Patents

Literature

341results about How to "Quick sanding" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

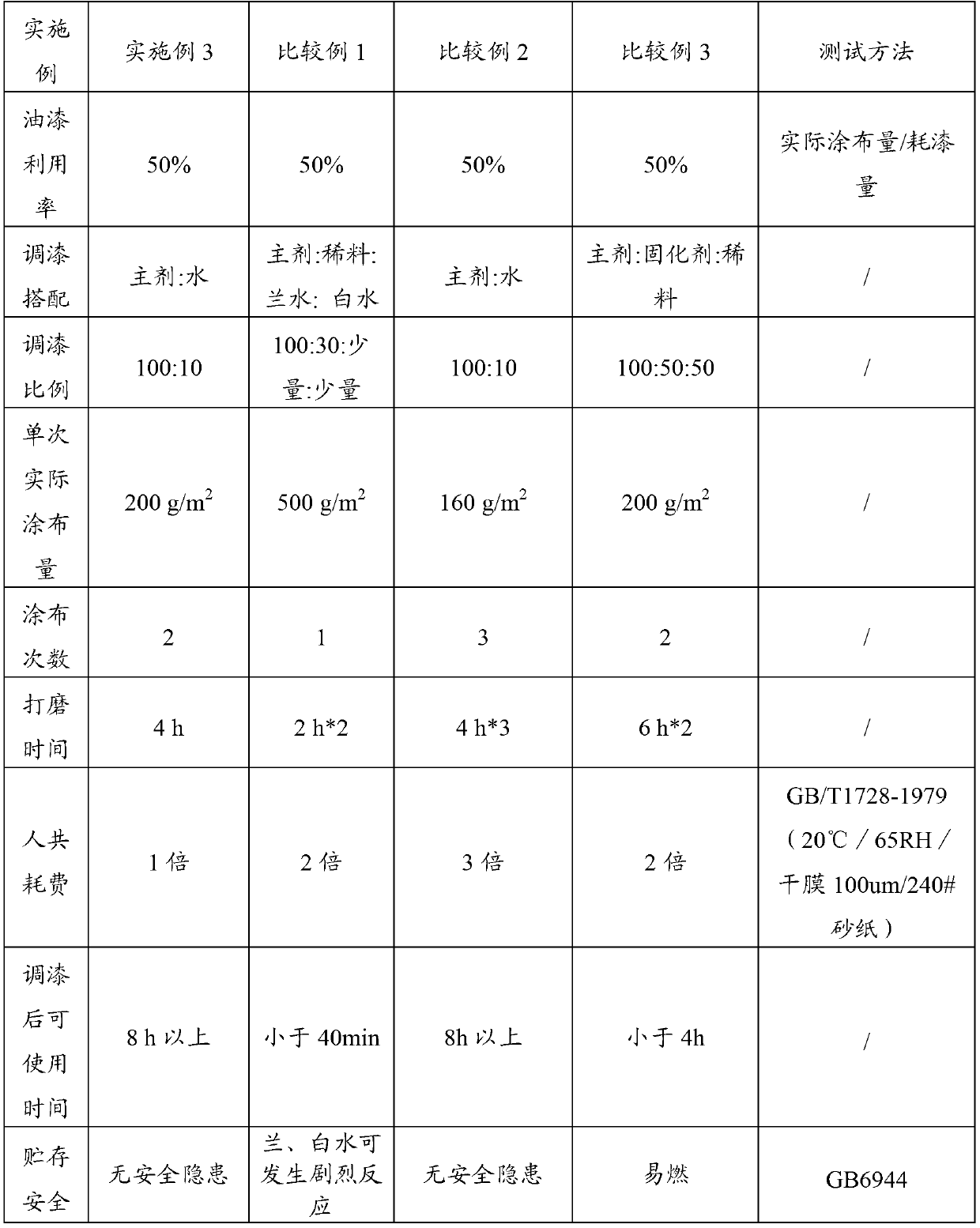

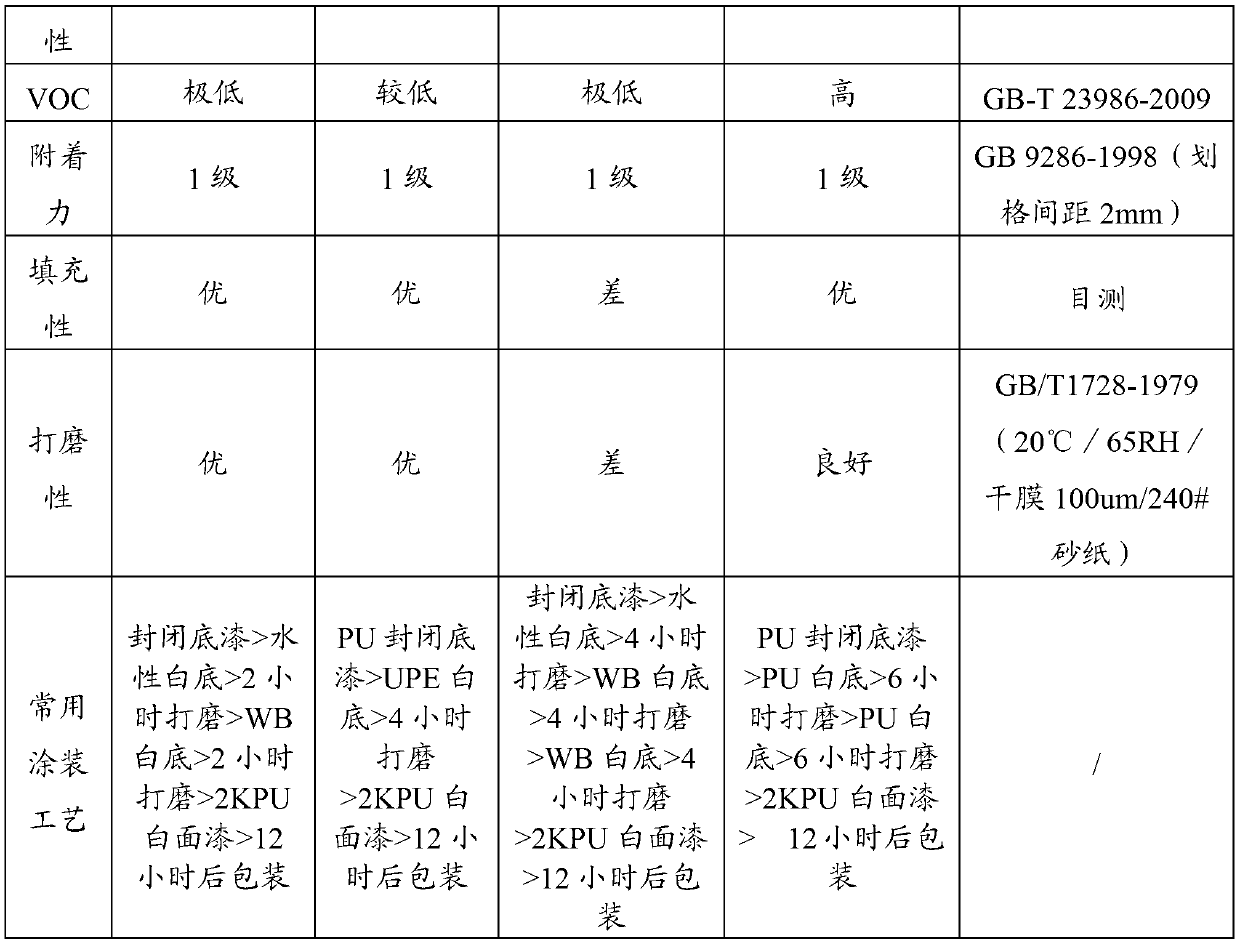

Water-based wood white primer as well as preparation method and use method thereof

ActiveCN103131284AHigh hardnessImprove adhesionAntifouling/underwater paintsPaints with biocidesWater basedLacquer

The invention relates to a water-based wood white primer as well as a preparation method and a use method thereof. The water-based wood white primer provided by the invention comprises the following components by weight: 15-35wt% of water-based resin, 0.2-0.6wt% of a defoaming agent, 0.5-1.5wt% of a wetting dispersant, 5-15wt% of titanium dioxide, 5-20wt% of talcum powder, 15-40wt% of coarse whiting, 0.2-0.8wt% of a thickening agent, 2-7wt% of a film-forming auxiliary agent, 0.1-0.4wt% of a substrate wetting agent, 0.1-0.4wt% of biocide mildewcide and 2-10wt% of water. The water-based wood white primer provided by the invention can be used together with solvent-based finishing paint, does not generate adverse film-painting defects, such as lifting, collapse and foaming adhesion, and has very low volatile content of VOC (Volatile Organic Compounds) and high value of environmental protection.

Owner:紫荆花制漆(成都)有限公司

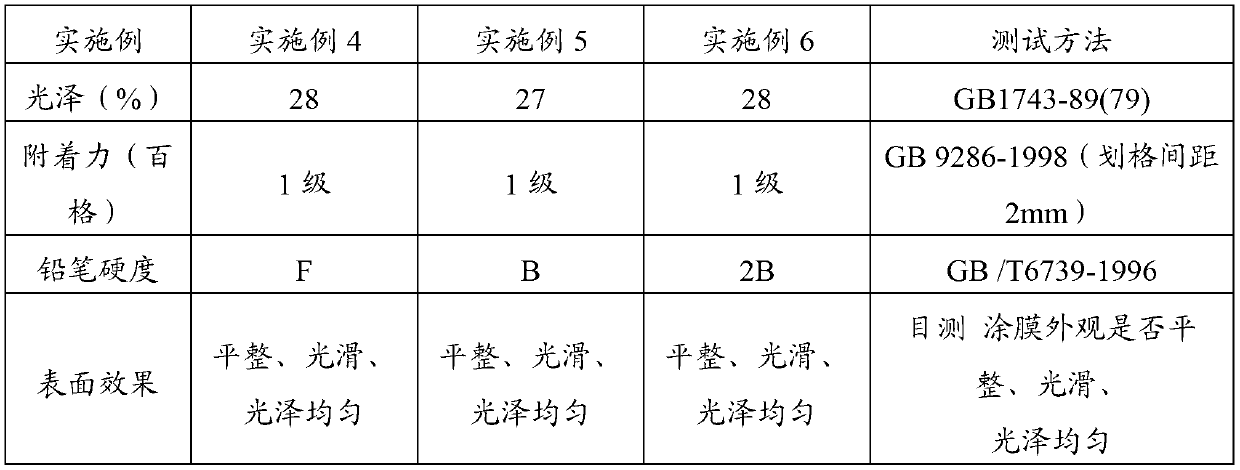

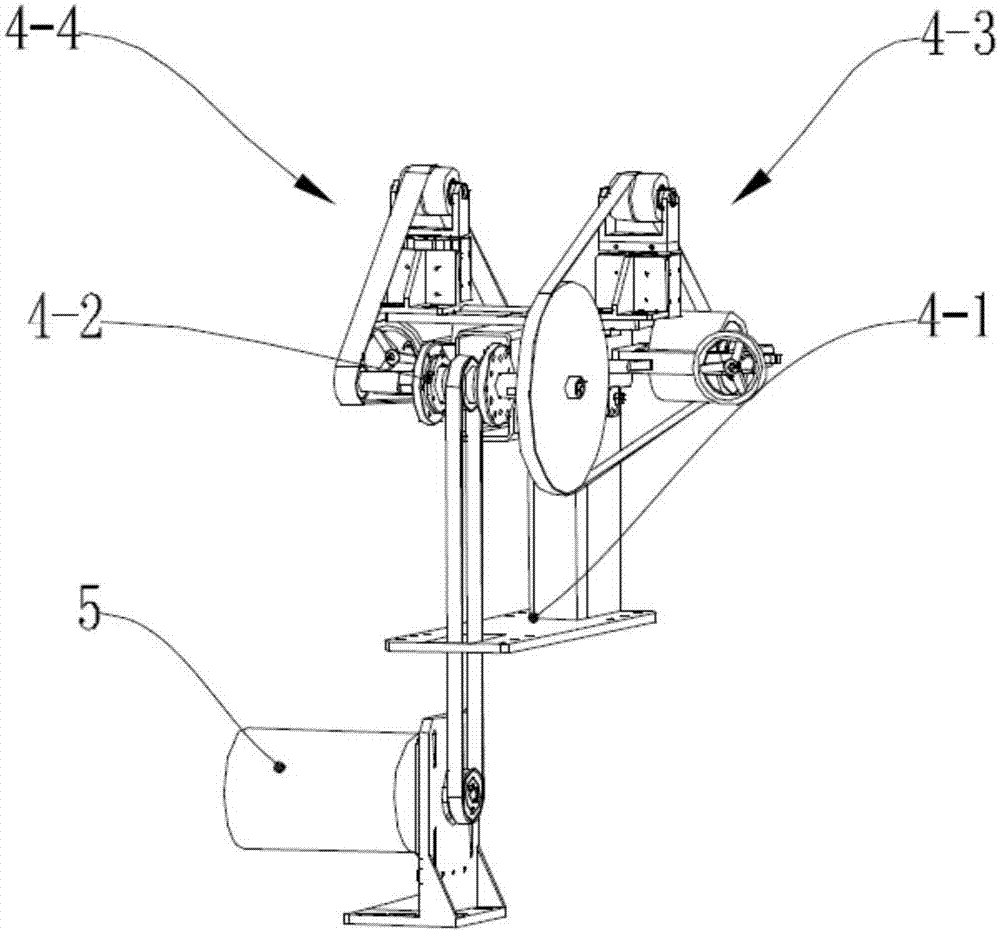

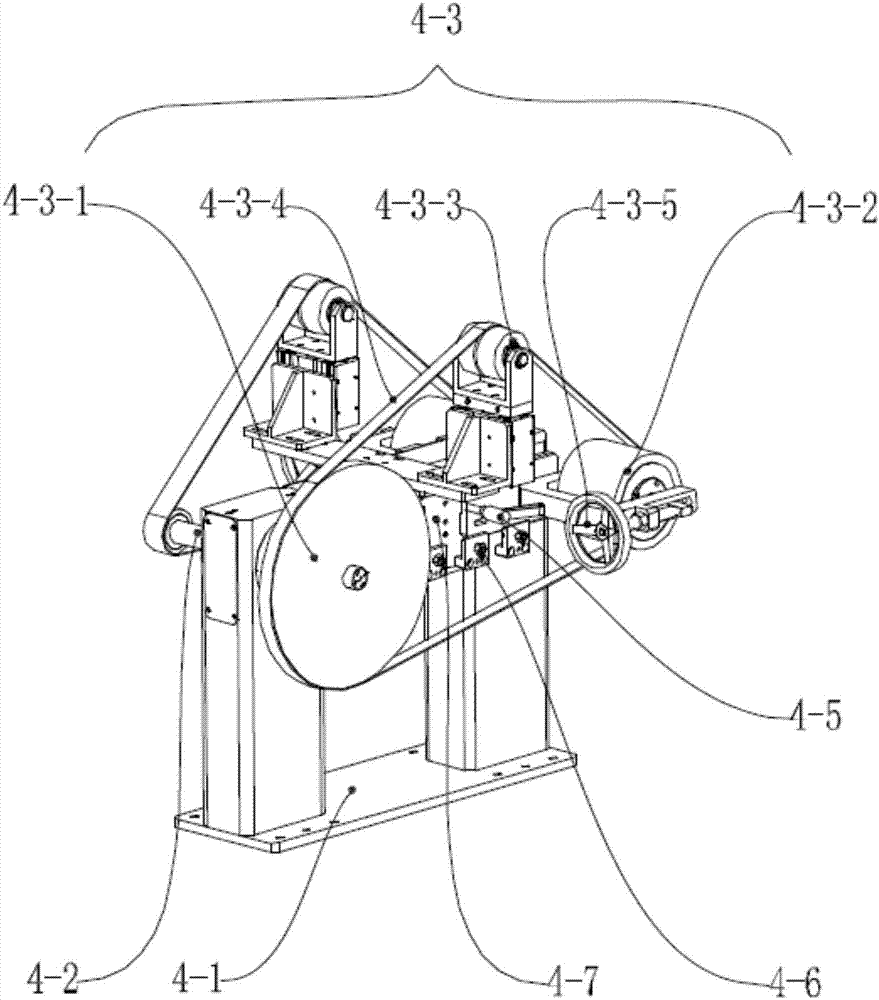

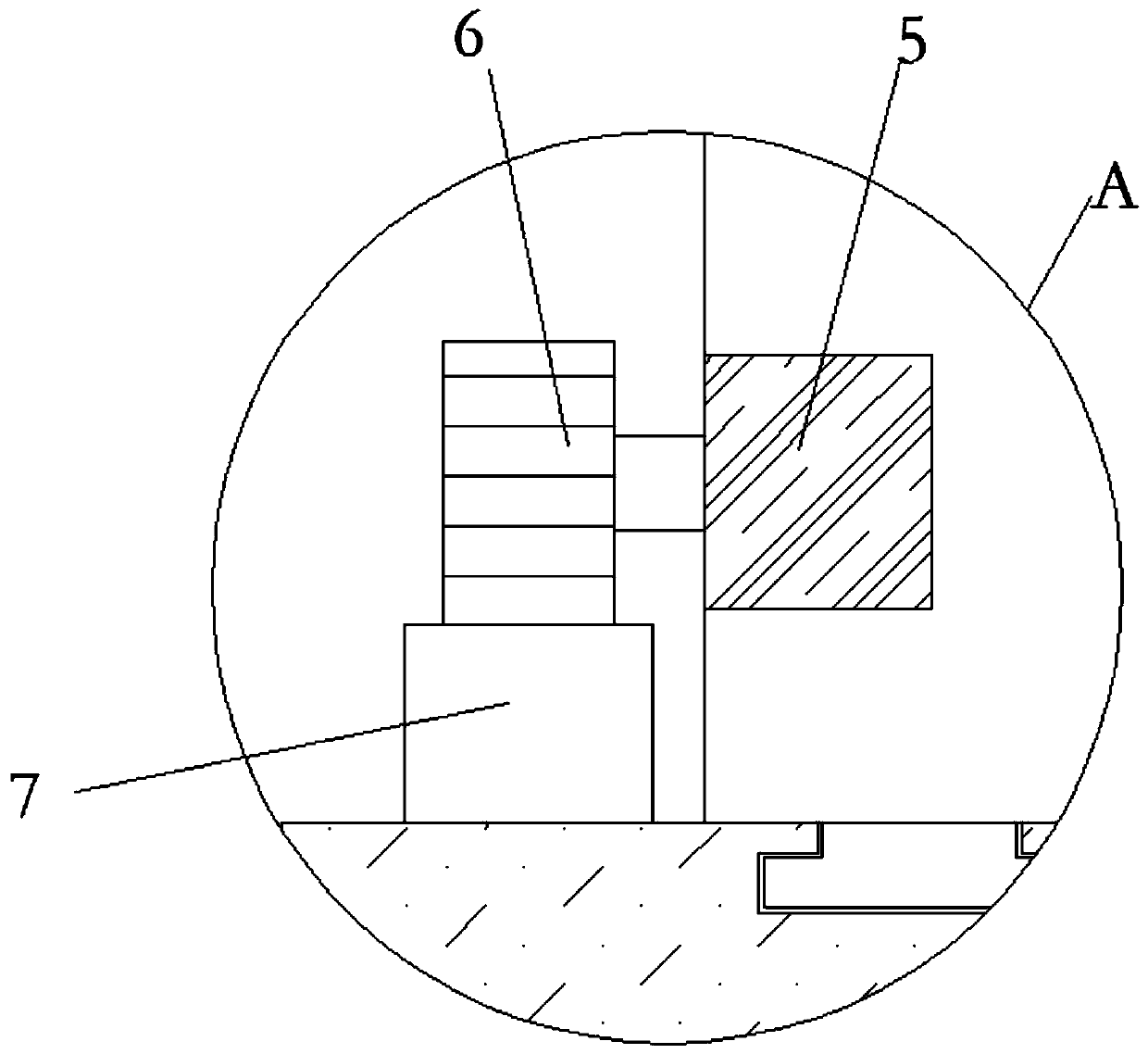

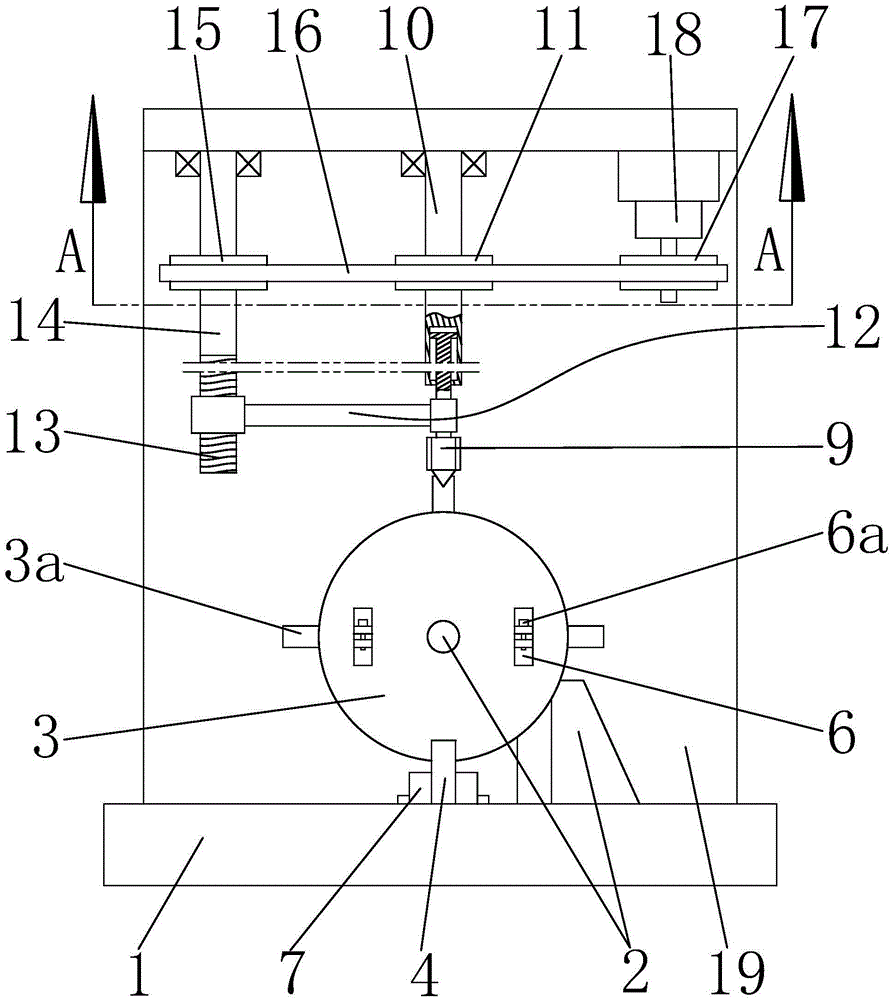

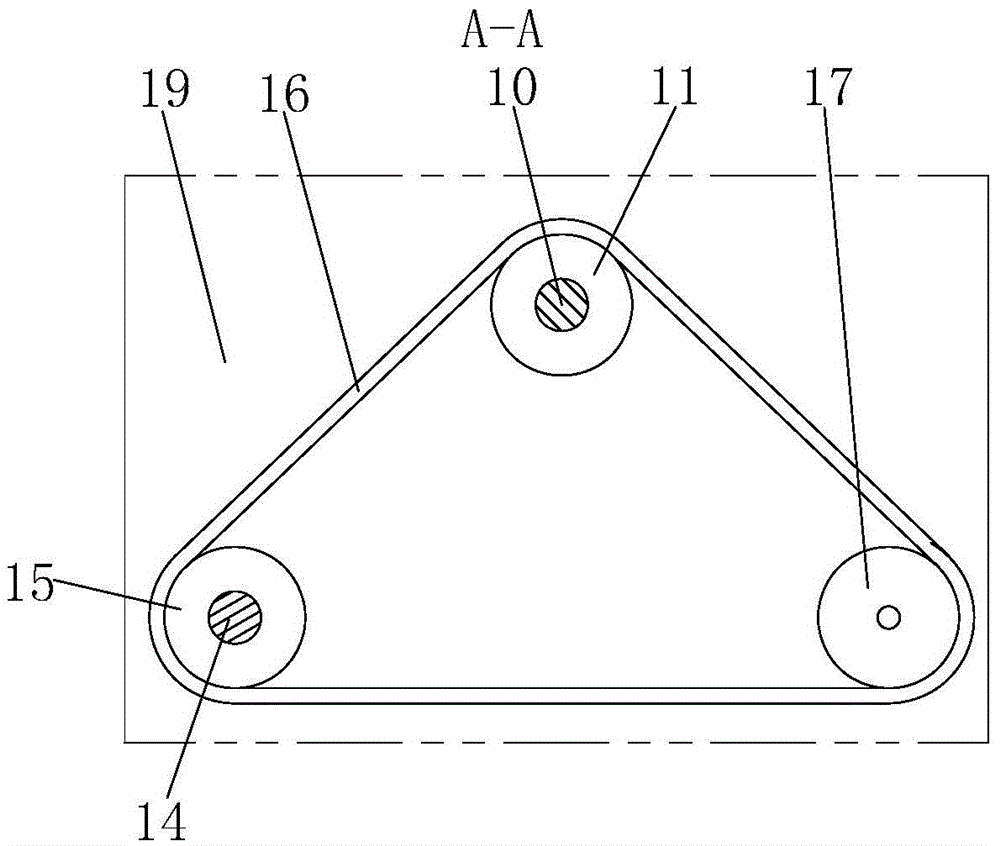

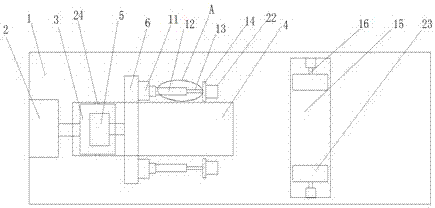

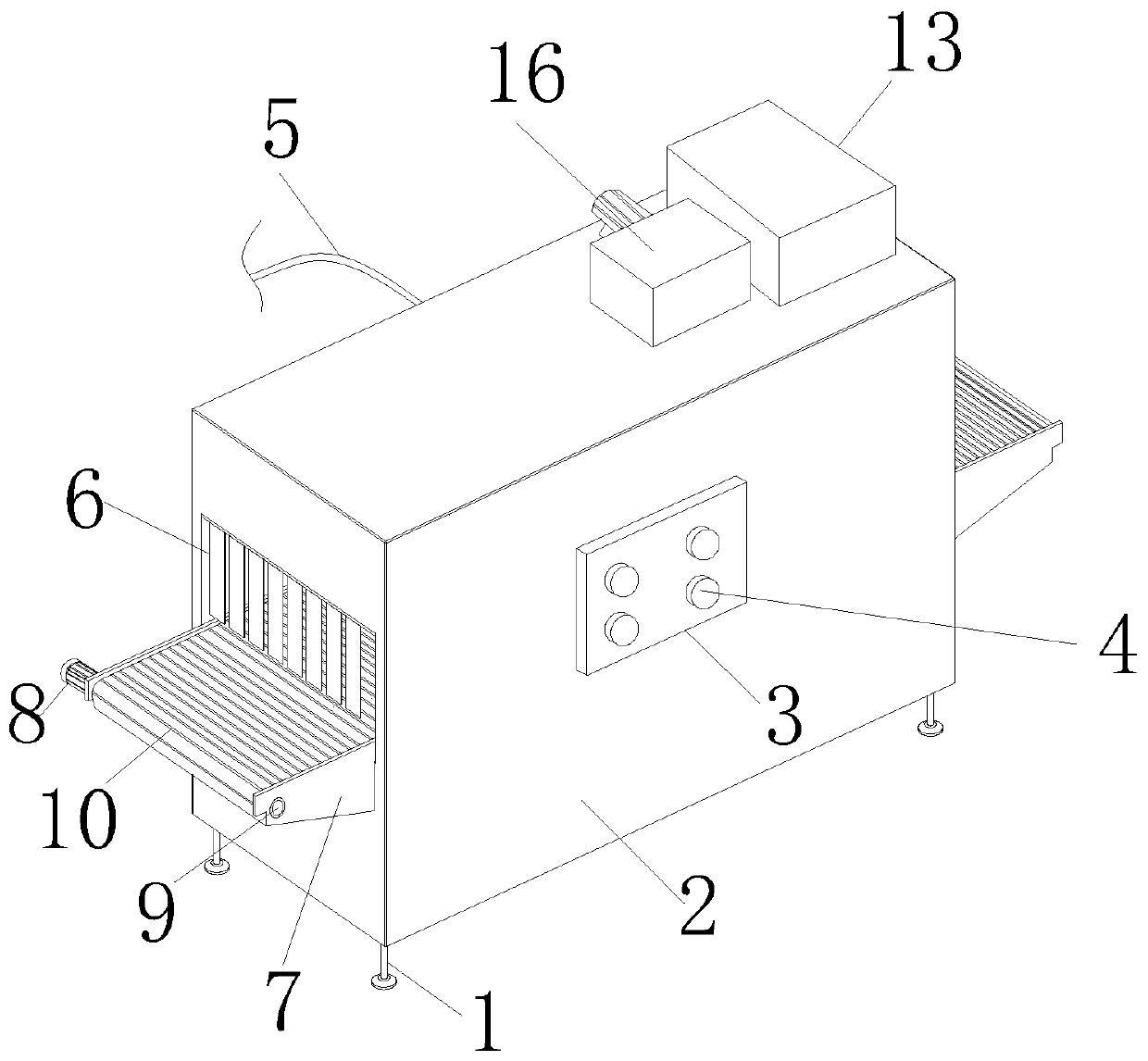

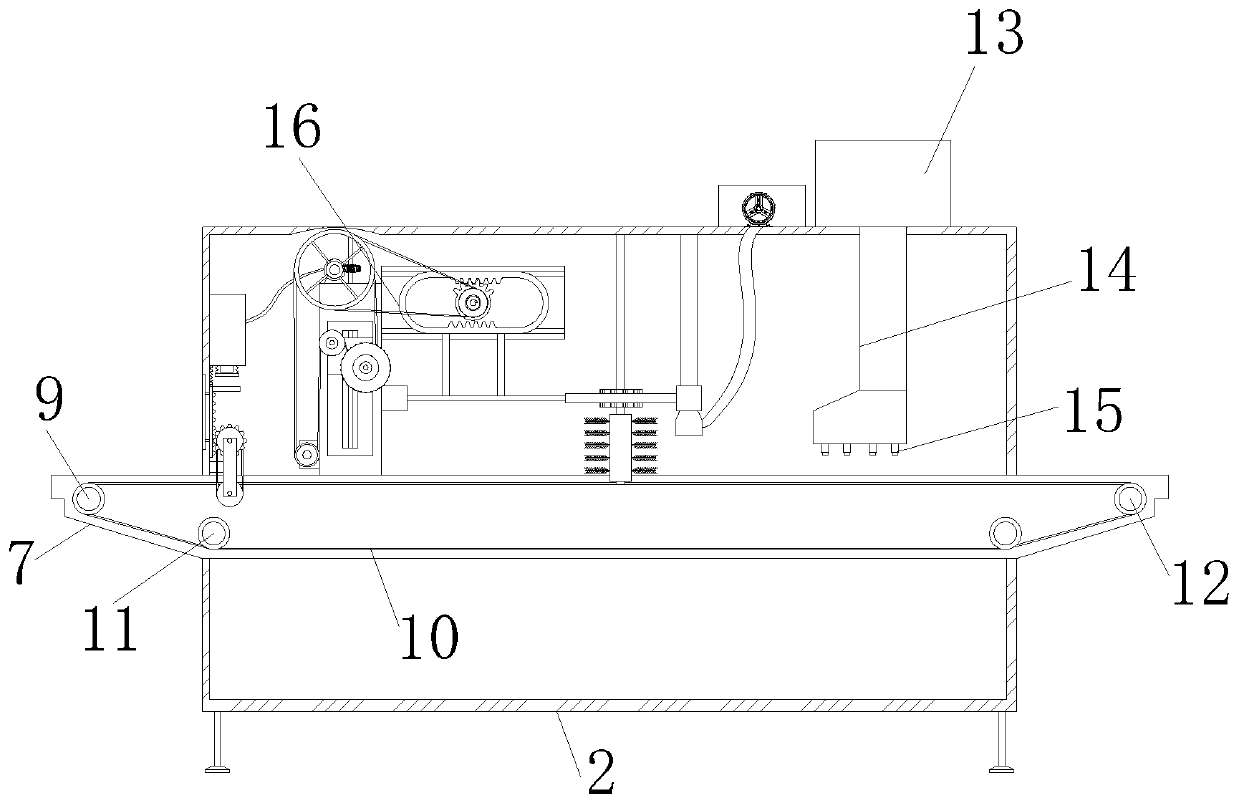

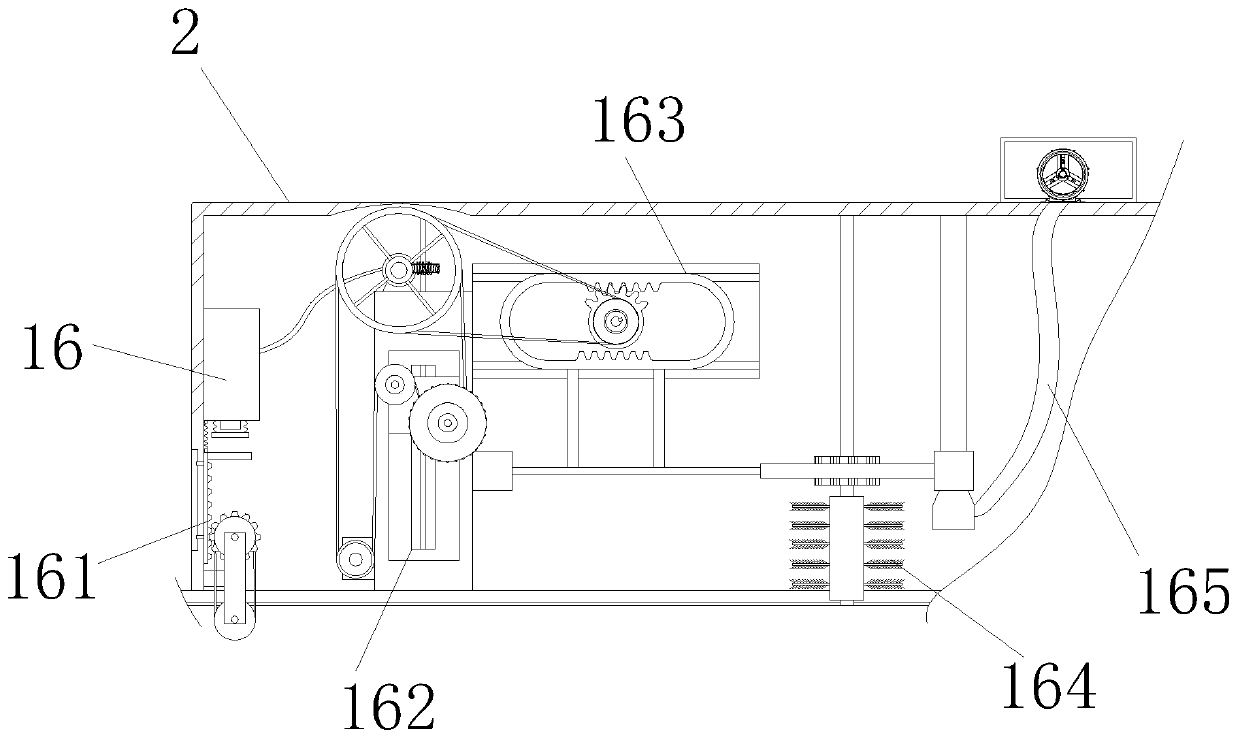

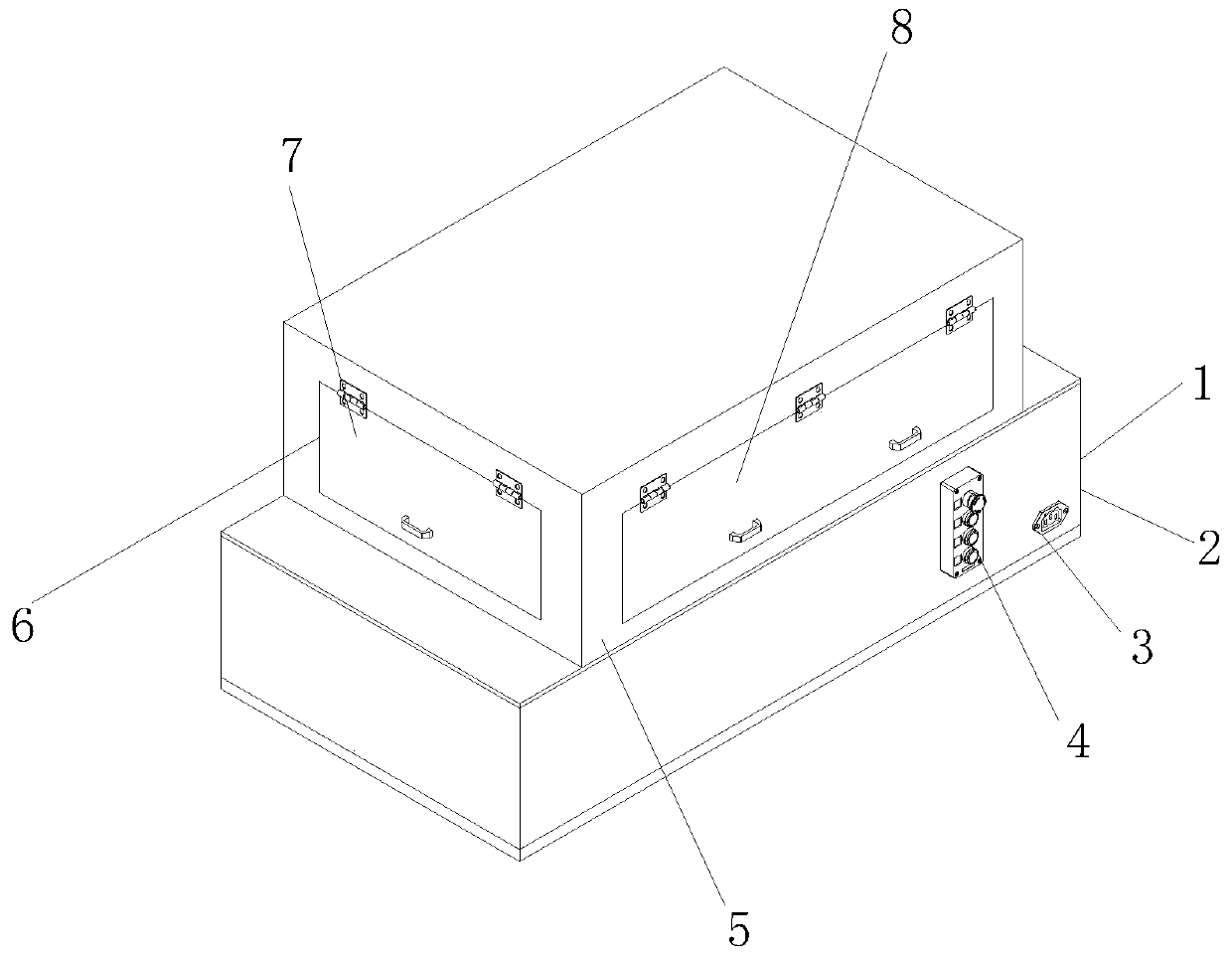

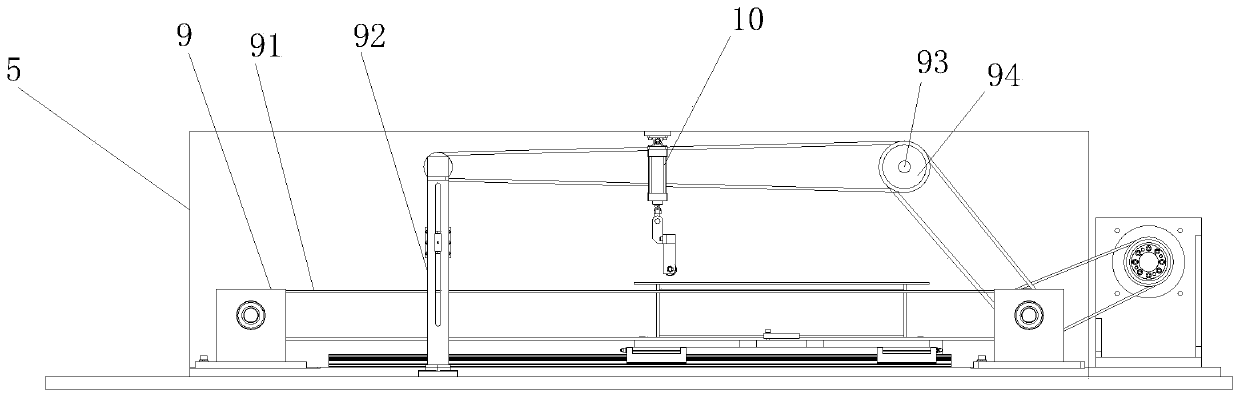

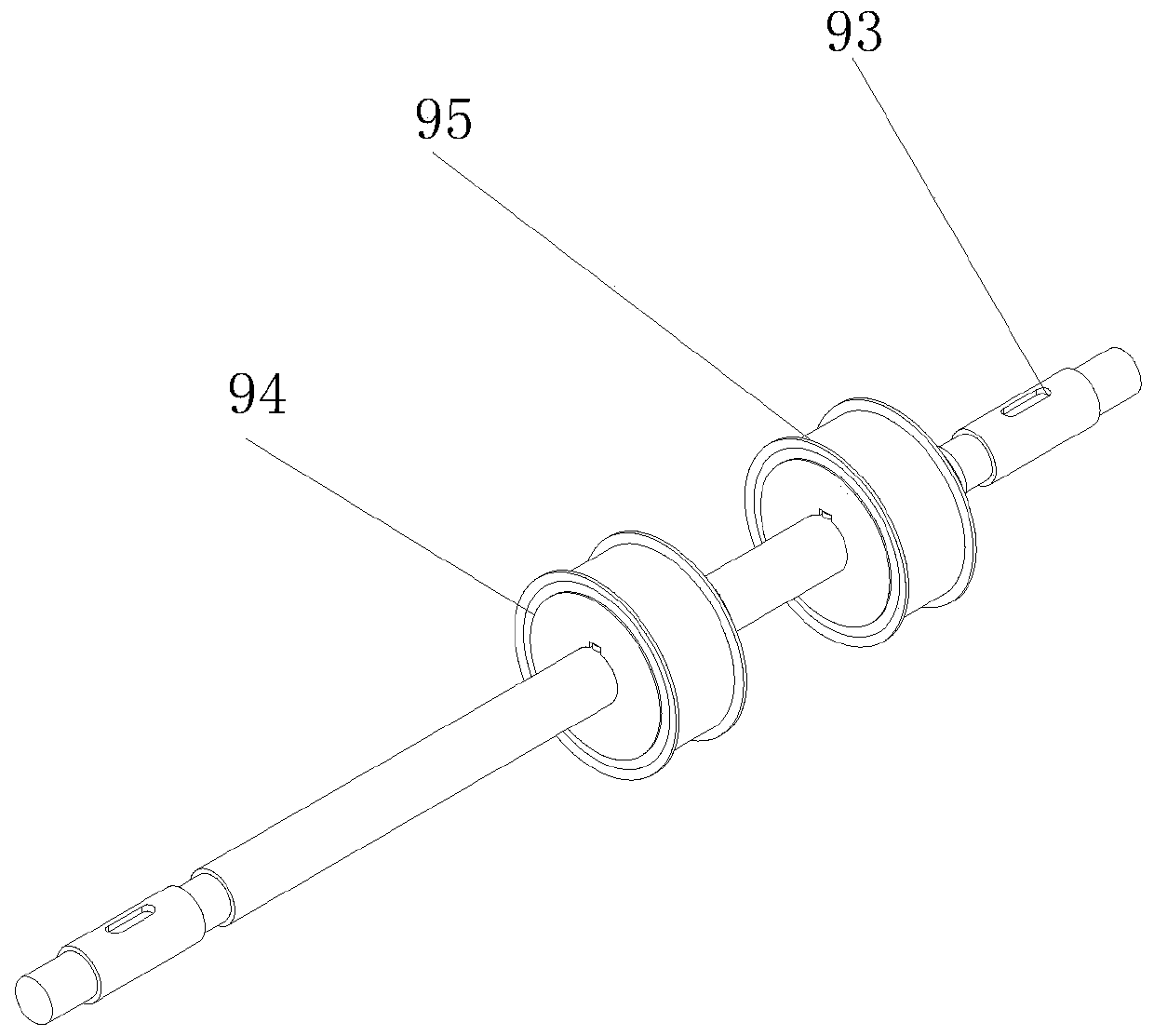

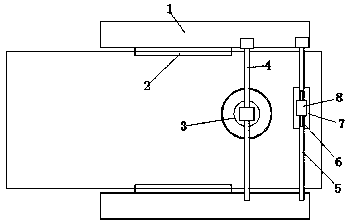

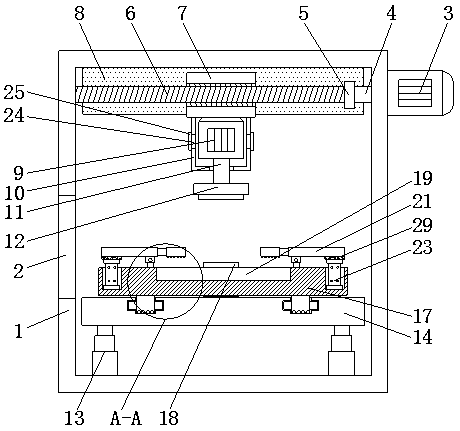

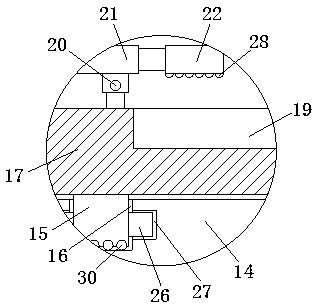

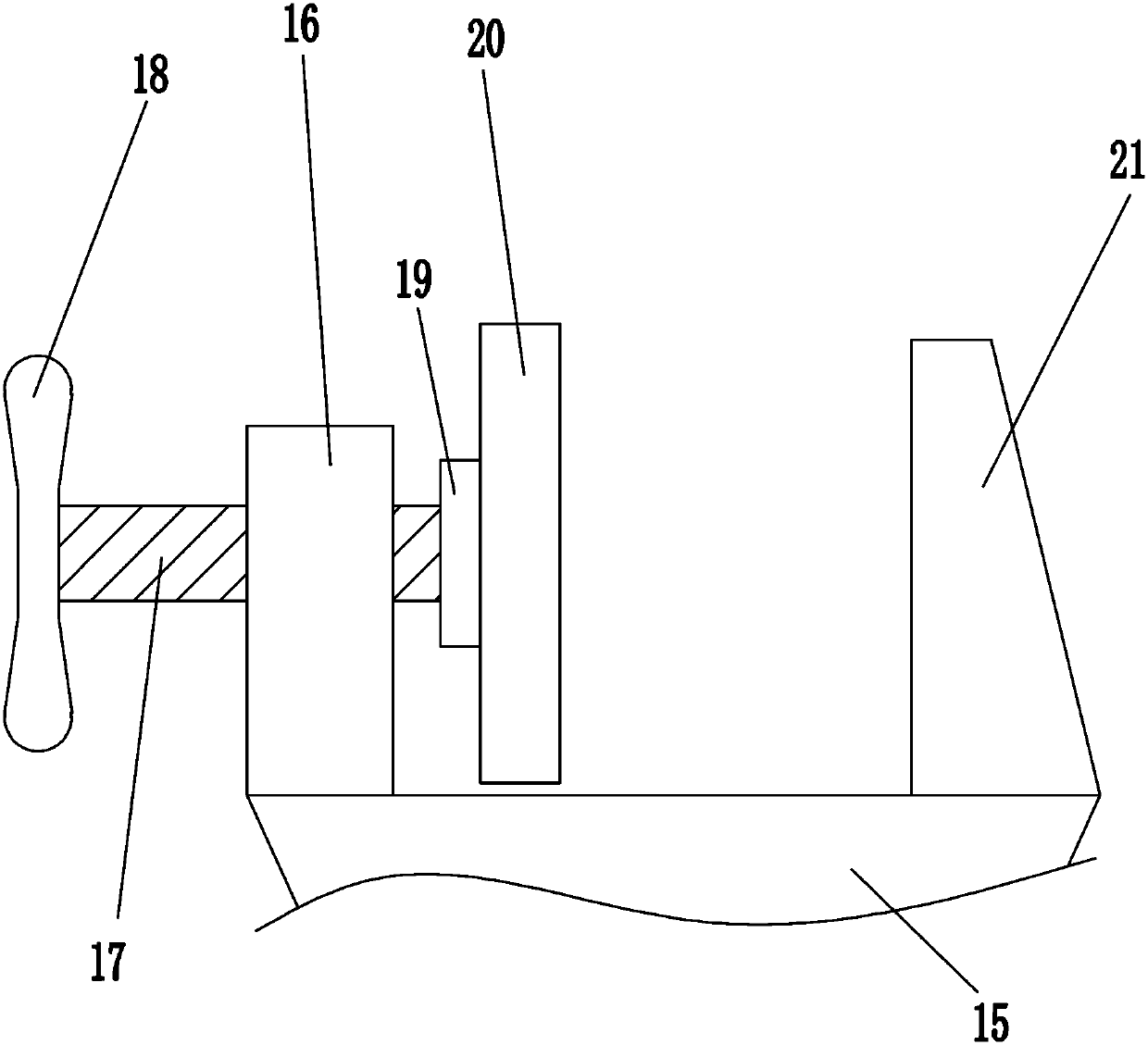

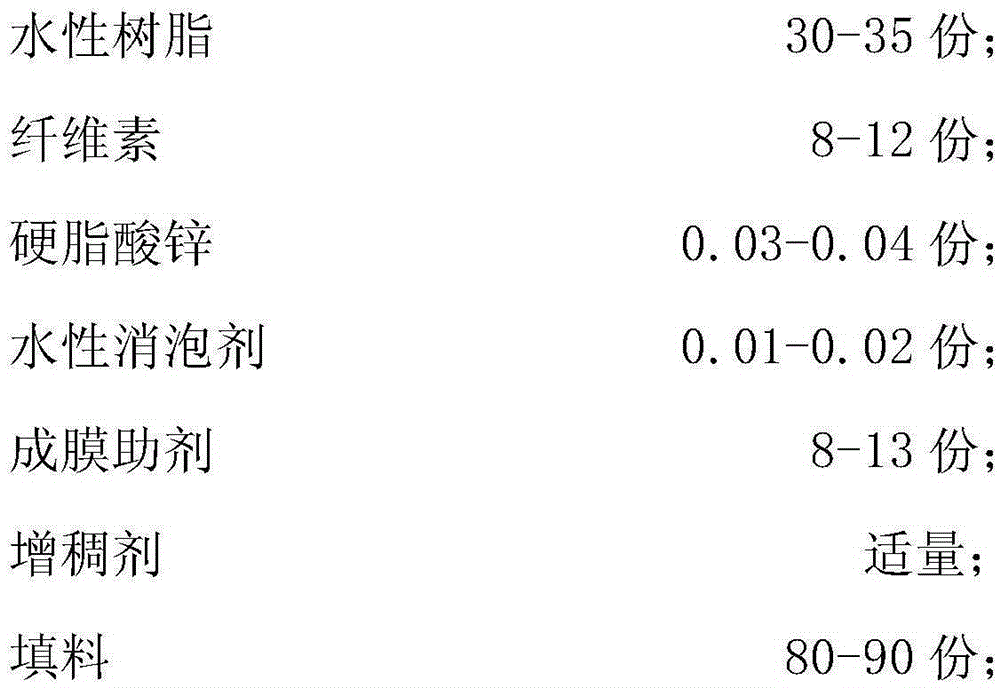

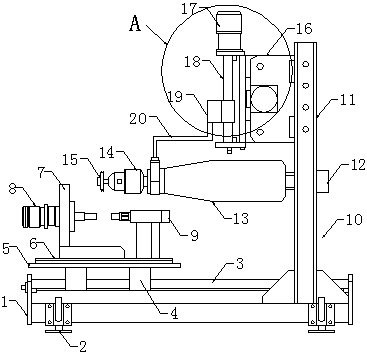

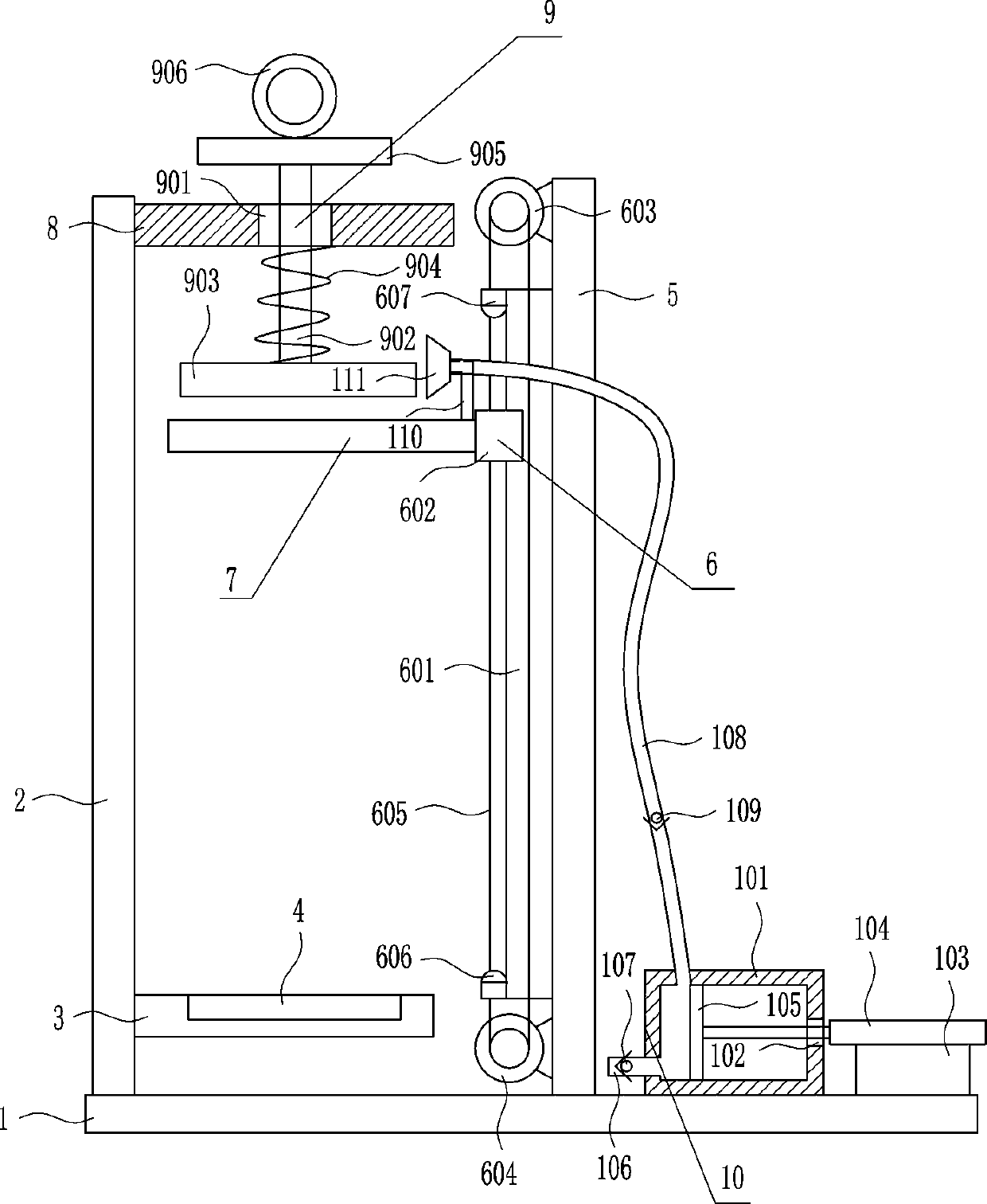

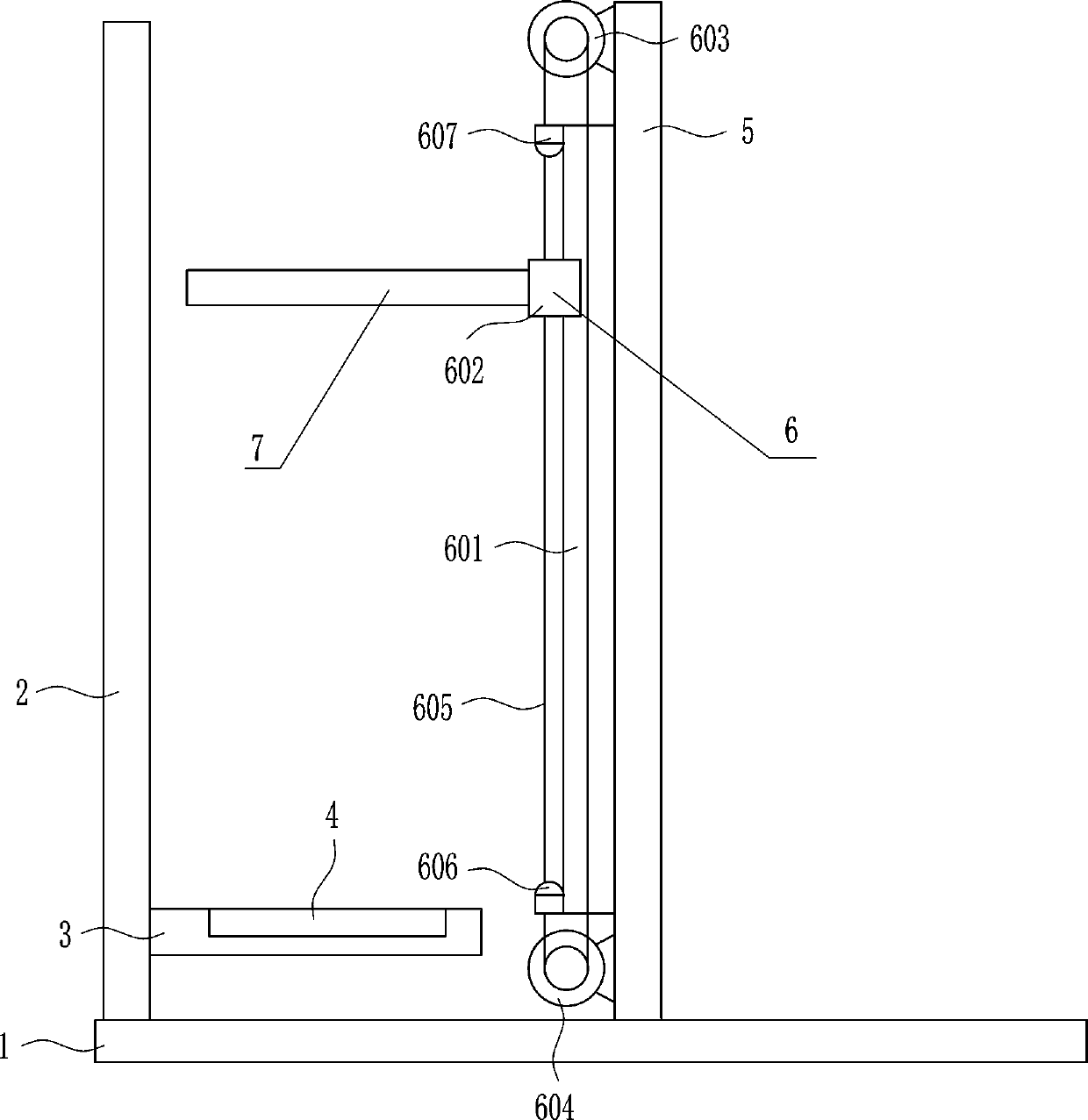

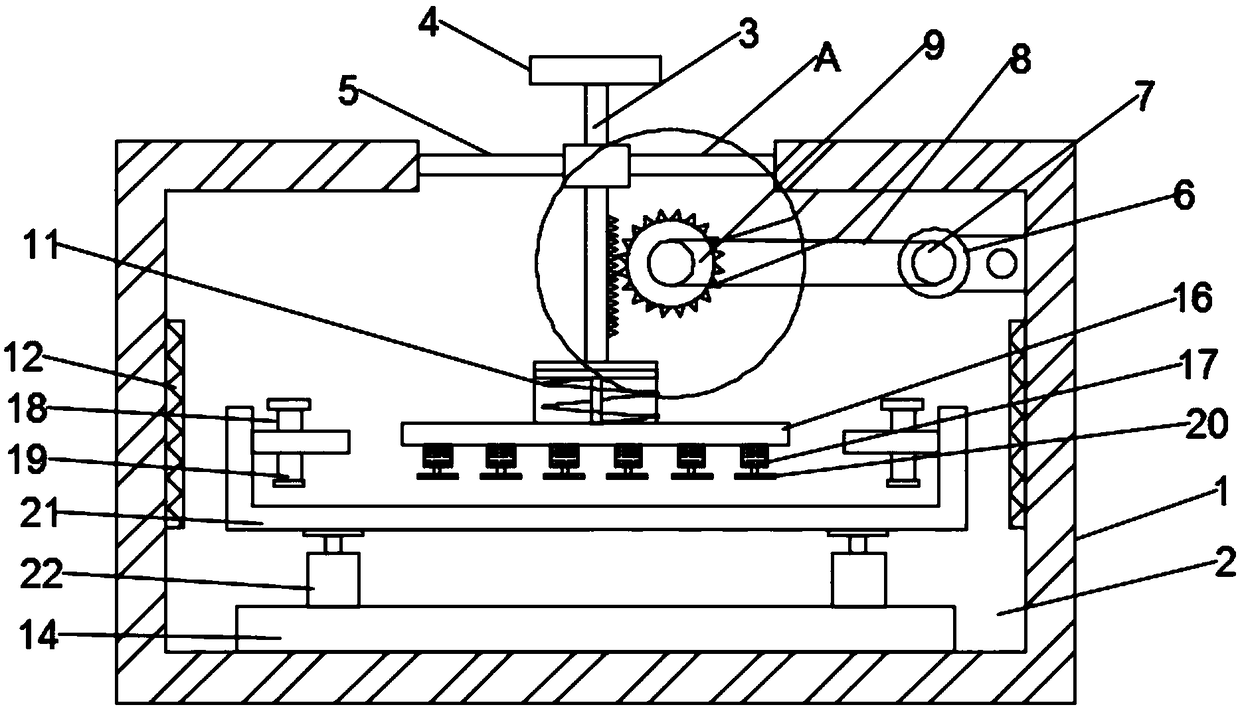

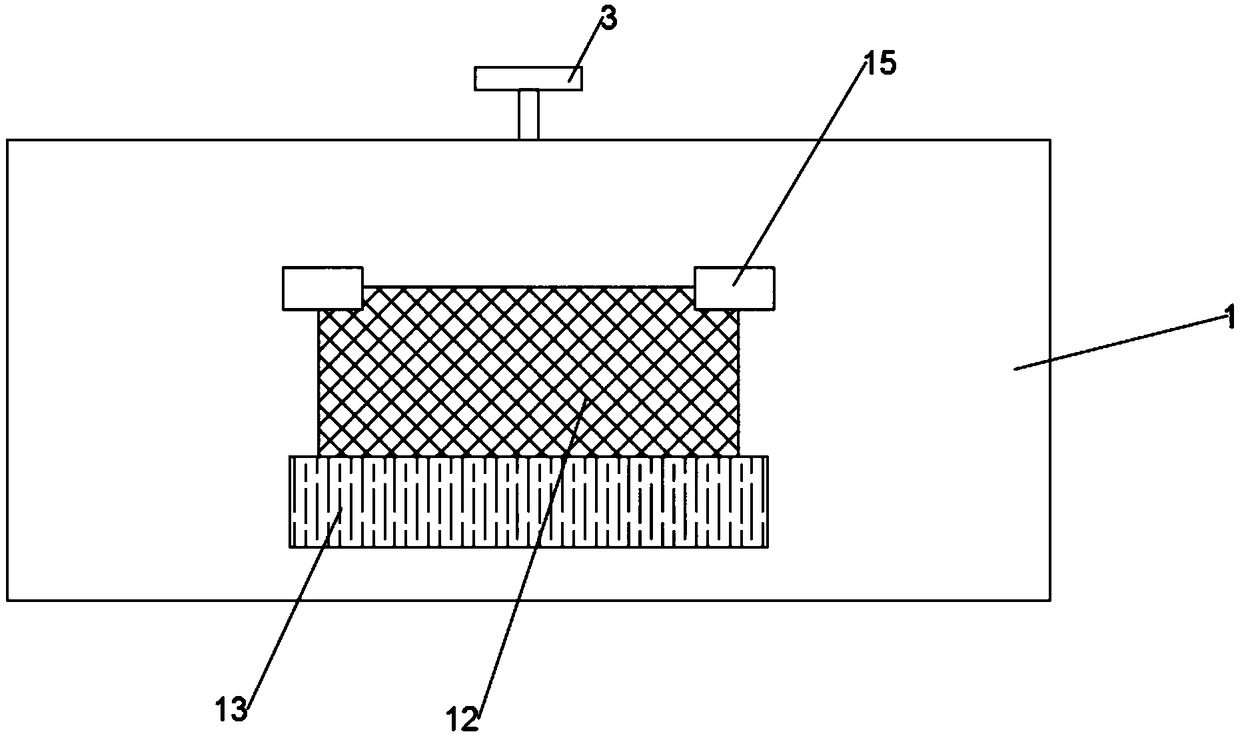

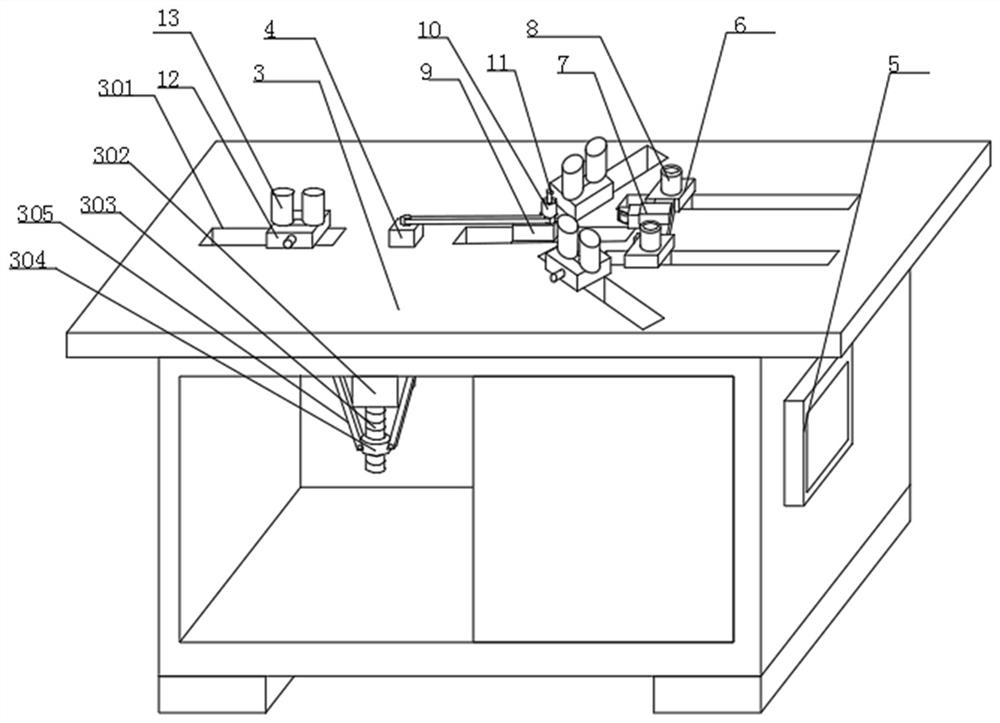

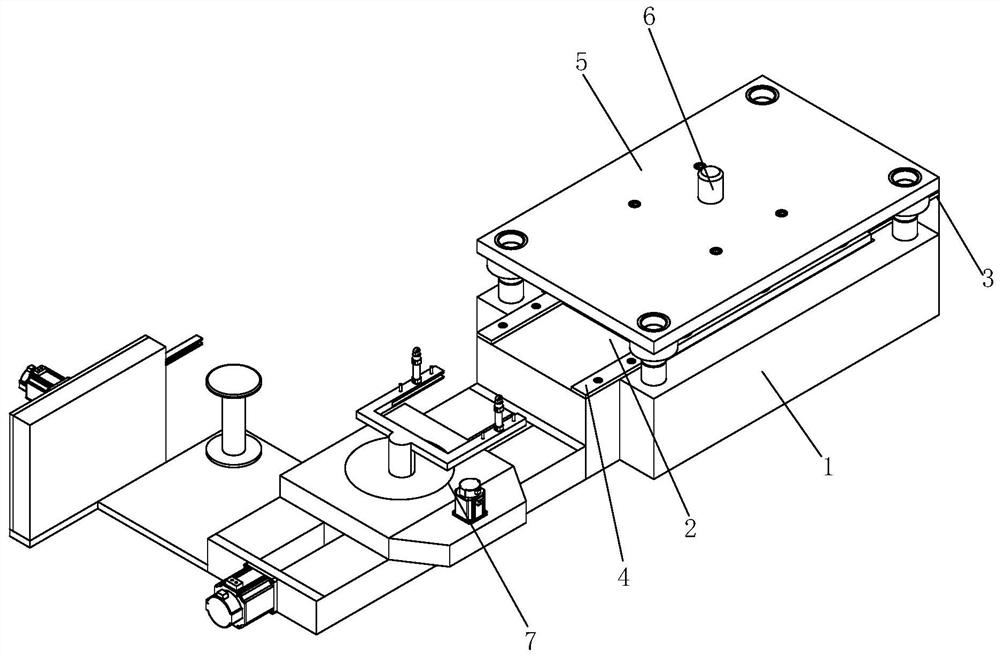

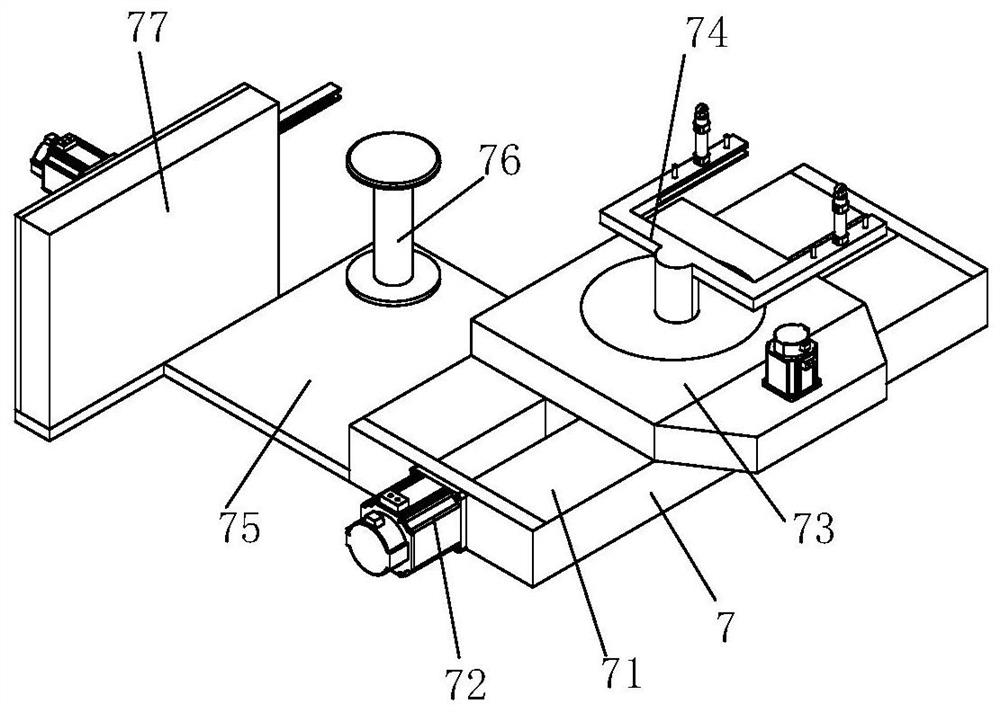

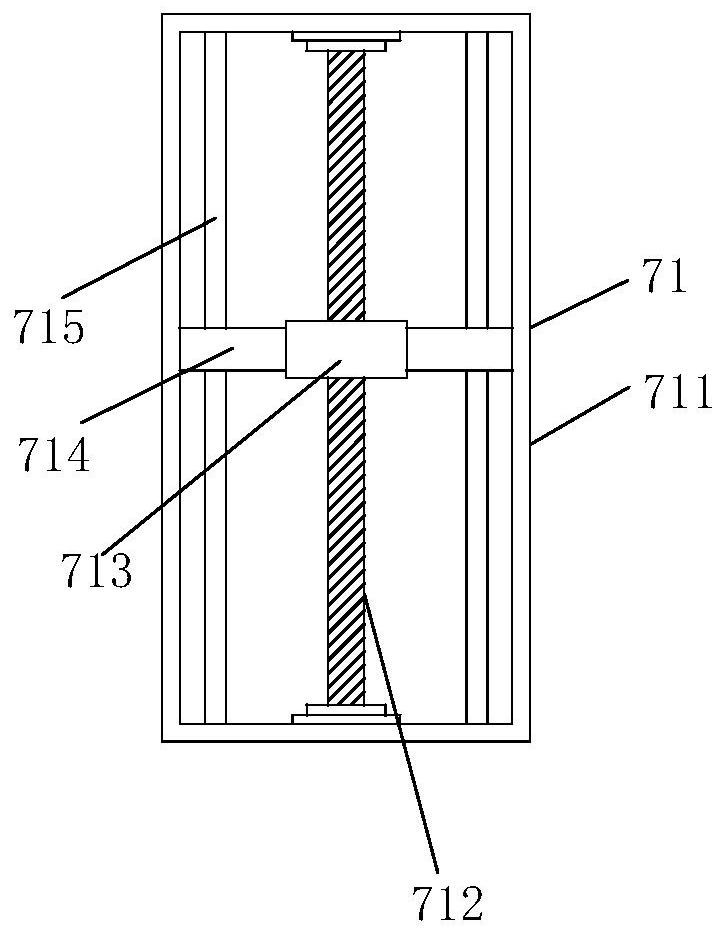

Desktop type grinding and polishing belt sander working table

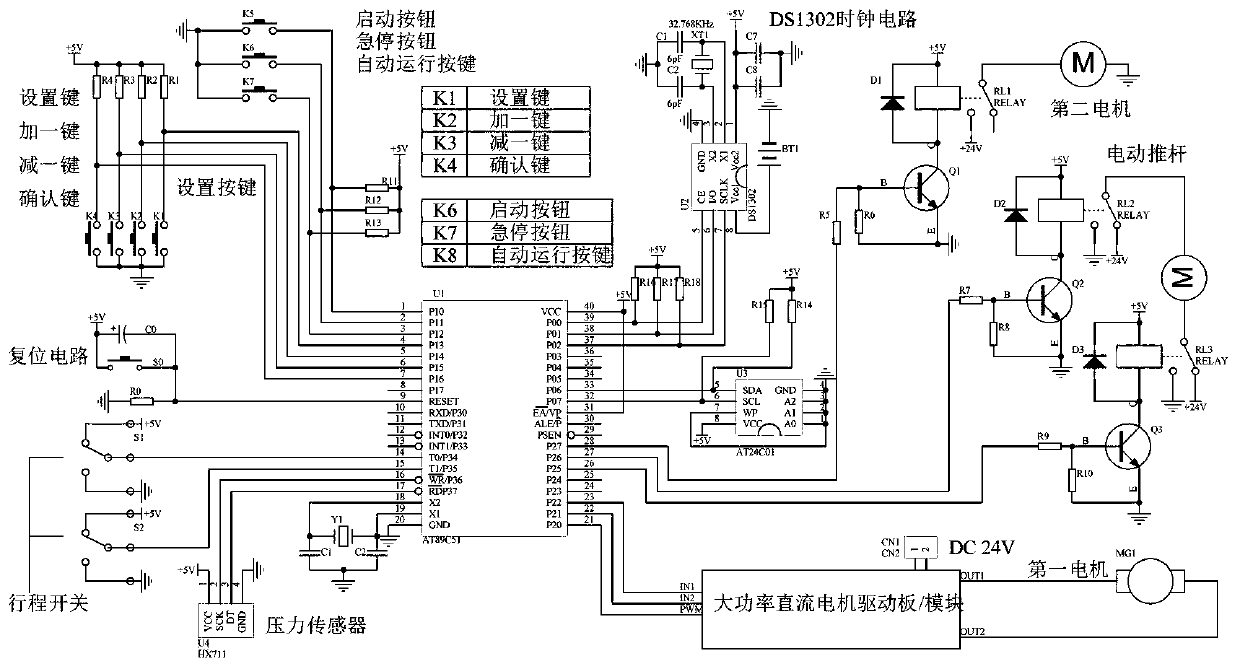

PendingCN106956188AQuick sandingQuick polishBelt grinding machinesGrinding feedersSanderProgrammable logic controller

The invention relates to a desktop type grinding and polishing belt sander working table. The working table comprises a mechanical arm, a fixture, a robot controller, a single-drive grinding and polishing mechanism, a grinding motor, a programmable logic controller (PLC) control system and a working table body; the mechanical arm and the single-drive grinding and polishing mechanism are mounted on the upper surface of the working table body; the fixture is mounted at the free end of the mechanical arm in a replaceable manner; the robot controller is arranged in the working table body to control the motion of the mechanical arm; the single-drive grinding and polishing mechanism is located in front of the free end of the mechanical arm and comprises a grinding mechanism and a polishing mechanism; and the PLC control system controls the grinding motor to drive the grinding mechanism and the polishing mechanism simultaneously to operate. The working table has the beneficial effects as follows: small machined parts can be ground and polished quickly, and the production efficiency is high; a belt sander is simple to operate, the precision is high, the flexibility is good, the occupied area is small, and movement and popularization are convenient; and multiple belt sanders can be combined for production, the automation degree is high, and modularization and standardization are easy to realize.

Owner:GUANGDONG LXD ROBOTICS CO LTD

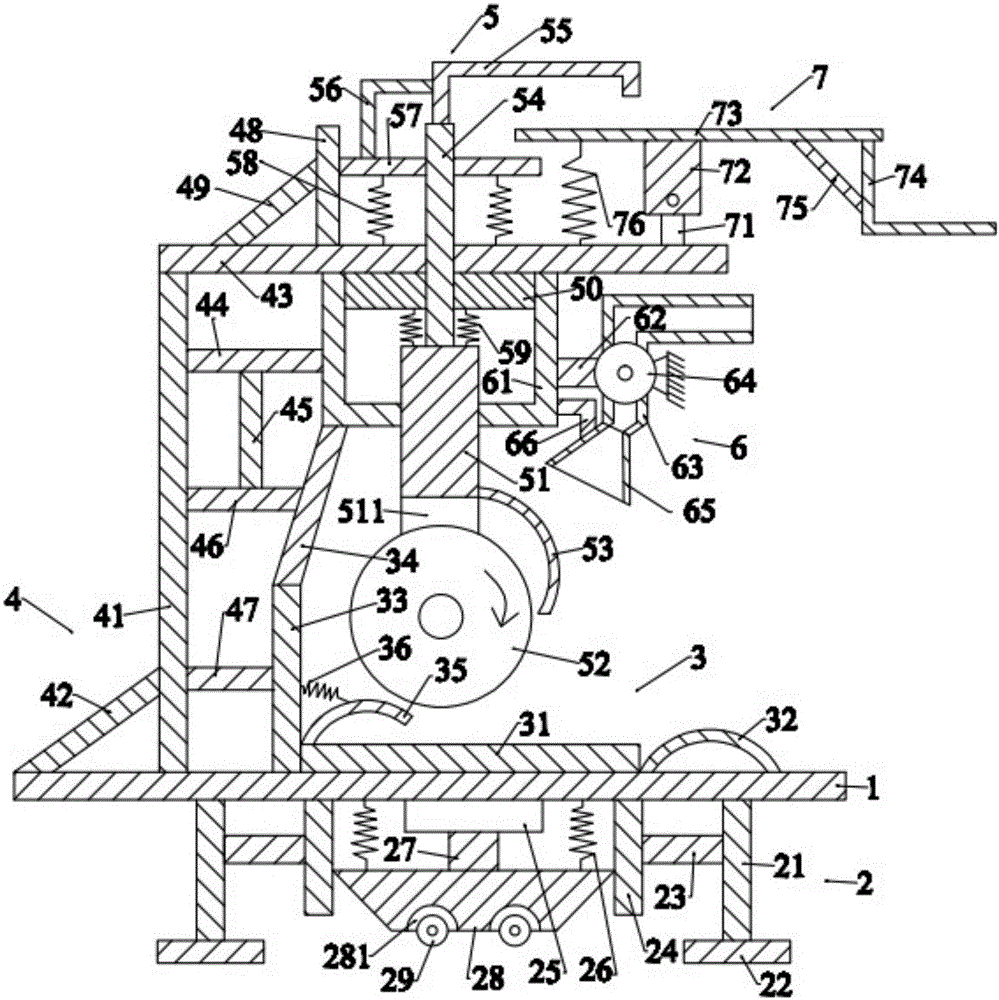

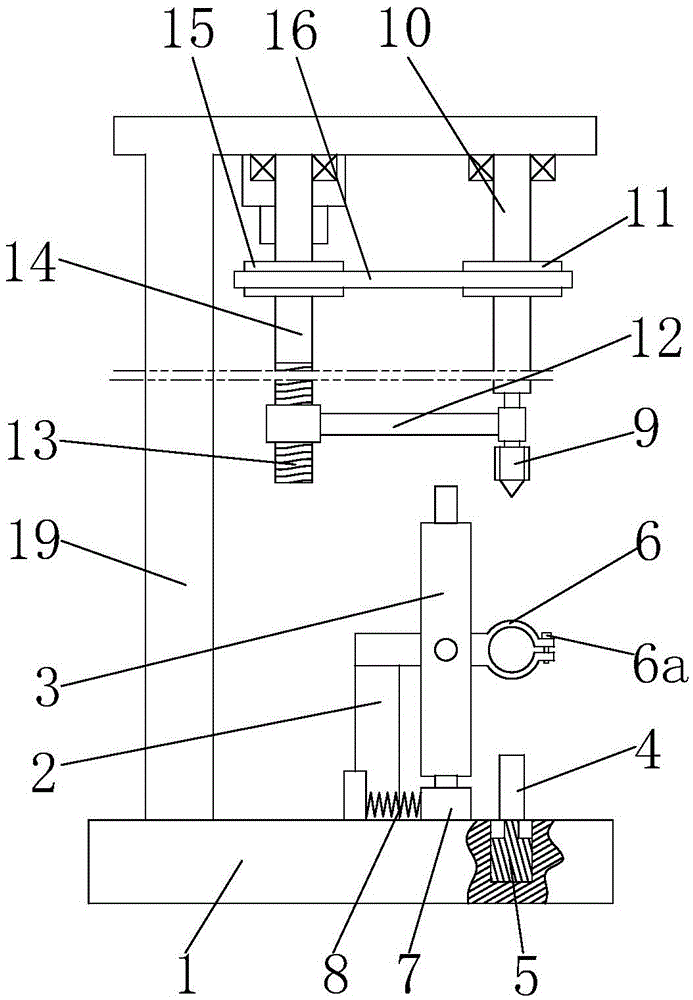

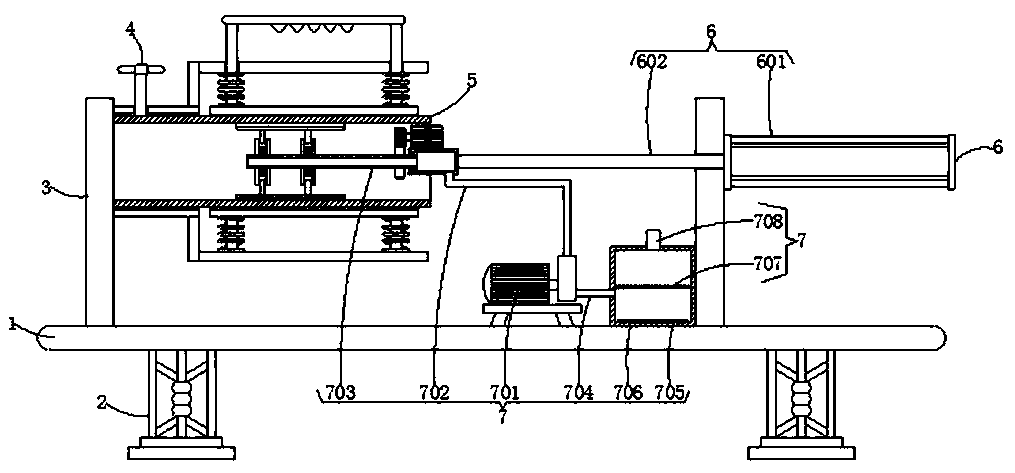

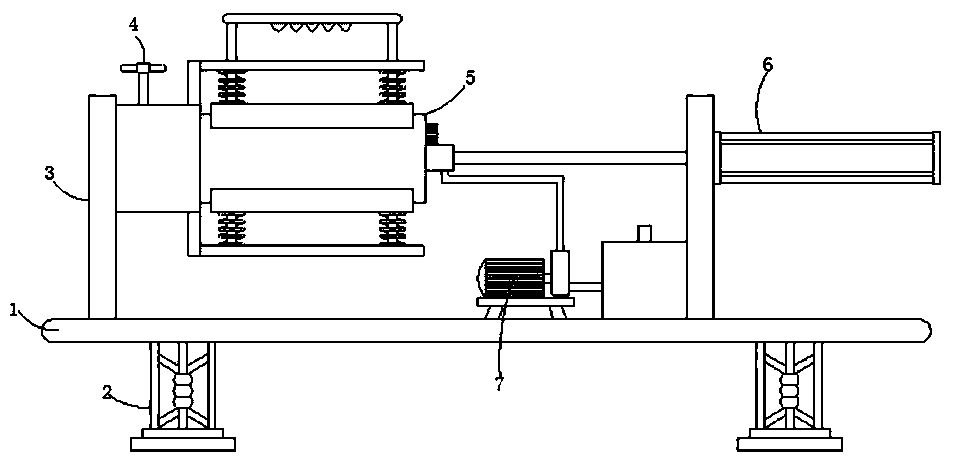

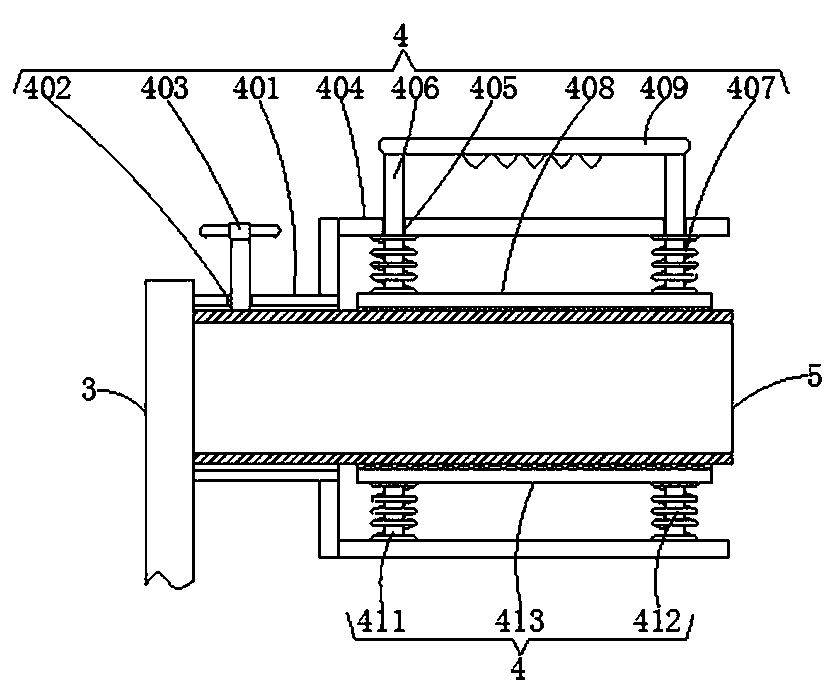

Polishing device for construction steel bar

ActiveCN106217206ASimple structureEasy to useGrinding carriagesGrinding machinesArchitectural engineeringRebar

The invention discloses a polishing device for a construction steel bar, comprising a bottom plate, a roller device, a magnet device, a support device, a polishing structure, a blowing device and a regulating device; the roller device comprises a first supporting rod, a first cushion block, a first cross rod, a first locating rod, an air cylinder, a first spring, a pushing rod, a supporting block and a first roller; the magnet device comprises a first magnet, a bent rod, a second magnet, a third magnet, a clamping rod and a second spring; the support device comprises a second supporting rod, a first inclined rod, a second cross rod, a third cross rod, a first vertical rod, a fourth cross rod, a fifth cross rod, a second vertical rod and a second inclined rod; the polishing structure comprises a moving rod, a polishing wheel, a baffle, a third vertical rod, a locating rack, a first support, a sixth cross rod, a third spring, a locating block and a fourth spring; and the blowing device comprises a fixed frame, a first connecting rod, a draught fan, a blow pipe and a blow hopper. The polishing device can be used for rapidly polishing the steel bar and is high in polishing efficiency.

Owner:广西华业建筑工程有限公司

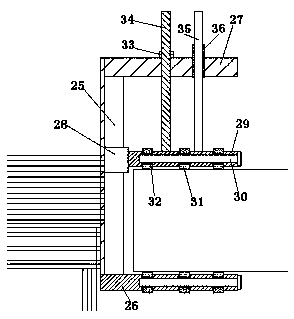

Device for full-automatic machining of graphene self-lubricating guide plates and machining method thereof

InactiveCN109866087AAvoid damageQuick sandingGrinding carriagesGrinding drivesBall bearingEngineering

The invention relates to the technical field of vehicle molds, and discloses a device for full-automatic machining of graphene self-lubricating guide plates. The device comprises a base; the same console is fixedly connected to four corners of the upper end of the base through support rods; the upper end of the console is slidingly connected with an U-shaped support plate; first motors are fixedlyembedded in the outer walls of the bottom ends of two vertical walls of the U-shaped support plate; output shafts of the first motors are fixedly connected with gears; the upper end of the console isfixedly connected with racks engaged with the gears; two opposite side walls of the U-shaped support plate near the upper end are rotationally connected with the same first screw rod through ball bearings; a second motor is fixedly connected to the outer wall of the U-shaped support plate; and an output shaft of the second motor penetrates through the side wall of the U-shaped support plate, andis fixedly connected with one end of the first screw rod. The device for full-automatic machining of the graphene self-lubricating guide plates and a machining method thereof have the advantages of capability of automatically polishing the guide plates and improvement of the polishing production efficiency.

Owner:浙江双展精密机械股份有限公司

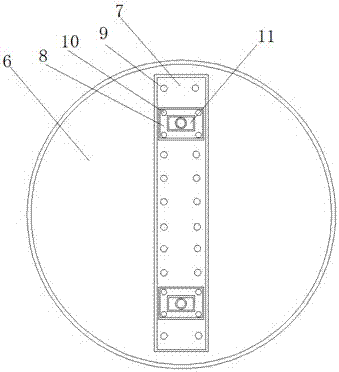

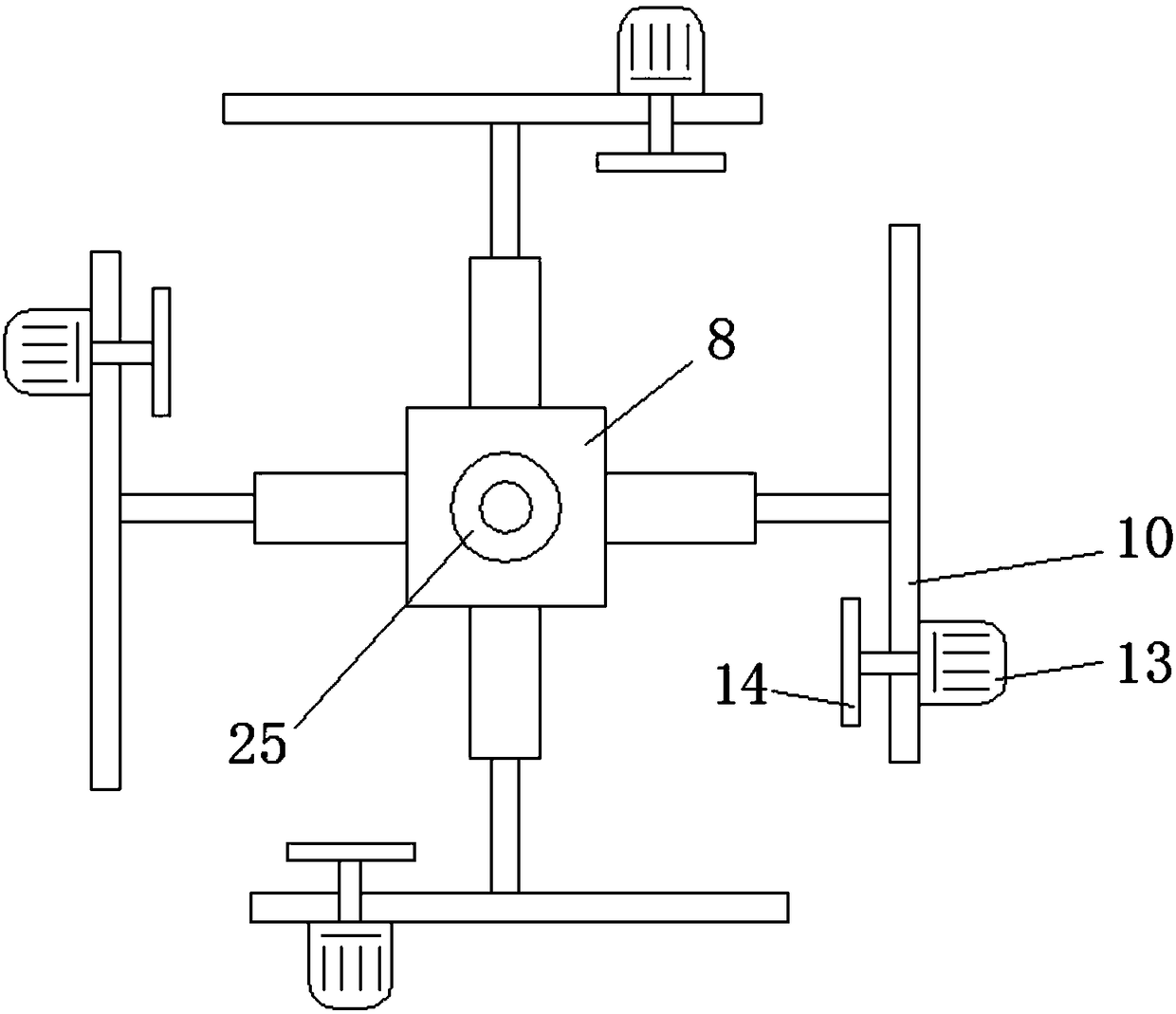

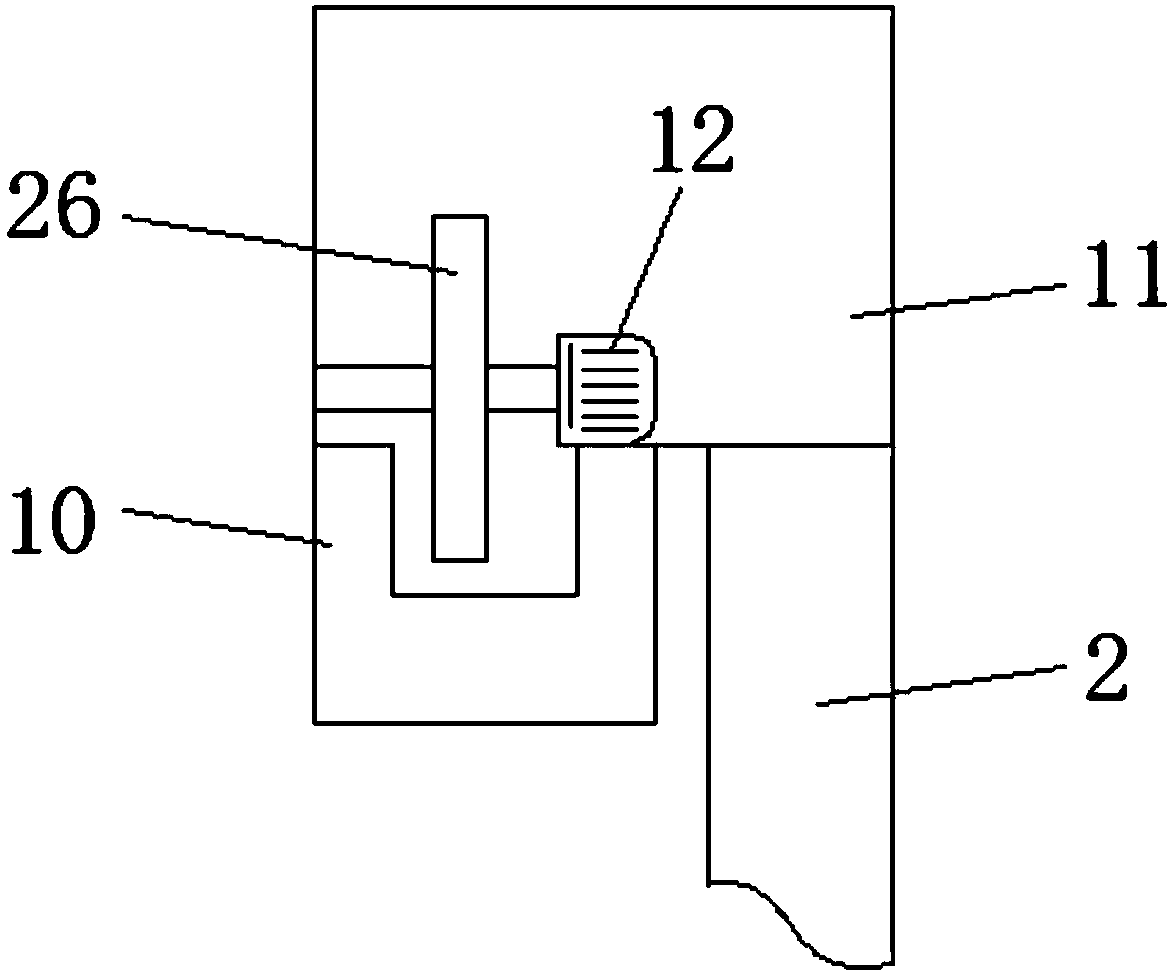

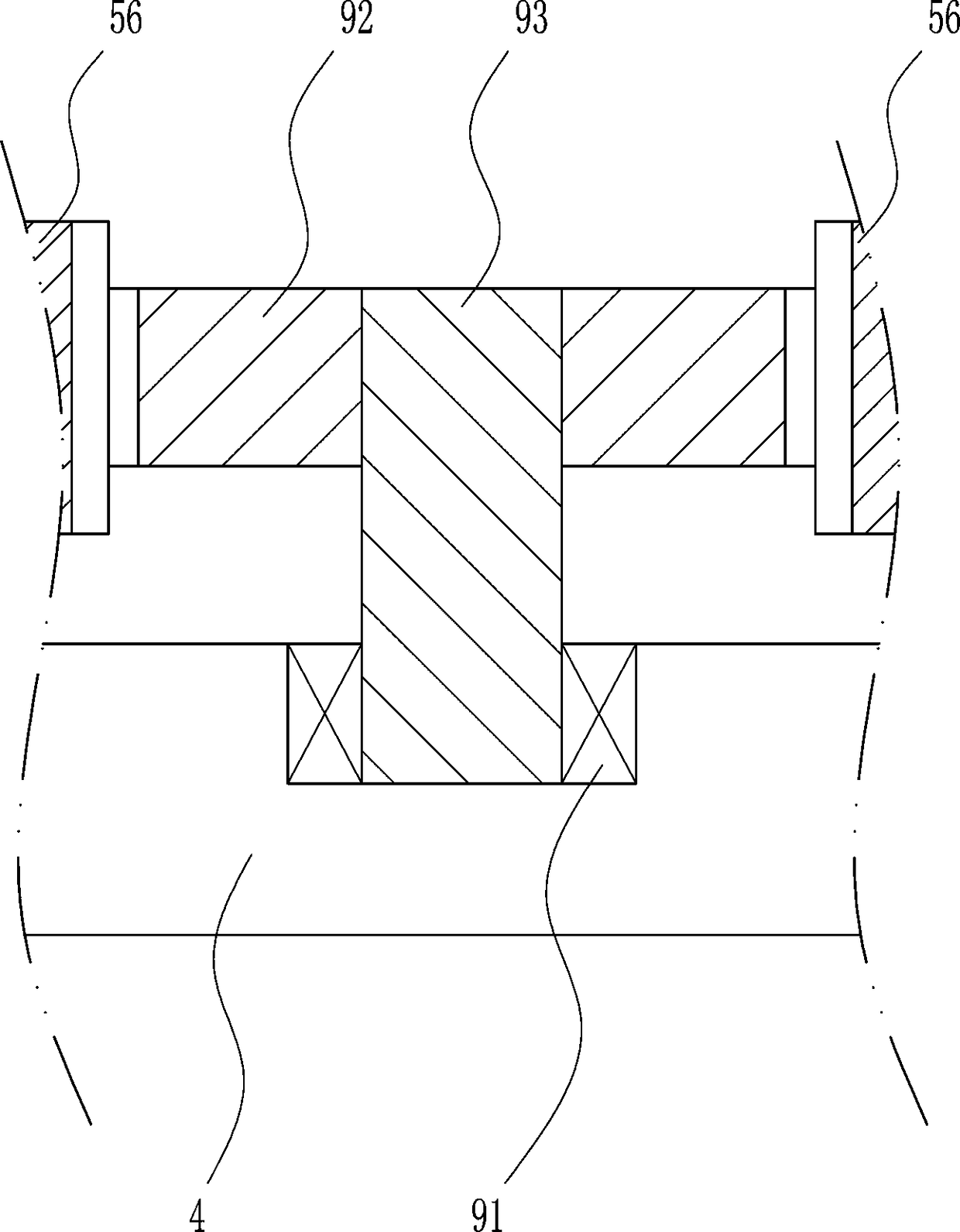

Cross joint pipe inner side wall polishing device

ActiveCN105563253AEffective sandingEasy to grindRevolution surface grinding machinesGrinding drivesMechanical engineering

The invention relates to a cross joint pipe inner side wall polishing device. The cross joint pipe inner side wall polishing device comprises a base and a mounting frame. A rotary plate is slidably mounted on the mounting frame, a positioning pin is disposed on the lower portion in front of the rotary plate, and the positioning pin is connected with an air cylinder; two C-shaped clamping openings are formed in the front end face of the rotary plate, and fastening bolts are mounted at the front ends of the clamping openings; four outwards extending plates are uniformly distributed on the circular arc end face of the rotary plate, a clamping seat is slidably mounted on the base, and the clamping seat is connected with a spring; a polishing driving assembly is disposed above the rotary plate and comprises a polisher, the position of the polisher is matched with that of the positioning pin, and a back frame for fixedly mounting the polishing driving assembly is disposed in rear of the polishing driving assembly. By means of the cross joint pipe inner side wall polishing device, the polisher can be controlled to automatically polish the single inner side pipe wall of a cross joint pipe, positioning shifting can be achieved by controlling the rotary plate to rotate by 90 degrees, and the polishing efficiency is improved.

Owner:临沂罗开投资有限公司

Pipe fitting inner wall polishing device

ActiveCN107081644AQuick sandingImprove grinding accuracyGrinding carriagesRevolution surface grinding machinesCircular discPipe fitting

The invention discloses a pipe fitting inner wall polishing device which comprises a base. One side of the top end of the base is provided with a first push rod motor. An output shaft of the first push rod motor is provided with a first slide block. The top end of the base is provided with a first slide groove. The first slide block is slidably mounted in the first slide groove and extends out of the first slide groove. A first servo motor is fixed to the end, located outside the first slide groove, of the first slide block through screws. An output shaft of the first servo motor is provided with a rotary disc. The end, away from the output shaft of the first servo motor, of the rotary disc is provided with a second slide groove. According to the pipe fitting inner wall polishing device, double cylindrical polishing heads are adopted to polish the inner wall of a pipe fitting, polishing efficiency is greatly improved, and by adjusting the positions of polishing motors on a circular disc, polishing of the polishing heads can be more accurately controlled, so that polishing precision is higher, and meanwhile, the polishing device can be suitable for pipe fittings of various diameters by arranging clamping blocks to be adjustable.

Owner:XINCHANG HENGSHENG MACHINERY

Building material surface coating equipment

The invention discloses building material surface coating equipment, which comprises a polishing and cleaning device, wherein the polishing and cleaning device comprises a polishing mechanism arrangedin a frame body; a second motor drives a driving belt pulley to rotate by means of a worm, so that the driving belt pulley drives a first belt pulley, a second belt pulley and a third belt pulley torotate by means of a second transmission belt; the third belt pulley further drives a polishing roller to rotate; a worm rotates to drive a worm wheel to rotate, so that the worm wheel drives a sliding plate to move towards the lower end by means of a ball screw, the polishing roller grinds the surface of a building material downwards, and the beneficial effect of polishing the surface of the building material can be quickly achieved; and a dust suction mechanism is arranged in the frame body, an exhaust fan is powered on to operate, the kinetic energy of a gas is improved by means of mechanical energy, and therefore a suction gas is generated, a gas suction head sucks dust to the inner side of the collecting frame to be collected by using a gas suction pipe, and the beneficial effect thatthe dust can be quickly sucked is achieved.

Owner:湖南中环高新材料技术有限公司

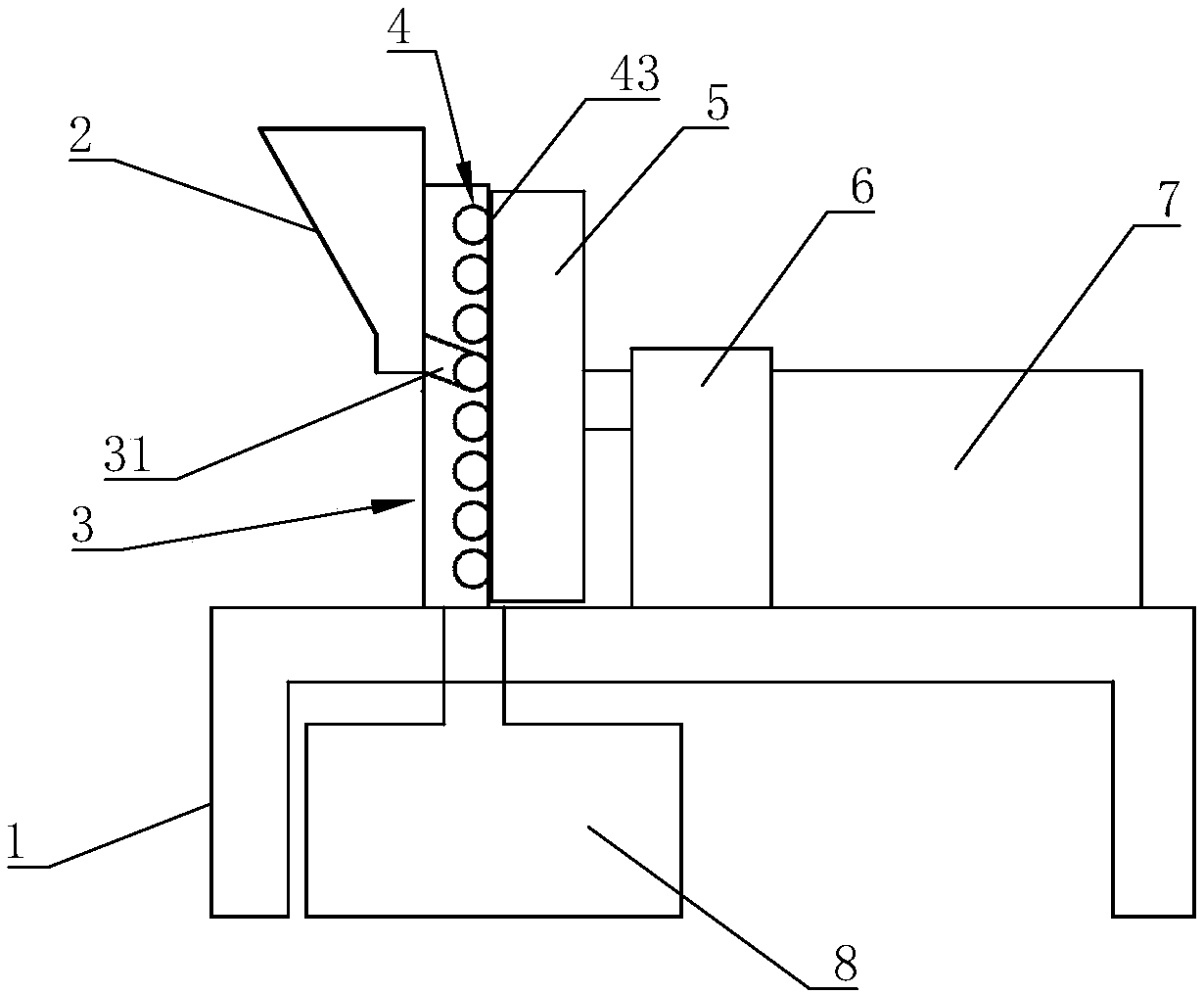

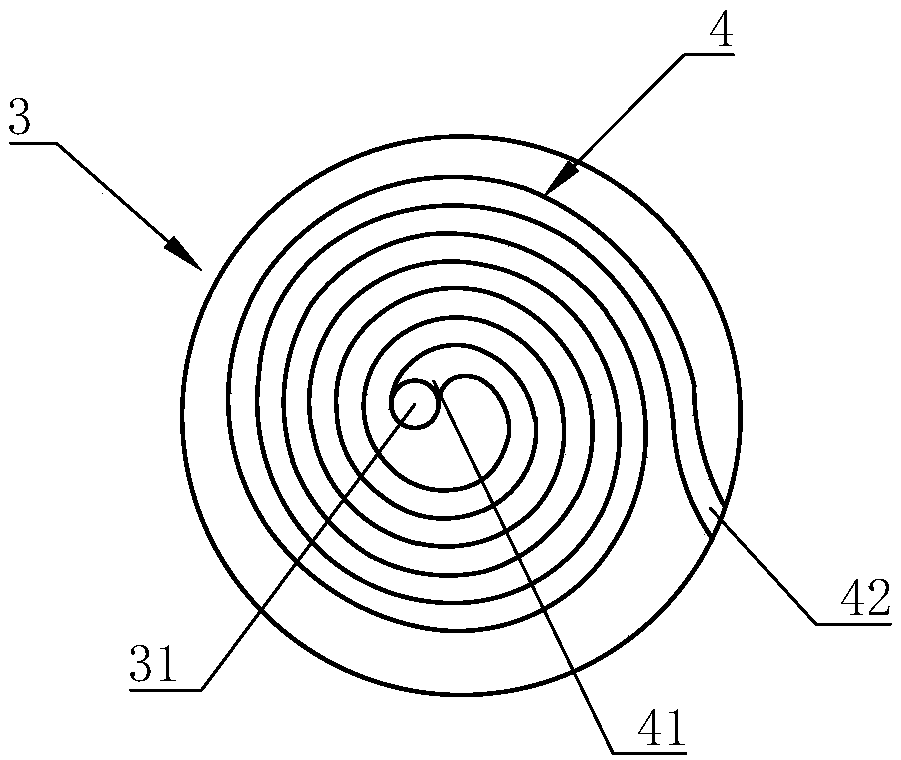

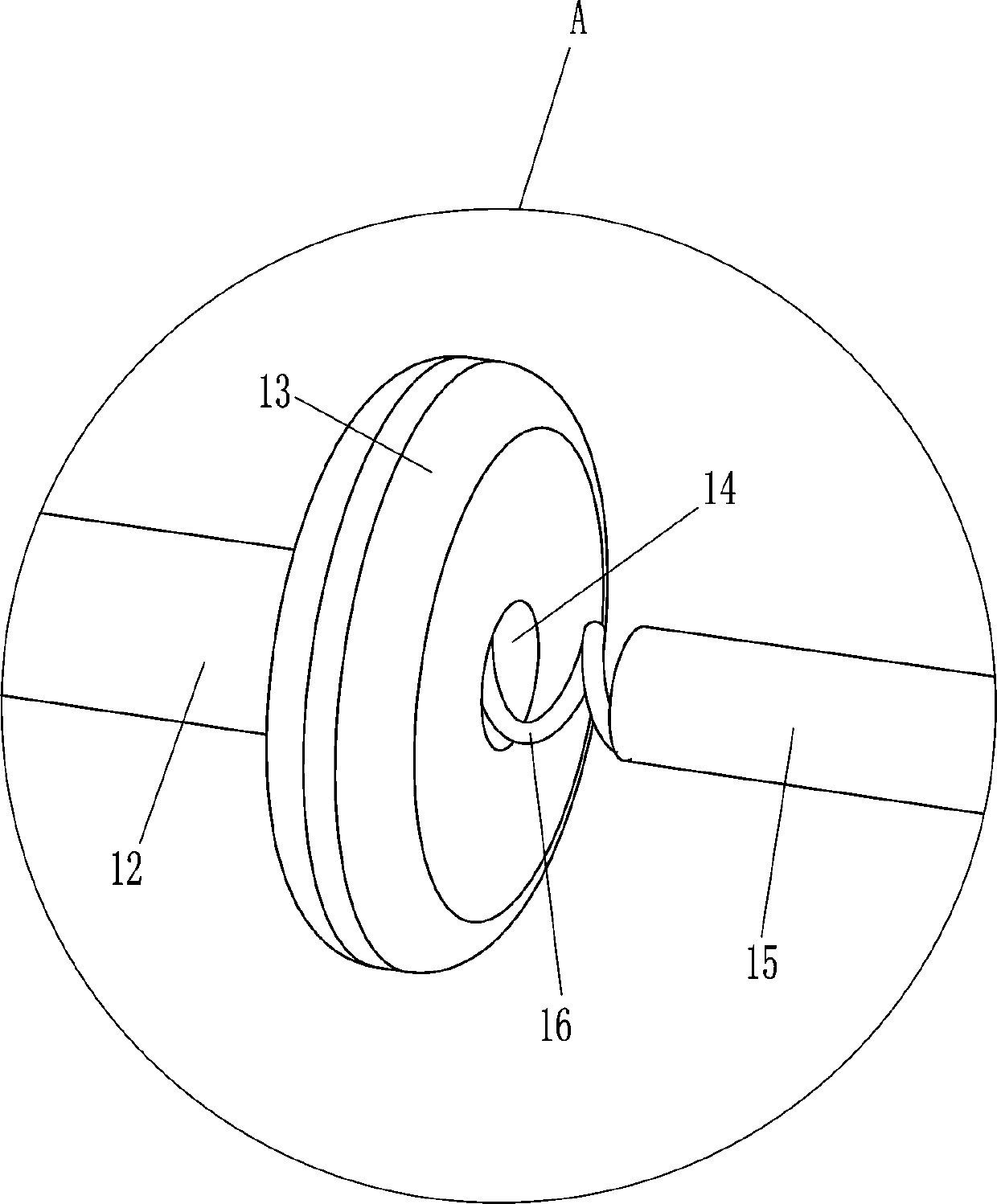

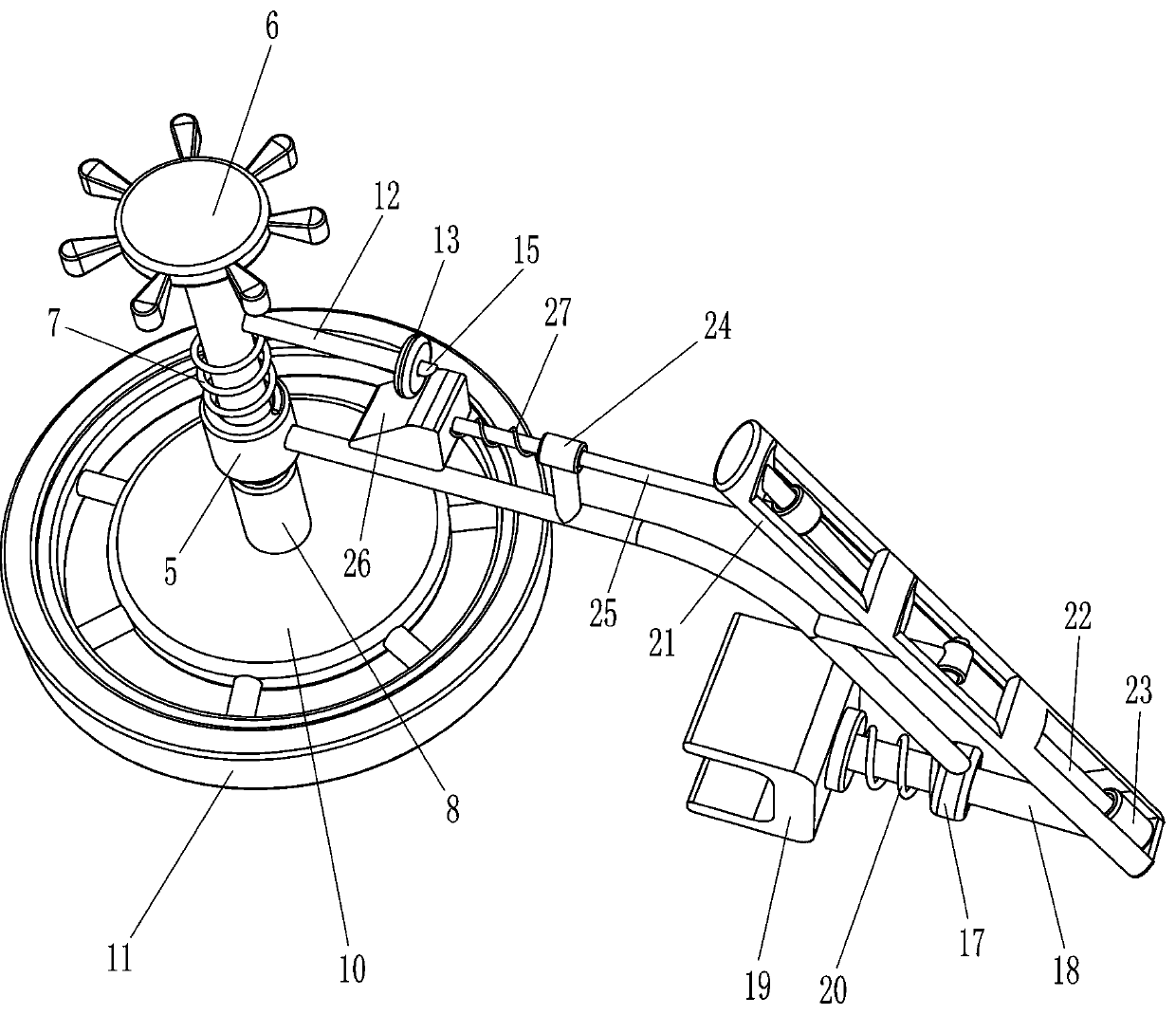

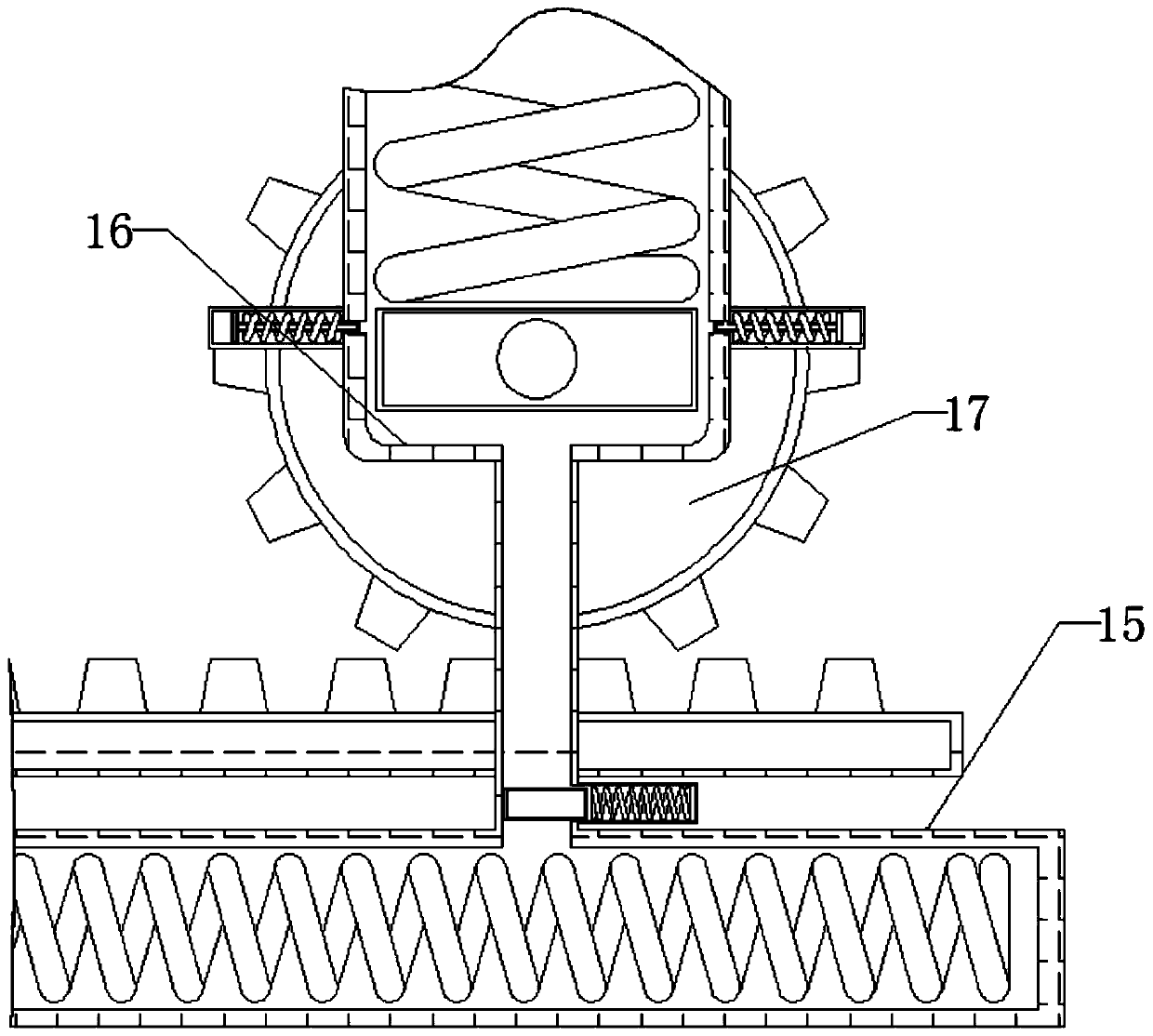

Polishing apparatus for grinding balls

ActiveCN108972228AQuick sandingGrinding speed is fastGrinding drivesSpherical surface grinding machinesEngineeringMechanical engineering

The invention discloses a polishing apparatus for grinding balls, comprising a frame; a polishing disc is vertically arranged on the frame; a feed bucket is arranged at the top end of one sidewall ofthe polishing disc; a turnplate is attached to the other side of the polishing disc; a power device for driving the turnplate to rotate is arranged on the frame; the side, close to the turnplate, of the polishing disc is provided with a polishing passage tube in spiral manner; the polishing passage tube is embedded in the polishing disc; the surface of the side, close to the turnplate, of the polishing passage tube is opened; the open side of the polishing passage tube is flush with the surface of the polishing disc; both the inner wall of the polishing passage tube and the surface, close to the polishing disc, of the turnplate are provided with polishing grains; the start end of the polishing passage tube is arranged close to the center of the polishing disc; the tail end of the polishingpassage tube is arranged at the edge of the polishing disc; both the start end and tail end of the polishing passage tube are opened; a through hole helping communicate the bottom end of the feed bucket and the start end of the polishing passage tube is obliquely arranged in the polishing disc. The polishing apparatus herein has higher polishing speed and higher polishing efficiency.

Owner:滦平县聚源矿业有限责任公司

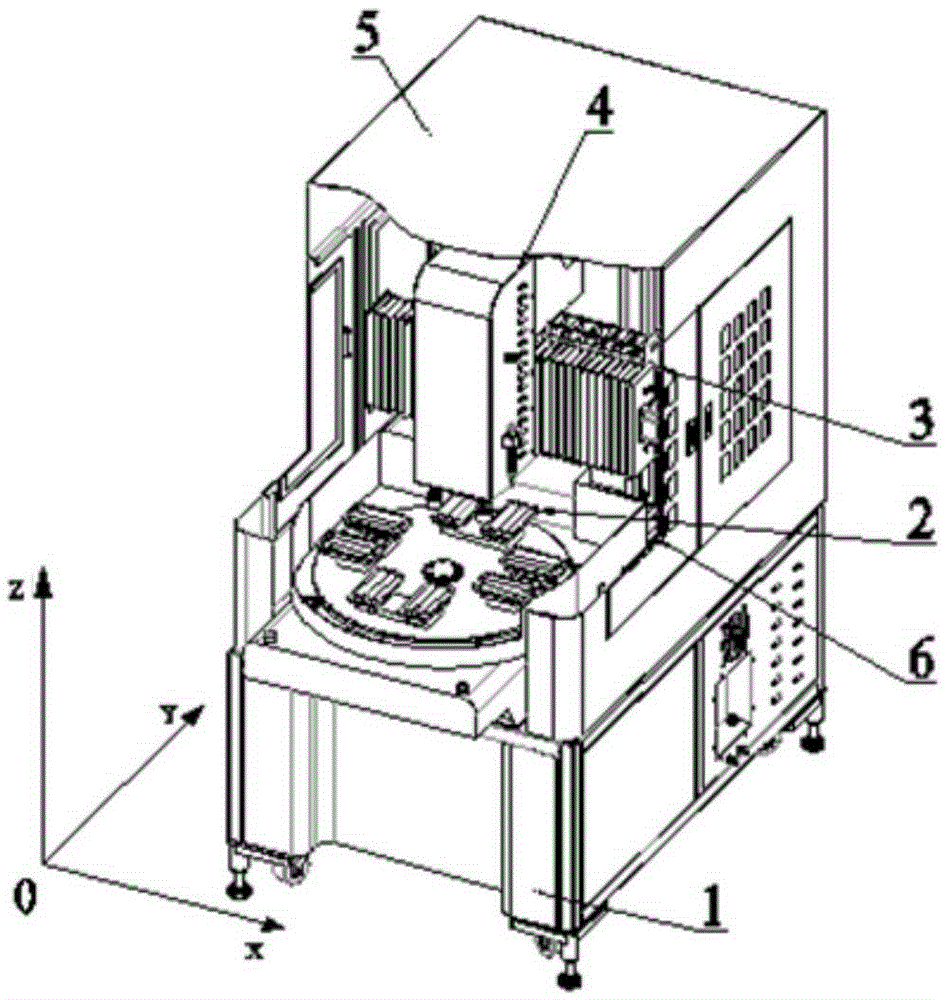

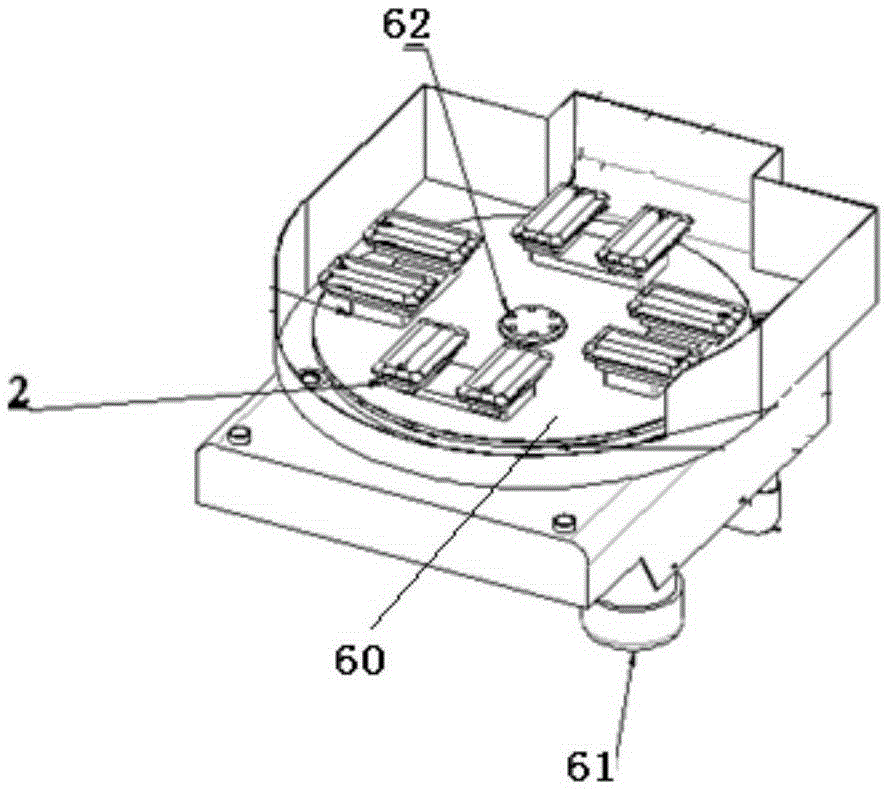

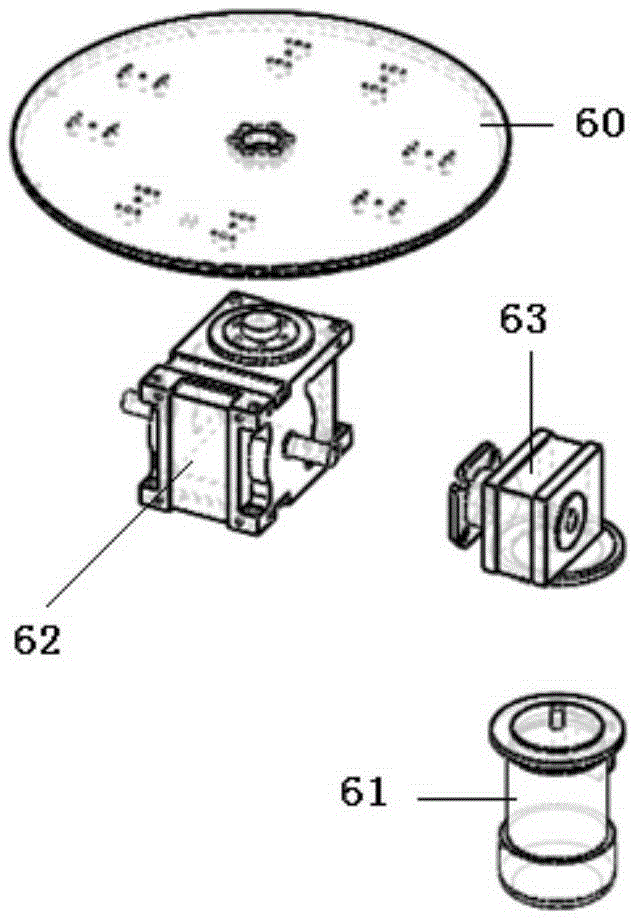

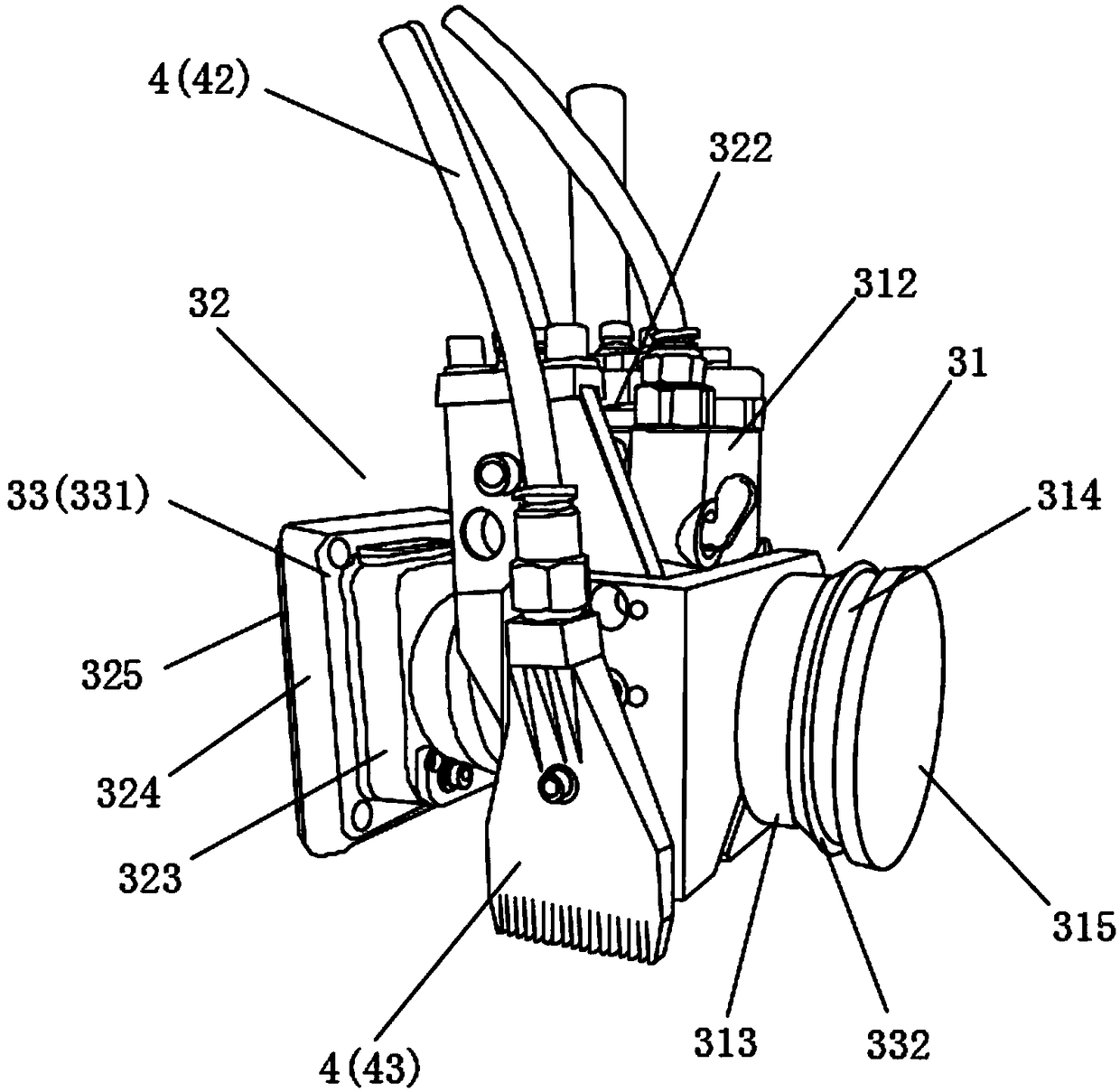

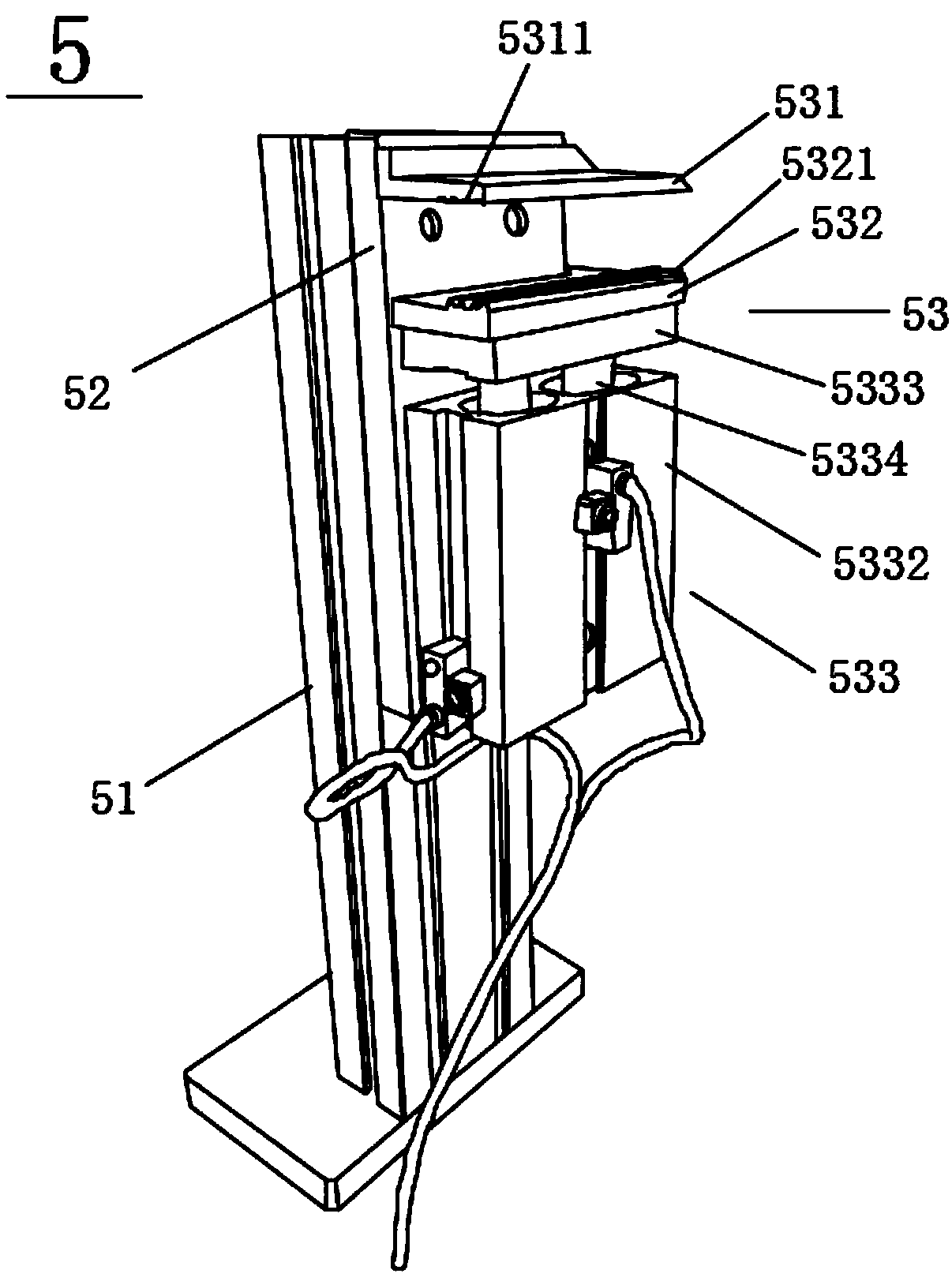

Disc grinder

A disc grinder comprises a jig assembly, a disc assembly, a grinding assembly and a three-axis carrying assembly. The jig assembly is mounted on the disc assembly, and the grinding assembly is mounted on the three-axis carrying assembly; the three-axis carrying assembly is used for carrying the grinding assembly to move in the vertical Z-axis direction, the horizontal X-axis direction and the horizontal Y-axis direction so as to achieve position adjustment of the grinding assembly, the X axis and the Y axis are perpendicular to each other; the disc assembly is used for driving the jig assembly to rotate for position transfer, and therefore a product fixed to the jig assembly is moved to the grinding position of the grinding assembly, and the grinding assembly is used for grinding the product fixed on the jig assembly. The disc grinder can improve the grinding efficiency, lower the cost and improve the product grinding quality.

Owner:GUANGDONG JANUS SMART GRP CO LTD +1

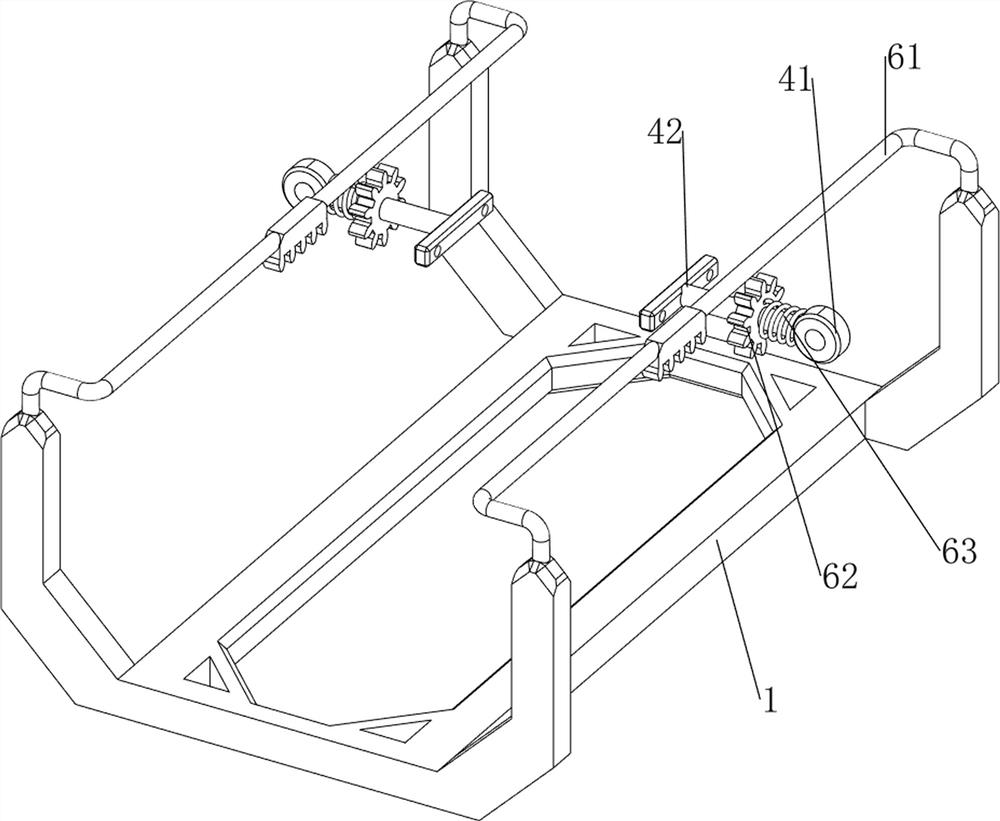

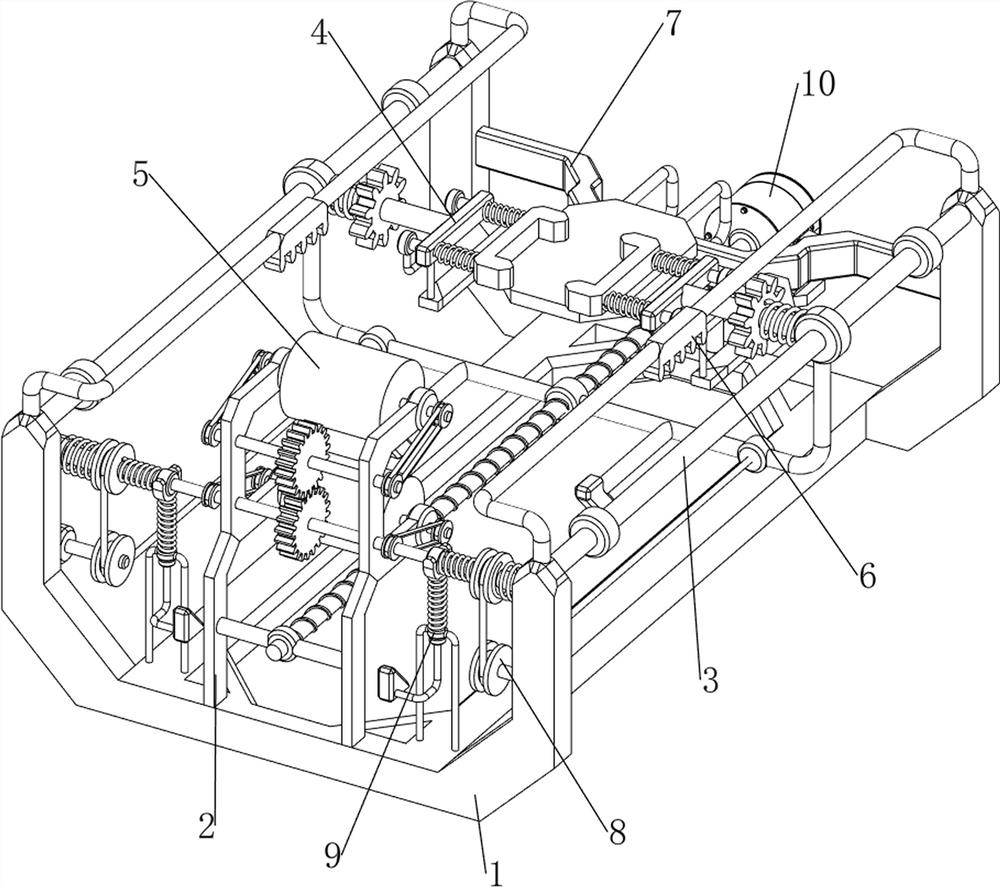

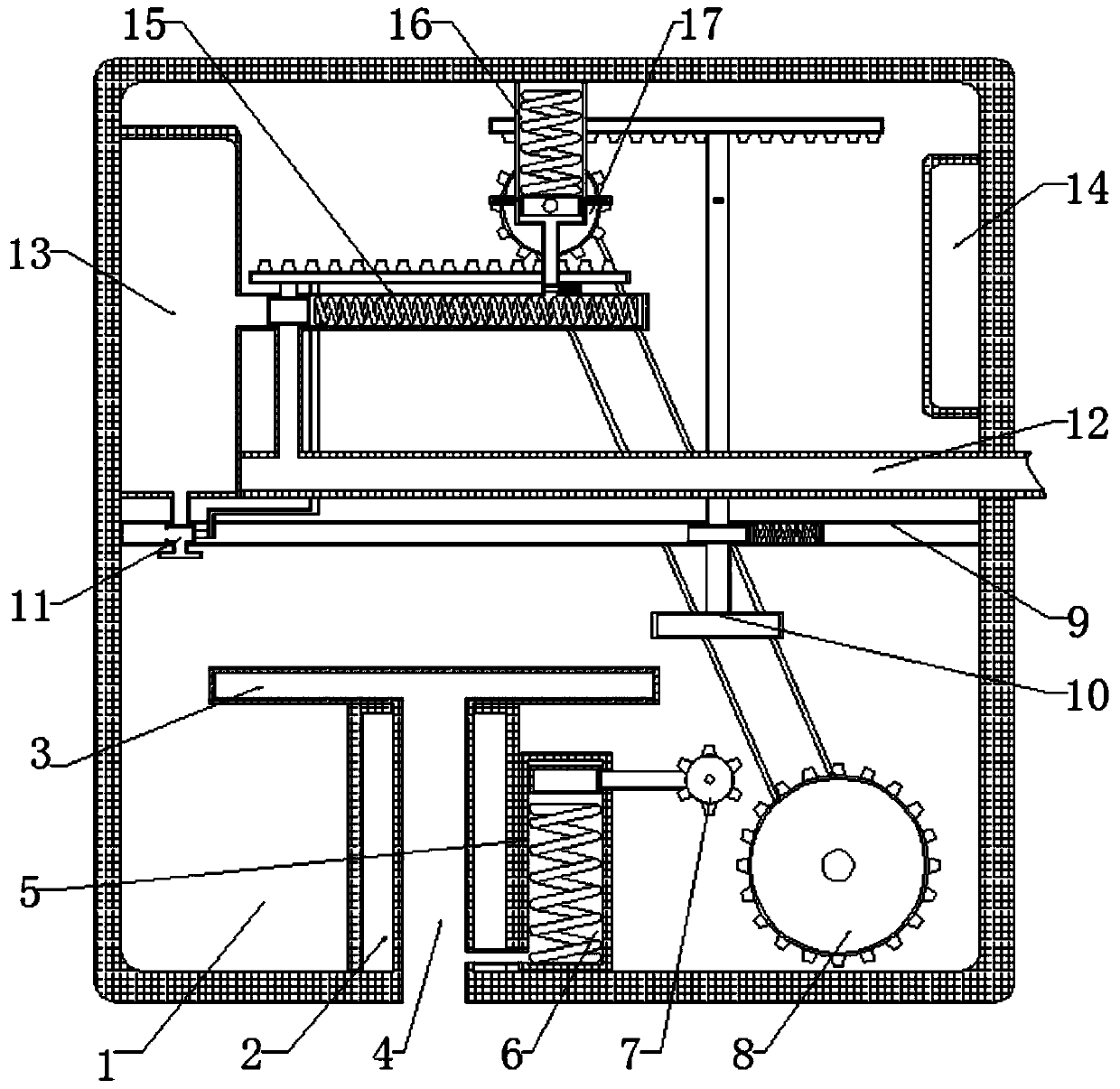

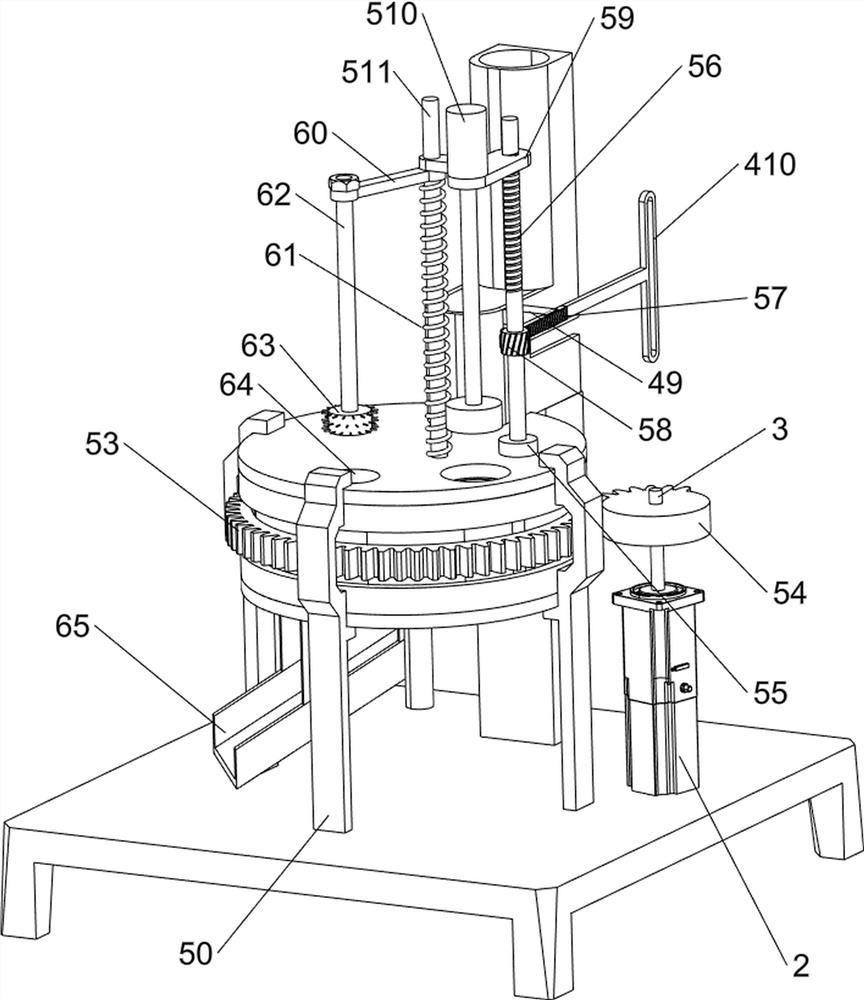

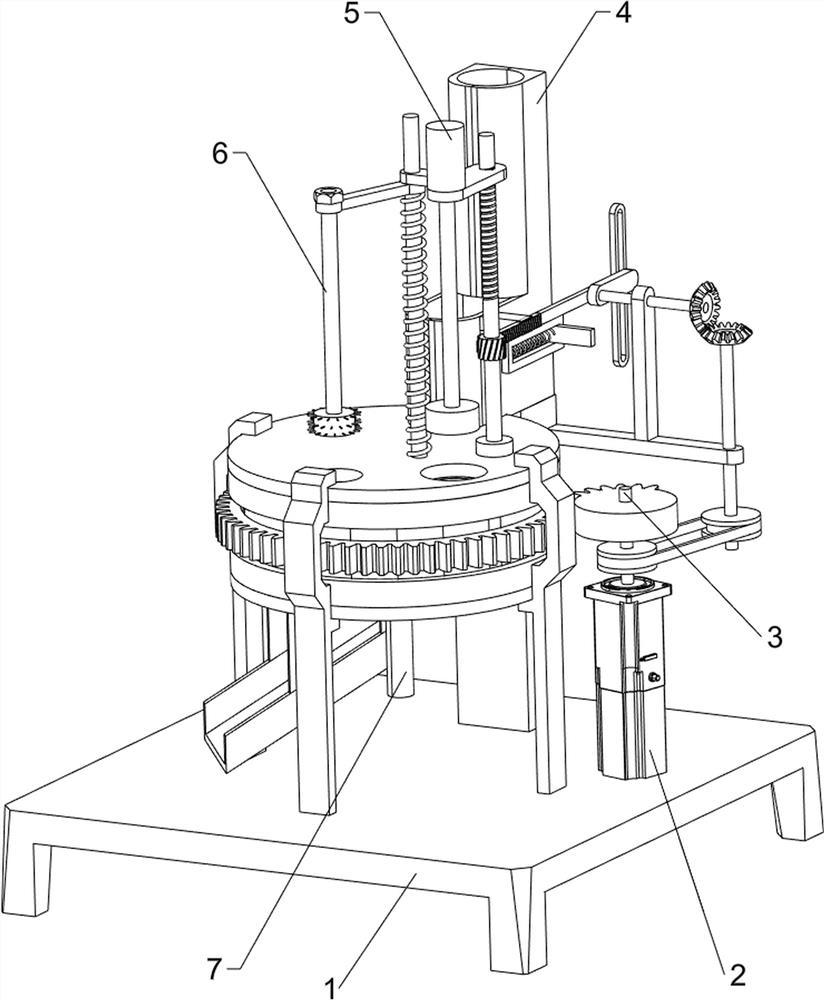

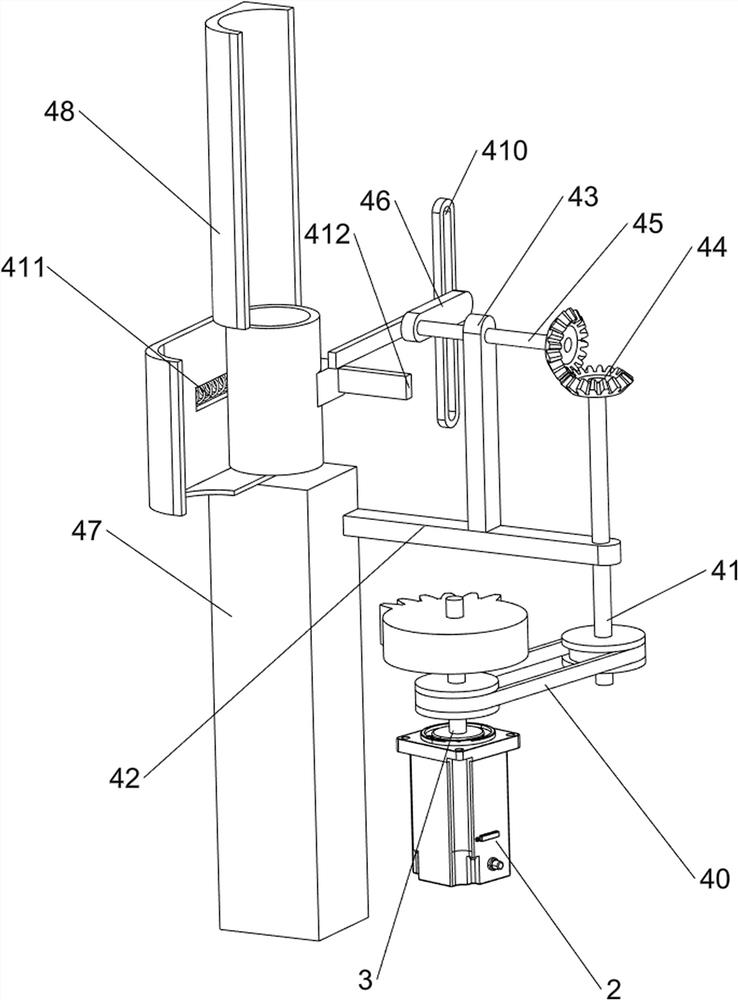

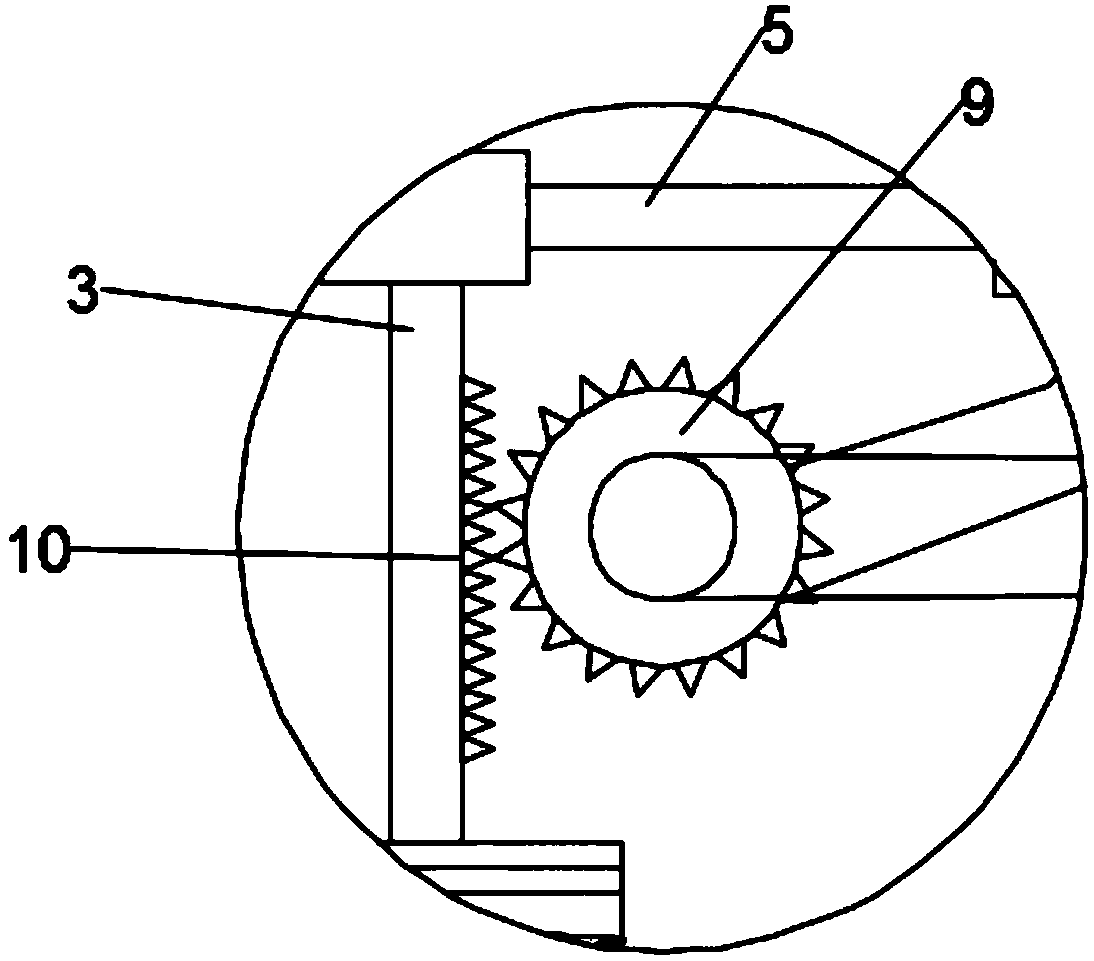

Grinding equipment for wood manufacturing

InactiveCN110421442AQuick sandingGood effectEdge grinding machinesGrinding carriagesBall bearingGear wheel

The invention discloses grinding equipment for wood manufacturing. A work bin is included and internally provided with a reciprocating deburring device. A reciprocating transmission mechanism is arranged at the bottom in the reciprocating deburring device, and a deburring mechanism is arranged at the left end of the reciprocating transmission mechanism. When a wood board is placed on a sliding base, a motor is started to drive a belt wheel for transmission, a connecting belt is made to drive a sliding block to slide on a sliding rail, the sliding base is made to slide, then, the belt wheel canbe in transmission, a rotation shaft in the deburring mechanism is driven to rotate, a bevel gear in a transmission box is in transmission so that a lead screw can rotate, and a ball bearing can drive a fixing plate so that a scraper can descend to conduct deburring on a target. The motor rotates forwards and reversely so that repeated machining can be achieved. A grinding device is arranged at the middle portion of the top end in the work bin, an inner air cylinder is connected with pneumatic equipment through an air port, a push rod at the bottom of the air cylinder drives a transverse rodso that a grinding roller at the bottom can descend, then, the wood board can be rapidly ground, the effect is good, efficiency is high, and stability and the yield are high.

Owner:山东福达木业有限公司

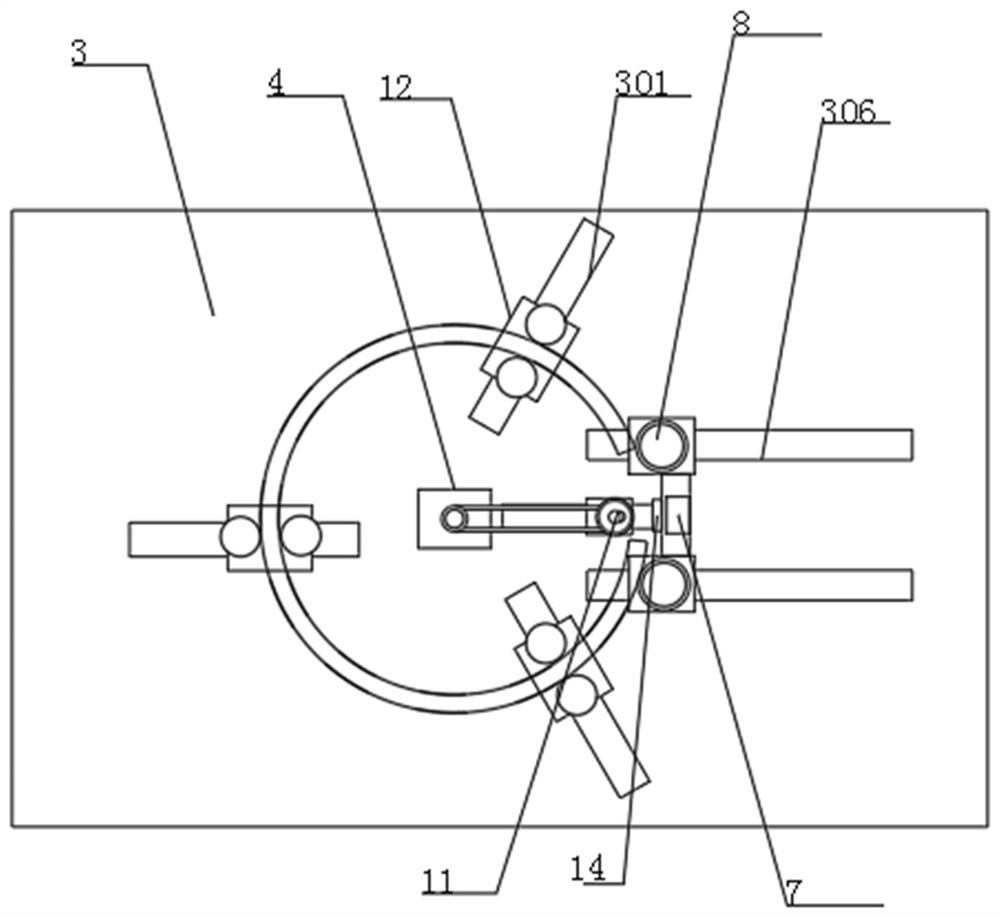

Polishing device for round glass of mahjong table

ActiveCN111266958AImprove securityAvoid scratchesEdge grinding machinesGrinding carriagesStructural engineeringManufacturing engineering

The invention relates to a polishing device, in particular to a polishing device for round glass of a mahjong table. The polishing device for the round glass of the mahjong table aims to rapidly polish the round glass, stably fix the round glass and improve working efficiency. The polishing device for the round glass of the mahjong table comprises a mounting frame, a motor, a placing assembly, a pressing assembly, a clamping assembly and a polishing assembly; the motor is arranged on the mounting frame, the placing assembly for fixedly placing the glass in an adsorption mode is arranged on themotor, the pressing assembly for pressing in a sliding mode is arranged on the mounting frame, and the clamping assembly for fixing in a sliding mode is arranged on the pressing assembly. According to the polishing device, the round glass can be fast fixed through the matching of a circular ring and a sucker, and a disc is matched with an annular pressing block, so that the working safety of workers is effectively improved, and the hands of people can be prevented from being scratched.

Owner:谢辉

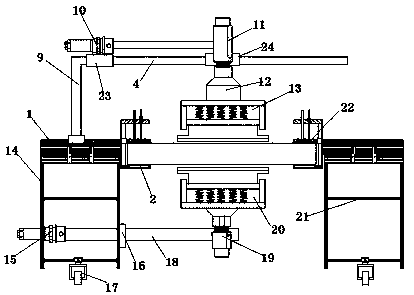

Cutting and grinding device for construction of decorative sheet

ActiveCN109227667AImprove grinding efficiencyStable supportGrinding headsMetal working apparatusEngineeringMechanical engineering

The invention discloses a cutting and grinding device for construction of a decorative sheet. The cutting and grinding device can rapidly grind the upper and lower surfaces of the decorative sheet atthe same time and has high grinding efficiency; meanwhile, the decorative sheet is supported on a clamping and positioning guide assembly, and during grinding, the decorative sheet can be ground and moves by simply pushing the decorative sheet to move in the length direction by hands; when the decorative sheet is ground to a required length, the well ground decorative sheet with a length in required specification can be obtained by simply cutting the decorative sheet with a cutting assembly, and during grinding, the decorative sheet is supported stably, moves stably and can be ground and cut rapidly; meanwhile, the clamping and positioning guide assembly can adapt to clamping and grinding of decorative sheets with different thicknesses; moreover, the cutting and grinding device can also beadjusted according to the width of the decorative sheets and adapt to requirements of the decorative sheets with different widths. The cutting and grinding device is high in adaptability and suitablefor construction sites of multiple decorative sheets.

Owner:CHONGQING WATER RESOURCES & ELECTRIC ENG COLLEGE

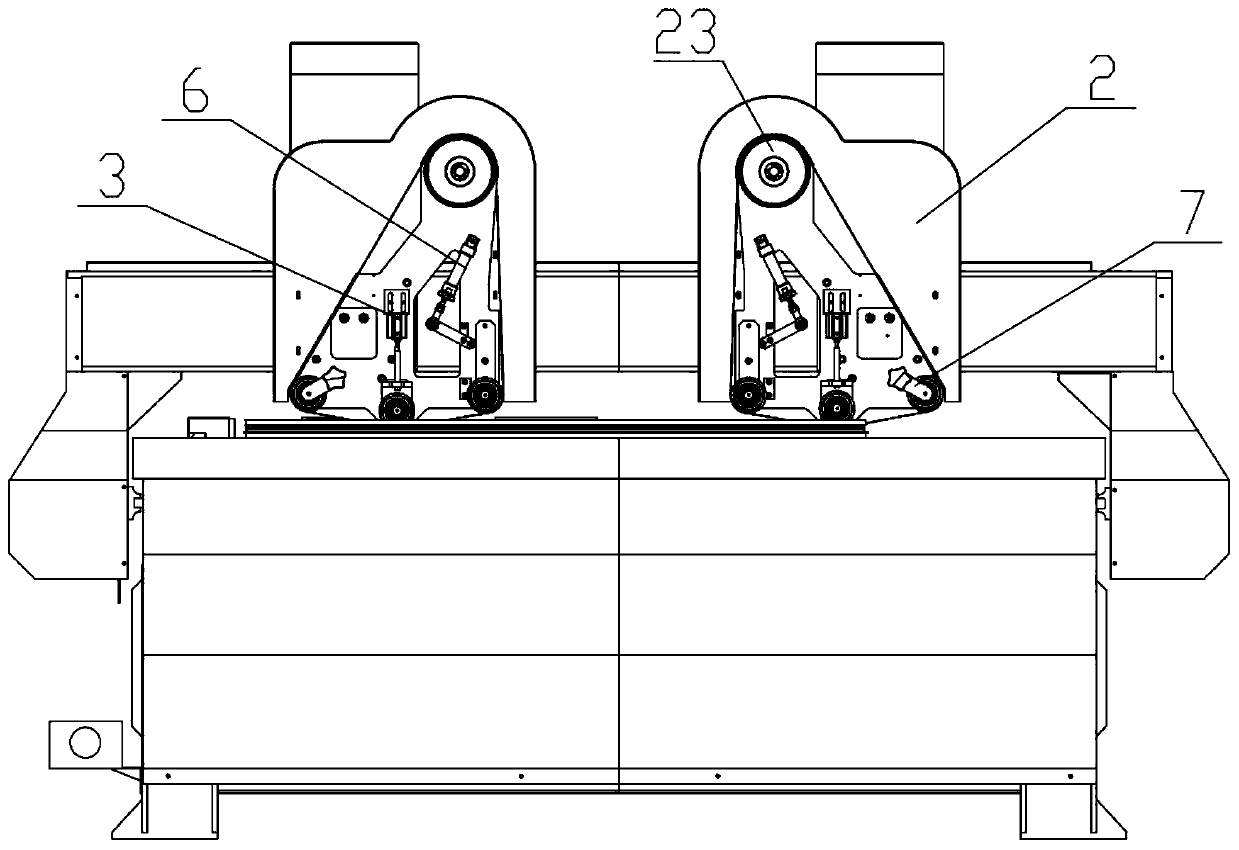

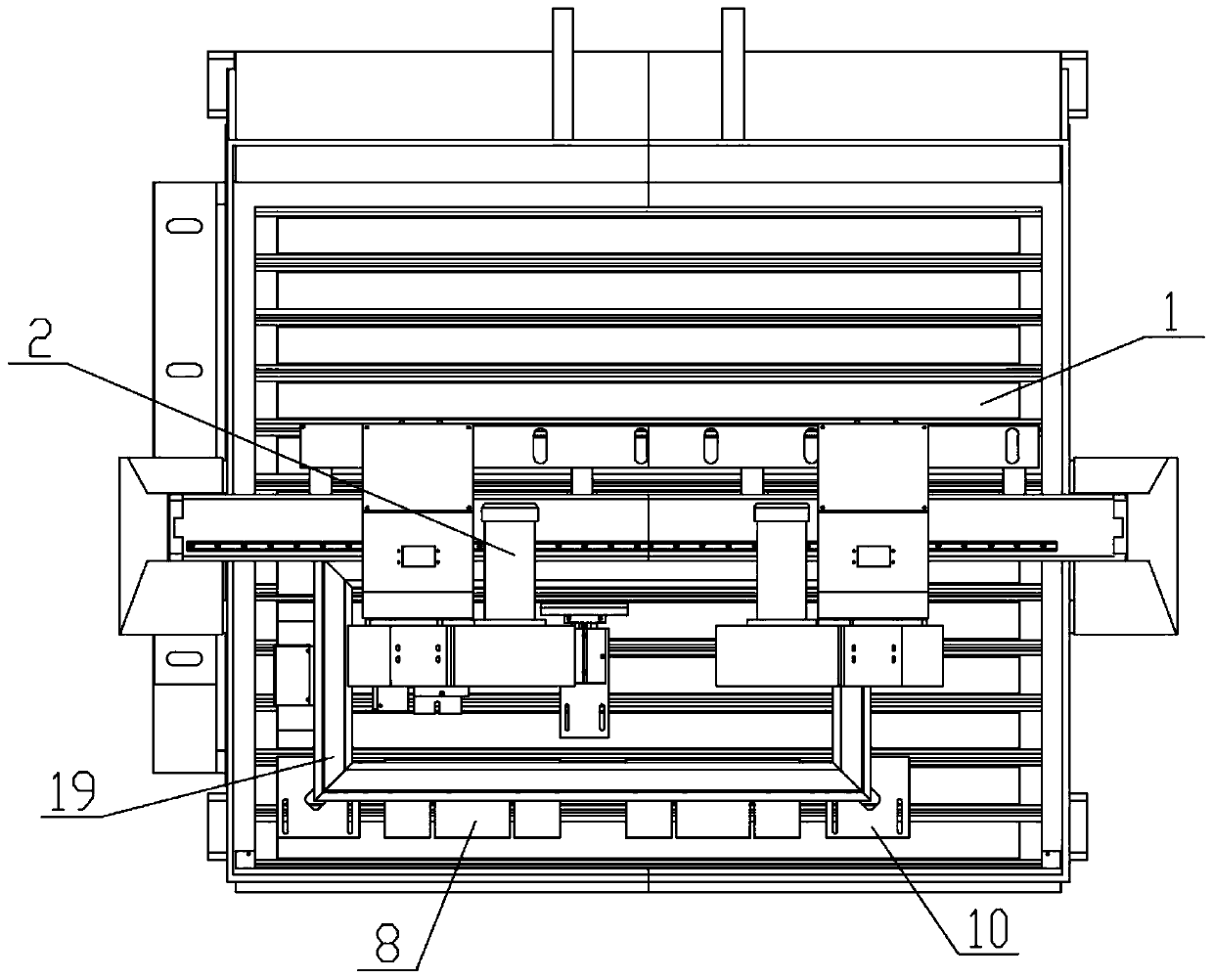

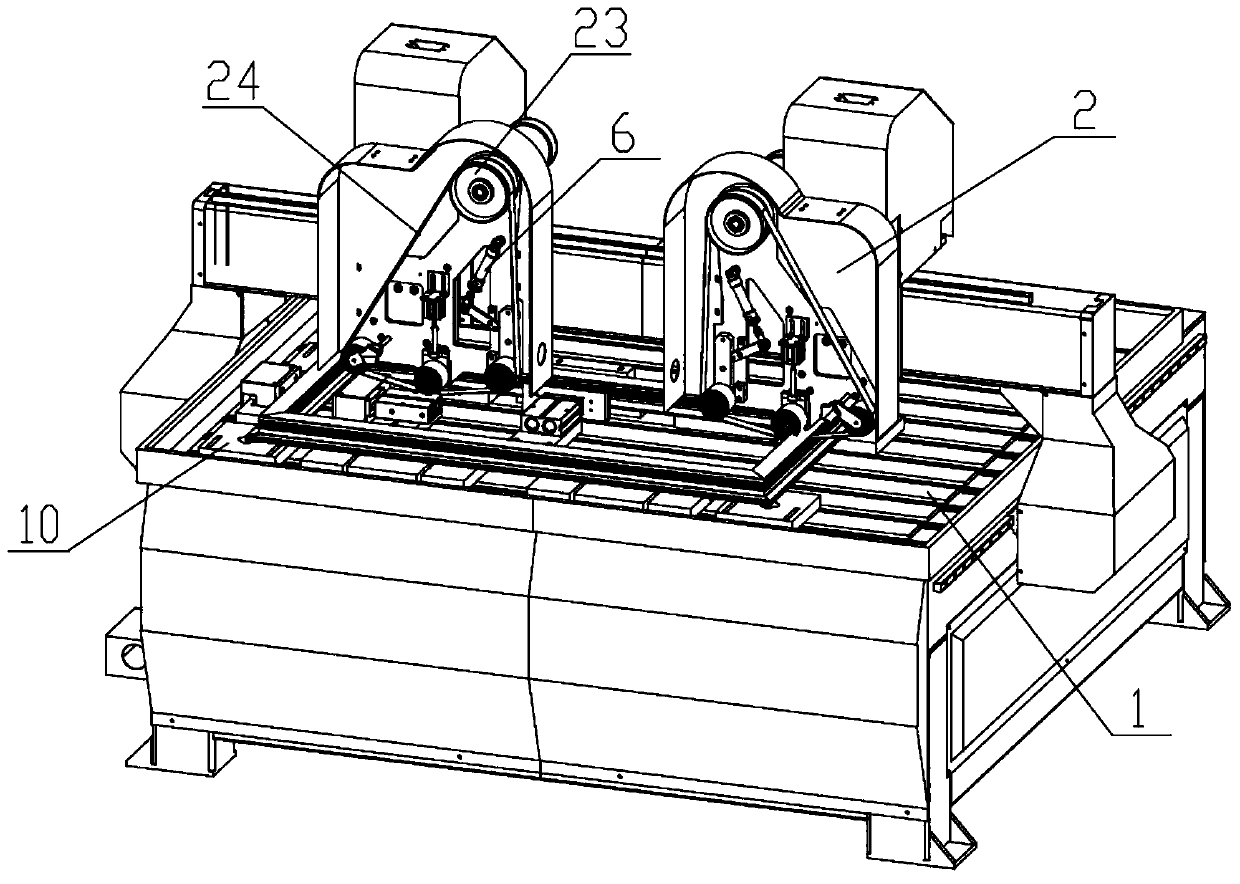

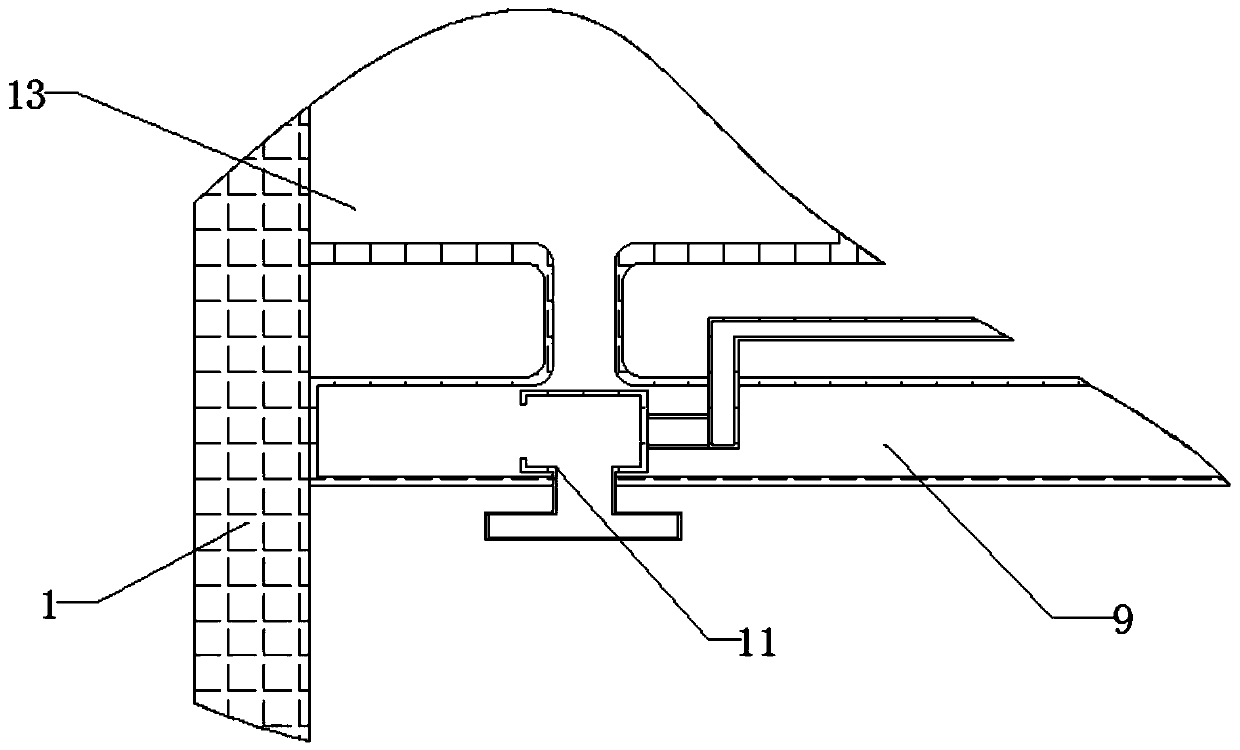

Aluminium profile door and window frame grinding device

The invention relates to the technical field of door and window production, and particularly discloses an aluminium profile door and window frame grinding device. The aluminium profile door and windowframe grinding device comprises a worktable and at least one group of grinding mechanisms located on the worktable, the grinding mechanisms comprise mounting plates, grinding motors, driving wheels and abrasive belts, wherein the grinding motors are located on one sides of the mounting plates and are connected with the driving wheels through flange discs; compacting wheels for pressing the abrasive belts downwards and further grinding frames are arranged under the driving wheels; lifting assemblies for driving the compacting wheels to move up and down to adjust distances between the abrasivebelts and the frames are arranged on the compacting wheels; first transmission wheels and second transmission wheels are arranged on the two sides above the compacting wheels; the first transmission wheels are provided with tensioning assemblies for adjusting the tensity of the abrasive belts; and position adjusting assemblies for adjusting positions of the abrasive belts relative to the second transmission wheels are arranged on one sides of the second transmission wheels. By arranging the lifting assemblies on the compacting wheels and arranging the tensioning assemblies and the position adjusting assemblies on the first transmission wheels and the second transmission wheels, the rapid grinding of the aluminium profile frames is realized and the abrasive belts are prevented from fallingoff.

Owner:广东泰格威机器人科技有限公司

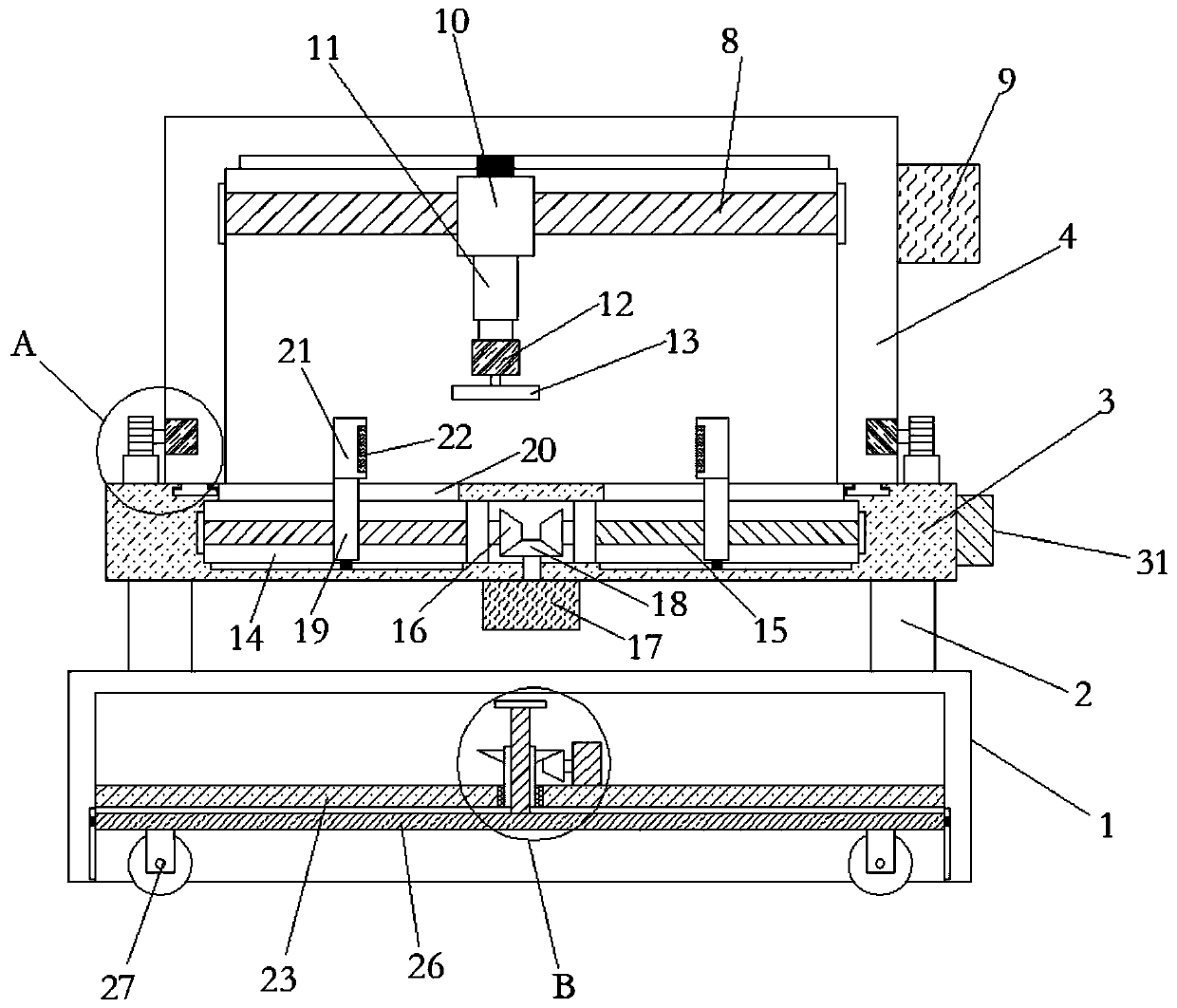

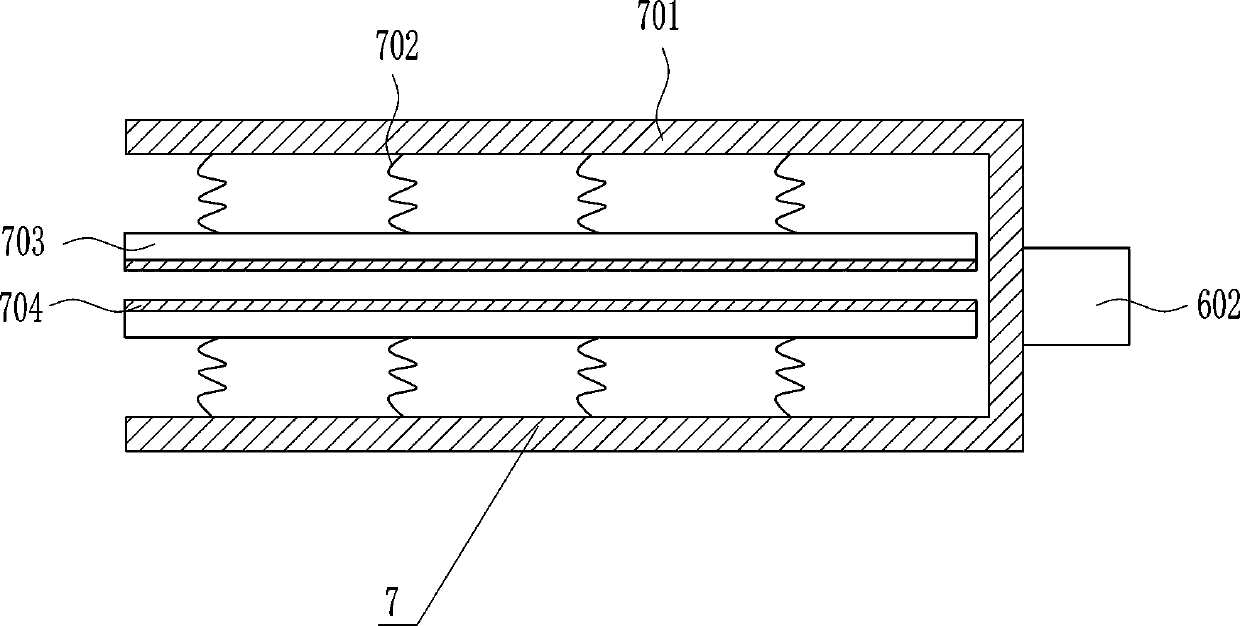

High-end device for polishing two surfaces of PCB

ActiveCN113043096AQuick sandingReduce labor intensityGrinding carriagesGrinding drivesPolishingStructural engineering

The invention relates to a polishing device, in particular to a high-end device for polishing the two surfaces of a PCB. According to the high-end device for polishing the two surfaces of the PCB, the two surfaces of the PCB can be subjected to high-end polishing rapidly; and meanwhile, the PCB can be fed and clamped, the PCB can be rotated to remove powder, and therefore the labor intensity of workers can be relieved. The high-end device for polishing the two surfaces of the PCB comprises bottom plates and fixing frames, and the fixing frames are symmetrically arranged on the bottom plates. First sliding rails are included and are arranged on the bottom plates. A clamping mechanism is included and is connected between the two first sliding rails in a sliding manner. And a polishing mechanism is included and is connected between the two fixing frames, and the clamping mechanism is matched with the polishing mechanism. According to the high-end device, the clamping mechanism is arranged, the clamping mechanism is matched with the polishing mechanism so that the PCB can be clamped, and meanwhile the two surfaces of the PCB can be polished. And through cooperation of the clamping mechanism and a rotating mechanism, powder and other impurities on the PCB can fall off.

Owner:广东恒兆丰科技有限公司

Plate material trimming and grinding device

ActiveCN108081057AQuick sandingImprove efficiencyEdge grinding machinesGrinding carriagesHydraulic cylinderEngineering

The invention discloses a plate material trimming and grinding device. The device comprises a mounting frame, grinding mechanisms, a conveying mechanism and a control box; a base is fixedly arranged at the lower end of the mounting frame, and a cantilever is fixedly arranged at the upper end of the mounting frame; a connecting rod is fixedly arranged on the lower surface of the end, far away froma mounting seat, of the cantilever, and a mounting table is fixedly arranged at the lower end of the connecting rod; first hydraulic cylinders are arranged in the middles of the outer sides of the mounting table, and guide rails are arranged at the ends of telescopic rods of the first hydraulic cylinders; the grinding mechanisms are composed of machine boxes and first motors, rolling wheels are installed on one sides of the lower ends of the outer parts of the machine boxes, and the lower ends of the rolling wheels are connected with the guide rails; and second motors are arranged inside the machine boxes, the output shaft ends of the second motors are connected with rotating shafts where the rolling wheels are located, and the first motors are fixedly connected with the outer walls of themachine boxes through connecting rods. According to the plate material trimming and grinding device, edges of plate material can be quickly polished, production efficiency is improved, and the platematerial is effectively prevented from being damaged.

Owner:JIANGSU JINYANG MACHINERY

High-efficiency polishing device used for production of mechanical parts

InactiveCN108818259AEasy to polishEasy to useGrinding machinesGrinding work supportsEconomic benefitsElectric machinery

The invention discloses a high-efficiency polishing device used for production of mechanical parts. The high-efficiency polishing device comprises a shell; an opening is formed in the left side of theinner wall of the shell; the top part of the right side of the shell is fixedly provided with a driving motor; the output shaft of the driving motor is fixedly connected with a driving rotating shaft; and the left end of the driving rotating shaft penetrates through the shell, extends into the shell and is fixedly connected with a threaded rod. By installing the driving motor, the threaded rod, athreaded sleeve, a limiting baffle, a fixed block, sliding chutes, sliding blocks, a holding plate, a first air cylinder, rotating shafts, expansion links, pressing blocks and second air cylinders, the high-efficiency polishing device disclosed by the invention solves the problem that a traditional polishing device used for production of mechanical parts is often not thorough in polishing and lowin polishing efficiency; the high-efficiency polishing device is simple in structure and convenient to operate; a user can perform rapid grinding and use more conveniently; the grinding speed and thegrinding effect are improved; normal mechanical production and manufacturing is guaranteed; economic cost is reduced; and economic benefit is increased.

Owner:杨岩

Steel pipe inner wall derusting equipment based on combined operation of grinding and dedusting

InactiveCN109434651APrecise positioningEasy to fixRevolution surface grinding machinesGrinding drivesOperation modeEngineering

The invention discloses steel pipe inner wall derusting equipment based on combined operation of grinding and dedusting, and relates to the technical field of steel pipes machining equipment. The steel pipe inner wall derusting equipment based on the combined operation of grinding and dedusting comprises a workbench, supporting legs, standing plates, a positioning device, a steel pipe body, a grinding device and a dedusting device, the top ends of the two supporting legs are fixedly connected with the two ends of the bottom surface of the workbench respectively, and the bottom ends of the twostanding plates are fixedly connected with the two ends of the top surface of the workbench respectively. According to the steel pipe inner wall derusting equipment based on the combined operation ofgrinding and dedusting, through usage of and cooperation among the positioning device, the grinding device and the dedusting device, the steel pipe body can be quickly positioned firstly, then grinding and derusting of the inner wall of the steel pipe can be rapidly completed, and operation mode of the device is very simple, so that labor intensity of workers is greatly reduced and practicabilityof the derusting equipment is further improved.

Owner:浙江工业大学上虞研究院有限公司

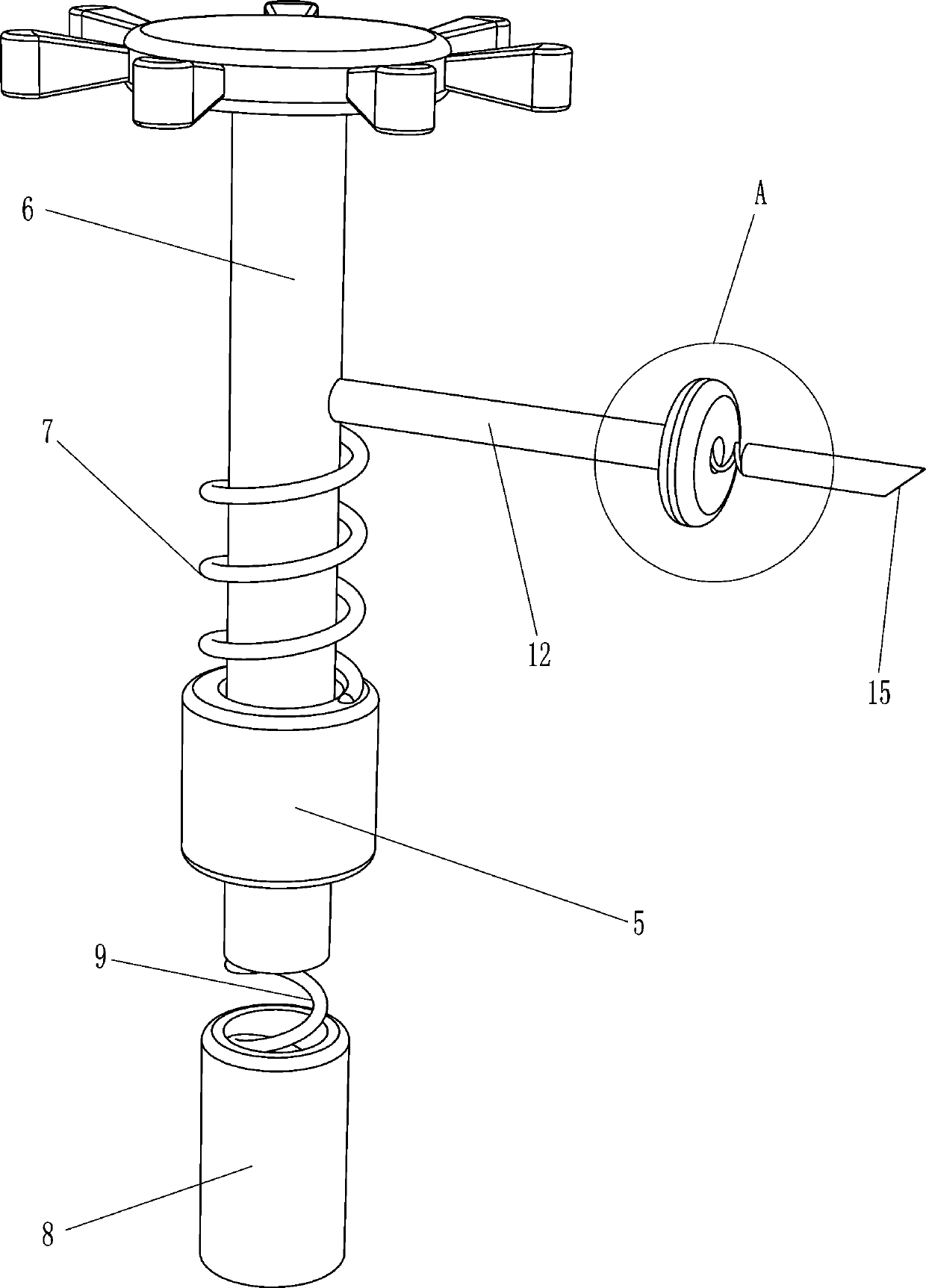

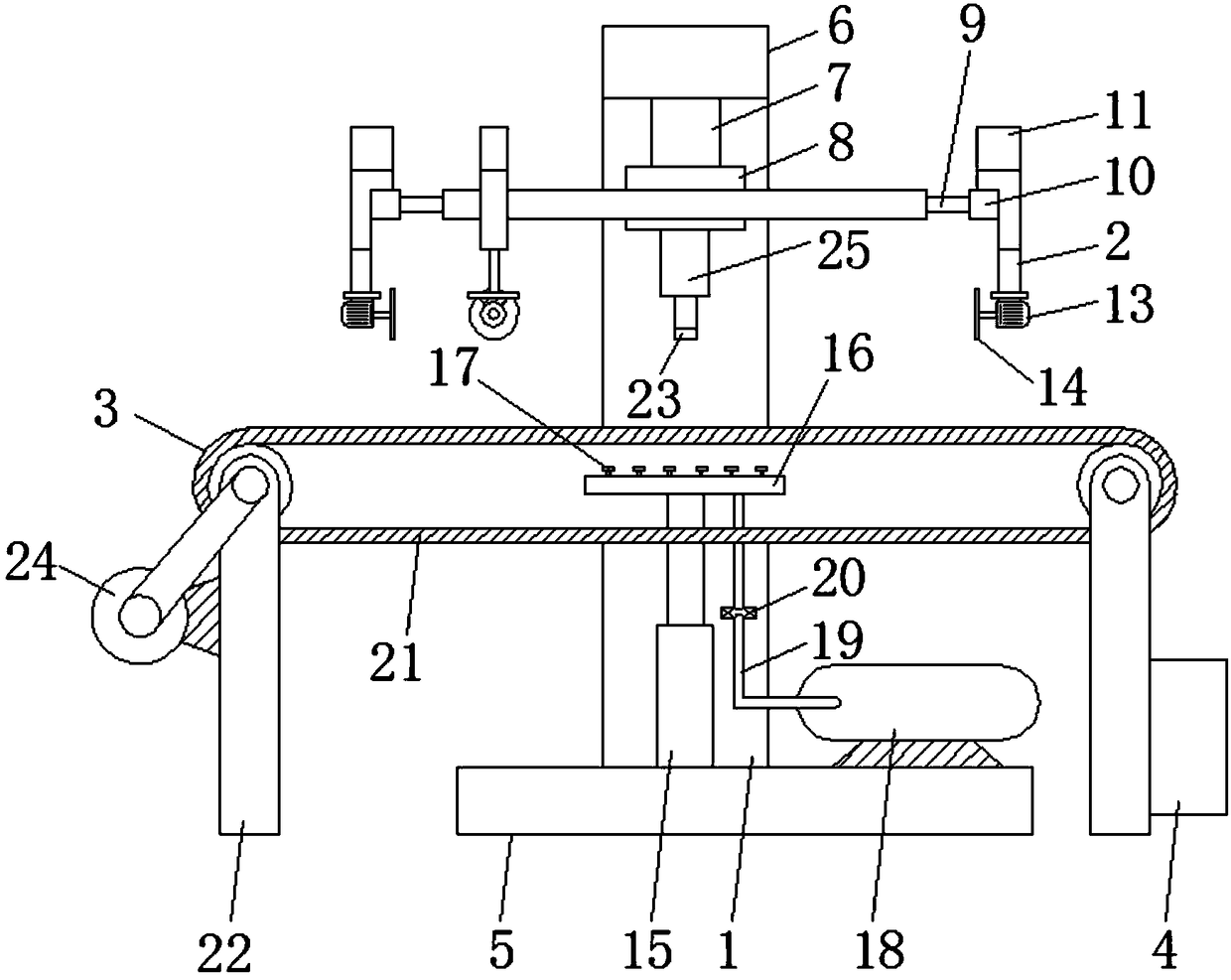

Device for automatically controlling rapid polishing of paint by using atmospheric pressure

ActiveCN111002177AAir pressure fastIncrease air pressureGrinding carriagesGrinding drivesPolishingSprayer

The invention relates to the technical field of furniture processing, and discloses a device for automatically controlling rapid polishing of paint by using atmospheric pressure. The device comprisesa processing machine, wherein a supporting rod is movably connected to the bottom of the interior of the processing machine, a fixed plate is movably connected to the upper part of the supporting rod,an air suction pipe is movably connected to the interior of the supporting rod, a control rail is movably connected to the right side of the supporting rod, a reset spring is movably connected to theinterior of the control rail, a power wheel is movably connected to the right side of the control rail, and a transmission wheel is movably connected to the right side of the power wheel. The paint in a paint box is pressurized by an air pressure pipe and enters a sprayer through a through hole of a paint spraying sliding block to perform paint spraying on the surface of a furniture panel, so that the interior of the paint box is rapidly pressurized, the surface of the panel is rapidly subjected to paint spraying treatment in a paint spraying mode, manual treatment is not needed, and the personal safety of workers is guaranteed.

Owner:朱香芽

Automatic grinding machine for surface of polygonal metal plate

ActiveCN110385645AQuick sandingAvoid damageGrinding carriagesGrinding drivesEngineeringGrinding wheel

The invention relates to an automatic grinding machine, in particular to an automatic grinding machine for the surface of a polygonal metal plate. The automatic grinding machine for the surface of thepolygonal metal plate aims to achieve the technical effects that workers can be more relaxed, and time can be saved. According to the technical embodiment scheme, the automatic grinding machine for the surface of the polygonal metal plate comprises a supporting seat, a first motor, a screw rod, a first nut, a mounting plate, a second motor, a grinding wheel, a bearing block, a guide rod and the like, wherein a first motor is arranged on the upper left part of the front side of the supporting seat. According to the automatic grinding machine for the surface of the polygonal metal plate, a control module can control the first motor to rotate clockwise to drive the grinding wheel to move rightwards to grind the surface of the polygonal metal plate so that the surface of the polygonal metal plate can be automatically polished, then the workers can be more relaxed and can quickly grind the surface of the polygonal metal plate, and then the time can be saved; and the manual operation can bereduced through the action of a travel switch, so that the operation is simpler.

Owner:TIANCHUANG ZHIKU CULTURE PROPAGATION SUZHOU CO LTD

Circular pipe polishing device for heating and ventilation

InactiveCN108747789AImprove polishing efficiencyReduce workloadPolishing machinesGrinding drivesEngineering

The invention relates to a polishing device, in particular to a circular pipe polishing device for heating and ventilation. According to the technical scheme, the circular pipe polishing device for heating and ventilation can be used for polishing multiple circular pipes, lightens the working burden of workers, and improves the polishing efficiency. The circular pipe polishing device for heating and ventilation comprises a base plate, a driving mechanism, a supporting seat, a first mounting plate, rotating mechanisms, a sliding rail, a sliding block, a lifting plate, a transmission mechanism,a polishing mechanism, a lifting mechanism and a second mounting plate. The second mounting plate is fixedly connected to the top of the base plate through the supporting seat, and the driving mechanism is fixedly connected to one side of the base plate. The multiple rotating mechanisms are fixedly connected to the first mounting plate at equal intervals. The circular pipe polishing device for heating and ventilation has the beneficial effects of comprehensively and quickly polishing the multiple circular pipes, improving the polishing efficiency, and lightening the working burden of the workers.

Owner:冯广吉

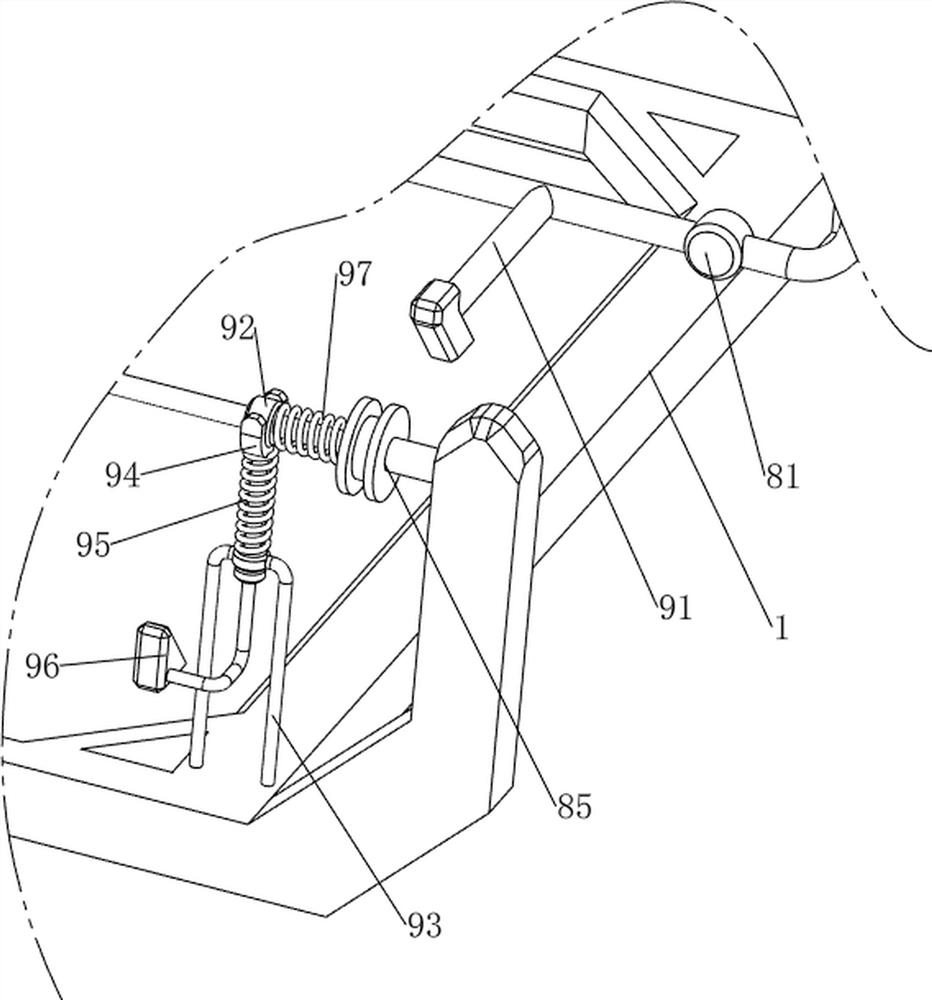

Hardware inner wall grinding equipment

PendingCN112355746ARealize intermittent feedingQuick sandingRevolution surface grinding machinesHollow article cleaningServoGrinding

The invention relates to grinding equipment, in particular to hardware inner wall grinding equipment. According to the hardware inner wall grinding equipment, chippings generated during hardware innerwall grinding can be cleared away, and people can collect the chippings conveniently. The hardware inner wall grinding equipment comprises a base, a first rotating shaft, a feeding mechanism and a grinding mechanism, wherein a servo motor is arranged on the base; the first rotating shaft is arranged on an output shaft of the servo motor; the feeding mechanism is arranged at the top of the base; and the grinding mechanism is arranged at the top of the base. The servo motor is started to achieve rotation of the first rotating shaft, then under cooperation of the feeding mechanism and the grinding mechanism, rapid grinding of hardware is achieved, and intermittent discharging of the hardware can be achieved through the feeding mechanism.

Owner:杨庆金

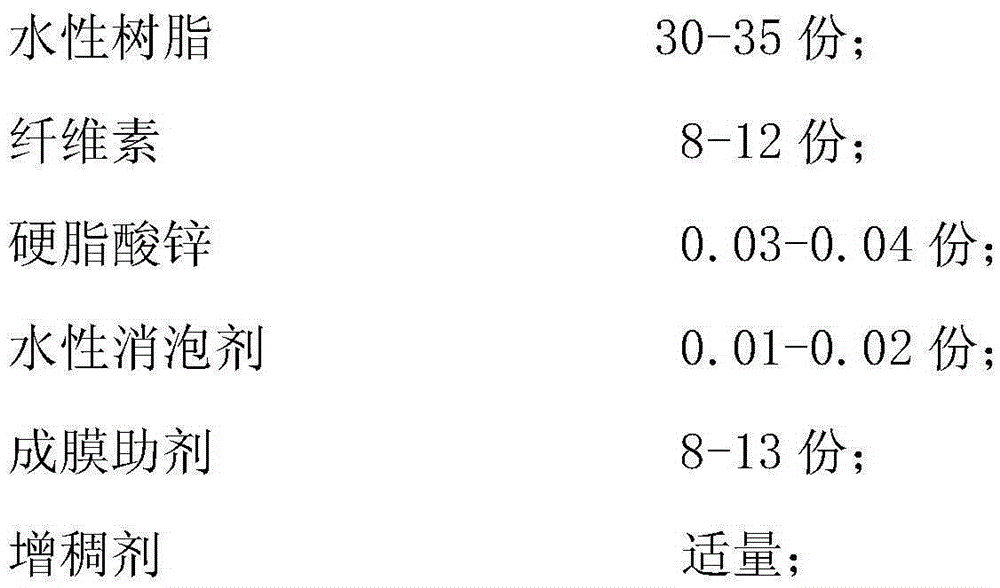

Water-based environmentally friendly wood putty and preparation method

InactiveCN105295495AMake up for the defects of perishable and smelly, which need to be adjusted and used immediatelyGuaranteed filling effectFilling pastesCelluloseWater based

The invention discloses water-based environmentally friendly wood putty and a preparation method, which belong to the technical field of coating, wherein the water-based environmentally friendly wood putty comprises components with parts by formula weight: water-base resins 30-35 parts, celluloses 8-12 parts, zinc stearate 0.03-0.04 part, water-based defoamer 0.01-0.02 part, coalescing agents 8-13 parts, a moderate amount of thickening agent and packing 80-90 parts. The water-base resins, the celluloses, the water-based defoamer and the coalescing agents are uniformly dispersed, and then the packing and the zinc stearate are added, and are added with a moderate amount of thickener to adjust thickness after being stirred for 5-8 min in 1000r / min, thereby being capable of obtaining the water-based environmentally friendly wood putty. The water-based environmentally friendly wood putty has the advantages that the water-based environmentally friendly wood putty is environmentally friendly and nontoxic, saves paint, is low in cost, long in storage time and wide in application range, also fundamentally improves existing residential environment, and has excellent development significance.

Owner:SHANDONG BAIER BUILDING MATERIAL CO LTD

Rapid grinding device for hardware parts

ActiveCN107717672AQuick sandingSave sanding timeGrinding carriagesGrinding drivesEngineeringDrive motor

The invention discloses a rapid grinding device for hardware parts. The rapid grinding device comprises a supporting base, brackets, a first transverse sliding rail, a sliding block, a worktable, a second transverse sliding rail, a clamping frame, a rotating motor, a positioning frame, a stand column, a longitudinal sliding rail, a lifting sliding seat, a driving motor, a spindle box, a grinding joint, a fixed piece, a screw stepper motor, a screw, a sleeve and a connecting part. The rapid grinding device is compact in structure and convenient to use, and the screw is driven to move through the screw stepper motor, so that the sleeve is lifted, and thus the grinding joint is driven to move vertically to facilitate grinding operation; and meanwhile, workpieces are fixed and clamped throughthe clamping frame and the positioning frame, and then the workpieces are rotated through the rotating motor, so that the rotating directions of the workpieces and the rotating directions of the grinding joint are opposite, the grinding time is further reduced, the operational efficiency is improved, the high practicality is achieved, the operation effect is ensured, various different working modes are adapted, the high stability and high accuracy are achieved, and the use of manpower is effectively reduced.

Owner:卓培琨

Efficient grinding device for metal kitchenware

ActiveCN107553260AQuick sandingImprove grinding efficiencyGrinding carriagesGrinding drivesMetalMaterials science

The invention relates to a grinding device for metal kitchenware, and particularly relates to an efficient grinding device for metal kitchenware. The technical problem to be solved by the invention isto provide an efficient grinding device for metal kitchenware, which is capable of saving time and labor, capable of increasing the grinding efficiency, simple to operate, and convenient to use. In order to solve the abovementioned technical problem, the invention provides an efficient grinding device for metal kitchenware. The efficient grinding device for the metal kitchenware comprises a bottom plate and the like, wherein a vertical plate is vertically connected to the left side of the top of the bottom plate through a bolt; a placement plate is horizontally connected to the lower part ofthe right side surface of the vertical plate through a bolt; a placement groove is formed in the top of the placement plate; a support plate is vertically arranged at the top of a part at the right side of the placement plate, of the bottom plate; an up-down moving device is arranged on the left side surface of the support plate; and a grinding device is arranged on the up-down moving device. Theefficient grinding device for the metal kitchenware achieves the effects of being capable of saving time and labor, capable of increasing the grinding efficiency, simple to operate, and convenient touse.

Owner:厦门景碧实业有限公司

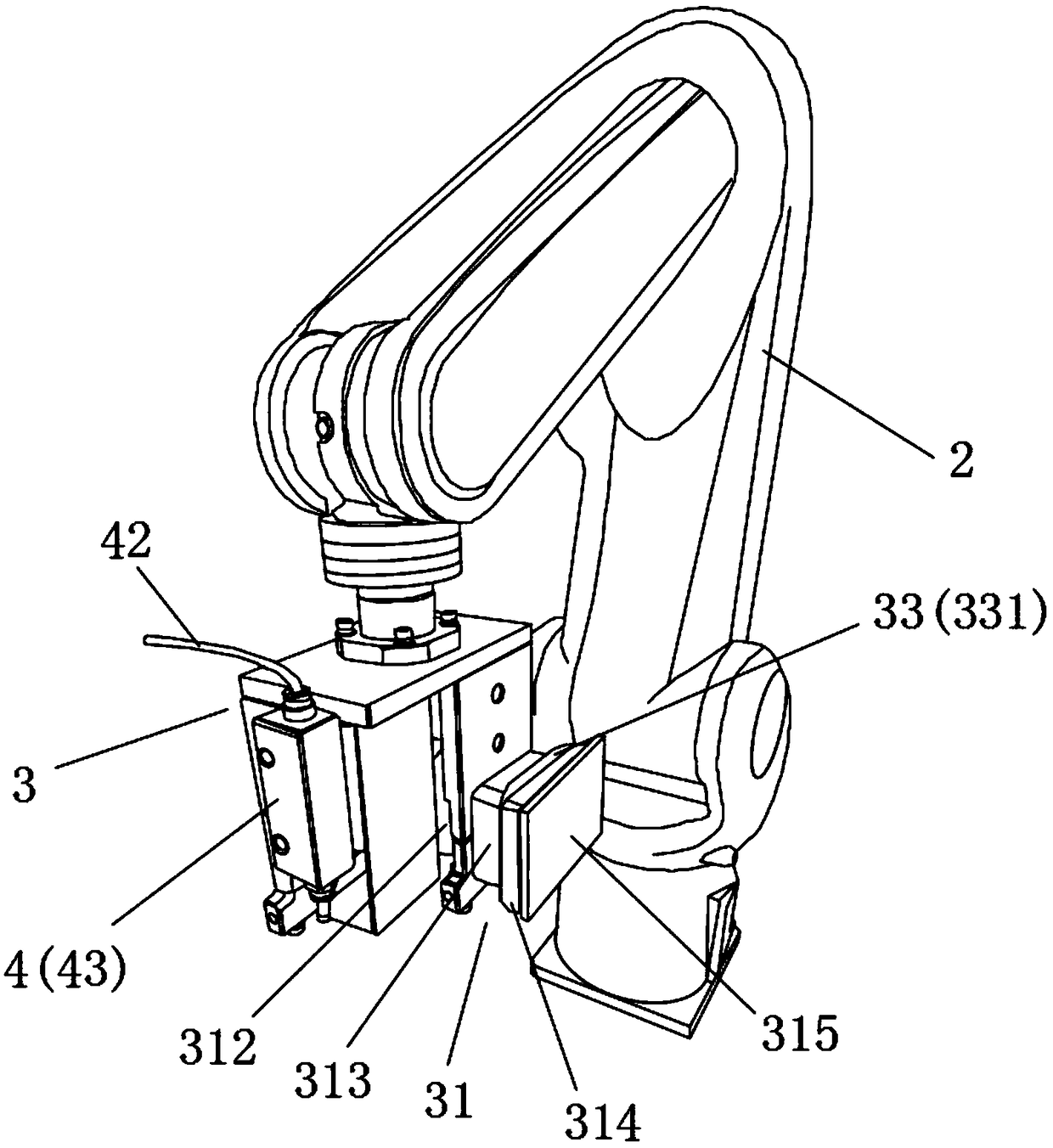

Automatic grinding device for plastic part joint lines

The invention discloses an automatic grinding device for plastic part joint lines. The automatic grinding device comprises a machine table, a mechanical arm and a grinding device body, the mechanicalarm is arranged on the machine table, the grinding device body is arranged at the end of the mechanical arm and can freely rotate by 360 degrees, the grinding device body comprises a coarse-grinding mechanism, the coarse-grinding mechanism comprises a coarse-grinding driving cylinder, a coarse-grinding pneumatic cam, a coarse-grinding base, a coarse-grinding elasticity grinding head and raw emerypaper, the coarse-grinding pneumatic cam is connected to the coarse-grinding driving cylinder, the coarse-grinding base is connected to the coarse-grinding pneumatic cam, the coarse-grinding elasticity grinding head is arranged on the outer end surface of the coarse-grinding base, the raw emery paper is stuck on the outer end surface of the coarse-grinding elasticity grinding head, the coarse-grinding driving cylinder and the coarse-grinding pneumatic cam drive the coarse-grinding elasticity grinding head to move along a preset grinding track in a vibration manner, and the joint lines on the plastic parts are comprehensively and coarsely grinded by the raw emery paper on the end surface of the coarse-grinding elasticity grinding head in a vibration manner. According to the automatic grinding device, the joint lines can be comprehensively, seamlessly, rapidly, accurately, coarsely and finely grinded. Compared with a manual grinding mode, grinding efficiency is greatly improved, and grinding accuracy is improved.

Owner:东莞顶钧塑胶模具有限公司

Efficient polishing device used for machining quartz crystals

The invention discloses an efficient polishing device used for machining quartz crystals. The efficient polishing device comprises a shell, a polishing cavity and a polishing motor. The polishing cavity is formed in the shell. A supporting base is installed in the middle position of the bottom surface of the polishing cavity. Supporting legs are symmetrically installed on the two sides of the upper surface of the supporting base. A polishing platform is fixedly welded to the upper ends of the supporting legs. The efficient polishing device is characterized in that the polishing platform is arranged to be of a groove shape with an opening formed in the upper portion, locating bolts are installed on the two sides of the inner surface of the polishing platform, an installing base is welded tothe upper portion of the polishing motor, a buffering block is fixedly connected to the middle position of the upper surface of the installing base, a lifting rod is vertically arranged above the buffering block, the lower end of the lifting rod is fixedly connected with the buffering block, and an electrostatic adsorption net is arranged in the middle positions of the two side walls of the polishing cavity. According to the efficient polishing device, errors occurring in the manual polishing process can be avoided, smoothness and precision of polishing are ensured, meanwhile, the polishing environment can be improved, and the body health of construction staff is guaranteed.

Owner:刘淑音

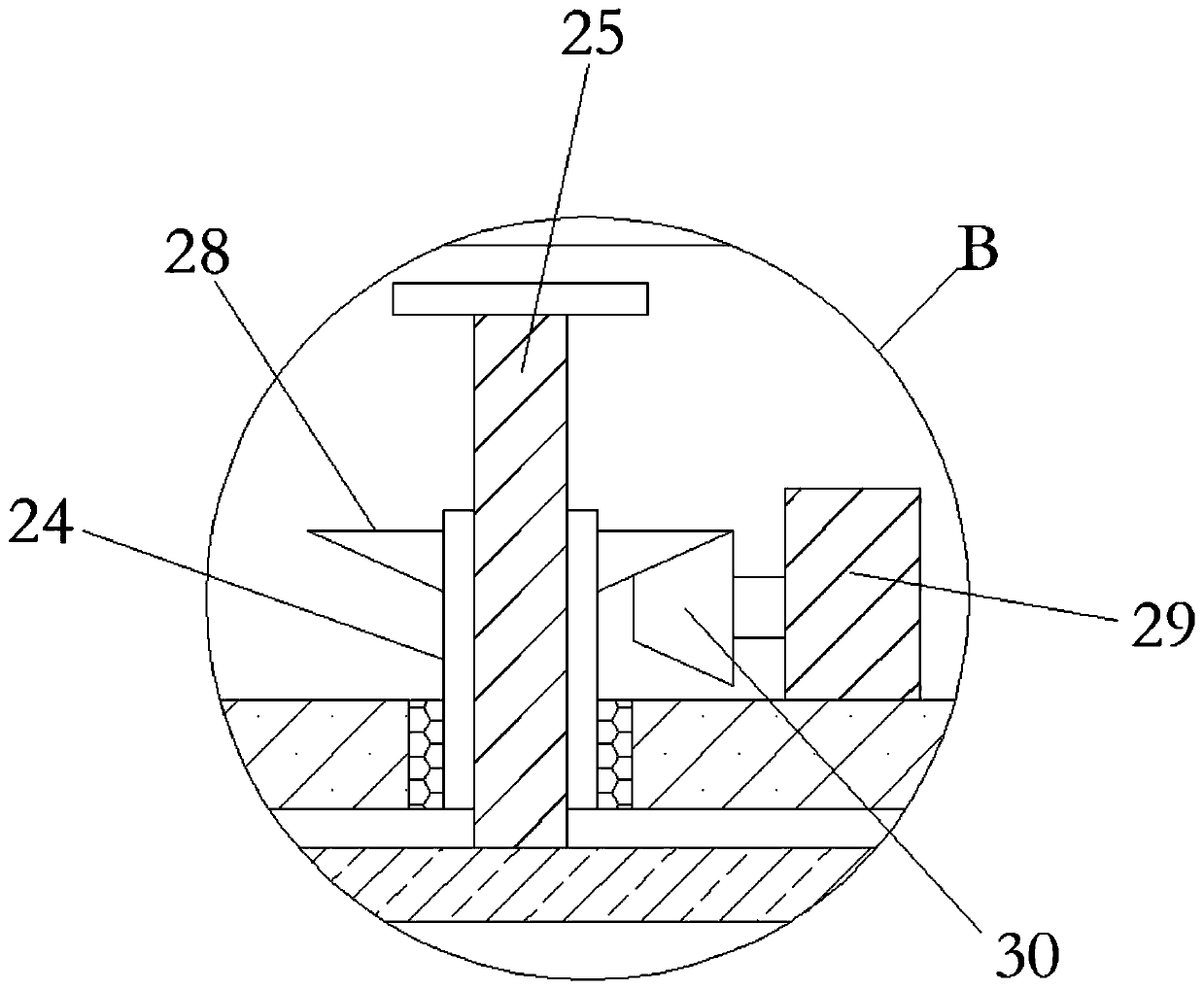

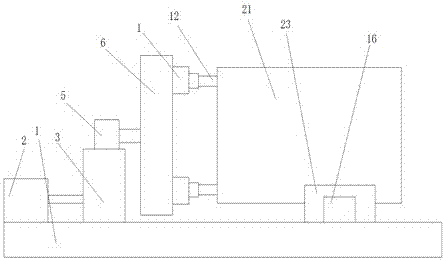

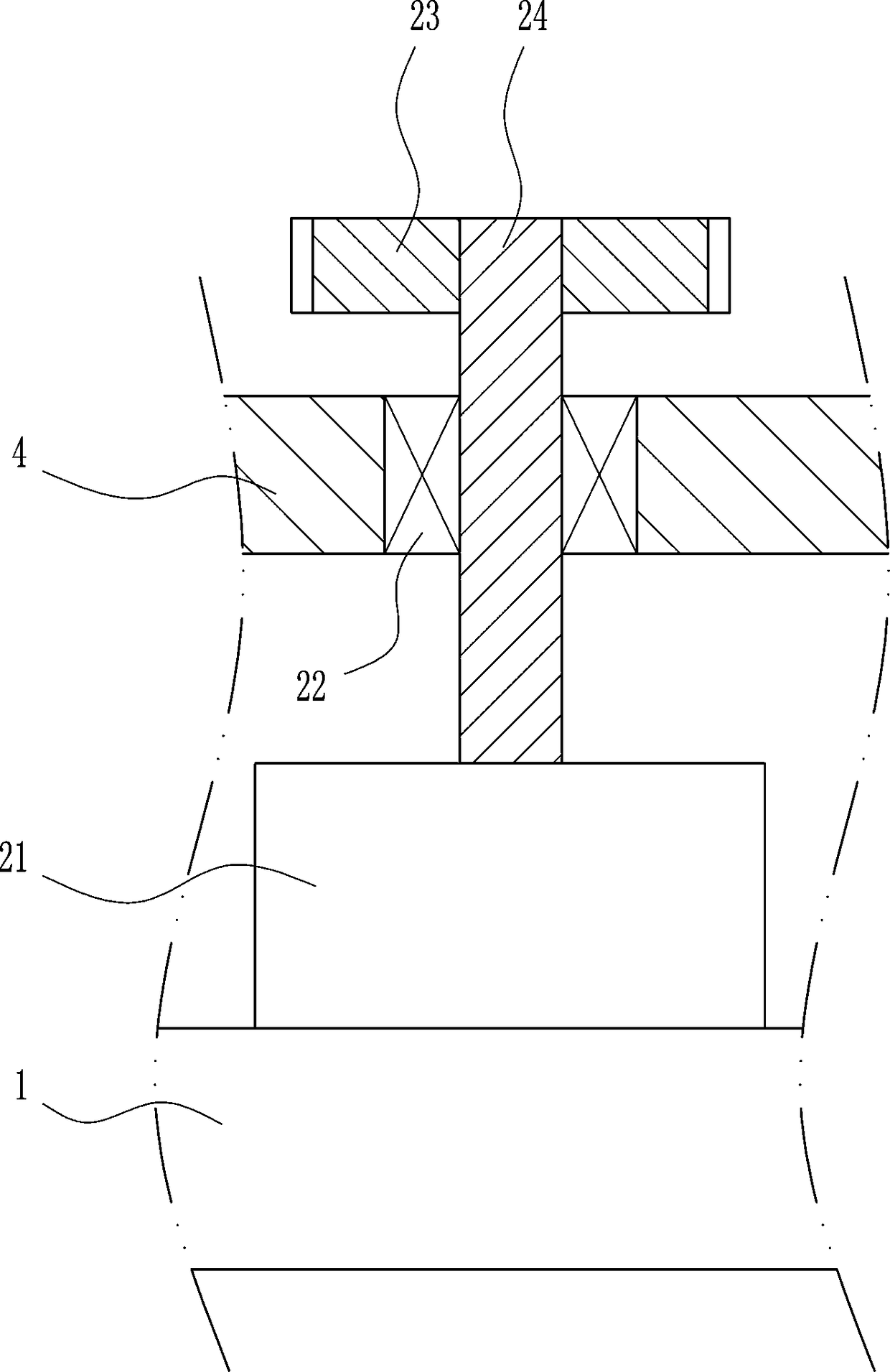

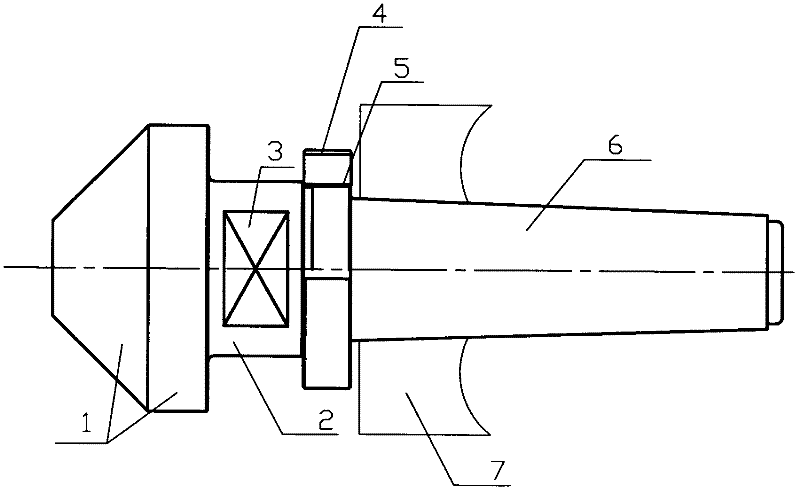

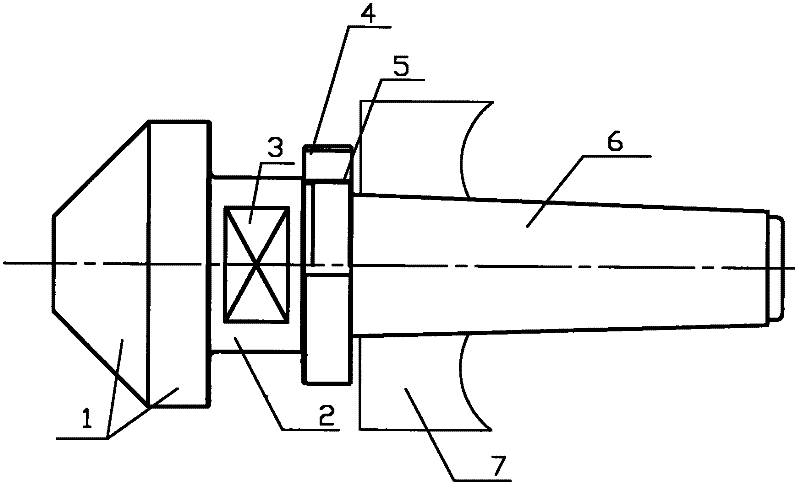

Central hole polishing device for hollow shaft of motor train unit

InactiveCN102179763AQuick sandingPrecision grindingPolishing machinesEngineeringMechanical engineering

The invention discloses a central hole polishing device for a hollow shaft of a motor train unit. The central hole polishing device solves the problems that the polishing and repair precision of the central hole is low and new excessive tolerance is easily generated in the prior art. The central hole polishing device comprises a polishing machine main body (1) and a conical polishing head (5) made of nylon; a conical tail connecting handle (2) of the conical polishing head (5) is connected together with the polishing machine main body (1) through a locking device (3); and the head of the conical polishing head (5) is provided with a cross abrasive paper fixing groove (6), and a transverse groove of the cross abrasive paper fixing groove (6) is wider than a vertical groove so as to embed abrasive paper of different thicknesses respectively. The device disclosed by the invention realizes quick and precise polishing of the central hole of the hollow shaft of the motor train unit.

Owner:ZHIBO LUCCHINI RAILWAY EQUIP

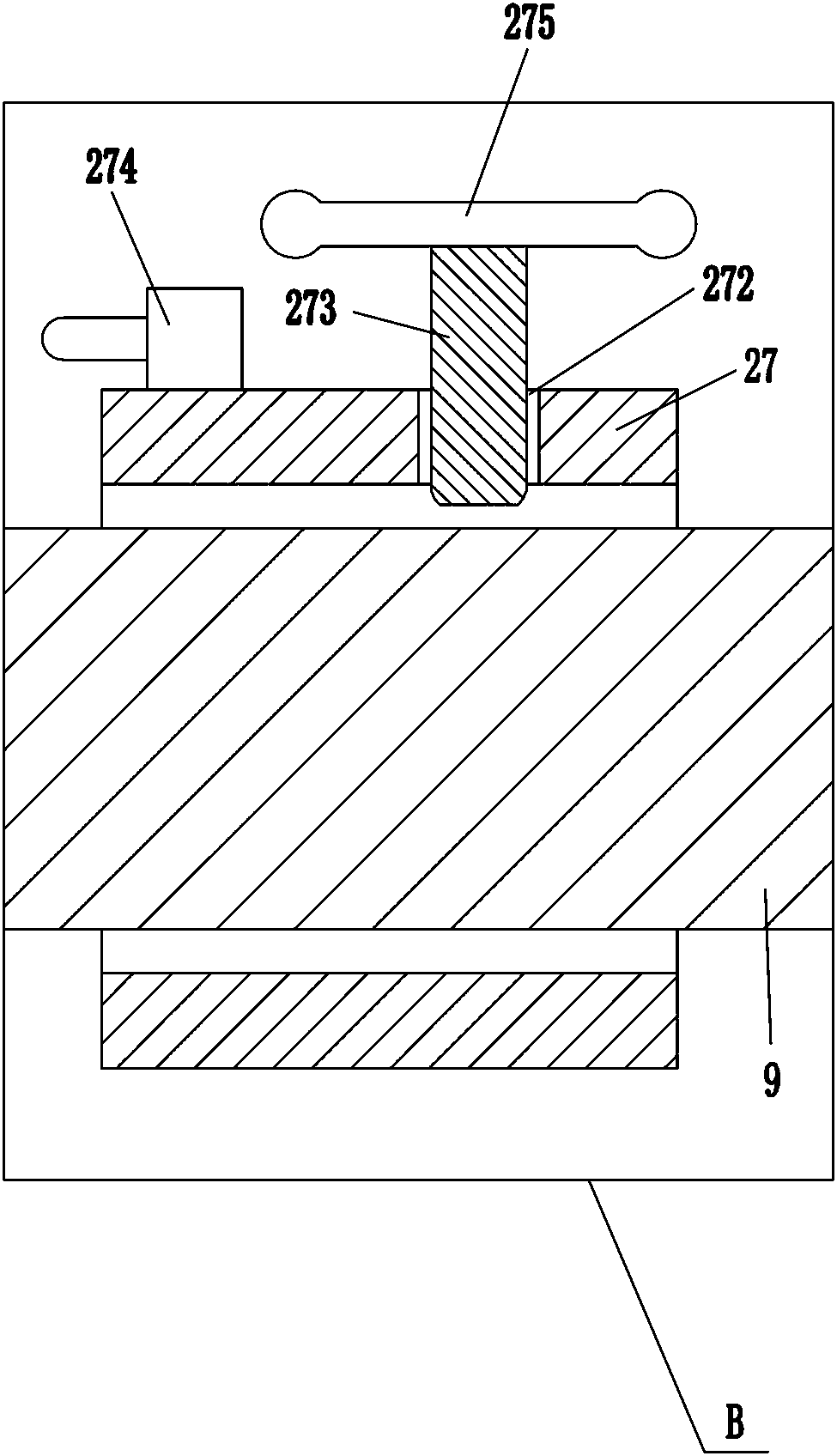

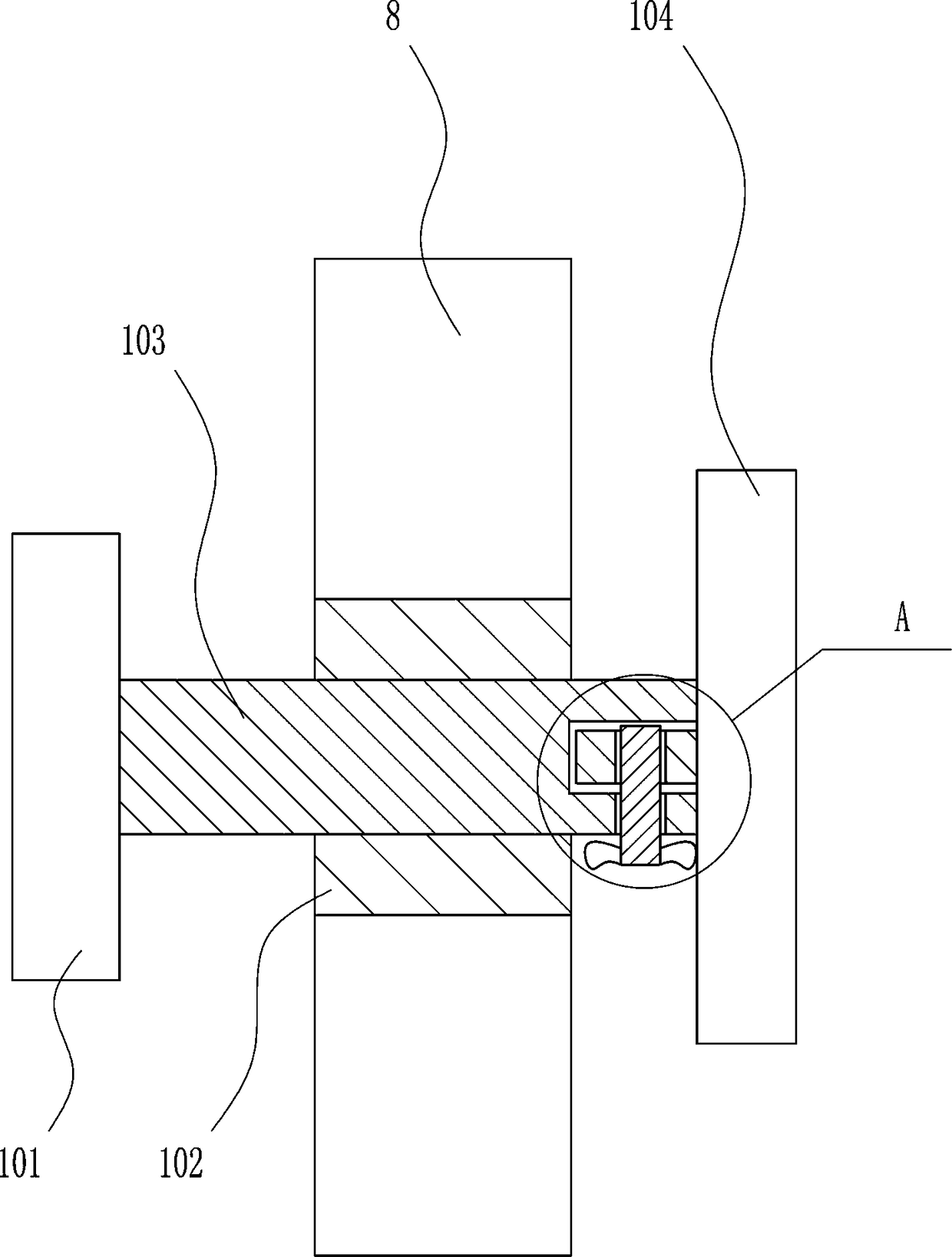

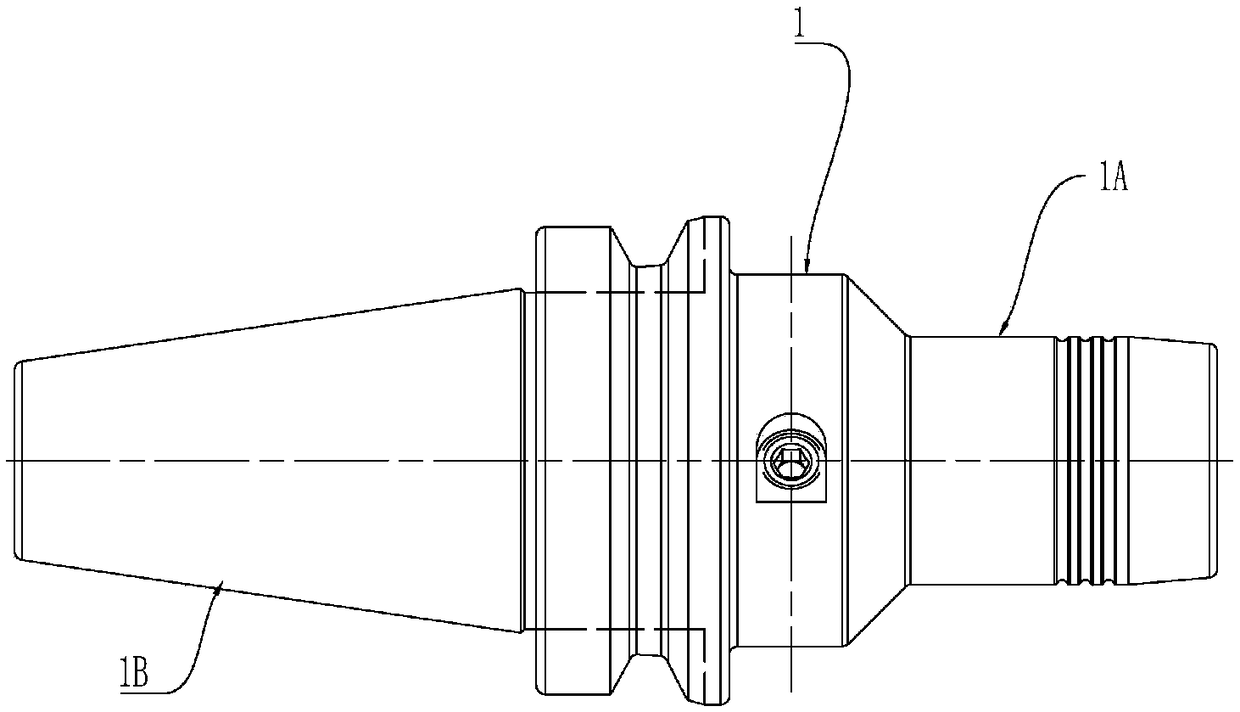

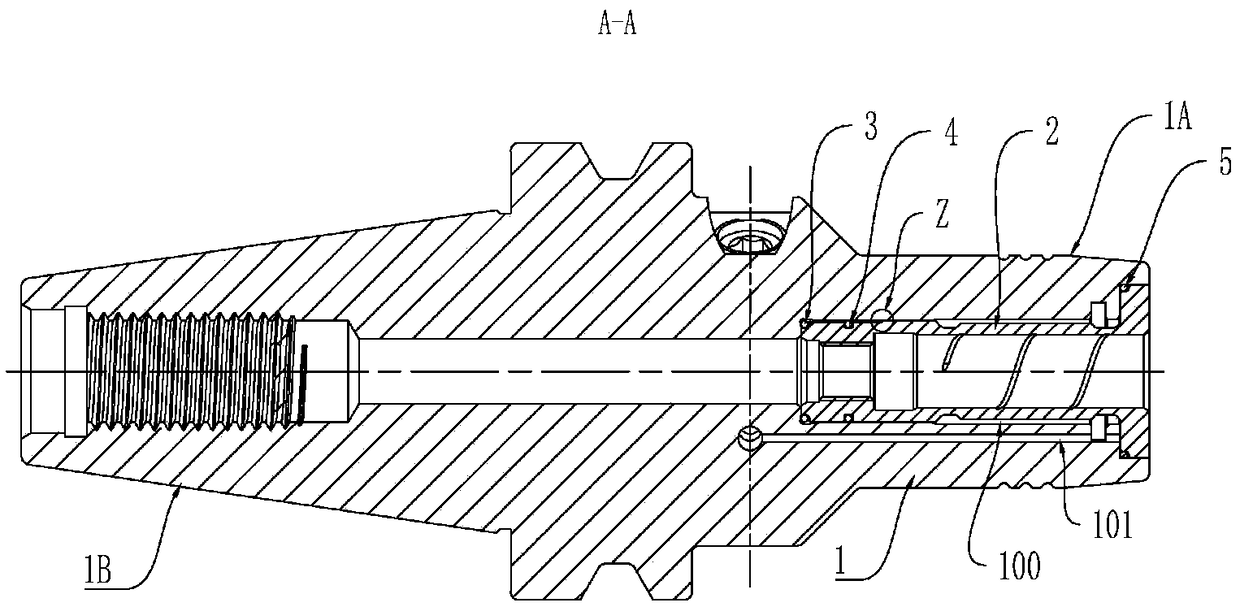

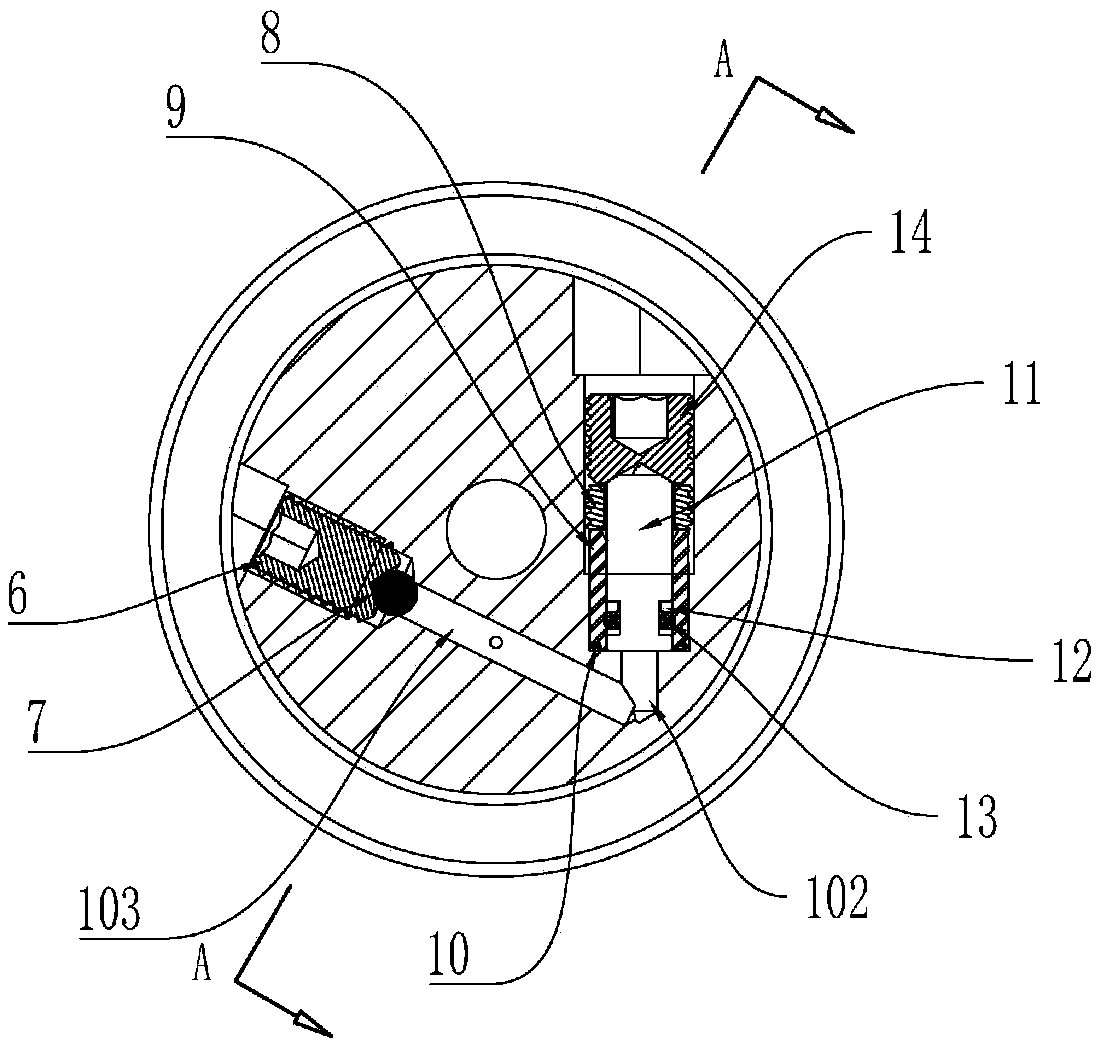

Composite connection type hydraulic knife handle

PendingCN108907776AImprove overall strengthPrevent extravasationPositioning apparatusMetal-working holdersThin walledEngineering

The invention relates to a composite connection type hydraulic knife handle. The composite connection type hydraulic knife handle comprises a main knife handle body and an elastic thin-wall inner ringarranged in the main knife handle body, wherein a hydraulic oil cavity is arranged between the main knife handle body and the elastic thin-wall inner ring; the elastic thin-wall inner ring is arranged as a barrel thin-wall structure with two thick ends and a thin middle part; and the side outer rings of the two ends of the elastic thin-wall inner ring make contact with the support surfaces of inner holes of the main knife handle body. The main knife handle body and the elastic thin-wall inner ring are fixed in a manner of combining brazed connection and interference fit connection, the effectof stress on the connection performance of the main knife handle body and the elastic thin-wall inner ring is reduced, the joint of the main knife handle body and the elastic thin-wall inner ring isprevented from tear under the high pressure state, and therefore the service life of the hydraulic knife handle is prolonged. Meanwhile, by improving the structure of a piston rod and the structure ofa piston sleeve, the piston sleeve is quickly maintained, the overall sealing performance of a hydraulic access is improved, and the overall strength of the hydraulic knife handle is improved.

Owner:成都成林数控刀具股份有限公司

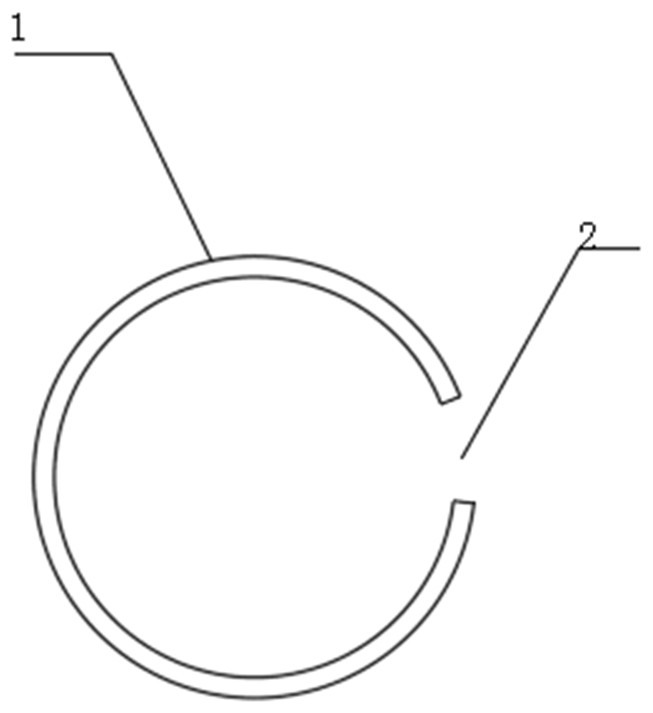

Synchronous grinding device for inner diameter surface and outer diameter surface of piston ring

ActiveCN113199350APrevent deviationImprove quality and efficiencyRevolution surface grinding machinesGrinding drivesPiston ringElectric machinery

The invention discloses a synchronous grinding device for the inner diameter surface and the outer diameter surface of a piston ring. The synchronous grinding device is used for synchronously grinding the inner diameter surface and the outer diameter surface of A ceramic aluminum alloy piston ring and comprises a grinding machining table, an inner diameter surface grinding motor is fixedly installed on the upper surface of the grinding machining table, and a controller is fixedly installed on the side face of the grinding machining table; and an outer sliding plate is slidably connected to the upper surface of the grinding machining table, and an end gap grinding module for grinding the inner wall of the end gap of the piston ring is fixedly mounted in the middle of the outer sliding plate. The synchronous grinding device for the inner diameter surface and the outer diameter surface of the piston ring can quickly grind the inner diameter surfaces and the outer diameter surfaces of ceramic aluminum alloy piston rings of different specifications simultaneously, and the ceramic aluminum alloy piston ring can be effectively prevented from deviating in the grinding process, so that the grinding quality and the grinding efficiency of the ceramic aluminum alloy piston ring are effectively improved. Meanwhile, the inner edge of the end gap of the ceramic aluminum alloy piston ring can be quickly ground while the inner wall and the outer wall of the ceramic aluminum alloy piston ring are ground.

Owner:安徽陶铝新动力科技有限公司

Blanking equipment for machining ultrahigh-strength steel plate for large-tonnage engineering machinery

PendingCN113198902AGood automation effectReduce manual operationsEdge grinding machinesGrinding drivesStructural engineeringIndustrial engineering

The invention discloses blanking equipment for machining an ultrahigh-strength steel plate for the large-tonnage engineering machinery. The blanking equipment for machining the ultrahigh-strength steel plate for the large-tonnage engineering machinery comprises a blanking device main body, a discharging position, a feeding position, a guide side plate, a pressing plate, a connecting column and an auxiliary device. According to the blanking equipment for machining the ultrahigh-strength steel plate for the large-tonnage engineering machinery provided by the invention, the auxiliary device is installed at the front end of the blanking device main body, a clamping mechanism is installed in the auxiliary device, and the clamping mechanism is matched with a sliding mechanism arranged below the clamping mechanism, so that a blanked steel plate can be clamped; then an adjusting mechanism rotates at equal angles and can drive the steel plate to move into a processing mechanism arranged at the left end, a grinding mechanism is installed in the processing mechanism, and the cutting edge position of the steel plate can be ground in a reciprocating mode, so that generated burrs are removed; and under the rotation of the adjusting mechanism, the materials are conveyed to external conveying equipment to enter the next station, so that the automation effect is good, the manual operation is reduced, and the production time efficiency is improved.

Owner:惠安县康杰机械设备商行

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com