Automatic grinding device for plastic part joint lines

A parting line, plastic parts technology, applied in grinding/polishing equipment, metal processing equipment, grinding machines, etc., can solve the problems of difficult to meet the requirements of grinding effect, high labor cost, low efficiency, etc., to achieve fast action and comprehensive grinding , Improve the effect of grinding accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

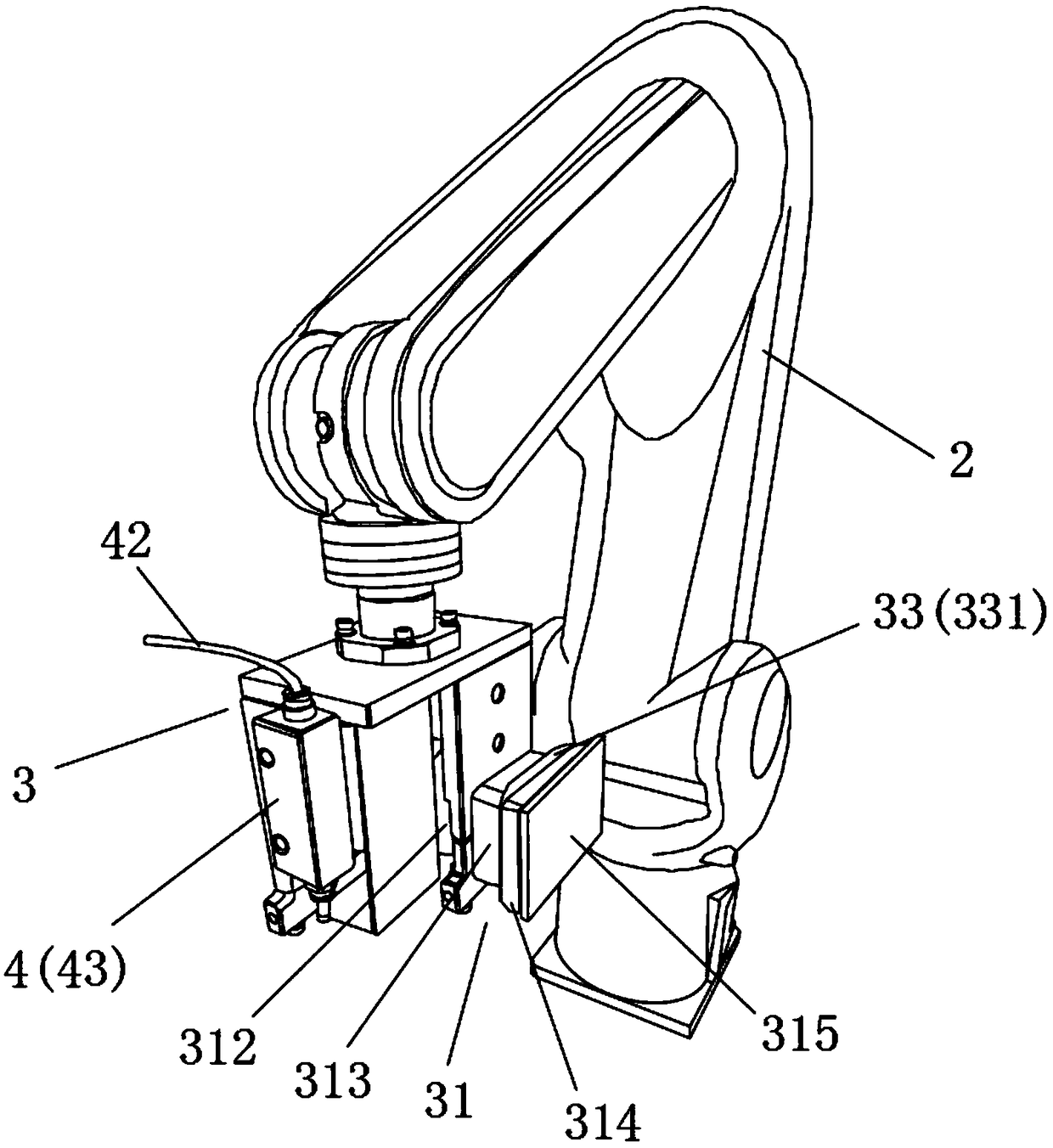

[0026] Please refer to figure 1 , This embodiment provides an automatic grinding equipment for a mold clamping line for plastic parts, including a machine, a mechanical arm 2 arranged on the machine, and a grinding device arranged at the end of the mechanical arm 2 and capable of rotating 360° freely 3. The grinding device 3 includes a rough grinding mechanism 31, which includes a rough grinding drive cylinder, a rough grinding pneumatic cam 312 connected to the rough grinding drive cylinder, and a rough grinding mechanism connected to the rough grinding pneumatic cam 312 Base 313, a rough grinding elastic grinding head 314 arranged on the outer end surface of the rough grinding base 313, and a rough sandpaper 315 pasted on the outer end surface of the rough grinding elastic grinding head 314; the rough grinding drives the cylinder and the rough grinding pneumatically Driven by the cam 312, the rough-grinding elastic sanding head 314 vibrates along a preset sanding track, and th...

Embodiment 2

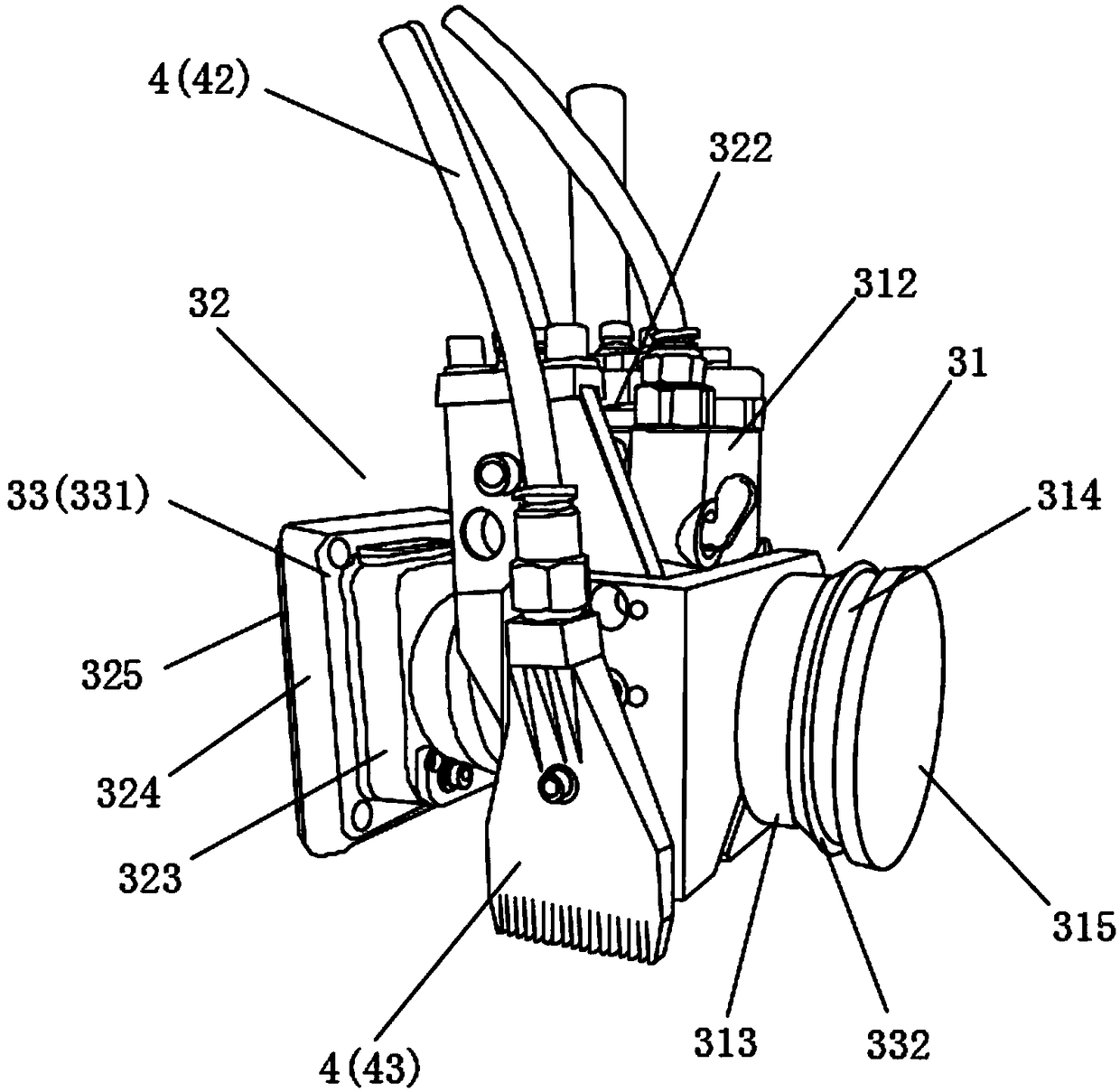

[0030] Please refer to figure 2 The main difference between this embodiment and the first embodiment is that the grinding device 3 also includes a fine grinding mechanism 32, which is located on the same line as the rough grinding mechanism 31, and the fine grinding mechanism 32 includes a fine grinding mechanism 32. Grinding driving cylinder, a fine grinding pneumatic cam 322 connected to the fine grinding driving cylinder, a fine grinding base 323 connected to the fine grinding pneumatic cam 322, and a fine grinding elastic grinding head arranged on the outer end surface of the fine grinding base 323 324, and a fine sandpaper 325 pasted on the outer end surface of the fine grinding elastic grinding head 324; when the surface smoothness of the plastic part is more stringent, the surface of the mold line needs to be further finely ground, and the fine grinding drives the cylinder Driven by the fine-grinding pneumatic cam 322, the fine-grinding elastic grinding head 324 vibrates...

Embodiment 3

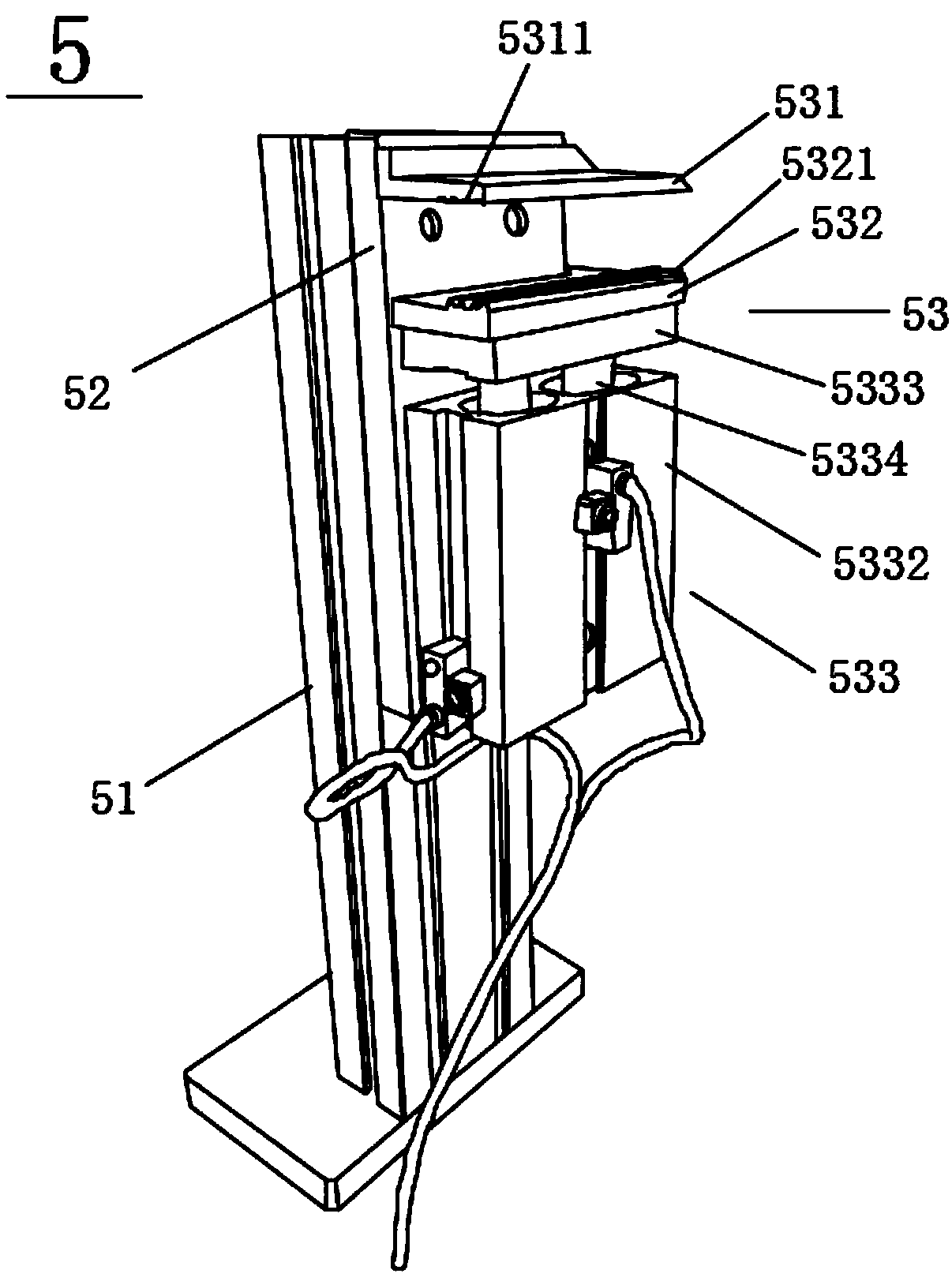

[0036] Please refer to image 3 Compared with the first or second embodiment, the main difference between this embodiment and the first or second embodiment is that: the automatic grinding equipment for the mold clamping line of plastic parts also includes an automatic sandpaper removal device 5 arranged on the machine table and located on the side of the robot arm 2. The automatic sandpaper removal device 5 includes a mounting side plate 51 arranged on the machine table, a mounting base plate 52 arranged on the inner side of the mounting side plate 51 and facing the robot arm 2, and a mounting base plate 52 arranged on the inner side of the mounting base plate 52 A sandpaper gripping mechanism 53, wherein the sandpaper gripping mechanism 53 includes an upper splint 531 fixed to the upper part of the inner side of the mounting base 52, and a lower splint movably arranged on the inner side of the mounting base 52 and directly below the upper splint 531 532, and an up-and-down dri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com