Patents

Literature

121results about How to "Quick polish" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Dielectric recording medium, and method of and apparatus for producing the same

InactiveUS6841220B2Remove electric charge on the recording surface rapidlyImprove abilitiesNanoinformaticsFerroelectric carrier recordingSingle crystalOptoelectronics

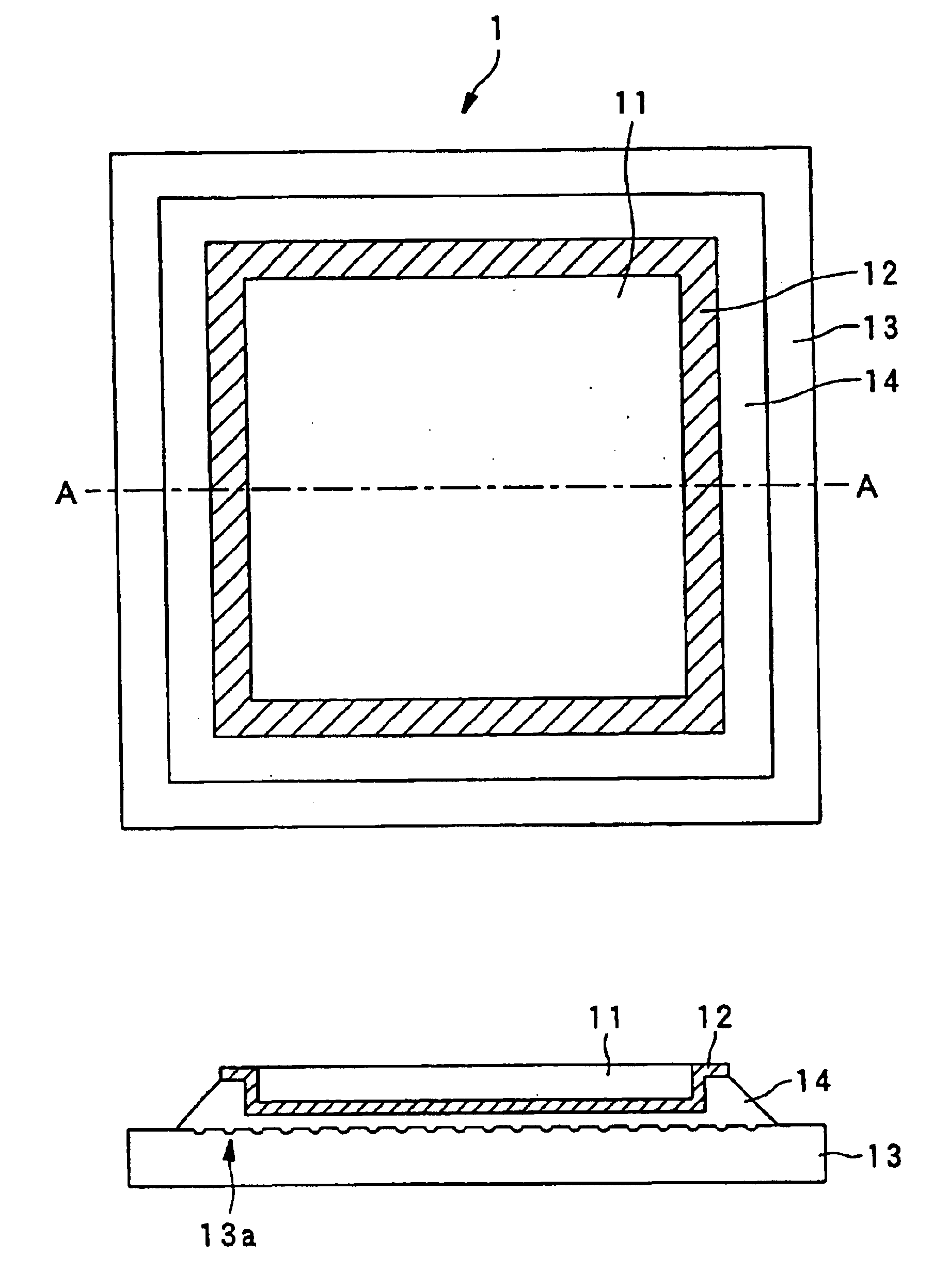

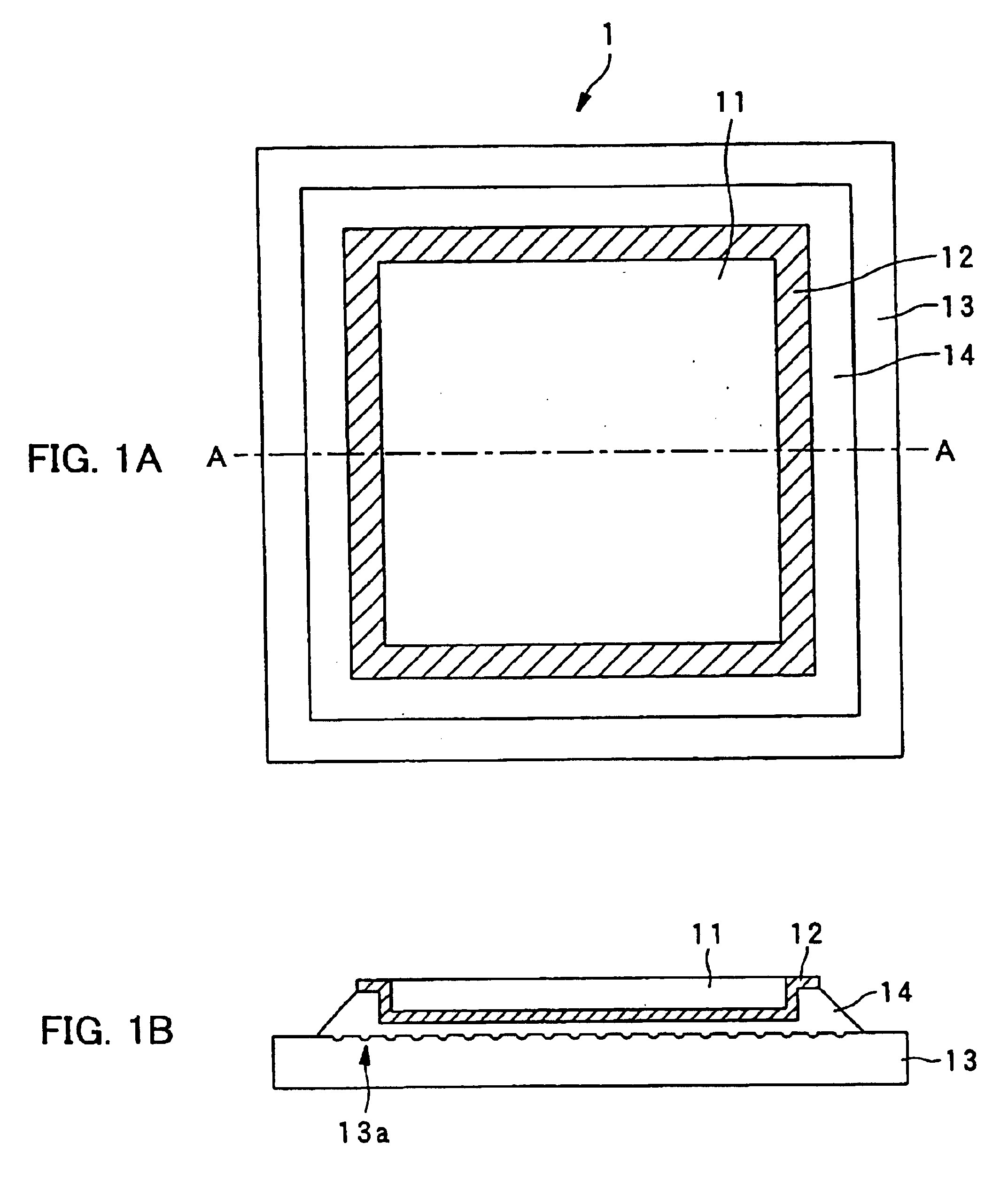

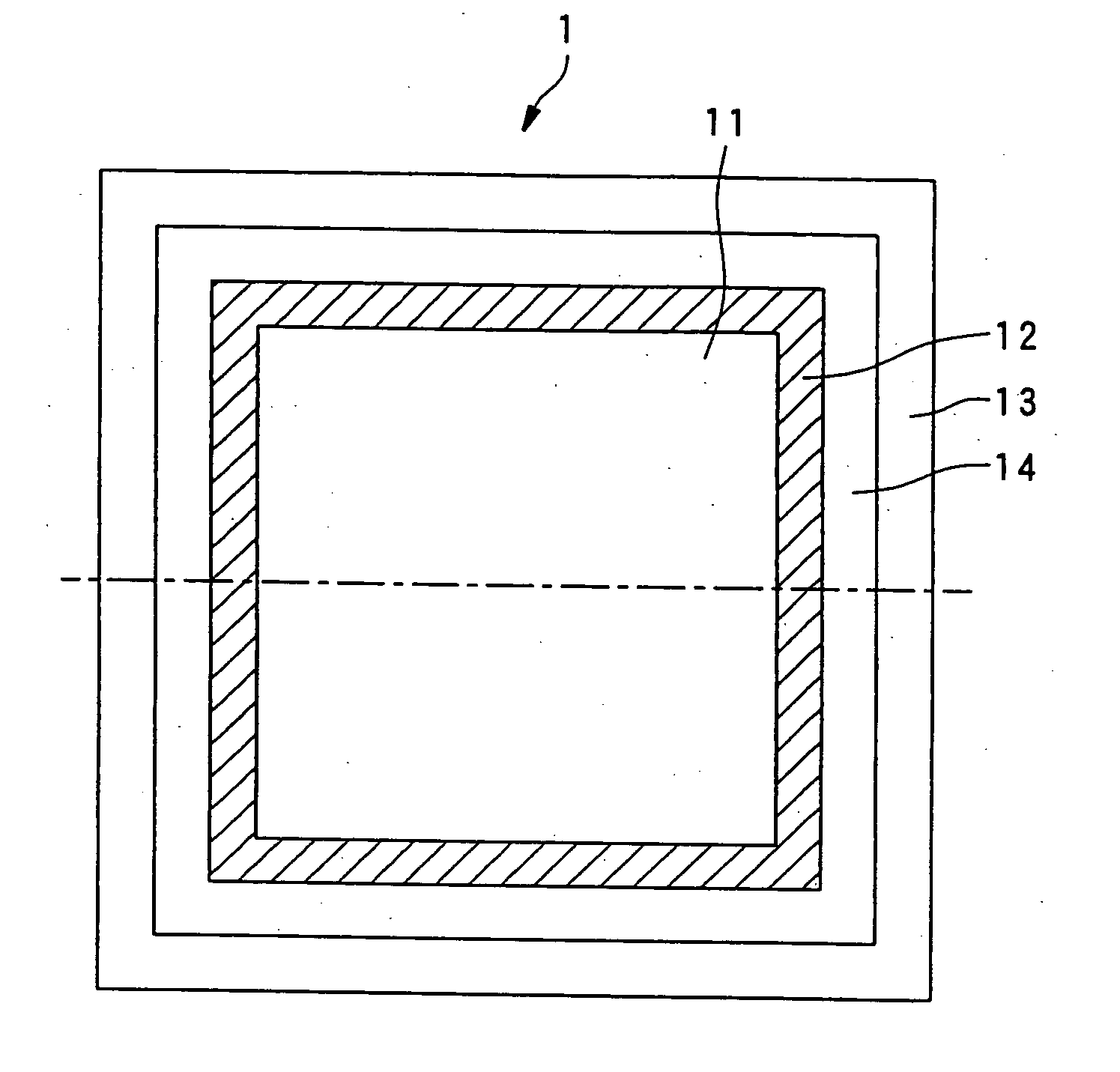

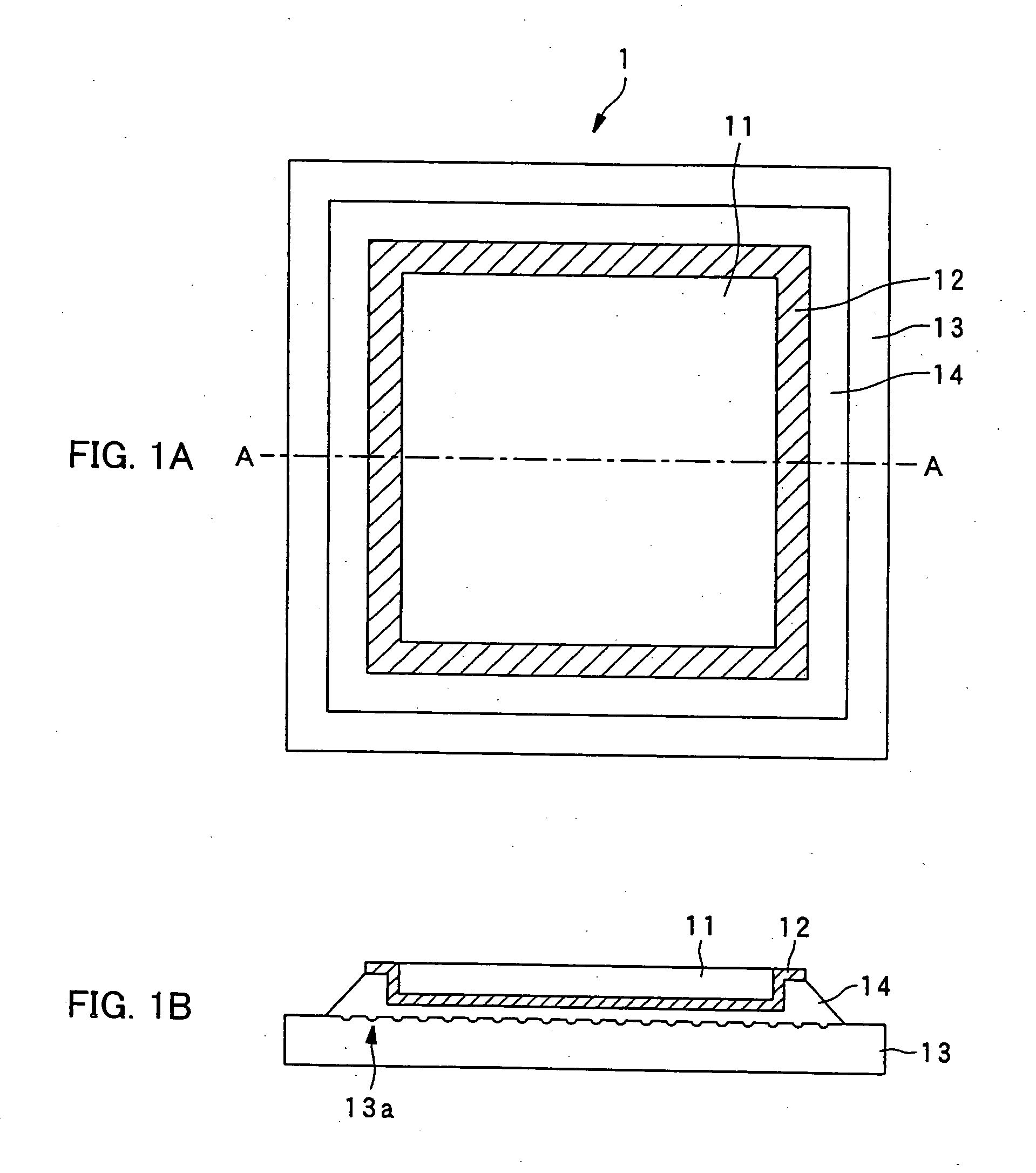

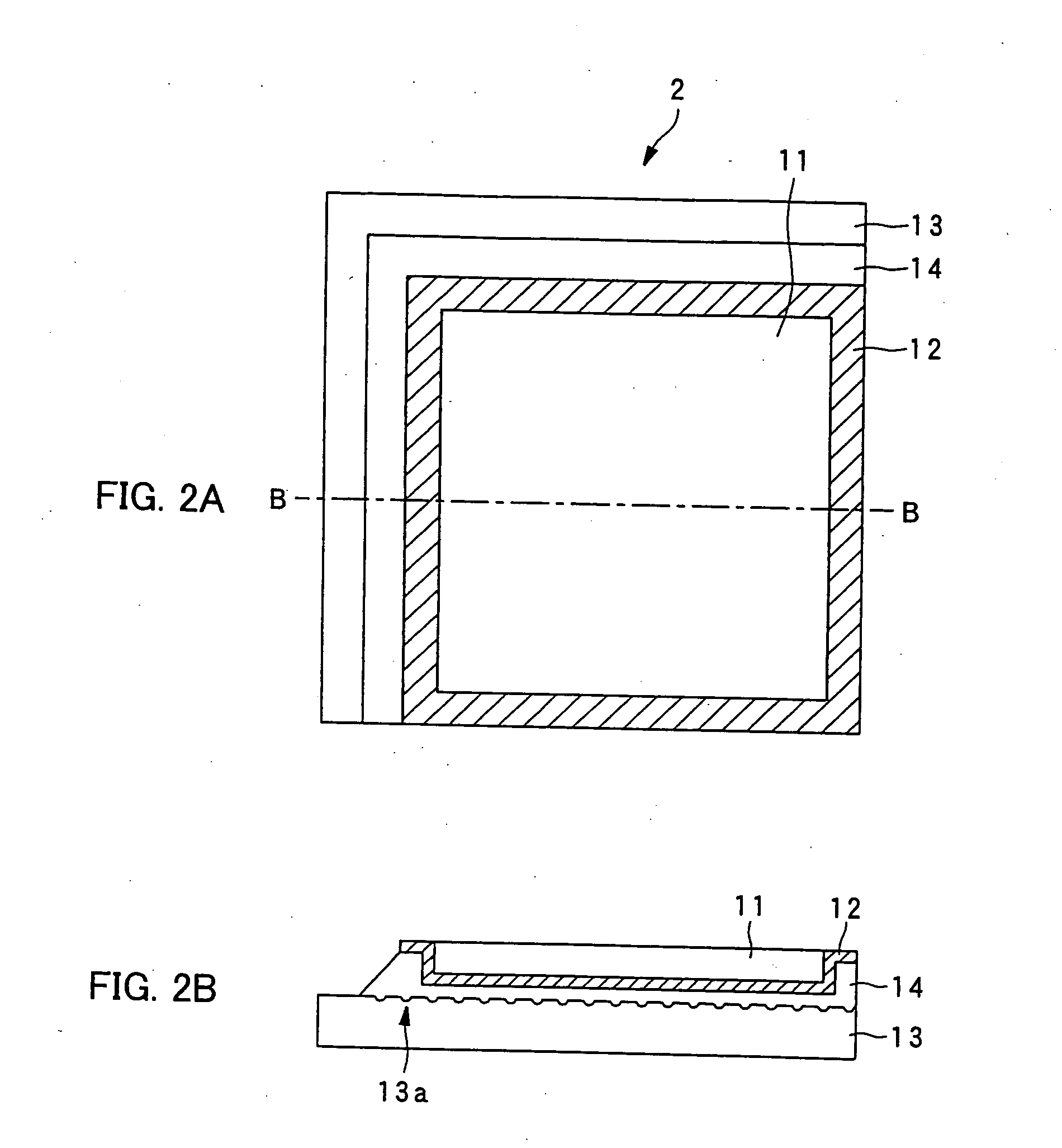

The dielectric recording medium is provided with a dielectric material, a conductive thin film, and a substrate. The conductive thin film and the substrate are bonded by a resin adhesive. The dielectric material is constructed of a ferroelectric single crystal having a uniform thickness, and its one surface is used for a recording and / or reproducing surface, on the order of mm on a side and about 5000 Å thick. The conductive thin film, about 1000 to 2000 Å thick, is placed on a surrounding portion and a back surface of the recording and / or reproducing surface of the dielectric material. The substrate is intended to preserve the thin dielectric material and maintain the planarity, and concave portions are formed on the adhesive surface. The concave portions absorb excessive resin adhesive when the dielectric material is bonded onto the substrate, which makes the adhesive surface uniform and flat.

Owner:PIONEER CORP +1

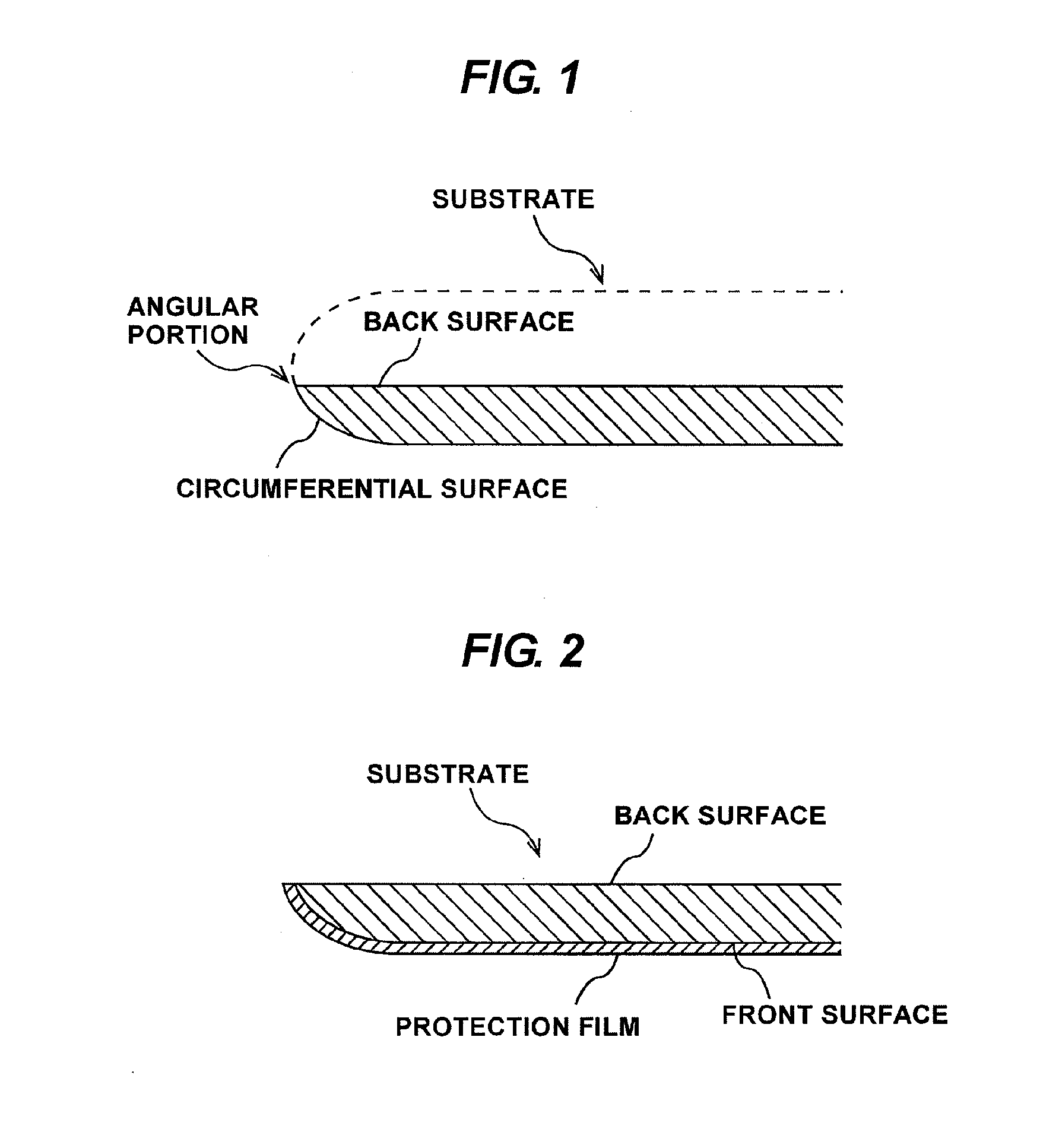

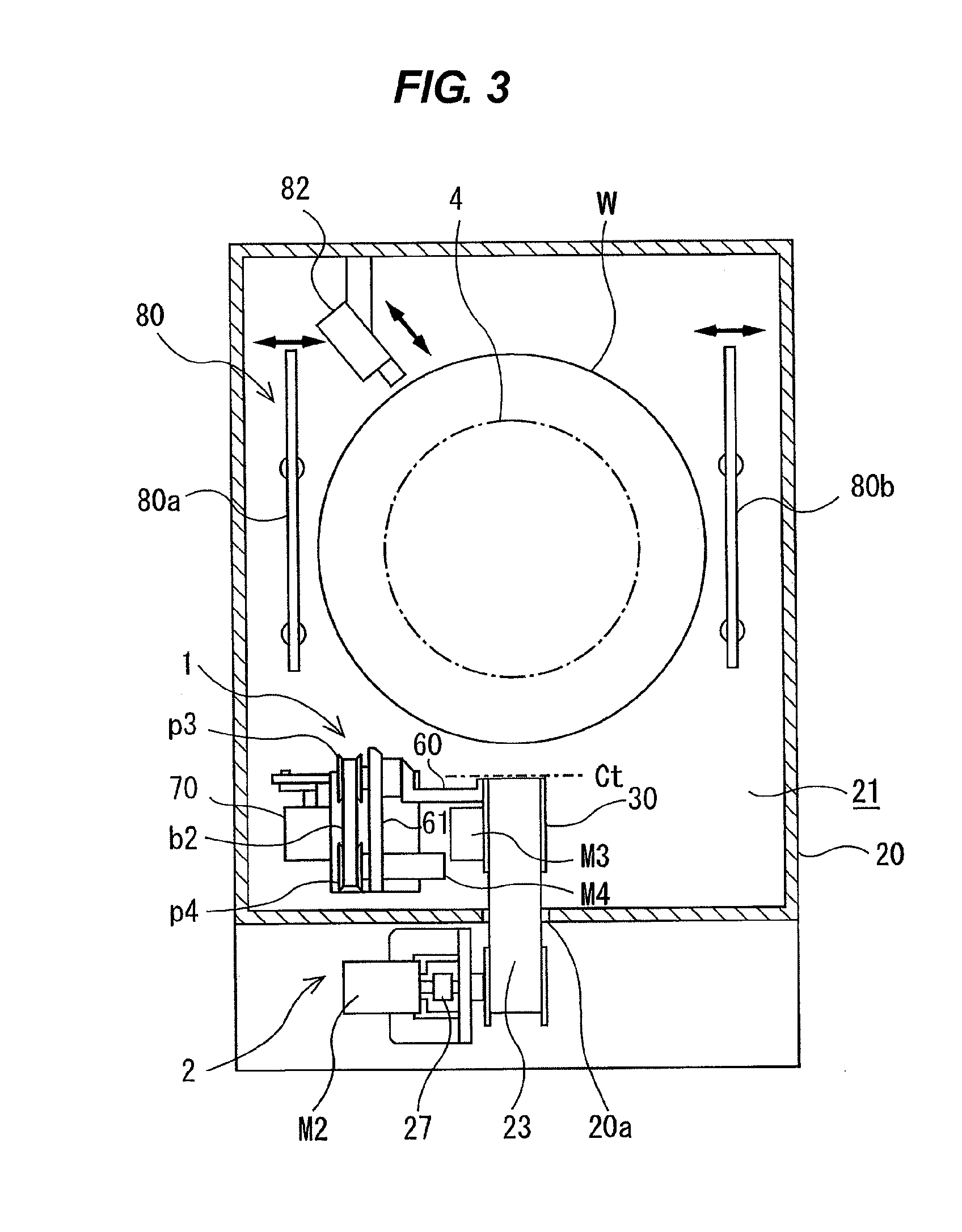

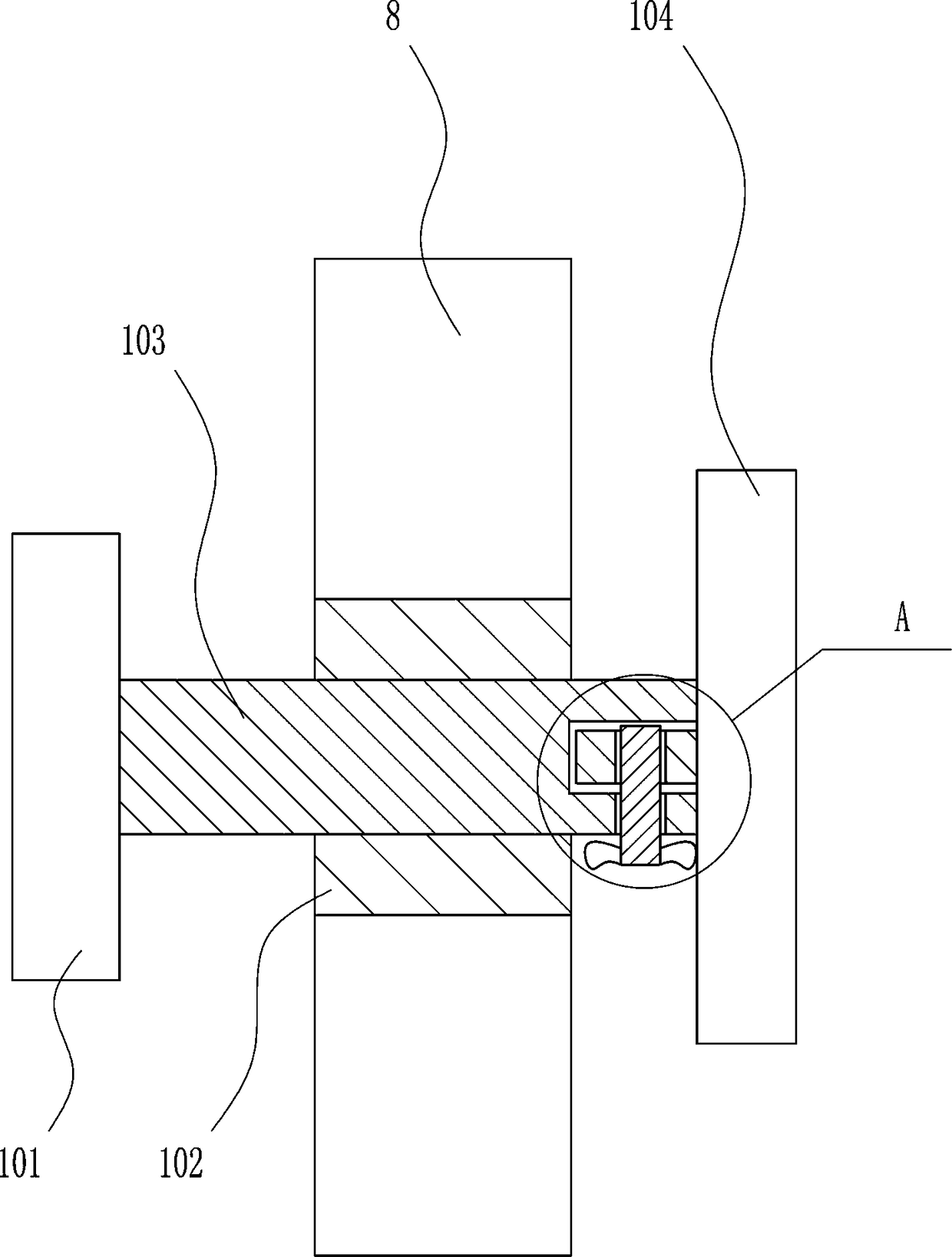

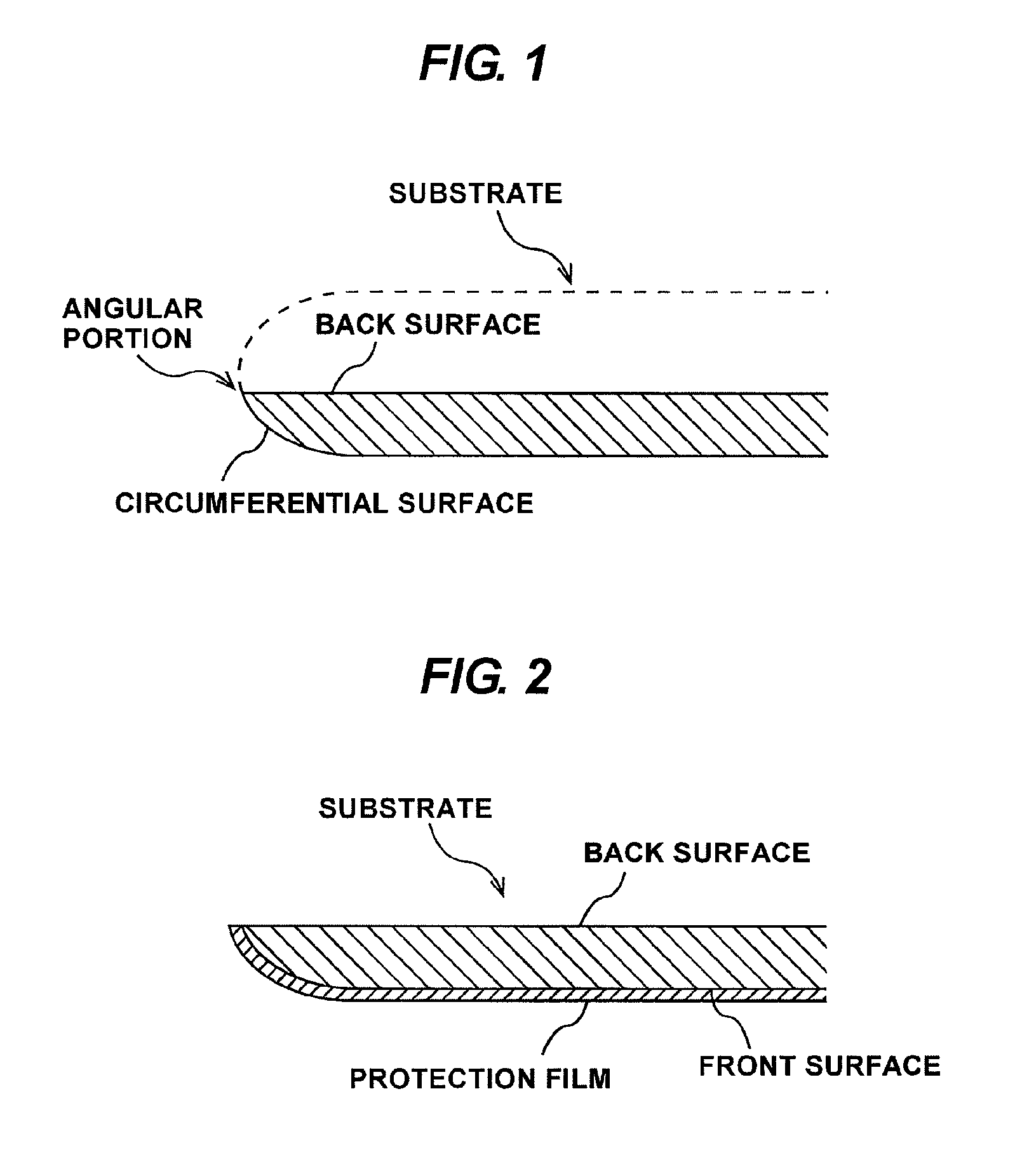

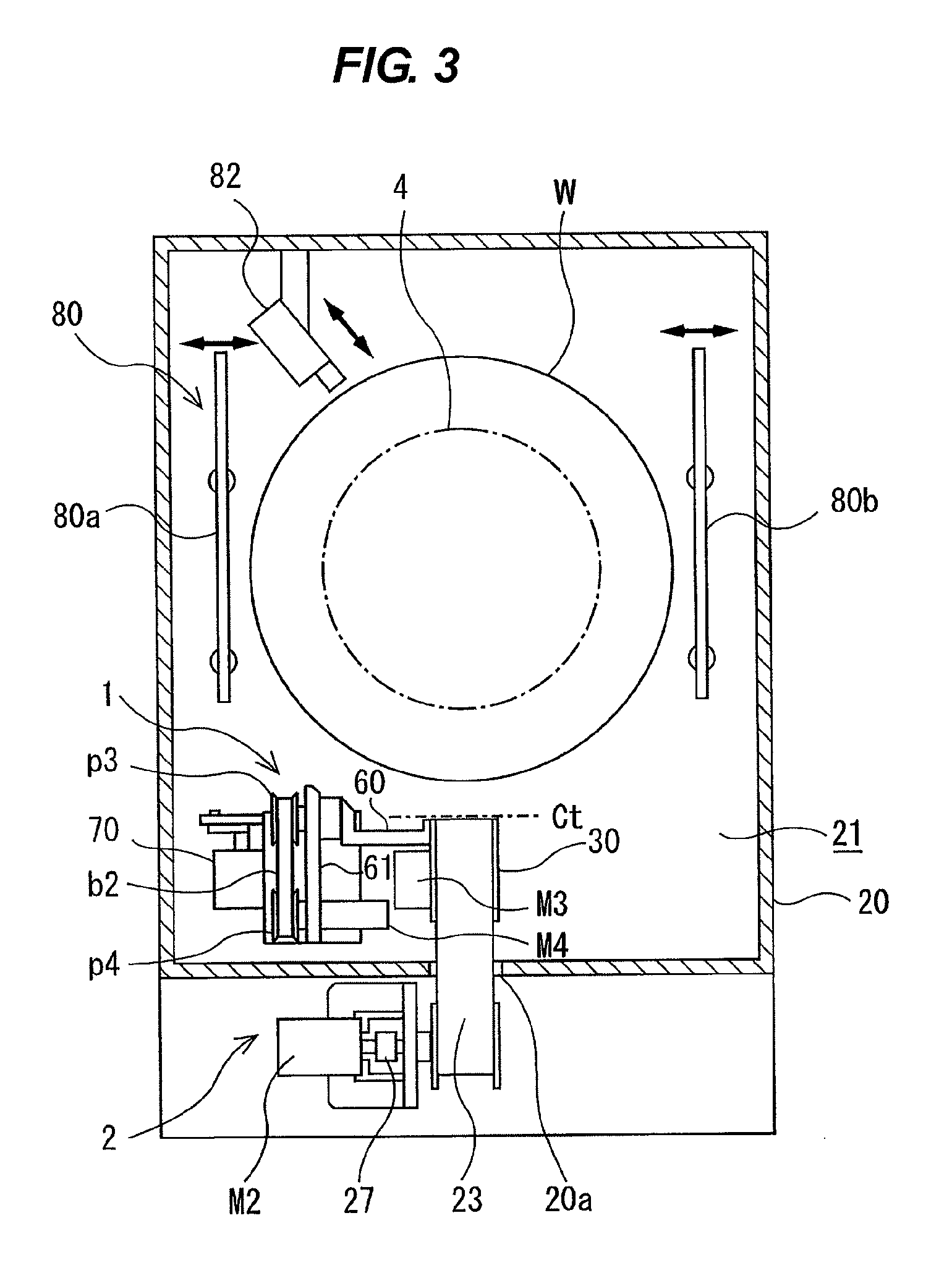

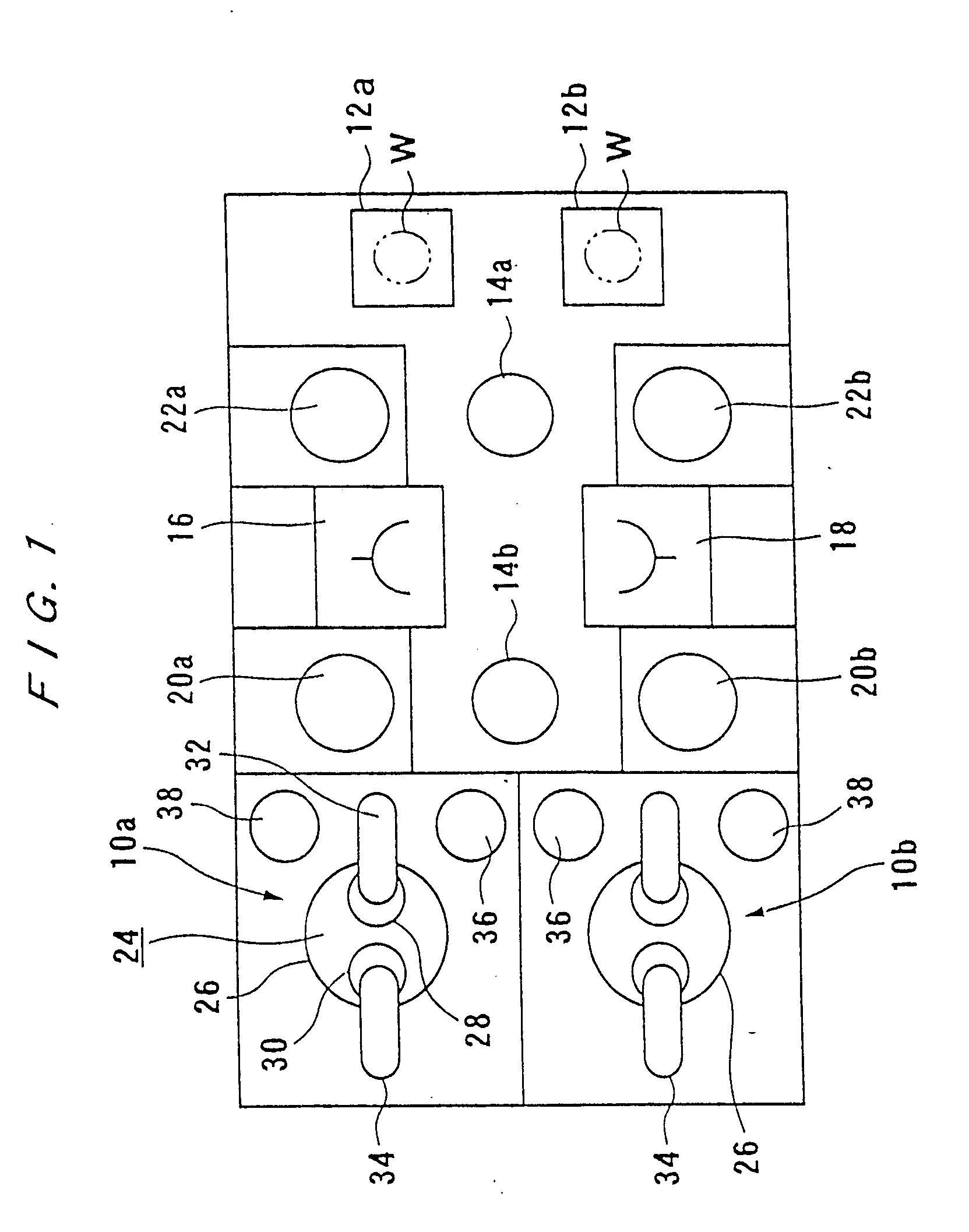

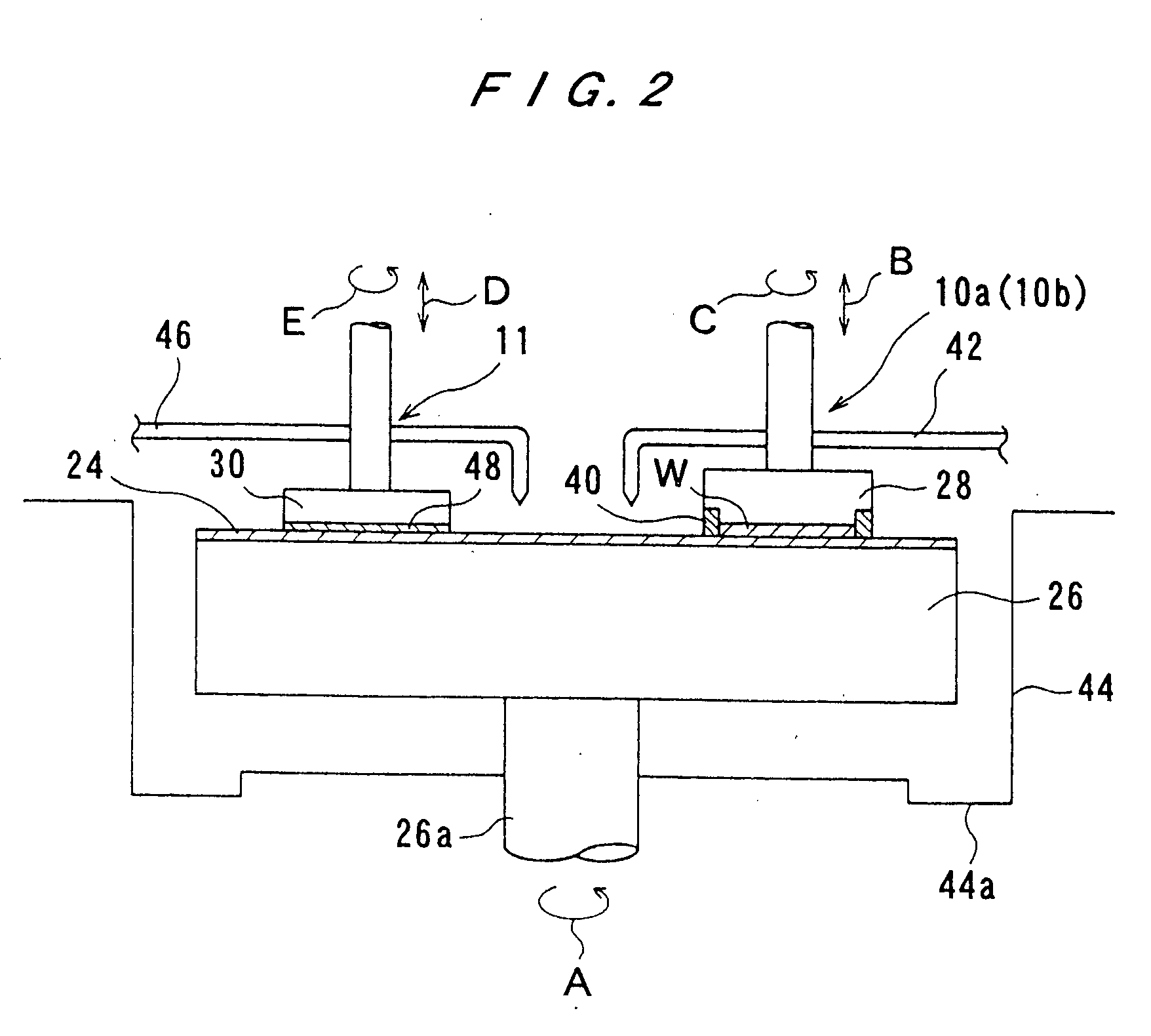

Method and apparatus for polishing a substrate having a grinded back surface

ActiveUS20110136411A1Polish uniformityShorten timeEdge grinding machinesPolishing machinesEngineeringMechanical engineering

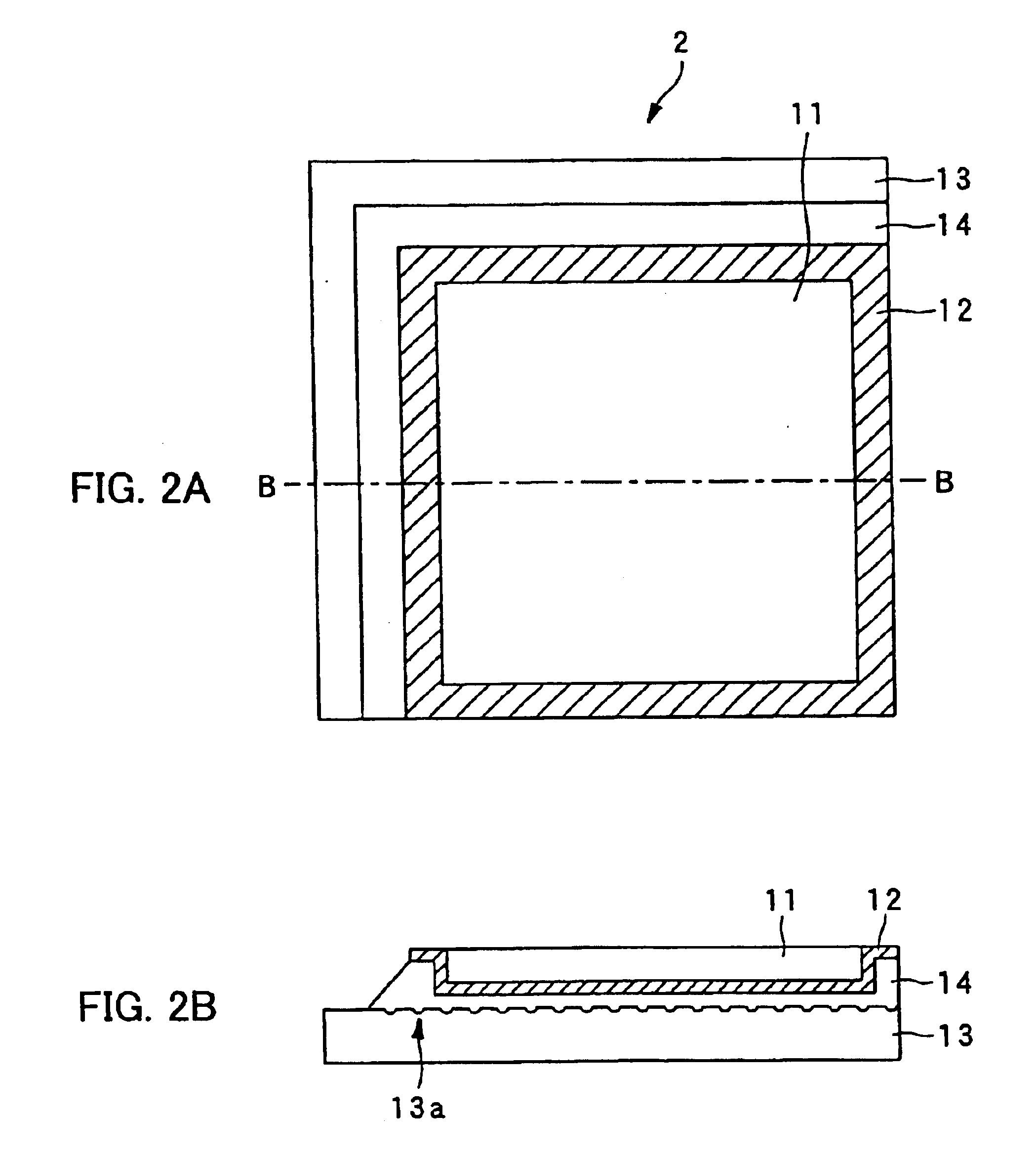

A method capable of quickly polishing an angular portion formed by a grinded back surface and a circumferential surface of a substrate without causing damages on the thin substrate is provided. The method includes rotating the substrate about its center, and pressing a polishing tape against the angular portion formed by the back surface and the circumferential surface of the substrate to polish the angular portion.

Owner:EBARA CORP

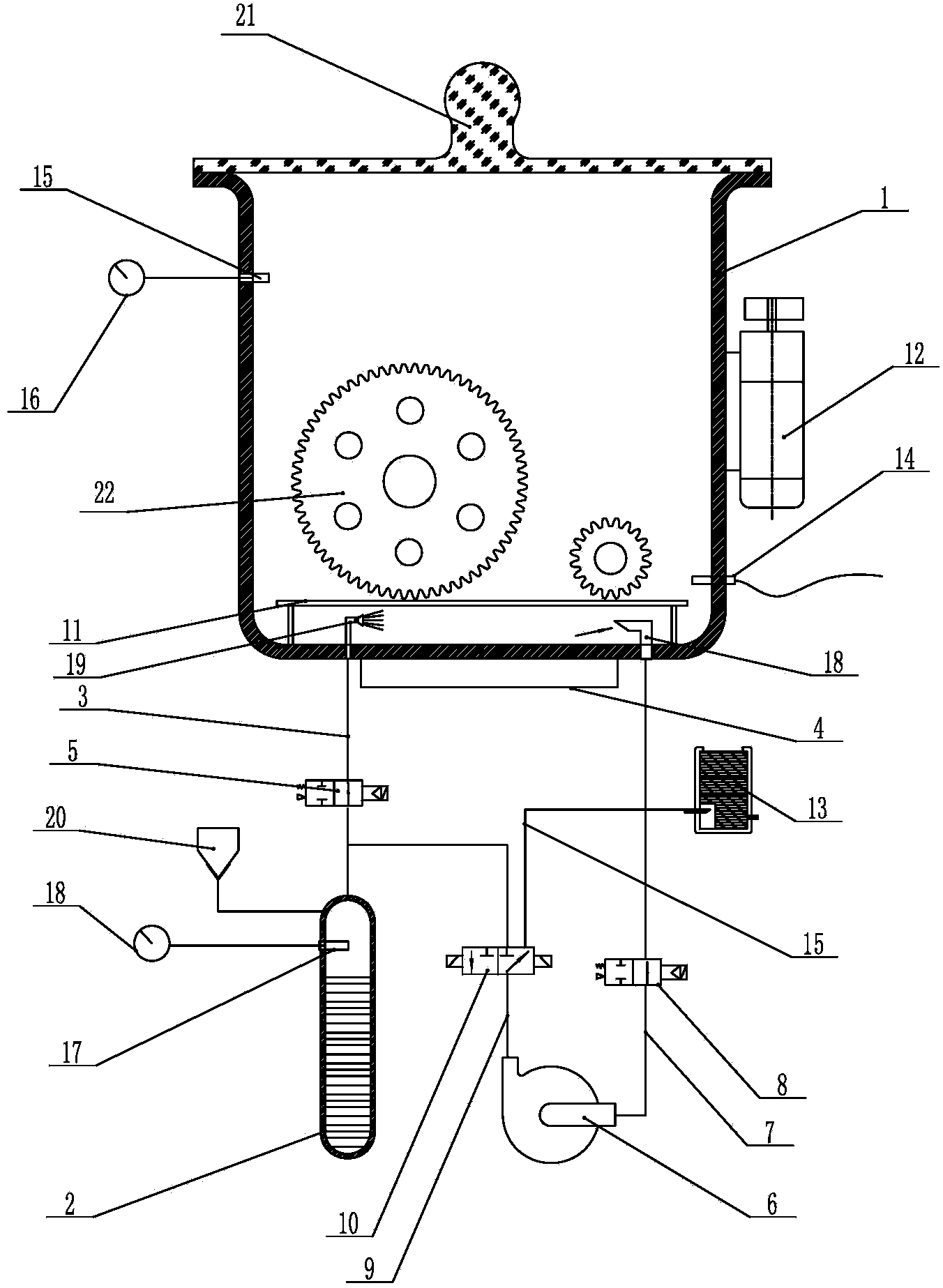

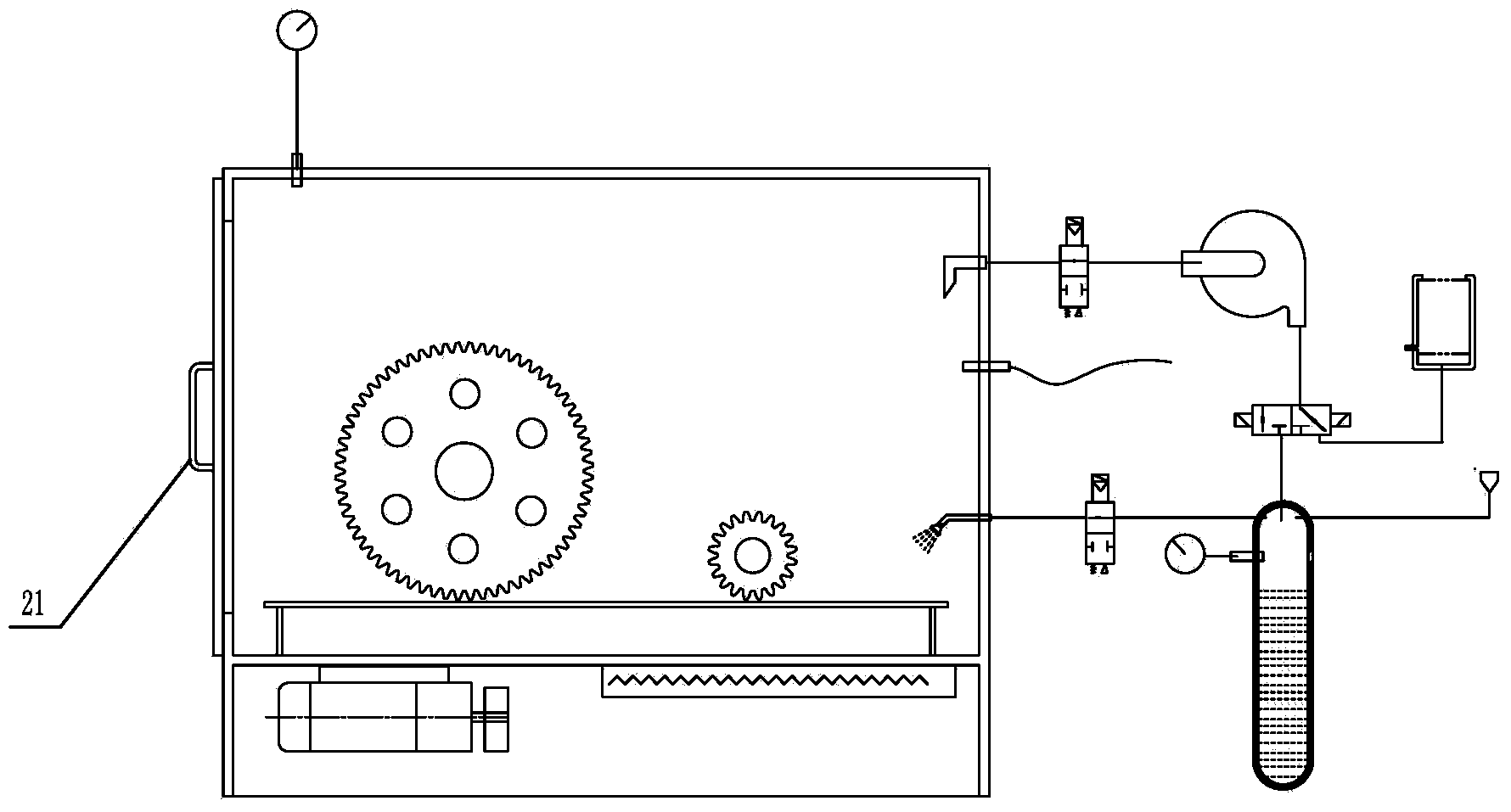

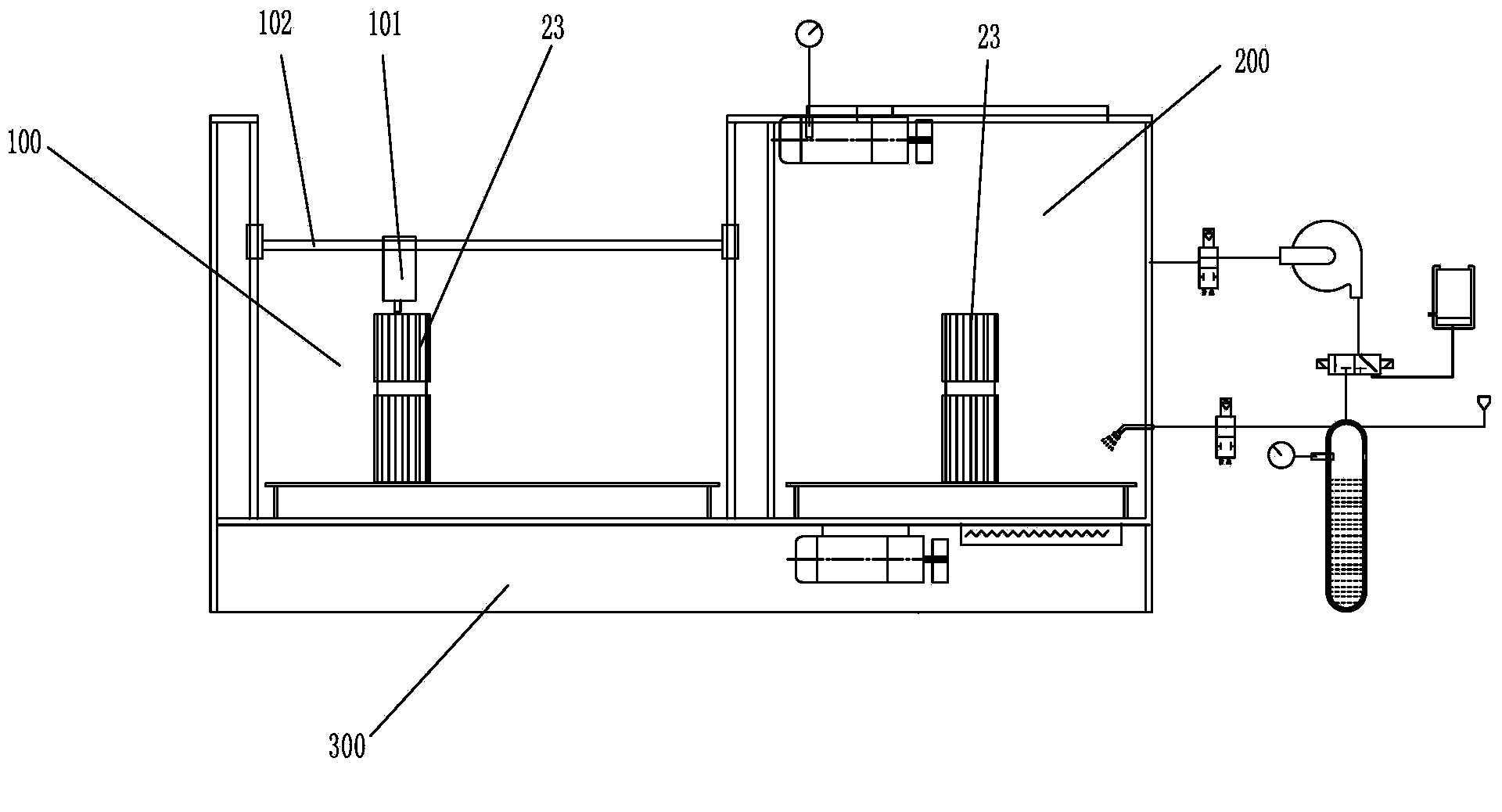

Apparatus and method for polishing three-dimensional printed plastic/resin pieces

The invention provides an apparatus for polishing three-dimensional printed plastic / resin pieces. The apparatus comprises a polishing chamber and a solvent storage tank which are communicated with each other by use of a liquid inlet pipe; the apparatus is characterized in that the polishing chamber is an airtight container, an exhaust opening of the polishing chamber is connected with an air inlet of a vacuum device, an air outlet of the vacuum device is connected to the outside atmosphere and the solvent storage tank, respectively, and a switch is used for controlling the vacuum device to be connected with or disconnected from the polishing chamber, the solvent storage tank and the outside atmosphere, respectively. The apparatus for polishing the three-dimensional printed plastic / resin pieces is environmentally-friendly, capable of effectively polishing to-be-polished pieces with complex structures, and also capable of quickly recovering the hardness of the polished pieces.

Owner:孙韶

Dielectric recording medium, and method of and apparatus for producing the same

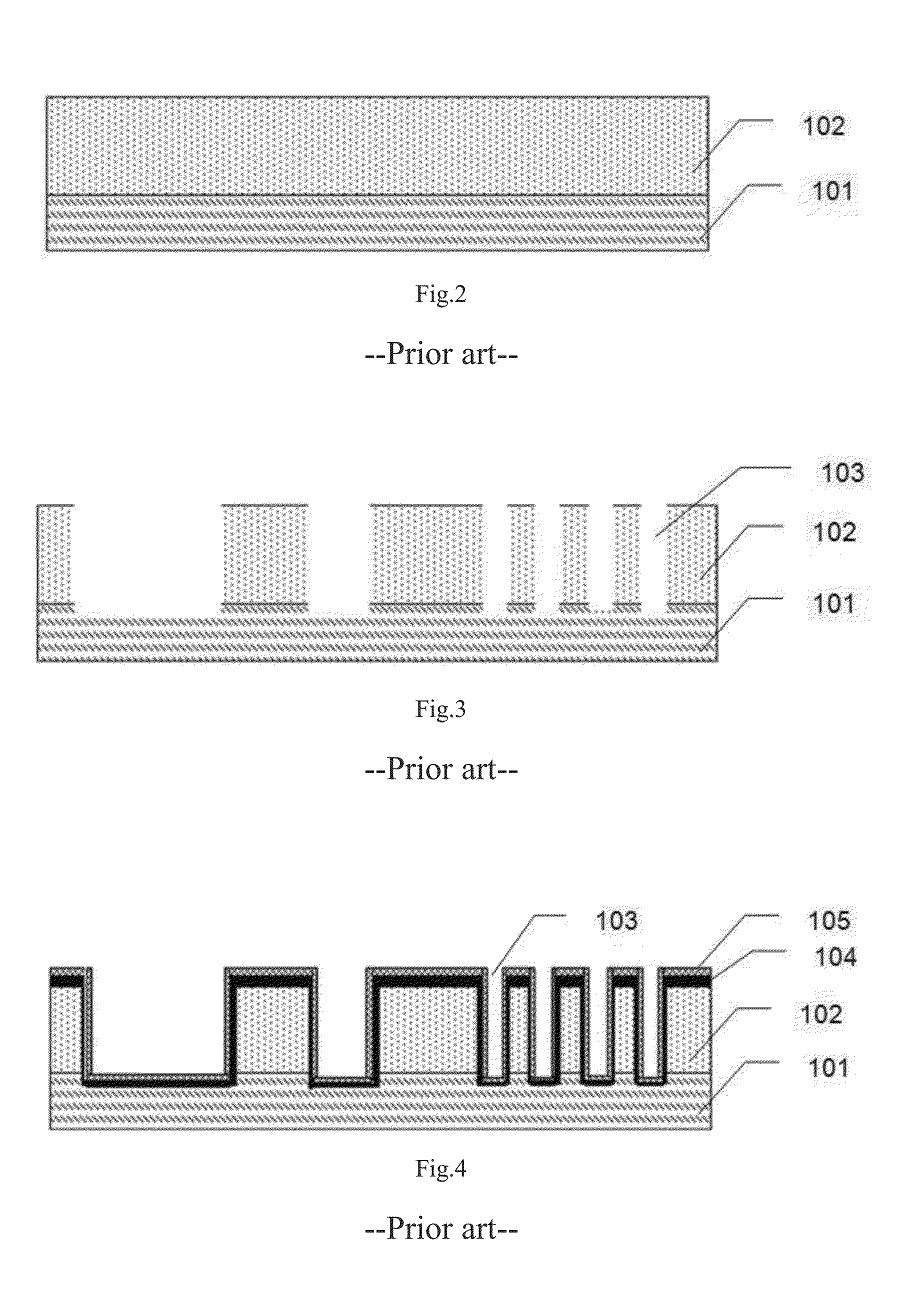

InactiveUS20050098532A1Remove electric charge on the recording surface rapidlyImprove abilitiesDecorative surface effectsNanoinformaticsSingle crystalResin adhesive

The dielectric recording medium is provided with a dielectric material, a conductive thin film, and a substrate. The conductive thin film and the substrate are bonded by a resin adhesive. The dielectric material is constructed of a ferroelectric single crystal having a uniform thickness, and its one surface is used for a recording and / or reproducing surface, on the order of mm on a side and about 5000 Å thick. The conductive thin film, about 1000 to 2000 Å thick, is placed on a surrounding portion and a back surface of the recording and / or reproducing surface of the dielectric material. The substrate is intended to preserve the thin dielectric material and maintain the planarity, and concave portions are formed on the adhesive surface. The concave portions absorb excessive resin adhesive when the dielectric material is bonded onto the substrate, which makes the adhesive surface uniform and flat.

Owner:PIONEER CORP +1

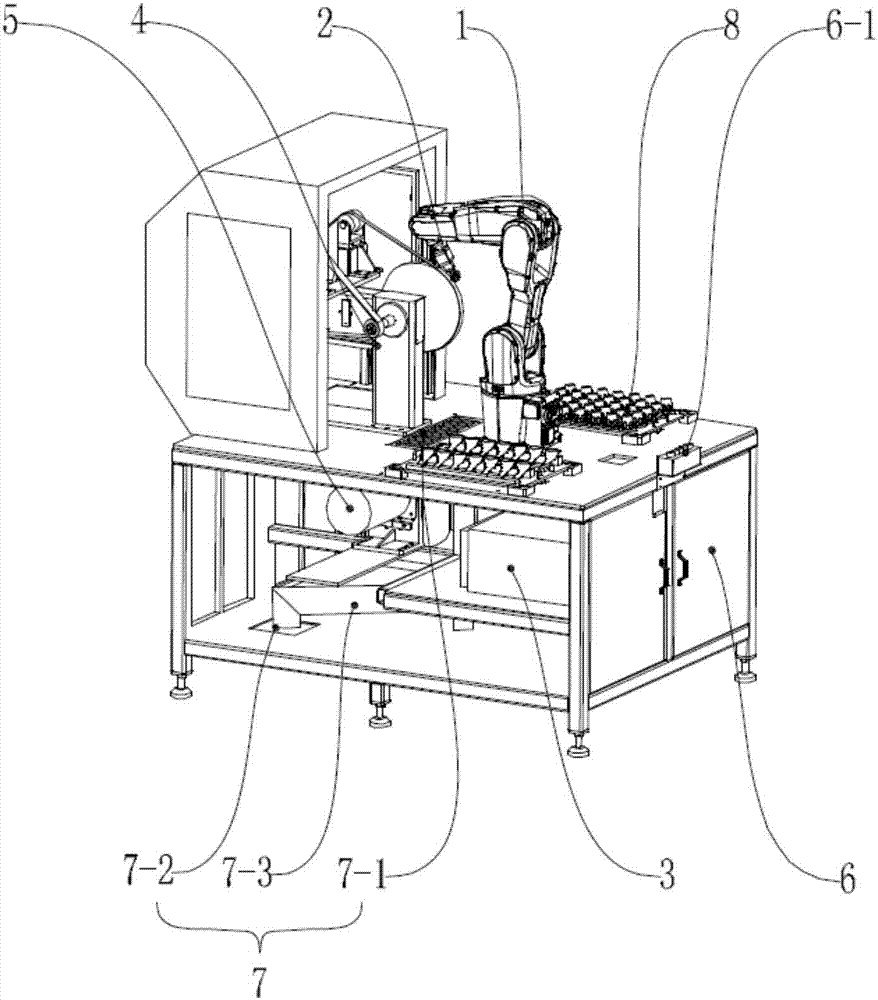

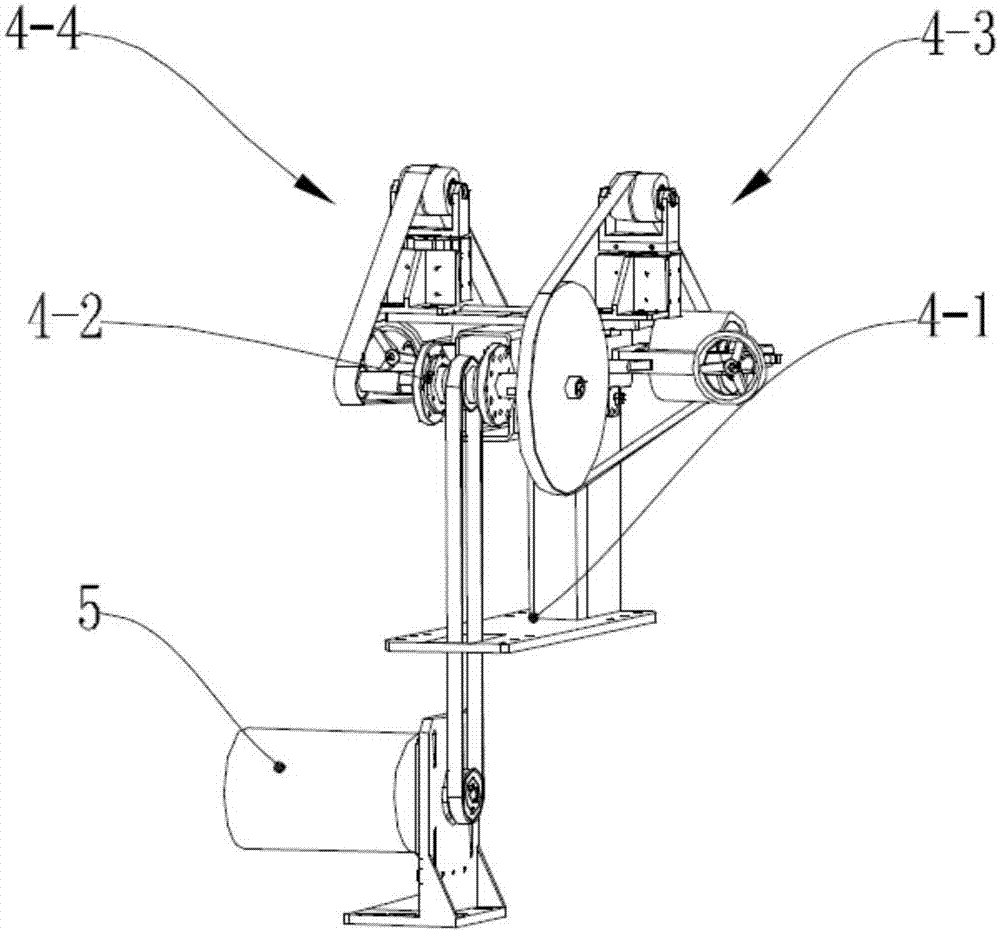

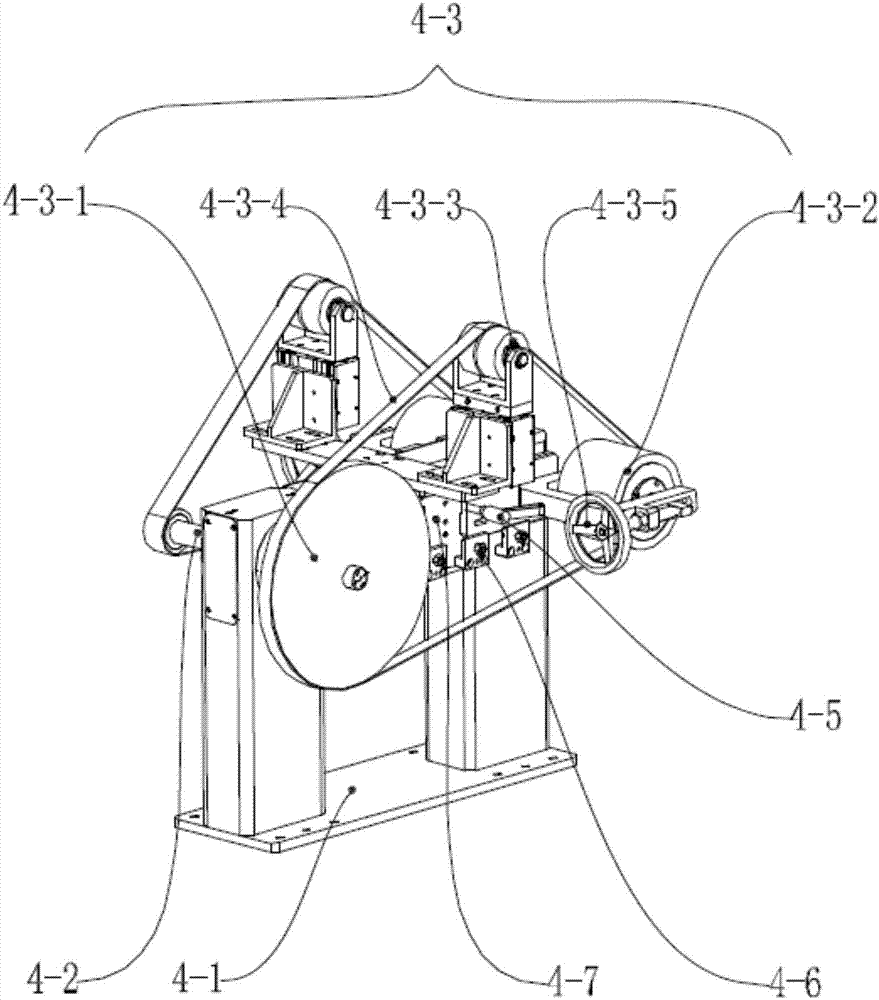

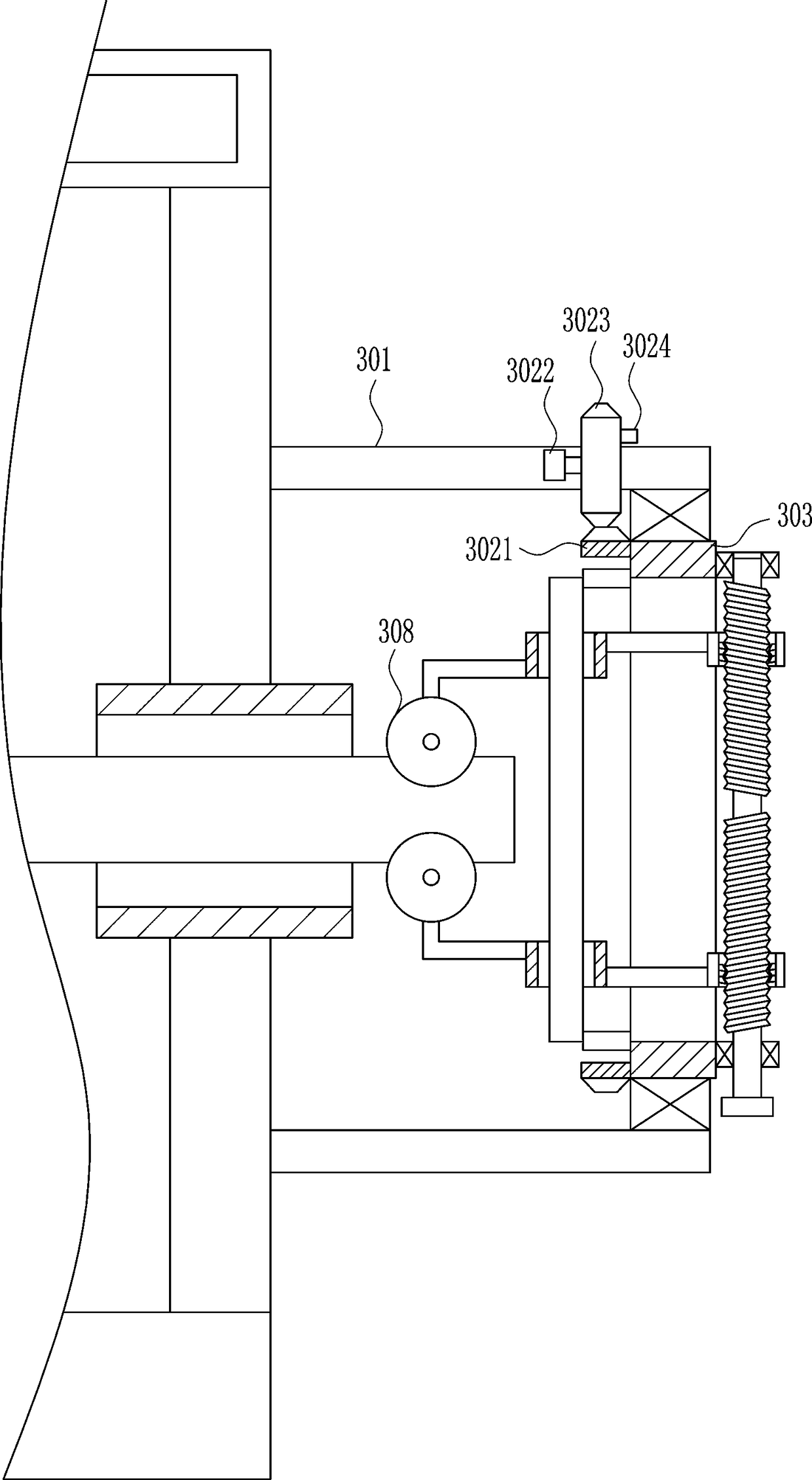

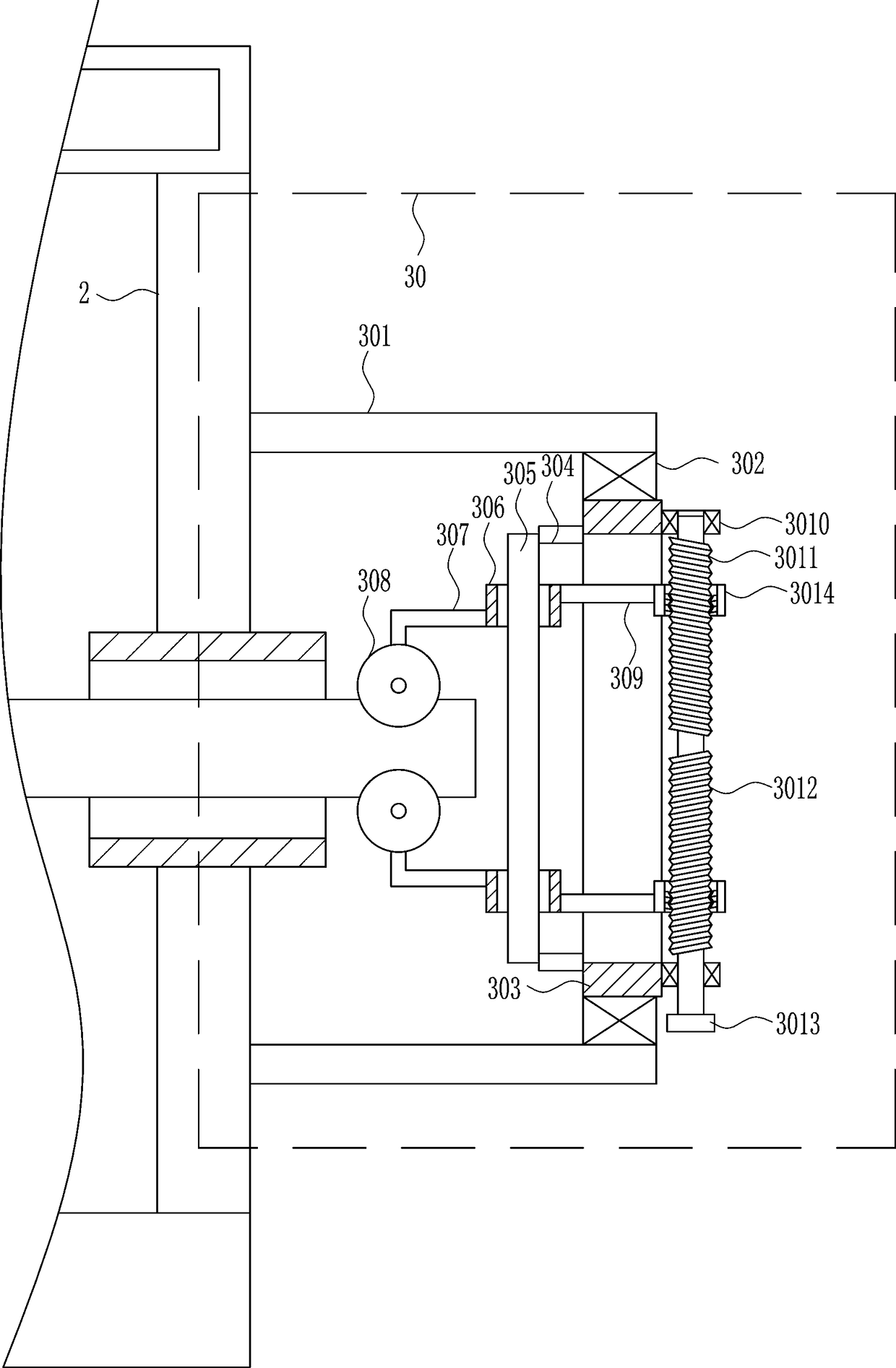

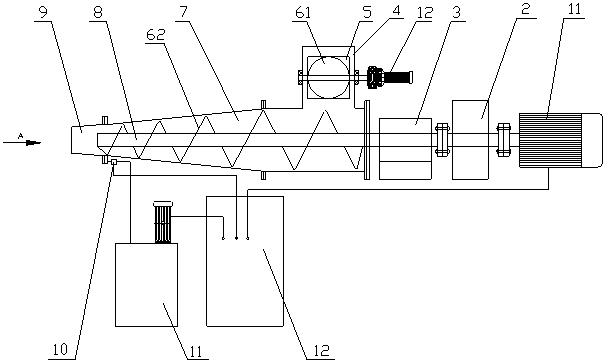

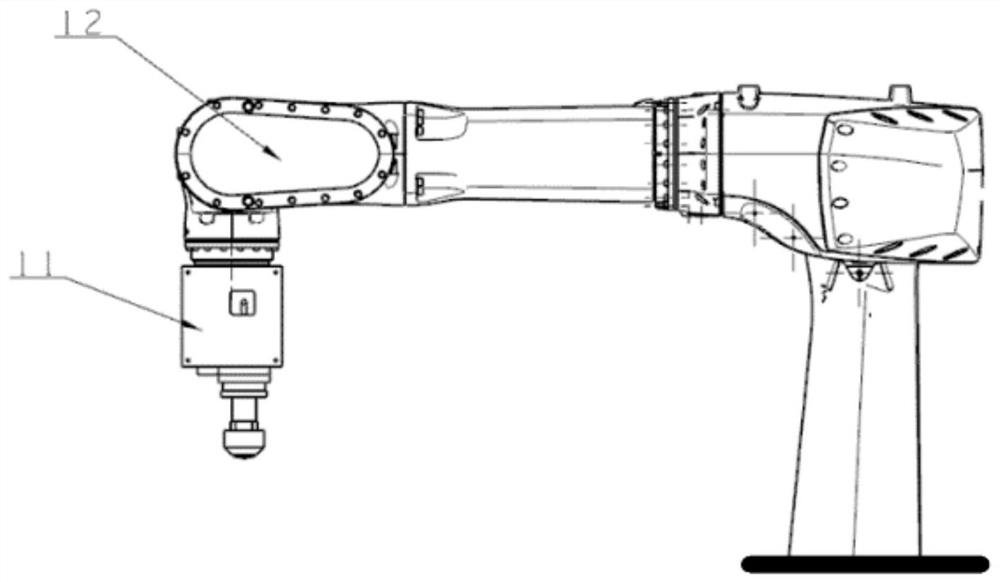

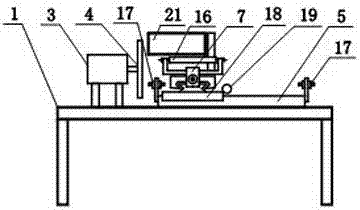

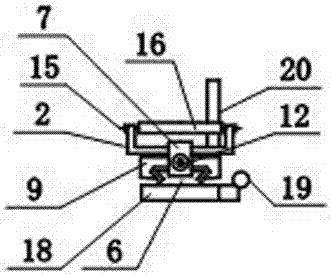

Desktop type grinding and polishing belt sander working table

PendingCN106956188AQuick sandingQuick polishBelt grinding machinesGrinding feedersSanderProgrammable logic controller

The invention relates to a desktop type grinding and polishing belt sander working table. The working table comprises a mechanical arm, a fixture, a robot controller, a single-drive grinding and polishing mechanism, a grinding motor, a programmable logic controller (PLC) control system and a working table body; the mechanical arm and the single-drive grinding and polishing mechanism are mounted on the upper surface of the working table body; the fixture is mounted at the free end of the mechanical arm in a replaceable manner; the robot controller is arranged in the working table body to control the motion of the mechanical arm; the single-drive grinding and polishing mechanism is located in front of the free end of the mechanical arm and comprises a grinding mechanism and a polishing mechanism; and the PLC control system controls the grinding motor to drive the grinding mechanism and the polishing mechanism simultaneously to operate. The working table has the beneficial effects as follows: small machined parts can be ground and polished quickly, and the production efficiency is high; a belt sander is simple to operate, the precision is high, the flexibility is good, the occupied area is small, and movement and popularization are convenient; and multiple belt sanders can be combined for production, the automation degree is high, and modularization and standardization are easy to realize.

Owner:GUANGDONG LXD ROBOTICS CO LTD

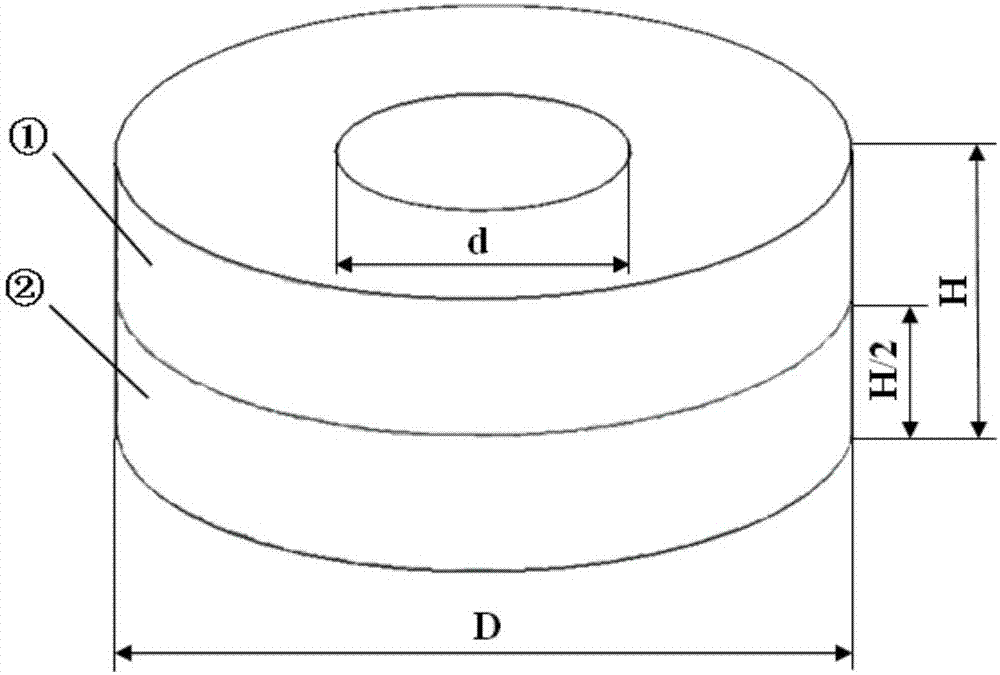

Preparation method of 42CrMo steel casting rolling forming ring member sample for EBSD testing

InactiveCN106896009AEasy to prepareSimple structureMaterial analysis using wave/particle radiationPreparing sample for investigationElectrolysisMetallurgy

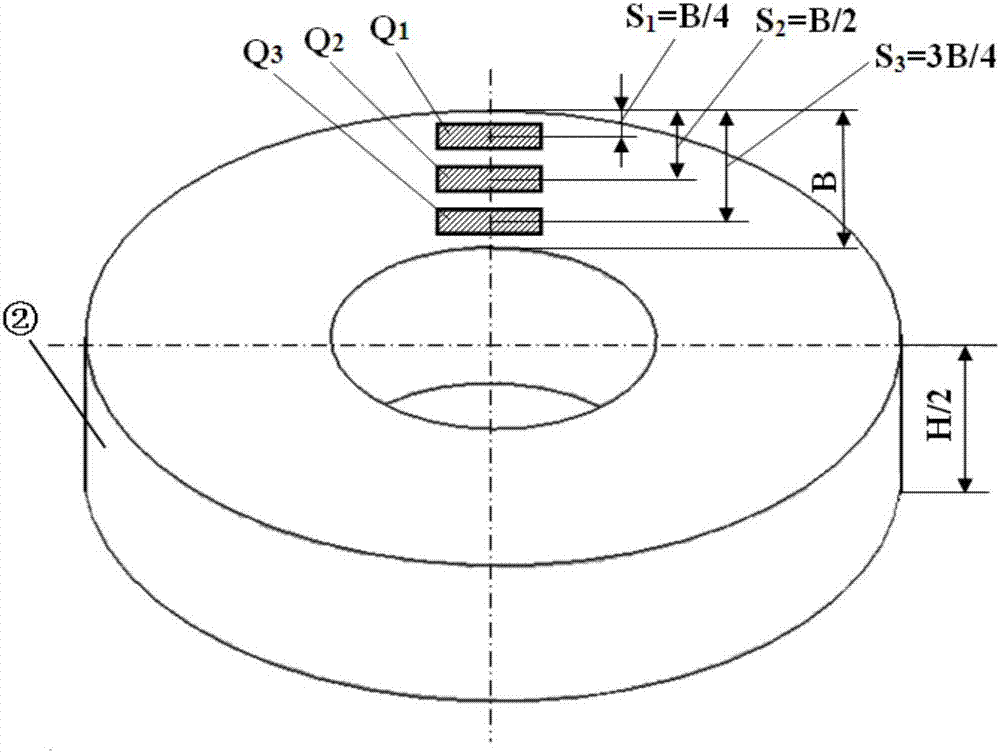

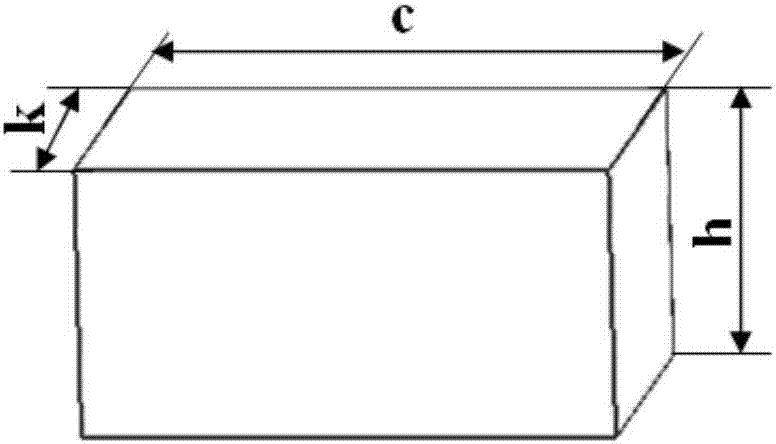

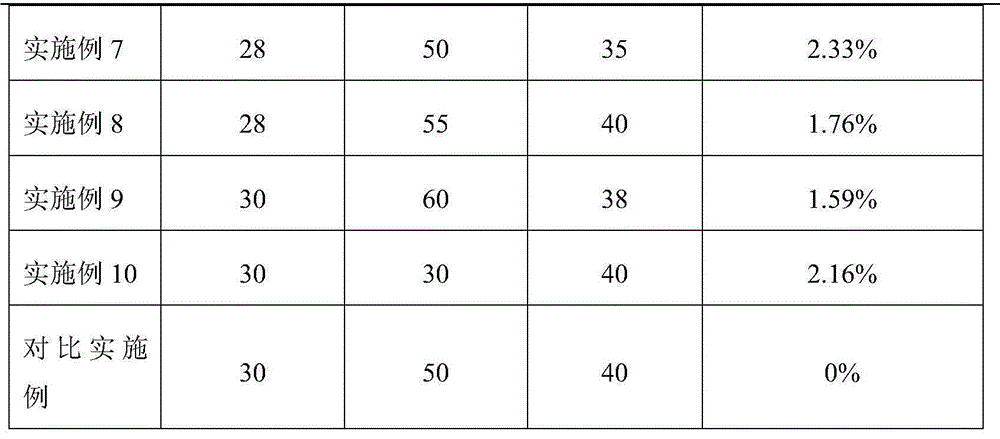

The invention discloses a preparation method of a 42CrMo steel casting rolling forming ring member sample for EBSD (electron back-scattered diffraction) testing and belongs to the technical field of ring member forming process electron microscope sample preparation. The preparation method is characterized by including following steps: (1), cutting sample units Q: cutting sample units Q1, Q2 and Q3 with length c=5-8mm, width k=3-4mm and height h=2-3mm at different positions along a radial wall thickness direction in a middle section in the height direction of a 42CrMo steel casting rolling forming ring member; (2), grinding: grinding the sample on an automatic grinder until glossiness of the surface is 12-13 grade; (3), ultrasonically cleaning; (4), preparing electrolysis polishing liquid; (5), electrolytically polishing: adopting self-made electrolysis polishing equipment to conduct a polishing experiment, wherein voltage is 25-30V, current is 0.6-0.8mA and time is 50-60s; (6), cleaning: sequentially putting 4-5 beakers containing a certain amount of anhydrous alcohol; (7), pre-observing: observing a slightly-corroded indistinctly-visible crystal boundary on the surface of the sample under a metalloscope. The preparation method is simple and low in investment, and the sample prepared by the method can be used for EBSD observation under a scanning electron microscope to obtain clear crystal boundary orientated images.

Owner:GUILIN UNIV OF ELECTRONIC TECH +1

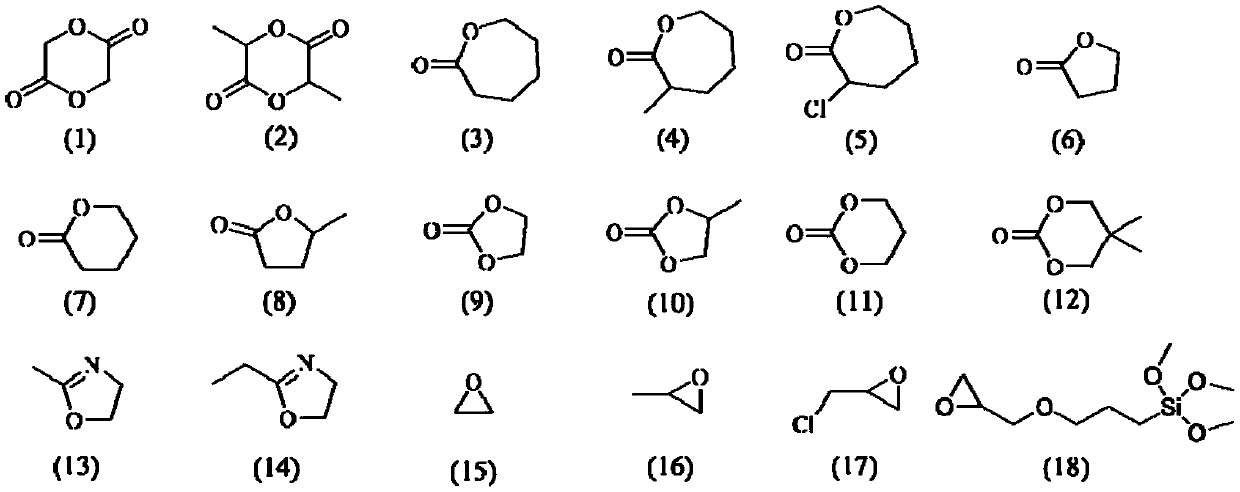

Degradable hyperbranched resin and preparation method and application thereof

ActiveCN110540652ASmall molecular weightAvoid pollutionAntifouling/underwater paintsPaints with biocidesPolymer scienceFunctional monomer

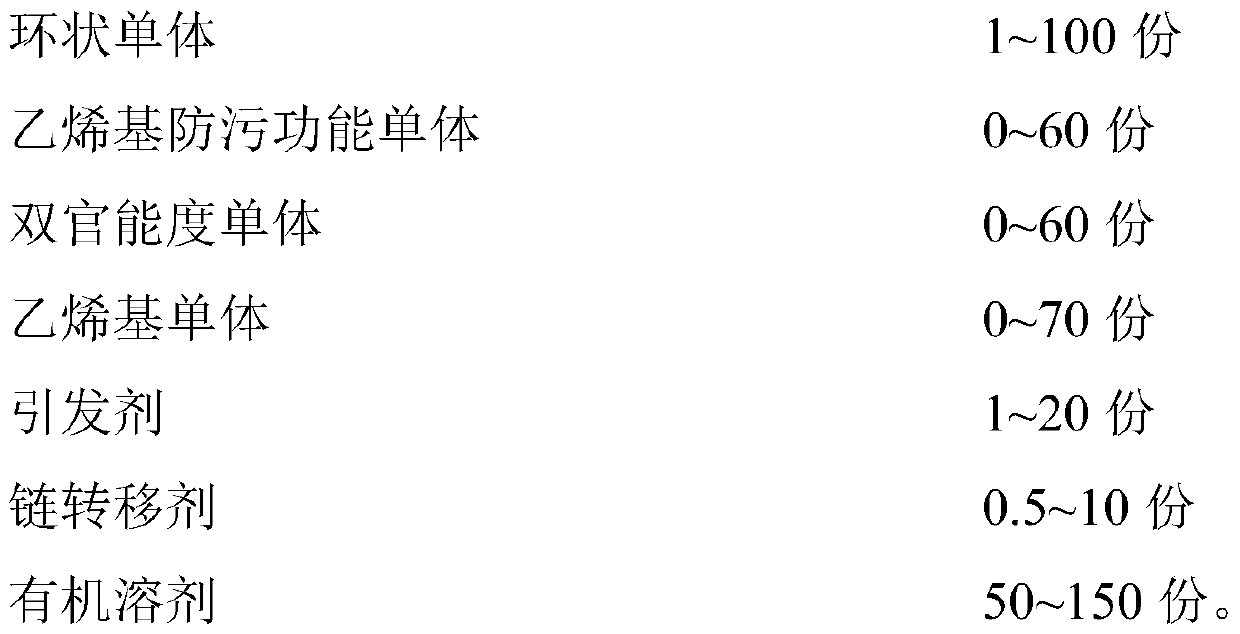

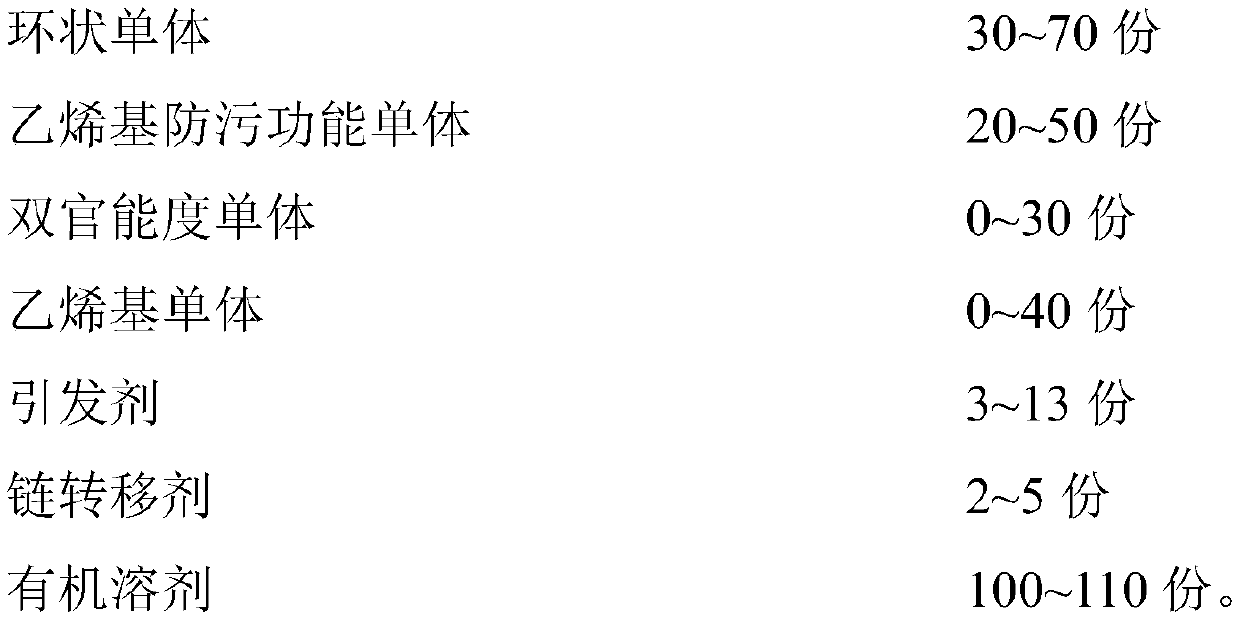

The invention belongs to the technical field of marine antifouling materials, and discloses degradable hyperbranched resin and a preparation method and application thereof. The degradable hyperbranched resin is prepared from the following components in parts by weight: 1-100 parts of a cyclic monomer, 0-60 parts of a vinyl antifouling functional monomer, 0-60 parts of a bifunctional monomer, 0-70parts of a vinyl monomer, 1-20 parts of an initiator, 0.5-10 parts of a chain transfer agent and 50-150 parts of an organic solvent. According to the invention, the bifunctional monomer and the chaintransfer agent are introduced in the process of polymerization, and a hyperbranched structure is prepared from traditional straight-chain polymer antifouling resin and is applied to the field of marine antifouling for the first time. Besides, the resin also has the same advantages of high solid content and low viscosity as a hyperbranched polymer; and the preparation method is simple and feasiblein process, low in cost and suitable for industrial production, and has good development prospects in the field of marine antifouling coatings.

Owner:广东海巍新材料科技有限公司

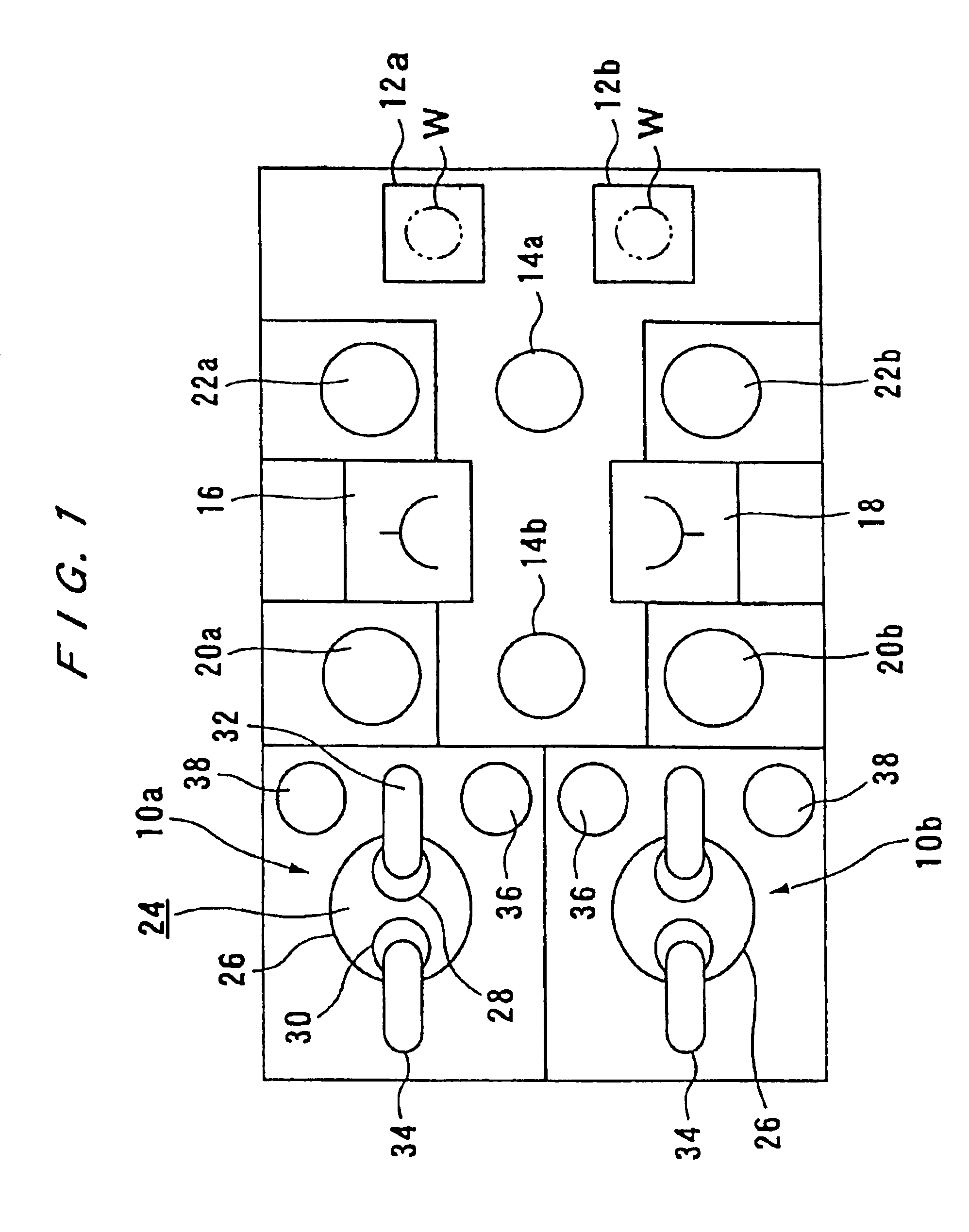

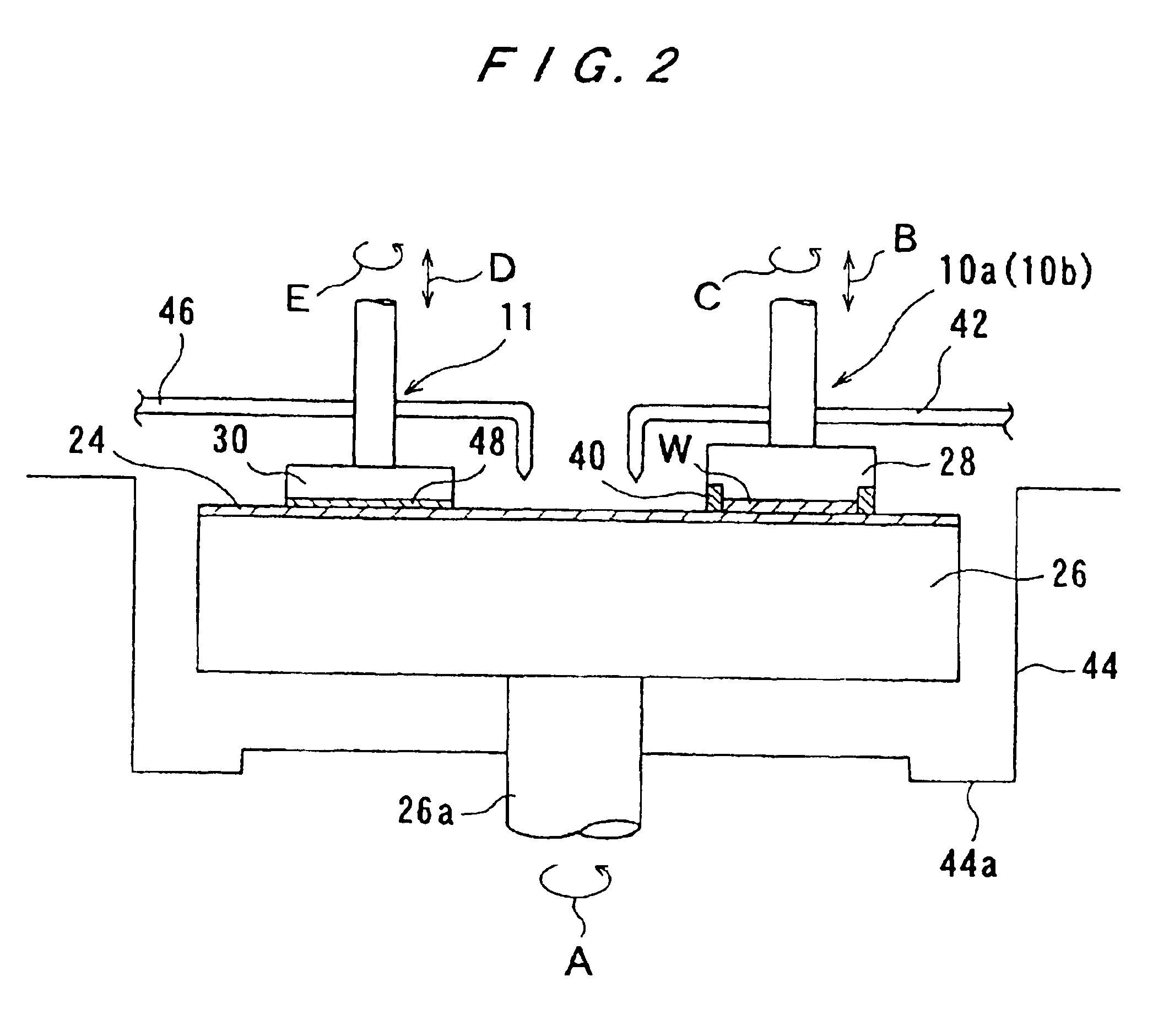

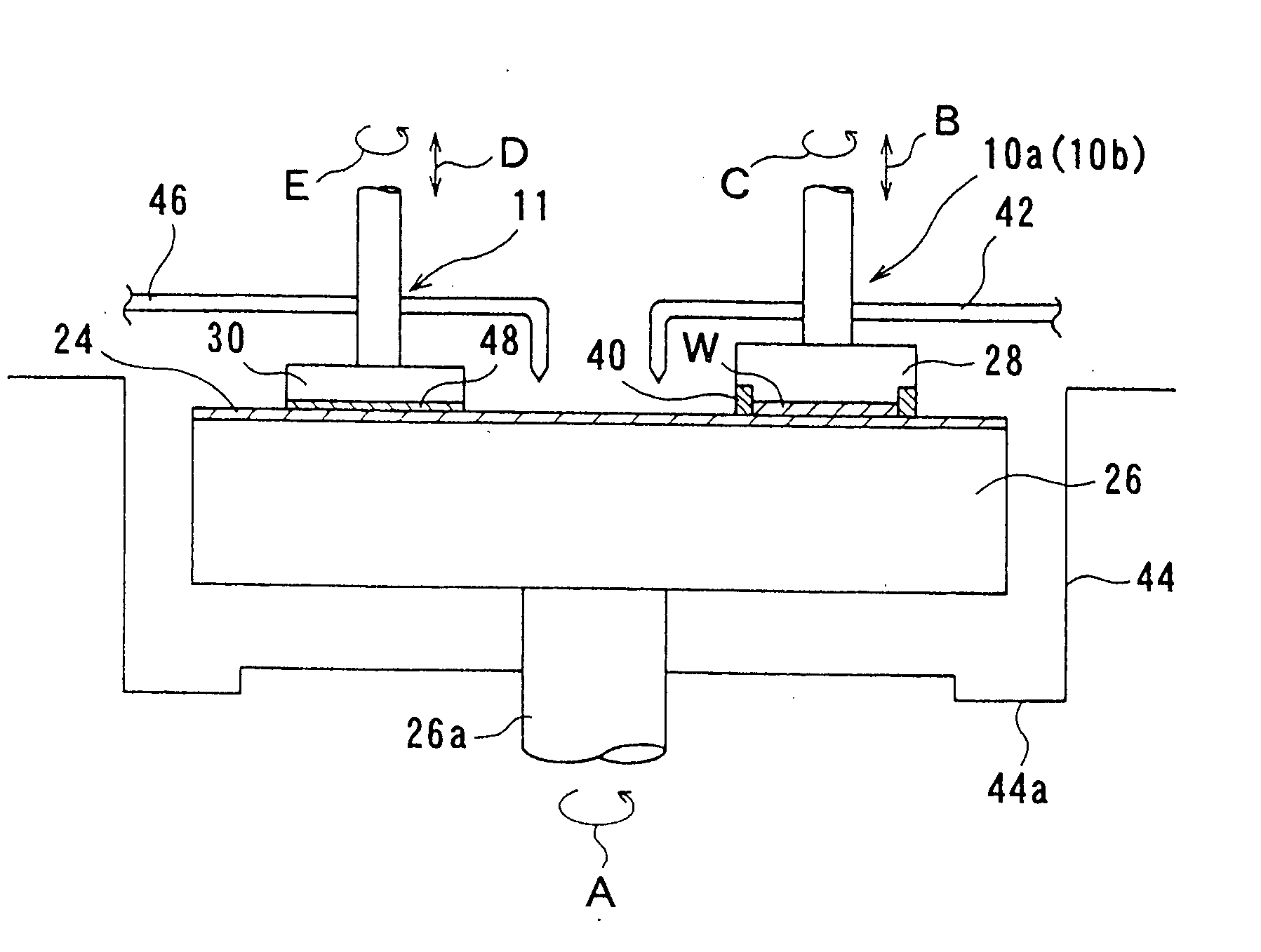

Polishing apparatus and method

InactiveUS6935932B2Easy to operateEfficient polishingEdge grinding machinesSemiconductor/solid-state device manufacturingCopperFlat mirror

A polishing apparatus and method has a function of polishing a surface of a film formed on a substrate to a flat mirror finish and a function of polishing unnecessary metal film such as copper film deposited on an outer peripheral portion of the substrate to remove such unnecessary metal film. The polishing apparatus comprises a surface polishing mechanism comprising a polishing table having a polishing surface and a top ring for holding the substrate and pressing the substrate against the polishing surface of the polishing table to thereby polish a surface of the substrate, and an outer periphery polishing mechanism for polishing an outer peripheral portion of the substrate.

Owner:KK TOSHIBA

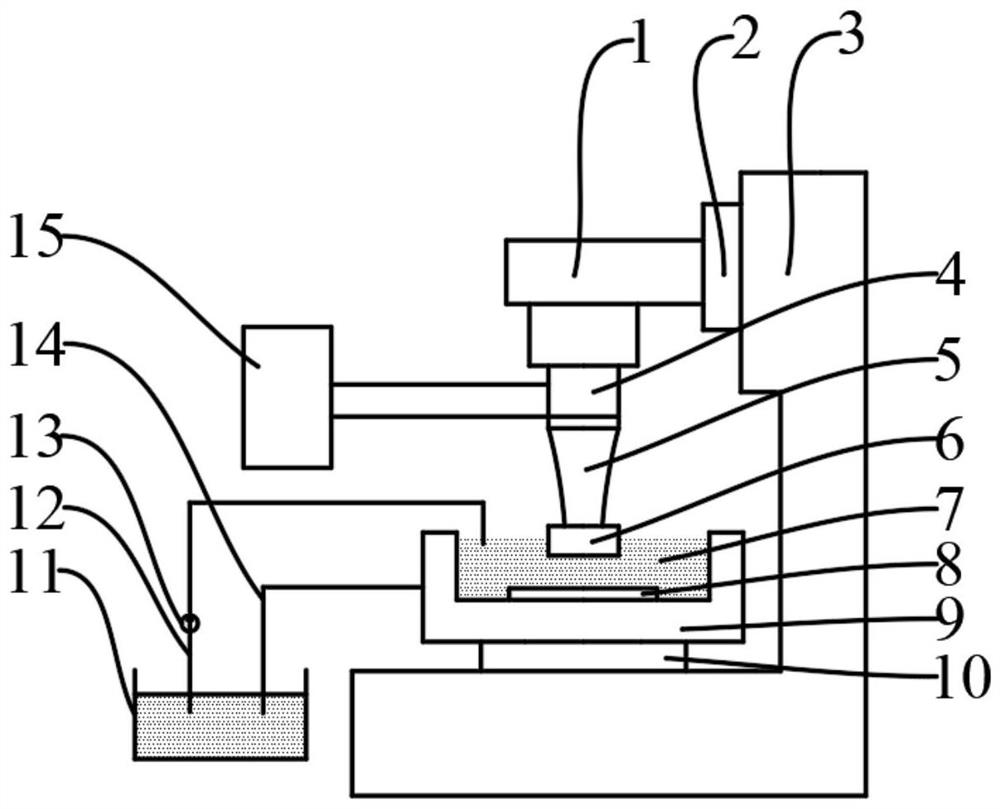

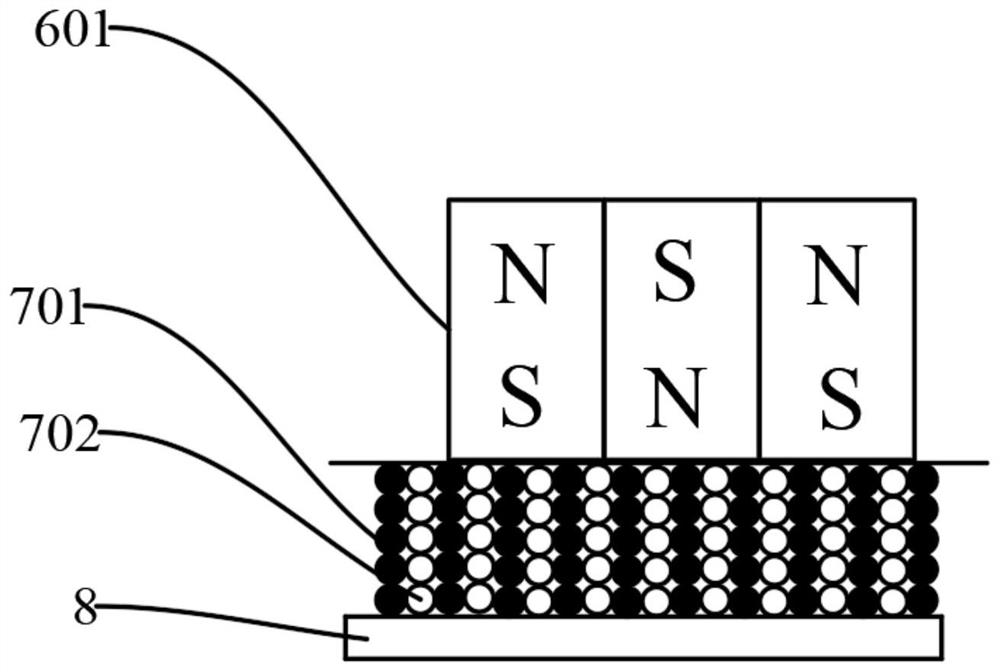

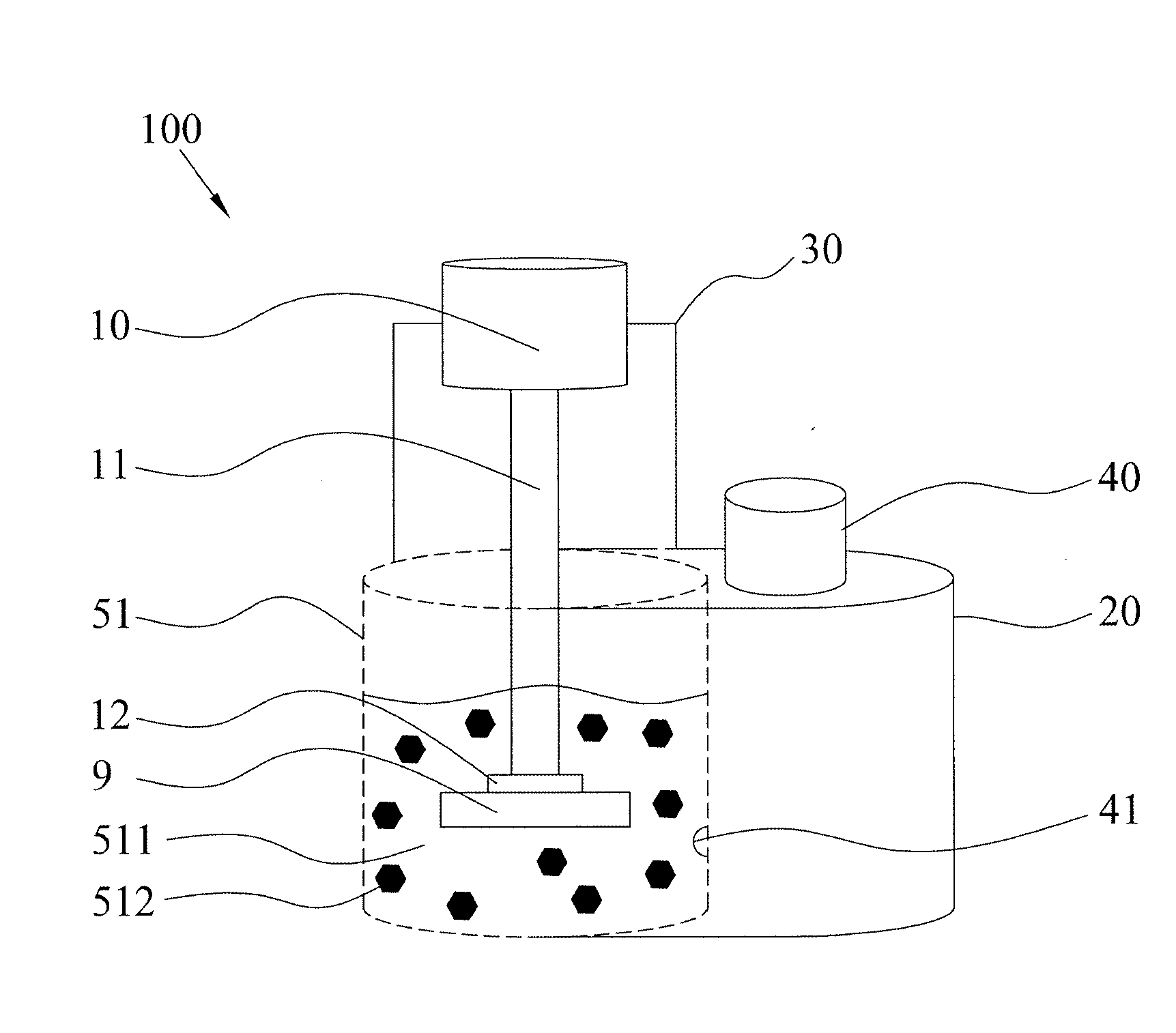

Ultrasonic magneto-rheological chemical composite polishing device and method

InactiveCN113334149AIncreased mechanical removal performanceImprove uniformityEdge grinding machinesPolishing machinesMagnetoEngineering

The invention provides an ultrasonic magneto-rheological chemical composite polishing device. The ultrasonic magneto-rheological chemical composite polishing device comprises a rack, a cup-shaped polishing disc, a magneto-rheological tool head and an ultrasonic vibration mechanism, wherein the cup-shaped polishing disc is arranged on the rack and used for containing a working solution and placing a workpiece to be machined, and the cup-shaped polishing disc can move back and forth in the horizontal plane relative to the rack; the magneto-rheological tool head has magnetism and is used for being inserted into the working solution and acting with the working solution to enable the working solution to form a magneto-rheological grinding head; and the ultrasonic vibration mechanism comprises an ultrasonic generator, an ultrasonic transducer electrically connected with the ultrasonic generator and ultrasonic amplitude transformers arranged at the output end of the ultrasonic transducer, the ultrasonic amplitude transformers are arranged up and down, the magneto-rheological tool head is arranged at the lower ends of the ultrasonic amplitude transformers, the upper ends of the ultrasonic amplitude transformers are connected with the output end of the ultrasonic transducer, and the ultrasonic transducer is arranged on the rack in an up-down moving mode. According to the polishing device, ultrasonic high-frequency vibration, the acoustic-chemical effect and the magneto-rheological effect are combined, and therefore the polishing effect can be effectively improved.

Owner:GUANGDONG POLYTECHNIC NORMAL UNIV

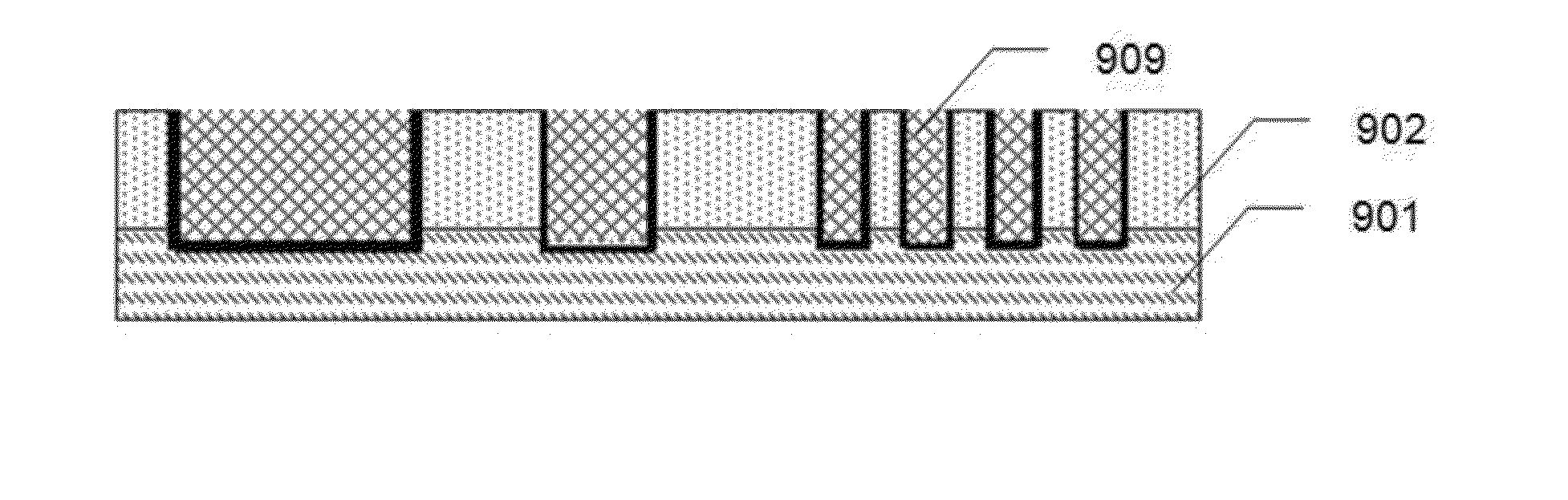

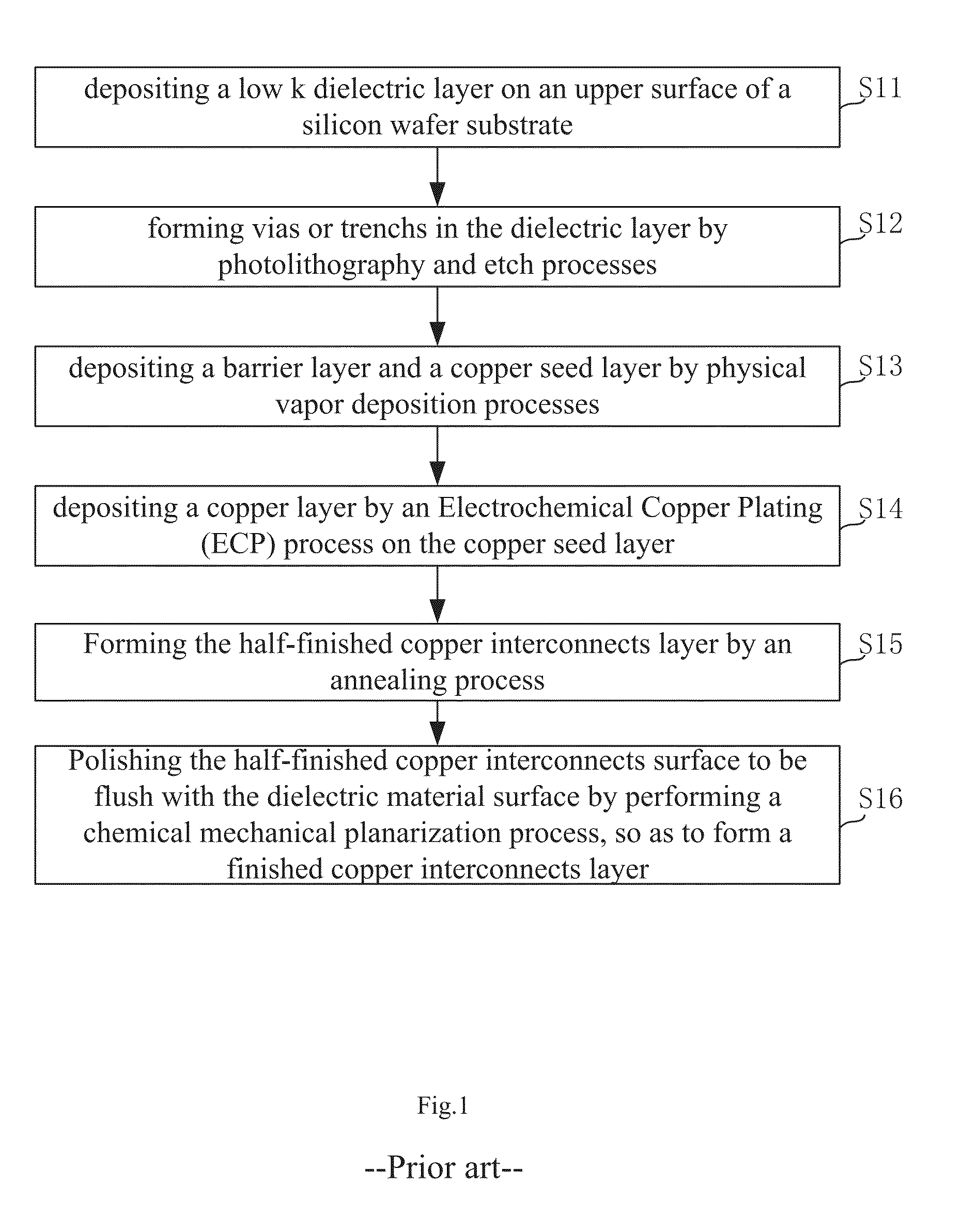

Method of forming copper interconnects

ActiveUS20160276169A1Effective thickness is minimized and avoidedUniform resistivitySemiconductor/solid-state device manufacturingCopper interconnectDielectric layer

A method of forming copper interconnects includes: depositing a dielectric layer on a silicon wafer substrate; forming vias and / or trenches in the dielectric layer; next, depositing a barrier layer and a copper seed layer sequentially from bottom to up on the dielectric layer; depositing a copper layer on the copper seed layer, and performing an annealing process; then performing a multi-step polishing process to remove bulk coppers and stopping at the barrier layer; performing a planarization process to remove the barrier layer on the surface of the dielectric layer, a portion of the dielectric layer, and a portion of the copper in the vias and / or trenches to form the copper interconnects in the dielectric layer.

Owner:SHANGHAI INTEGRATED CIRCUIT RES & DEV CENT

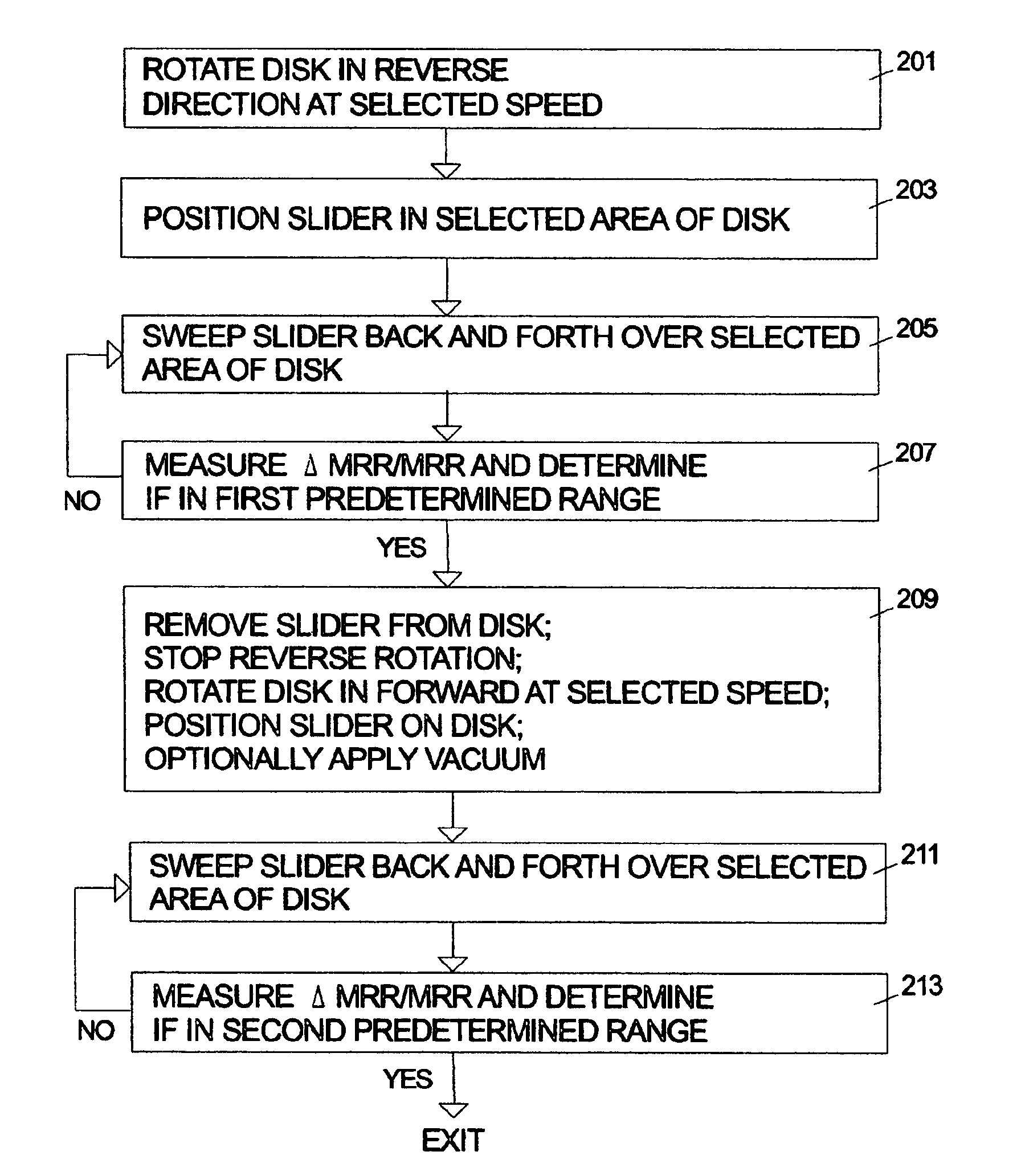

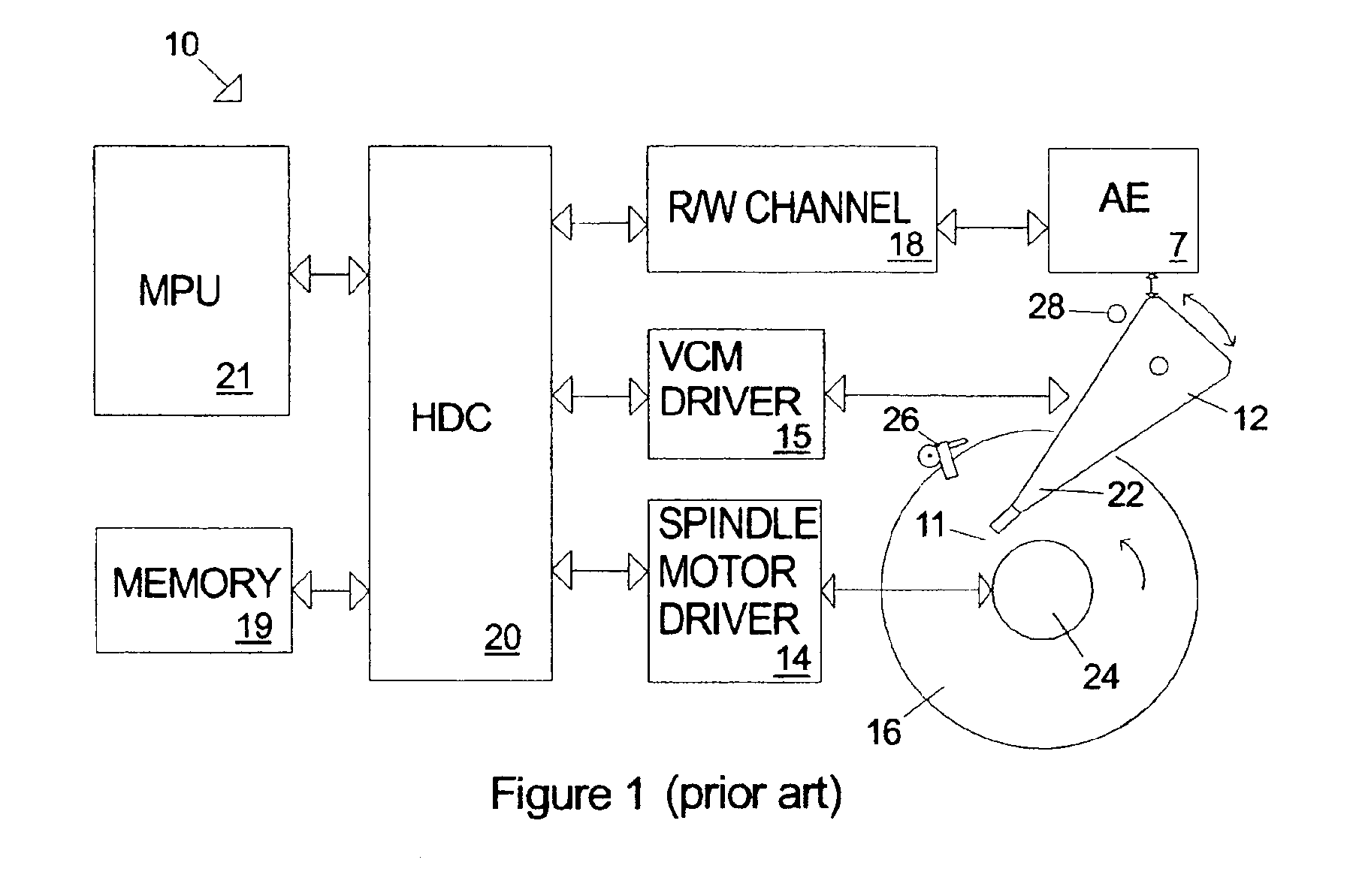

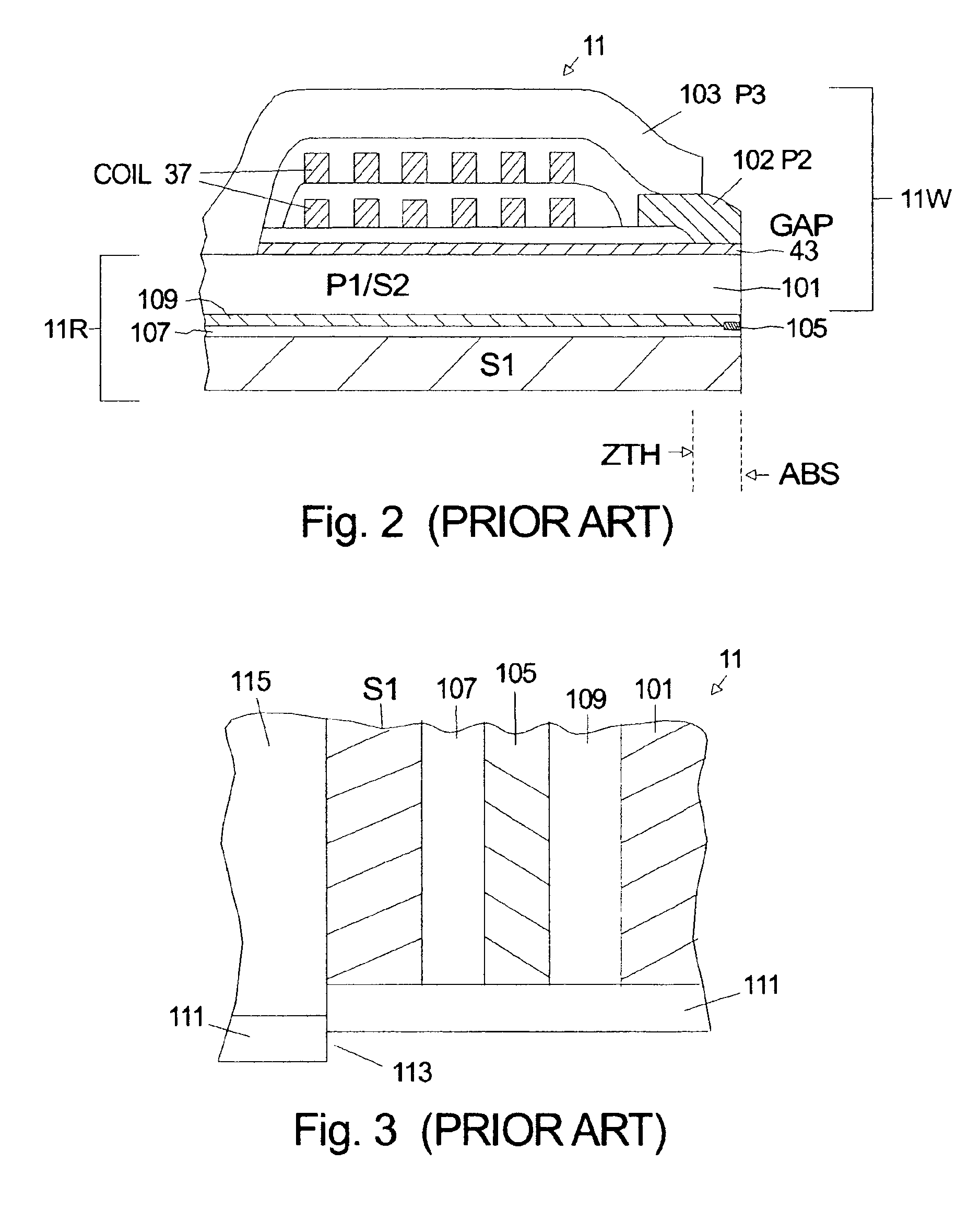

Method and apparatus using reverse disk rotation to achieve slider contact with a disk surface

InactiveUS6934101B2Quick polishHigh precisionFilamentary/web record carriersFluid-dynamic spacing of headsMagnetic transducersAir bearing

A method for burnishing a slider in a disk drive in which the disk is rotated in the opposite or reverse direction from that used to develop the air-bearing and to read and write data is described. Rotating the disk in the reverse direction results in no air-bearing being formed and the slider being in contact with the disk surface. The burnishing removes material over the magnetic transducers in the slider which separate the transducers from the disk resulting in greater sensitivity. Optionally the stopping point for burnishing can be determined by monitoring measurable parameters such as the change in the MR resistance (MRR), i.e., ΔMRR / MRR until a selected range is achieved. The invention can be used to remove an overcoat from the air-bearing surface of the slider, remove protruding areas from the slider and to remove debris from the disk surface.

Owner:WESTERN DIGITAL TECH INC

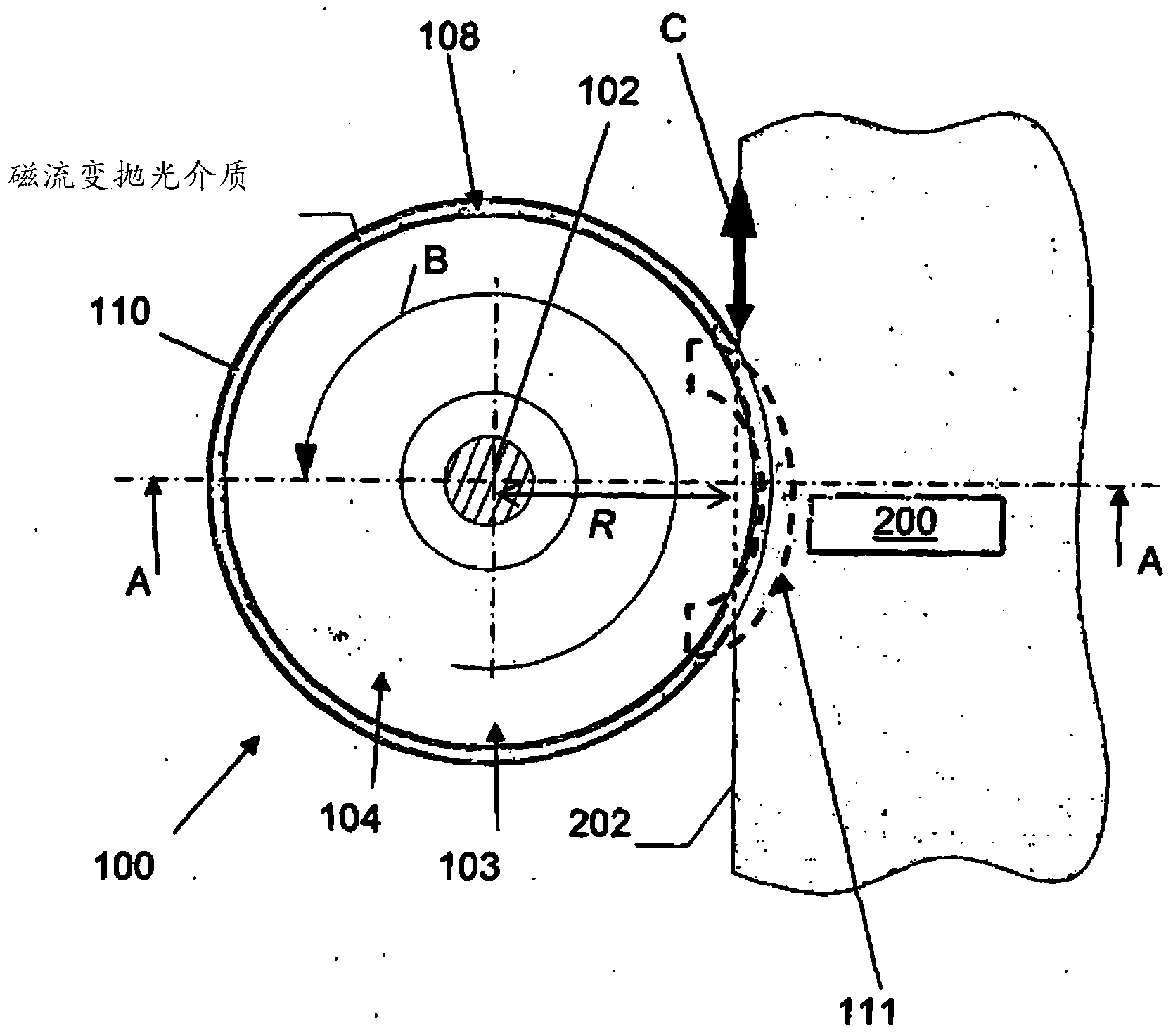

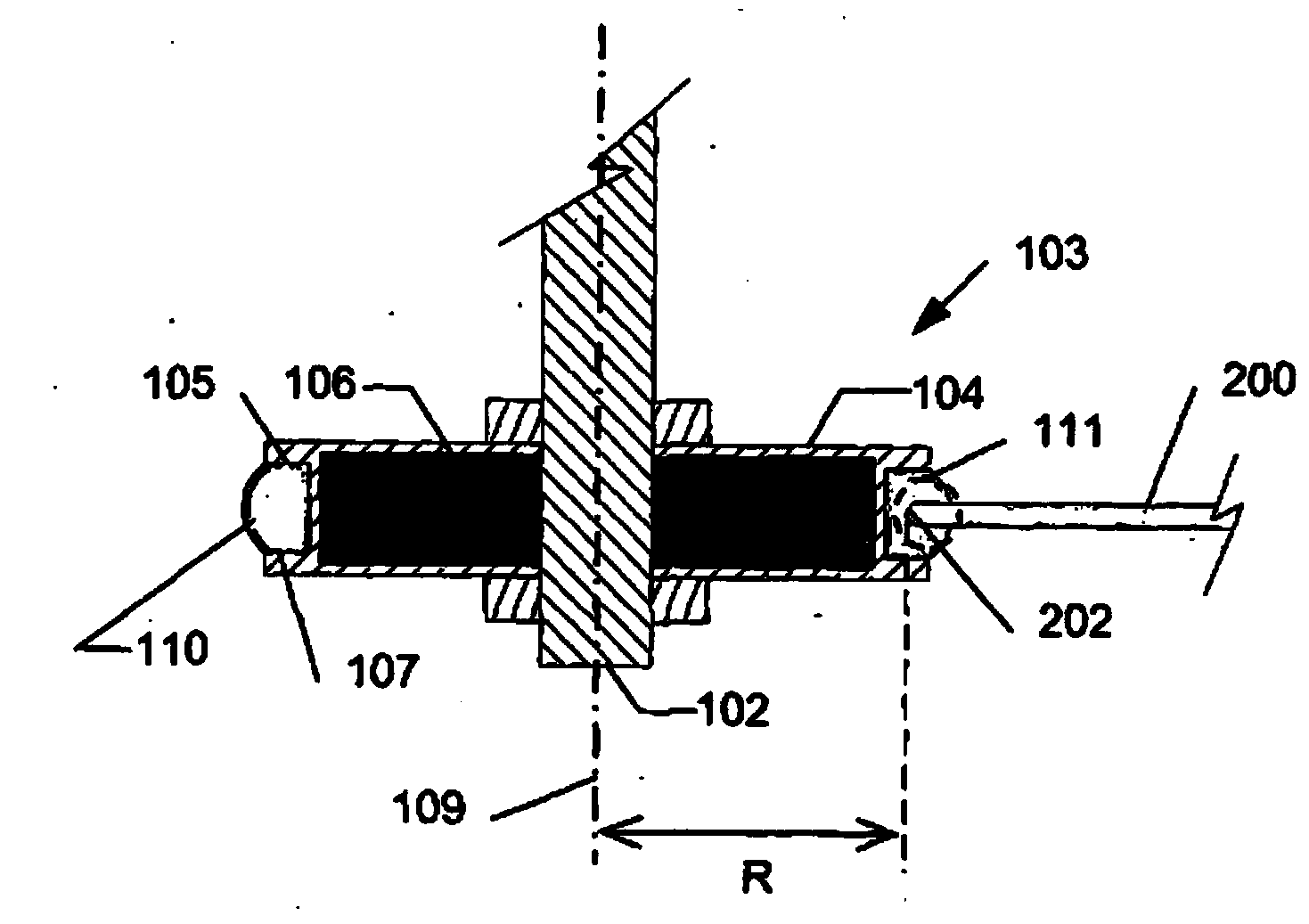

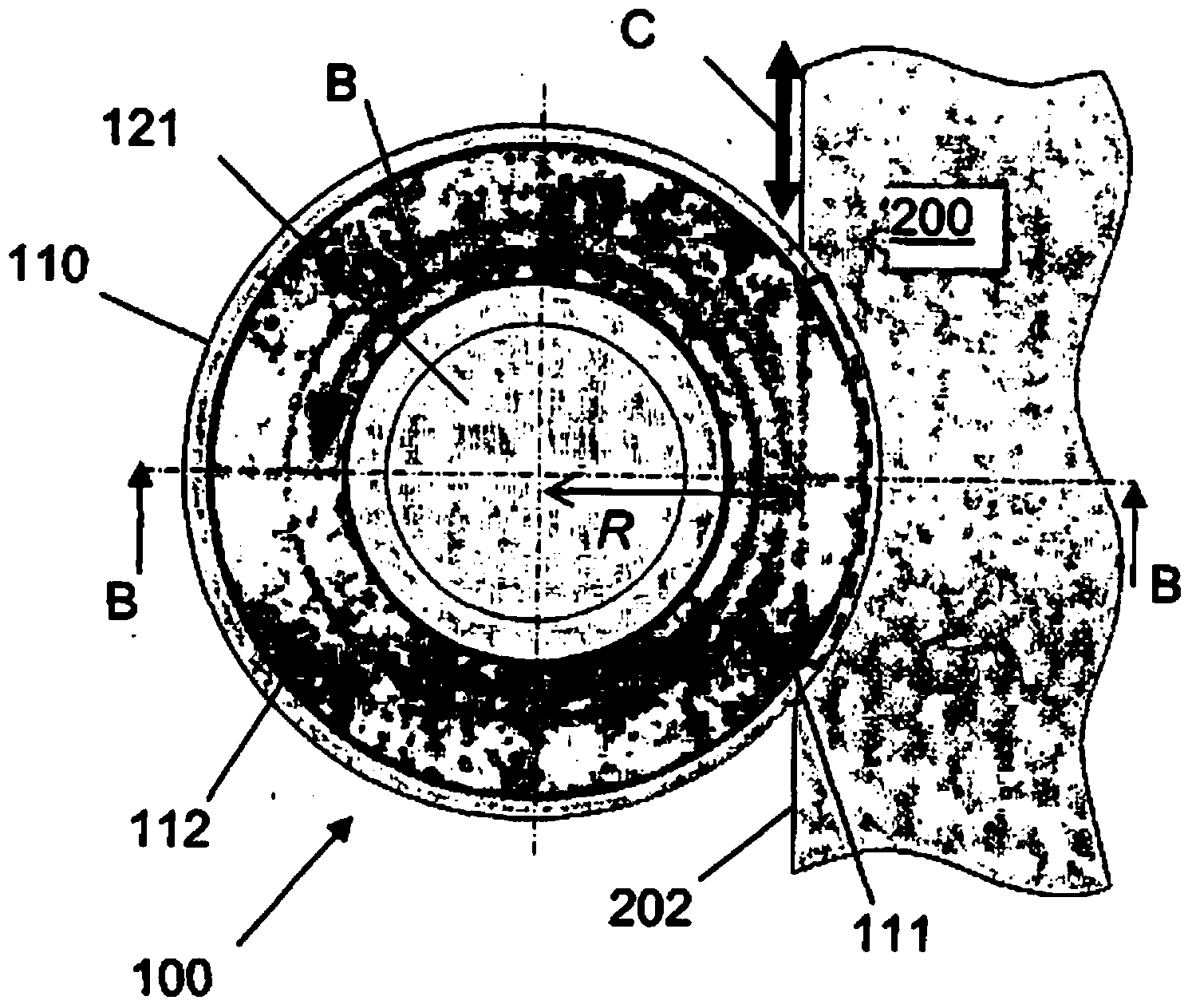

Apparatus and method for polishing an edge of an article using magnetorheological (MR) fluid

InactiveCN103402704AImprove removal rateShorten polishing timeEdge grinding machinesSuperfinishing machinesRelative motionEngineering

Disclosed is a method and apparatus for polishing an edge of an article involving providing at least one carrier including: first and second opposing surfaces defining a groove, the first and second opposing surfaces being spaced apart in a first direction to receive the edge; and magnetic field generator configured to provide a magnetic field in the groove to stiffen magnetorheological (MR) fluid disposed in the groove to provide at least one polishing zone; receiving the edge in the polishing zone; and driving relative motion between the at least one carrier and the edge in a second direction substantially transverse to the first direction.

Owner:AGENCY FOR SCI TECH & RES

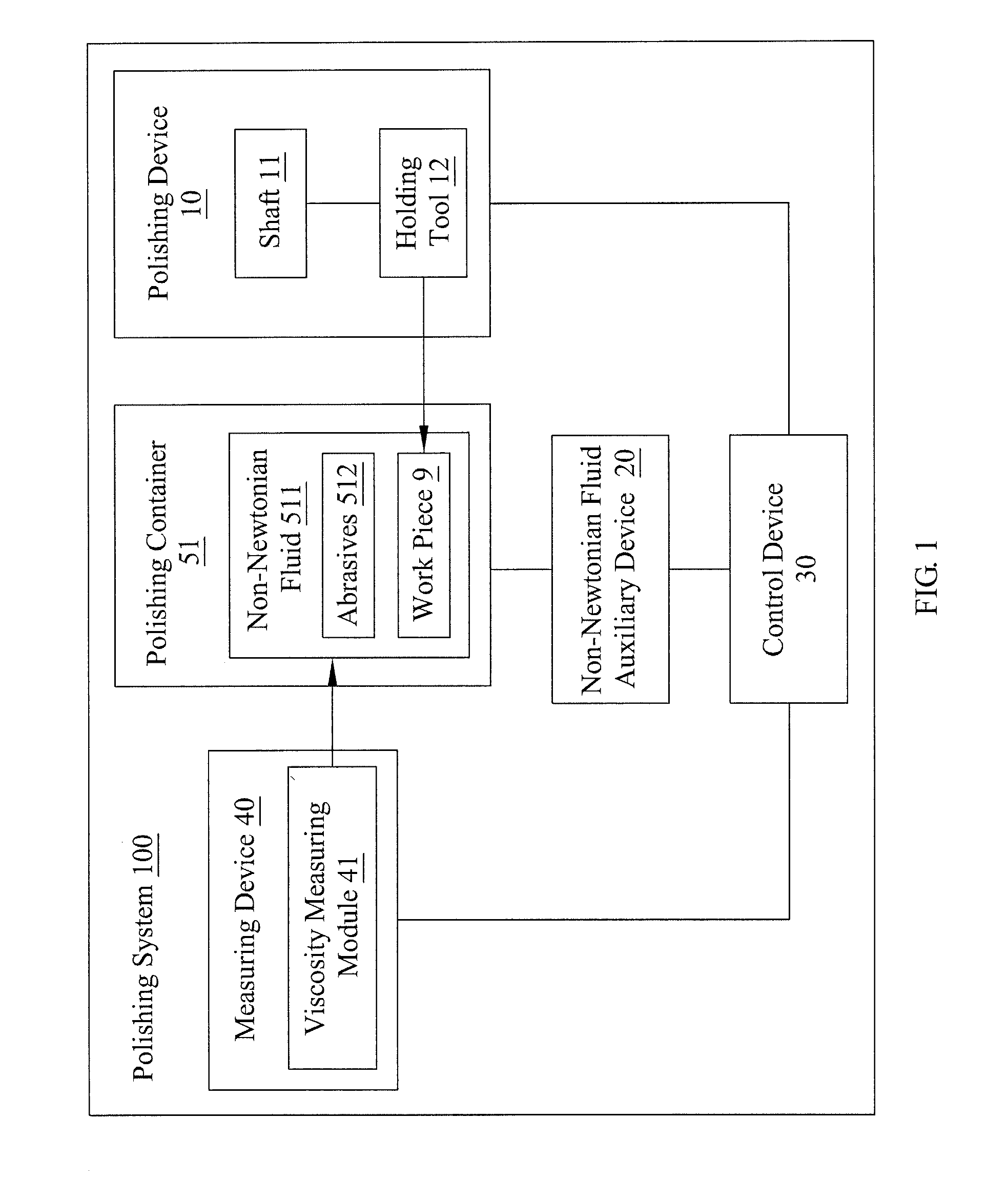

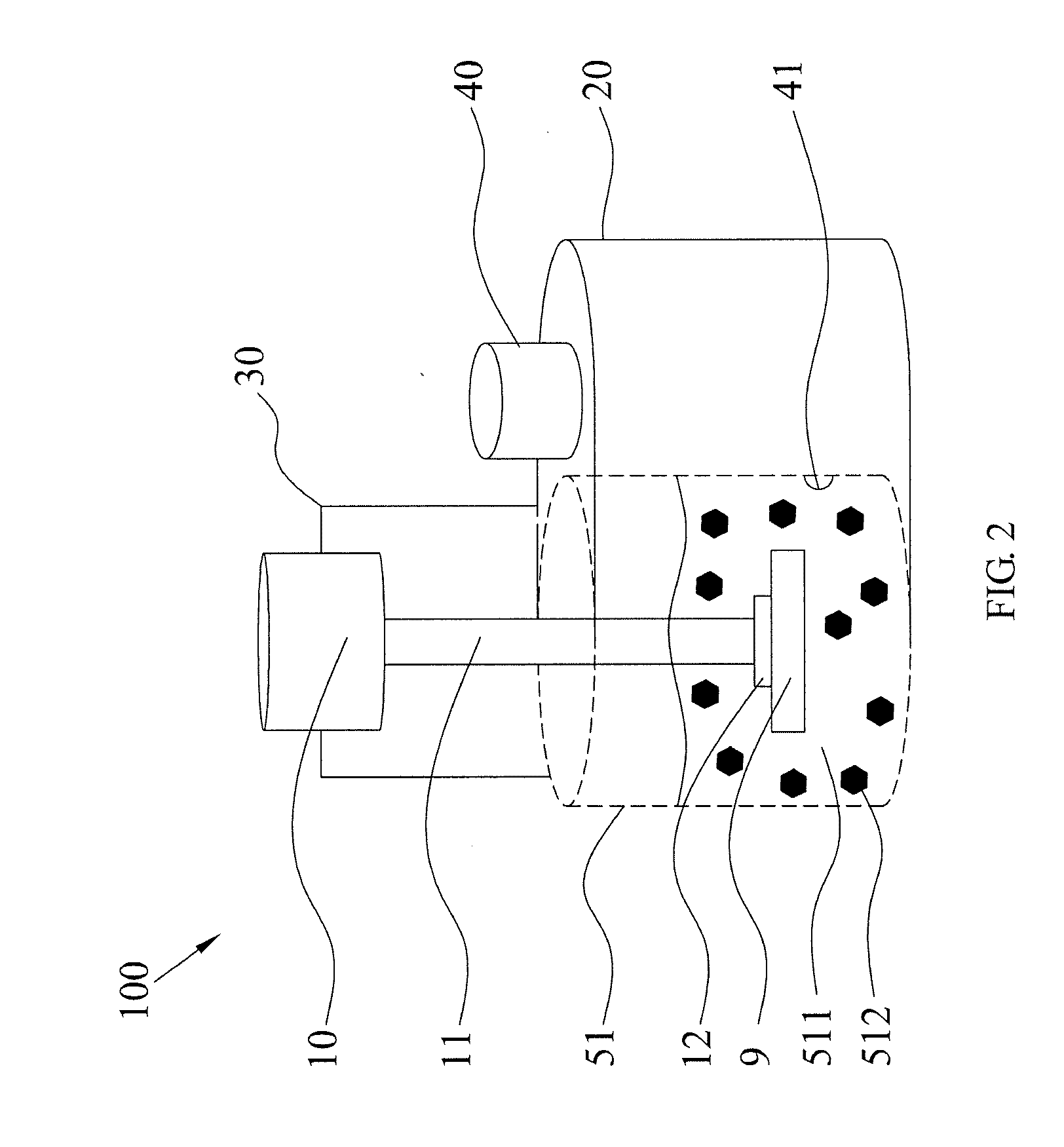

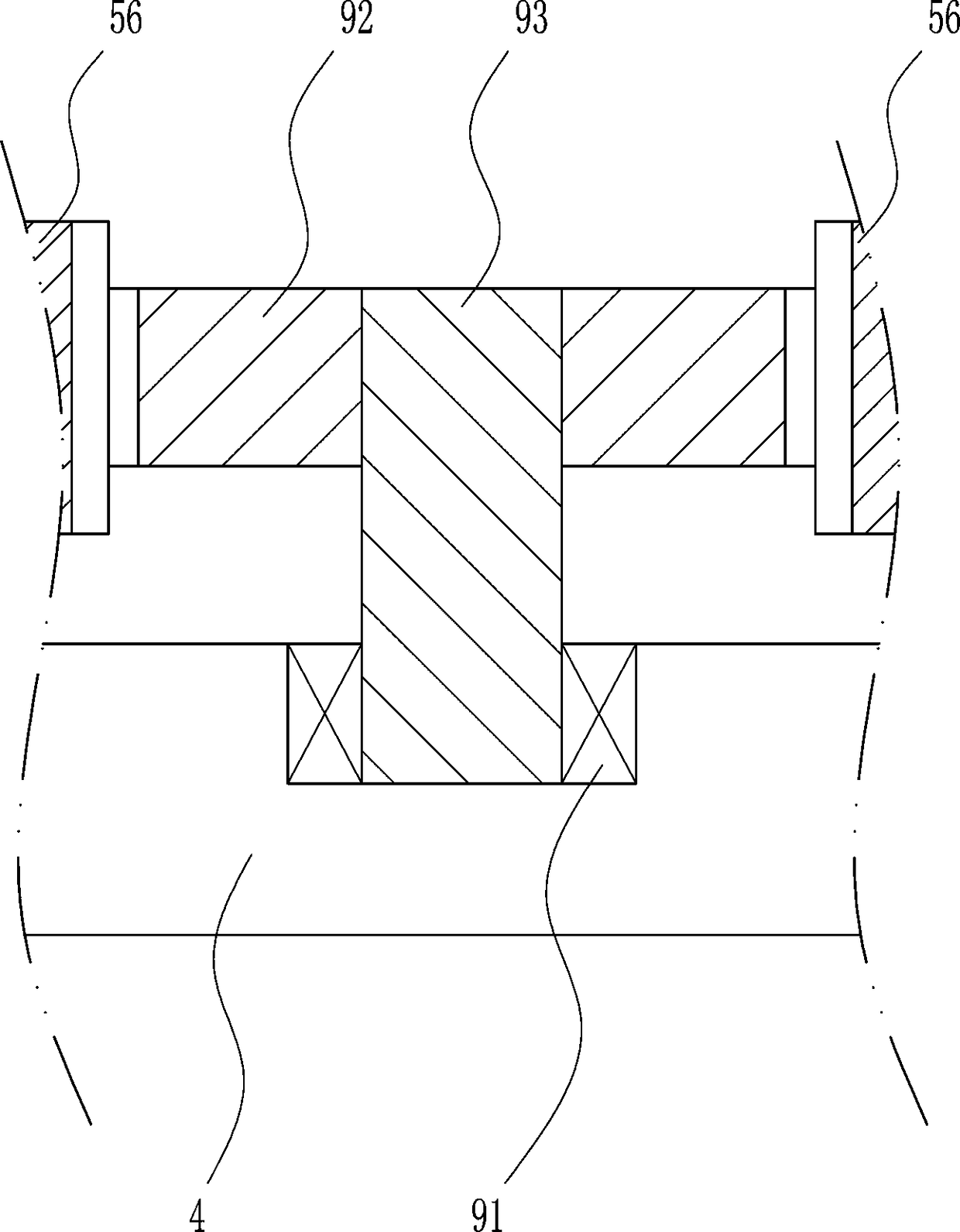

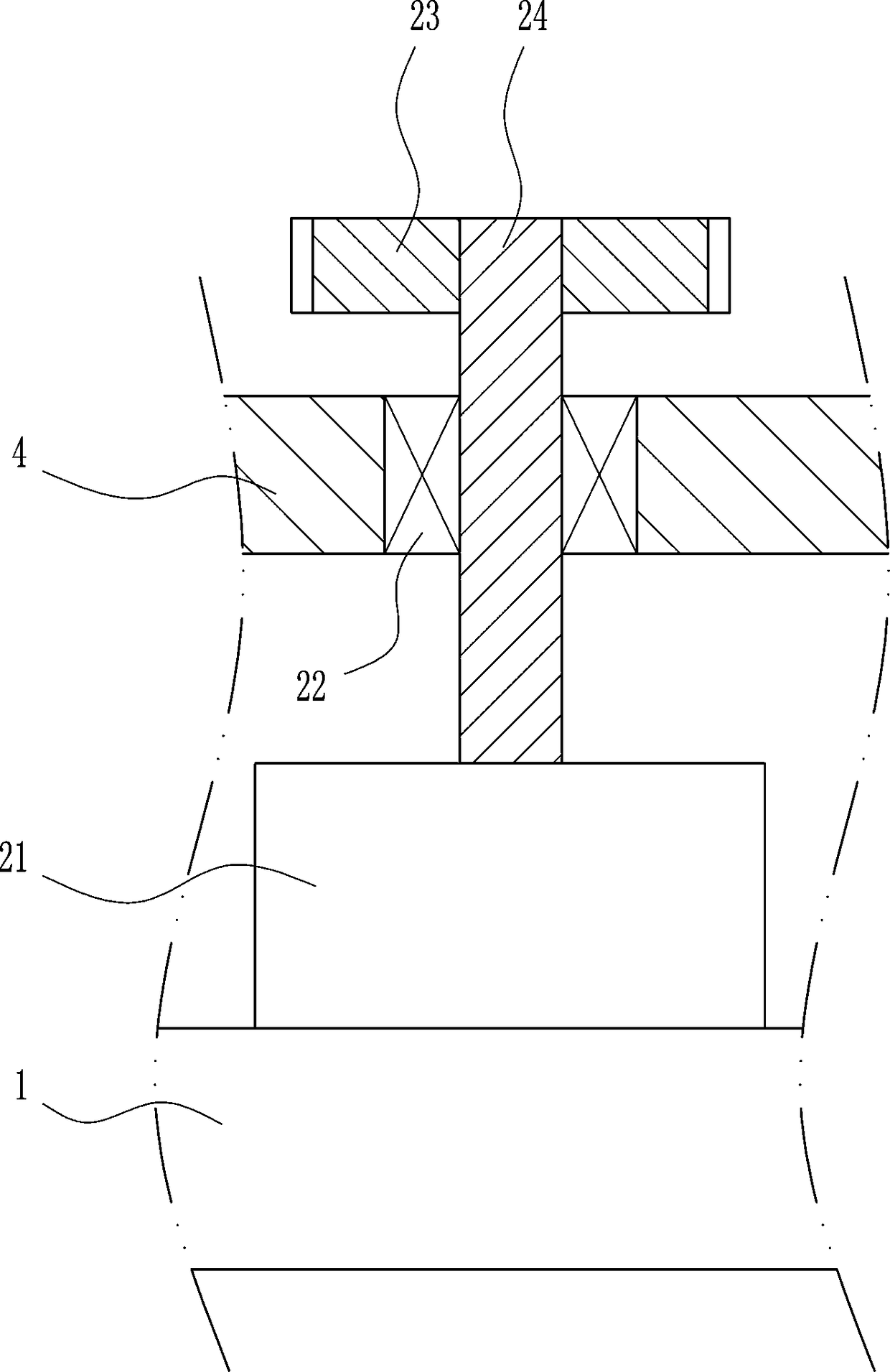

Polishing system based on the non-newton fluid and polishing method thereof

InactiveUS20170050285A1Uniform surface finishPrecise of polishing processEdge grinding machinesPolishing machinesAbrasive agentThree dimensional shape

A polishing system based on a non-Newtonian fluid and a polishing method thereof are provided. The polishing system includes a polishing device, a non-Newtonian fluid auxiliary device and a control device. The polishing device is able to move a work piece in a polishing container containing the non-Newtonian fluid with abrasives that cause the polishing action. The non-Newtonian fluid auxiliary device is able to manipulate the viscosity of the non-Newtonian fluid by varying the pressure, speed, vibration or ultrasonic frequency, which causes the abrasives to polish the work piece. The control device is used to optimize the polishing process by controlling how the polishing device moves the work piece inside the polishing container. In this way, by using the polishing method, the polishing system provided is able to polish a work piece with any three-dimensional shape.

Owner:KUNSHAN NANO NEW MATERIAL TECH

Circular pipe polishing device for heating and ventilation

InactiveCN108747789AImprove polishing efficiencyReduce workloadPolishing machinesGrinding drivesEngineering

The invention relates to a polishing device, in particular to a circular pipe polishing device for heating and ventilation. According to the technical scheme, the circular pipe polishing device for heating and ventilation can be used for polishing multiple circular pipes, lightens the working burden of workers, and improves the polishing efficiency. The circular pipe polishing device for heating and ventilation comprises a base plate, a driving mechanism, a supporting seat, a first mounting plate, rotating mechanisms, a sliding rail, a sliding block, a lifting plate, a transmission mechanism,a polishing mechanism, a lifting mechanism and a second mounting plate. The second mounting plate is fixedly connected to the top of the base plate through the supporting seat, and the driving mechanism is fixedly connected to one side of the base plate. The multiple rotating mechanisms are fixedly connected to the first mounting plate at equal intervals. The circular pipe polishing device for heating and ventilation has the beneficial effects of comprehensively and quickly polishing the multiple circular pipes, improving the polishing efficiency, and lightening the working burden of the workers.

Owner:冯广吉

Low-pressure CMP (Chemico-mechanical Polishing) method for grand-scale integrated circuit copper wiring surface

InactiveCN101966688AStrong chelating abilityQuick polishOther chemical processesSemiconductor/solid-state device manufacturingVery large scale integrated circuitsNano sio2

The invention relates to a low-pressure CMP (Chemico-mechanical Polishing) method for grand-scale integrated circuit copper wiring surface, comprising the following steps of: (1) preparing a polishing solution by uniformly mixing the following components in percentage by weight: 35-80% of nano SiO2 abrasive material, 12-60% of deionized water, 1-3% of oxidizing agent, 1-4% of activating agent and 0.5-1.5% of FA / OII type chelating agent; and (2) setting polishing technique parameters, wherein the polishing pressure is 2-5KPa, the polishing temperature is 20-50 DEG C, the flow rate is 120-250ml / min, and the rotating speed is 30-60rpm / min. The oxidizing agent in the polishing solution is used for oxidizing the copper, and the FA / OII type chelating agent self with extremely strong chelating capability quickly reacts with the oxidized copper to generate soluble chelate fast removing from the copper surface, thereby avoiding the situation of removing the surface copper depending on the mechanical friction mainly and realizing the purpose of copper polishing under low mechanical strength. The removal of materials in the chelating process is realized by breaking down molecular bond, which has small damage on the material surface; in addition, the influence of mechanical action on the polishing speed is compensated by reinforcing the CMP chemical action under low pressure.

Owner:TIANJIN HEBEI UNIV OF TECH ASSET MANAGEMENT LTD

Surface bothway polishing rust removing equipment for mechanical steel tube parts

ActiveCN108177078AQuick polishFully polishedGrinding carriagesPolishing machinesMechanical componentsEngineering

The invention relates to mechanical part machining equipment, in particular to surface bothway polishing rust removing equipment for mechanical steel tube parts. The surface bothway polishing rust removing equipment for the mechanical steel tube parts can polish the surfaces of the steel tubes rapidly and comprehensively, and time and labor can be saved in the polishing process. The surface bothway polishing rust removing equipment for the mechanical steel tube parts comprises a base plate, supporting plates, sliding sleeves, a connecting plate, a sliding rail, a sliding block, a first guide sleeve and the like. The left side and the right side of the upper side of the base plate are both connected with the supporting plates. The lower portions of the front sides of the supporting plates are both connected with the corresponding sliding sleeves. By adoption of the surface bothway polishing rust removing equipment, the effects of being capable of polishing the surfaces of the steel tubes rapidly and comprehensively and further capable of saving the time and labor in the polishing process are achieved; and by adoption of the mode that a first polishing wheel and a second polishing wheel are used for polishing the upper sides and the lower sides of the steel tubes separately, the surfaces of the steel tubes can be polished quickly, and the danger caused due to the fact that usersdirectly operate a polishing machine can be avoided in the polishing process.

Owner:HANDAN HANGANG AFFILIATED ENTERPRISE CO LTD

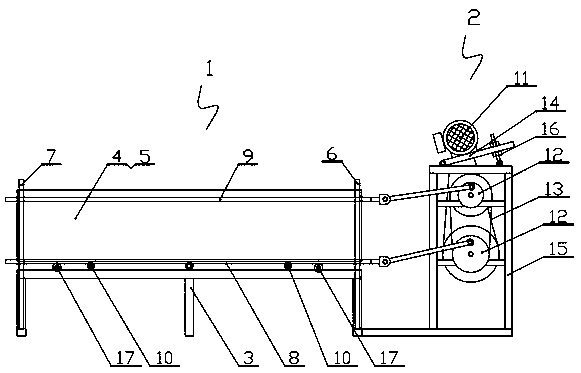

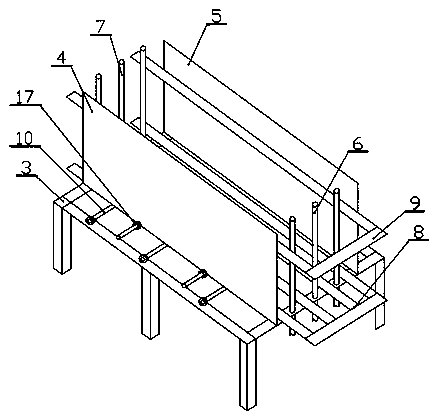

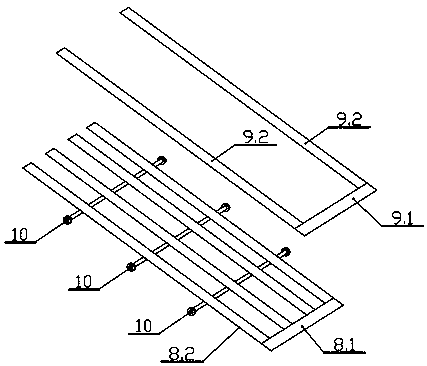

Thin bamboo stick polishing machine and method

PendingCN108161705AQuick polishClose kneading relationshipEdge grinding machinesPolishing machinesReciprocating motionEngineering

The invention relates to a thin bamboo stick polishing machine and method. The thin bamboo stick polishing machine comprises a polishing main body and a power mechanism. The polishing main body comprises a thin bamboo stick polishing space constituted by a left side plate, a right side plate, front blocking rods, rear blocking rods, a bottom bracket and an upper pressing frame. The spacing betweenthe left side plate and the right side plate is adjustable so as to adapt to processing requirements of thin bamboo sticks with different lengths; rolling pieces or sliding pieces are arranged at thebottom of the bottom bracket; groove channels avoiding the front blocking rods and the rear blocking rods are formed in the bottom bracket, and the bottom bracket is connected with the power mechanism so that the bottom bracket can move forwards and backwards in a reciprocating mode; and groove channels avoiding the front blocking rods and the rear blocking rods are formed in the upper pressing frame, and the upper pressing frame is connected with the power mechanism so that the upper pressing frame can move forwards and backwards in a reciprocating mode. Peripheral movement of the thin bamboo sticks is limited through the left side plate, the right side plate, the front blocking rods and the rear blocking rods, and then the bottom bracket and the upper pressing frame vertically clamp thethin bamboo sticks and move back and forth, so that the close mutual-rubbing relation between the thin bamboo sticks is formed, and accordingly the thin bamboo sticks are rapidly polished.

Owner:福建鑫隆达竹木科技有限公司

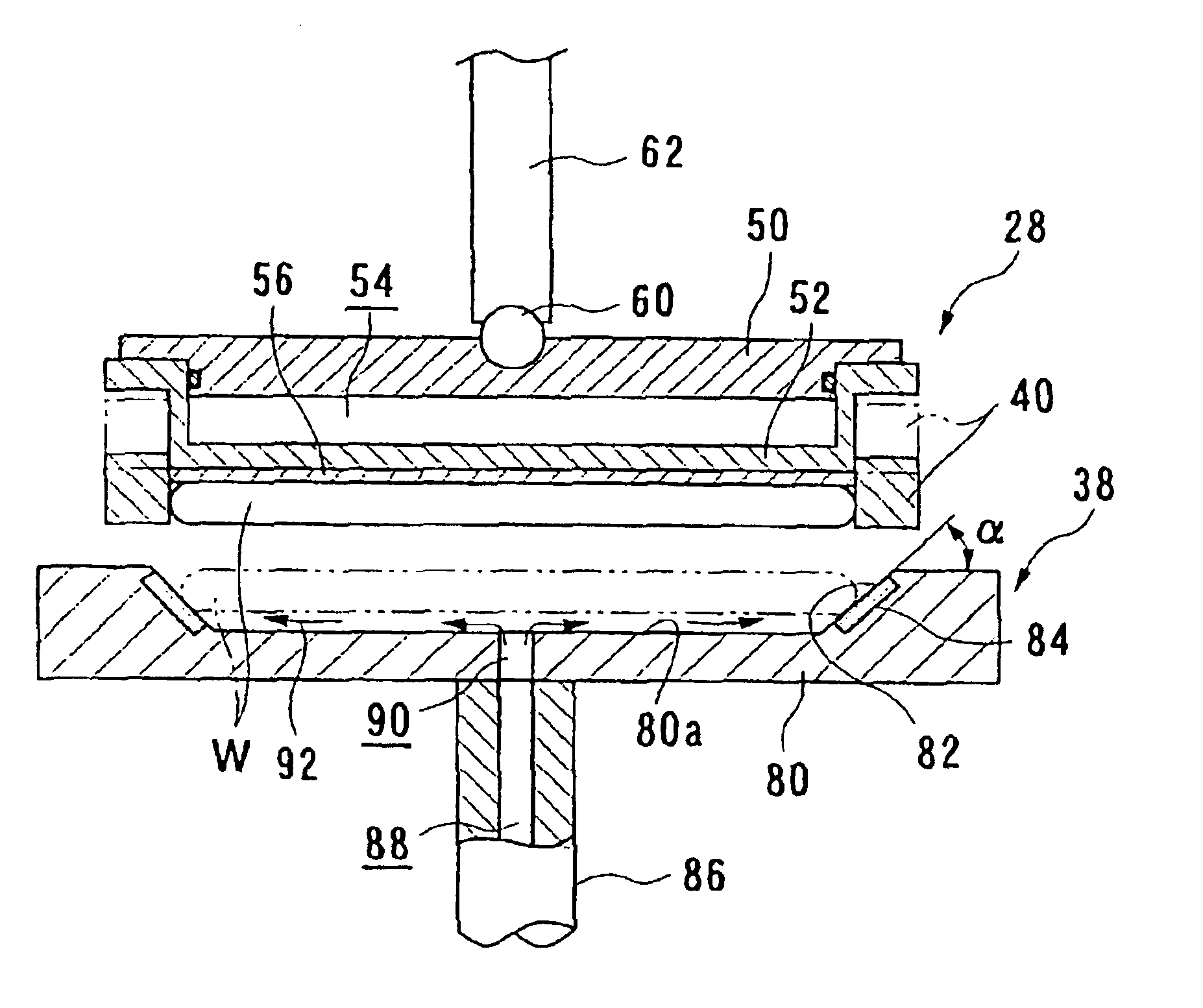

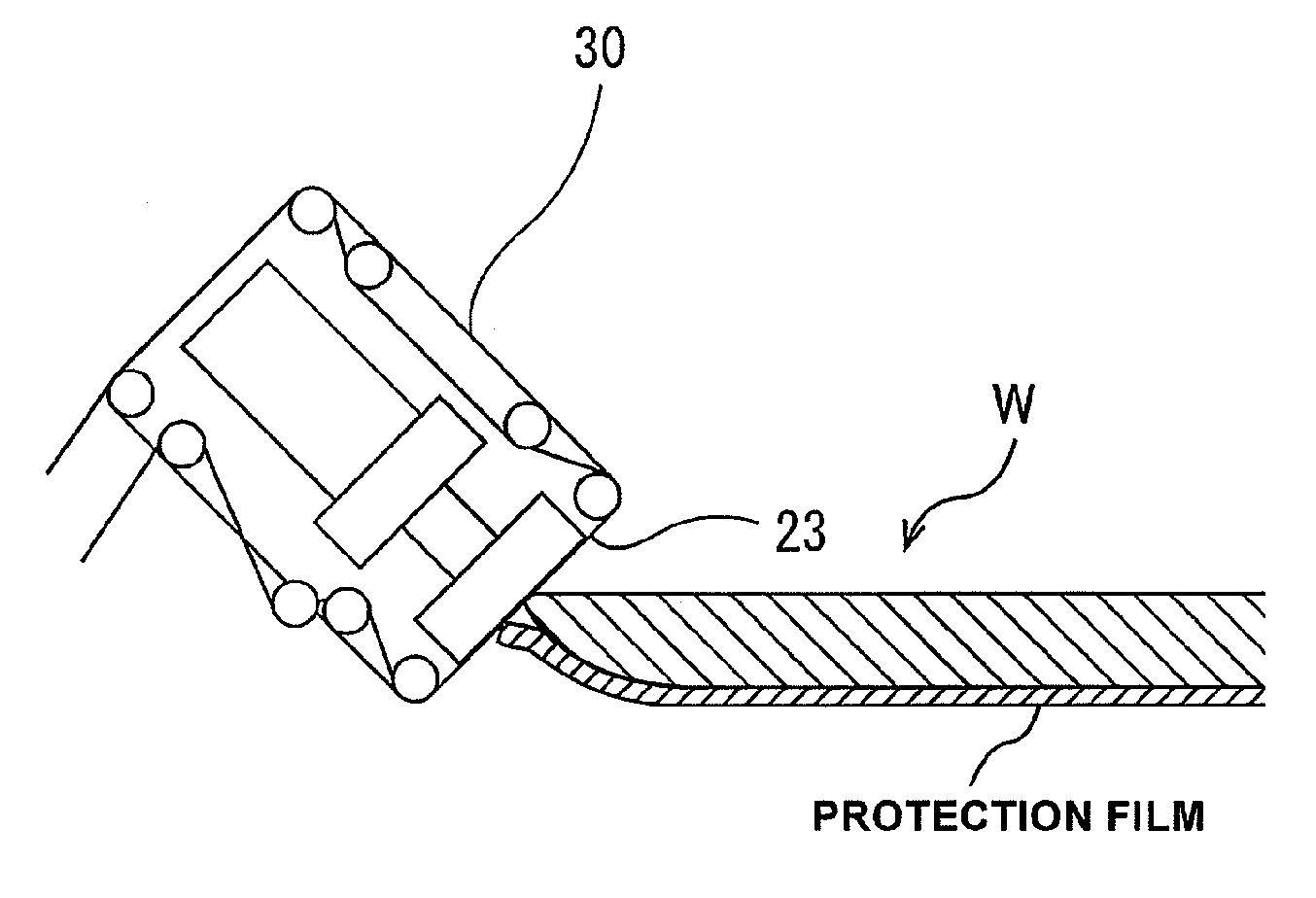

Method and apparatus for polishing a substrate having a grinded back surface

ActiveUS8535117B2Quick polishFast approachEdge grinding machinesPolishing machinesEngineeringMechanical engineering

A method capable of quickly polishing an angular portion formed by a grinded back surface and a circumferential surface of a substrate without causing damages on the thin substrate is provided. The method includes rotating the substrate about its center, and pressing a polishing tape against the angular portion formed by the back surface and the circumferential surface of the substrate to polish the angular portion.

Owner:EBARA CORP

Slurry composition for polishing high stepped region

InactiveUS20190316003A1Reduce decreaseQuick polishOther chemical processesSemiconductor/solid-state device manufacturingSlurryPolymer

The present invention relates to a slurry composition for polishing a high stepped region. The slurry composition for polishing a high stepped region according to an embodiment of the present invention comprises: a polishing liquid containing metal oxide abrasive particles dispersed by positive charges; and an additive liquid containing a polymer comprising at least one element capable of being activated as a positive charge, wherein the polishing selection ratio of the stepped region removal rate in an oxide film pattern wafer having convex portions and concave portions and the stepped region removal rate in an oxide film flat wafer is at least 5:1.

Owner:K C TECH

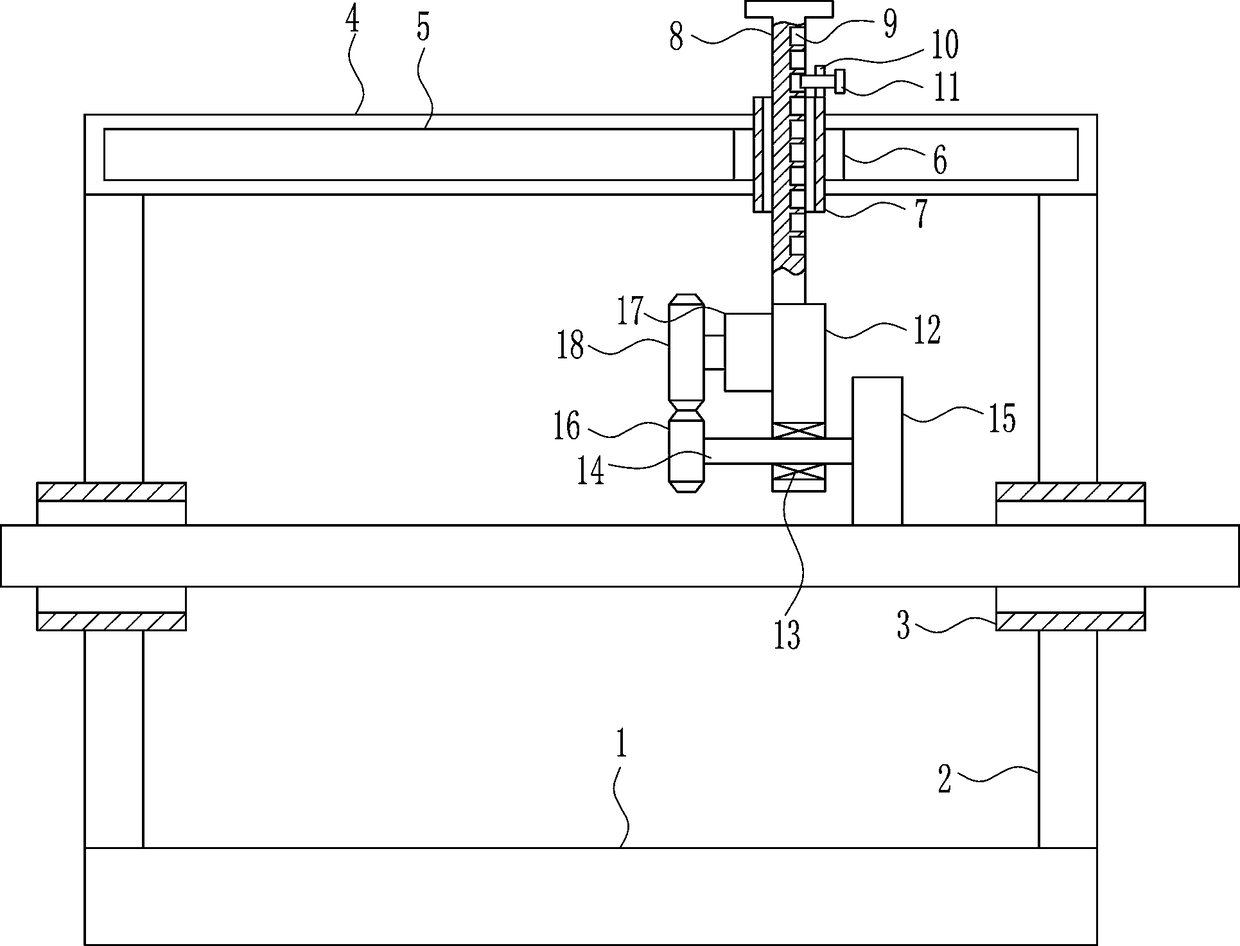

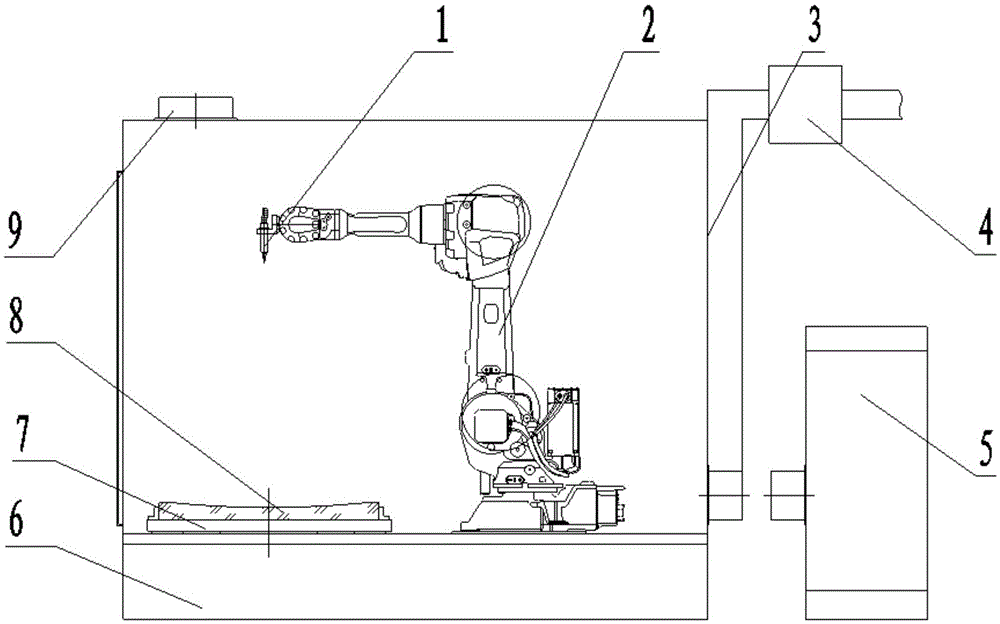

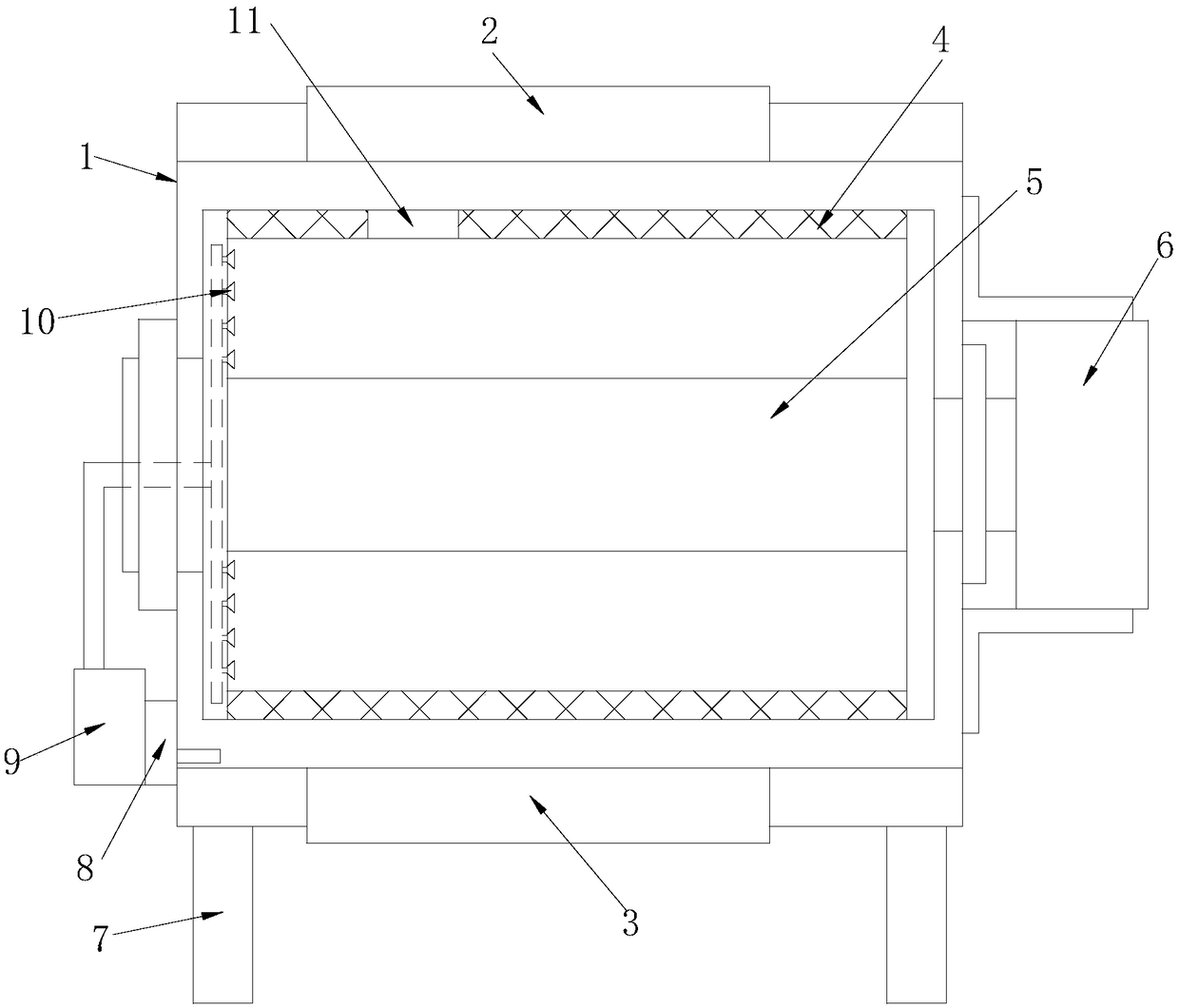

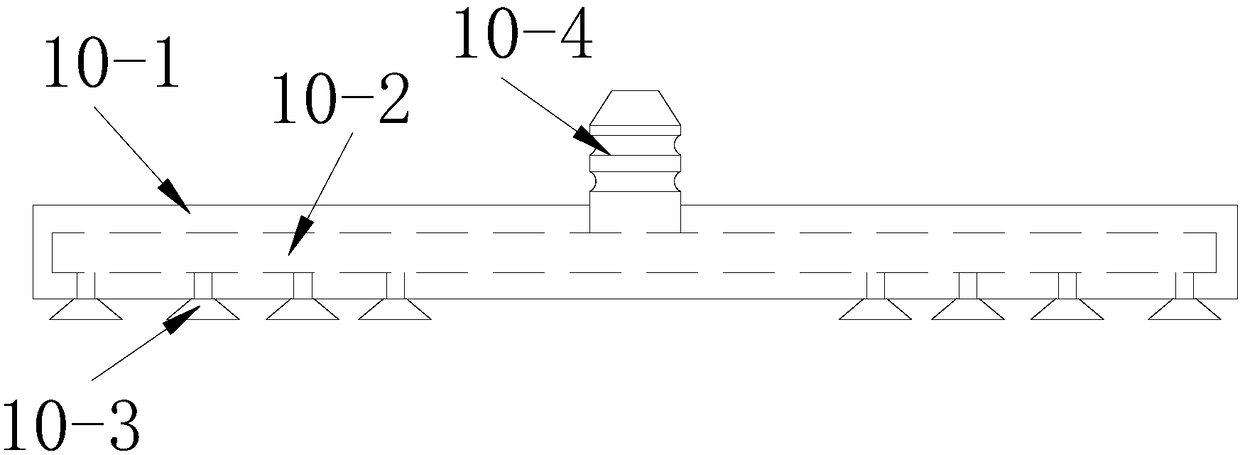

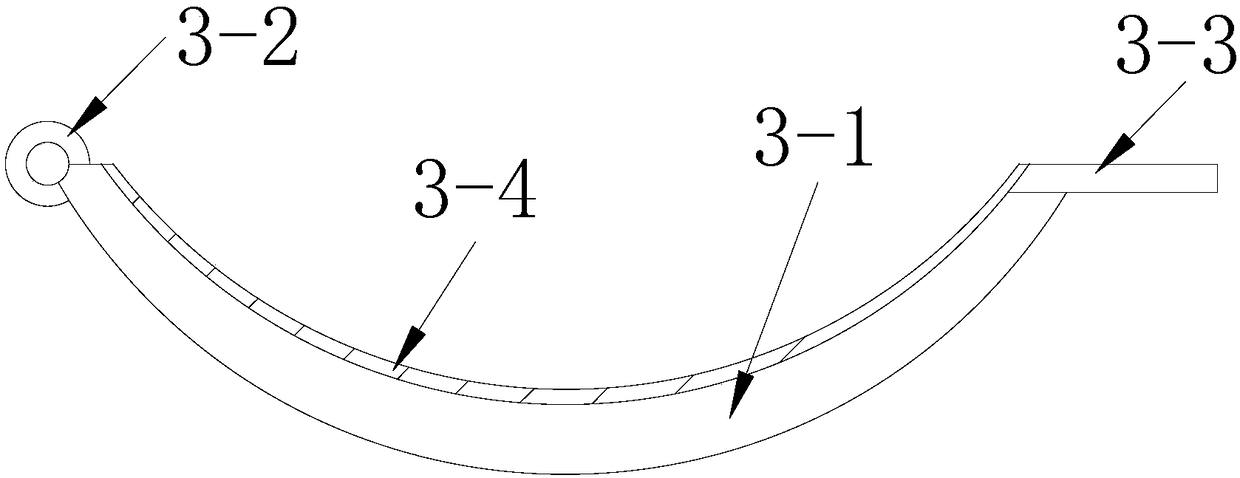

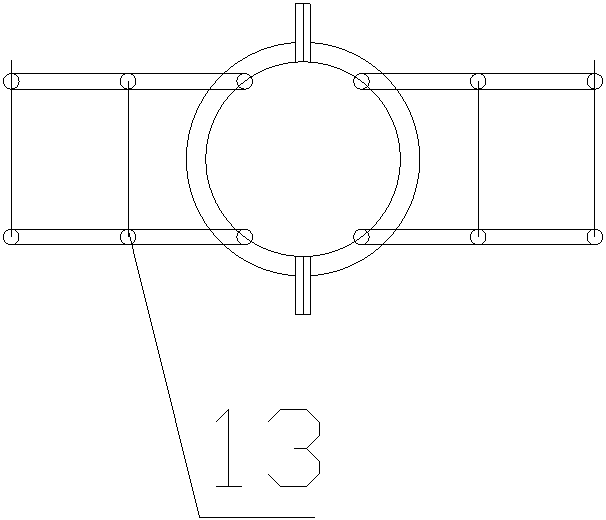

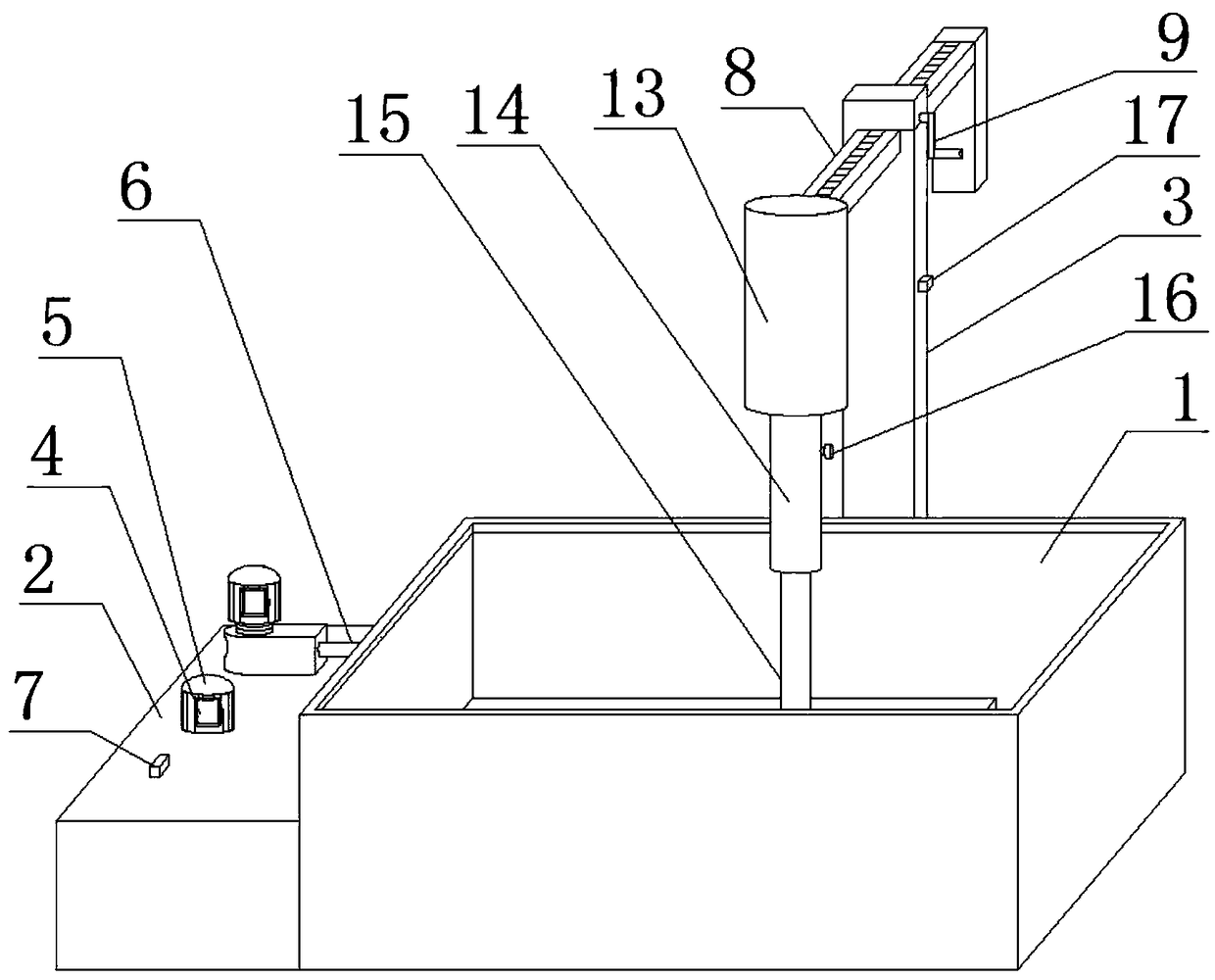

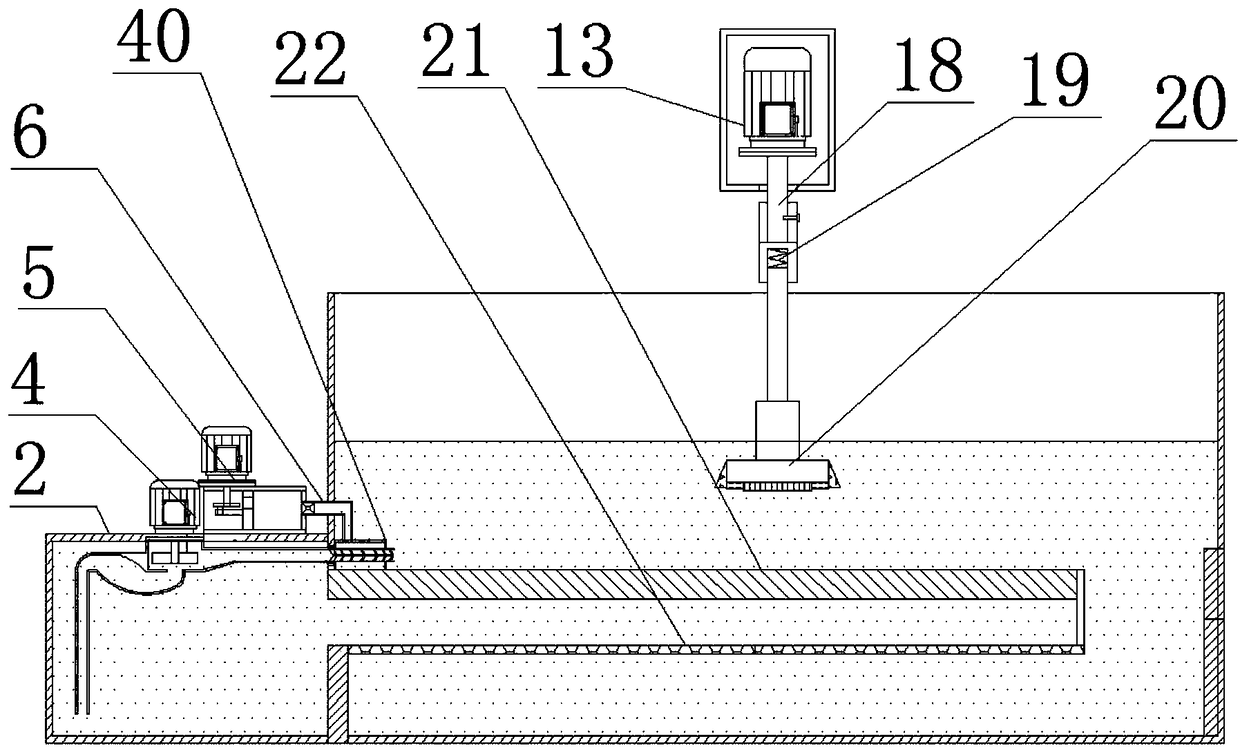

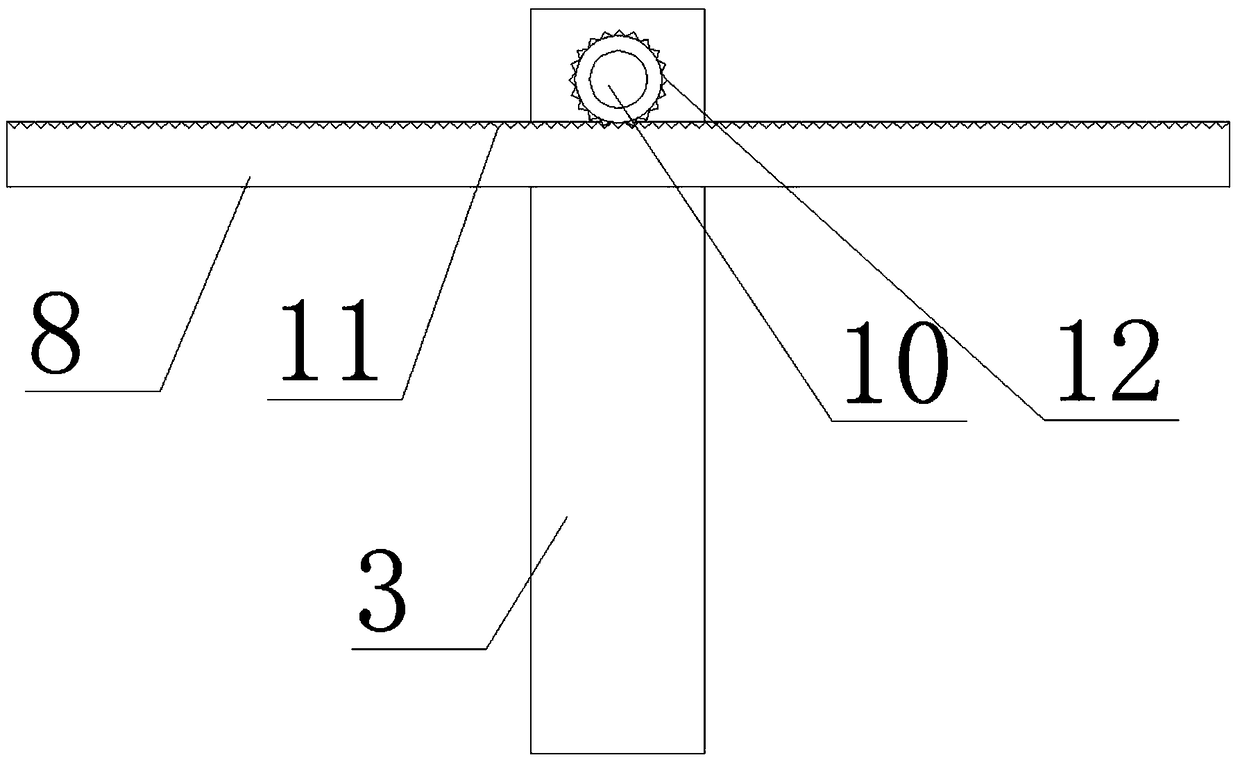

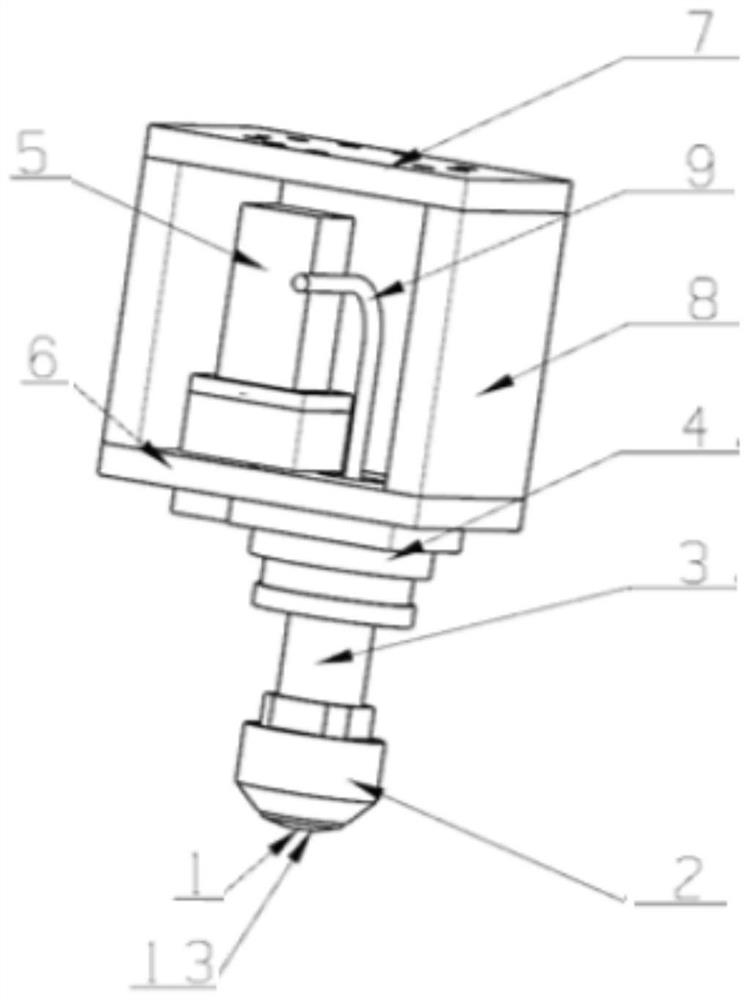

Plasma polishing device used for quickly polishing aspheric surfaces with medium and large calibers

InactiveCN105619205AAvoid surface residual stress and subsurface damageShorten the processing cycleOptical surface grinding machinesRobot controlNitrogen gas

The invention discloses a plasma polishing device used for quickly polishing aspheric surfaces with medium and large calibers. The plasma polishing device consists of a plasma source, a robot, a sealing part, an argon-fluorine waste gas treatment part, an electrical control system, a base, a polishing workbench, a to-be-processed optical part and a nitrogen gas inlet part, wherein the robot, the to-be-processed optical part and the polishing workbench are arranged on the base; the plasma source is positioned above the to-be-processed optical part; the to-be-processed optical part is clamped on the polishing workbench; the robot controls a movement posture of the plasma source, so that the plasma source is always perpendicular to the surface of the to-be-processed optical part; the sealing part adopts an integral sealing structure which is isolated from the outside atmosphere; the polishing of the whole device is controlled by the electrical control system; the nitrogen gas inlet part can be used for charging nitrogen with concentration which meets experimental requirements; and the argon-fluorine waste gas treatment part is used for exhausting the treated waste gas into the atmosphere. The plasma polishing device has the main advantages that the robot is adopted for control, processing operation instrumentation can be conveniently realized, and engineering production application can be realized.

Owner:CHANGCHUN EQUIP TECH RES INST

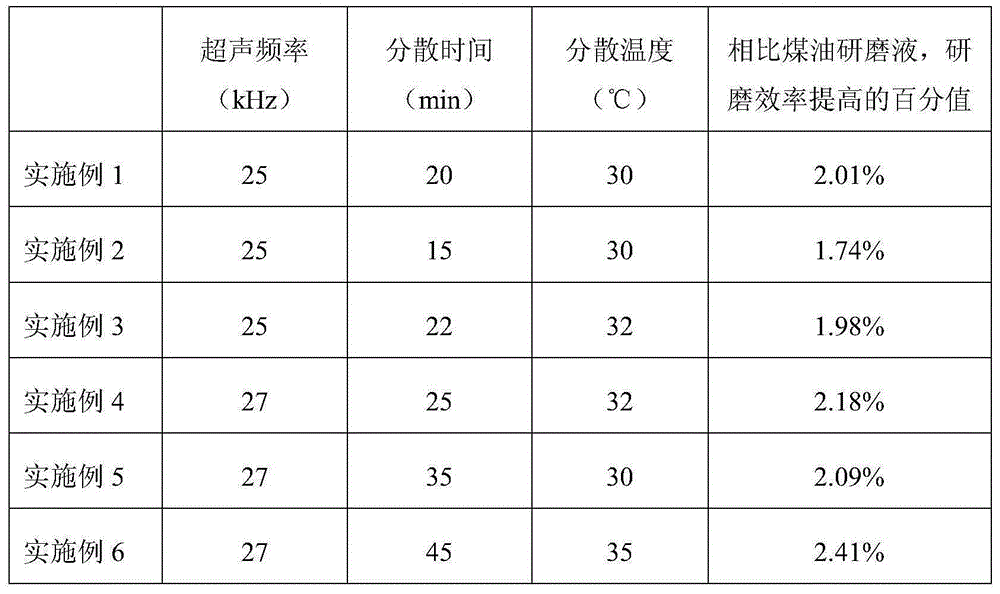

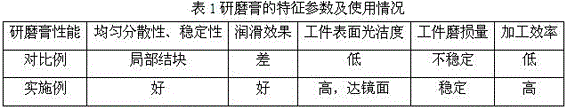

Diamond grinding fluid dedicated for sapphire polishing and preparation method thereof

ActiveCN106318219AGood dispersionImprove suspension stabilityOther chemical processesPolishing compositions with abrasivesSapphireMaterials science

The invention provides a diamond grinding fluid dedicated for sapphire polishing and a preparation method thereof. The diamond grinding fluid is composed of white mineral oil, plant oil, and diamond micropowder according to a ratio of 10-40 mL: 15-45 mL: 0.3-1.2 g. Diamond micropowder is well dispersed and stably suspended in the compound dispersion system composed of white mineral oil and plant oil. The diamond grinding fluid has the advantages of high grinding efficiency, environment-friendliness, and low cost.

Owner:LENS TECH

Method for complexly treating 5CrMnMo hot work die steel

ActiveCN107619909AHigh hardnessImprove heat absorptionElectron beam welding apparatusAlcoholSurface roughness

The invention discloses a method for complexly treating 5CrMnMo hot work die steel. The method comprises the following steps of (1) pretreating: cleaning a milled workpiece through an alcohol ether solvent, then spraying an accelerant at an outer surface of the cleaned workpiece, and obtaining a pretreated workpiece; (2) warming: placing the pretreated workpiece into a drying oven, enabling the temperature of the pretreated workpiece to reach 65 to 78 DEG C, and obtaining a warmed workpiece; and (3) treating with an electronic beam. According to the process adopted by the invention, not only can the hardness of the 5CrMnMo hot work die steel be improved, but also the surface roughness of the 5CrMnMo hot work die steel is reduced, the occurrence of a pit phenomenon of a volcanic vent is reduced, and the method has wide market promotion value.

Owner:GUILIN UNIV OF ELECTRONIC TECH

Multifunctional minitype steel ball polishing machine

PendingCN108481178AAdjust polishing speedVersatileEdge grinding machinesPolishing machinesAgricultural engineeringSteel ball

The invention discloses a multifunctional minitype steel ball polishing machine, and relates to the technical field of steel ball production tools. Supporting feet are mounted at the bottom of an outer box body. An upper box cover and a lower box cover are mounted at the upper end and the lower end of the outer box body correspondingly. A polishing barrel is arranged in the outer box body. A rotating shaft of the polishing barrel is mounted on the outer box body through a bearing pedestal. A polishing shaft body is mounted in the polishing barrel. A drive motor is mounted on the right side wall of the outer box body through a support. A shaft of the drive motor is connected with a shaft of the polishing barrel through a shaft sleeve. A spraying disc is mounted on the left side wall of thepolishing barrel. A water inlet is arranged on the lower left side wall of the outer box body. A filter is mounted on the outer side wall of the water inlet. A water pump is mounted on a water outletof the filter. A water outlet of the water pump is connected with a spraying pipe through a water pipe. According to the multifunctional minitype steel ball polishing machine, fast polishing and cleaning can be achieved, meanwhile, cyclic spray washing can be achieved, and the multifunctional minitype steel ball polishing machine is convenient to use and easy and convenient to operate; and when the multifunctional minitype steel ball polishing machine is used, the polishing speed can be adjusted, meanwhile, functional diversification can be achieved, and the efficiency can be improved.

Owner:南通市精艺钢球有限公司

Novel straw compression forming equipment

The invention provides novel straw compression forming equipment, and relates to a compression forming device of fiber materials. The novel straw compression forming equipment comprises a main driving mechanism, a precompression mechanism and a compression mechanism. The precompression mechanism comprises a second motor, a feeding box, a precompression packing auger and a forced feeding turnover plate, a reinforcing compression cavity is formed in the outlet end of a compression cavity, and is of a left-and-right buckling structure, the two sides of the reinforcing compression cavity are connected with connecting rod mechanisms respectively, the connecting rod mechanisms are connected with a hydraulic station, the hydraulic station is controlled by an electric drive travel switch, and the hydraulic station and the electric drive travel switch are in linkage and automatic control through a PLC control cabinet. Based on the working principle that main machine volume variable physical extrusion and auxiliary machine forced feeding extrusion are combined, the materials are conveyed, extruded and dehydrated, the equipment is especially suitable for compression forming of straw type biomass, and the compressed materials are low in water content and small in density.

Owner:河南天冠纤维乙醇有限公司

Polishing apparatus and method

InactiveUS20050260933A1Easy to operatePolish the outer peripheral portion of the workpiece efficientlyEdge grinding machinesPolishing machinesCopperFlat mirror

A polishing apparatus and method has a function of polishing a surface of a film formed on a substrate to a flat mirror finish and a function of polishing unnecessary metal film such as copper film deposited on an outer peripheral portion of the substrate to remove such unnecessary metal film. The polishing apparatus comprises a surface polishing mechanism comprising a polishing table having a polishing surface and a top ring for holding the substrate and pressing the substrate against the polishing surface of the polishing table to thereby polish a surface of the substrate, and an outer periphery polishing mechanism for polishing an outer peripheral portion of the substrate.

Owner:TOSHIBA MEMORY CORP

Water-oil soluble nanocarbon crystal abrasive paste and preparation method thereof

InactiveCN106010441ANo reunionUniform and stable dispersionOther chemical processesPolishing compositions with abrasivesKeroseneAlloy

The invention discloses water-oil soluble nanocarbon crystal abrasive paste. The water-oil soluble nanocarbon crystal abrasive paste is mainly prepared from, by weight, 10-25 parts of nano carbon crystals, 1-10 parts of water, 20-30 parts of oleic acid, 10-20 parts of vaseline, 15-30 parts of kerosene, 15-25 parts of peanut oil, 5-15 parts of fungicide, 0.2-2 parts of sorbitan fatty acid ester and 0.2-2 parts of an OP-emulsifier. The invention further discloses a preparation method of the water-oil soluble nanocarbon crystal abrasive paste. The prepared abrasive paste has the advantages of being green, environmentally friendly, non-corrosive, low in cost and good in grinding effect and is applicable to measuring tools, cutting tools and optical instruments made from glass, ceramic, hard alloy, natural diamonds, precious stones and other hard materials and machining of other high-finish-degree workpieces.

Owner:ZHENGZHOU ARTIFICIAL DIAMOND & PROD ENG TECH RES CENT

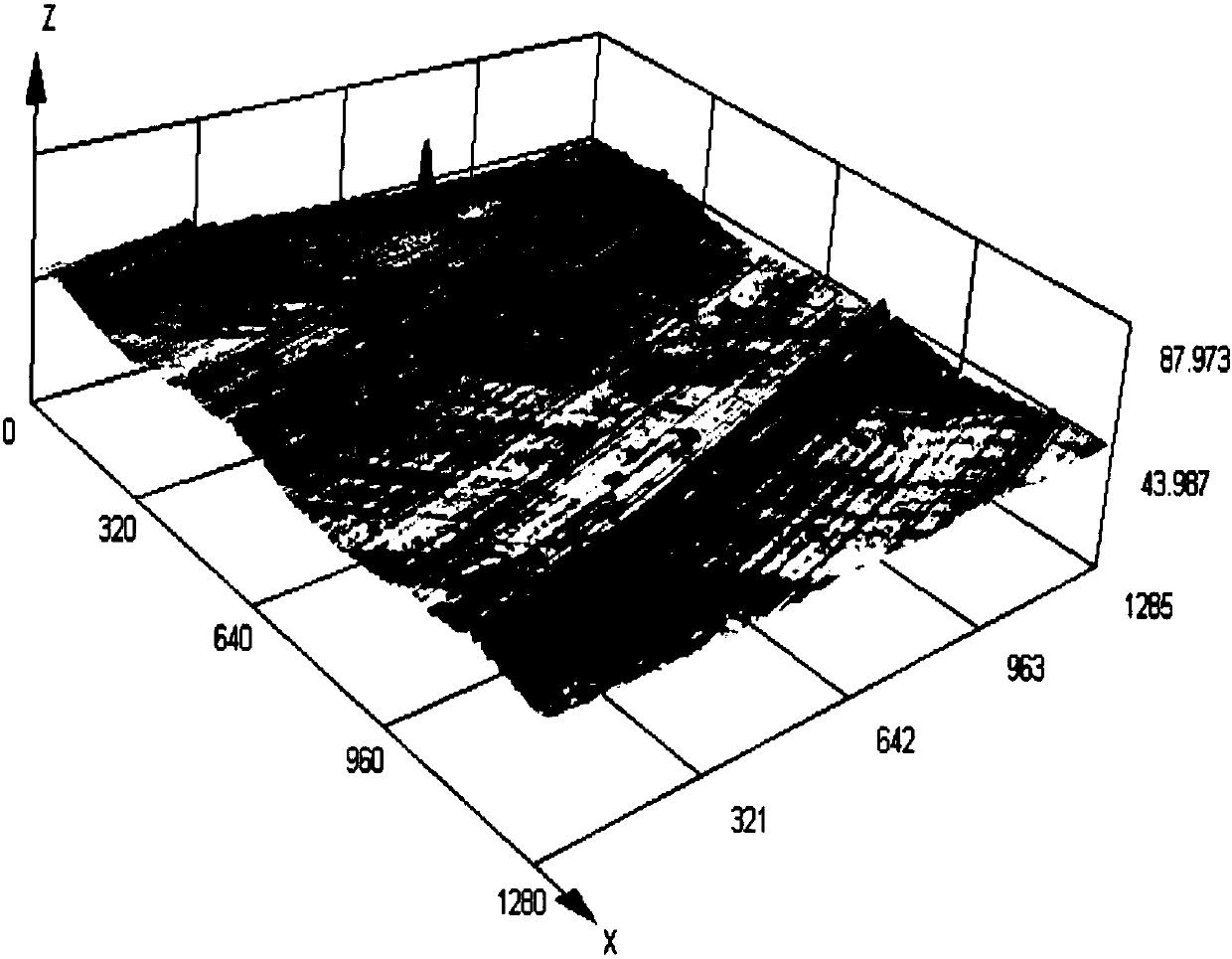

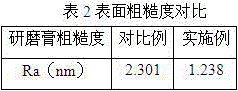

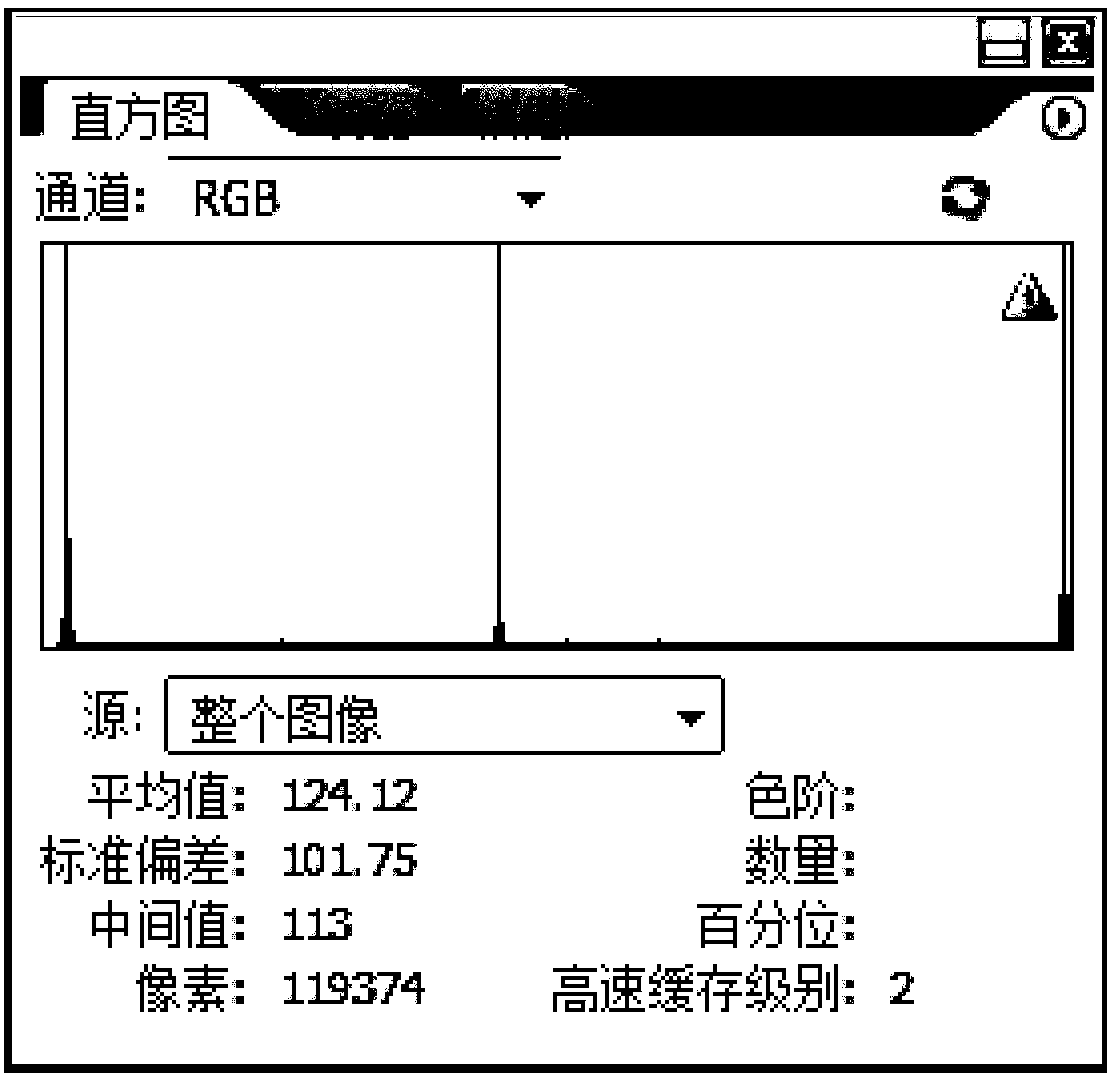

Method for measuring volume fraction of gamma' phase in nickel-based single crystal superalloy

InactiveCN107607565AEasy to operateAccurate measurementMaterial analysis using wave/particle radiationSingle crystal superalloyAlloy

The invention discloses a method for measuring volume fraction of gamma' phase in nickel-based single crystal superalloy, and belongs to the technical field of nickel-base single crystal high temperature microstructure analysis. The method comprises the following steps: (1) preparing a sample; (2) obtaining an image; (3) processing the image; (4) measuring and calculating; and the like. The calculation method for measuring the volume fraction of the gamma' phase in the nickel-based single crystal superalloy aims at the problems that in the prior art the method for measuring the volume fractionof the gamma' phase in the nickel-based single crystal superalloy has relatively-big errors in measurement results and poor repeatability, is not suitable for the measurement of the volume fraction of the gamma' phase in a micro zone. The calculation method for measuring the volume fraction of the gamma' phase in the nickel-based single crystal superalloy has the advantages of accurate measurement calculation results, small error, good repeatability, reliability, simple operation, convenience, quickness, and the lik, and can be used to measure the volume fraction of the gamma' phase in the nickel-based single crystal superalloy. The method is easy to implement and is suitable for the measurement and calculation of the volume fraction of the gamma' phase in the nickel-based single crystalsuperalloy.

Owner:HUANENG POWER INTERNATIONAL +1

Polishing device for carrying out hardware machining through micro-bubbles

ActiveCN109483335AAvoid damageQuick resectionPolishing machinesGrinding drivesMicro bubbleEngineering

The invention provides a polishing device for carrying out hardware machining through micro-bubbles. The polishing device comprises a main box, an auxiliary box and a support, wherein a water pump iswelded to the top of the auxiliary box, an air pump is arranged on one side of the water pump, one side of the air pump is provided with an air guide pipe in a welded mode, the top of the auxiliary box is provided with a switch I through a bolt, the switch I is arranged on one side of the water pump, a sliding rod I is clamped at the top of the support, a crank is installed on one side of the support, the crank is installed on the support through a rotating shaft, the other end of the rotating shaft is provided with a gear I, the bottom of the sliding rod I is provided with a tooth ripple I, one end of the sliding rod I is provided with a motor in a welded mode, a sleeve rod is arranged at the bottom of the motor, a connecting rod is arranged at the bottom of the sleeve rod, a fixing pin is installed on one side of the sleeve rod, and a main shaft is welded at the bottom of the motor. According to the polishing device for carrying out hardware machining through the micro-bubbles, design is reasonable, use is convenient, and the device is suitable for polishing hardware products.

Owner:东莞市玛雅精密模具有限公司

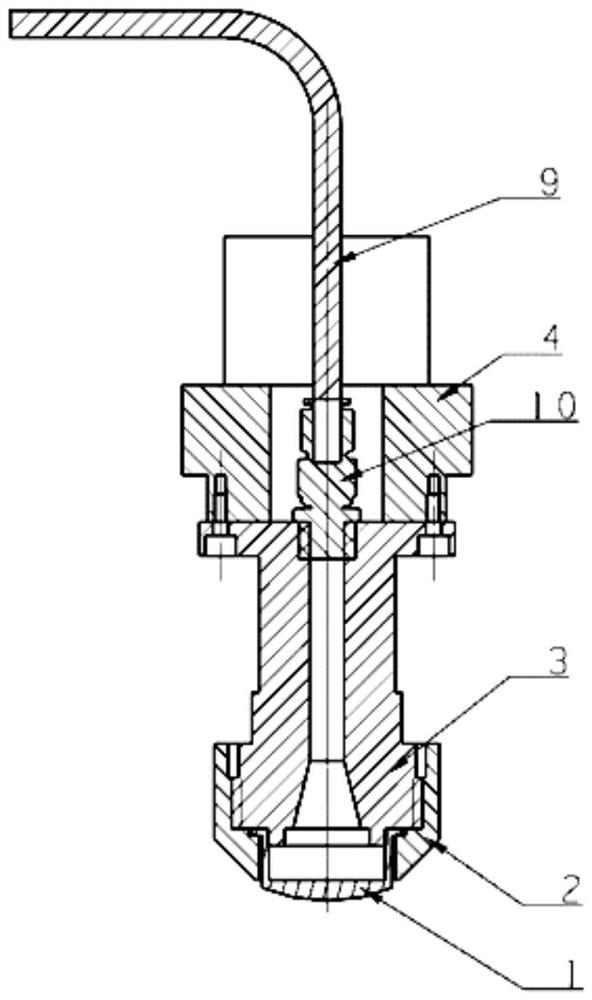

Robot air bag polishing device

PendingCN113579914AIncrease speedQuick polishGrinding carriagesOptical surface grinding machinesPolishingEngineering

The invention relates to a robot air bag polishing device. A polyurethane polishing piece is pasted on a rubber grinding head, a grinding head pressing block and a base are connected and fixed through threads, the rubber grinding head is clamped between the grinding head pressing block and the base, a hollow rotating platform is installed on a platform installing plate, one end of the platform installing plate is connected with the base, the other end of the platform installing plate is connected with a servo motor, the platform installing plate and a robot installing plate are connected through a connecting plate, the robot installing plate is installed on a six-axis robot, a waterproof plate is installed on the platform installing plate and the robot installing plate, an air compressor is connected with an air pipe, and the air pipe is inserted into a high-speed rotating connector. The robot air bag polishing device provided by the invention can be used for surface contact polishing and can also be used for surface finishing similar to point contact; compared with a traditional planetary motion grinding head, the rotating speed is higher, and polishing can be conducted faster; and the six-axis robot is adopted to replace a traditional machine tool, so that displacement is more flexible, and aspheric workpieces with higher machining difficulty can be machined.

Owner:武汉大衍精密光电技术有限公司

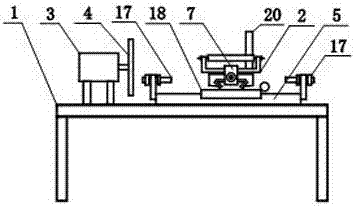

Profile end face polishing equipment

ActiveCN107009211AGuaranteed flatnessIncrease productivityGrinding carriagesGrinding work supportsPolishingElectric machinery

The invention discloses profile end face polishing equipment which comprises a rack, a motor and two supports. The motor and the supports are arranged on the rack. A polishing sheet is arranged on the motor. The two supports are arranged on the rack through rails. The rails comprise the first rail arranged on the rack and a second rail which is arranged on the first rail and is perpendicular to the first rail. The second rail is in sliding connection with the first rail through a first sliding block. The support is in sliding connection with the second rail through a second sliding block. Baffles are arranged at the two ends of the second rail. The supports are of U-shaped structures, and a fixed plates connected with the baffles are arranged in grooves of the supports. By means of the arrangement of the two perpendicular rails, the end face of a profile can be polished through movement of two freedom degrees, the equipment can be suitable for multiple profiles, production efficiency is improved, and the flatness of the profile is guaranteed.

Owner:XINXIANG HUIHUANG SPRING

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com