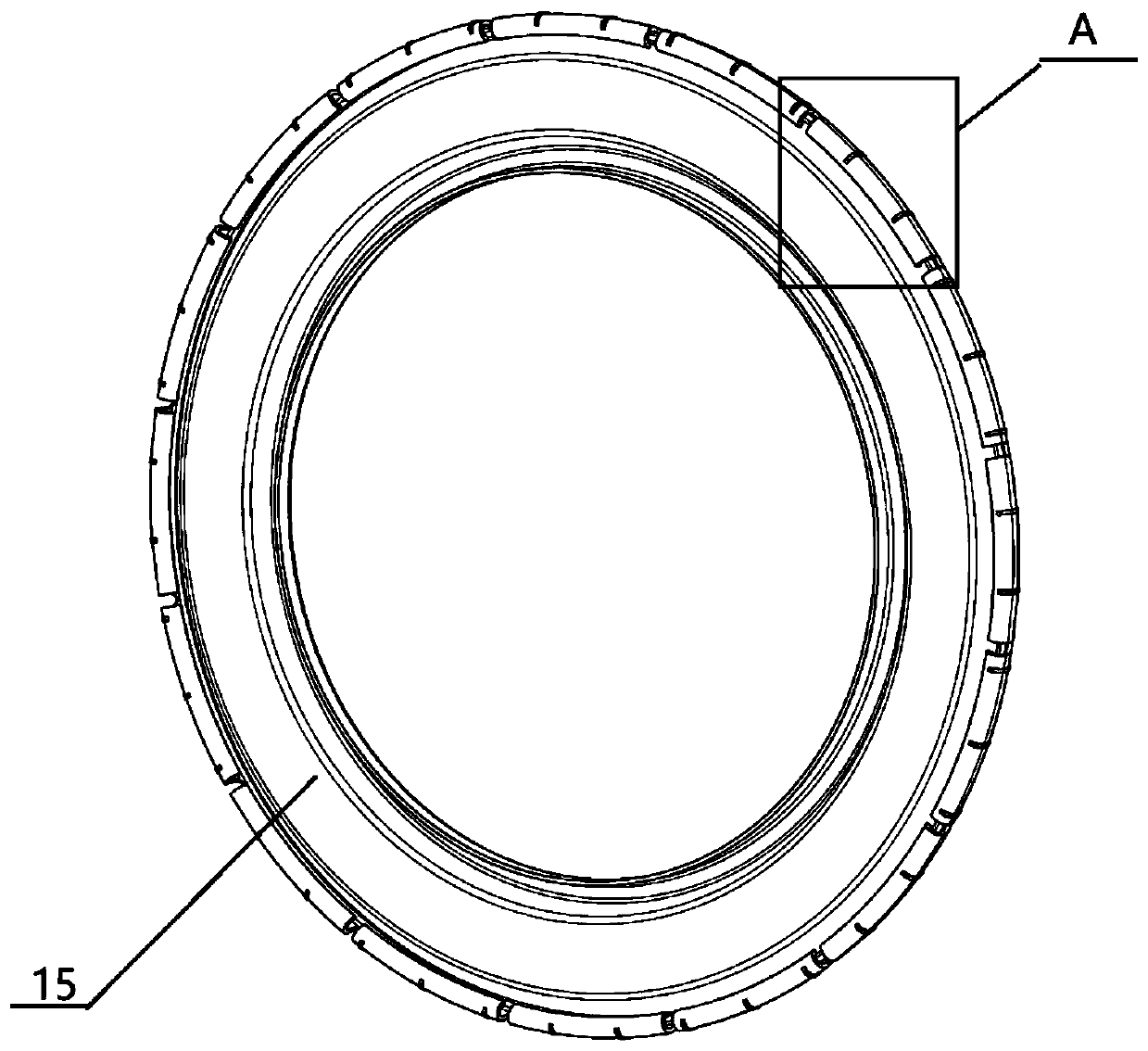

Bearing and bearing dust cover

InactiveCN110307261AReduce sheddingReduce the likelihood of sheddingBearing componentsArchitectural engineering

Owner:SCHAEFFLER TECH AG & CO KG

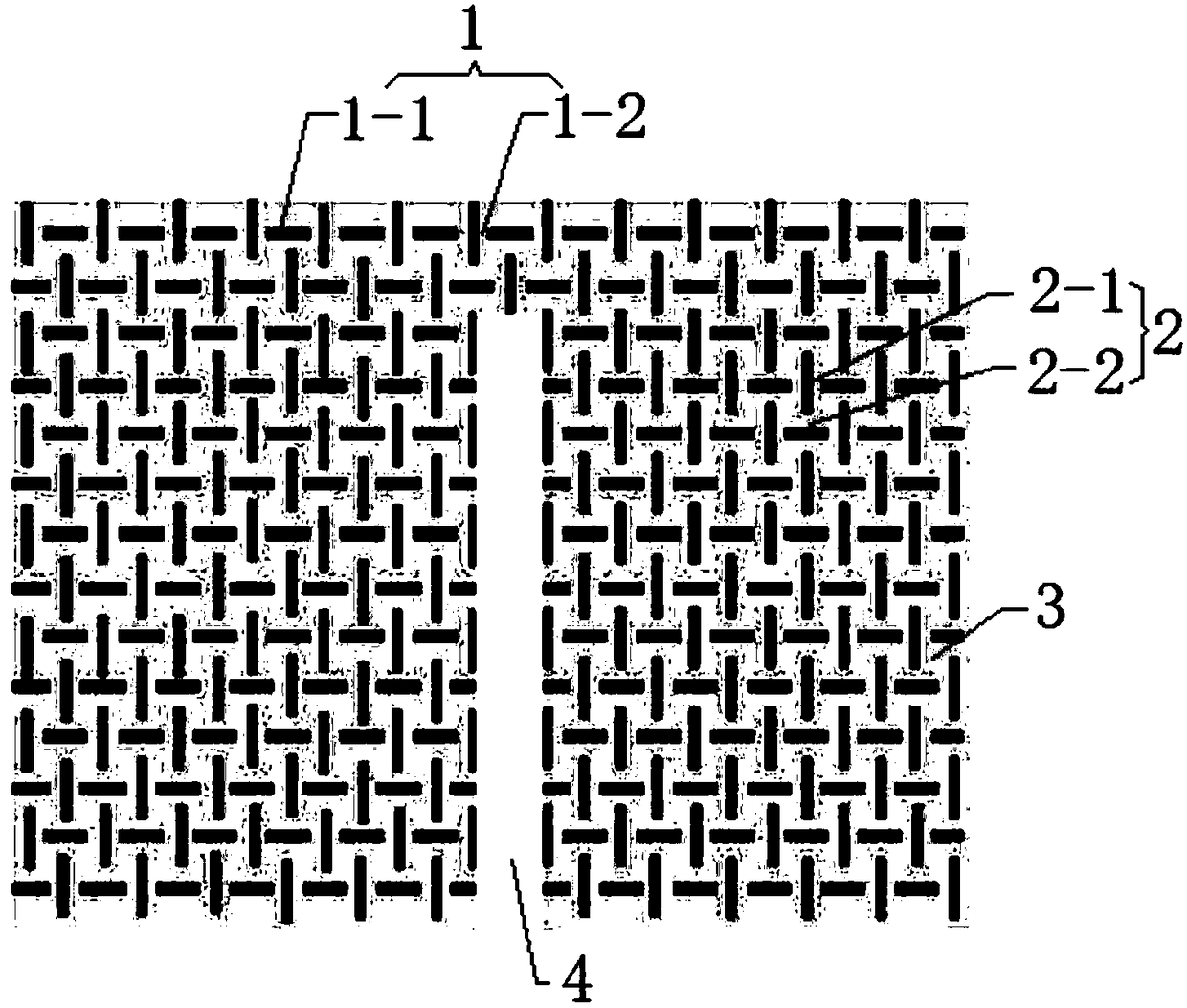

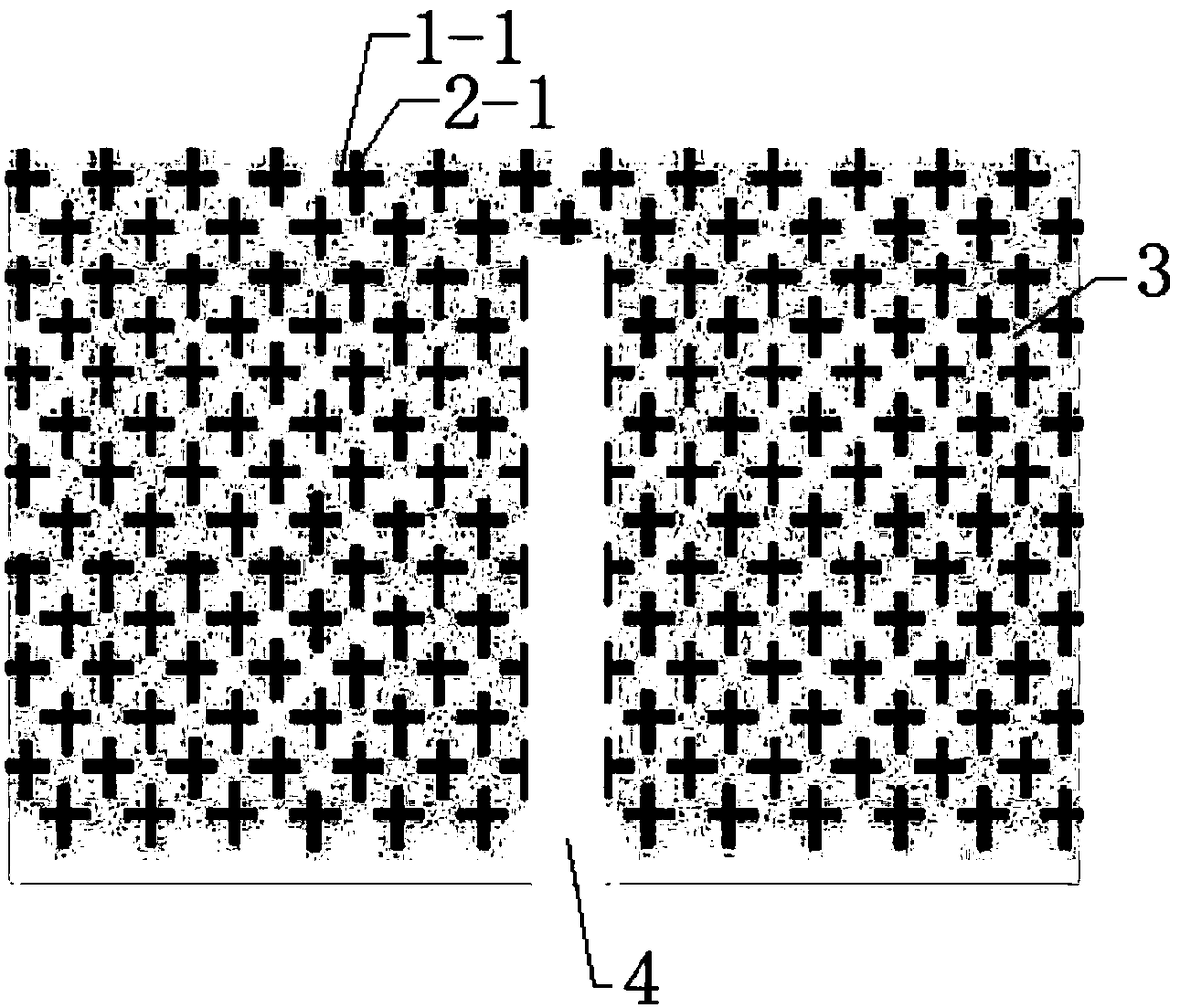

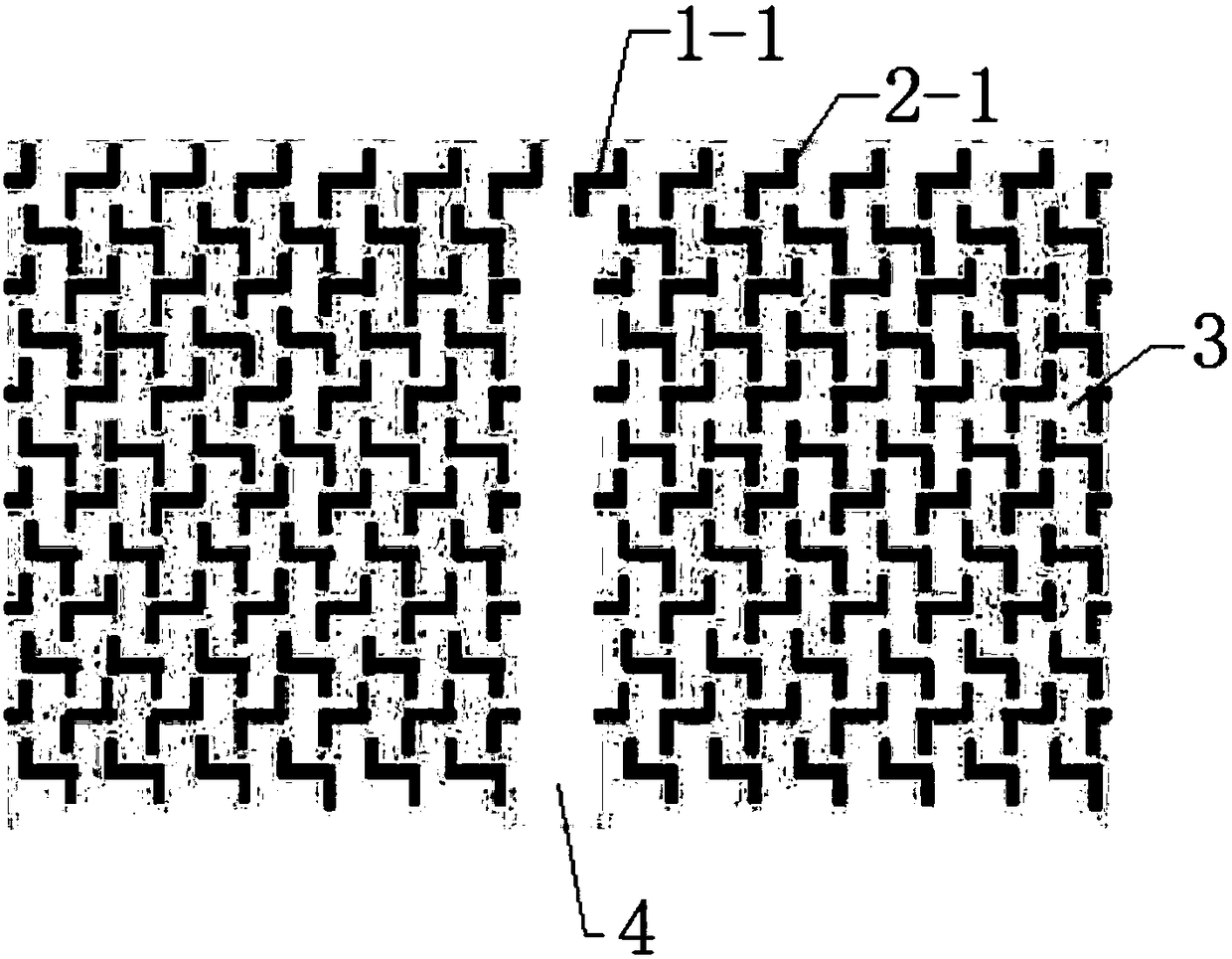

Back face passivated laser slotted solar cell and manufacturing method thereof

PendingCN108336161AImprove directionShorten the transmission pathFinal product manufacturePhotovoltaic energy generationSurface layerSolar cell

The invention discloses a back face passivated laser slotted solar cell and a manufacturing method thereof, and relates to the technical field of solar cell manufacturing. The solar cell comprises a solar grade crystal silicon wafer which is provided with a back passivation film, a plurality of parallel-arranged septal lines and vertically arranged septal lines perpendicularly intersected with theparallel-arranged septal lines are uniformly arranged on the back passivation film, the parallel-arranged septal lines include parallel solid line segments slotted by a laser and non-slotted paralleldashed line segments, and the vertically arranged septal lines include vertical solid line segments slotted by the laser and non-slotted vertical dashed line segments. According to the solar cell, the parallel-arranged septal lines and the vertically arranged septal lines are combined to reduce the action area of the laser on the crystal silicon wafer, reduce the loss of the back passivation filmon a surface layer and achieve photo-generated carrier collection in parallel and vertical directions to improve battery efficiency.

Owner:TONGWEI SOLAR ENERGY (CHENGDU) CO LID

Check valve

ActiveCN110397770AExtended service lifeSingle flowOperating means/releasing devices for valvesCheck valvesEngineeringCheck valve

The invention provides a check valve. The check valve is characterized by comprising a valve body assembly, an electromagnetic assembly and a diversion assembly, wherein the valve body assembly is provided with a valve flap, a valve seat, a connecting pipe and a push rod, the valve flap is shaped like an inverted trapezoid, and the lower end of the push rod is connected with the upper end of the valve flap; the outer wall of the electromagnetic assembly is connected with the connecting pipe, and a coil, a movable iron core and a spring are arranged in the outer wall of the electromagnetic assembly; a sliding block is arranged in a diversion pipeline of the diversion assembly, conductive blocks are arranged on the sliding block, two conductive contact points are arranged in the diversion pipeline, and the conductive blocks enable the two conductive contact points to be connected or disconnected; and the two conductive contact points are connected with the coil, a power supply and a circuit switch in series. According to the check valve, the valve flap can be completely pulled out of a medium between a valve body inlet and a valve body outlet, so that when the check valve is connected, the pressure and the flow of the medium cannot be affected, and the check valve can be used for the situation with large flow; and meanwhile, the impact of the medium to the valve flap and abrasionbetween the valve flap and a valve body are reduced, and the service life of the check valve is prolonged.

Owner:JIANGSU SHENGTAI VALVE CO LTD

Socket and spigot type jacking pipe and assembling method thereof

PendingCN111561605AGuaranteed coaxialityProtect inner diameterSleeve/socket jointsPipe laying and repairArchitectural engineeringAxial force

The invention provides a socket and spigot type jacking pipe and an assembling method thereof, and belongs to the technical field of jacking construction. The socket and spigot type jacking pipe comprises a socket, a spigot and a pipe body and further comprises a force bearing ring. The force bearing ring is of an annular structure with an L-shaped cross section, the side A of the force bearing ring is matched with the lining layer of the pipe body and is parallel to the axis of the pipe body, and the edge B of the force bearing ring is matched with the inner end surface of the socket, is perpendicular to the axis of the pipe body and is used for bearing axial force transmitted by a spigot of an adjacent jacking pipe in the jacking operation process. According to the socket and spigot typejacking pipe, jacking force at the end of the spigot can be evenly dispersed and transmitted to the socket, internal stress concentration of the socket caused by the jacking force is prevented, and the socket is protected during connection operation. Moreover, the inner diameter of the socket is reduced due to the L shape of the force bearing ring, the spigot abuts against the edge B of the forcebearing ring and can be effectively prevented from moving inwards, and the coaxiality of two jacking pipes in the connecting process is guaranteed.

Owner:XINXING DUCTILE IRON PIPES CO LTD +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com