Multifunctional glass polishing machine

A polishing machine, multi-functional technology, applied in the direction of grinding/polishing equipment, grinding/polishing safety device, gantry grinding machine, etc. The effect of improving stability and safety, improving processing efficiency, and improving quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

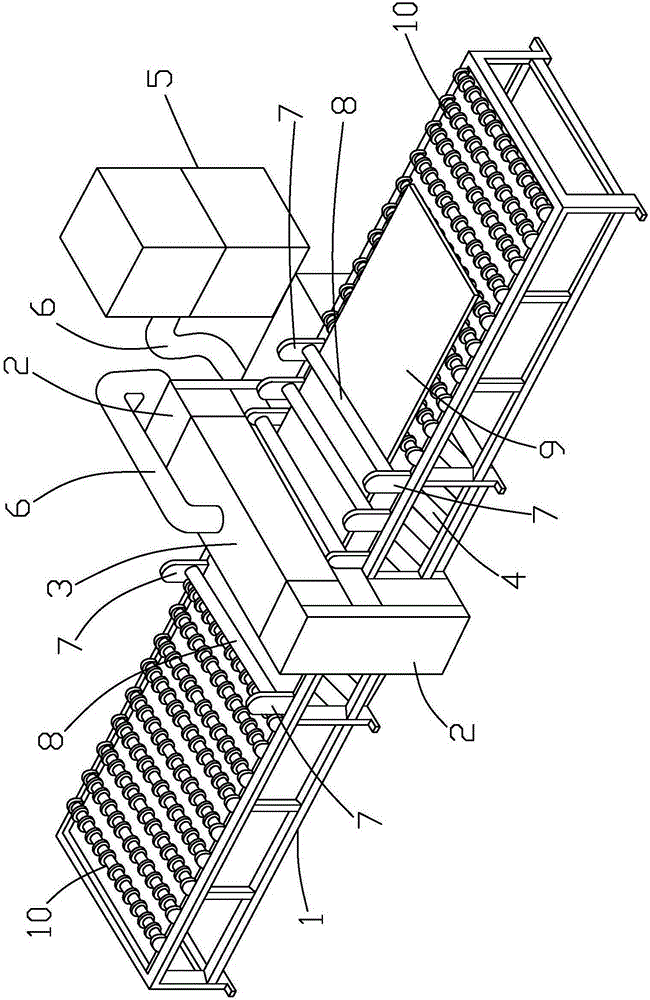

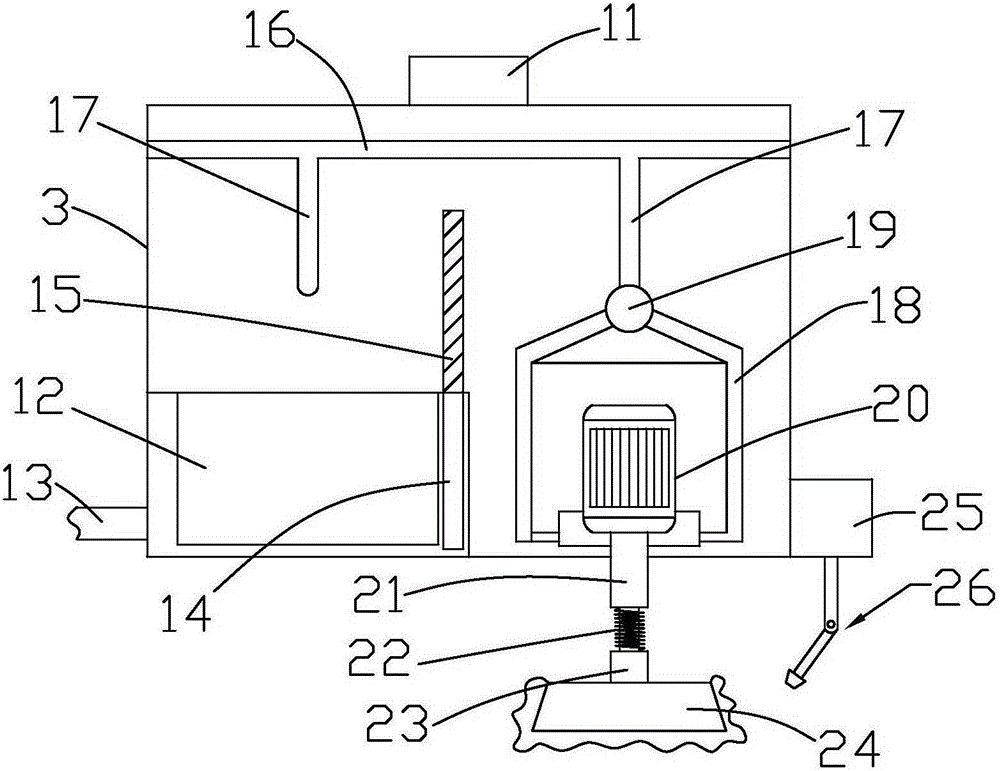

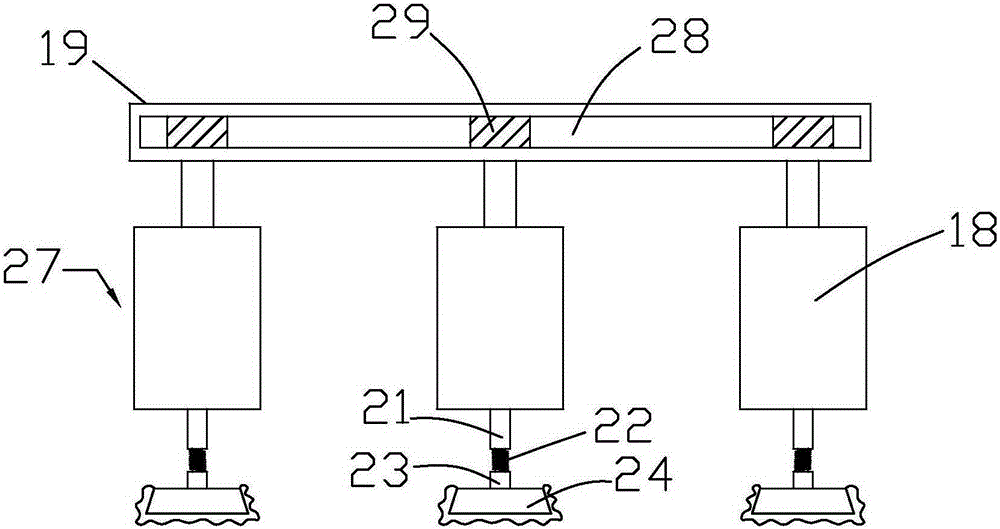

[0032] Such as Figure 1 to Figure 7 As shown, it is a multifunctional glass polishing machine of the present invention. The glass polishing machine includes a loading frame body 1 and a polishing device. The loading frame body 1 is evenly provided with support rollers 10. The polishing device includes a mobile control box 2, a suspension beam 3. The bottom console 4 and the water tank 5, the suspension beam 3 is fixedly connected between the two mobile control boxes 2, the interior of the suspension beam 3 is provided with a cleaning tank 12, a horizontal slide rail 16, a vertical slide rail 17 and an upper polishing mechanism 27, The vertical slide rail 17 is fixedly connected below the horizontal slide rail 16, and the upper polishing mechanism 27 is connected on the cantilever bar 19 by the support frame 18, and the cantilever bar 19 is limited on the vertical slide rail 17, and the cantilever bar 19 is provided with a positioning Groove 28, positioning groove 28 is provid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com