Blanking equipment for machining ultrahigh-strength steel plate for large-tonnage engineering machinery

A construction machinery, ultra-high-strength technology, applied in metal processing equipment, grinding machine parts, grinding/polishing equipment, etc., can solve the problems of reduced production and processing timeliness, low automation effect, increased labor costs, etc., to achieve automation Good effect, reduce manual operation, improve the effect of aging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

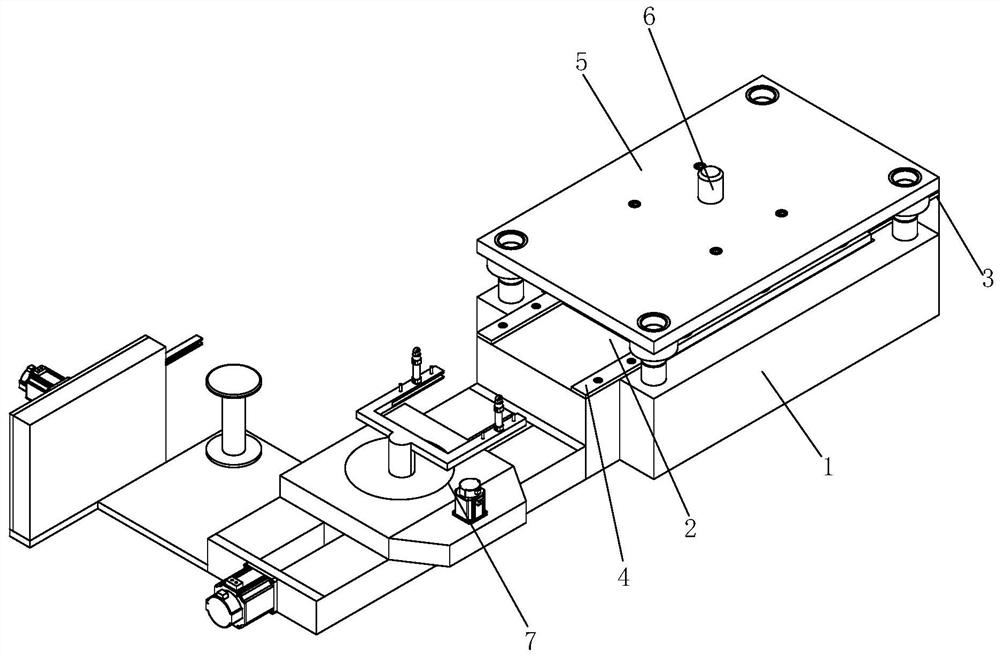

[0035] see figure 1 , the present invention provides a punching equipment for processing ultra-high-strength steel plates for large-tonnage engineering machinery through improvement, including a punching device main body 1, the front end of the punching device body 1 is a discharge position 2, and the rear end is a feed position 3 , the two ends of the top of the discharge position 2 are equipped with guide side plates 4, the top of the main body of the punching device 1 is connected to the pressing plate 5, the middle part of the top of the pressing plate 5 is provided with a connecting column 6, and the lower end of the front surface of the main body of the punching device 1 is connected to the auxiliary device 7 catch.

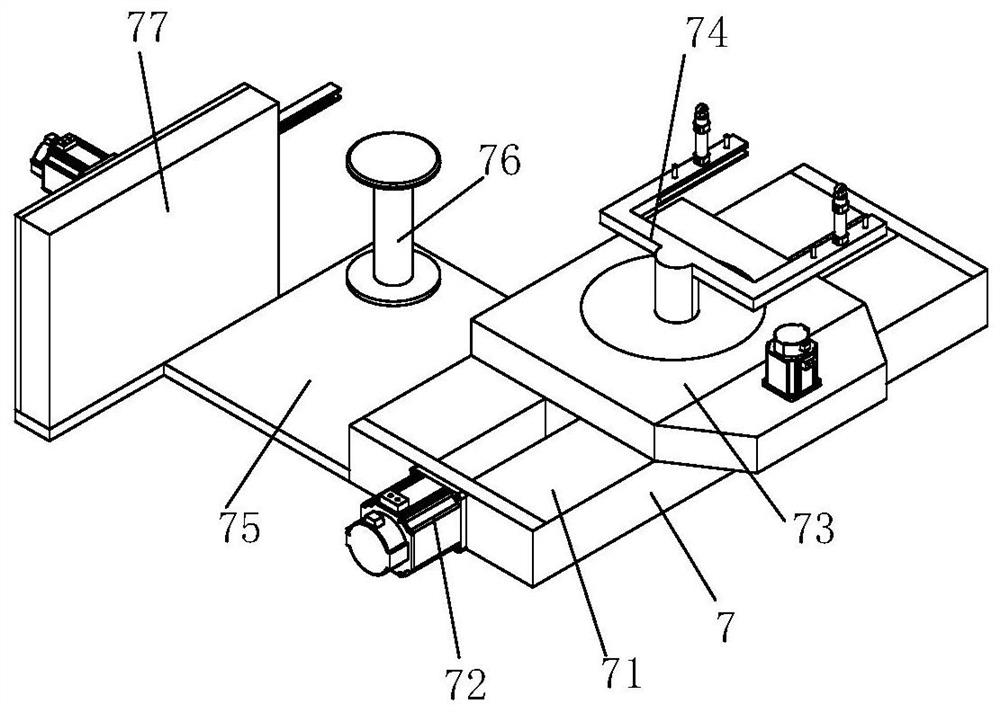

[0036] see figure 2, the present invention provides a punching equipment for large-tonnage construction machinery with ultra-high-strength steel plate processing through improvement. The auxiliary device 7 includes a sliding mechanism 71, a first motor 72...

Embodiment 2

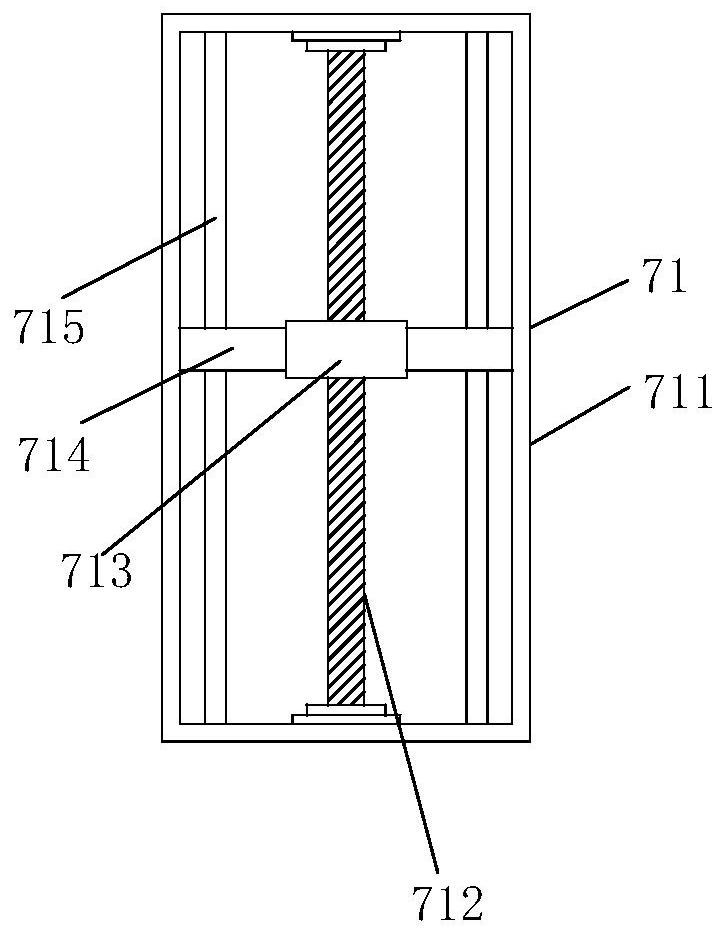

[0044] The present invention provides a punching equipment for processing ultra-high-strength steel plates for large-tonnage construction machinery through improvement. The inner middle part of the sliding part 713 has internal threads, and the inner middle part of the sliding part 713 is threaded with the threaded rod 712 to facilitate sliding. The sliding part 713 is stable; the outer side of the rotating disk 732 and the contact position of the transmission box 731 are bonded with a rubber layer to achieve stability during rotation, with high friction and strong stability; the four ends of the intermittent wheel 7318 are separated by the strip groove 73181. Inner concave arc shape, and the inner concave arc position is close to the outer side of the limiter 7315, which effectively limits the position after rotation to prevent rotation; the bottom of the placement groove 743, the top of the support member 76 and the top of the lower grinding sheet 7739 are the same Flat surfa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com