Patents

Literature

221results about How to "Achieve polish" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

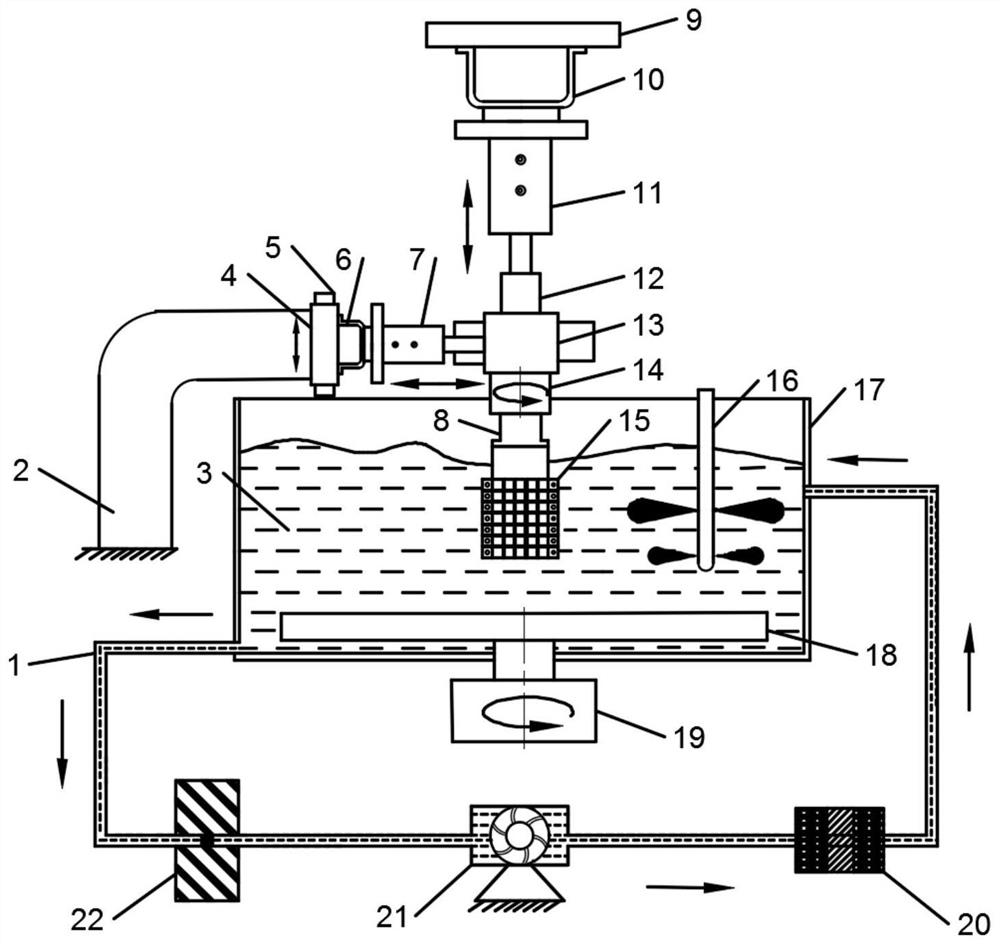

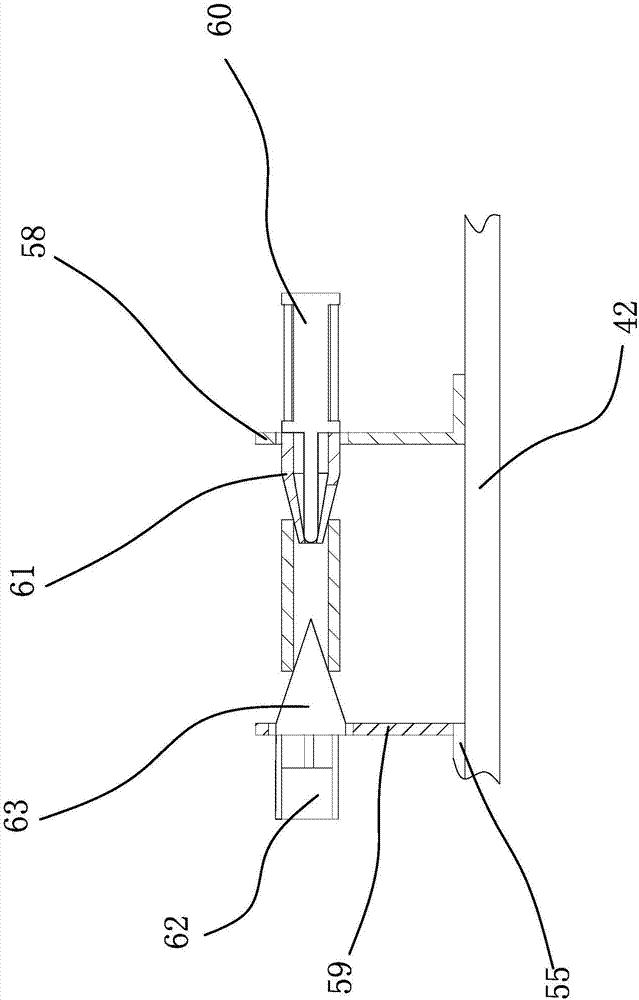

Abrasive flow micropore polishing device and polishing process thereof

InactiveCN104440584AAchieve polishReduce roughnessAbrasive feedersAbrasive machine appurtenancesCavitationWear particle

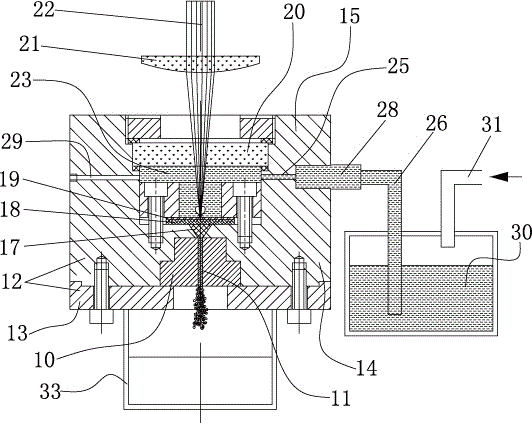

The invention discloses an abrasive flow micropore polishing device, comprising a clamping tool, a base plate, a cavity, a separation device, a laser high-transparency protective lens, a laser, a focusing lens, a flow guiding passage and a one-way valve, wherein the clamping tool is used for clamping a workpiece and locating micropores of the workpiece; the base plate is arranged on the clamping tool; the cavity is arranged in the base plate and the clamping tool and correspondingly communicate with the micropores; the separation device is arranged in the cavity and divides the cavity into a cavitation cavity and a liquid storage cavity; the laser high-transparent protective lens covers the cavitation cavity; the laser can generate laser beams facing to the cavitation cavity; the focusing lens is arranged between the laser and the laser high-transparent protective lens and is used for focusing laser beams in the cavitation cavity; the flow guiding passage can guide deionized water into the caviation cavity; the one-way valve is arranged in the flow guiding passage. According to the abrasive flow micropore polishing device, lasers are focused to cavitate the deionized water to form a large local pressure and impact the separation device, and the abrasive fluid flows and is pushed into the micropores at high speed and rubs the pore walls of the micropores to reduce the roughness of the inner surface of the micropores, so as to achieve the polishing on the micropores. The invention further discloses an abrasive flow micropore polishing process for highly effectively and ultra-precisely polishing the micropores.

Owner:GUANGDONG UNIV OF TECH

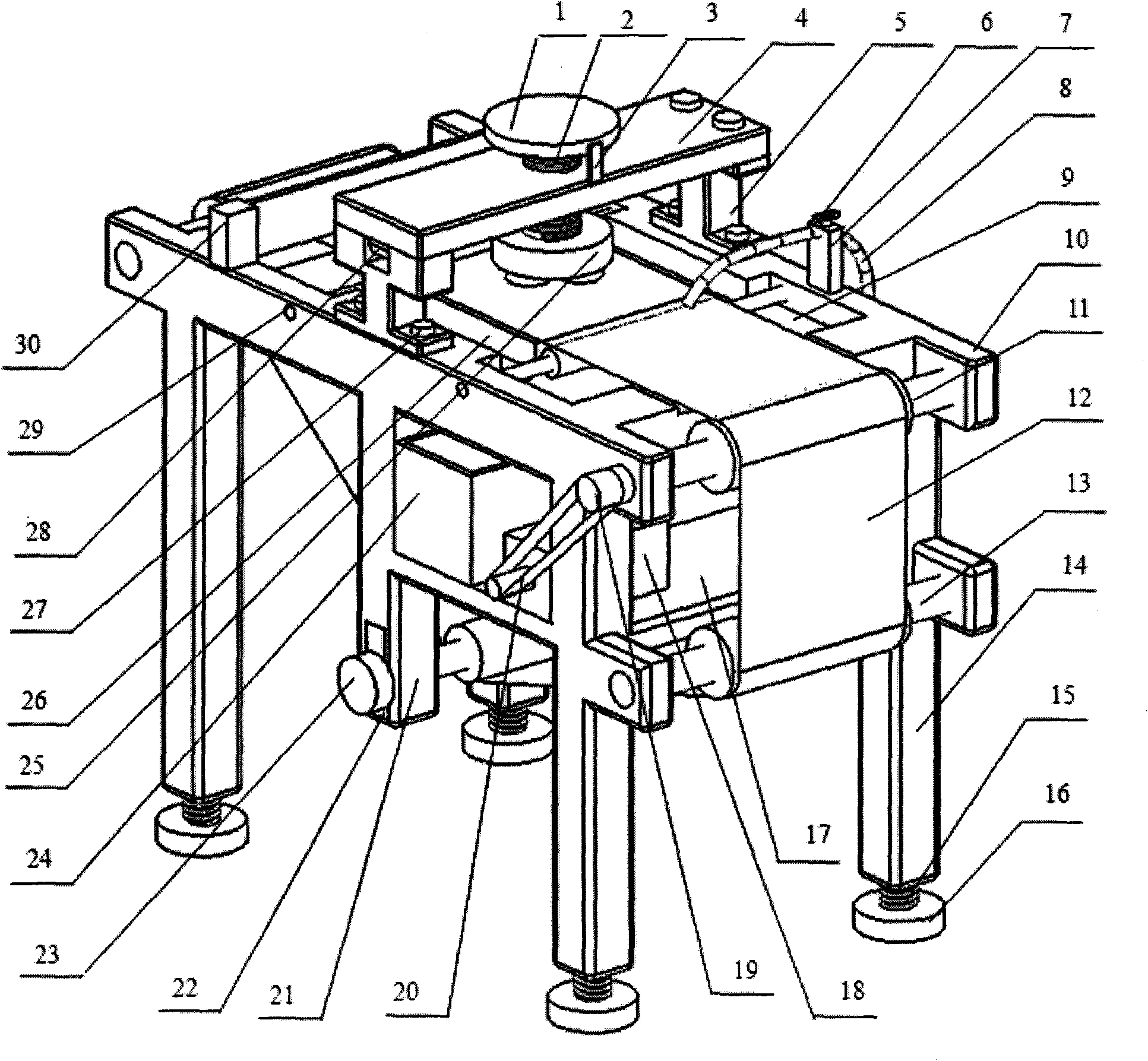

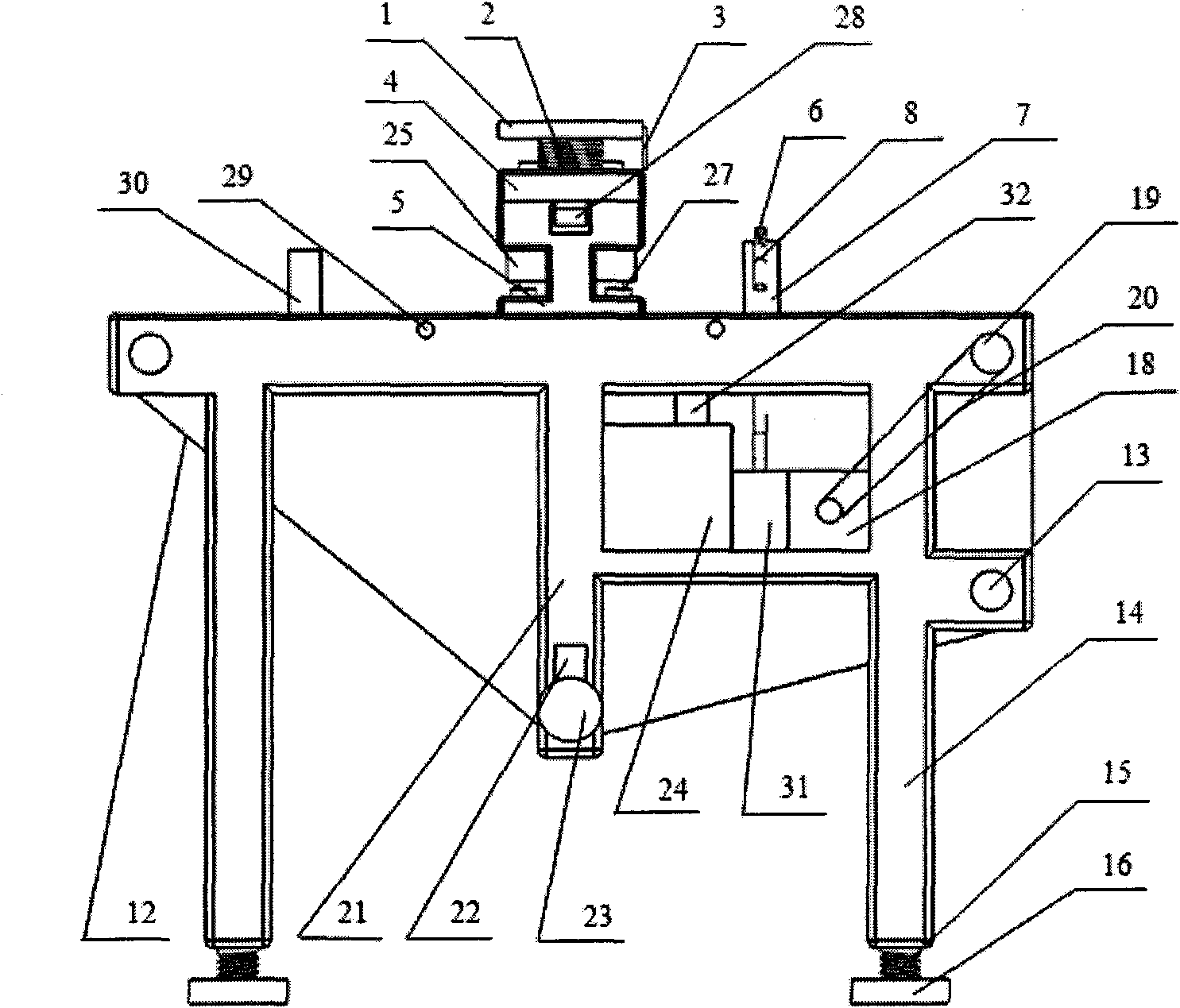

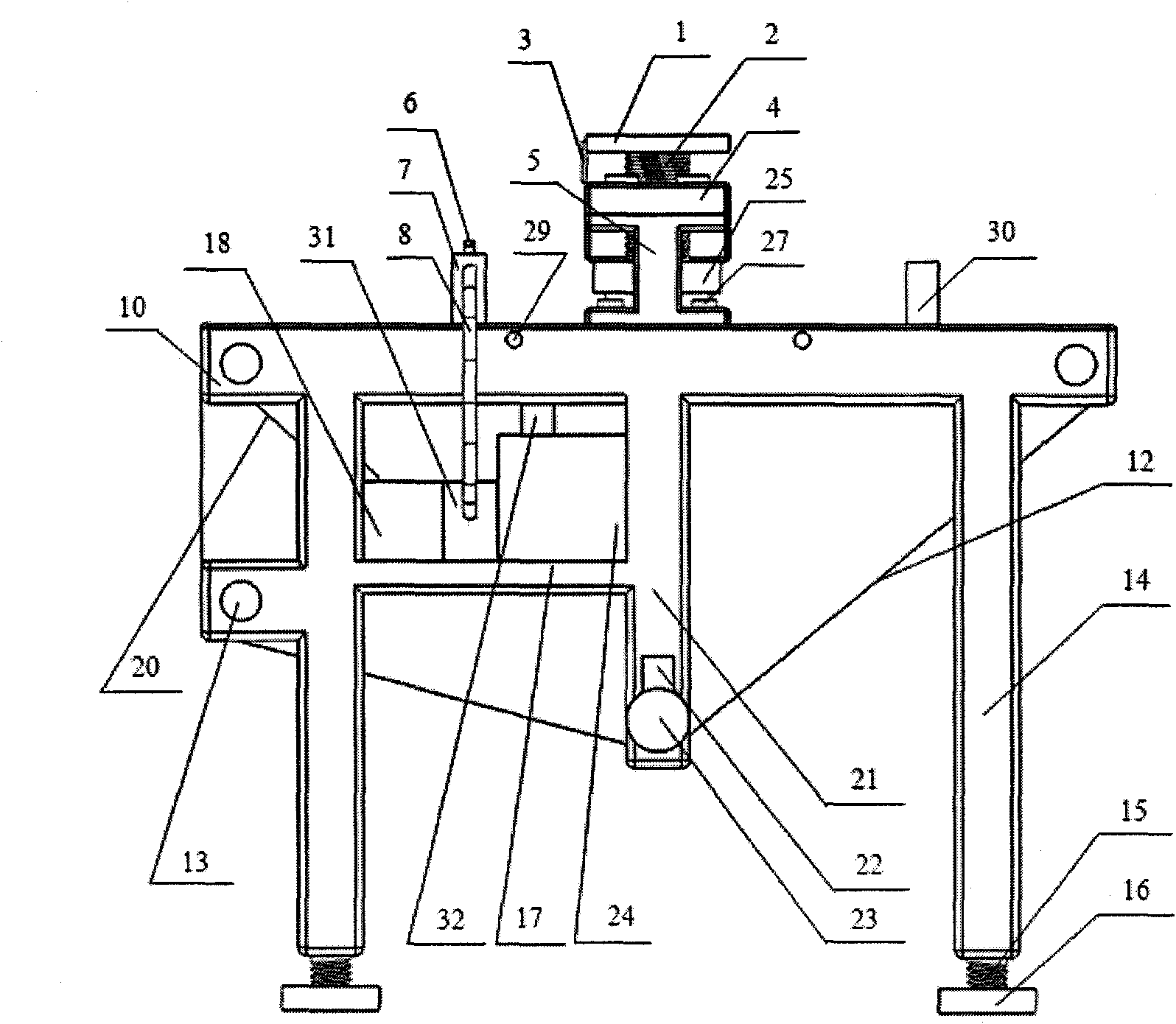

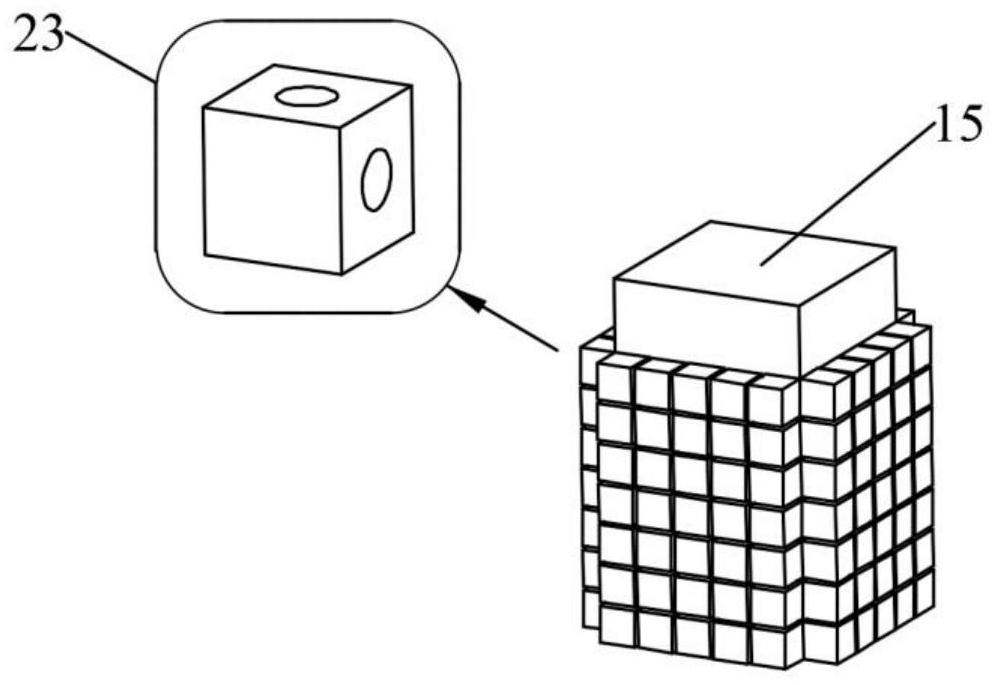

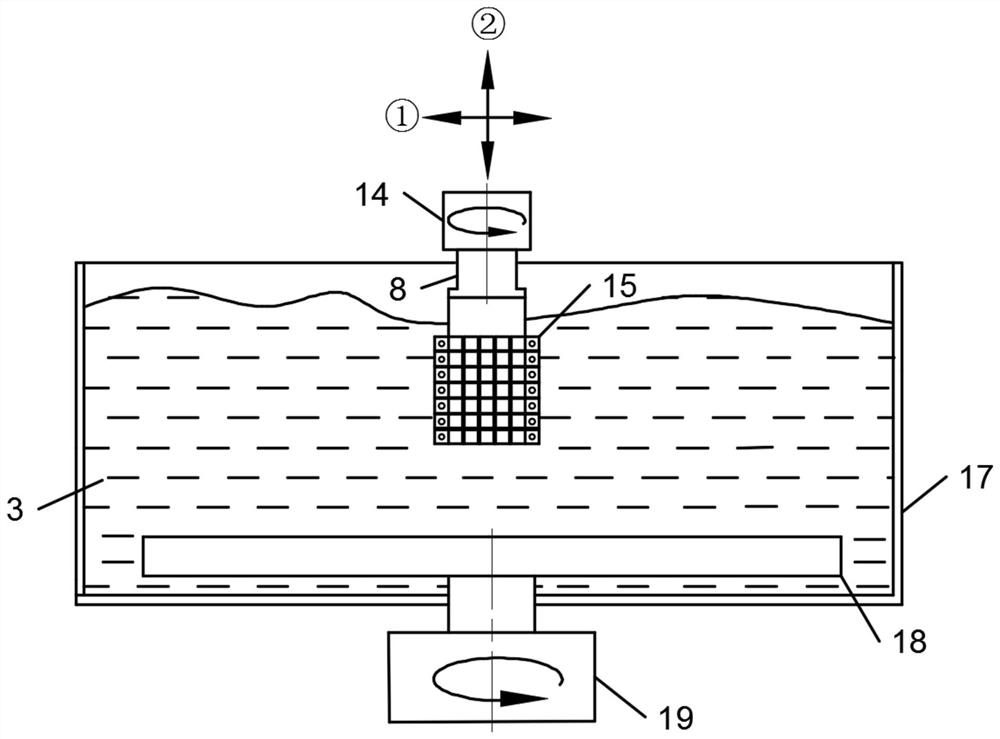

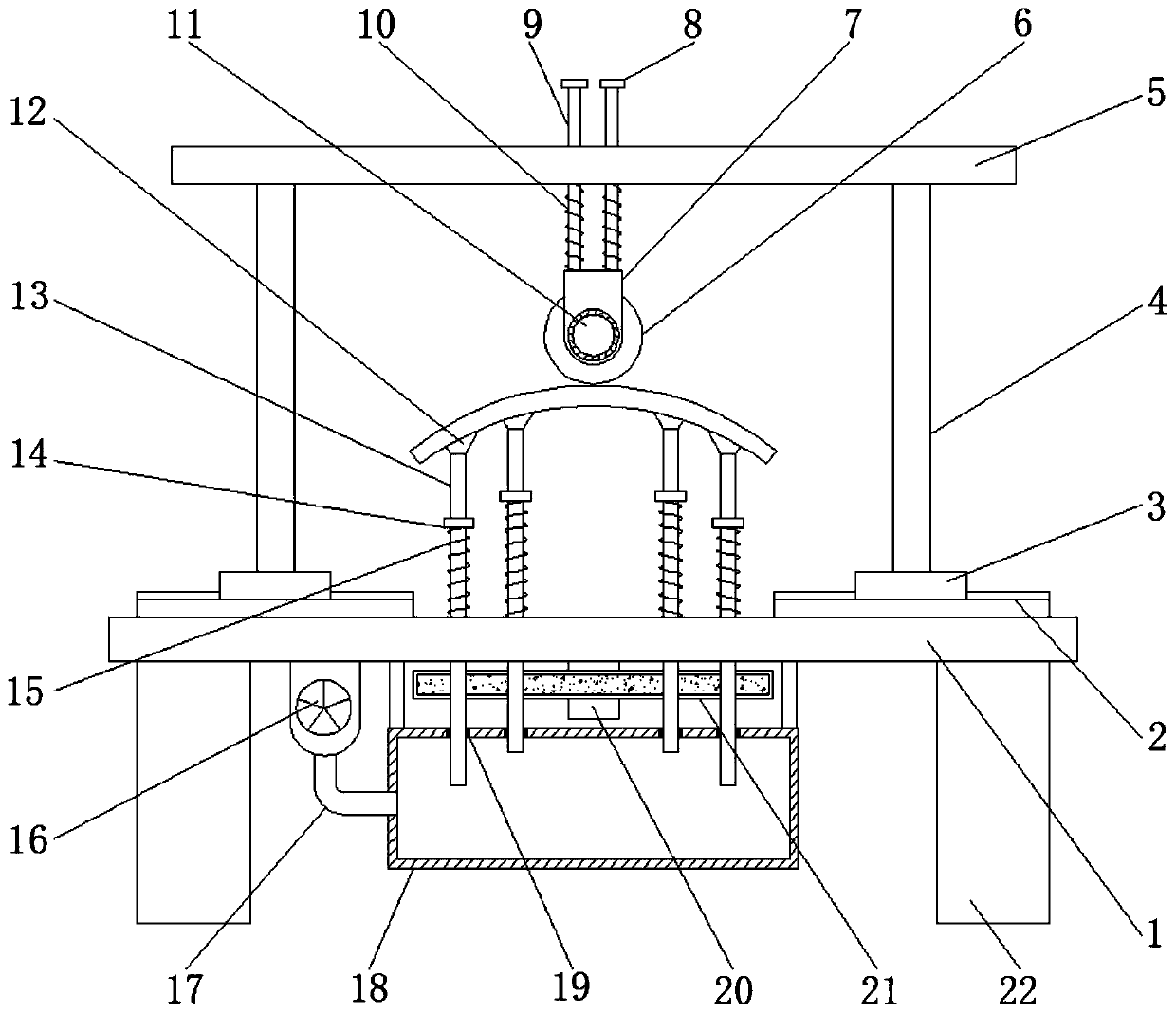

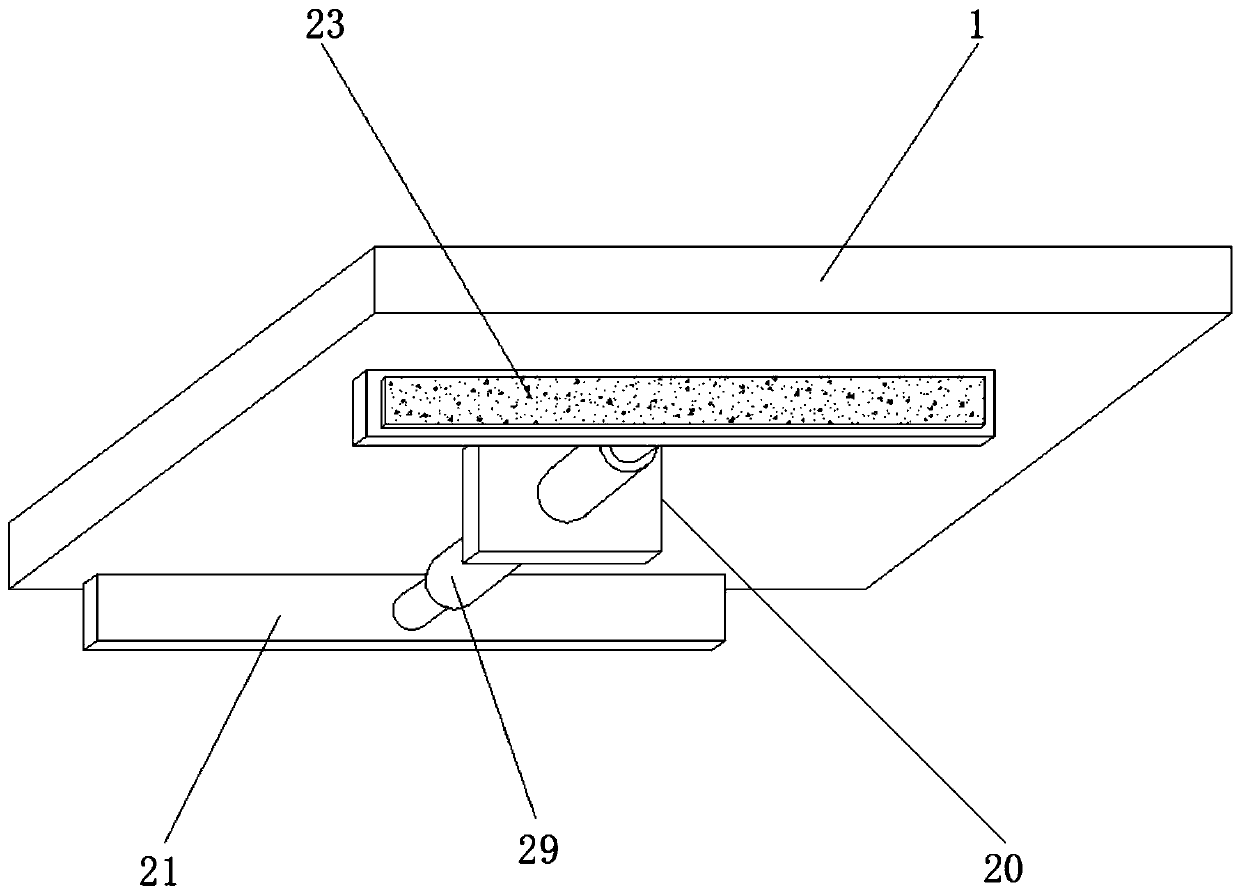

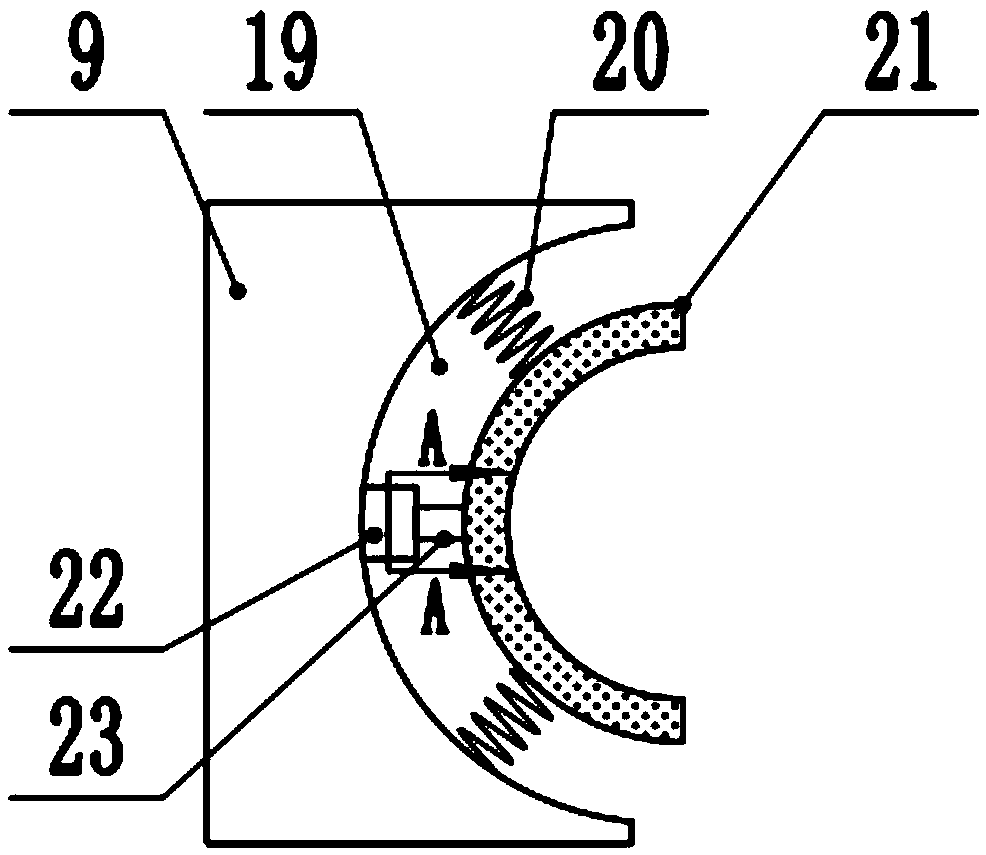

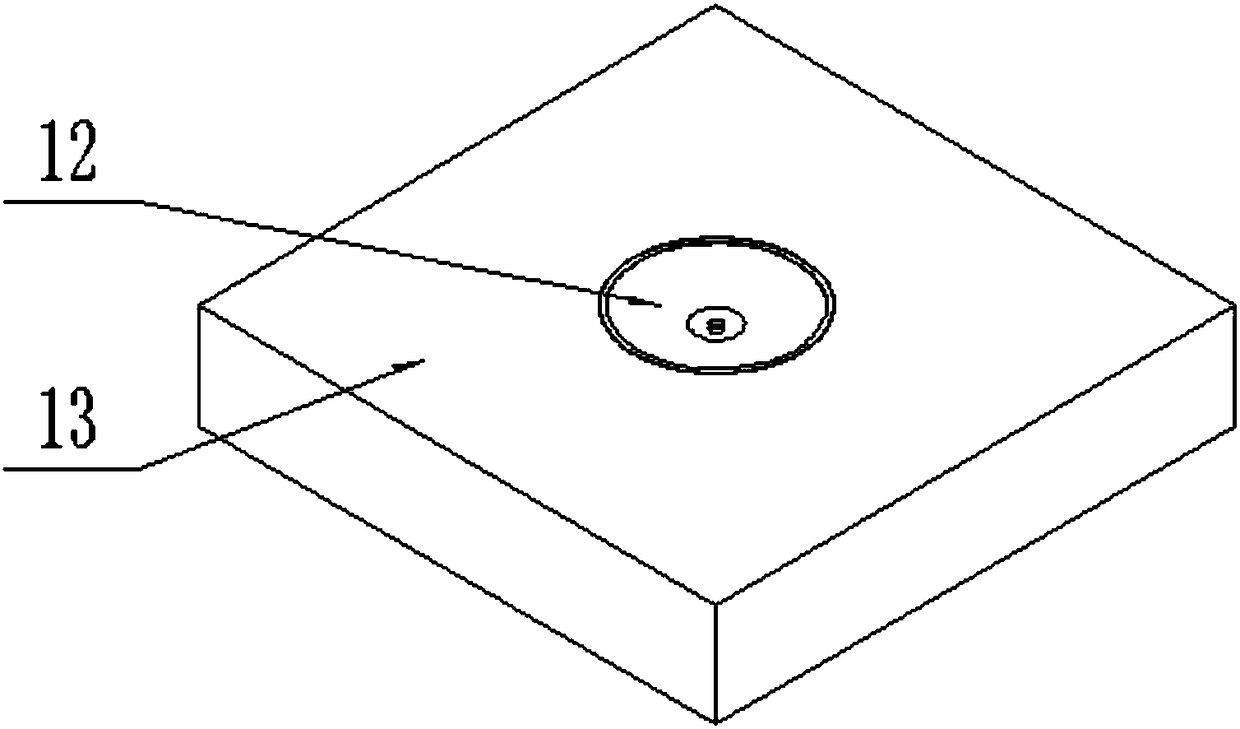

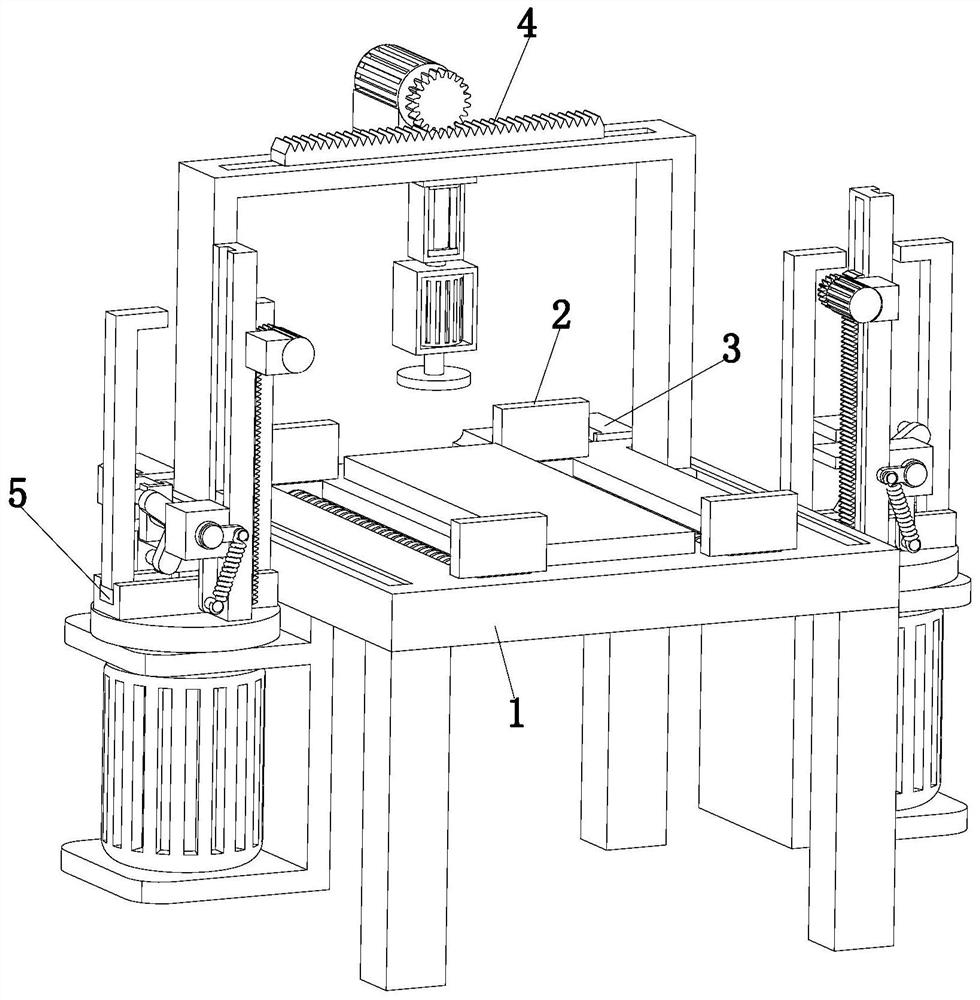

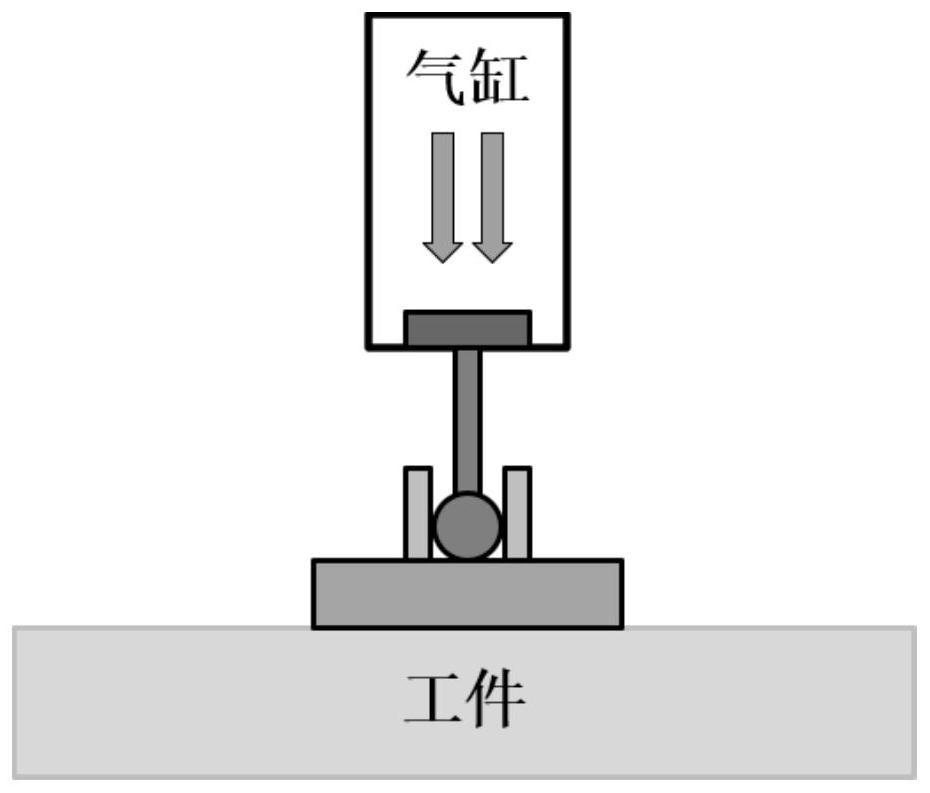

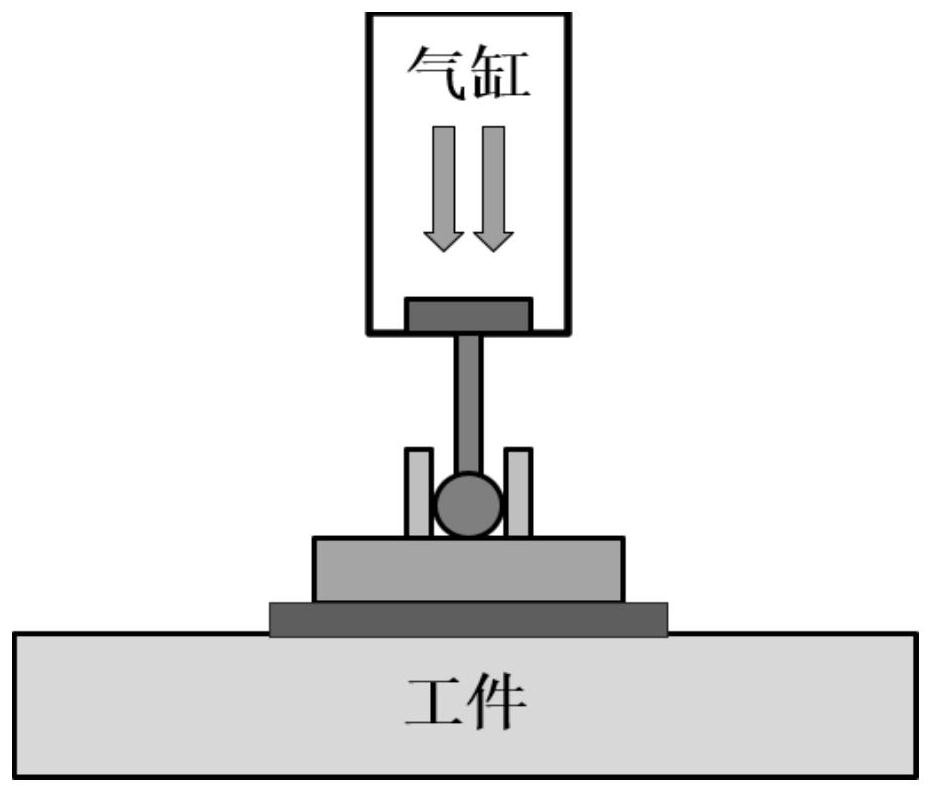

Metallographic phase grinding sample pressure adjusting device and metallographic phase grinding and polishing device and method

ActiveCN105904336AAchieve polishAdjustable speedLapping machinesWork carriersPulp and paper industryFastener

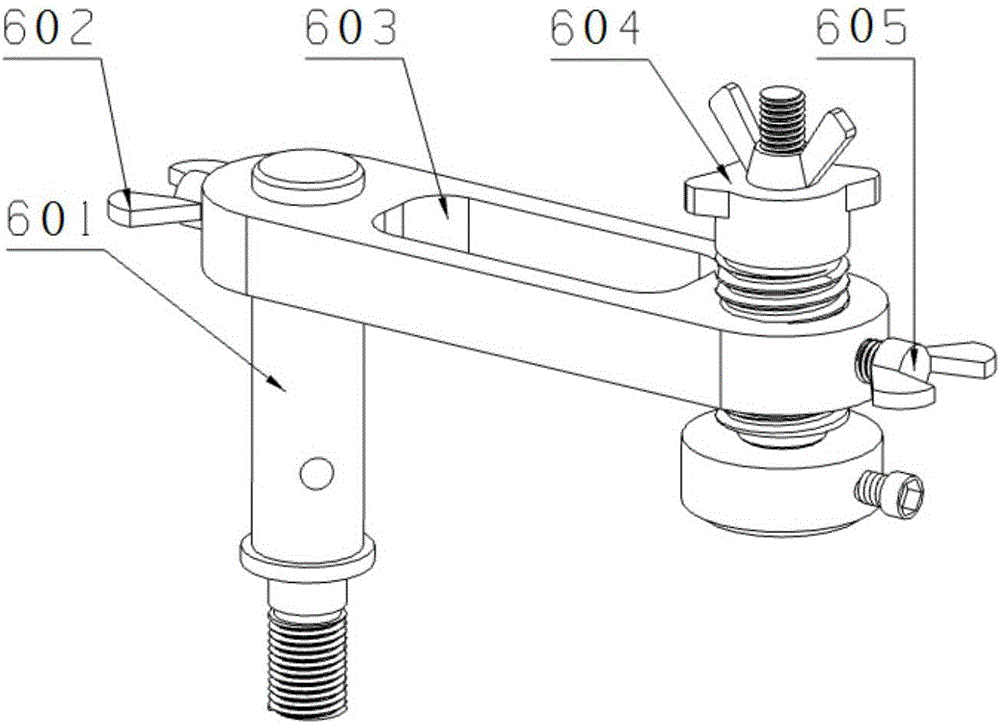

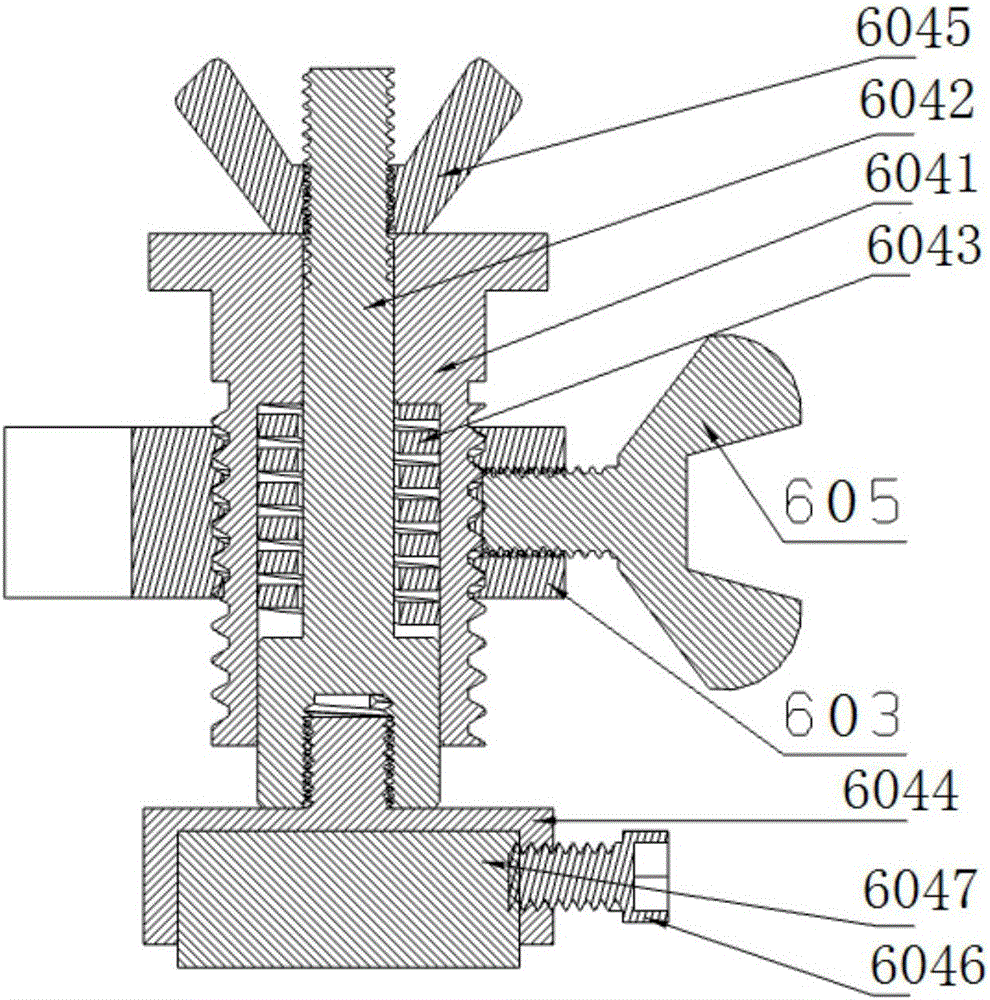

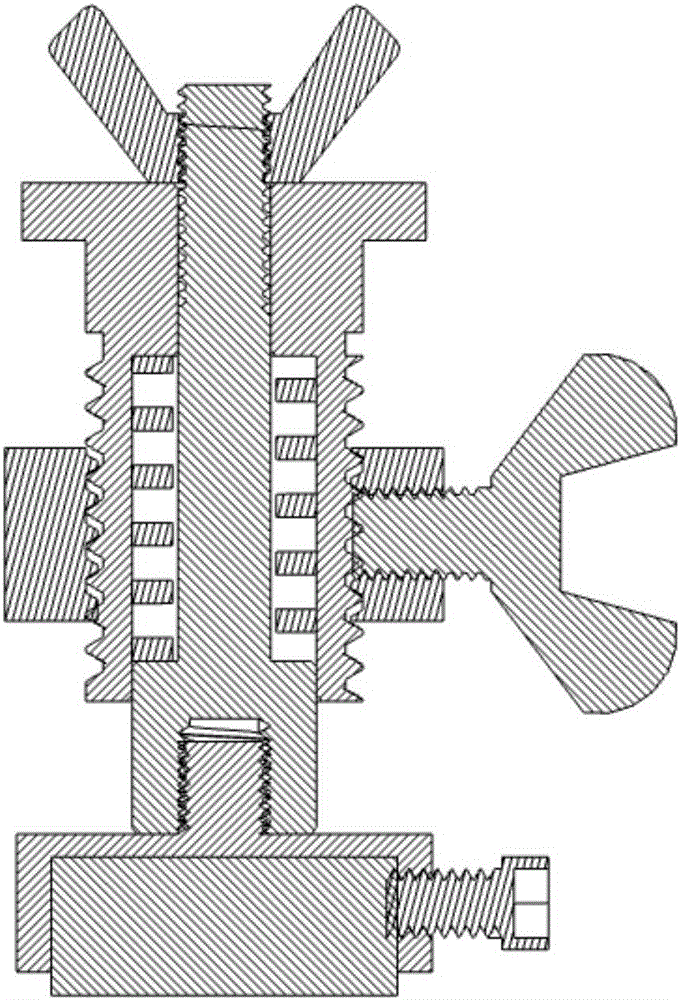

The invention relates to the technical field of metallographic phase grinding, in particular to a metallographic phase grinding sample pressure adjusting device and a metallographic phase grinding and polishing device and method. The metallographic phase grinding sample pressure adjusting device comprises a fixed rod, a rotary connection rod and a sample clamping mechanism which are all sequentially connected; the sample clamping mechanism comprises an adjusting sleeve, a pin shaft arranged in the adjusting sleeve, a fastener installed at the upper end of the pin shaft, a spring arranged on the pin shaft in a sleeving manner and pressed in the adjusting sleeve through the pin shaft, and a sample clamping sleeve detachably installed at the lower end of the pin shaft and used for clamping a metallographic phase sample. The metallographic phase grinding and polishing device comprises the metallographic phase grinding sample pressure adjusting device, a cushion plate, a grinding and polishing disk and a motor. During grinding and polishing, firstly, pressure is preset, and then by adjusting the fastener of the pin shaft to be connected with the adjusting sleeve, the pressure is loaded onto the metallographic phase sample. According to the metallographic phase grinding sample pressure adjusting device and the metallographic phase grinding and polishing device and method, one or more metallographic phase samples can be pre-ground and polished on the same equipment, and pressure acting on the samples is adjustable and can be automatically released.

Owner:NORTHEASTERN UNIV

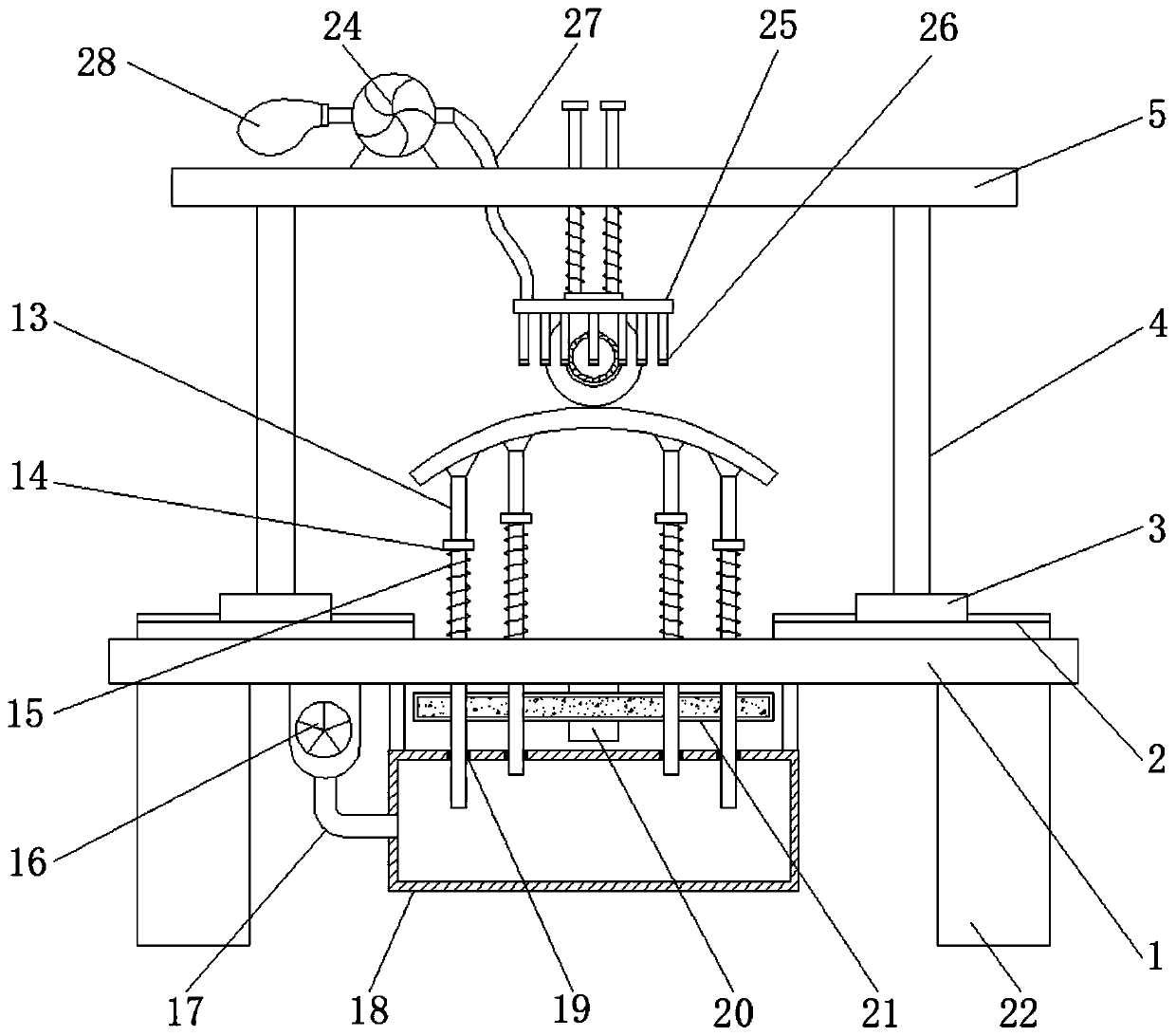

Metallographic specimen grinding and polishing machine

InactiveCN102218690ASimple structureEasy to operateBelt grinding machinesManufacturing efficiencyManufacturing quality

The invention discloses a metallographic specimen grinding and polishing machine. An upper supporting plate and a lower supporting plate are arranged on a machine body; a grinding and polishing bottom plate is arranged in the middle of the upper supporting plate and is enclosed by a drainage tank; two ends of the upper supporting plate are provided with an abrasive belt driving shaft and an abrasive belt transmission shaft; a pressing plate is correspondingly arranged on the upper part of the grinding and polishing bottom plate; a screw is arranged on the pressing plate; a rotary pressing disc and a specimen fixture disc are arranged at two ends of the screw; an abrasive belt adjusting shaft is arranged in an adjusting groove on the lower part of the upper supporting plate; a water tank and a motor are arranged on the lower supporting plate; water is supplied to the grinding and polishing bottom plate through a water pump; the motor drives the abrasive belt driving shaft; and the abrasive belt is tensioned on the abrasive belt driving shaft, the abrasive belt transmission shaft, an abrasive belt supporting shaft and the abrasive belt adjusting shaft. The metallographic specimen grinding and polishing machine is simple in structure, convenient to operate and high in specimen manufacturing efficiency, and can effectively guarantee the manufacturing quality of a metallographic specimen.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

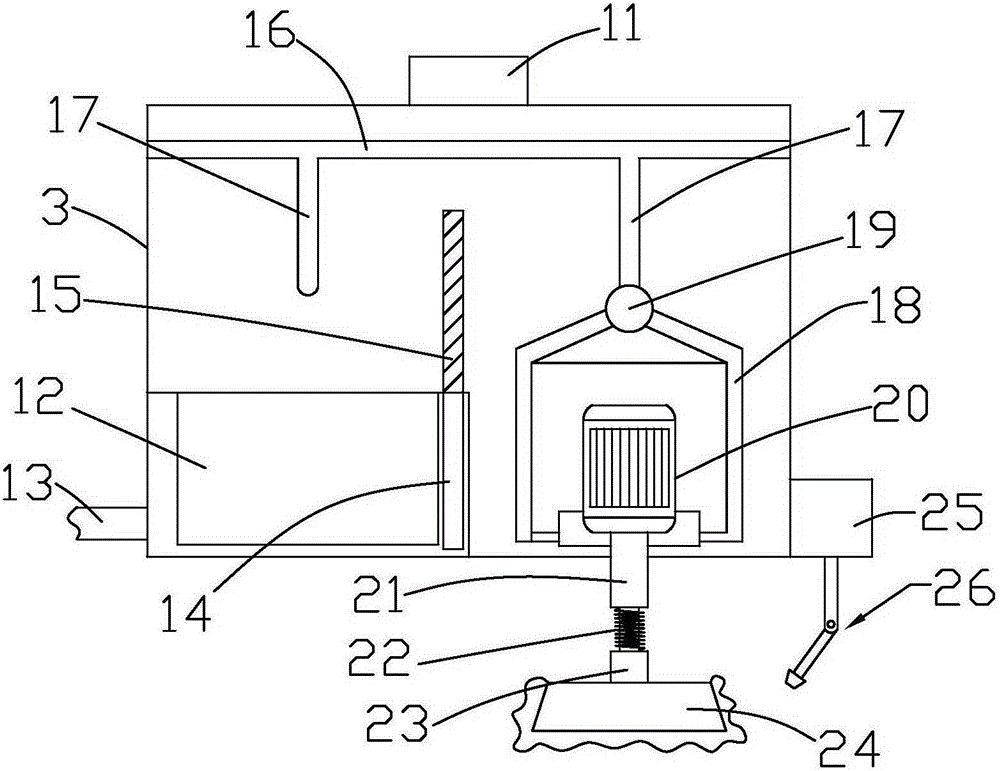

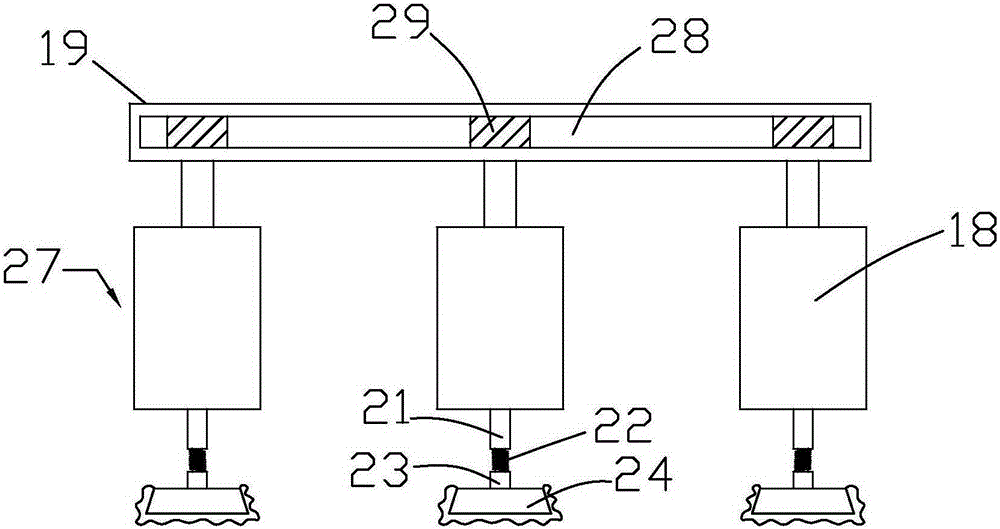

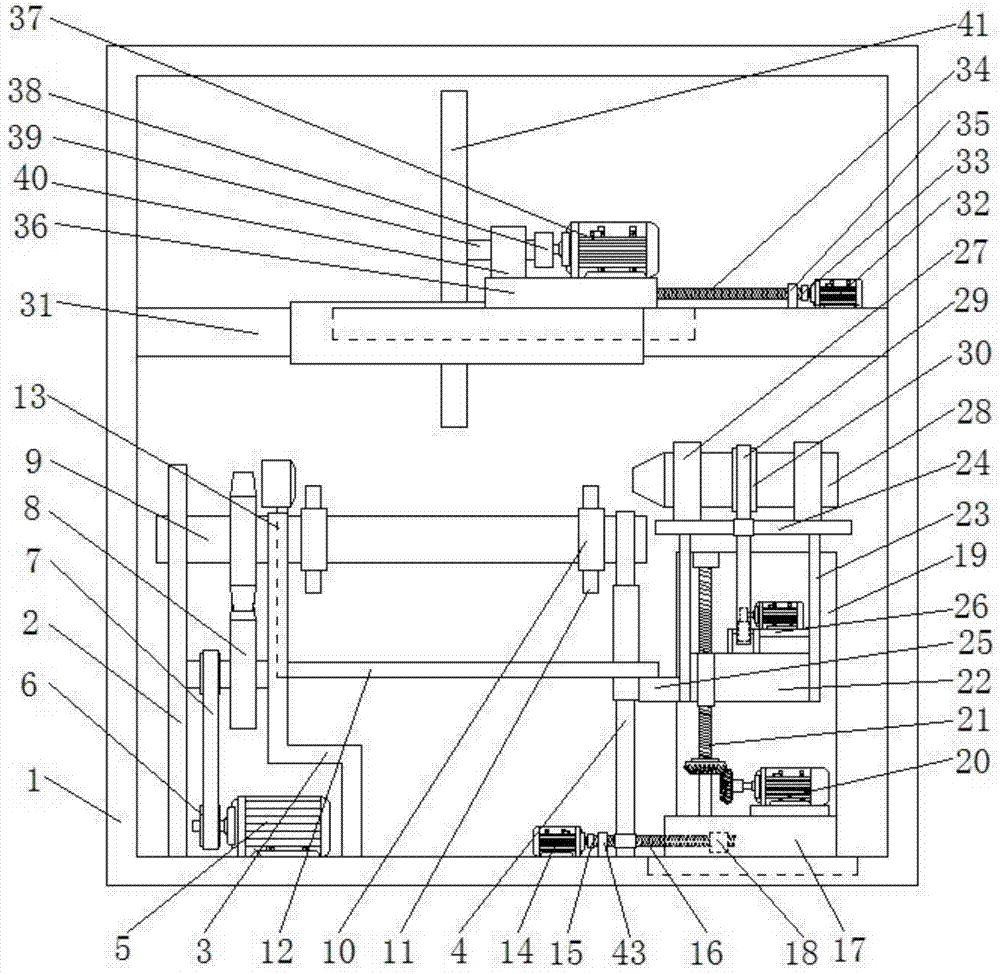

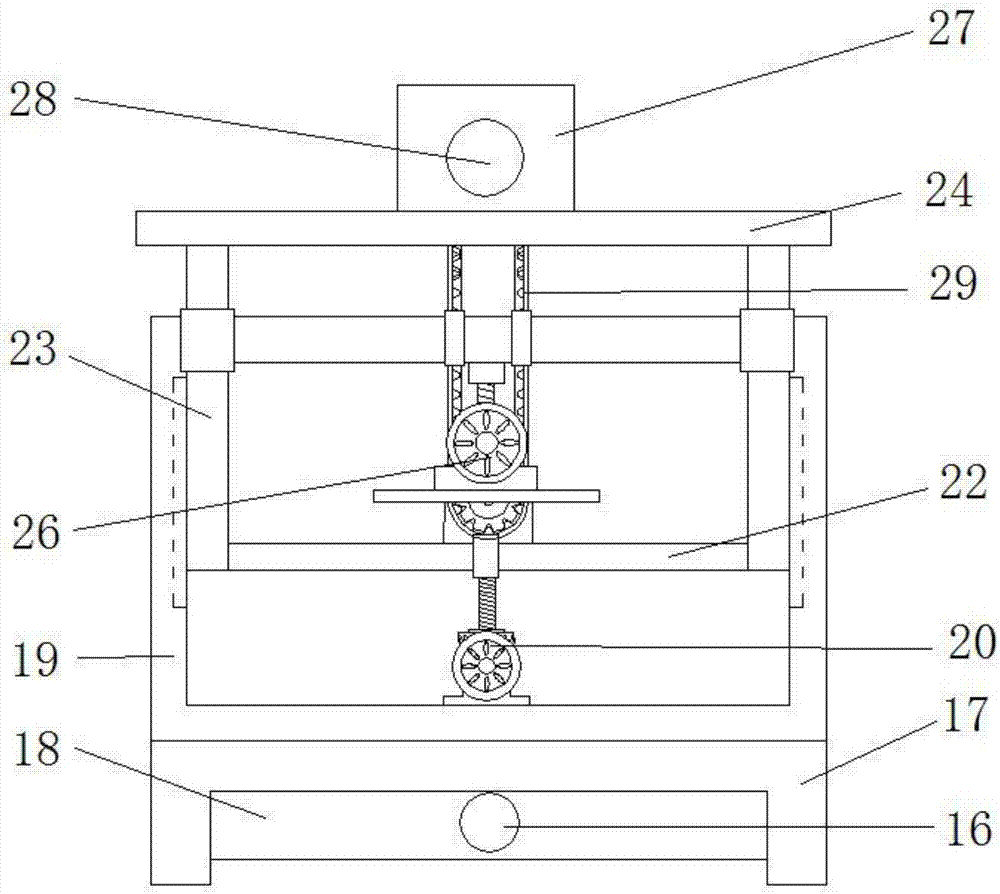

Multifunctional glass polishing machine

InactiveCN105215805ASatisfied with polishingImprove processing efficiencyGrinding drivesGrinding feedersEngineeringSewage treatment

The invention discloses a multifunctional glass polishing machine which comprises a feeding frame and a polishing device. The polishing device comprises moving control boxes, a cantilever, a bottom operating table and a water tank. A cleaning trough, a horizontal slide rail, vertical slide rails and upper polishing mechanisms are arranged in the cantilever. The upper polishing mechanisms are connected to a cantilever rod through supporting frames. The feeding frame horizontally penetrates through the moving control boxes. The bottom operating table is located below the feeding frame, and a lifting table, a supporting plate, a sewage disposal pool and a lower polishing mechanism are arranged in the bottom operating table. The lower polishing mechanism is arranged on the top face of the lifting table. Pressing mechanisms are arranged on the two sides of the cantilever. The water tank is located on one side of the feeding frame and connected with the cantilever through a conveying pipe. The multifunctional glass polishing machine is simple in structure and high in practicability, can be used for polishing both plain glass and curved glass, and improves the efficiency and quality of polishing.

Owner:SHENGZHOU HUANDING GLASS TECH CO LTD

Polishing disk for polishing crystal glass

InactiveCN102120315AExtended service lifeHydrophilicAbrasion apparatusWater solubleHigh wear resistance

The invention relates to a polishing disk for polishing crystal glass. In the polishing disk for polishing crystal glass, a polishing layer comprises the following components in percentage by mass: 5 to 60 percent of grinding material, 10 to 60 percent of unsaturated resin with water swelling property, 0.5 to 5 percent of curing agent, 0.1 to 30 percent of water soluble additive and 0.05 to 8 percent of functional regulating additive, wherein the total mass percentage of the components is 100 percent. The grinding material may be diamond, carborundum and aluminum oxide. The polishing disk solves the problem that the diamond, carborundum, aluminum oxide and the like, which are harder than workpieces, cannot be used as a grinding material on the polishing disk, and has the advantages of high processing efficiency, high wear resistance and long service life.

Owner:ZHEJIANG PUJIANG MINRUI PRECISION MACHINERY TECH

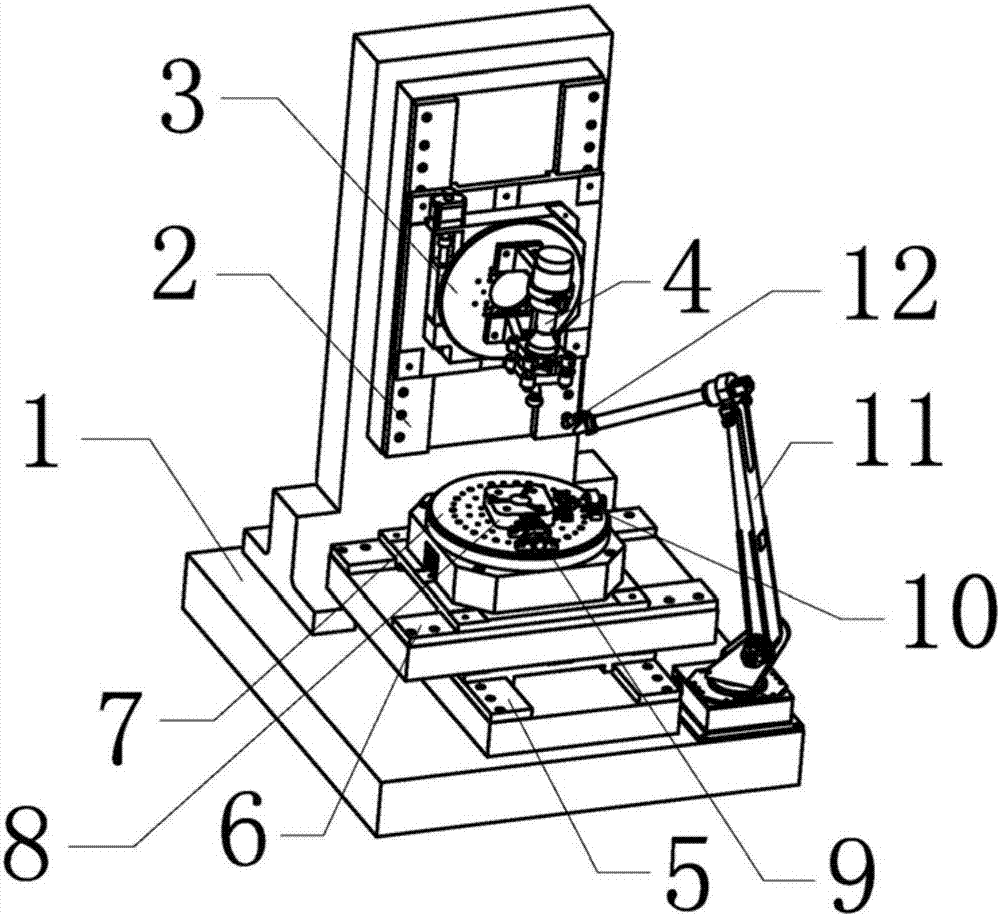

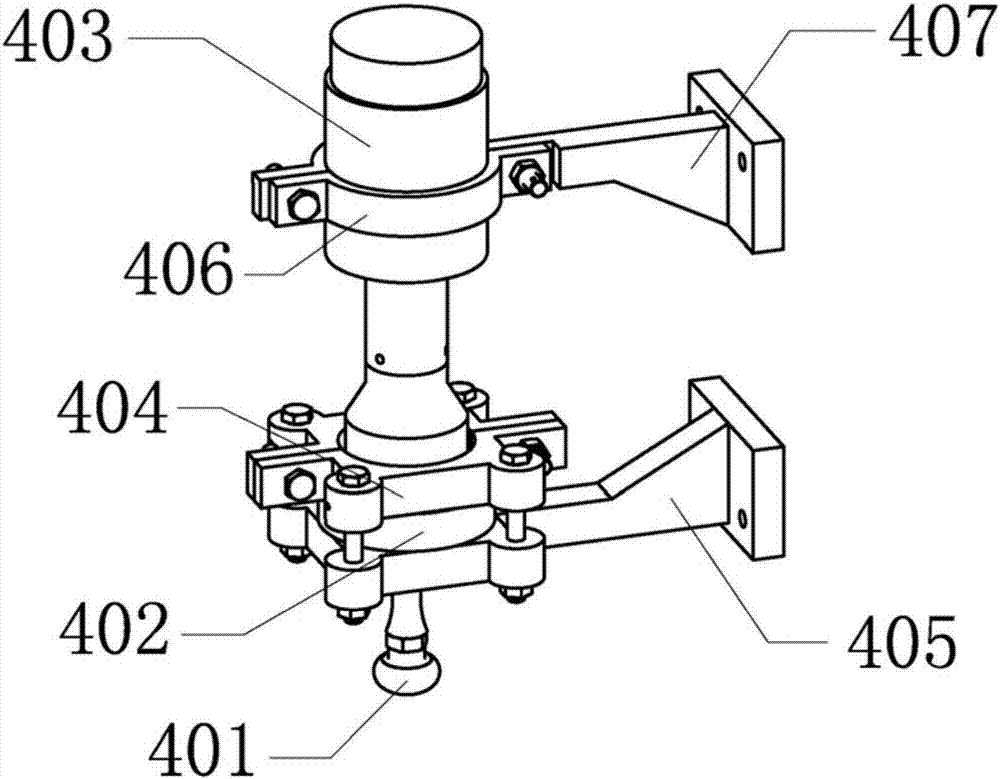

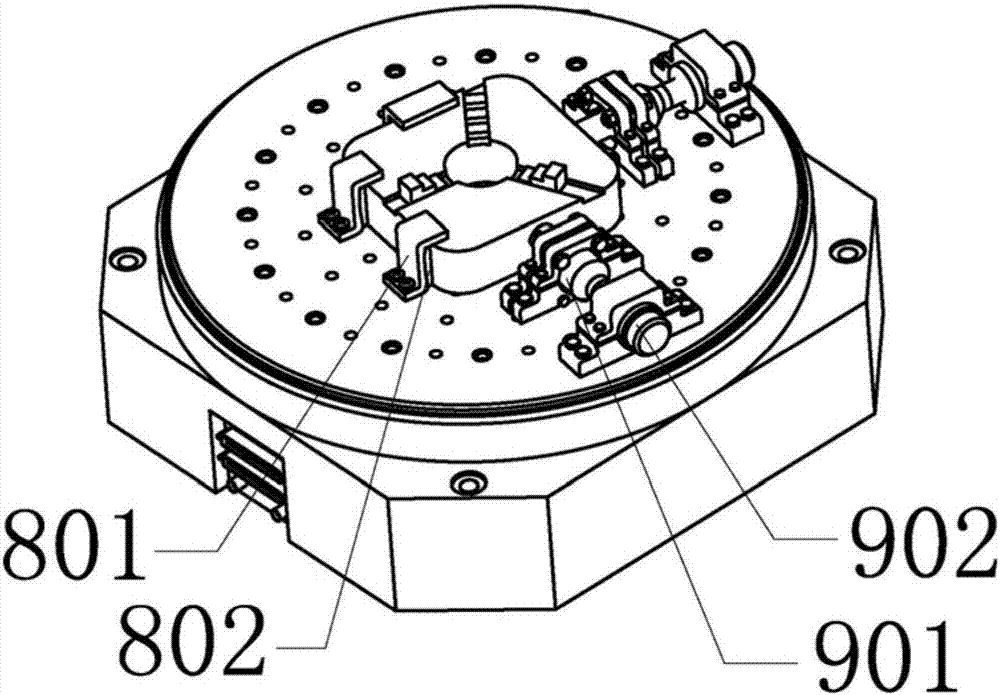

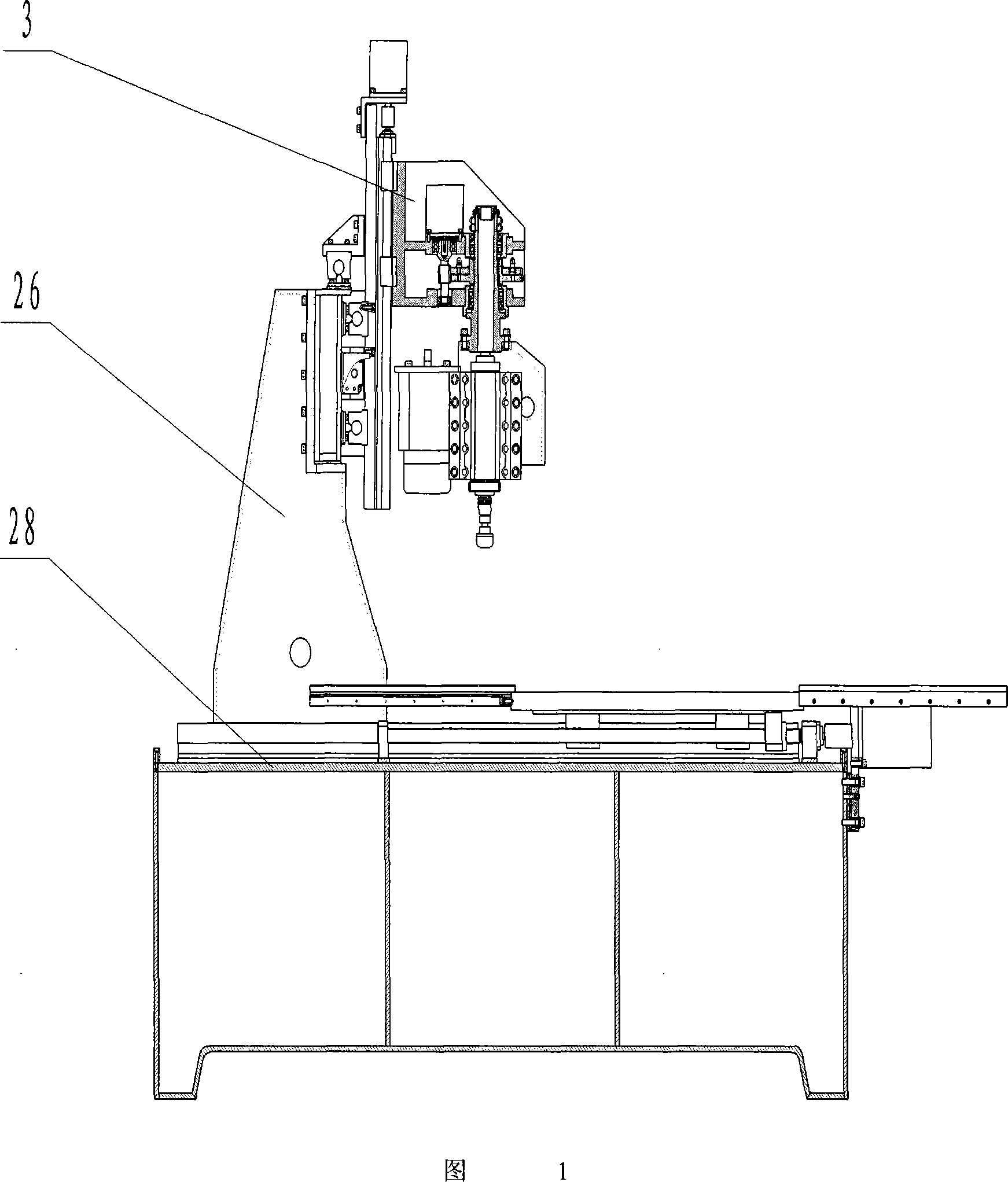

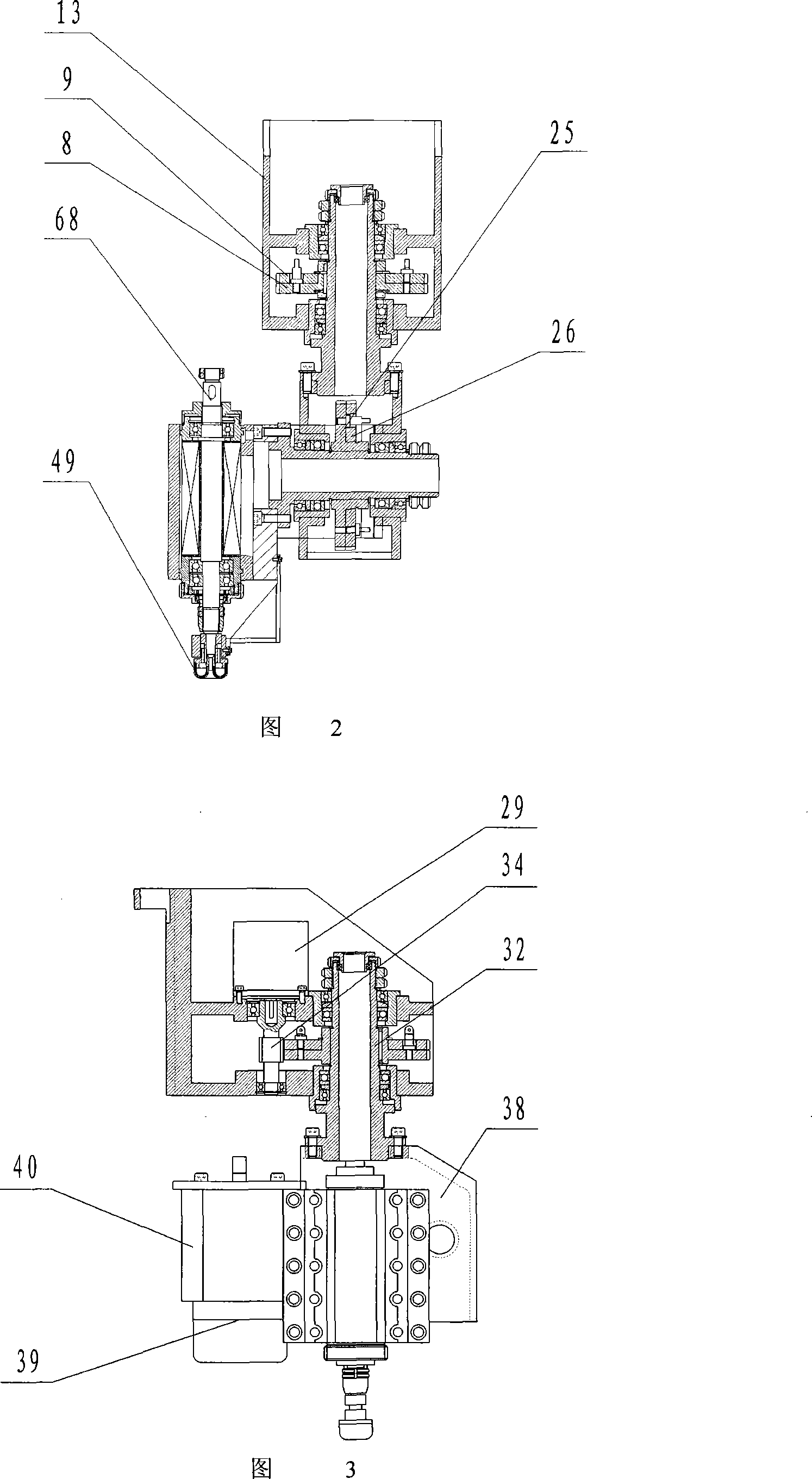

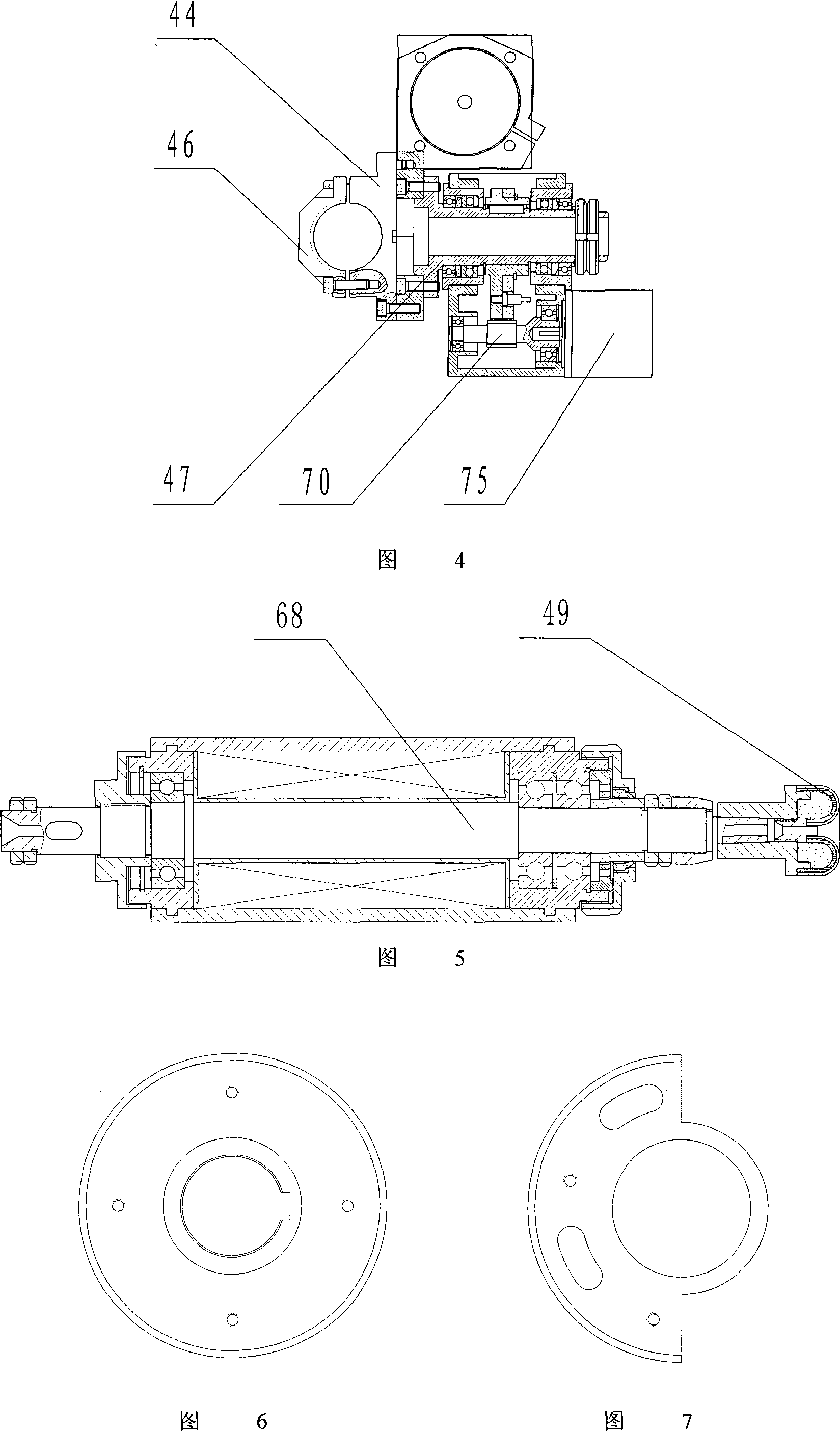

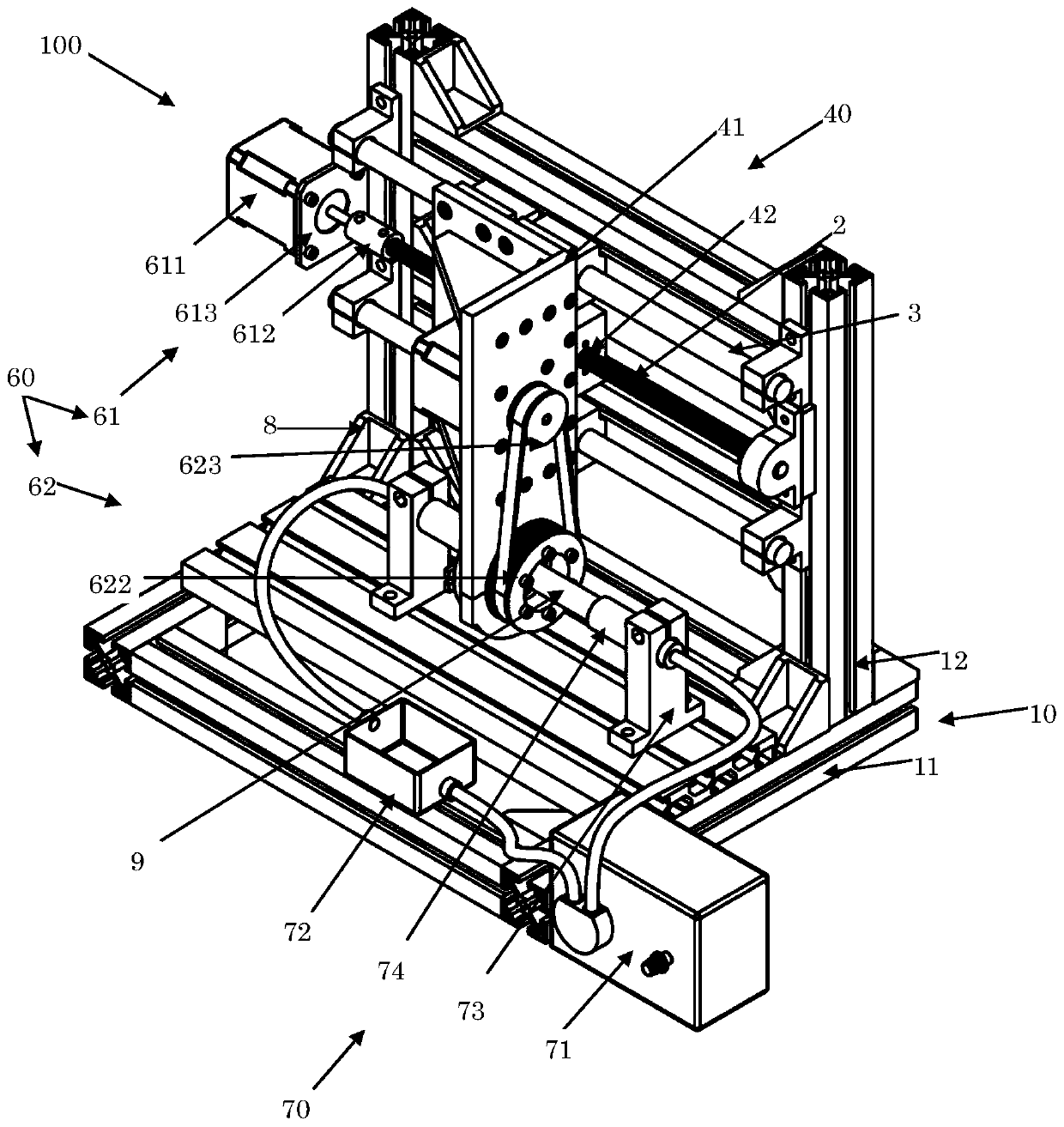

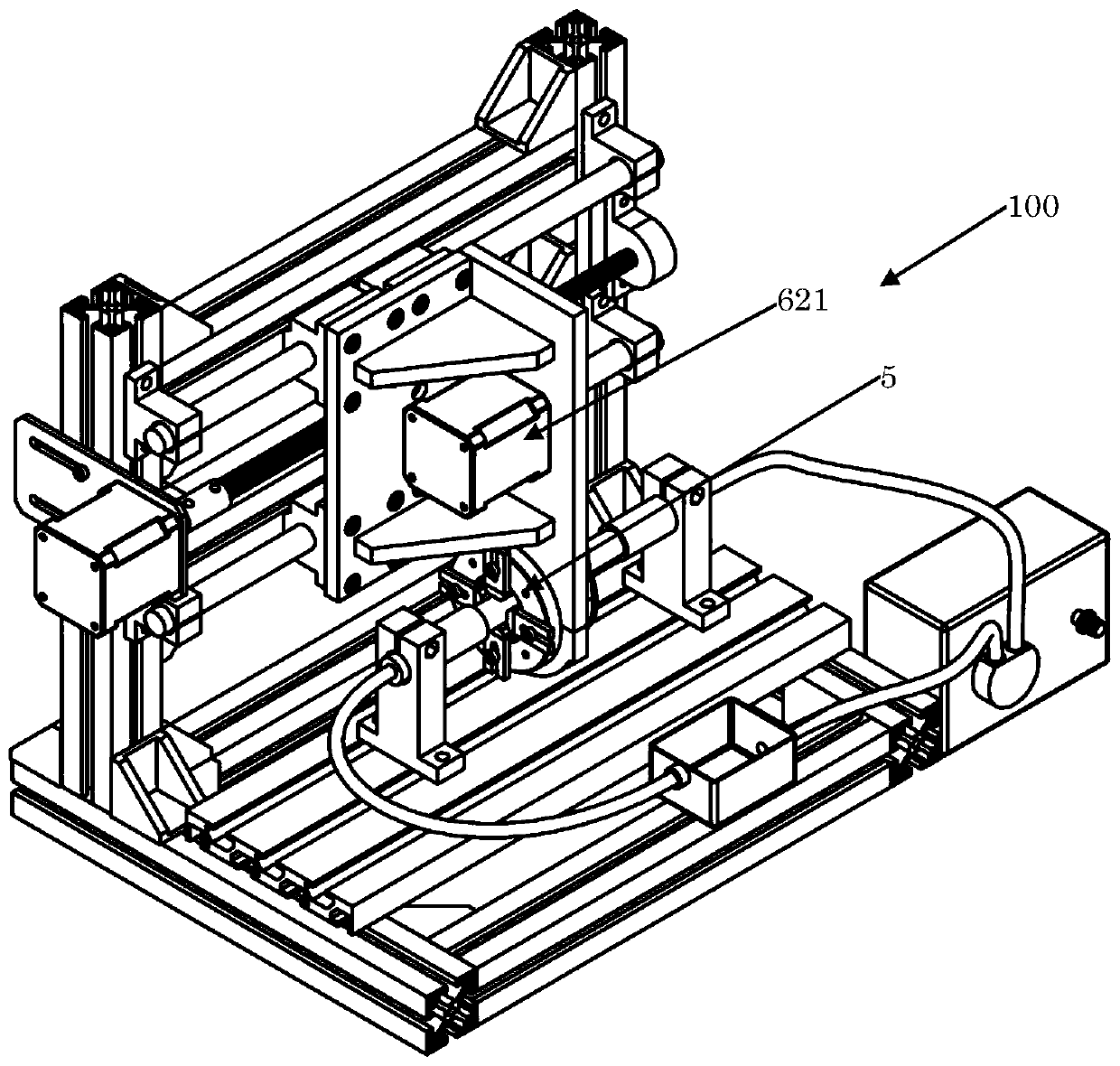

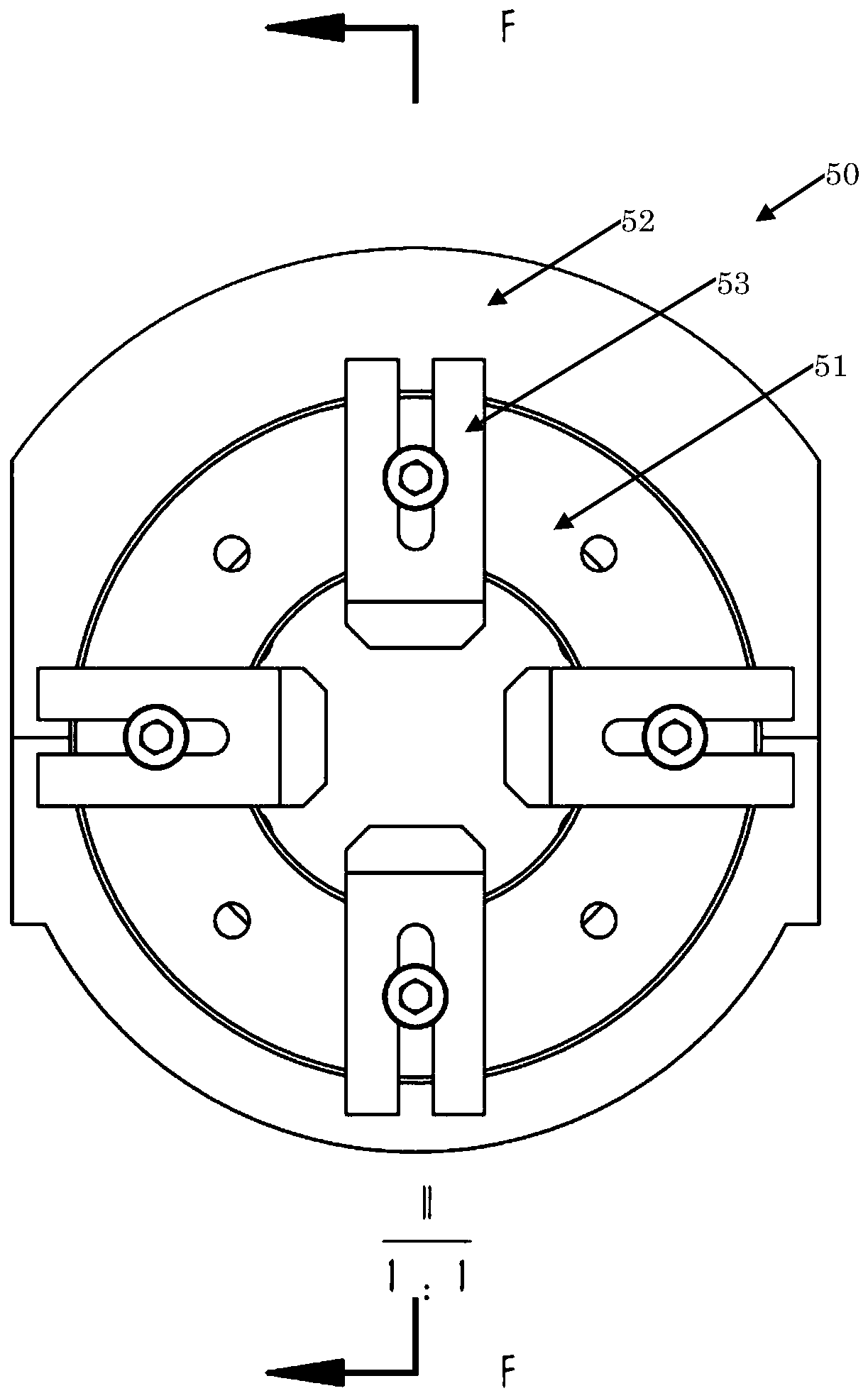

High-precision five-shaft multi-dimensional ultrasonic polishing device

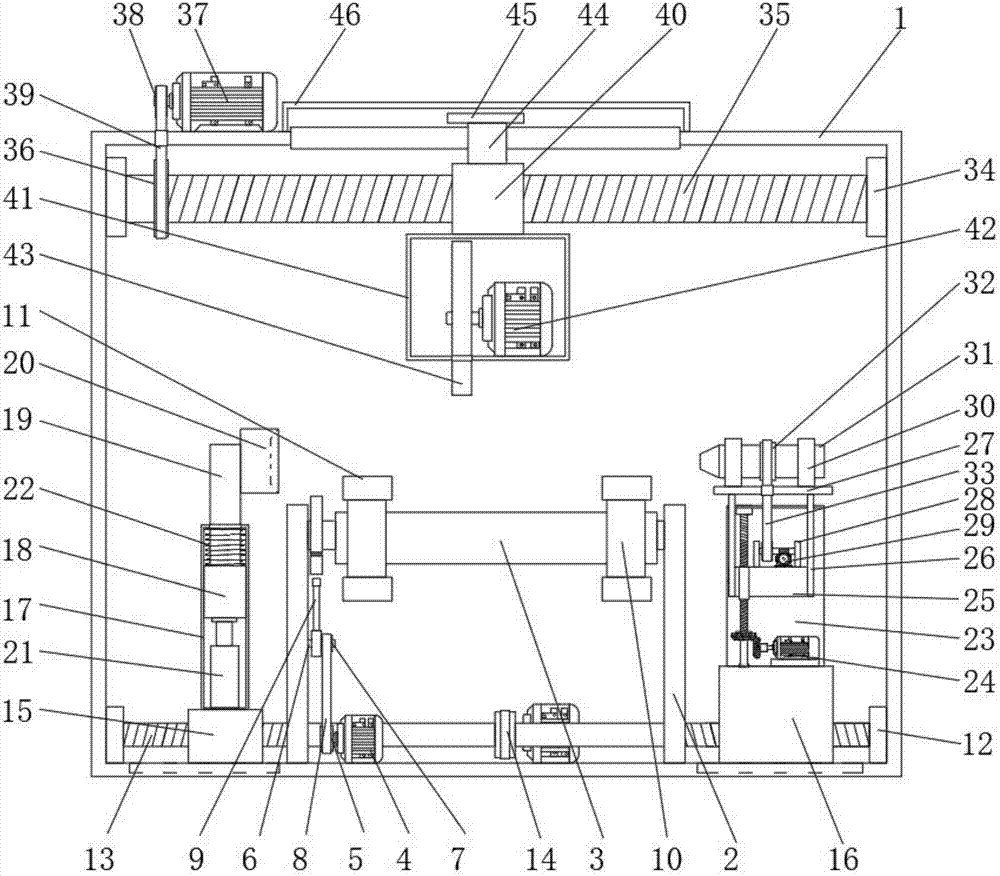

PendingCN107009200AChange processing characteristicsSmooth vibrationGrinding carriagesPolishing machinesRotary stagePolishing

The invention relates to a high-precision five-shaft multi-dimensional ultrasonic polishing device, and belongs to the field of polishing of a complicated curved surface element which has high precision and is difficult to machine. An upright guide rail is arranged at the upper part of an L-shaped base; an upright rotary table capable of moving up and down is arranged on the upright guide rail; a polishing tool head vibrator assembly is arranged on the upright rotary table; a horizontal guide rail I is arranged at the lower part of the L-shaped base; a horizontal guide rail II capable of moving forwards and backwards is arranged on the horizontal guide rail I; a horihzontal rotary tool table capable of moving leftwards and rightwards is arranged on the horizontal guide rail II; the vibration radiation surfaces of ultrasonic vibration exciting assemblies I and II in the horizontal rotary tool table are respectively in contact with two mutually perpendicular side surfaces of a workpiece clamp; one end of a three-degree-of-freedom mechanical arm is connected to the lower part of the L-shaped base in a rotatable manner; and an ultrasonic atomization spraying head is arranged at the other end of the three-degree-of-freedom mechanical arm. The device comprises multiple guide rails and the rotary table, thus providing five degrees of freedom, and can realize polishing of a complicated curved surface to complete machining of a complicated part which is difficult to machine with an existing machine tool.

Owner:NORTHEASTERN UNIV LIAONING

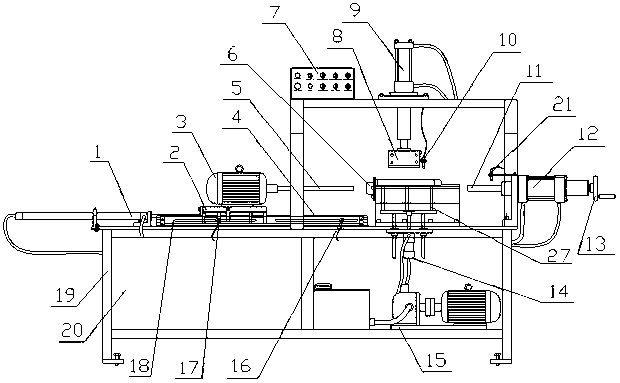

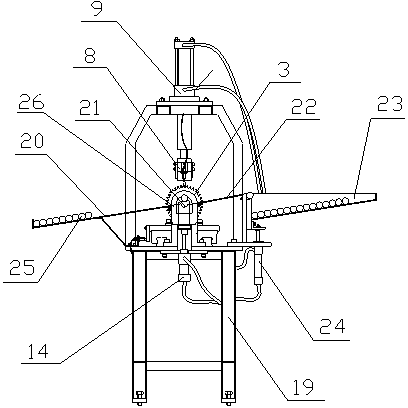

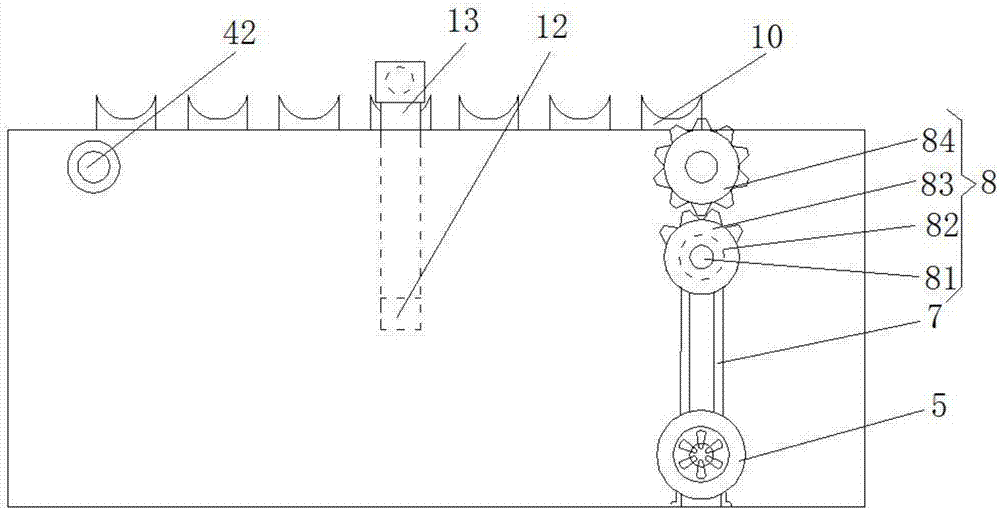

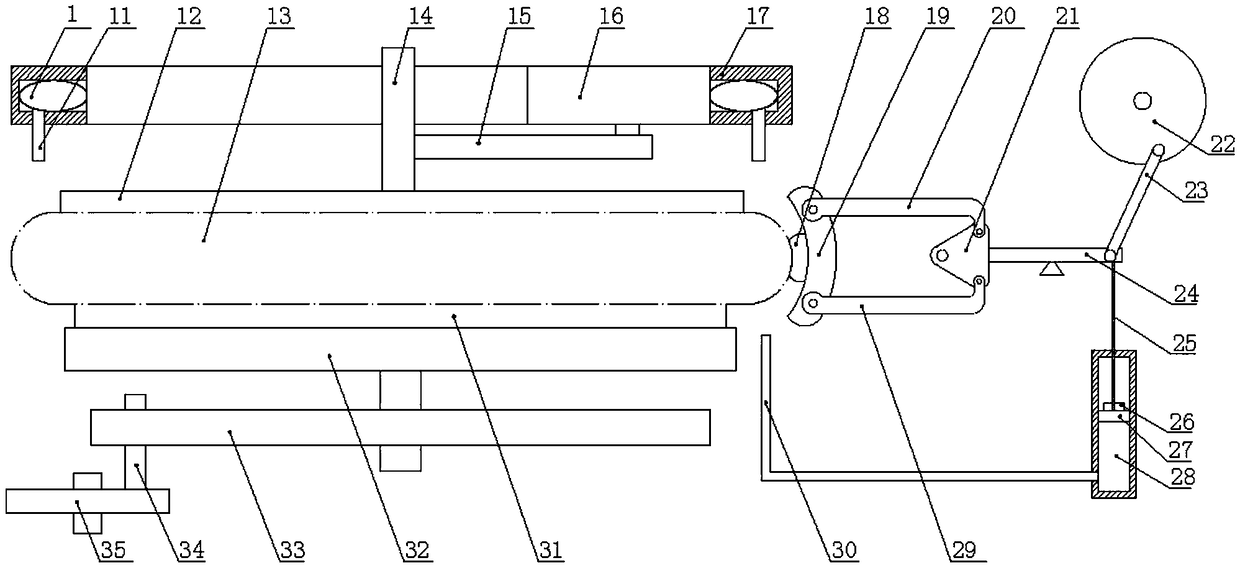

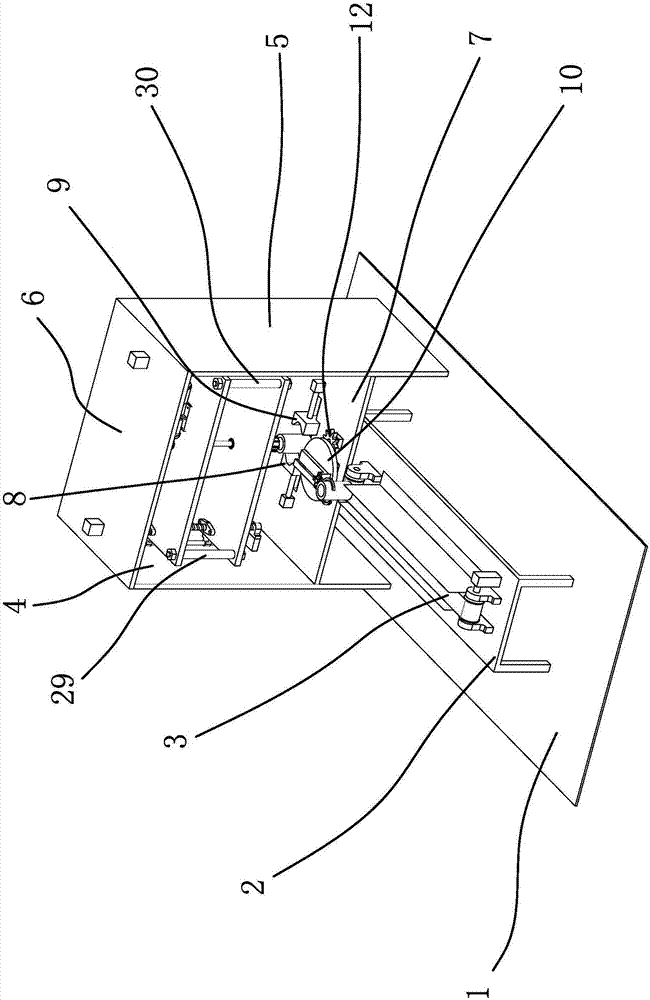

Automatic continuous inner hole polishing machine for steel tubes

InactiveCN103009225ARealize automatic feedingRealize dischargePolishing machinesSheet steelEngineering

The invention discloses an automatic continuous inner hole polishing machine for steel tubes. The automatic continuous inner hole polishing machine comprises a frame and a workbench arranged on the upper part of the frame, wherein an electric control device and a hydraulic device are arranged inside the frame; a fixing device, a sample conveying device and a polishing device are arranged on the workbench; the fixing device comprises an upper pressing die and a lower pressing die; a pressing oil cylinder is arranged above the upper pressing die; the sample conveying device comprises a feeding disk, a receiving disk and a connecting plate which is positioned between the feeding disk and the receiving disk; the polishing device comprises a polishing motor and a polishing shaft which is arranged at the front end of the polishing motor; the upper pressing die and the lower pressing die are positioned on the upper side and the lower side of the connecting plate respectively; the polishing motor is positioned in front of the connecting plate; the connecting plate is a steel plate with a certain inclination angle; and one end, which is close to the feeding disk, of the connecting plate is higher than the end, which is close to the receiving disk, of the connecting plate. The sample conveying device specific to the shapes of steel tubes is arranged, so that automatic feeding and discharging of steel tubes, and polishing of the inner walls of steel tubes under the condition of not turning round are realized.

Owner:QINGDAO ZHANGSHI MACHINERY

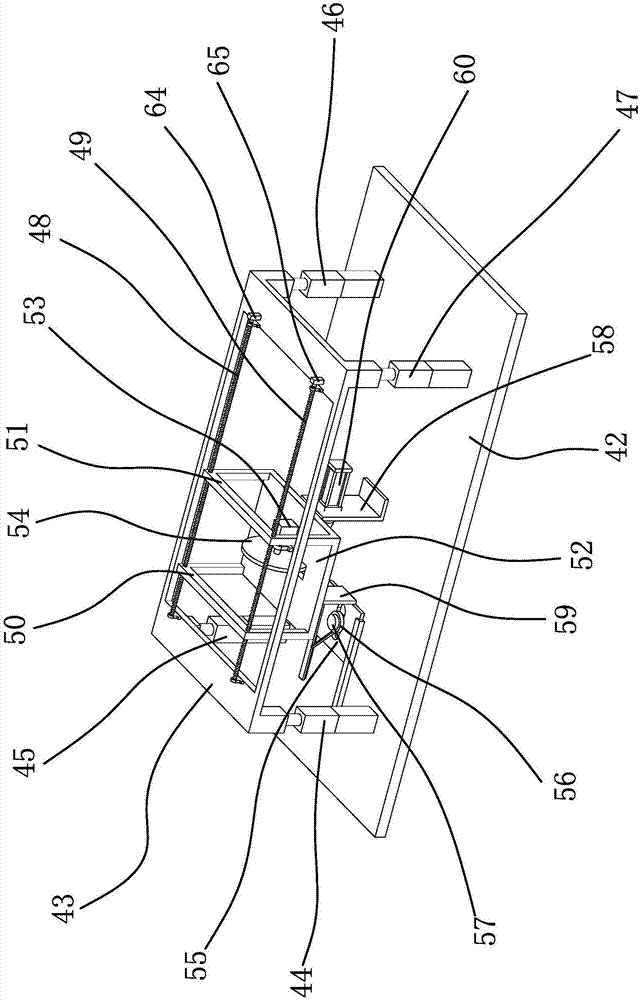

Complicated structure polishing method and device

ActiveCN111716157AAchieve polishPolished evenlyEdge grinding machinesPolishing machinesVertical vibrationChemical reaction

The invention provides a complicated structure polishing method and device and belongs to the field of precise / ultra-precise processing. The method and device are realized based on shear thickening and chemical compound effect. The device comprises a polishing system, a polishing solution circulation device, a horizontal vibration device and a vertical vibration device. The method comprises the steps that, a polishing solution with shear thickening effect is prepared, chemical substance in the polishing solution is used for realizing rapid oxidation of the surface of a workpiece and generatingan easy-to-remove chemical reaction layer; the condition that the polishing solution can generate a shear thickening phenomenon is guaranteed in a manner of coupling of workpiece vibration and polishing solution rotation, and the chemical reaction layer is removed through micro cutting effect of a particle cluster; and a fresh surface is further subjected to chemical reaction and a chemical reaction layer is further removed. Through the shear thickening and chemical compound effect, the polishing efficiency can be greatly improved, and an ultra-smooth and little / zero-damage polished surface can be obtained. The method and device can be used for solving the problems that special positions of a complicated structure are difficult to polish, polishing evenness is poor, polishing efficiency is low, and a polished surface is of low quality.

Owner:DALIAN UNIV OF TECH

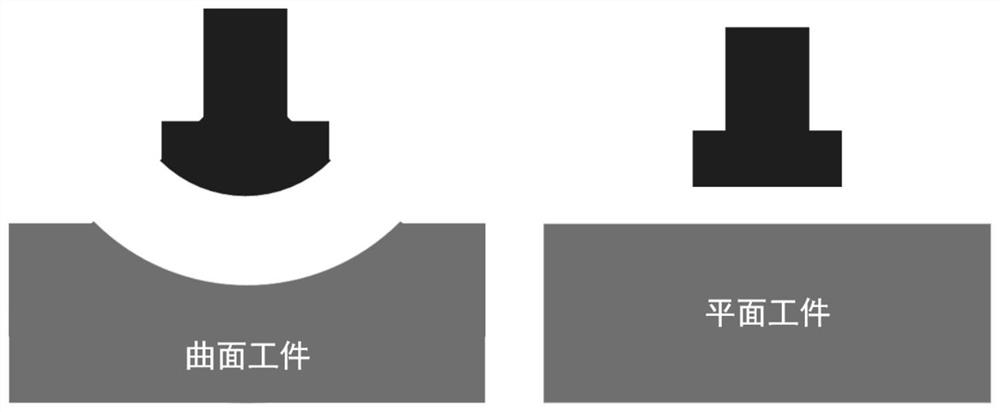

Arc-shaped panel polishing device for machining of electromechanical equipment

ActiveCN110919520AAchieve polishAchieve supportGrinding carriagesPolishing machinesPolishingMachining

The invention discloses an arc-shaped panel polishing device for machining of electromechanical equipment. The arc-shaped panel polishing device comprises a workbench and is characterized in that electric sliding rails are correspondingly connected with the four corners of the outer wall of the top of the workbench through bolts, a sliding block is slidably connected with the inner wall of each electric sliding rail, a standing column is welded to the outer wall of the top of each sliding block, a top plate is arranged on the outer wall of the top of each standing column, a sliding hole is formed in the outer wall of the top of the top plate, a sliding rod is slidably connected with the inner wall of the sliding hole, a fixing frame is welded to the outer wall of the bottom of the slidingrod, an electric motor is connected with the outer wall of one side of the fixing frame through bolts, and a polishing roller is arranged at one end of the output end of the electric motor. Accordingto the arc-shaped panel polishing device, polishing on different arc-shaped panels can be effectively achieved, the use is more flexible, the supporting function for the arc-shaped panels with different radian is effectively achieved, the use effect is better, the panel cannot shake and drop during polishing accordingly, and the polishing effect is better.

Owner:佛山市和为自动化科技有限公司

Diamond film polishing method

The invention relates to a polishing method of a diamond membrane. The polishing method of the diamond membrane is characterized in that the invention includes the steps that 1) at first a pure metal or alloy which can form strong carbide with the carbon is plated on the surface of the diamond membrane; 2) the heating is carried out in a vacuum furnace with the vacuum ranging from 10-1 Pa to 10-4 Pa, heating temperature more than 800 DEG C, and the time ranging from 5 minutes to 30 minutes, and the carbide layer is formed on the surface with the thickness ranging from 0.05 microns to 0.5 microns; 3) the SiC or Al2O3 with the hardness lower than that of the diamond is adopted as the grinding material on the mechanical polishing machine, and the diamond membrane obtained from step 2) is polished with the time ranging from 5 min to 30 min; 4) the diamond membrane after polished by the mechanism is cleaned by the acetone solvent ultrasonic, dried and disposed for 3 min through 10 min by adopting the oxygen plasma; after that, the diamond membrane is cleaned by the acetone solvent ultrasonic; 5) the step 1) through step 4) are repeated form 1 time through 30 times. The invention has the advantages of perfect coarseness and smoothness, low polishing cost and high polishing efficiency.

Owner:WUHAN INSTITUTE OF TECHNOLOGY

Grinding wheel head driving mechanism for mold freedom curved surface flexible polishing machine

InactiveCN101214630AReduce gear mesh backlashSmooth transmissionPolishing machinesGrinding drivesFree formRotation control

A grinding head driving mechanism of the flexible polishing machine of the free-form curved surface of a mould comprises a rotating support, a rotation control motor, a rotating gear shaft, a rotation driving gear and a rotating shaft firmly connected with a grinding head, wherein, the rotation control motor is mounted on the rotating support, the output shaft of the rotation control motor is jointed with the rotating gear shaft, which is engaged with the rotation driving gear firmly nested on the rotating shaft, the rotating shaft is mounted on the rotating support via a bearing, and the grinding head driving mechanism also includes a grinding head swinging mechanism. The present invention provides the grinding head driving mechanism of the flexible polishing machine of the free-form curved surface of the mould, which has the functions of the rotation and swing of the grinding head and high polishing efficiency.

Owner:ZHEJIANG UNIV OF TECH

Polishing and dyeing one-bath process for fabric

The invention discloses a polishing and dyeing one-bath process for a fabric. The method comprises the following specific steps of: 1, boiling and bleaching: boiling and bleaching grey cloth; 2, discharging water and introducing water: discharging primary boiled and bleached bath foam, and introducing secondary bath foam; and 3, polishing and dyeing: keeping the temperature of the secondary bath foam at 52-58 DEG C, and adjusting the PH value of the secondary bath foam to 6-8; adding a one-bath enzyme fur eliminating agent into the secondary bath foam; adding a dye stuff, dissolving for 18-22minutes, and running for 5-8 minutes; adding anhydrous sodium sulphate, dissolving for 22-28 minutes, and running for 5-8 minutes; adding alkali, and adjusting the PH value of the secondary bath foam to 11+ / -0.5; and heating the secondary bath foam to 60 DEG C, and preserving heat for 20-30 minutes. Due to the adoption of the polishing and dyeing one-bath process, polishing and dyeing one-bath can be realized, the entire process can be finished by only adding water twice, and energy and cost are saved.

Owner:JIANGSU JINCHENZHEN TEXTILE

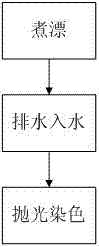

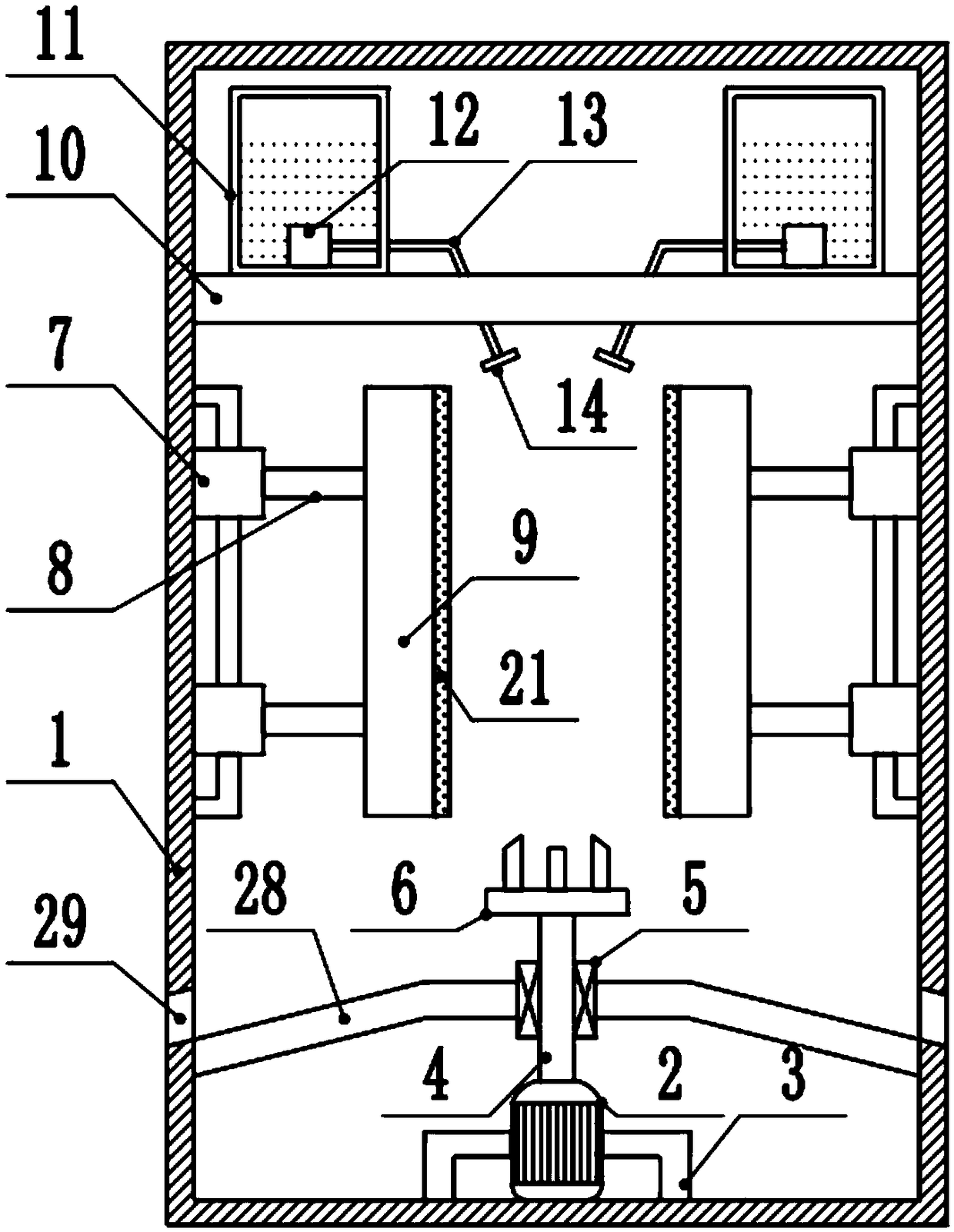

Novel material metal pipe outer surface polishing device for engineering

InactiveCN109015277AImprove polishing efficiencyPracticalPolishing machinesGrinding drivesElectric machineryEngineering

The invention discloses a novel material metal pipe outer surface polishing device for engineering. The novel material metal pipe outer surface polishing device for engineering comprises a polishing box, wherein a fixed rod is fixedly connected to the positions, in a box body, on the left side and the right side of the lower part of the inner part of the polishing box; a bearing is arranged in theinner part of the middle of the fixed rod; a rotary rod is connected to the inner part of the middle of the vertical direction of the bearing; a fixed seat is fixedly connected to the upper end of the rotary rod; a motor is connected to the lower end of the rotary rod; telescopic motors are arranged in the middle parts of the box body on the left side and the right side of the inner part of the polishing box and are fixed through a fixed frame; telescopic rods are connected to the other ends of the telescopic motors; and fixed blocks are fixedly connected to the other ends of the telescopic rods. According to the novel material metal pipe outer surface polishing device for engineering provided by the invention, the polishing efficiency of metal pipes is improved; and according to the sizes of the metal pipes, the telescopic motors control the telescopic rods to lift up and lower down so as to adjust the distance between the surface of a polishing piece and a metal pipe, so that the metal pipes with different sizes are further polished, and the practicability is high.

Owner:苏州荔记得机械工程科技有限公司

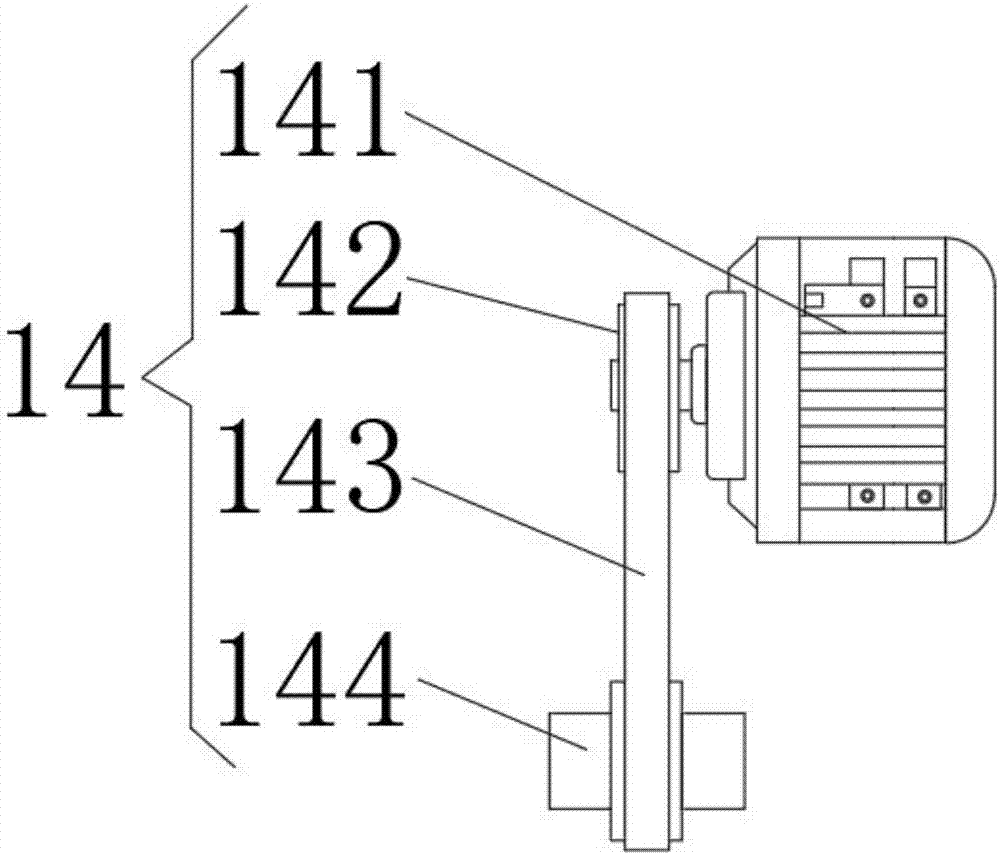

Polishing machine used for machining automobile crankshaft

ActiveCN107336121AFeed realizationRealize automatic feedingPolishing machinesGrinding drivesCouplingControl engineering

The invention discloses a polishing machine used for machining an automobile crankshaft and relates to the field of machining of automobile parts. The polishing machine comprises a box. A first motor is fixedly connected to the bottom of the inner wall of the box. A first belt wheel is fixedly connected to one end of an output shaft of the first motor. The surface of the first belt wheel is in transmission connection with a feeding device through a first belt. A second motor is fixedly connected to the bottom of the inner wall of the box. A first lead screw is fixedly connected to the output shaft end of the second motor through a first coupling. A sliding table is slidably connected to the bottom of the inner wall of the box and located on the right side of a third vertical plate. A supporting rod is fixedly connected between the two sides of the inner wall of the sliding table. The first lead screw is connected with the supporting rod in an engaged mode. A third motor is fixedly connected to the top of the sliding table. A lifting device is fixedly connected to the output end of the third motor. By adoption of the polishing machine for machining the automobile crankshaft, the problems that traditional crankshaft polishing equipment is complex in structure, and manual clamping is needed are solved, cost is reduced, labor is saved, and production efficiency is improved.

Owner:湖州五左机械有限公司

Polishing device for furniture plate

PendingCN108705438AAchieve polishImprove processing efficiencyEdge grinding machinesGrinding carriagesEngineeringFurniture manufacturing

The invention relates to the technical field of furniture manufacturing, in particular to a polishing device for furniture plates. The polishing device comprises a processing table. A sucker is arranged on the processing table. A grooved wheel is rotationally connected to the lower portion of the processing table. A rotating wheel is rotationally arranged at one side of the grooved wheel. A roundpin is arranged on the rotating wheel. The round pin is intermittently and slidably connected with a groove of the grooved wheel. A turntable is rotationally arranged at one side of the processing table. An upper connecting rod and a lower connecting rod are correspondingly arranged at the upper part and the lower part of the turntable. Both the upper connecting rod and the lower connecting rod are hinged with the turntable. An arc-shaped polishing plate is arranged at one side of the turntable. A polishing wheel is arranged on the polishing plate. The free end of the upper connecting rod andthe free end of the lower connecting rod are correspondingly hinged with the two ends of the polishing plate. A driving mechanism is arranged on the other side of the turntable. The driving mechanismis connected with the turntable. The polishing device solves the problems of troublesome operation and low efficiency of edge polishing of circular plates in the prior art.

Owner:四川三虎家居有限公司重庆分公司

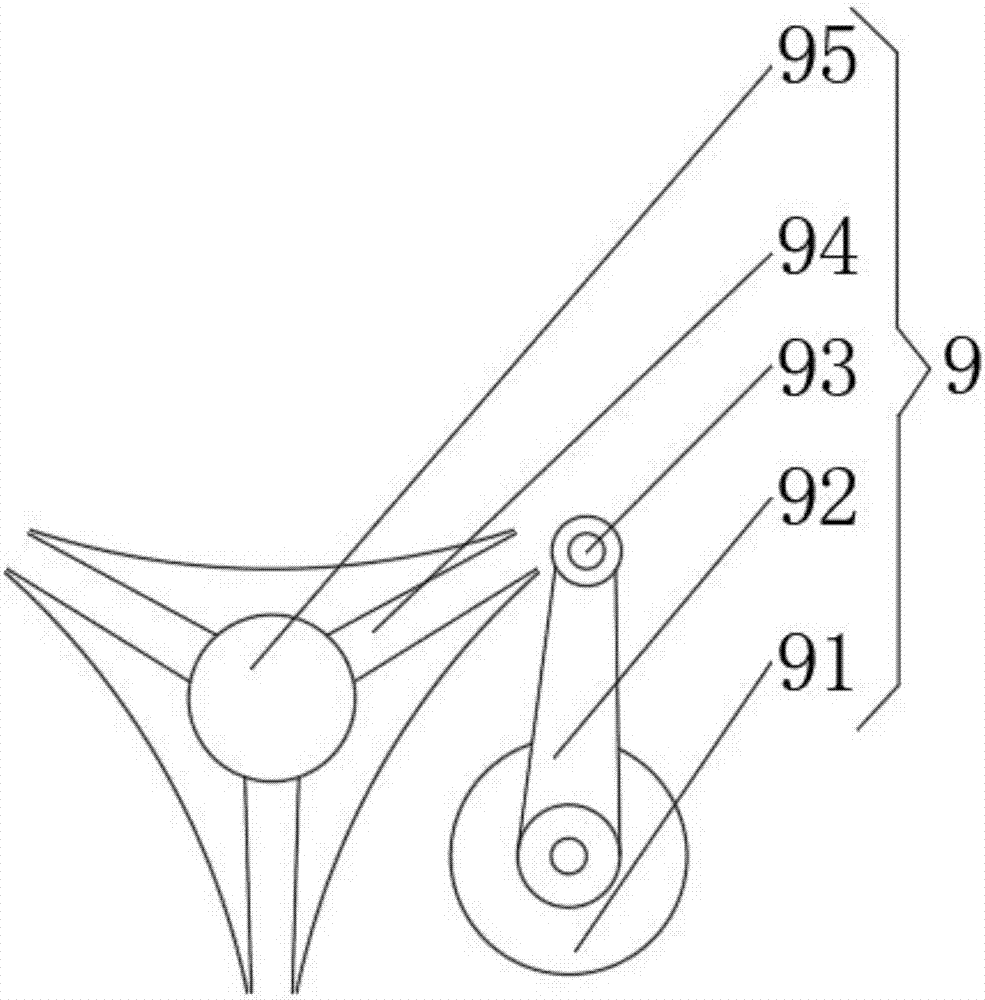

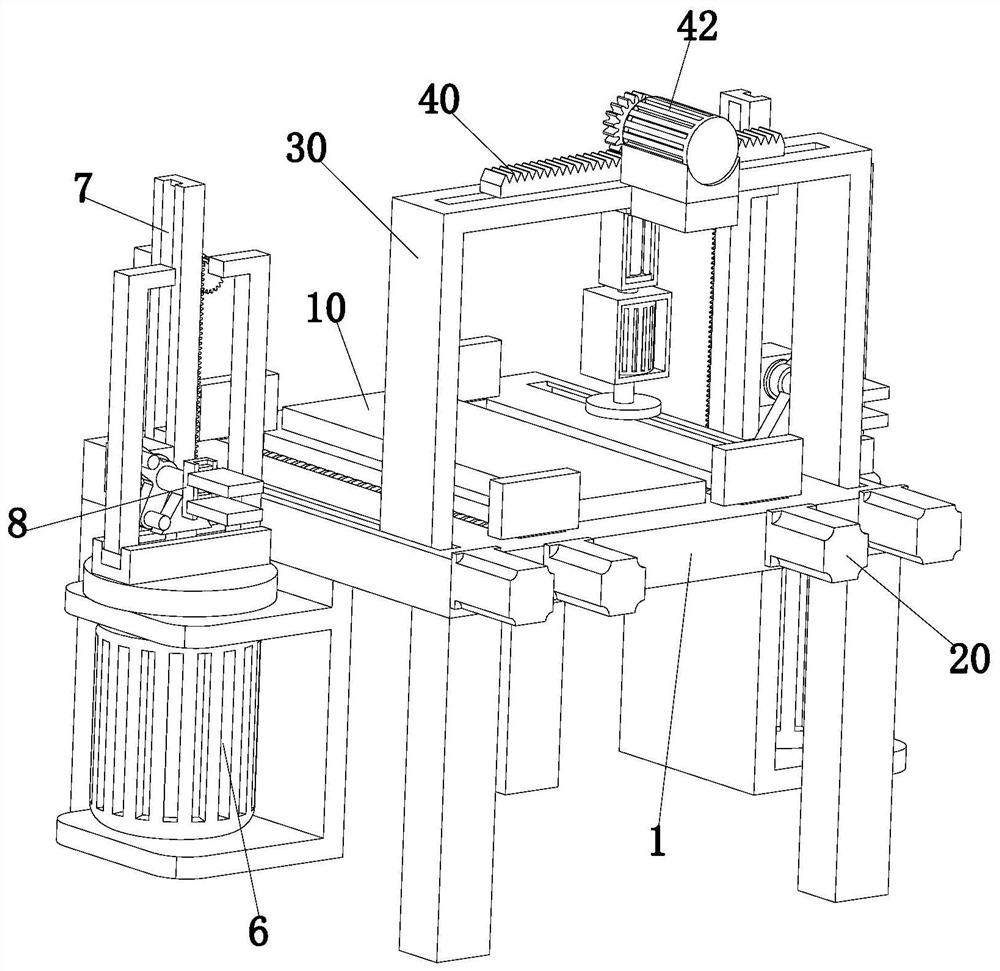

Polishing machining equipment for gear shaft in automobile transmission

ActiveCN107953235ARealize automatic feedingIncrease productivityPolishing machinesGrinding feedersEngineeringAutomotive transmission

The invention discloses polishing machining equipment for a gear shaft in an automobile transmission and relates to the technical field of manufacturing of automobile parts. The polishing machining equipment for the gear shaft in the automobile transmission comprises a box body. A pair of vertical plates are fixedly connected with the bottom of the inner wall of the box body. A pair of transmission roller wheels are rotationally connected between two opposite sides of the vertical plates. A first screw rod is rotationally connected with the two opposite sides of the inner wall of the box bodythrough first bases. The middle of the first screw rod is in transmission connection with a transmission device. The surface of the first screw rod is sequentially connected with a first sliding seatand a second sliding seat in a threaded mode. The top of a sliding rod is fixedly connected with a shaft seat. The top between the two opposite sides of the inner wall of the box body is rotationallyconnected with a second screw rod through second bases. The surface of the second screw rod is fixedly connected with a third motor through a moving block, and an output shaft end of the third motor is fixedly connected with a polishing piece. According to the polishing machining equipment for the gear shaft in the automobile transmission, the problem of complex structure of a traditional polishing machine is solved, automatic clamping is realized at the same time, and production efficiency is improved.

Owner:TIANCHANG TIANXIANG GRP

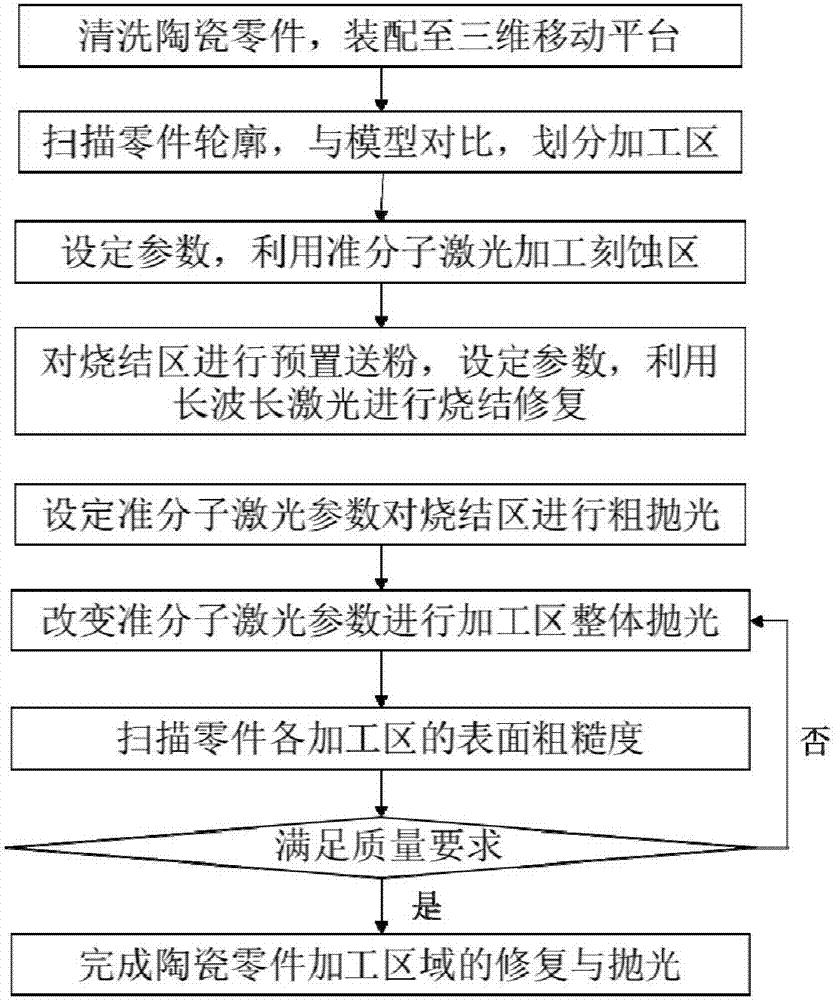

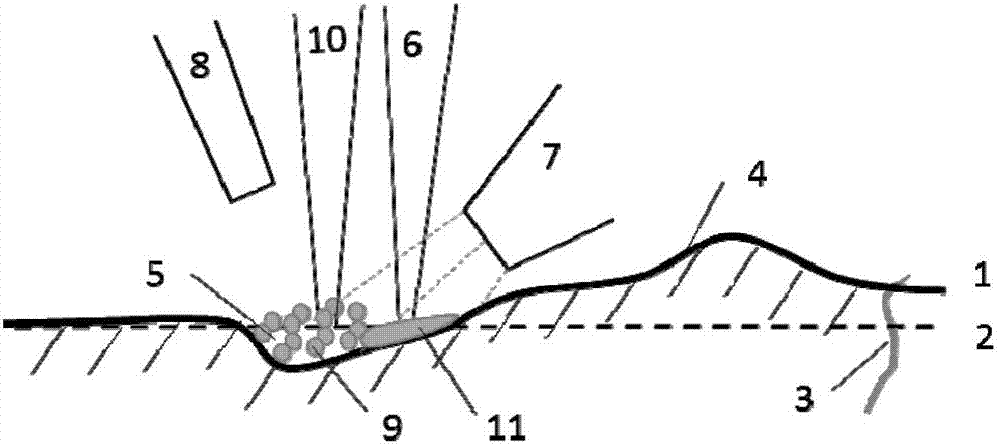

Method for repairing and polishing ceramic part through laser

ActiveCN107378276ARealize modelingAchieve fixWelding/soldering/cutting articlesLaser beam welding apparatusMetallurgySurface roughness

The invention discloses a method for repairing and polishing ceramic parts through laser. The method comprises the steps of S1, cleaning the ceramic part, and assembling the ceramic part to a three-dimensional moving platform; S2, scanning the surface contour of the ceramic part, comparing the scanned contour model with a standard model, and dividing the surface of the ceramic part into an etching region, a polishing region and a sintering region; S3, processing the etching region by using excimer laser equipment; S4, carrying out preset powder feeding on the sintering region, and carrying out sintering repair by using long-wavelength laser; S5, carrying out rough polishing on the sintering region; S6, carrying out overall polishing on the processing area; and S7, scanning the surface roughness of the ceramic part, executing the step S6 if the roughness does not meet the requirement, and completing the excimer laser polishing process if the roughness meets the requirement. The method has the advantages that the controllability is good, the automatic production can be realized conveniently, the precise processing of the micro-area can be realized, any curved surface and any part can be treated, the influence on a ceramic matrix is remarkably reduced, and the precision, the quality and the efficiency of part repairing and polishing are guaranteed.

Owner:RAINBOW SOURCE LASER RSLASER

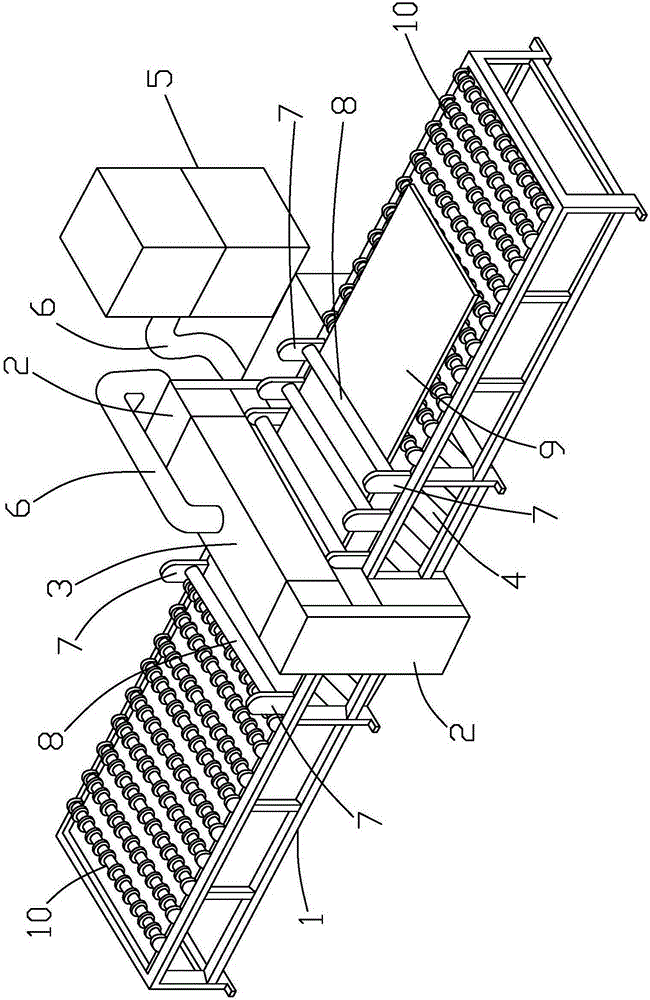

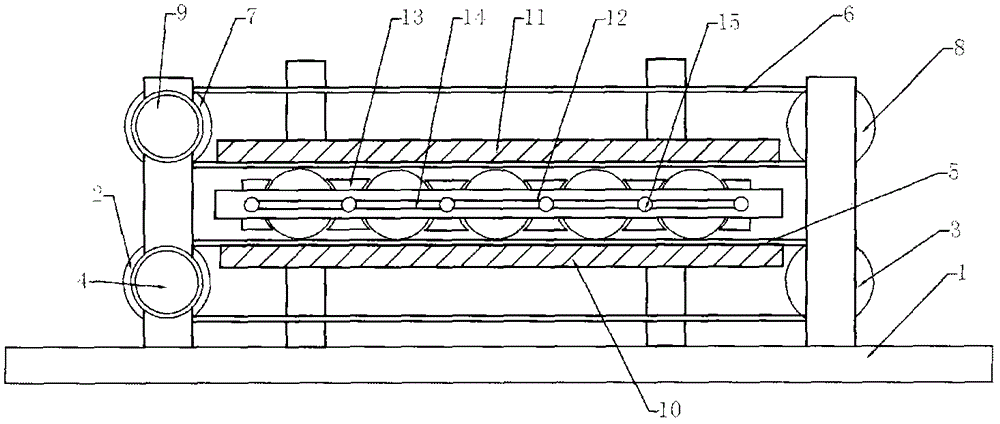

Multi-station bar polishing tool

InactiveCN105881158ASimple structureAchieve polishBelt grinding machinesDrive shaftElectric machinery

The invention discloses a multi-station bar polishing tool which comprises a rack. A first driving shaft and a first driven shaft which are parallel to each other are arranged on the rack. The first driving shaft is connected with a first drive motor. The periphery of the first driving shaft and the periphery of the first driven shaft are sleeved with a first sanding belt. A second sanding belt is arranged above the first sanding belt in parallel. The second sanding belt is driven by a second driving shaft and a second driven shaft to move. The second driving shaft is connected with a second driving motor. A fixture used for allowing bars to be embedded therein is arranged between the opposite faces of the first sanding belt and the second sanding belt. The rotating direction of the first driving shaft is opposite to that of the second driving shaft. The multi-station bar polishing tool is simple in structure; the multiple bars are placed in the fixture between the first sanding belt and the second sanding belt so that the multiple bars can be polished at the same time; and compared with operation that a bur is handheld to be clamped between polishing wheels in the prior art, the safety coefficient is high.

Owner:高幸荣

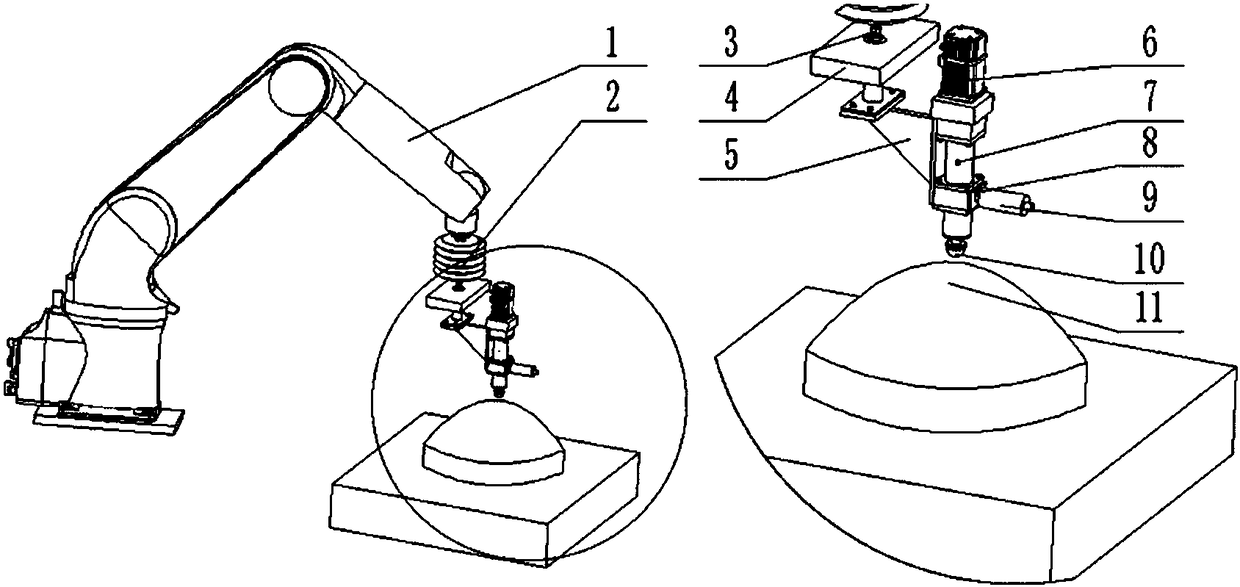

Method for polishing SIC optical freedom curve by Fenton-assisted rigidity-variable pneumatic grinding wheel

InactiveCN108372442AHigh profile precisionNo surfaceGrinding carriagesOptical surface grinding machinesSurface layerFenton reagent

The invention relates to a method for polishing an SIC optical freedom curve by a Fenton-assisted rigidity-variable pneumatic grinding wheel. The method comprises the following steps of firstly, sheathing the non-processing surface of an SIC workpiece with an isolation material; then, completely submerging into a reaction cell with a Fenton reagent, reacting for a period of time, uniformly forminga SiO2 surface layer with equal thickness at the surface of the SIC workpiece, fetching out the SIC workpiece, and fixing the SIC workpiece onto a worktable by a limiting device; uniformly removing the generated SiO2 surface layer after reaction by a floating connecting device; adjusting the location and gesture of a tool system corresponding to the workpiece by a mechanical arm, changing the airpressure of compressed air entering the rigidity-variable pneumatic grinding wheel to adjust the rigidity of the rigidity-variable pneumatic grinding wheel, attaching the rigidity-variable pneumaticgrinding wheel and the SIC workpiece with freedom curve, and finally polishing the SIC workpiece with the freedom curve by the rigidity-variable pneumatic grinding wheel. The method for polishing theSIC optical freedom curve by the Fenton-assisted rigidity-variable pneumatic grinding wheel has the advantages that the efficiency is high, and the cost is low.

Owner:ZHEJIANG UNIV OF TECH

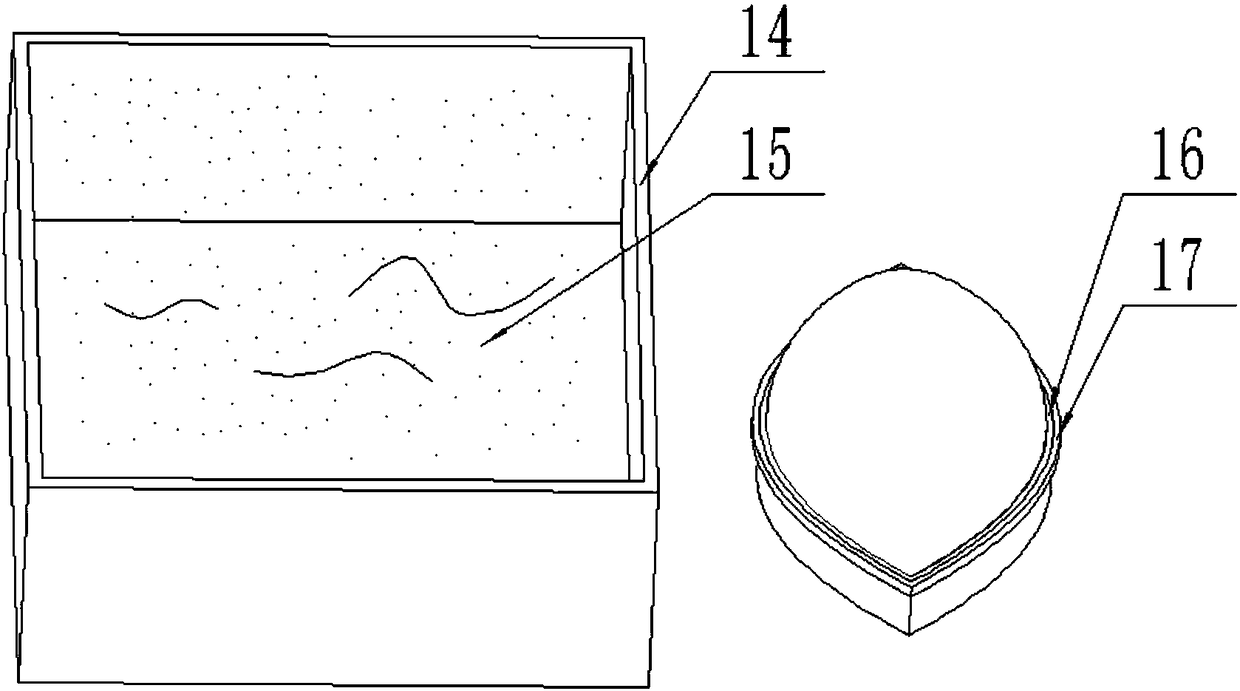

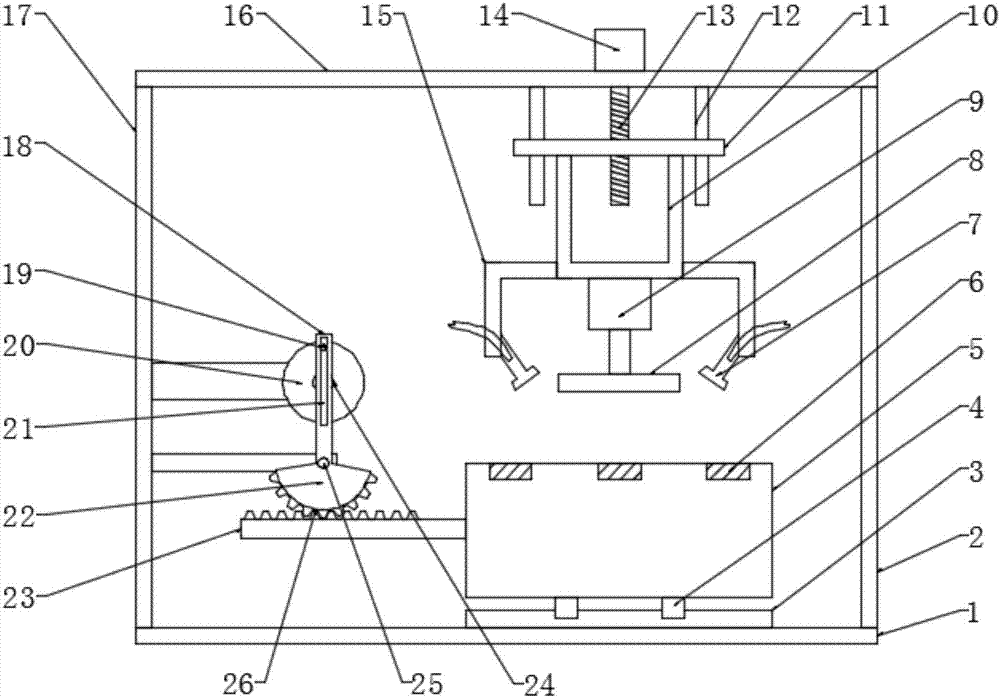

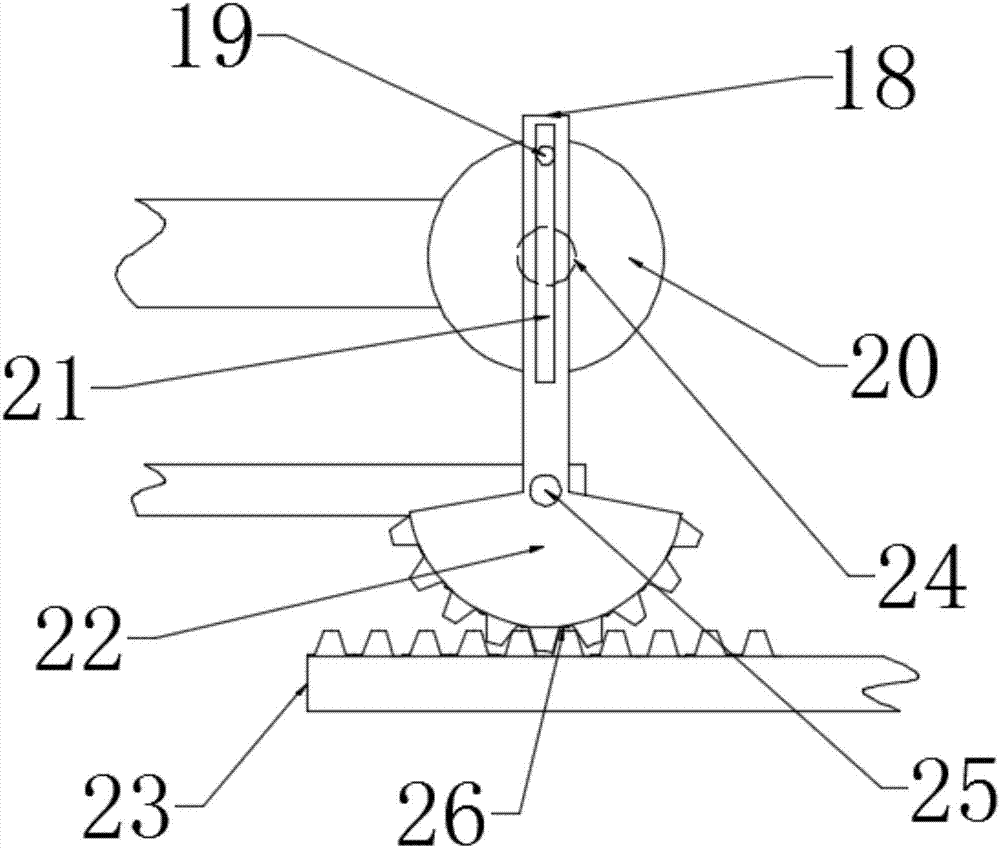

Efficient polishing equipment for metal plate production

InactiveCN107160283AAchieve polishExtrude evenlyPolishing machinesGrinding drivesCircular discElectric machinery

The invention discloses efficient polishing equipment for metal plate production. The efficient polishing equipment comprises a bottom plate, a left side plate, a right side plate, a top plate, a worktable, sliding blocks, a sliding rail, a power mechanism, a second motor, a thread rod, a supporting plate, a U-shaped plate, a third motor, a polishing wheel, a fixed rod and polishing agent extruding nozzles. The power mechanism is arranged and comprises a first motor, a disc, a connecting rod, a fan-shaped gear and a rack, a plate is overall polished through matching of the parts, and polishing efficiency is high; the second motor, the thread rod and the U-shaped plate are arranged, the parts are matched to adapt metal plates with different thicknesses, and the different plates can be polished; and the polishing agent extruding nozzles are arranged, polishing agents are extruded in a uniform speed through the polishing agent extruding nozzles at the time of polishing, the polishing agents are uniformly and sufficiently extruded while the working efficiency is improved, and the polishing effect is good.

Owner:FOSHAN ZHENGLUE INFORMATION TECH CO LTD

Magnetic composite fluid polishing device for inner wall of small thin pipe

InactiveCN110281083AMagnetic field stabilizationAchieve polishEdge grinding machinesGrinding carriagesMagnetEngineering

The invention provides a magnetic composite fluid polishing device for the inner wall of a small thin pipe, and belongs to the field of polishing devices. The magnetic composite fluid polishing device for the inner wall of the small thin pipe comprises a support, a lead screw, polished rods, a polishing head support, a magnetic unit, a drive portion and a polishing portion. The polishing portion comprises a conveying pump, a magnetic composite fluid container and a workpiece seat. The output end of the conveying pump is connected to the magnetic composite fluid input end of a workpiece through a pipeline, the magnetic composite fluid output end of the workpiece communicates with the magnetic composite fluid container through a pipeline, the input end of the conveying pump is connected to the magnetic composite fluid container, and a complete loop is formed. In the device, a permanent magnet in the magnetic unit can rotate and can move left and right relative to the workpiece, and therefore a stable magnetic field can be generated, then Bingham fluid is formed by magnetofluid under the action of the magnetic field, shearing force is generated by the Bingham fluid, and the inner wall in an irregular shape of the workpiece is polished.

Owner:UNIV OF SHANGHAI FOR SCI & TECH

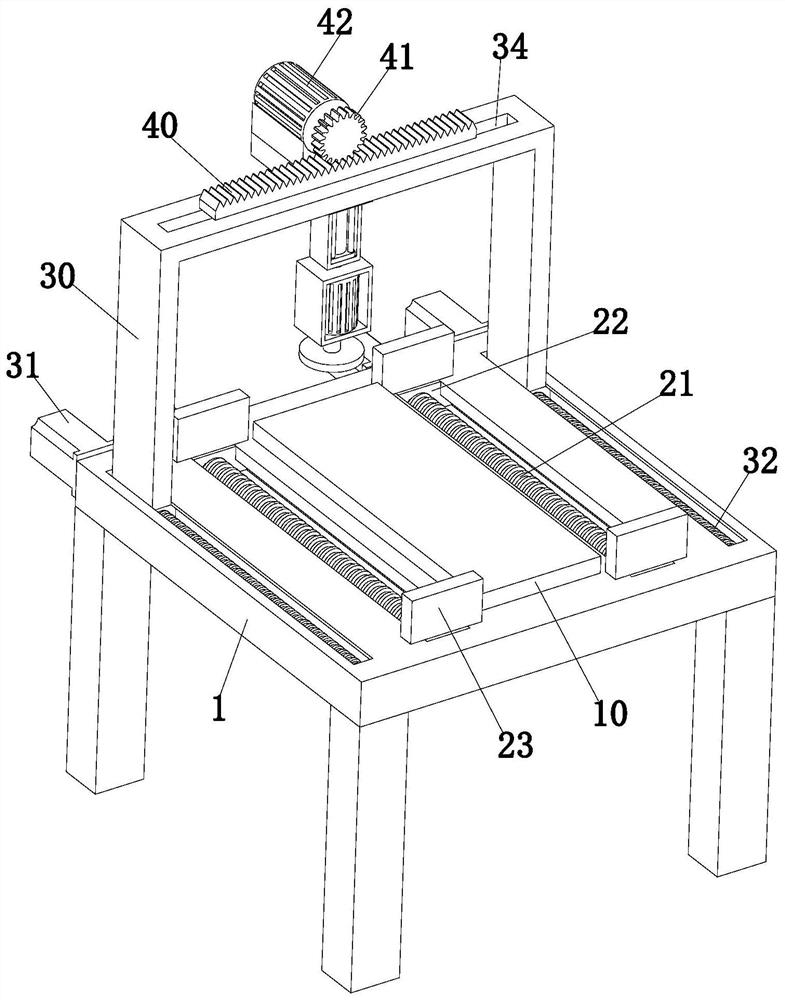

Aluminum alloy door and window machining deburring device

InactiveCN112440179AImprove polishing effectEasy to install laterEdge grinding machinesGrinding carriagesStructural engineeringManufacturing engineering

The invention relates to the technical field of aluminum alloy door and window machining, and particularly relates to an aluminum alloy door and window machining deburring device. The aluminum alloy door and window machining deburring device comprises a machining table, clamping devices, a moving device, a polishing device and overturning devices, wherein a cushion plate is arranged on the machining table; the machining table is provided with a rectangular groove and a sliding groove which are symmetric; the clamping devices are symmetrically arranged on the machining table; the moving deviceis arranged beside the clamping devices; the polishing device is arranged on the moving device; the two overturning devices are arranged; and each overturning device comprises a rotation component, alifting component and an overturning component, wherein the rotation component is arranged beside the machining table, the lifting component is arranged on the rotation component, and the overturningcomponent is arranged on the lifting component. Through the mutual cooperation work of the arranged devices, the double faces of a door and a window can be polished, the polishing effect is improved,subsequent installation is convenient, manual assistance is not needed, the door and the window are automatically overturned, and the polishing efficiency is improved.

Owner:安徽黎搏装饰工程有限公司

Dust removal air duct polishing method

PendingCN107414613AAchieve circumferential polishingAchieve clampingEdge grinding machinesRevolution surface grinding machinesPolishingDust control

The invention provides a dust removal air duct polishing method, and belongs to the technical field of machinery. The dust removal air duct polishing method is characterized by comprising the following steps that firstly, a prepared dust removal air duct is clamped to an outer wall polishing machine, a polishing disc is started, the outer wall of the dust removal air duct is polished to remove burrs, and outer wall polishing lasts for 8-12 min; secondly, the dust removal air duct obtained after the outer wall is polished is placed in a conveying device; thirdly, the dust removal air duct is conveyed to a transfer mechanism through a conveying belt on the conveying device and transferred to the position between a first clamping block and a second clamping block through a mechanical arm on the transferring mechanism to be clamped; fourthly, an inner wall polishing machine is started, a polishing brush is rotated, the position relation between the polishing brush and the dust removal air duct is adjusted, the inner wall of the dust removal air duct is polished, and inner wall polishing lasts for 3-5 min; fifthly, inner wall polishing of the dust removal air duct is completed, and the dust removal air duct is conveyed out. The method has the advantage of being capable of polishing the dust removal air duct more conveniently.

Owner:ZHEJIANG JIEYU ENVIRONMENTAL PROTECTION EQUIPCO

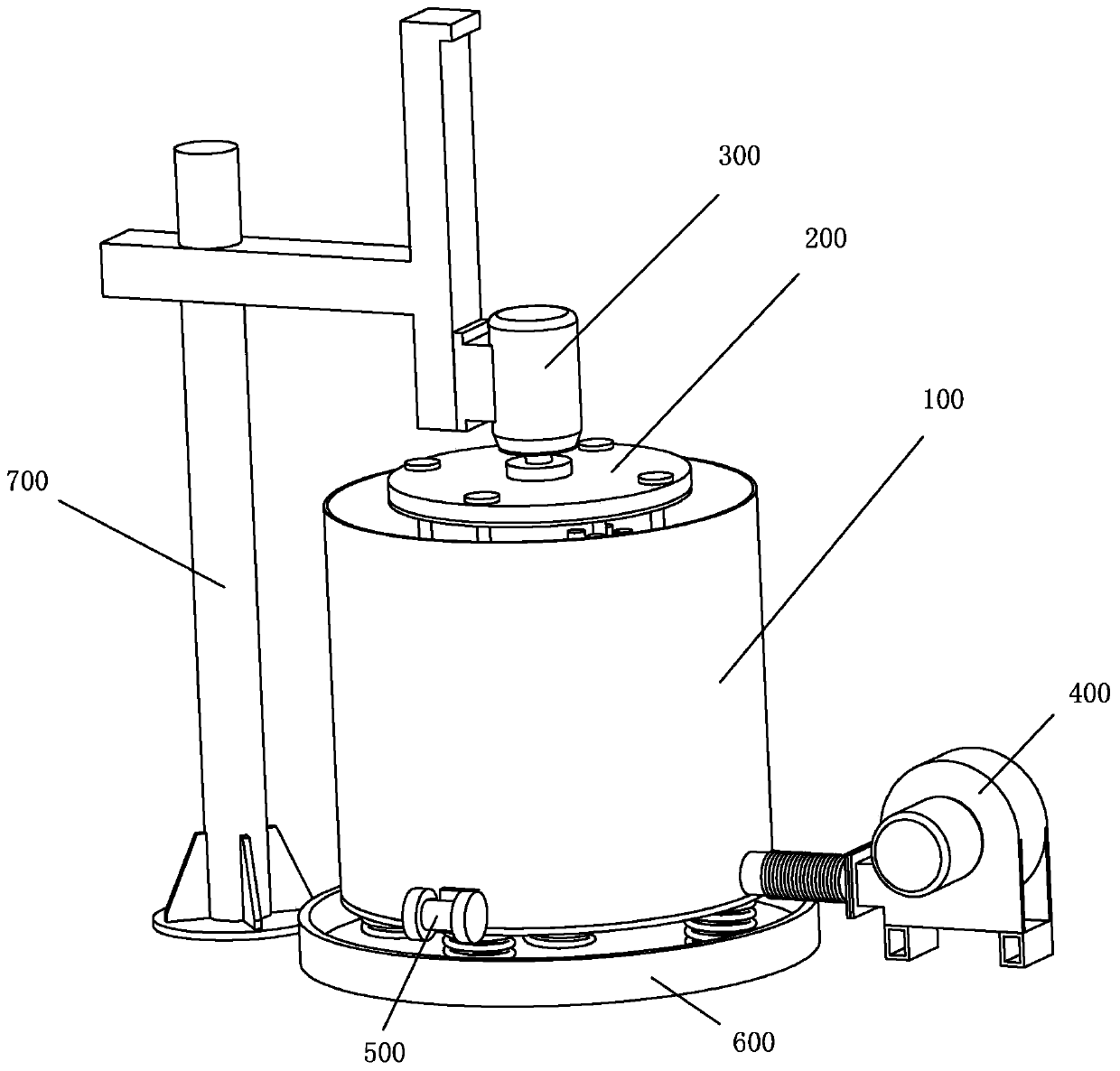

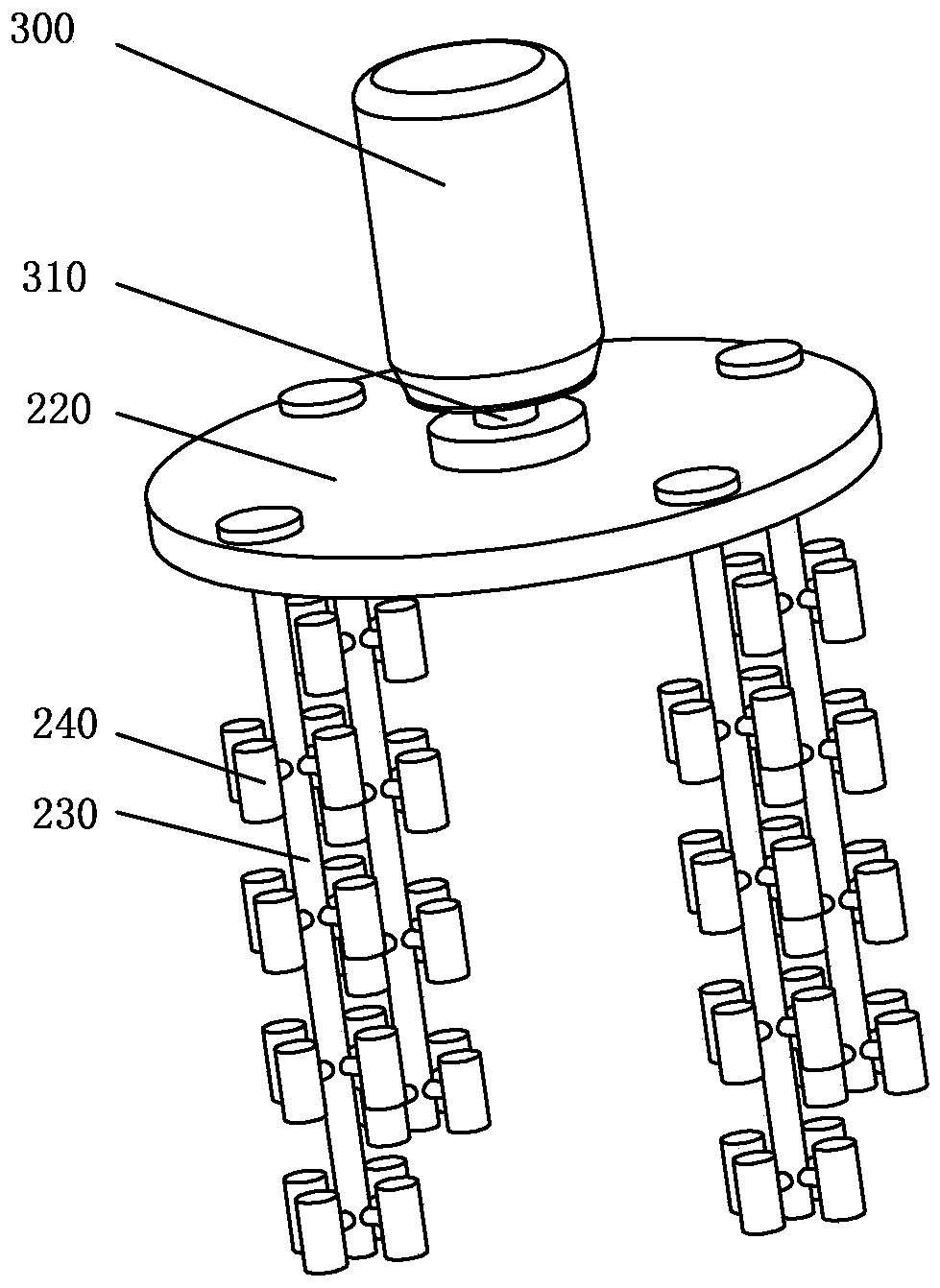

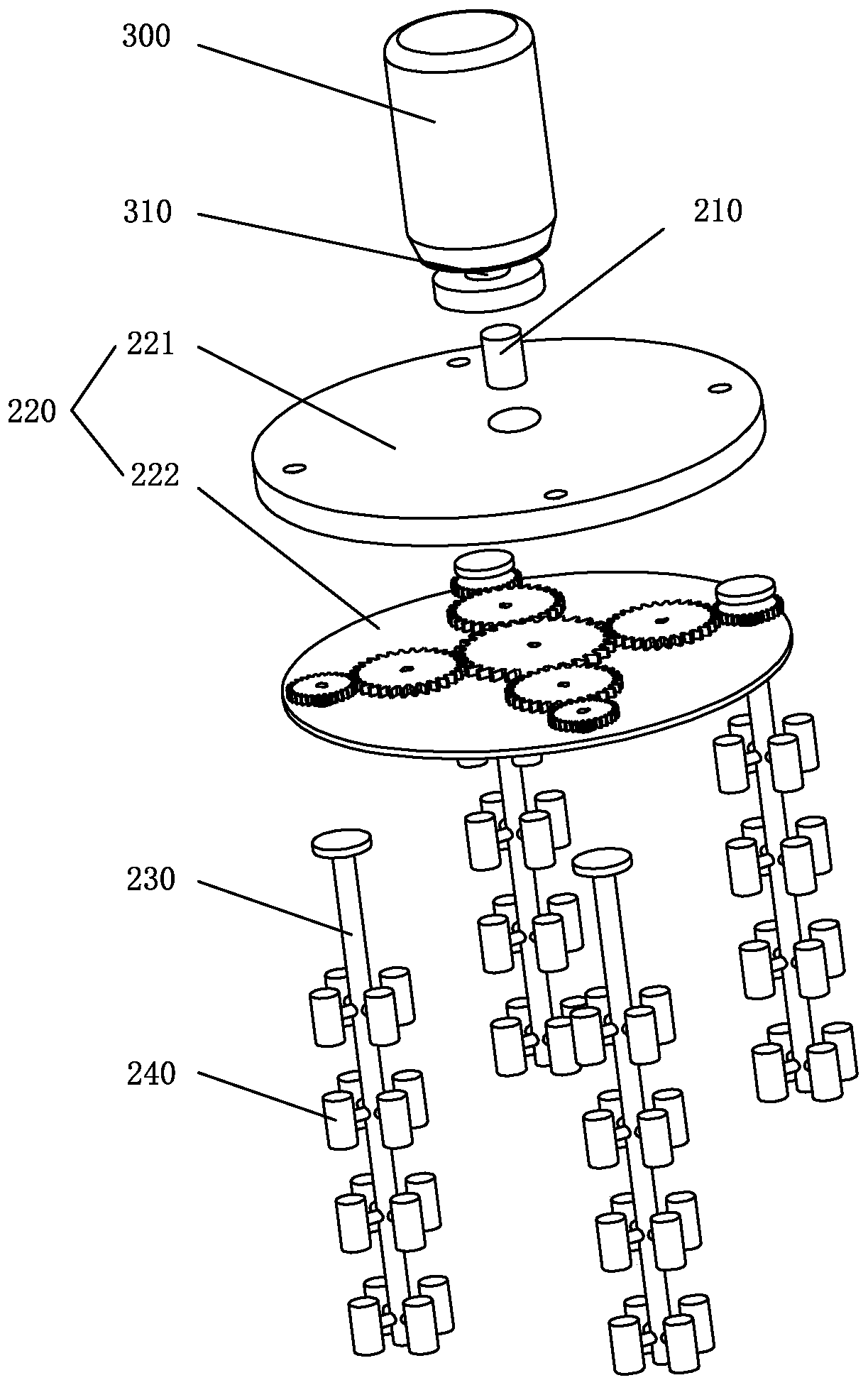

Polishing device

PendingCN111283542ARapid realization of the polishing processAchieve polishEdge grinding machinesPolishing machinesMechanical engineeringPhysics

The invention discloses a polishing device. The polishing device comprises a cylinder body, a rotating clamping mechanism, a first driving mechanism and a blowing mechanism. A sand floating net and polishing sand grains placed on the sand floating net are arranged in the cylinder body, a sand floating net plate divides the cylinder body into a working cavity and a sand lifting cavity which are arranged up and down, vent holes are uniformly distributed in the sand floating net, and the grain size of the polishing sand grains is larger than the diameter of the vent holes; the rotating clamping mechanism includes a support and a rotating fixture connected to the support, and the rotating fixture is arranged in the working cavity; the first driving mechanism is connected with the rotating fixture and drives the rotating fixture to rotate in the working cavity; and the blowing mechanism communicates with the sand lifting cavity and outputs sand floating airflow, and the sand floating airflow passes through the sand floating net and floats the polishing sand grains in the working cavity. The polishing device quickly realizes the polishing process of workpieces by utilizing the floating polishing sand grains and the rotating action of the rotating fixture, thereby greatly improving the polishing efficiency and realizing the all-round polishing process.

Owner:珠海东荣金属制品有限公司

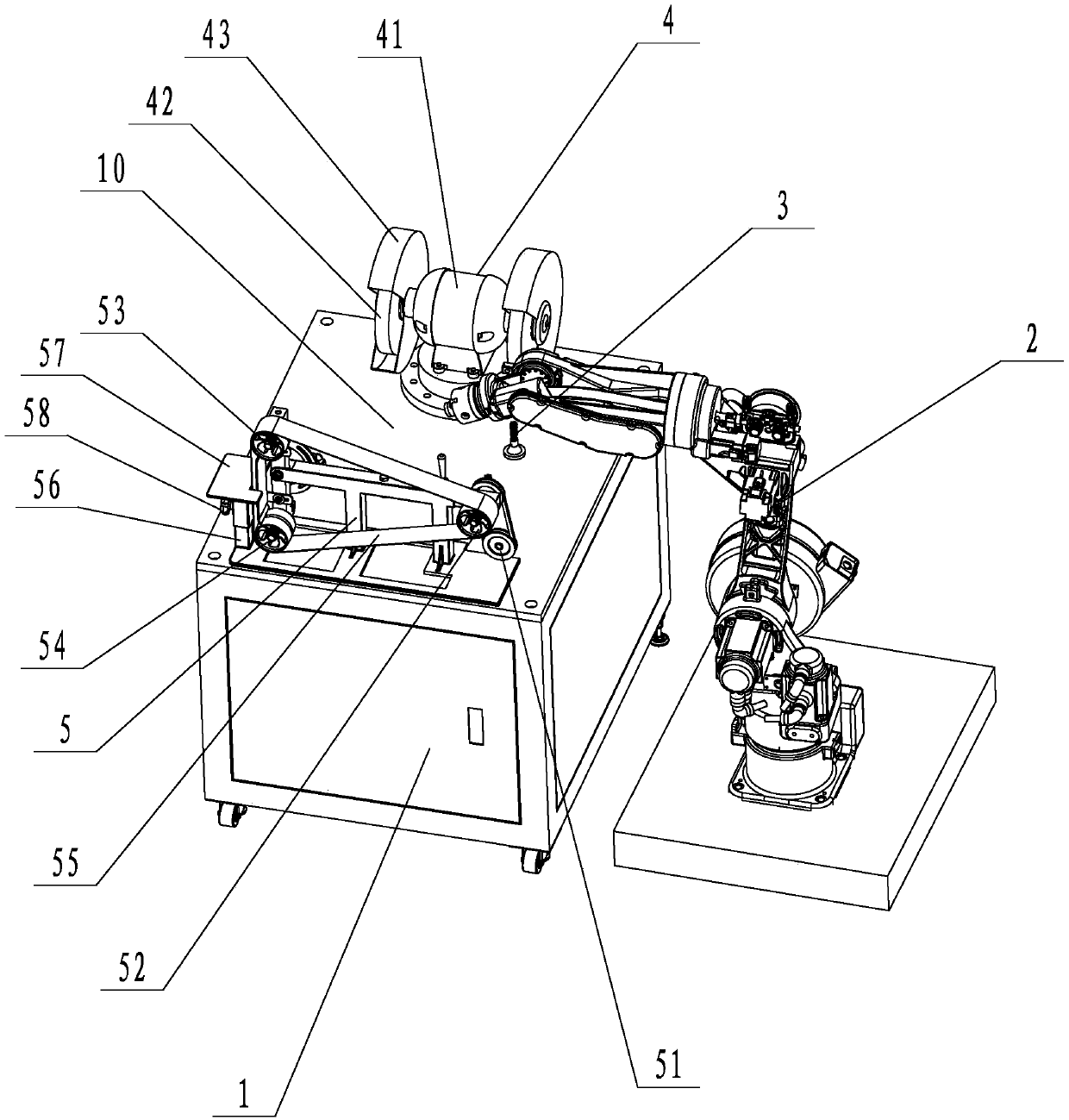

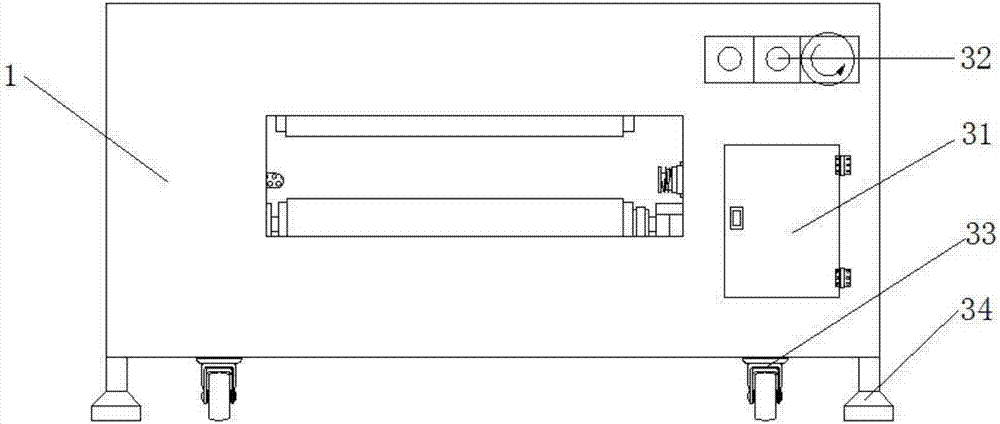

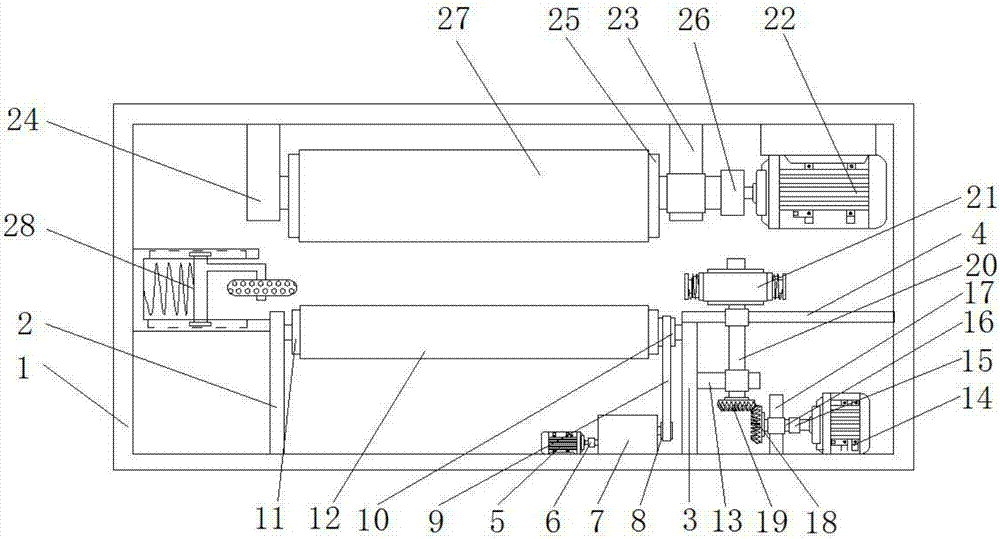

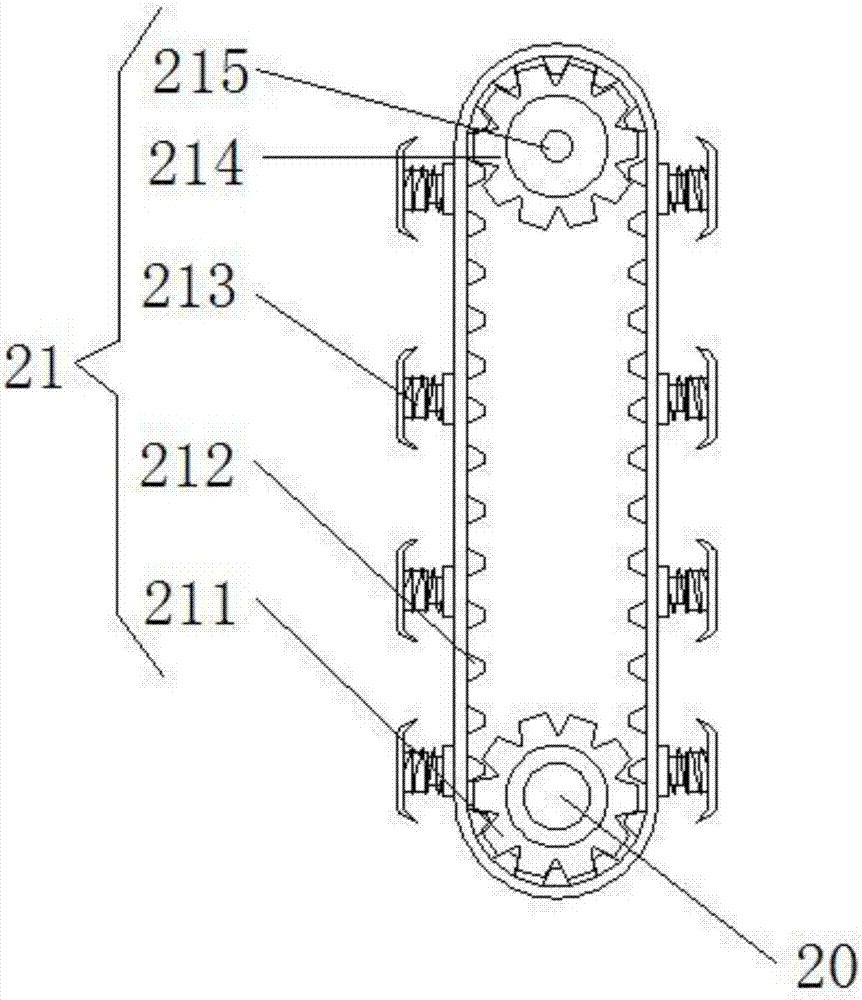

Grinding and polishing robot

The invention discloses a grinding and polishing robot. The grinding and polishing robot comprises a polishing workbench and a mechanical arm, wherein the mechanical arm is capable of moving a workpiece; a working area is arranged on the polishing workbench, milling cutters are arranged at the front end of the working area, and the two sides of the milling cutters are provided with a belt sander and a polishing wheel mechanism respectively; during operation, a conveying device conveys the workpiece to the working area on the polishing workbench, then the mechanical arm is used for grabbing andplaces the workpiece on the milling cutters to be subjected for surface milling, so that the size of the workpiece is more uniform before fine polishing; and then the mechanical arm moves the workpiece to the sanding belt machine for rough grinding of the surface, then the mechanical arm is used for grabbing and moving the workpiece to the polishing wheel mechanism for finish polishing, and grabbing the workpiece and placing the workpiece to the conveying device for being conveyed to the next working procedure after the polishing is finished. According to the grinding and polishing robot, through the above arrangement, fine polishing of the workpiece can be achieved, and the workpiece does not need to be clamped many times, the efficiency is high, and the practicability is relatively high.

Owner:江门市蓬江区科技中心

Bamboo wood processing polishing device

InactiveCN107186586AImprove work efficiencyAchieve polishGrinding drivesBelt grinding machinesGear wheelCoupling

The invention discloses a bamboo and wood processing and polishing device, which includes a box body, a first motor is fixedly connected to the bottom side of the inner wall of the box, and the output shaft end of the first motor is fixedly connected to a transmission through a first shaft coupling. The output end of the box is driven by a belt with a first polishing belt, the right side of the bottom of the inner wall of the box is fixedly connected with a second motor, the output shaft end of the second motor is fixedly connected with a transmission device through gear transmission, and the left side of the inner wall of the box is fixedly connected with a transmission device. A pushing device is fixedly connected, and the top of the inner wall of the box is fixedly connected with a first base, a second base, and a third motor in sequence from left to right, and the output shaft end of the third motor is fixed by a third coupling A third roller is connected, and the invention relates to the technical field of bamboo and wood processing machinery. The bamboo and wood processing and polishing device realizes simultaneous polishing on both sides through two polishing belts, improves production efficiency, reduces labor, and reduces the harm of dust to human body.

Owner:安吉县瑞旺竹木制品厂

Low-pressure CMP (Chemico-mechanical Polishing) method for grand-scale integrated circuit copper wiring surface

InactiveCN101966688AStrong chelating abilityQuick polishOther chemical processesSemiconductor/solid-state device manufacturingVery large scale integrated circuitsNano sio2

The invention relates to a low-pressure CMP (Chemico-mechanical Polishing) method for grand-scale integrated circuit copper wiring surface, comprising the following steps of: (1) preparing a polishing solution by uniformly mixing the following components in percentage by weight: 35-80% of nano SiO2 abrasive material, 12-60% of deionized water, 1-3% of oxidizing agent, 1-4% of activating agent and 0.5-1.5% of FA / OII type chelating agent; and (2) setting polishing technique parameters, wherein the polishing pressure is 2-5KPa, the polishing temperature is 20-50 DEG C, the flow rate is 120-250ml / min, and the rotating speed is 30-60rpm / min. The oxidizing agent in the polishing solution is used for oxidizing the copper, and the FA / OII type chelating agent self with extremely strong chelating capability quickly reacts with the oxidized copper to generate soluble chelate fast removing from the copper surface, thereby avoiding the situation of removing the surface copper depending on the mechanical friction mainly and realizing the purpose of copper polishing under low mechanical strength. The removal of materials in the chelating process is realized by breaking down molecular bond, which has small damage on the material surface; in addition, the influence of mechanical action on the polishing speed is compensated by reinforcing the CMP chemical action under low pressure.

Owner:TIANJIN HEBEI UNIV OF TECH ASSET MANAGEMENT LTD

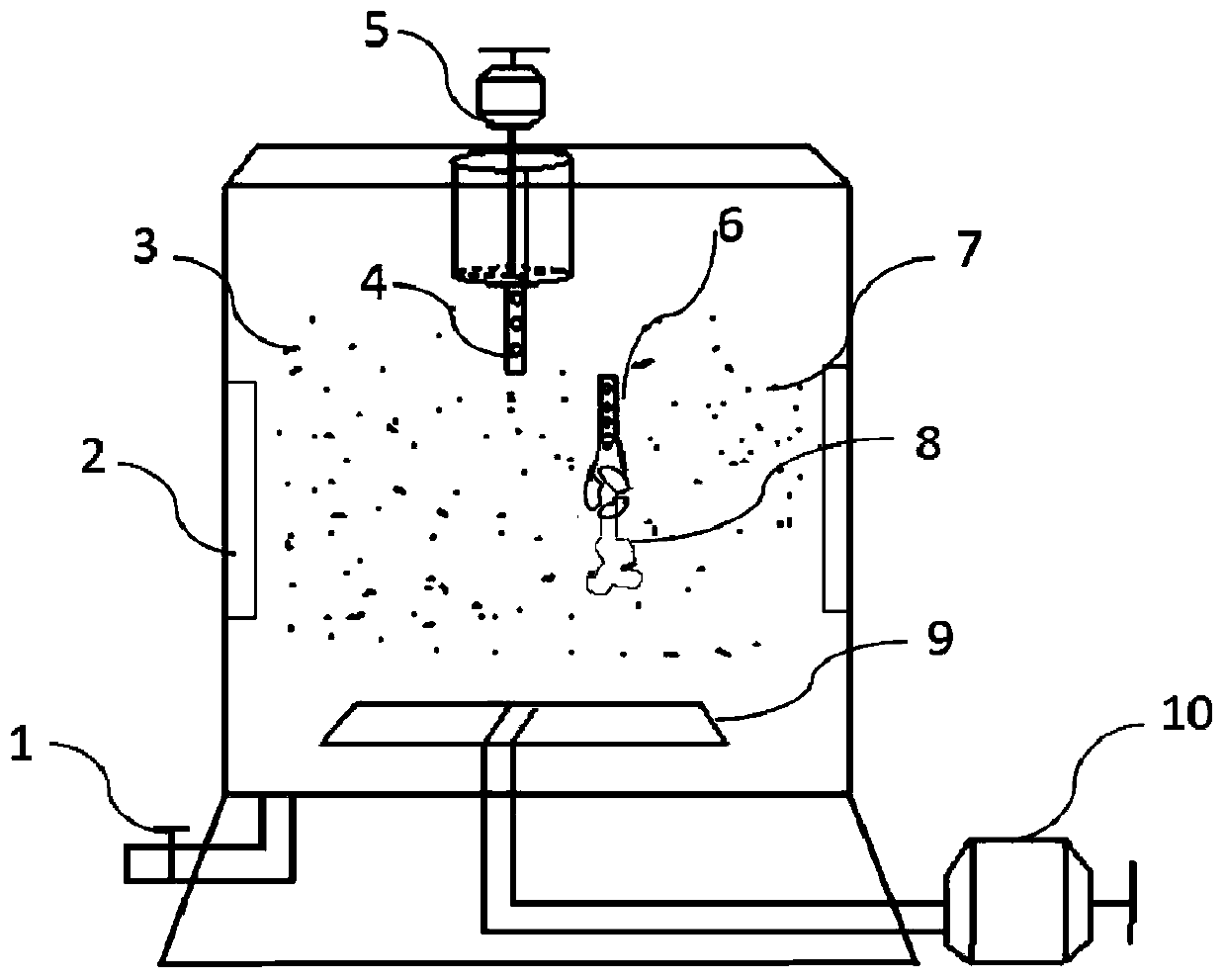

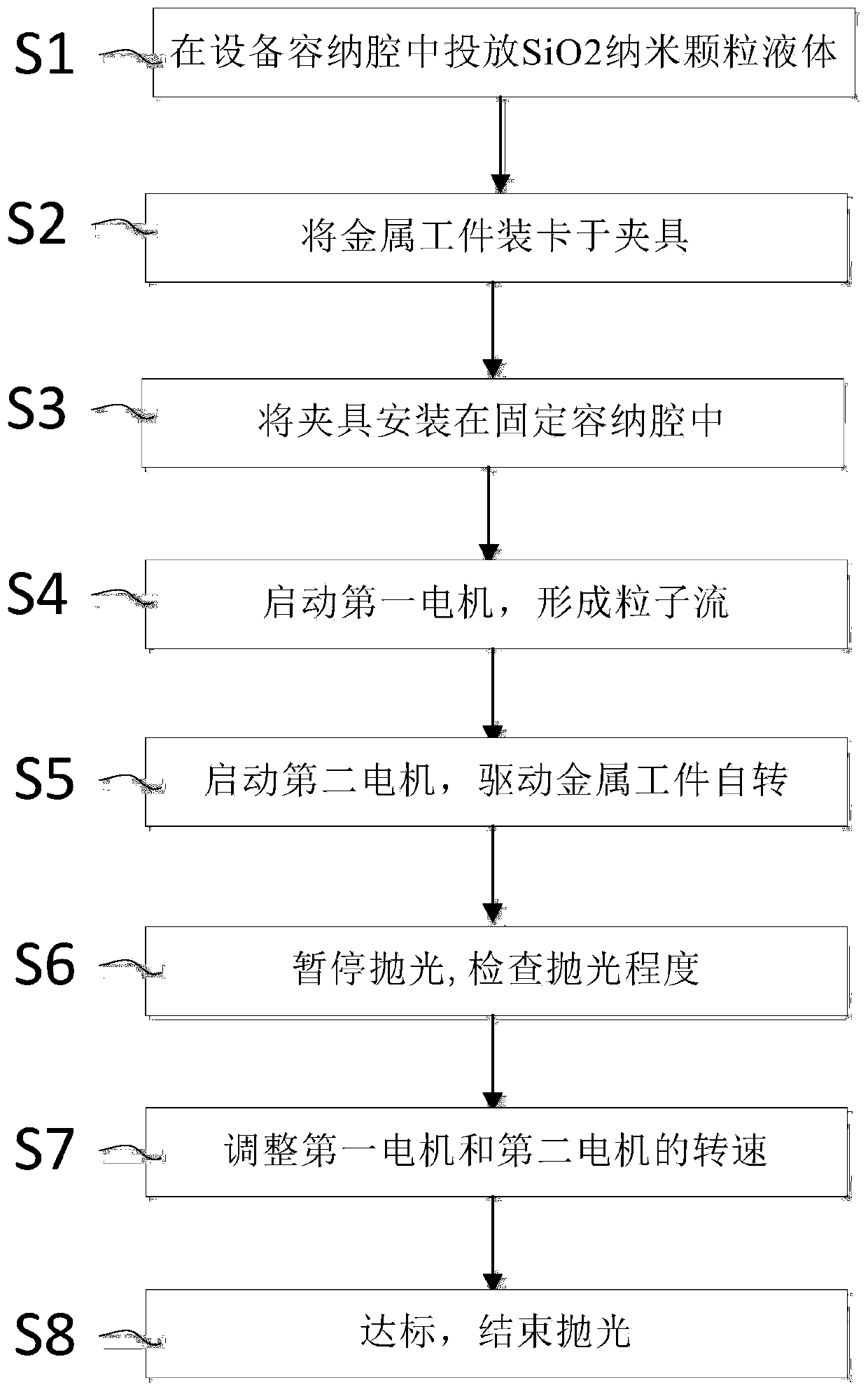

Polishing device, polishing method and polishing solution

PendingCN110370161AAvoid overall structural impactAvoid damageEdge grinding machinesPolishing machinesEngineeringMetal

The invention discloses a polishing device, a polishing method and a polishing solution. The polishing device, the polishing method and the polishing solution are suitable for polishing metal workpieces with complicated surface structures. The polishing device comprises a polishing barrel, a first motor, a stirrer and a clamp, wherein the polishing barrel comprises a side wall and a base plate, the side wall and the base plate define a containing cavity, the containing cavity is used for containing SiO2 nano-particle liquid, the first motor is fixed to the polishing barrel, the stirrer is located at the bottom of the containing cavity and driven by the first motor to rotate, the stirrer stirs the SiO2 nano-particle liquid in the containing cavity, the clamp is fixed into the polishing barrel and used for fixing a metal workpiece. According to the polishing device, the polishing method and the polishing solution, high-speed liquid flow mixed with SiO2 nano-particles is utilized to makefriction with the surface of the metal workpiece, protrusions on the surface of the metal workpiece generate plastic deformation and even shear under high-speed collision of the SiO2 nano-particles, so that surface polishing of the metal workpiece is achieved; since the polishing medium is the fluid mixed with the SiO2 nano-particles, the damage to the integrity and the surface of the workpiece bychemical polishing and electrochemical polishing is avoided, and overall polishing of a special-shaped surface is achieved.

Owner:飞而康快速制造科技有限责任公司

CCOS shear thickening polishing method

ActiveCN112658812AAchieve polishRealize modificationOptical surface grinding machinesPolishing compositions with abrasivesPolishingChanging equipment

The invention discloses a CCOS shear thickening polishing method. A shear thickening polishing solution is led in for thickening in the process of machining a workpiece by adopting a polishing disk in a CCOS process, so as to improve the flatness and the surface shape precision of CCOS machining. The method has the capacity of modifying the surface of a low-precision workpiece, a medium-precision workpiece and a high-precision workpiece, it is not necessary to apply all machining equipment, various errors caused by equipment replacement are avoided, the surface of the workpiece can be modified, and meanwhile, the flatness and the surface shape precision of the surface of the workpiece can be improved. The method has the advantages that a device is simple, easy to build and low in cost.

Owner:NAT UNIV OF DEFENSE TECH

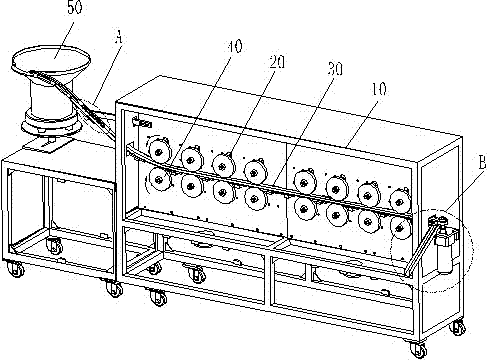

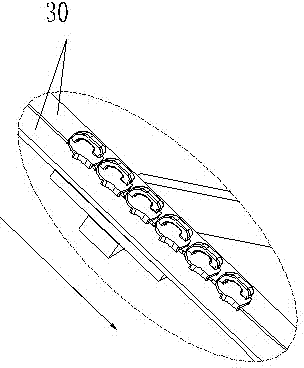

Full-automatic pull head polishing machine

InactiveCN104759975AImplement sliding connectionsAchieve polishGrinding carriagesPolishing machinesEngineeringProcess conditions

The invention provides a full-automatic pull head polishing machine which is used for polishing pull heads. The full-automatic pull head polishing machine comprises a frame and a driving device; polishing wheels and guide rails are arranged in the frame, wherein the guide rails are arranged in a parallel mode; every two adjacent guide rails are arranged separately to form an accommodating space which is used for placing the corresponding pull head to be polished; every pull head to be polished comprises a pull head top surface and a pull head bottom surface; two inner grooves are formed between every pull head top surface and the corresponding pull head bottom surface; every two adjacent guide rails are connected with the two corresponding inner grooves in a sleeving mode respectively so as to implement the sliding connection of the corresponding pull head to be polished and the two guide rails; the polishing wheels comprise a first polishing wheel and a second polishing wheel; the driving device is used for driving the first polishing wheel and the second polishing wheel to rotate; the first polishing wheel is arranged on the upper portion of every pull head to be polished; the circumferential surface of the first polishing wheel is in contact with every pull head top surface; the second polishing wheel is arranged on the lower portion of every pull head to be polished; the circumferential surface of the second polishing wheel is in contact with every pull head bottom surface. According to the full-automatic pull head polishing machine, the technical problems that the production efficiency is low, the labor cost is high, and the product quality consistency is poor under the existing pull head polishing process conditions are solved.

Owner:GUANGZHOU LIUXI ZIPPER DEV CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com