Complicated structure polishing method and device

A complex structure and polishing device technology, which is applied to polishing compositions containing abrasives, grinding/polishing equipment, surface polishing machine tools, etc., can solve problems such as low polishing efficiency, poor polishing uniformity, and poor polished surface quality. To achieve the effect of improving polishing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The principles and technical solutions of the present invention will be clearly and completely described below in conjunction with the embodiments and accompanying drawings.

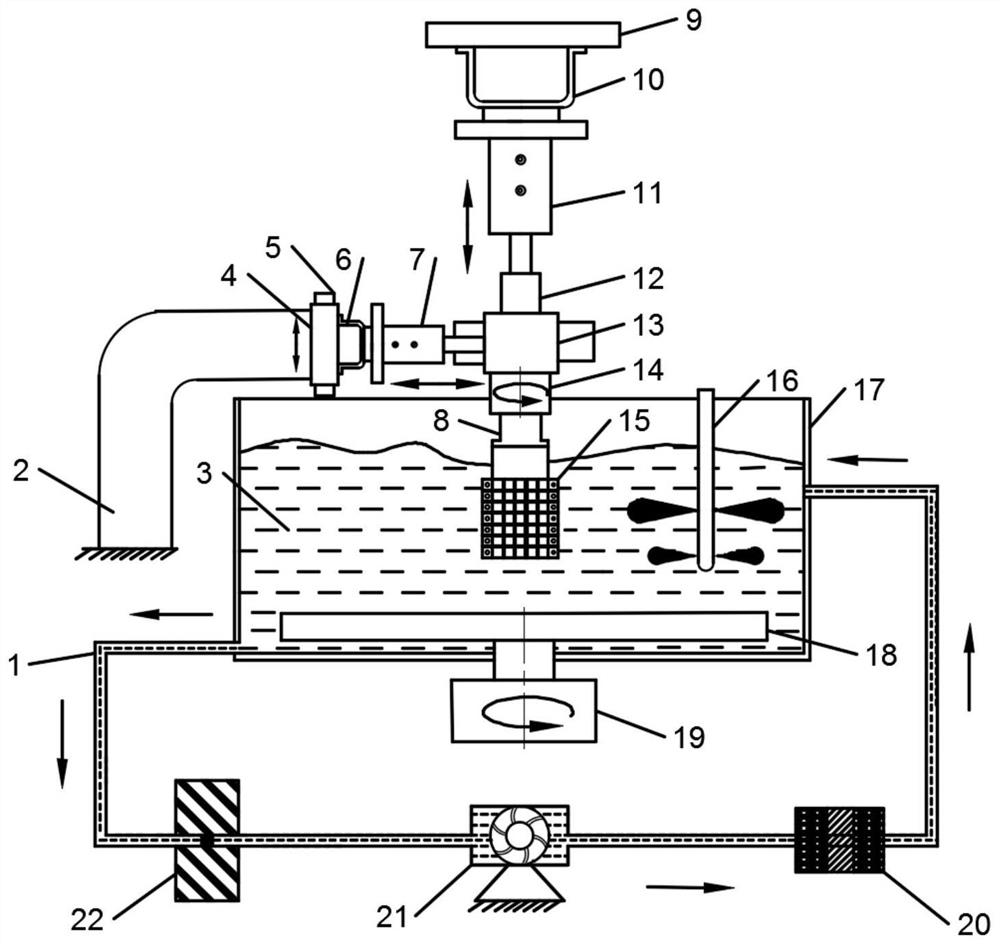

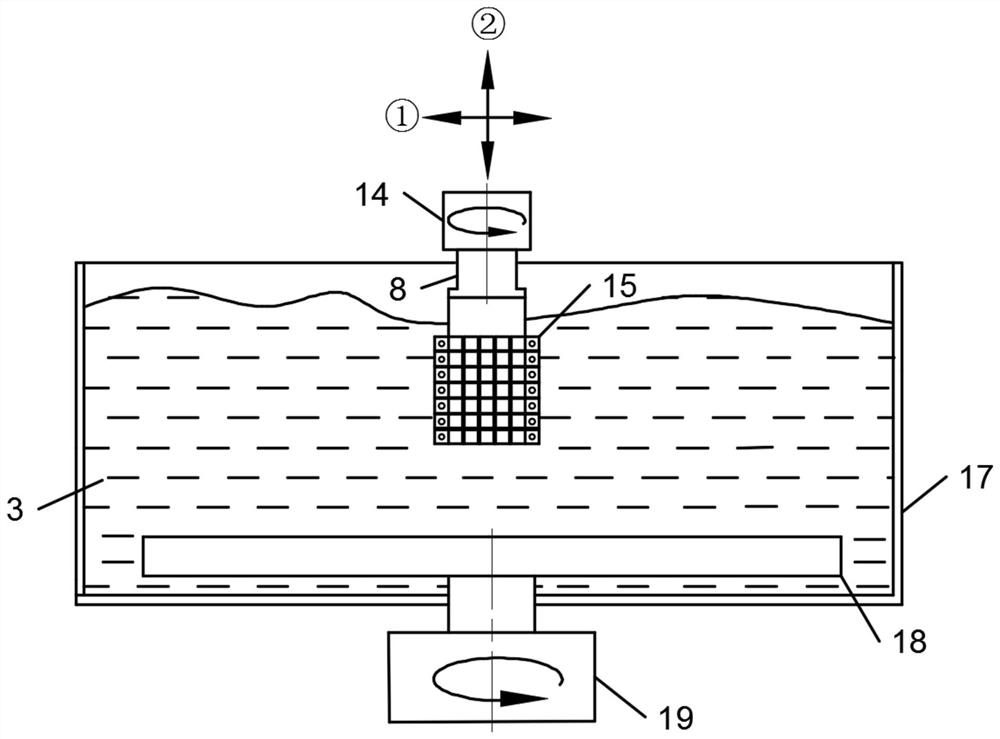

[0030] Attached figure 1 The schematic diagram of the device is shown and referred to figure 2 , 3 , 4(a), 4(b), and 5 realize the polishing of the entire working surface of complex structures.

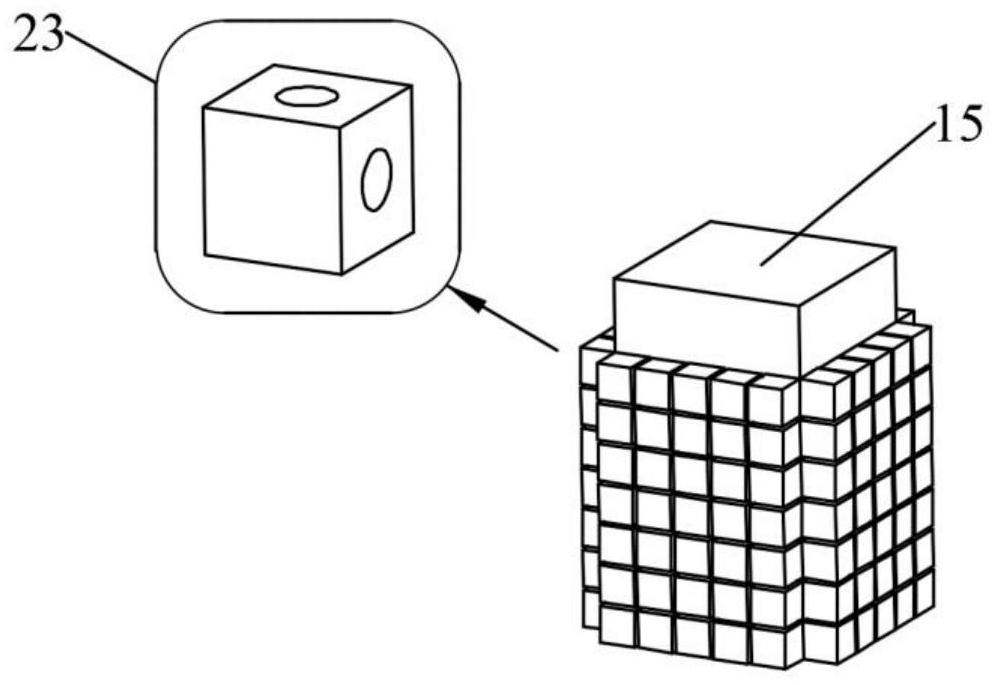

[0031] A device for vibrating complex structures based on shear thickening and chemical composite effects, including a polishing system, a polishing liquid circulation device, a horizontal vibration device and a vertical vibration device. The polishing system includes a polishing liquid 3 , a polishing pool 17 , a rotating disc 18 , a stepping motor 19 and a stirring device 16 . The polishing liquid 3 is ultrasonically mixed in deionized water by abrasive grains 24, polyhydroxy polymer 25, pH regulator, oxidizing agent and preservative, which can produce a shear thickening effect. The rotating disc 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com